NISSAN ALMERA N16 2001 Electronic Repair Manual

ALMERA N16 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57351/w960_57351-0.png

NISSAN ALMERA N16 2001 Electronic Repair Manual

Trending: power steering fluid, Air conditioning, diagram, EL page 71, Blower, Ventilation, airbag

Page 1541 of 2493

SAT023JB

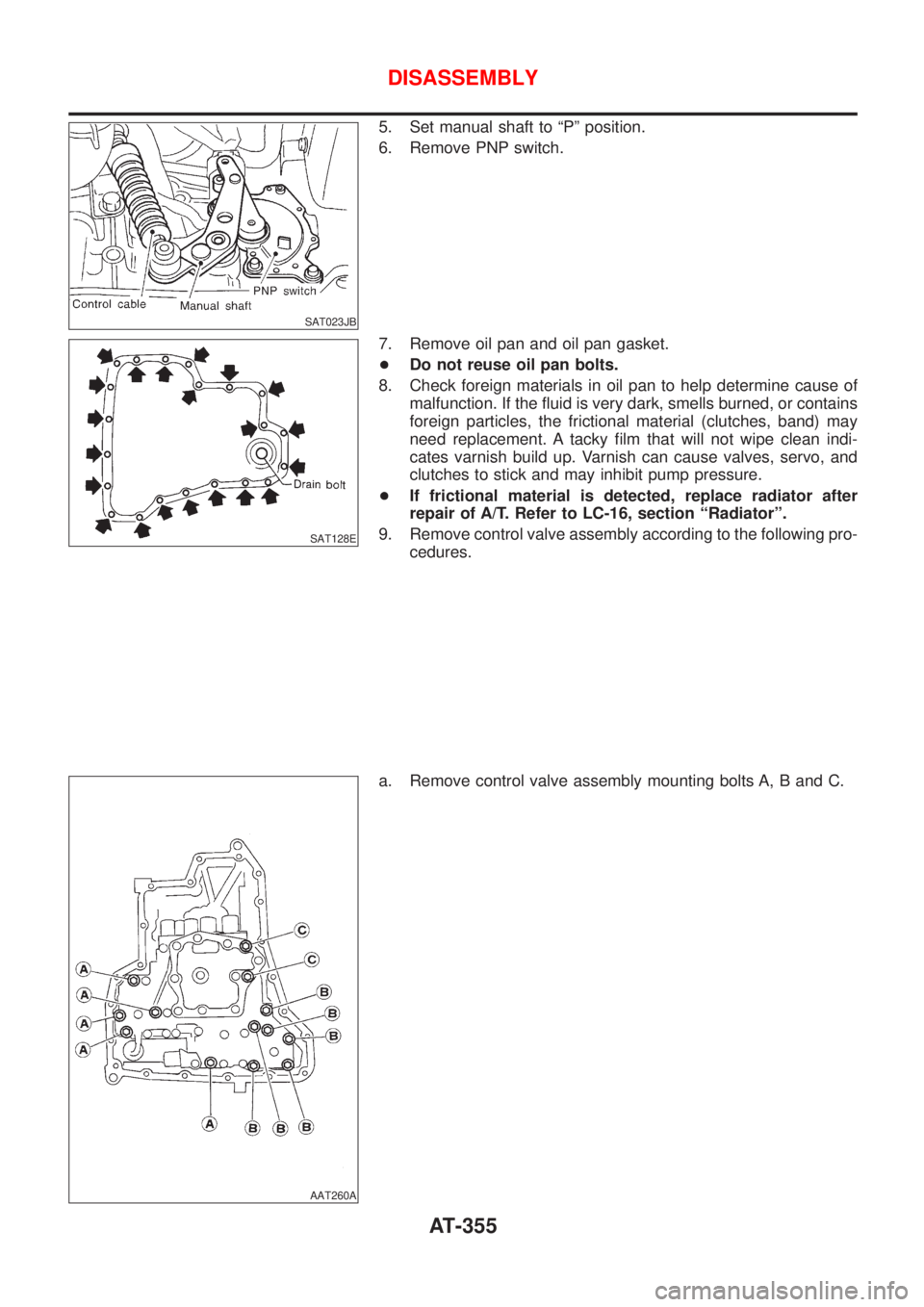

5. Set manual shaft to ªPº position.

6. Remove PNP switch.

SAT128E

7. Remove oil pan and oil pan gasket.

+Do not reuse oil pan bolts.

8. Check foreign materials in oil pan to help determine cause of

malfunction. If the fluid is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indi-

cates varnish build up. Varnish can cause valves, servo, and

clutches to stick and may inhibit pump pressure.

+If frictional material is detected, replace radiator after

repair of A/T. Refer to LC-16, section ªRadiatorº.

9. Remove control valve assembly according to the following pro-

cedures.

AAT260A

a. Remove control valve assembly mounting bolts A, B and C.

DISASSEMBLY

AT-355

Page 1542 of 2493

AAT262A

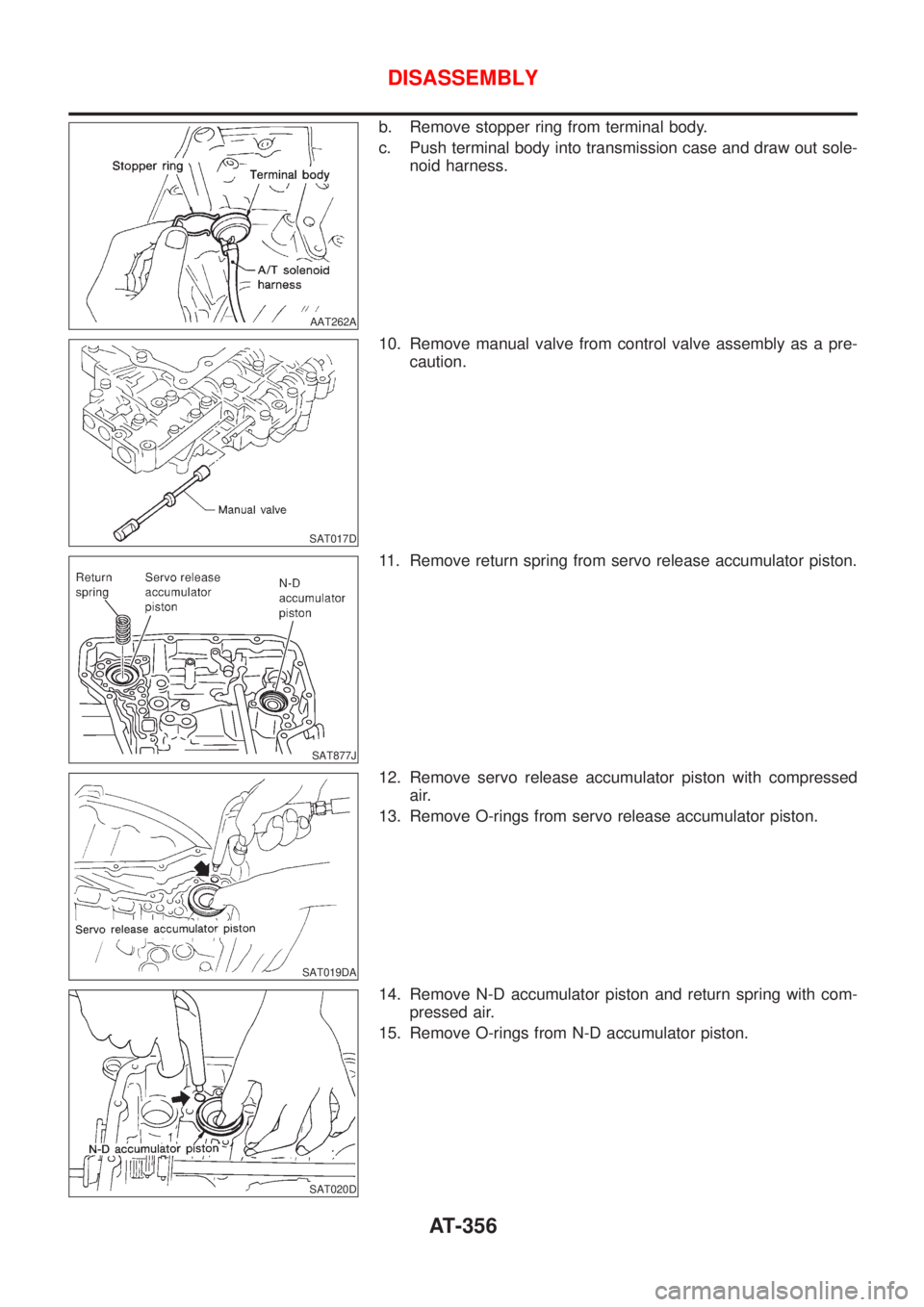

b. Remove stopper ring from terminal body.

c. Push terminal body into transmission case and draw out sole-

noid harness.

SAT017D

10. Remove manual valve from control valve assembly as a pre-

caution.

SAT877J

11. Remove return spring from servo release accumulator piston.

SAT019DA

12. Remove servo release accumulator piston with compressed

air.

13. Remove O-rings from servo release accumulator piston.

SAT020D

14. Remove N-D accumulator piston and return spring with com-

pressed air.

15. Remove O-rings from N-D accumulator piston.

DISASSEMBLY

AT-356

Page 1543 of 2493

SAT023DA

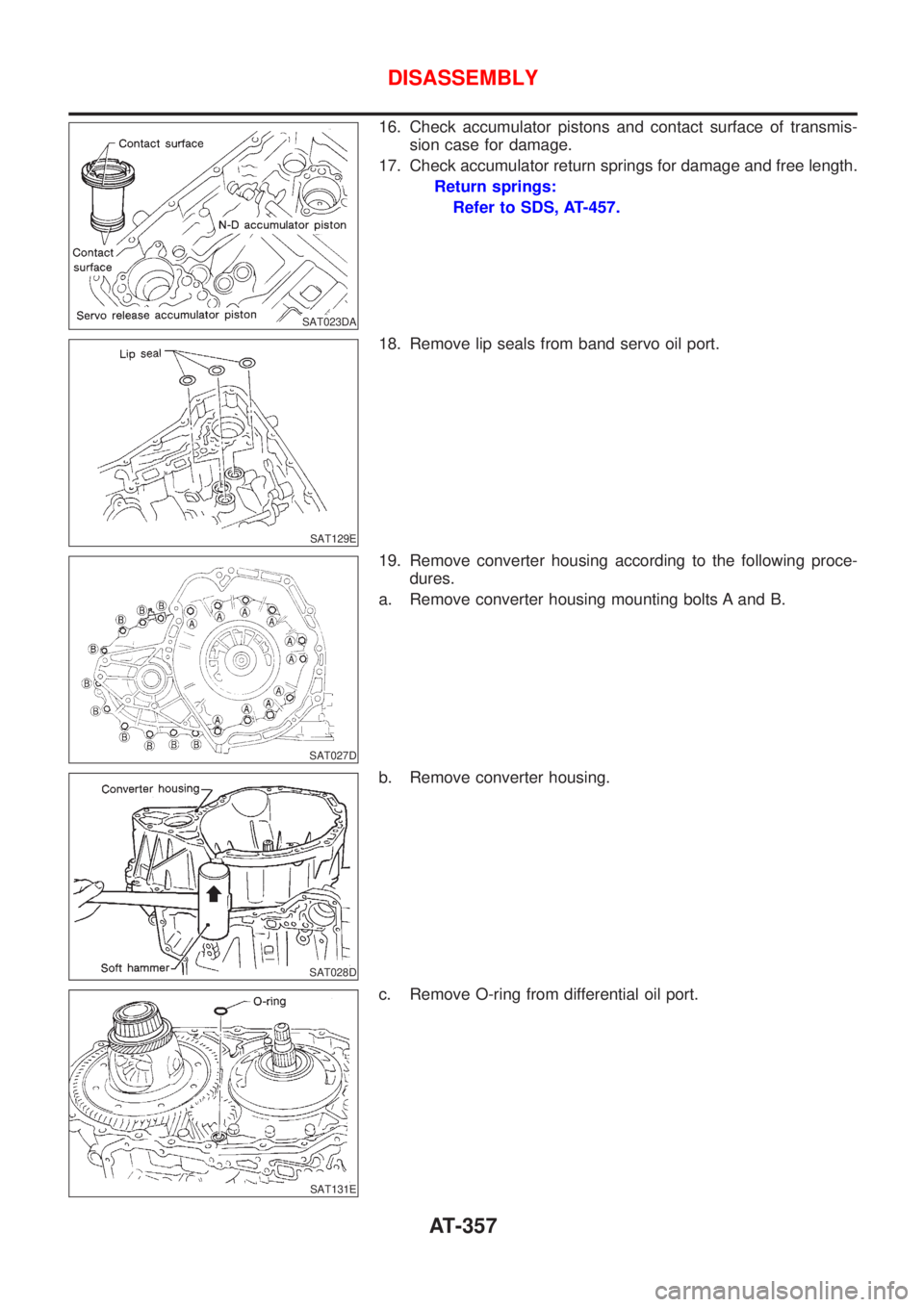

16. Check accumulator pistons and contact surface of transmis-

sion case for damage.

17. Check accumulator return springs for damage and free length.

Return springs:

Refer to SDS, AT-457.

SAT129E

18. Remove lip seals from band servo oil port.

SAT027D

19. Remove converter housing according to the following proce-

dures.

a. Remove converter housing mounting bolts A and B.

SAT028D

b. Remove converter housing.

SAT131E

c. Remove O-ring from differential oil port.

DISASSEMBLY

AT-357

Page 1544 of 2493

SAT030D

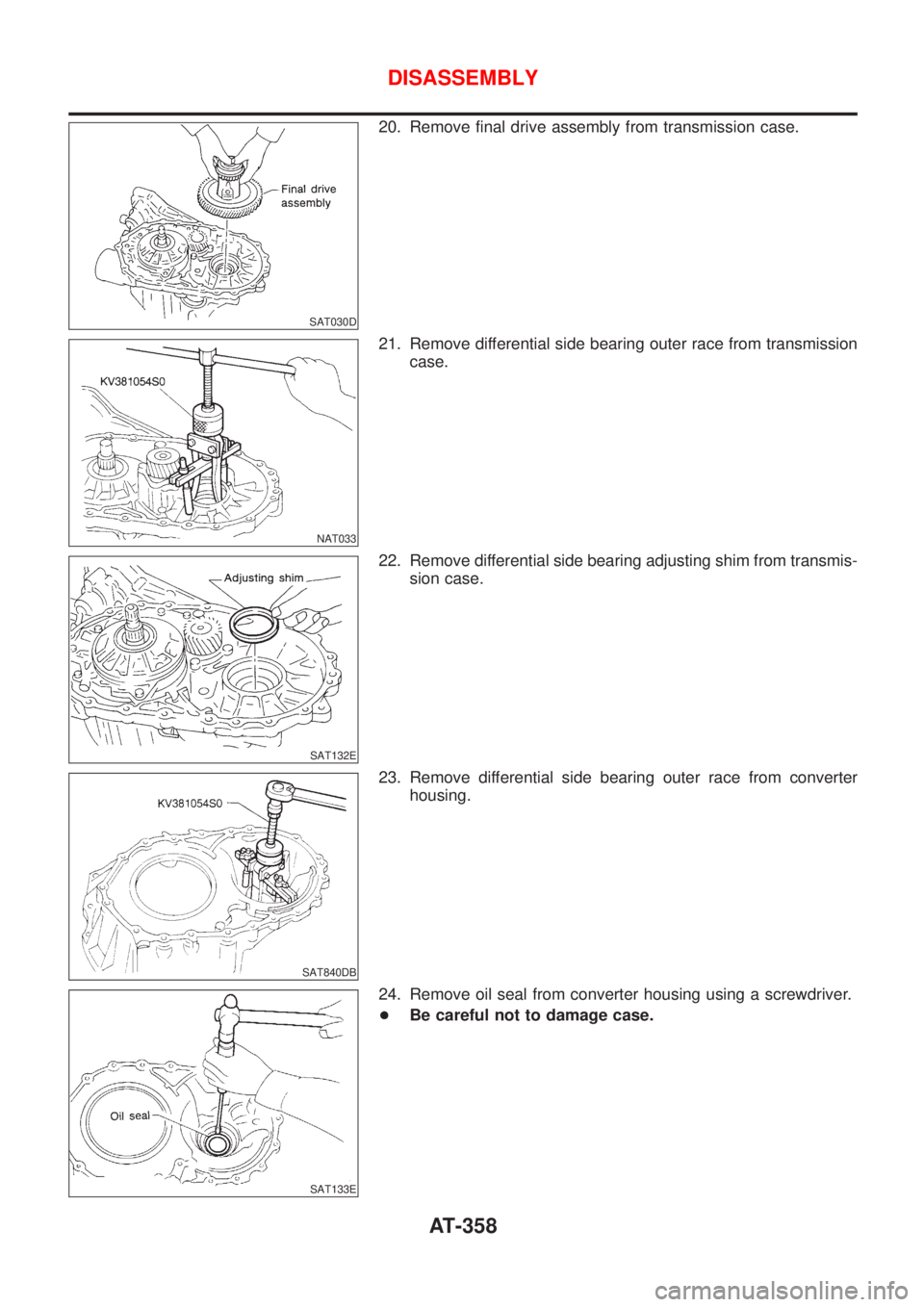

20. Remove final drive assembly from transmission case.

NAT033

21. Remove differential side bearing outer race from transmission

case.

SAT132E

22. Remove differential side bearing adjusting shim from transmis-

sion case.

SAT840DB

23. Remove differential side bearing outer race from converter

housing.

SAT133E

24. Remove oil seal from converter housing using a screwdriver.

+Be careful not to damage case.

DISASSEMBLY

AT-358

Page 1545 of 2493

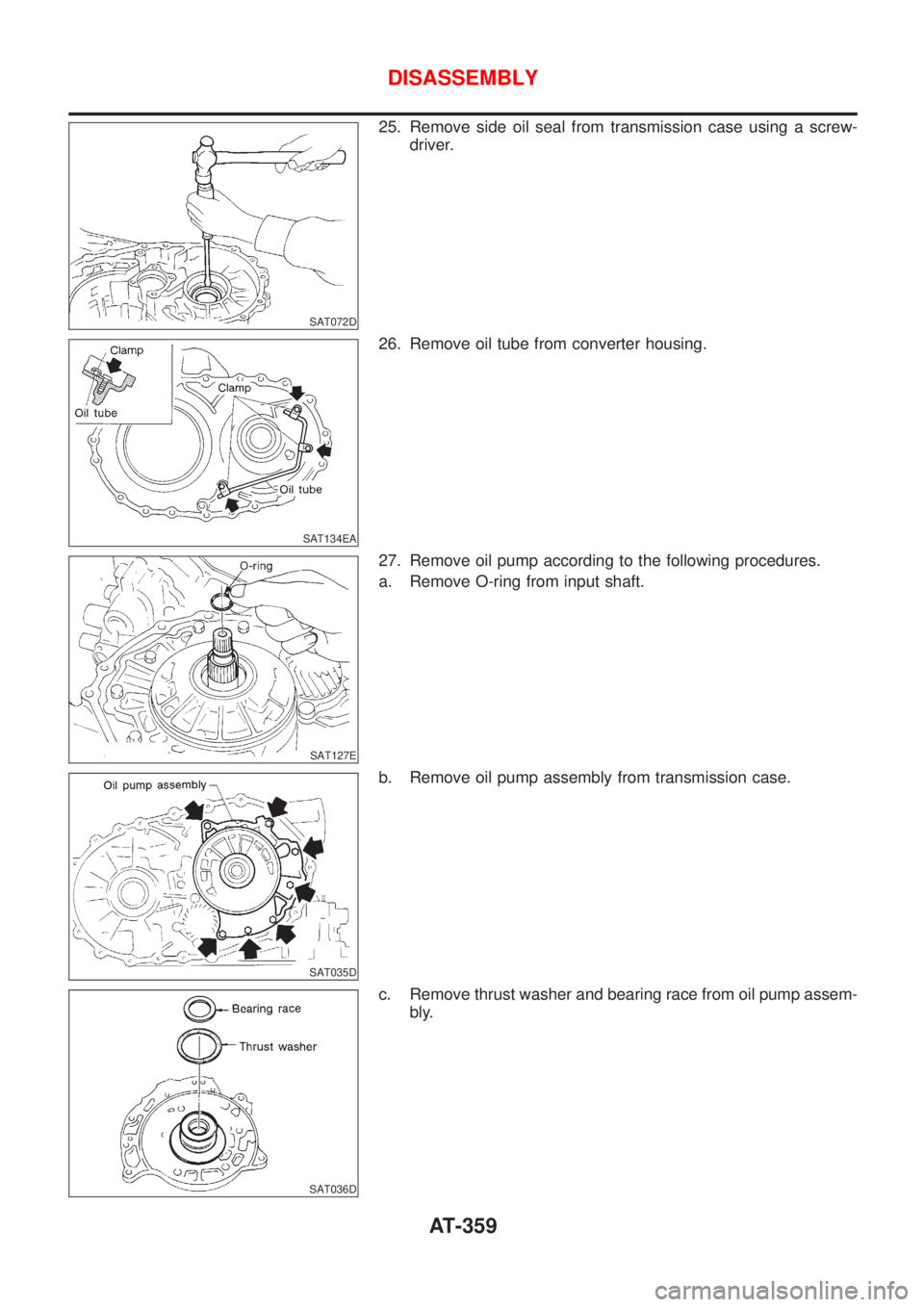

SAT072D

25. Remove side oil seal from transmission case using a screw-

driver.

SAT134EA

26. Remove oil tube from converter housing.

SAT127E

27. Remove oil pump according to the following procedures.

a. Remove O-ring from input shaft.

SAT035D

b. Remove oil pump assembly from transmission case.

SAT036D

c. Remove thrust washer and bearing race from oil pump assem-

bly.

DISASSEMBLY

AT-359

Page 1546 of 2493

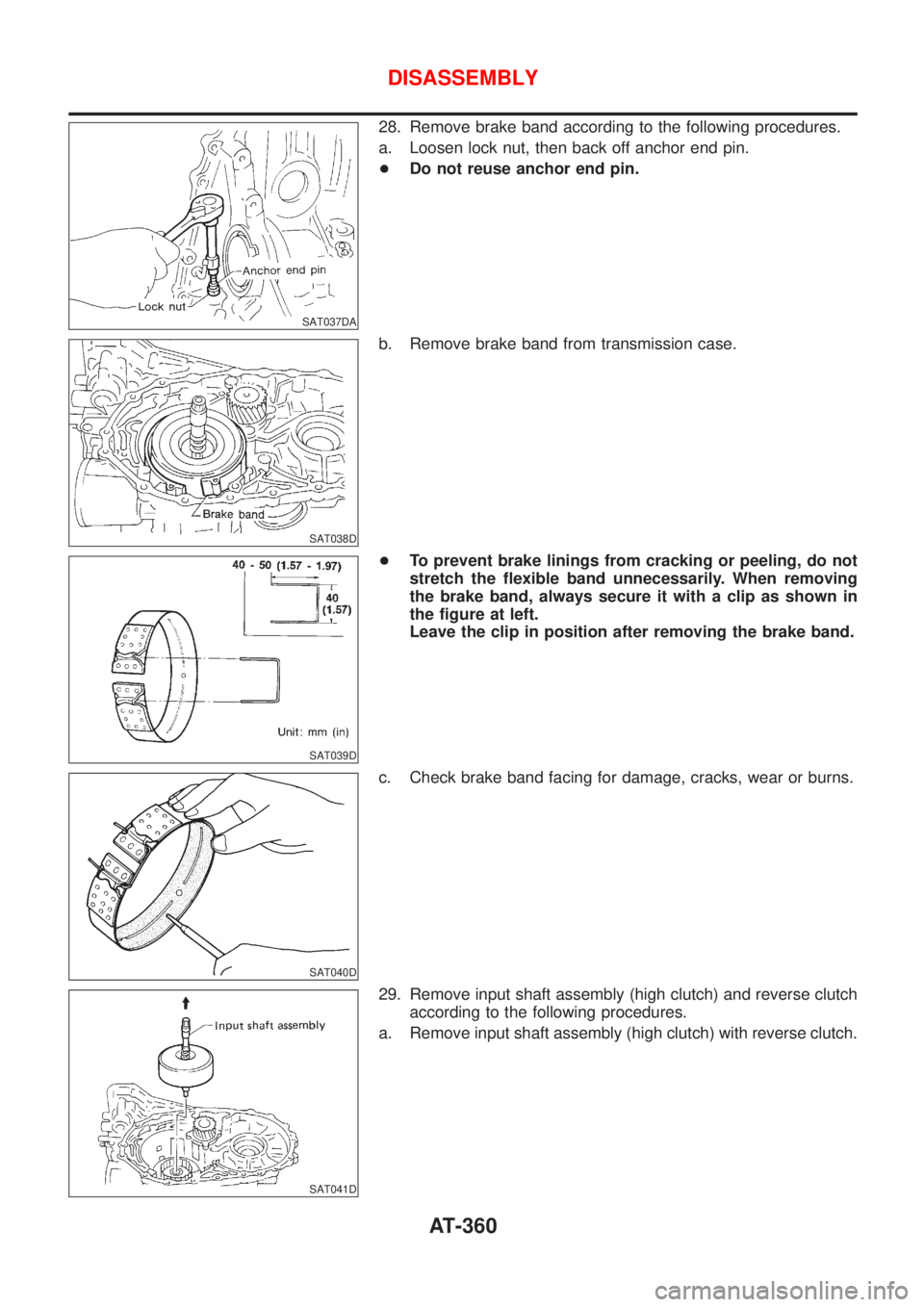

SAT037DA

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pin.

+Do not reuse anchor end pin.

SAT038D

b. Remove brake band from transmission case.

SAT039D

+To prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

the figure at left.

Leave the clip in position after removing the brake band.

SAT040D

c. Check brake band facing for damage, cracks, wear or burns.

SAT041D

29. Remove input shaft assembly (high clutch) and reverse clutch

according to the following procedures.

a. Remove input shaft assembly (high clutch) with reverse clutch.

DISASSEMBLY

AT-360

Page 1547 of 2493

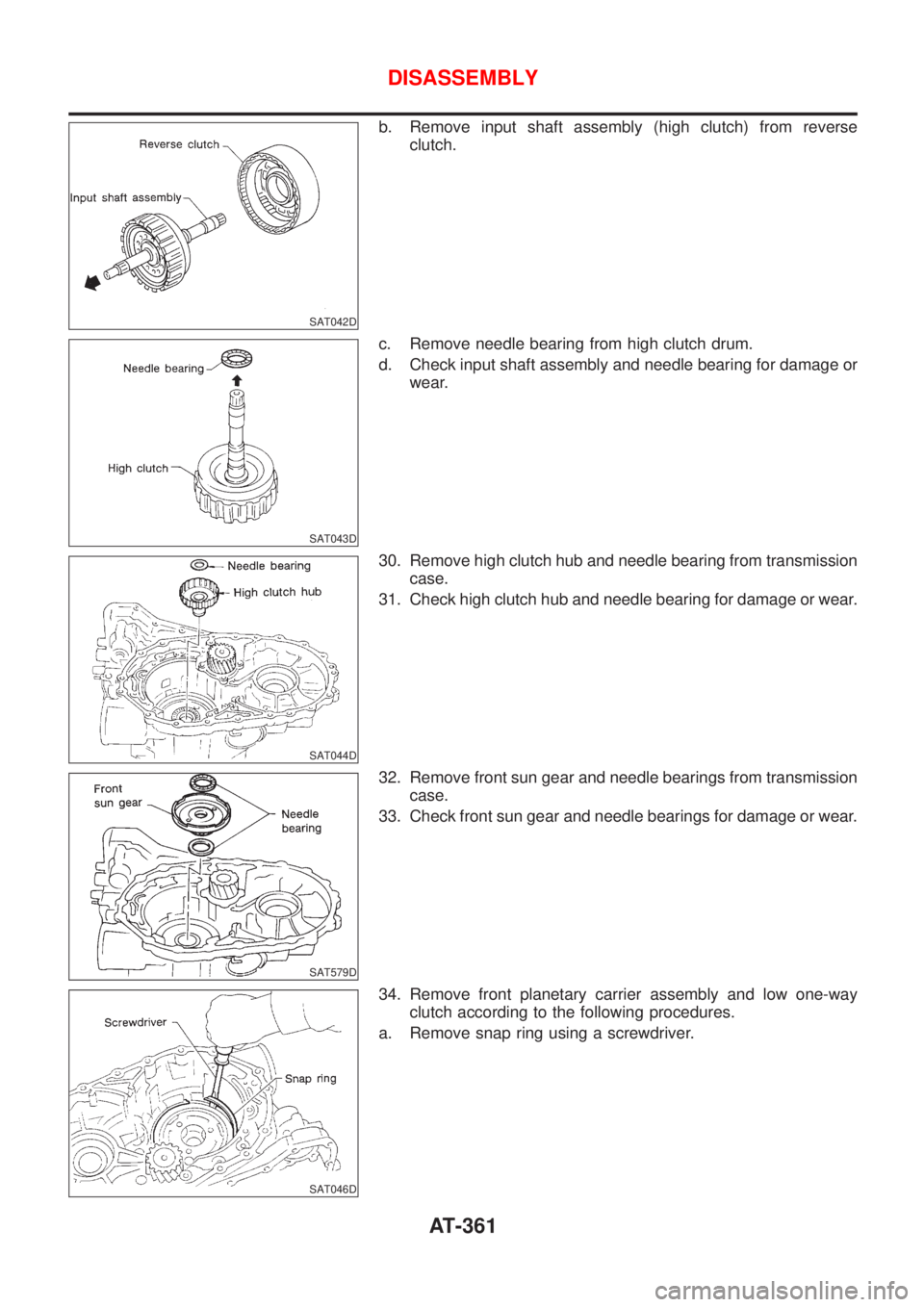

SAT042D

b. Remove input shaft assembly (high clutch) from reverse

clutch.

SAT043D

c. Remove needle bearing from high clutch drum.

d. Check input shaft assembly and needle bearing for damage or

wear.

SAT044D

30. Remove high clutch hub and needle bearing from transmission

case.

31. Check high clutch hub and needle bearing for damage or wear.

SAT579D

32. Remove front sun gear and needle bearings from transmission

case.

33. Check front sun gear and needle bearings for damage or wear.

SAT046D

34. Remove front planetary carrier assembly and low one-way

clutch according to the following procedures.

a. Remove snap ring using a screwdriver.

DISASSEMBLY

AT-361

Page 1548 of 2493

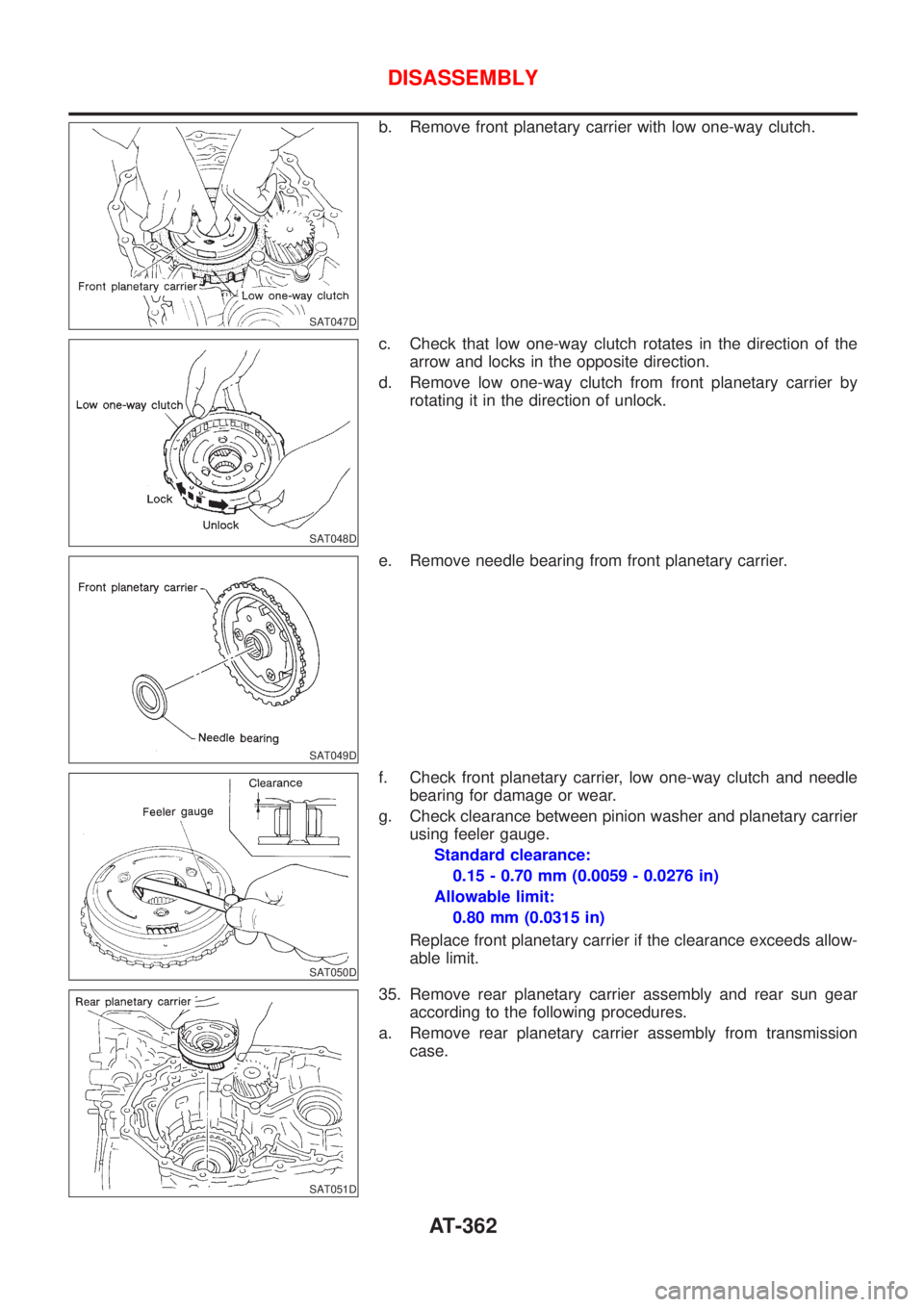

SAT047D

b. Remove front planetary carrier with low one-way clutch.

SAT048D

c. Check that low one-way clutch rotates in the direction of the

arrow and locks in the opposite direction.

d. Remove low one-way clutch from front planetary carrier by

rotating it in the direction of unlock.

SAT049D

e. Remove needle bearing from front planetary carrier.

SAT050D

f. Check front planetary carrier, low one-way clutch and needle

bearing for damage or wear.

g. Check clearance between pinion washer and planetary carrier

using feeler gauge.

Standard clearance:

0.15 - 0.70 mm (0.0059 - 0.0276 in)

Allowable limit:

0.80 mm (0.0315 in)

Replace front planetary carrier if the clearance exceeds allow-

able limit.

SAT051D

35. Remove rear planetary carrier assembly and rear sun gear

according to the following procedures.

a. Remove rear planetary carrier assembly from transmission

case.

DISASSEMBLY

AT-362

Page 1549 of 2493

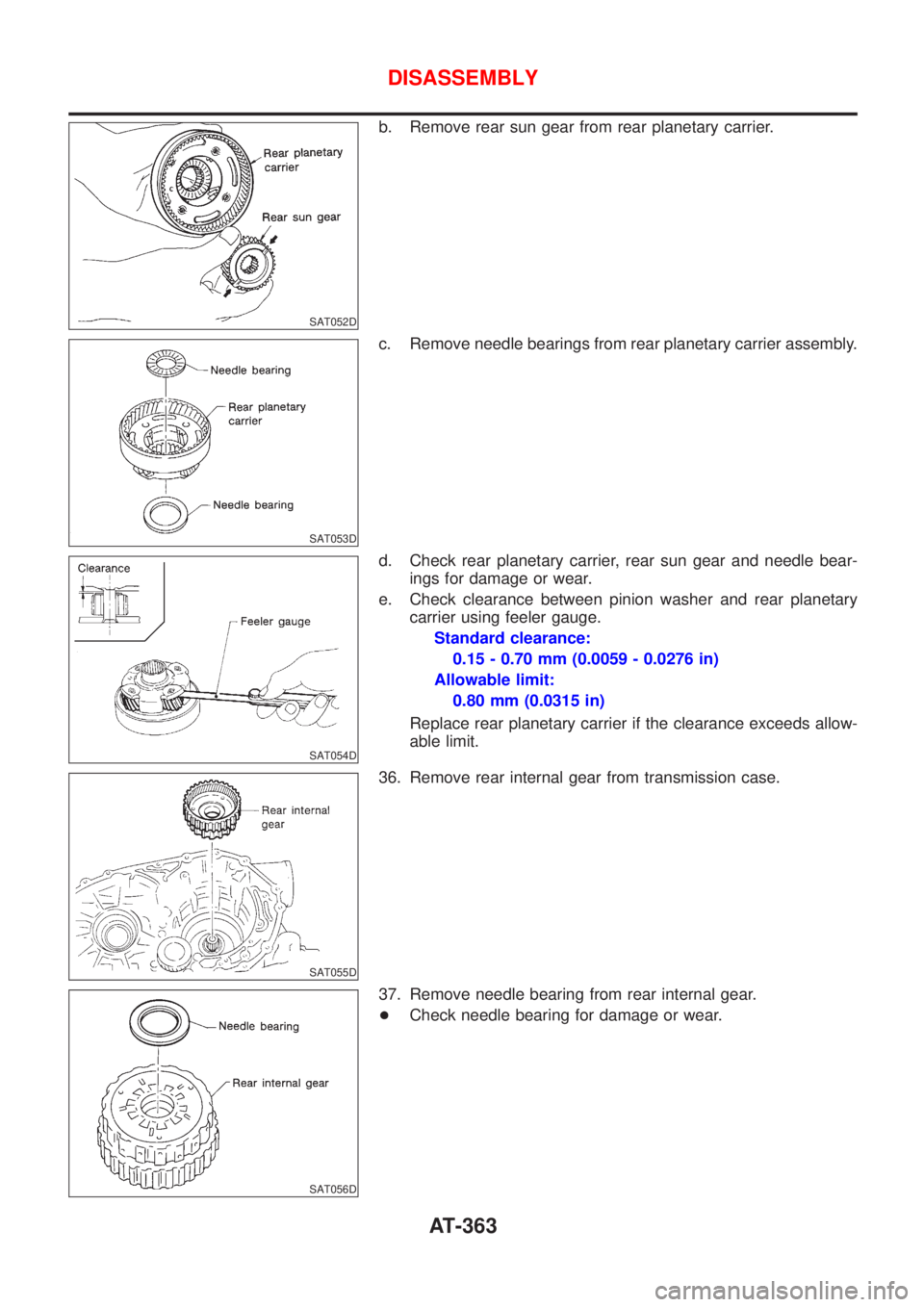

SAT052D

b. Remove rear sun gear from rear planetary carrier.

SAT053D

c. Remove needle bearings from rear planetary carrier assembly.

SAT054D

d. Check rear planetary carrier, rear sun gear and needle bear-

ings for damage or wear.

e. Check clearance between pinion washer and rear planetary

carrier using feeler gauge.

Standard clearance:

0.15 - 0.70 mm (0.0059 - 0.0276 in)

Allowable limit:

0.80 mm (0.0315 in)

Replace rear planetary carrier if the clearance exceeds allow-

able limit.

SAT055D

36. Remove rear internal gear from transmission case.

SAT056D

37. Remove needle bearing from rear internal gear.

+Check needle bearing for damage or wear.

DISASSEMBLY

AT-363

Page 1550 of 2493

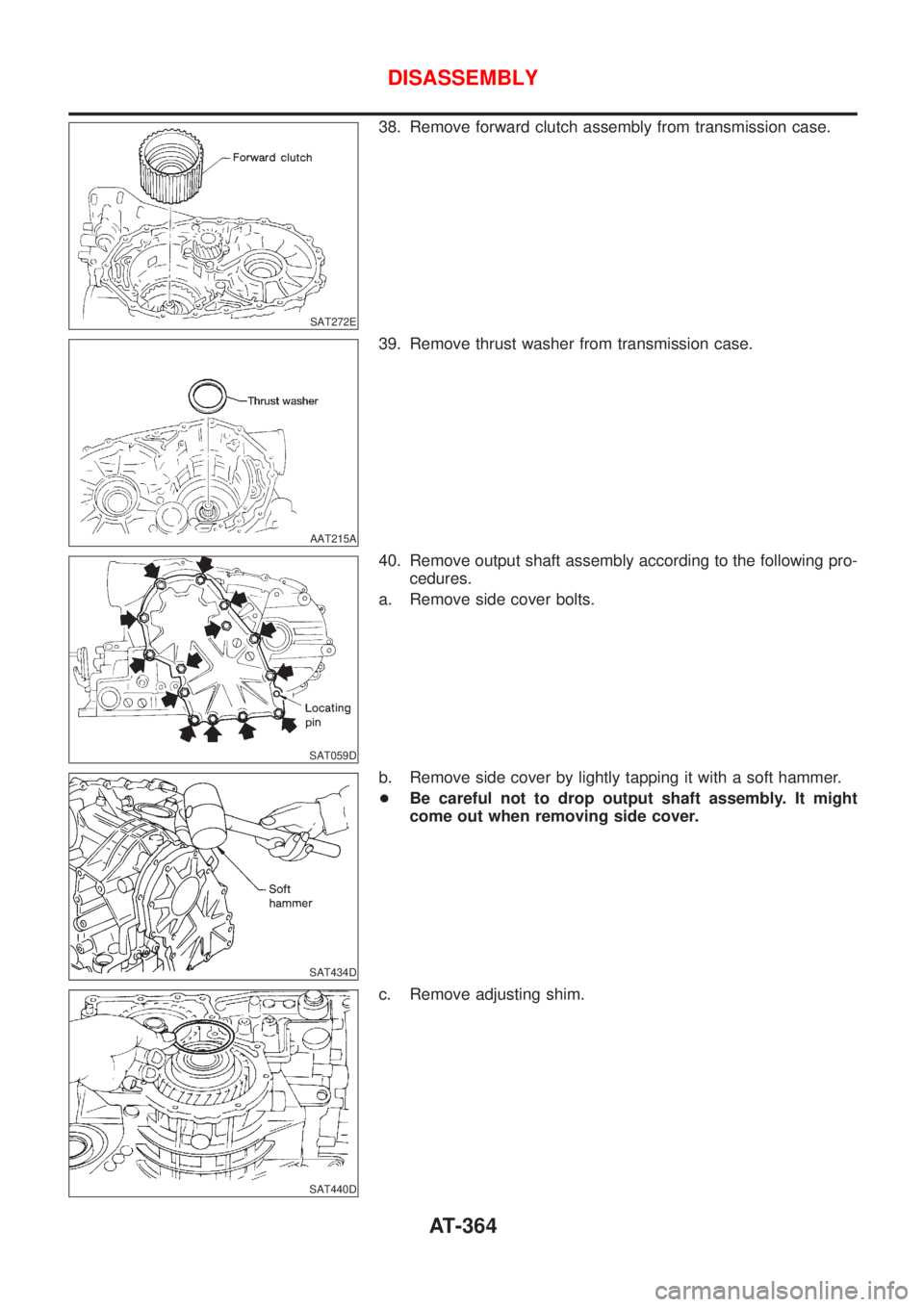

SAT272E

38. Remove forward clutch assembly from transmission case.

AAT215A

39. Remove thrust washer from transmission case.

SAT059D

40. Remove output shaft assembly according to the following pro-

cedures.

a. Remove side cover bolts.

SAT434D

b. Remove side cover by lightly tapping it with a soft hammer.

+Be careful not to drop output shaft assembly. It might

come out when removing side cover.

SAT440D

c. Remove adjusting shim.

DISASSEMBLY

AT-364

Trending: Résistance, filter, engine oil, load capacity, Hand break, jack points, seats