NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1521 of 2493

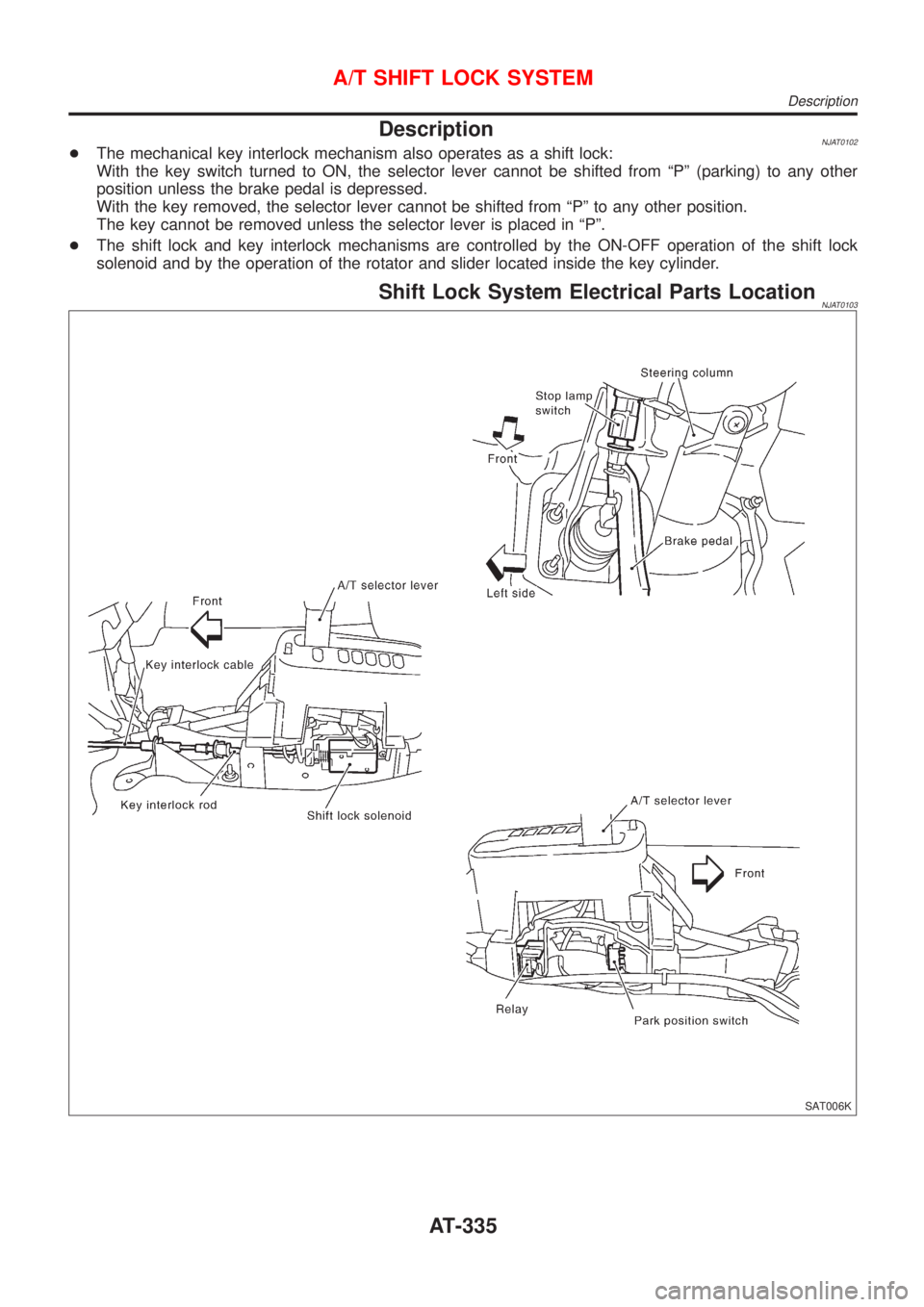

DescriptionNJAT0102+The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from ªPº (parking) to any other

position unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from ªPº to any other position.

The key cannot be removed unless the selector lever is placed in ªPº.

+The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock

solenoid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationNJAT0103

SAT006K

A/T SHIFT LOCK SYSTEM

Description

AT-335

Page 1522 of 2493

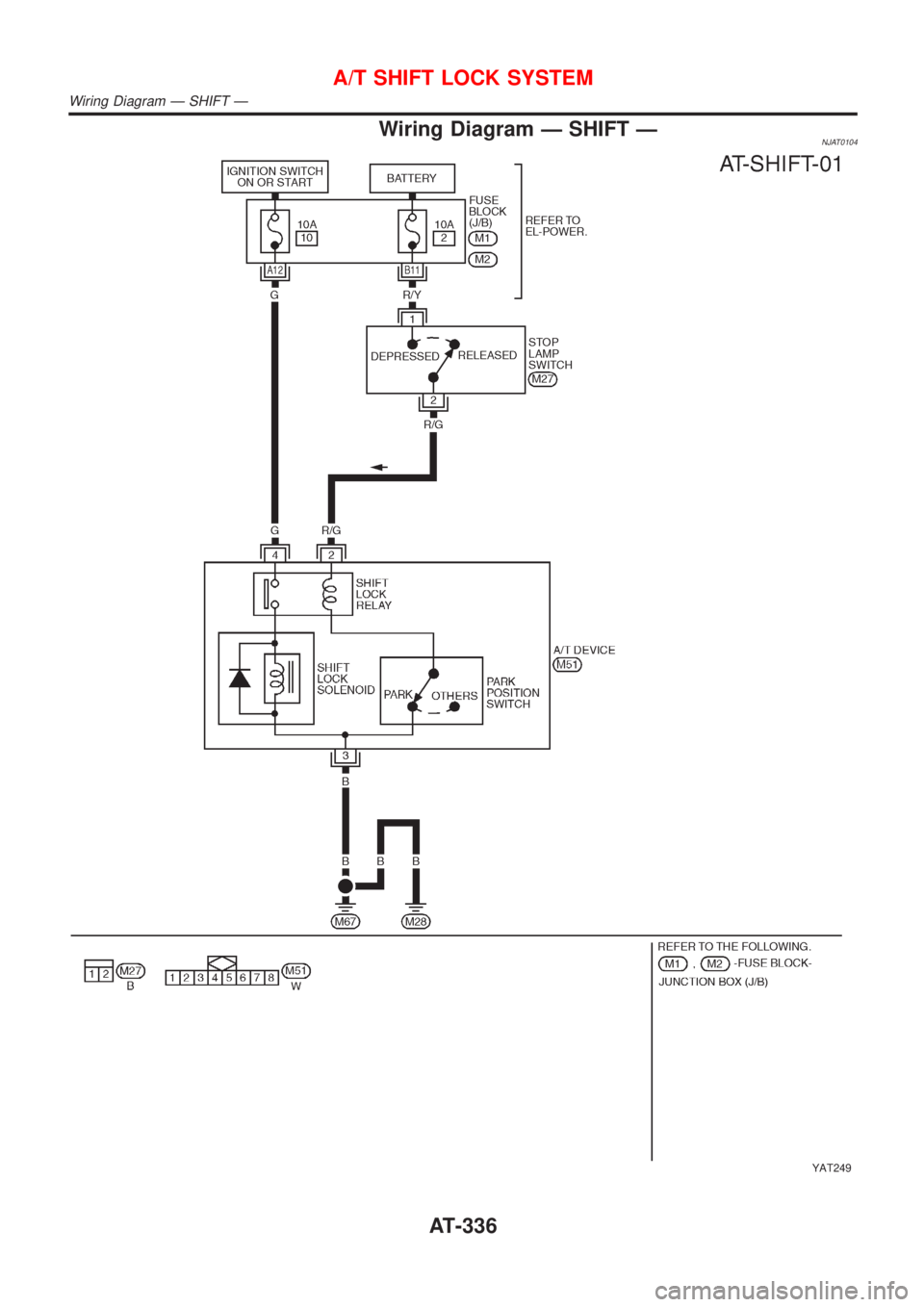

Wiring Diagram Ð SHIFT ÐNJAT0104

YAT249

A/T SHIFT LOCK SYSTEM

Wiring Diagram Ð SHIFT Ð

AT-336

Page 1523 of 2493

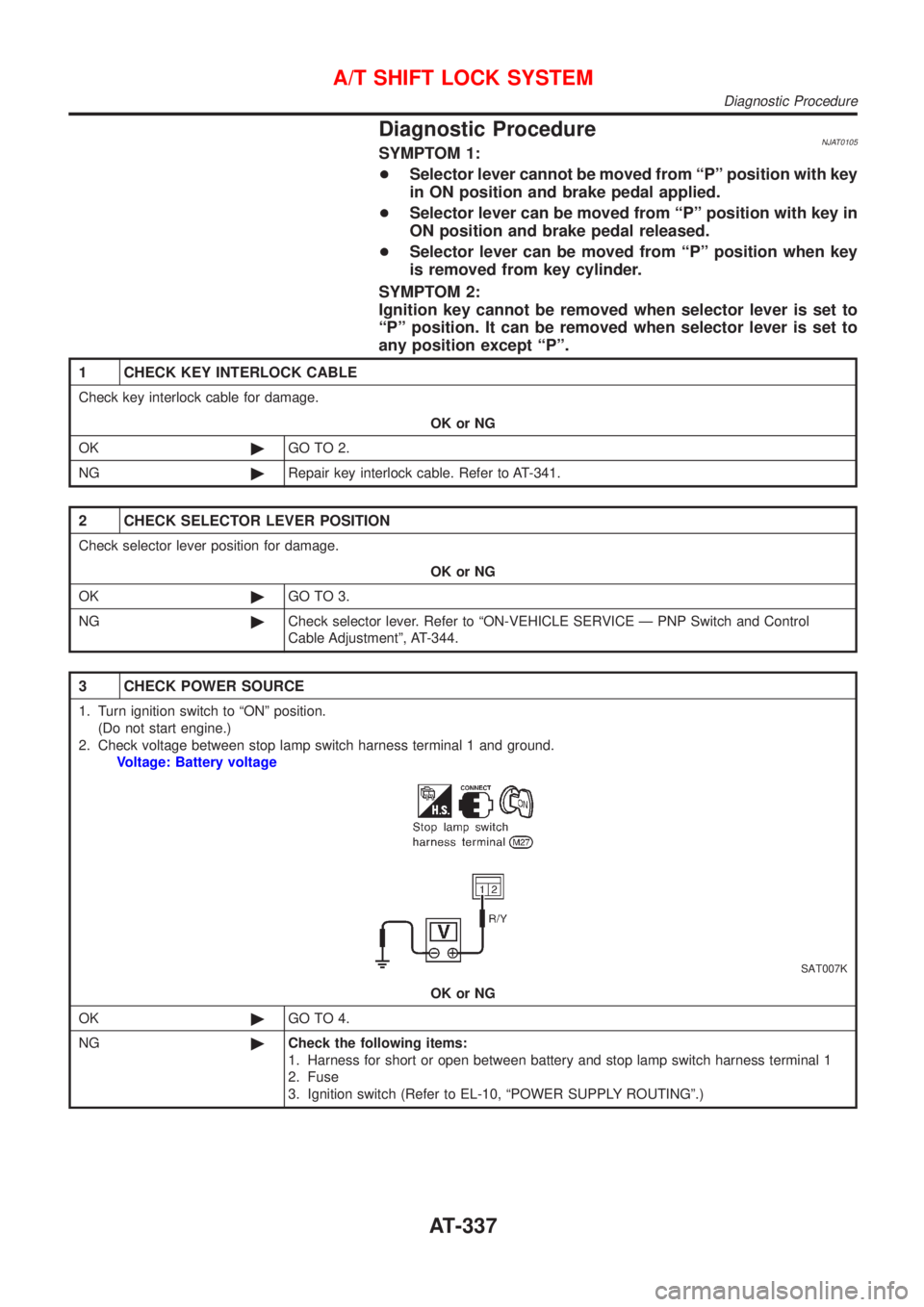

Diagnostic ProcedureNJAT0105SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-341.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-344.

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT007K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL-10, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-337

Page 1524 of 2493

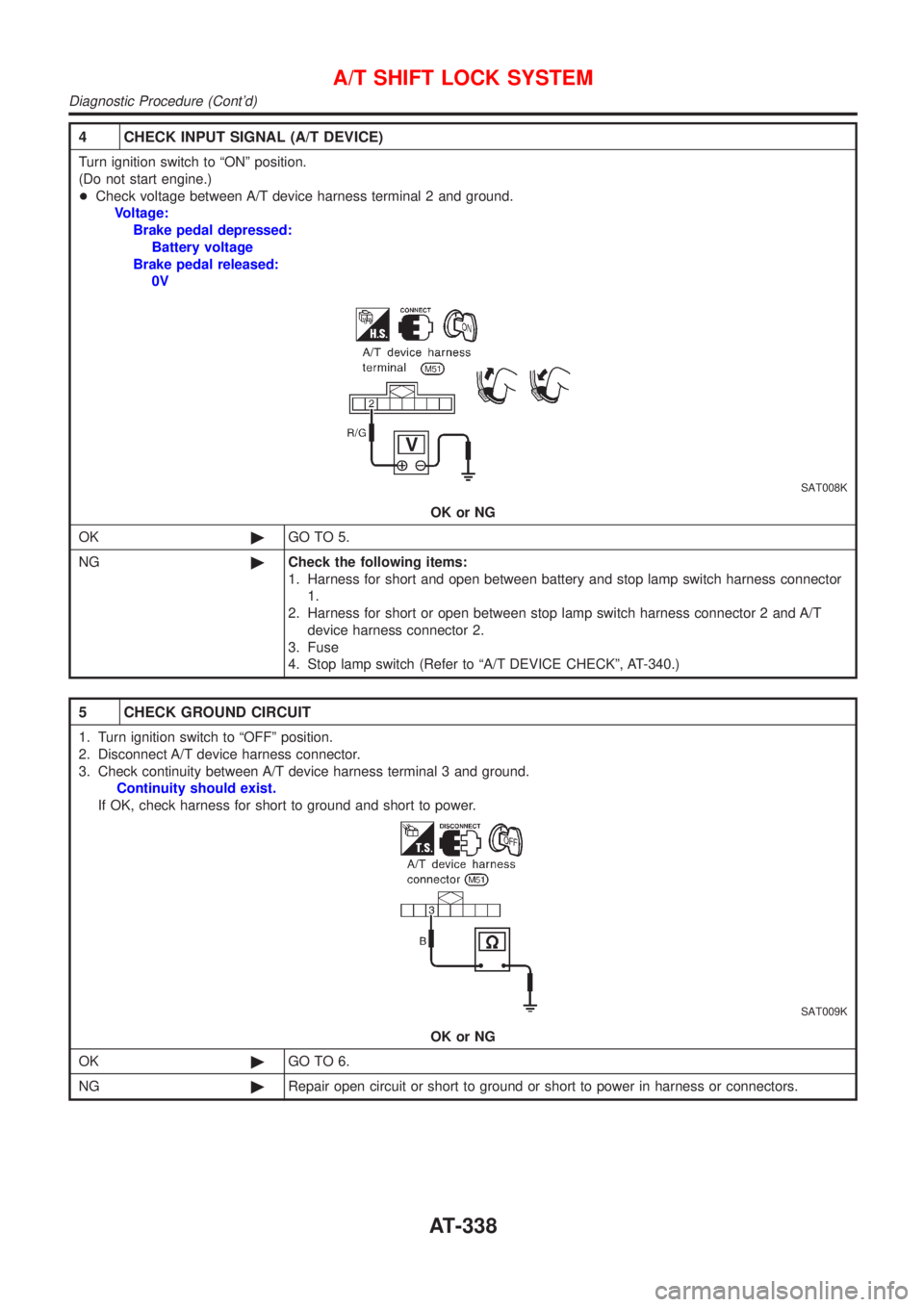

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 2 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT008K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 2.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-340.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 3 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT009K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-338

Page 1525 of 2493

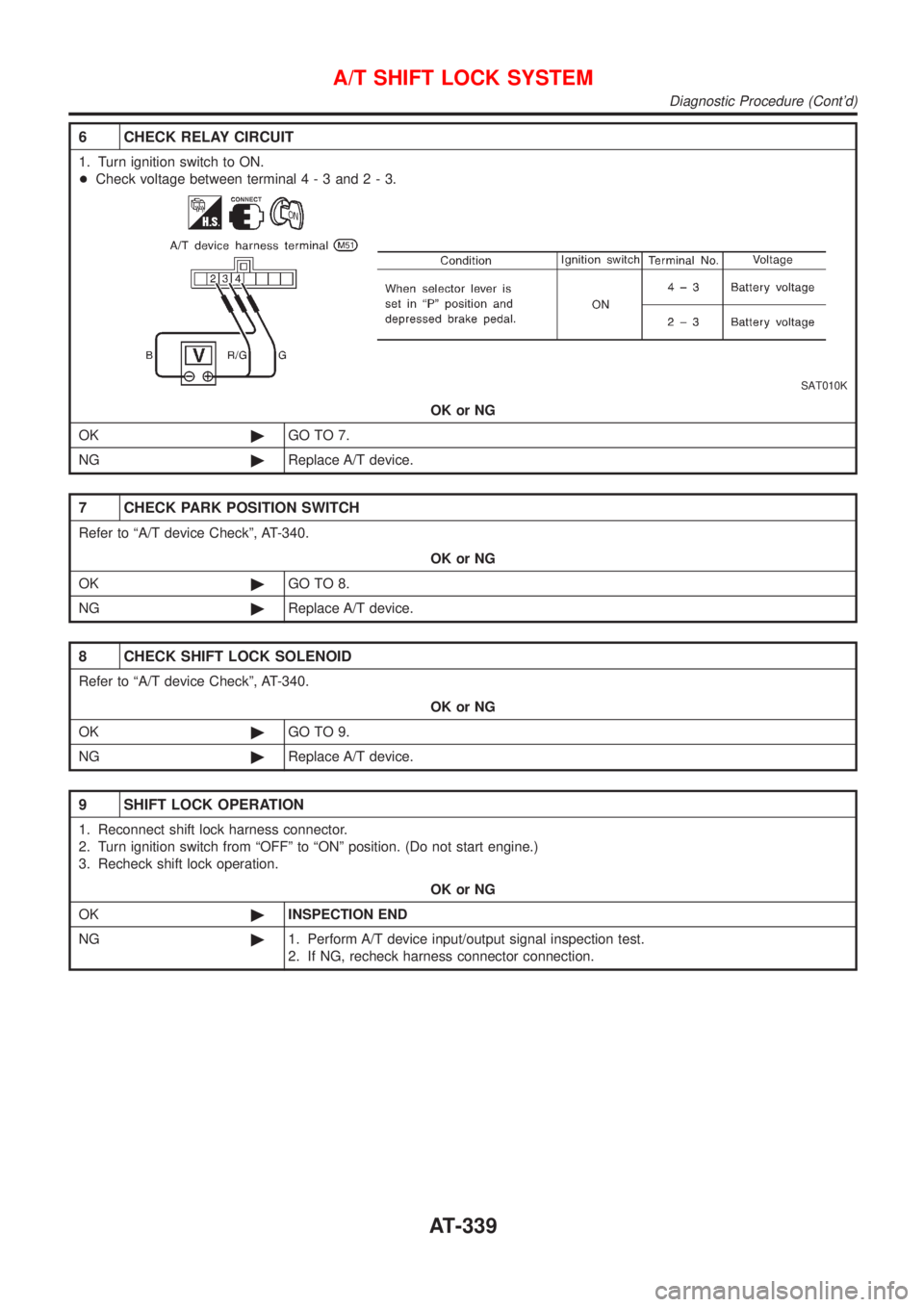

6 CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

+Check voltage between terminal4-3and2-3.

SAT010K

OK or NG

OK©GO TO 7.

NG©Replace A/T device.

7 CHECK PARK POSITION SWITCH

Refer to ªA/T device Checkº, AT-340.

OK or NG

OK©GO TO 8.

NG©Replace A/T device.

8 CHECK SHIFT LOCK SOLENOID

Refer to ªA/T device Checkº, AT-340.

OK or NG

OK©GO TO 9.

NG©Replace A/T device.

9 SHIFT LOCK OPERATION

1. Reconnect shift lock harness connector.

2. Turn ignition switch from ªOFFº to ªONº position. (Do not start engine.)

3. Recheck shift lock operation.

OK or NG

OK©INSPECTION END

NG©1. Perform A/T device input/output signal inspection test.

2. If NG, recheck harness connector connection.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-339

Page 1526 of 2493

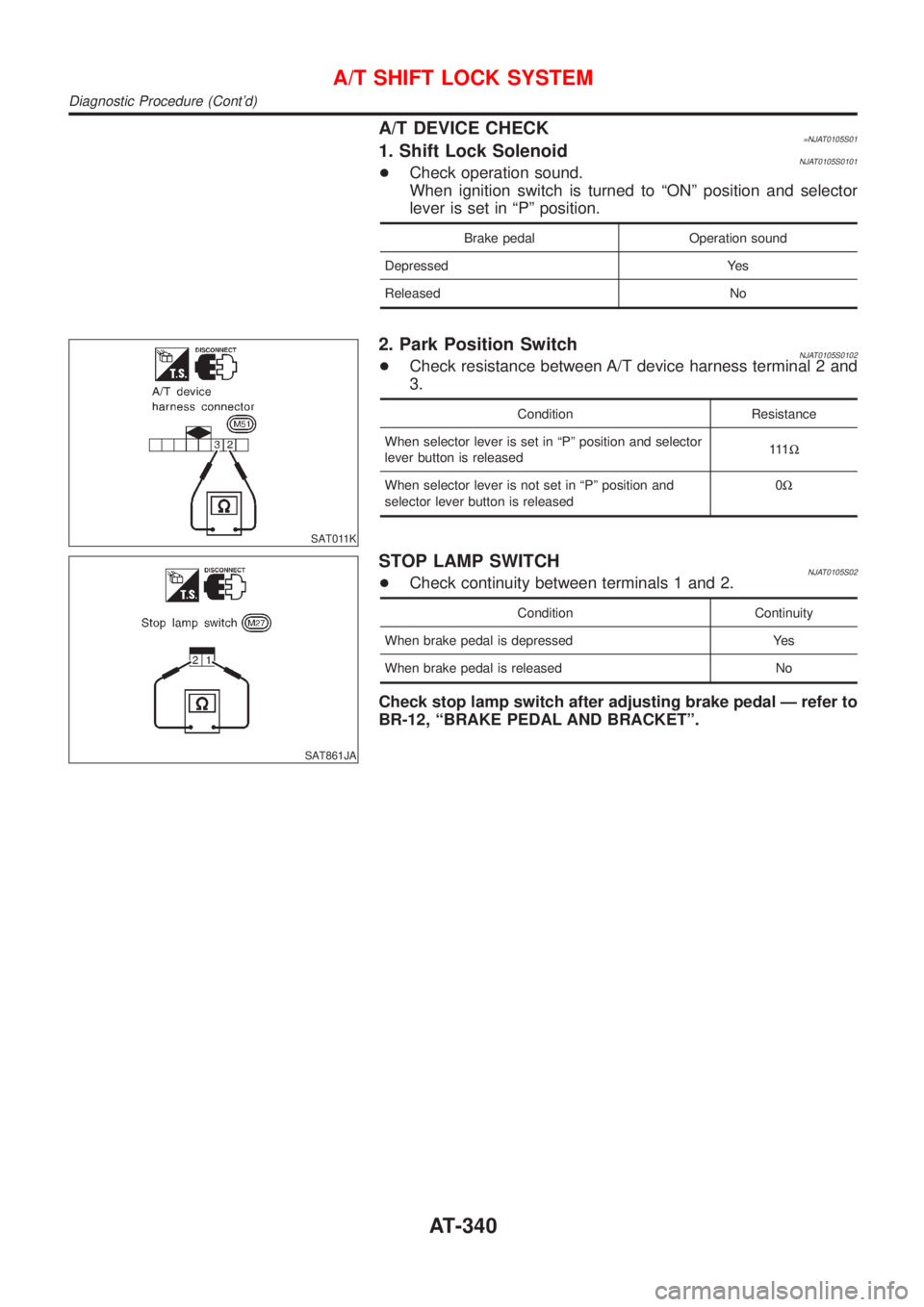

A/T DEVICE CHECK=NJAT0105S011. Shift Lock SolenoidNJAT0105S0101+Check operation sound.

When ignition switch is turned to ªONº position and selector

lever is set in ªPº position.

Brake pedal Operation sound

Depressed Yes

Released No

SAT011K

2. Park Position SwitchNJAT0105S0102+Check resistance between A/T device harness terminal 2 and

3.

Condition Resistance

When selector lever is set in ªPº position and selector

lever button is released111W

When selector lever is not set in ªPº position and

selector lever button is released0W

SAT861JA

STOP LAMP SWITCHNJAT0105S02+Check continuity between terminals 1 and 2.

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

Check stop lamp switch after adjusting brake pedal Ð refer to

BR-12, ªBRAKE PEDAL AND BRACKETº.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-340

Page 1527 of 2493

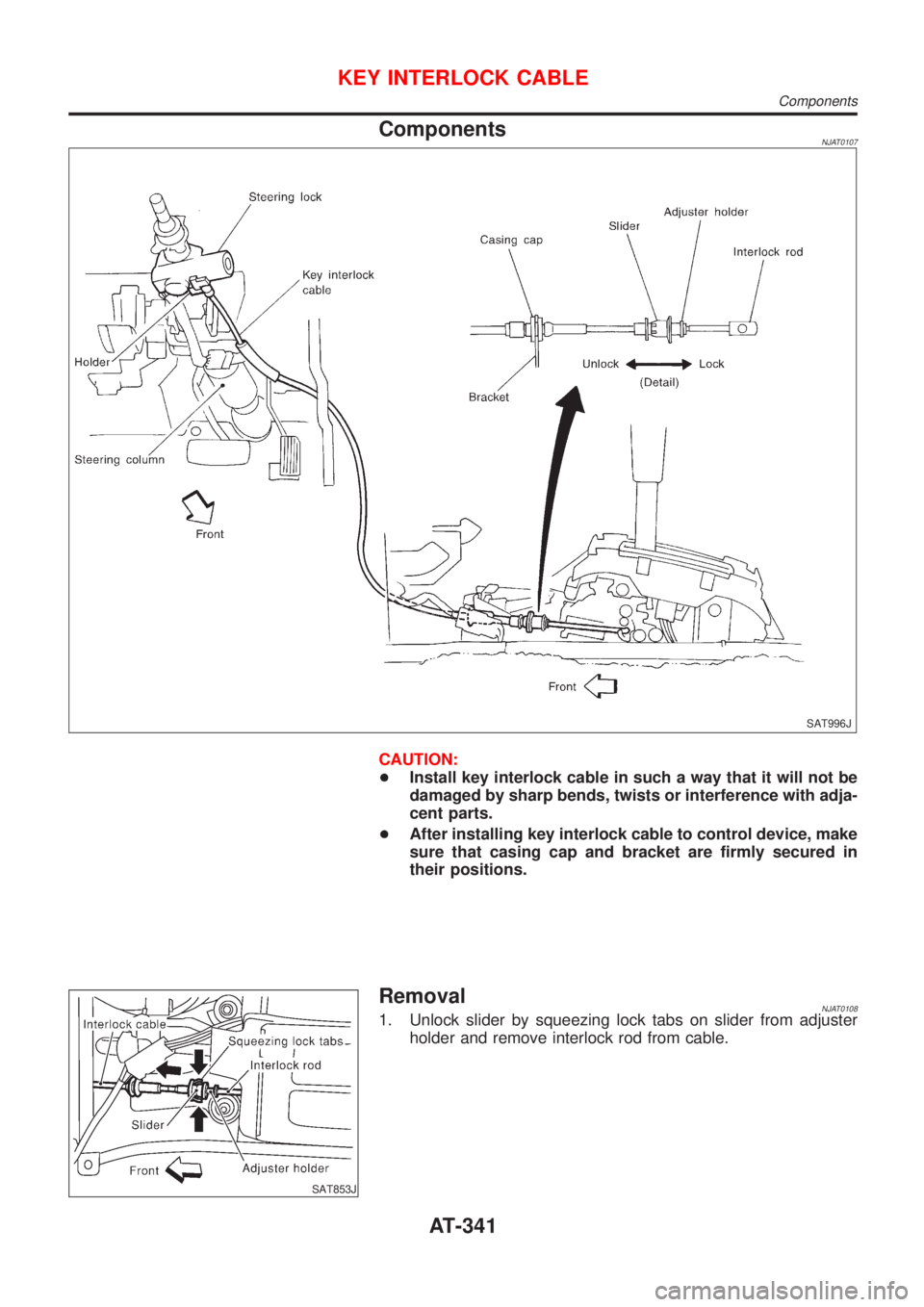

ComponentsNJAT0107

SAT996J

CAUTION:

+Install key interlock cable in such a way that it will not be

damaged by sharp bends, twists or interference with adja-

cent parts.

+After installing key interlock cable to control device, make

sure that casing cap and bracket are firmly secured in

their positions.

SAT853J

RemovalNJAT01081. Unlock slider by squeezing lock tabs on slider from adjuster

holder and remove interlock rod from cable.

KEY INTERLOCK CABLE

Components

AT-341

Page 1528 of 2493

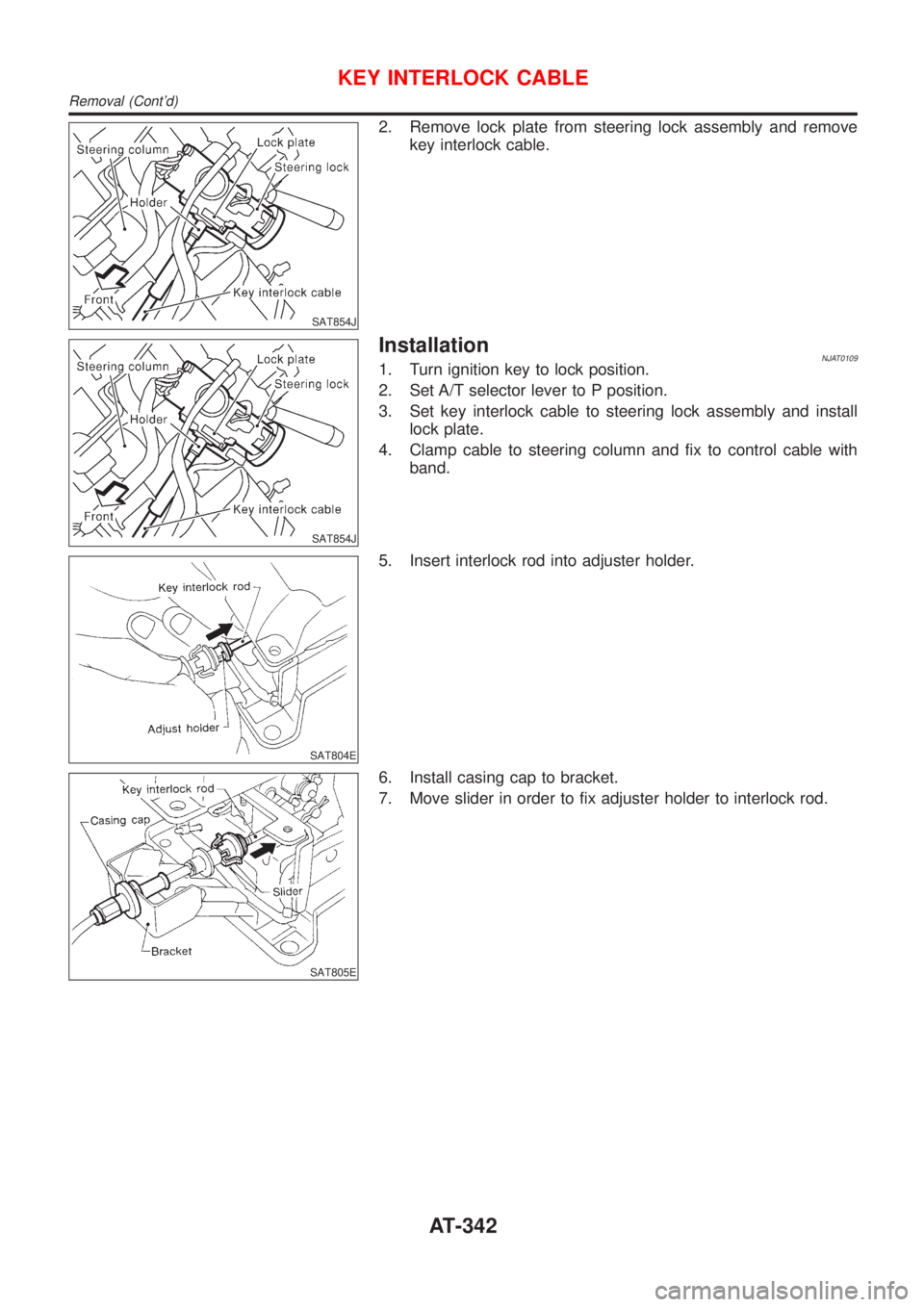

SAT854J

2. Remove lock plate from steering lock assembly and remove

key interlock cable.

SAT854J

InstallationNJAT01091. Turn ignition key to lock position.

2. Set A/T selector lever to P position.

3. Set key interlock cable to steering lock assembly and install

lock plate.

4. Clamp cable to steering column and fix to control cable with

band.

SAT804E

5. Insert interlock rod into adjuster holder.

SAT805E

6. Install casing cap to bracket.

7. Move slider in order to fix adjuster holder to interlock rod.

KEY INTERLOCK CABLE

Removal (Cont'd)

AT-342

Page 1529 of 2493

SAT992C

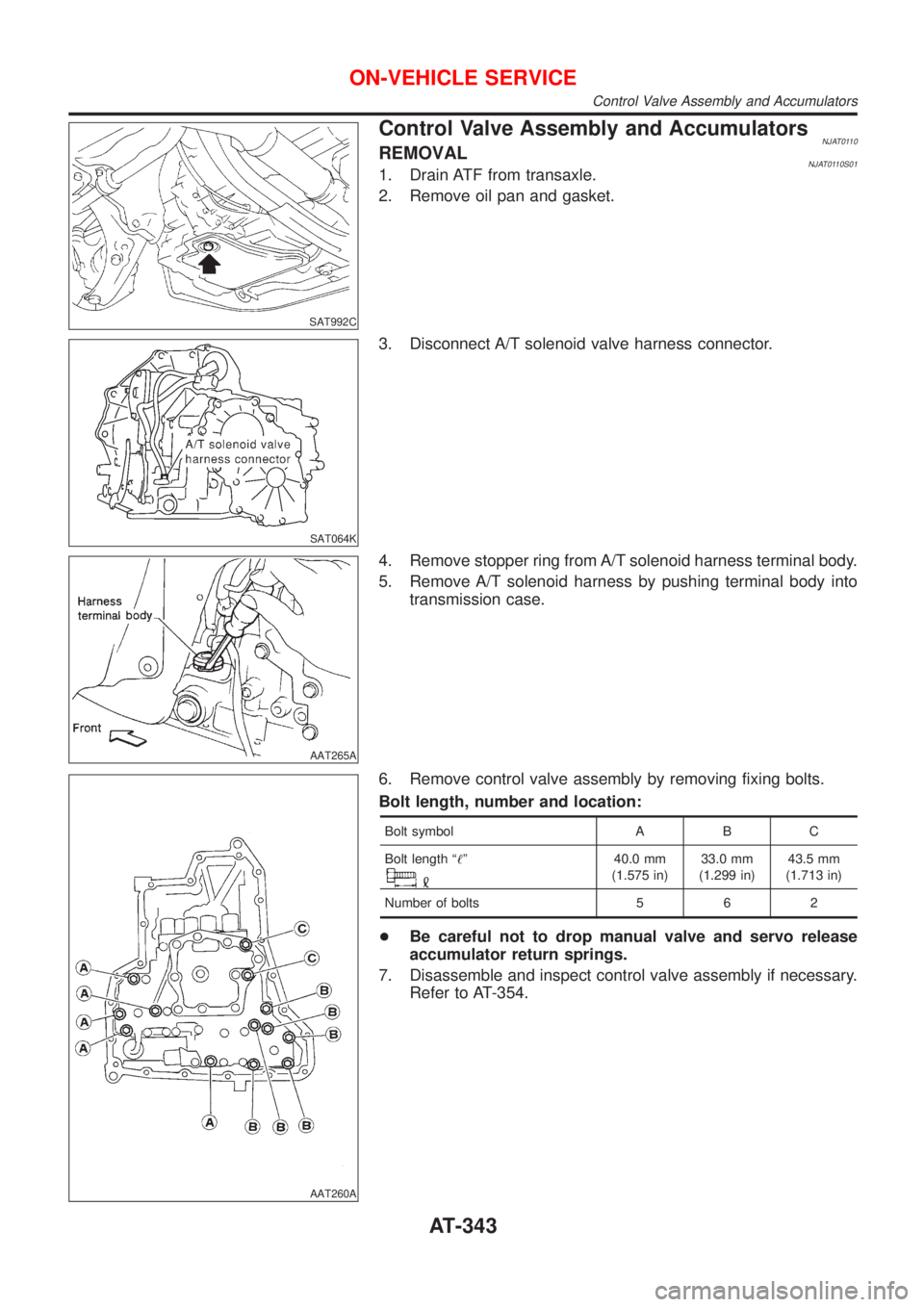

Control Valve Assembly and AccumulatorsNJAT0110REMOVALNJAT0110S011. Drain ATF from transaxle.

2. Remove oil pan and gasket.

SAT064K

3. Disconnect A/T solenoid valve harness connector.

AAT265A

4. Remove stopper ring from A/T solenoid harness terminal body.

5. Remove A/T solenoid harness by pushing terminal body into

transmission case.

AAT260A

6. Remove control valve assembly by removing fixing bolts.

Bolt length, number and location:

Bolt symbol A B C

Bolt length ª!º

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

+Be careful not to drop manual valve and servo release

accumulator return springs.

7. Disassemble and inspect control valve assembly if necessary.

Refer to AT-354.

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators

AT-343

Page 1530 of 2493

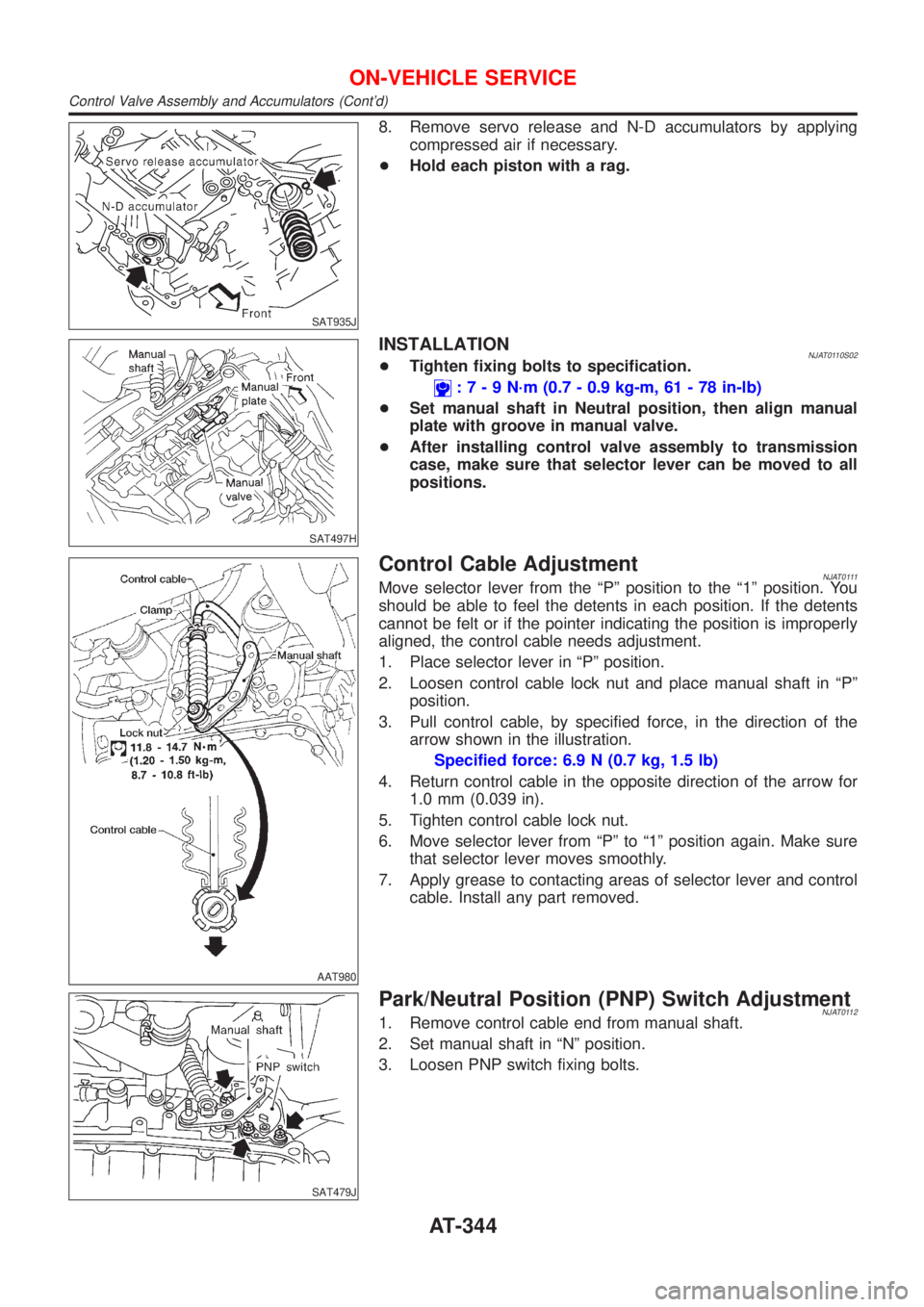

SAT935J

8. Remove servo release and N-D accumulators by applying

compressed air if necessary.

+Hold each piston with a rag.

SAT497H

INSTALLATIONNJAT0110S02+Tighten fixing bolts to specification.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

+Set manual shaft in Neutral position, then align manual

plate with groove in manual valve.

+After installing control valve assembly to transmission

case, make sure that selector lever can be moved to all

positions.

AAT980

Control Cable AdjustmentNJAT0111Move selector lever from the ªPº position to the ª1º position. You

should be able to feel the detents in each position. If the detents

cannot be felt or if the pointer indicating the position is improperly

aligned, the control cable needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen control cable lock nut and place manual shaft in ªPº

position.

3. Pull control cable, by specified force, in the direction of the

arrow shown in the illustration.

Specified force: 6.9 N (0.7 kg, 1.5 lb)

4. Return control cable in the opposite direction of the arrow for

1.0 mm (0.039 in).

5. Tighten control cable lock nut.

6. Move selector lever from ªPº to ª1º position again. Make sure

that selector lever moves smoothly.

7. Apply grease to contacting areas of selector lever and control

cable. Install any part removed.

SAT479J

Park/Neutral Position (PNP) Switch AdjustmentNJAT01121. Remove control cable end from manual shaft.

2. Set manual shaft in ªNº position.

3. Loosen PNP switch fixing bolts.

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators (Cont'd)

AT-344