EL page 71 NISSAN ALMERA N16 2001 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 363 of 2493

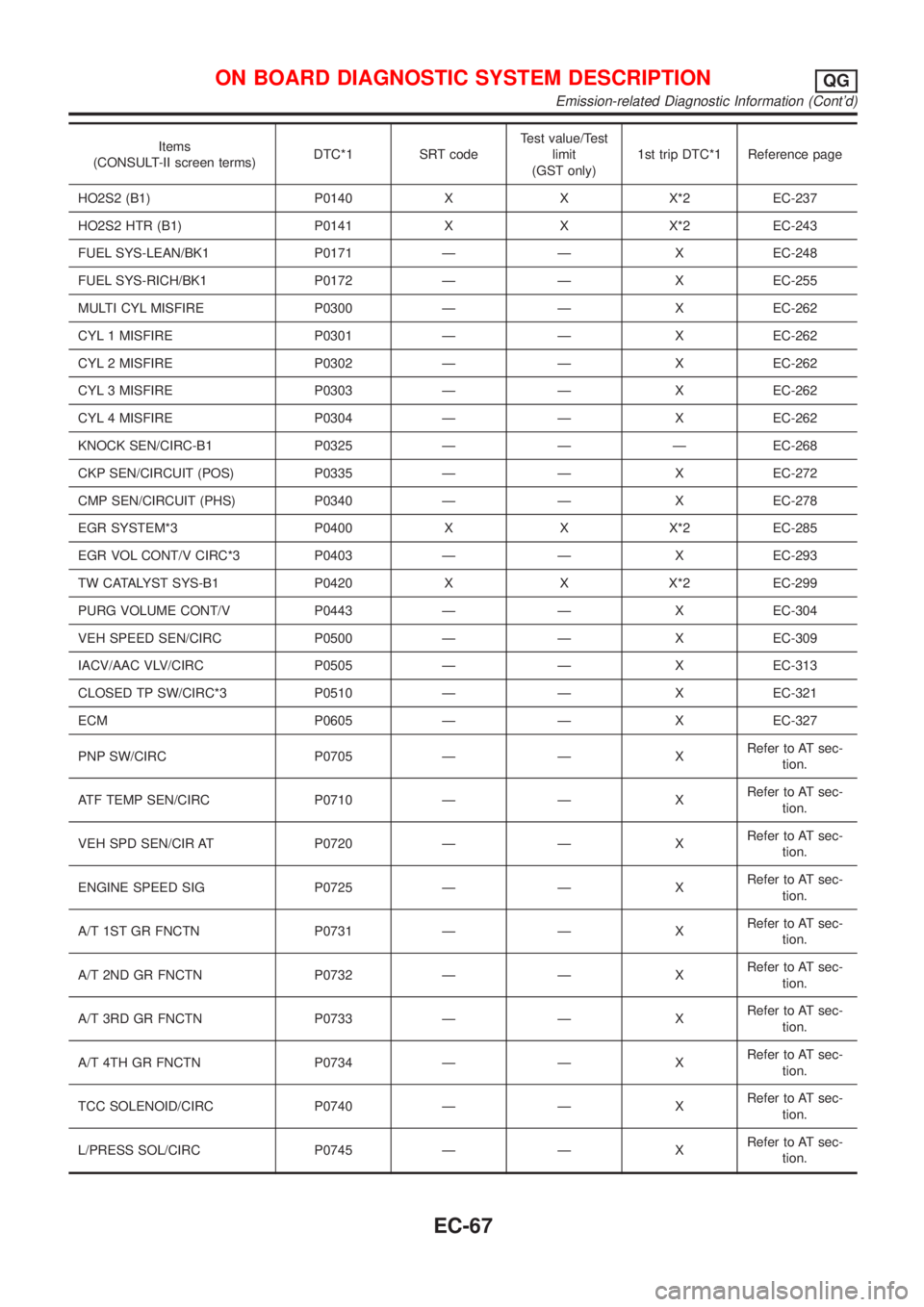

Items

(CONSULT-II screen terms)DTC*1 SRT codeTest value/Test

limit

(GST only)1st trip DTC*1 Reference page

HO2S2 (B1) P0140 X X X*2 EC-237

HO2S2 HTR (B1) P0141 X X X*2 EC-243

FUEL SYS-LEAN/BK1 P0171 Ð Ð X EC-248

FUEL SYS-RICH/BK1 P0172 Ð Ð X EC-255

MULTI CYL MISFIRE P0300 Ð Ð X EC-262

CYL 1 MISFIRE P0301 Ð Ð X EC-262

CYL 2 MISFIRE P0302 Ð Ð X EC-262

CYL 3 MISFIRE P0303 Ð Ð X EC-262

CYL 4 MISFIRE P0304 Ð Ð X EC-262

KNOCK SEN/CIRC-B1 P0325 Ð Ð Ð EC-268

CKP SEN/CIRCUIT (POS) P0335 Ð Ð X EC-272

CMP SEN/CIRCUIT (PHS) P0340 Ð Ð X EC-278

EGR SYSTEM*3 P0400 X X X*2 EC-285

EGR VOL CONT/V CIRC*3 P0403 Ð Ð X EC-293

TW CATALYST SYS-B1 P0420 X X X*2 EC-299

PURG VOLUME CONT/V P0443 Ð Ð X EC-304

VEH SPEED SEN/CIRC P0500 Ð Ð X EC-309

IACV/AAC VLV/CIRC P0505 Ð Ð X EC-313

CLOSED TP SW/CIRC*3 P0510 Ð Ð X EC-321

ECM P0605 Ð Ð X EC-327

PNP SW/CIRC P0705 Ð Ð XRefer to AT sec-

tion.

ATF TEMP SEN/CIRC P0710 Ð Ð XRefer to AT sec-

tion.

VEH SPD SEN/CIR AT P0720 Ð Ð XRefer to AT sec-

tion.

ENGINE SPEED SIG P0725 Ð Ð XRefer to AT sec-

tion.

A/T 1ST GR FNCTN P0731 Ð Ð XRefer to AT sec-

tion.

A/T 2ND GR FNCTN P0732 Ð Ð XRefer to AT sec-

tion.

A/T 3RD GR FNCTN P0733 Ð Ð XRefer to AT sec-

tion.

A/T 4TH GR FNCTN P0734 Ð Ð XRefer to AT sec-

tion.

TCC SOLENOID/CIRC P0740 Ð Ð XRefer to AT sec-

tion.

L/PRESS SOL/CIRC P0745 Ð Ð XRefer to AT sec-

tion.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

Emission-related Diagnostic Information (Cont'd)

EC-67

Page 364 of 2493

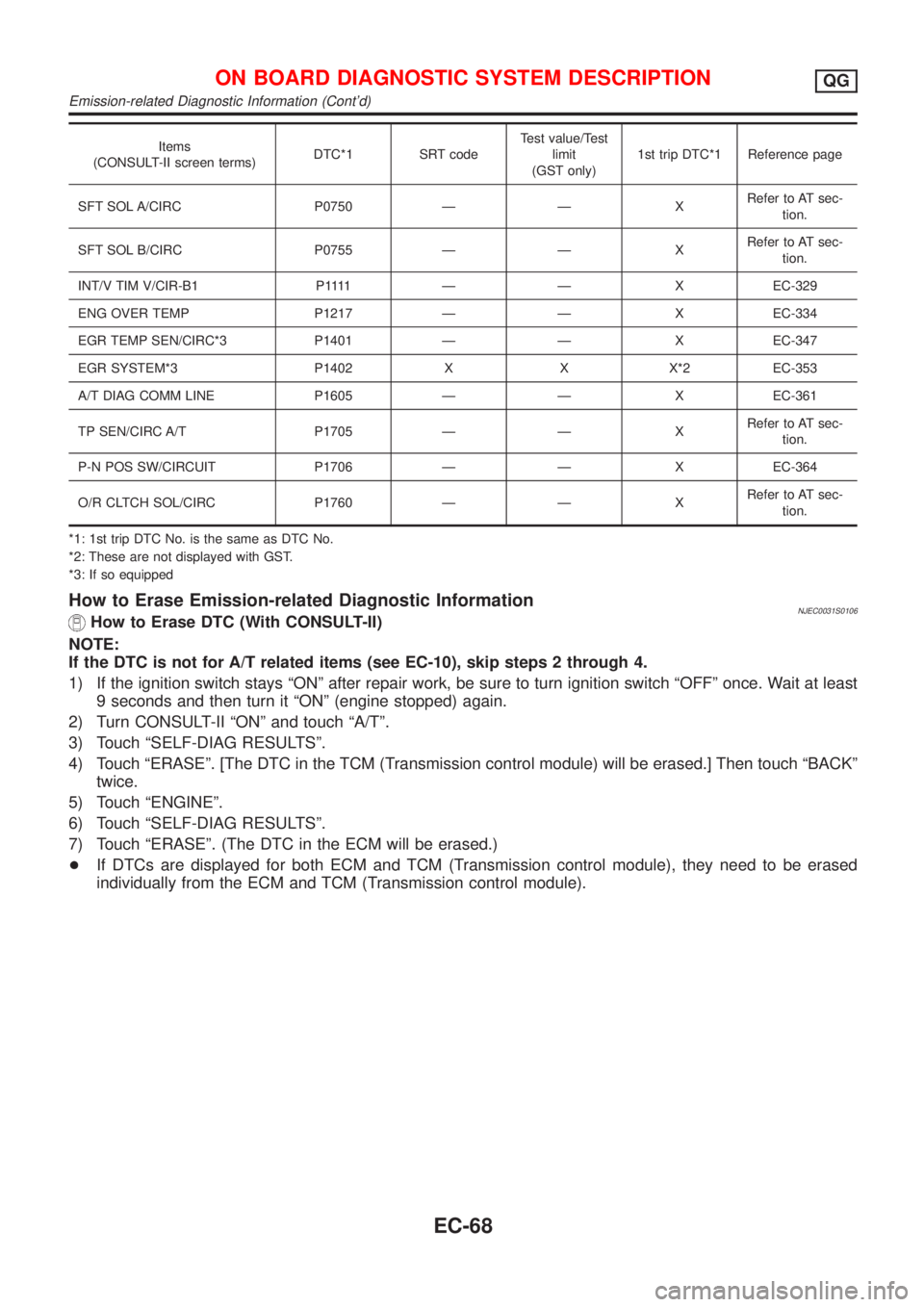

Items

(CONSULT-II screen terms)DTC*1 SRT codeTest value/Test

limit

(GST only)1st trip DTC*1 Reference page

SFT SOL A/CIRC P0750 Ð Ð XRefer to AT sec-

tion.

SFT SOL B/CIRC P0755 Ð Ð XRefer to AT sec-

tion.

INT/V TIM V/CIR-B1 P1111 Ð Ð XEC-329

ENG OVER TEMP P1217 Ð Ð X EC-334

EGR TEMP SEN/CIRC*3 P1401 Ð Ð X EC-347

EGR SYSTEM*3 P1402 X X X*2 EC-353

A/T DIAG COMM LINE P1605 Ð Ð X EC-361

TP SEN/CIRC A/T P1705 Ð Ð XRefer to AT sec-

tion.

P-N POS SW/CIRCUIT P1706 Ð Ð X EC-364

O/R CLTCH SOL/CIRC P1760 Ð Ð XRefer to AT sec-

tion.

*1: 1st trip DTC No. is the same as DTC No.

*2: These are not displayed with GST.

*3: If so equipped

How to Erase Emission-related Diagnostic InformationNJEC0031S0106How to Erase DTC (With CONSULT-II)

NOTE:

If the DTC is not for A/T related items (see EC-10), skip steps 2 through 4.

1) If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

9 seconds and then turn it ªONº (engine stopped) again.

2) Turn CONSULT-II ªONº and touch ªA/Tº.

3) Touch ªSELF-DIAG RESULTSº.

4) Touch ªERASEº. [The DTC in the TCM (Transmission control module) will be erased.] Then touch ªBACKº

twice.

5) Touch ªENGINEº.

6) Touch ªSELF-DIAG RESULTSº.

7) Touch ªERASEº. (The DTC in the ECM will be erased.)

+If DTCs are displayed for both ECM and TCM (Transmission control module), they need to be erased

individually from the ECM and TCM (Transmission control module).

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

Emission-related Diagnostic Information (Cont'd)

EC-68

Page 368 of 2493

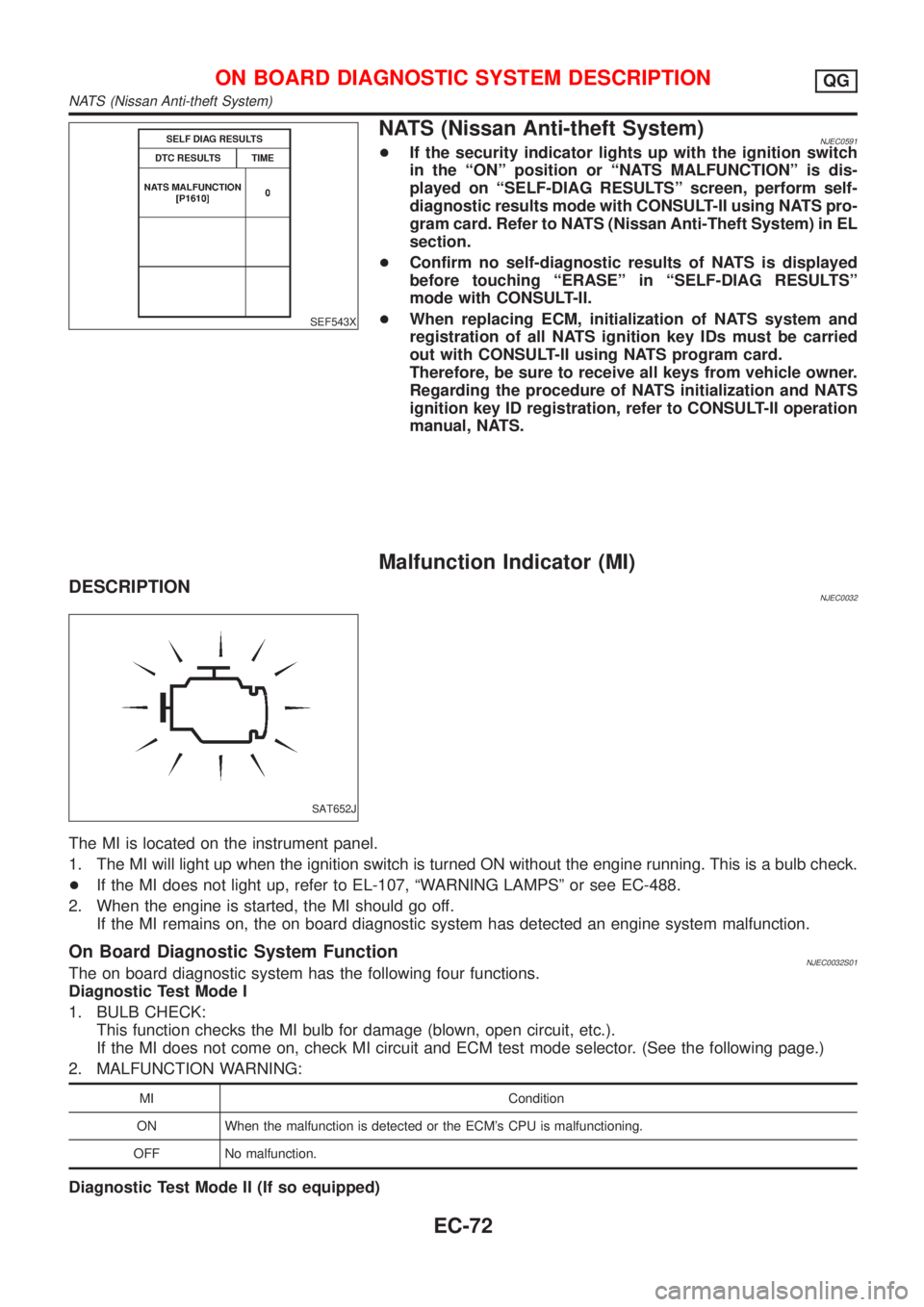

SEF543X

NATS (Nissan Anti-theft System)NJEC0591+If the security indicator lights up with the ignition switch

in the ªONº position or ªNATS MALFUNCTIONº is dis-

played on ªSELF-DIAG RESULTSº screen, perform self-

diagnostic results mode with CONSULT-II using NATS pro-

gram card. Refer to NATS (Nissan Anti-Theft System) in EL

section.

+Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº

mode with CONSULT-II.

+When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried

out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedure of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTIONNJEC0032

SAT652J

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON without the engine running. This is a bulb check.

+If the MI does not light up, refer to EL-107, ªWARNING LAMPSº or see EC-488.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnostic System FunctionNJEC0032S01The on board diagnostic system has the following four functions.

Diagnostic Test Mode I

1. BULB CHECK:

This function checks the MI bulb for damage (blown, open circuit, etc.).

If the MI does not come on, check MI circuit and ECM test mode selector. (See the following page.)

2. MALFUNCTION WARNING:

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

Diagnostic Test Mode II (If so equipped)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

NATS (Nissan Anti-theft System)

EC-72

Page 386 of 2493

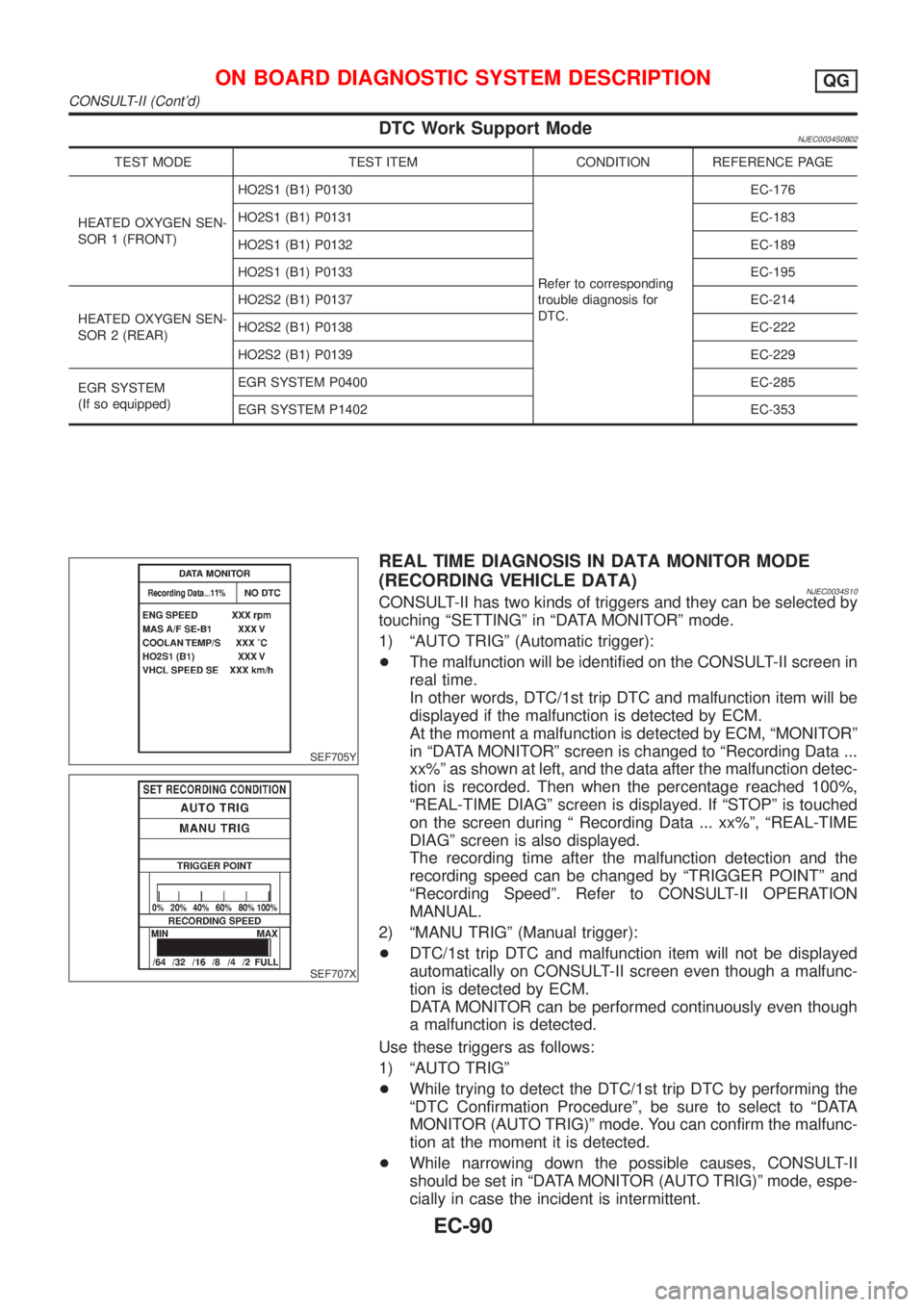

DTC Work Support ModeNJEC0034S0802

TEST MODE TEST ITEM CONDITION REFERENCE PAGE

HEATED OXYGEN SEN-

SOR 1 (FRONT)HO2S1 (B1) P0130

Refer to corresponding

trouble diagnosis for

DTC.EC-176

HO2S1 (B1) P0131 EC-183

HO2S1 (B1) P0132 EC-189

HO2S1 (B1) P0133 EC-195

HEATED OXYGEN SEN-

SOR 2 (REAR)HO2S2 (B1) P0137 EC-214

HO2S2 (B1) P0138 EC-222

HO2S2 (B1) P0139 EC-229

EGR SYSTEM

(If so equipped)EGR SYSTEM P0400 EC-285

EGR SYSTEM P1402 EC-353

SEF705Y

SEF707X

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

(RECORDING VEHICLE DATA)

NJEC0034S10CONSULT-II has two kinds of triggers and they can be selected by

touching ªSETTINGº in ªDATA MONITORº mode.

1) ªAUTO TRIGº (Automatic trigger):

+The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC/1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, ªMONITORº

in ªDATA MONITORº screen is changed to ªRecording Data ...

xx%┬║ as shown at left, and the data after the malfunction detec-

tion is recorded. Then when the percentage reached 100%,

ªREAL-TIME DIAGº screen is displayed. If ªSTOPº is touched

on the screen during ª Recording Data ... xx%º, ªREAL-TIME

DIAG┬║ screen is also displayed.

The recording time after the malfunction detection and the

recording speed can be changed by ªTRIGGER POINTº and

ªRecording Speedº. Refer to CONSULT-II OPERATION

MANUAL.

2) ªMANU TRIGº (Manual trigger):

+DTC/1st trip DTC and malfunction item will not be displayed

automatically on CONSULT-II screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though

a malfunction is detected.

Use these triggers as follows:

1) ªAUTO TRIGº

+While trying to detect the DTC/1st trip DTC by performing the

ªDTC Confirmation Procedureº, be sure to select to ªDATA

MONITOR (AUTO TRIG)┬║ mode. You can confirm the malfunc-

tion at the moment it is detected.

+While narrowing down the possible causes, CONSULT-II

should be set in ªDATA MONITOR (AUTO TRIG)º mode, espe-

cially in case the incident is intermittent.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

CONSULT-II (Cont'd)

EC-90

Page 388 of 2493

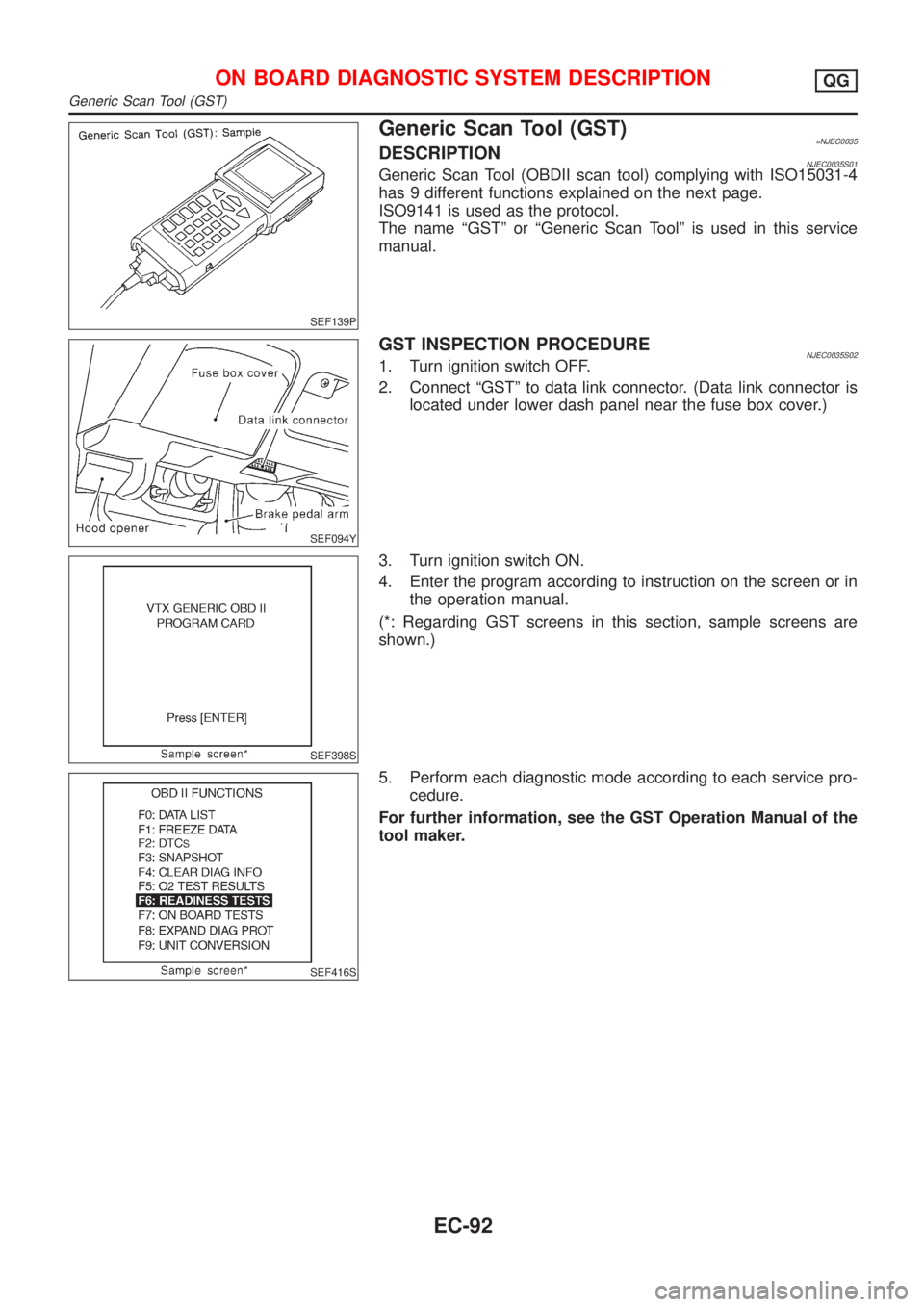

SEF139P

Generic Scan Tool (GST)=NJEC0035DESCRIPTIONNJEC0035S01Generic Scan Tool (OBDII scan tool) complying with ISO15031-4

has 9 different functions explained on the next page.

ISO9141 is used as the protocol.

The name ªGSTº or ªGeneric Scan Toolº is used in this service

manual.

SEF094Y

GST INSPECTION PROCEDURENJEC0035S021. Turn ignition switch OFF.

2. Connect ªGSTº to data link connector. (Data link connector is

located under lower dash panel near the fuse box cover.)

SEF398S

3. Turn ignition switch ON.

4. Enter the program according to instruction on the screen or in

the operation manual.

(*: Regarding GST screens in this section, sample screens are

shown.)

SEF416S

5. Perform each diagnostic mode according to each service pro-

cedure.

For further information, see the GST Operation Manual of the

tool maker.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

Generic Scan Tool (GST)

EC-92

Page 390 of 2493

MEF036D

SEF233G

SEF234G

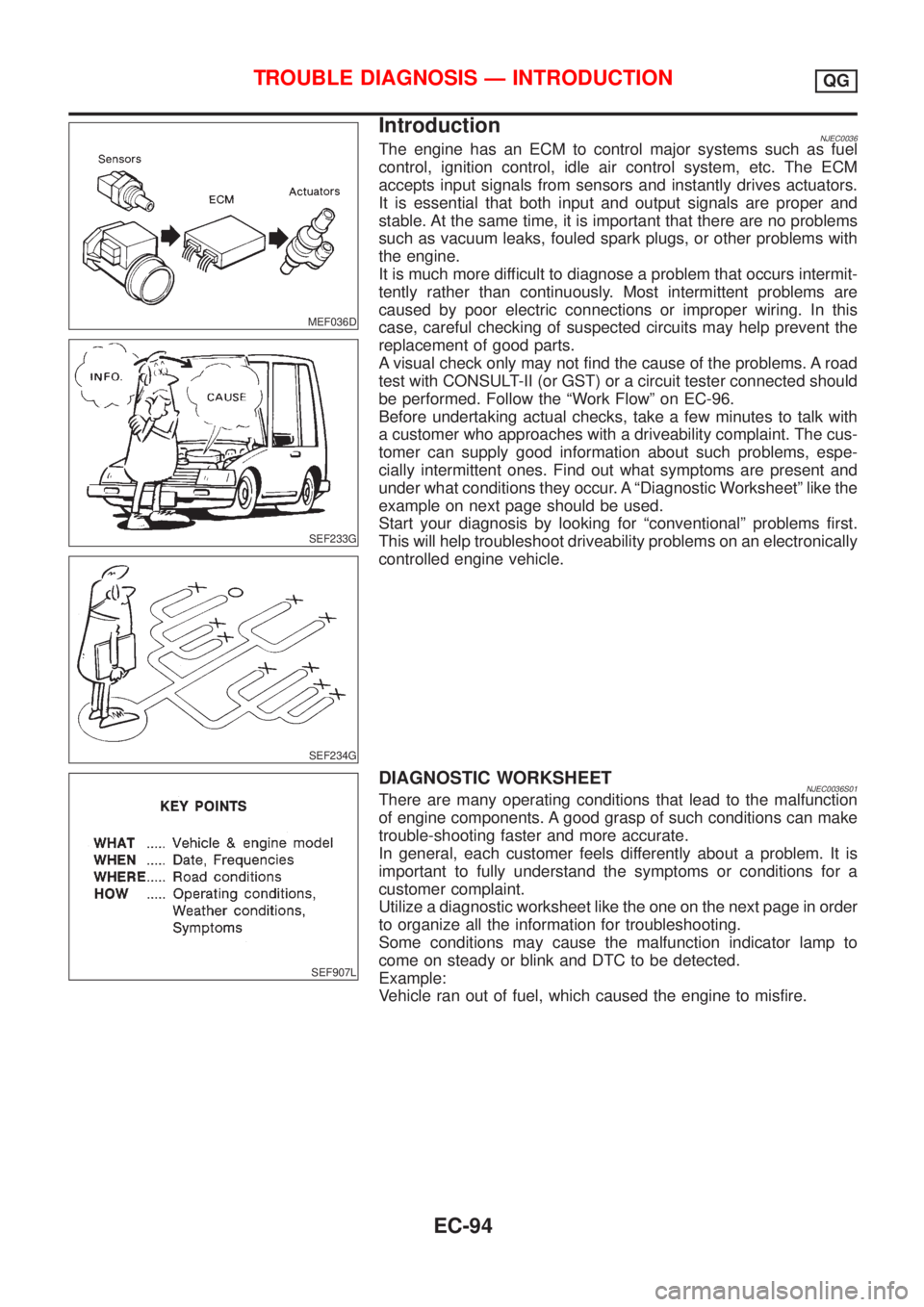

IntroductionNJEC0036The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-96.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

SEF907L

DIAGNOSTIC WORKSHEETNJEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the malfunction indicator lamp to

come on steady or blink and DTC to be detected.

Example:

Vehicle ran out of fuel, which caused the engine to misfire.

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG

EC-94

Page 420 of 2493

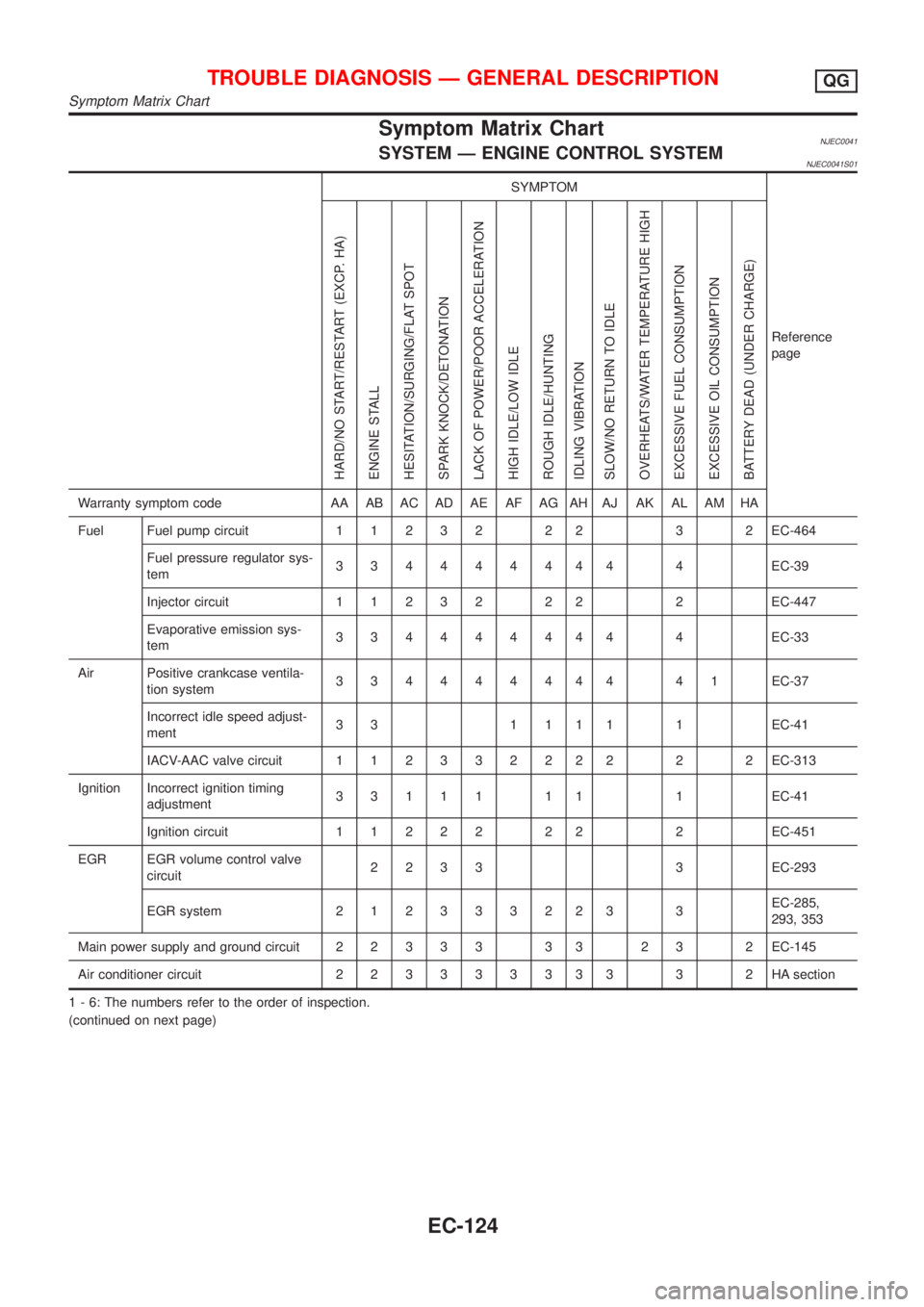

Symptom Matrix ChartNJEC0041SYSTEM Ð ENGINE CONTROL SYSTEMNJEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 22 3 2EC-464

Fuel pressure regulator sys-

tem334444444 4EC-39

Injector circuit11232 22 2EC-447

Evaporative emission sys-

tem334444444 4EC-33

Air Positive crankcase ventila-

tion system334444444 41EC-37

Incorrect idle speed adjust-

ment3 3 1 1 1 1 1 EC-41

IACV-AAC valve circuit112332222 2 2EC-313

Ignition Incorrect ignition timing

adjustment33111 11 1EC-41

Ignition circuit11222 22 2EC-451

EGR EGR volume control valve

circuit2233 3EC-293

EGR system212333223 3EC-285,

293, 353

Main power supply and ground circuit22333 33 23 2EC-145

Air conditioner circuit223333333 3 2HAsection

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart

EC-124

Page 421 of 2493

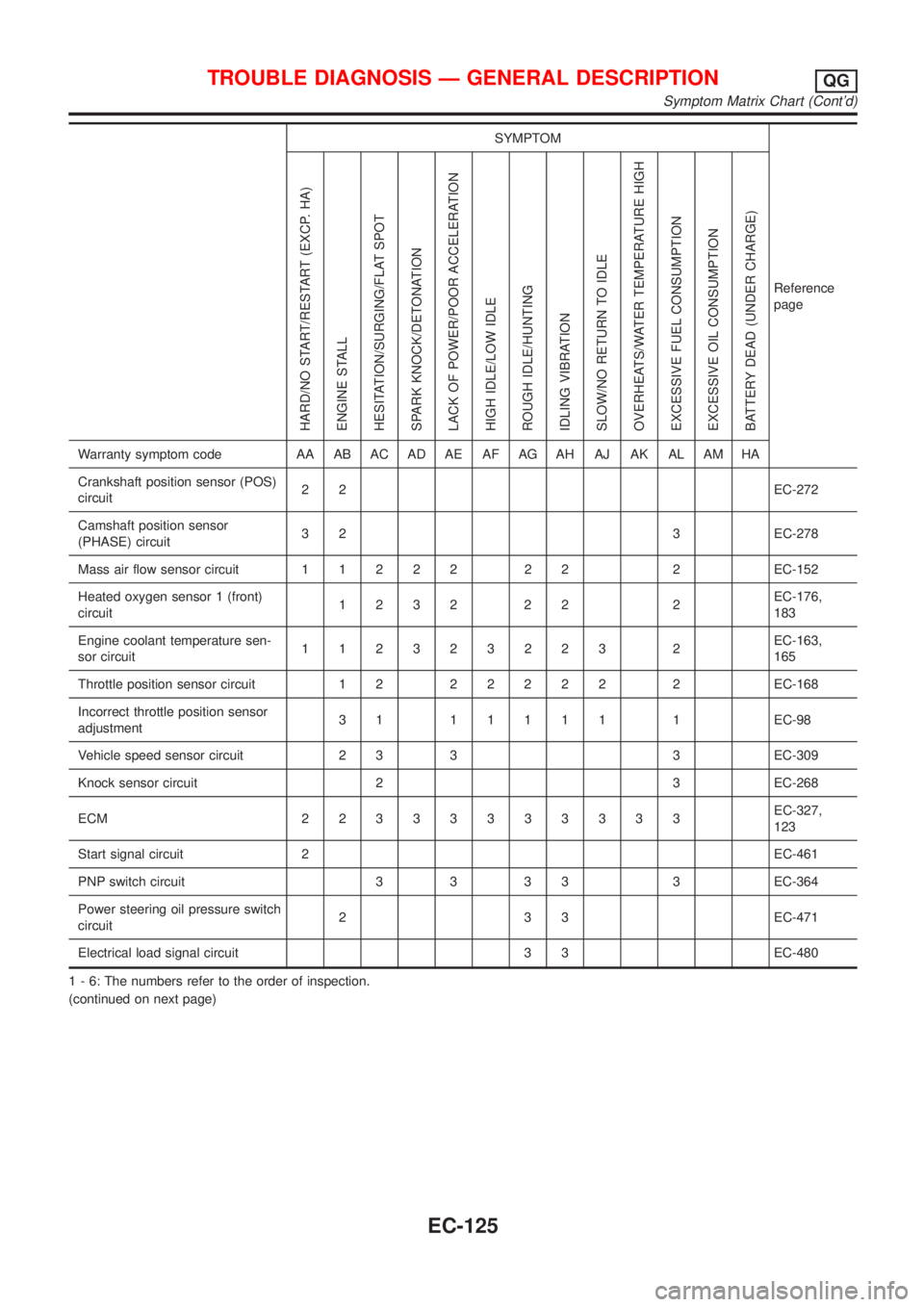

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Crankshaft position sensor (POS)

circuit22EC-272

Camshaft position sensor

(PHASE) circuit3 2 3 EC-278

Mass air flow sensor circuit11222 22 2EC-152

Heated oxygen sensor 1 (front)

circuit1232 22 2EC-176,

183

Engine coolant temperature sen-

sor circuit112323223 2EC-163,

165

Throttle position sensor circuit 1 222222 2EC-168

Incorrect throttle position sensor

adjustment31 11111 1EC-98

Vehicle speed sensor circuit 2 3 3 3 EC-309

Knock sensor circuit 2 3 EC-268

ECM 22333333333EC-327,

123

Start signal circuit 2EC-461

PNP switch circuit 3 3 3 3 3 EC-364

Power steering oil pressure switch

circuit2 3 3 EC-471

Electrical load signal circuit 3 3 EC-480

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-125

Page 422 of 2493

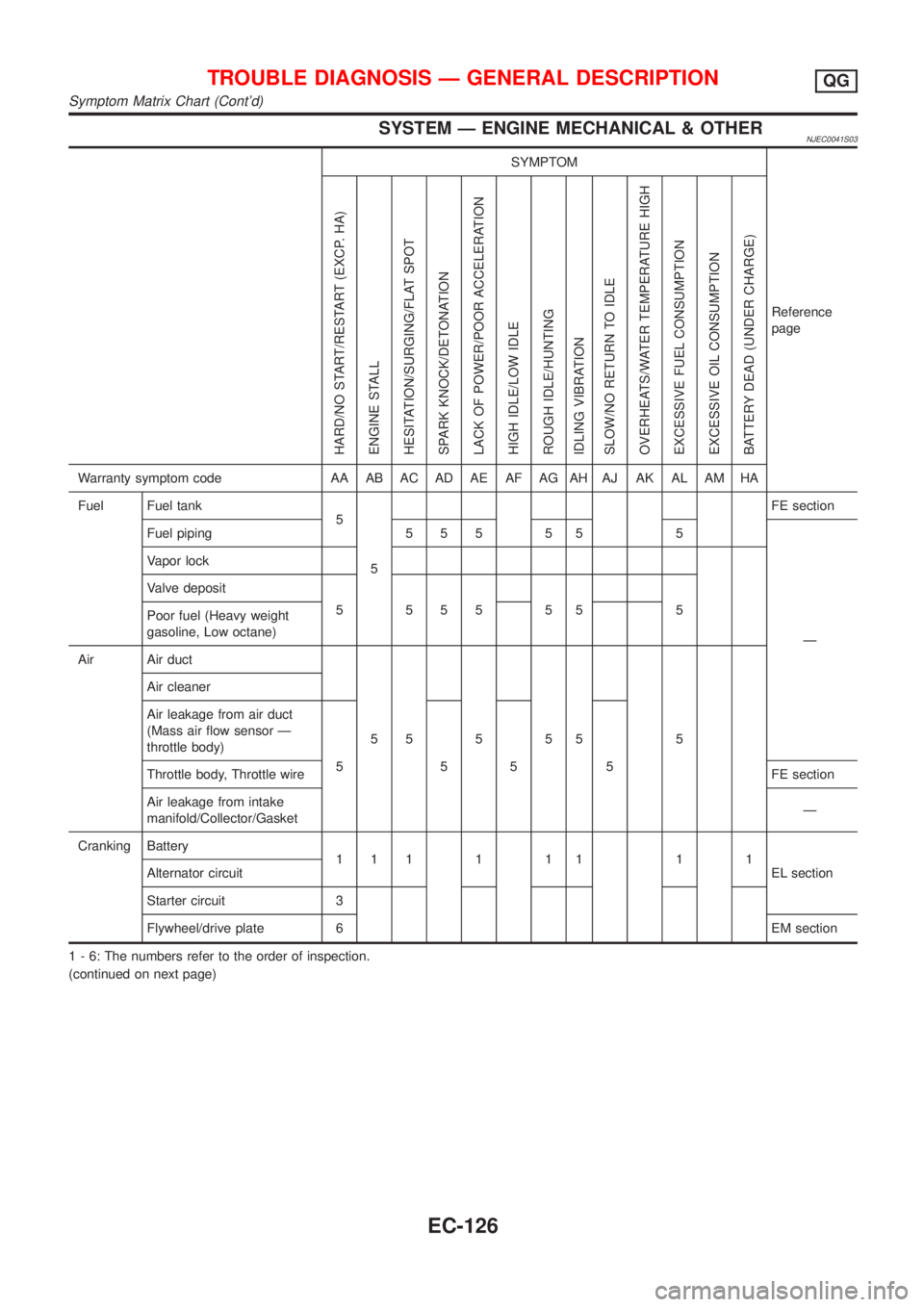

SYSTEM Ð ENGINE MECHANICAL & OTHERNJEC0041S03

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 55 5

Poor fuel (Heavy weight

gasoline, Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð

throttle body)

5555

Throttle body, Throttle wireFE section

Air leakage from intake

manifold/Collector/GasketÐ

Cranking Battery

111111 11

EL section Alternator circuit

Starter circuit 3

Flywheel/drive plate 6EM section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-126

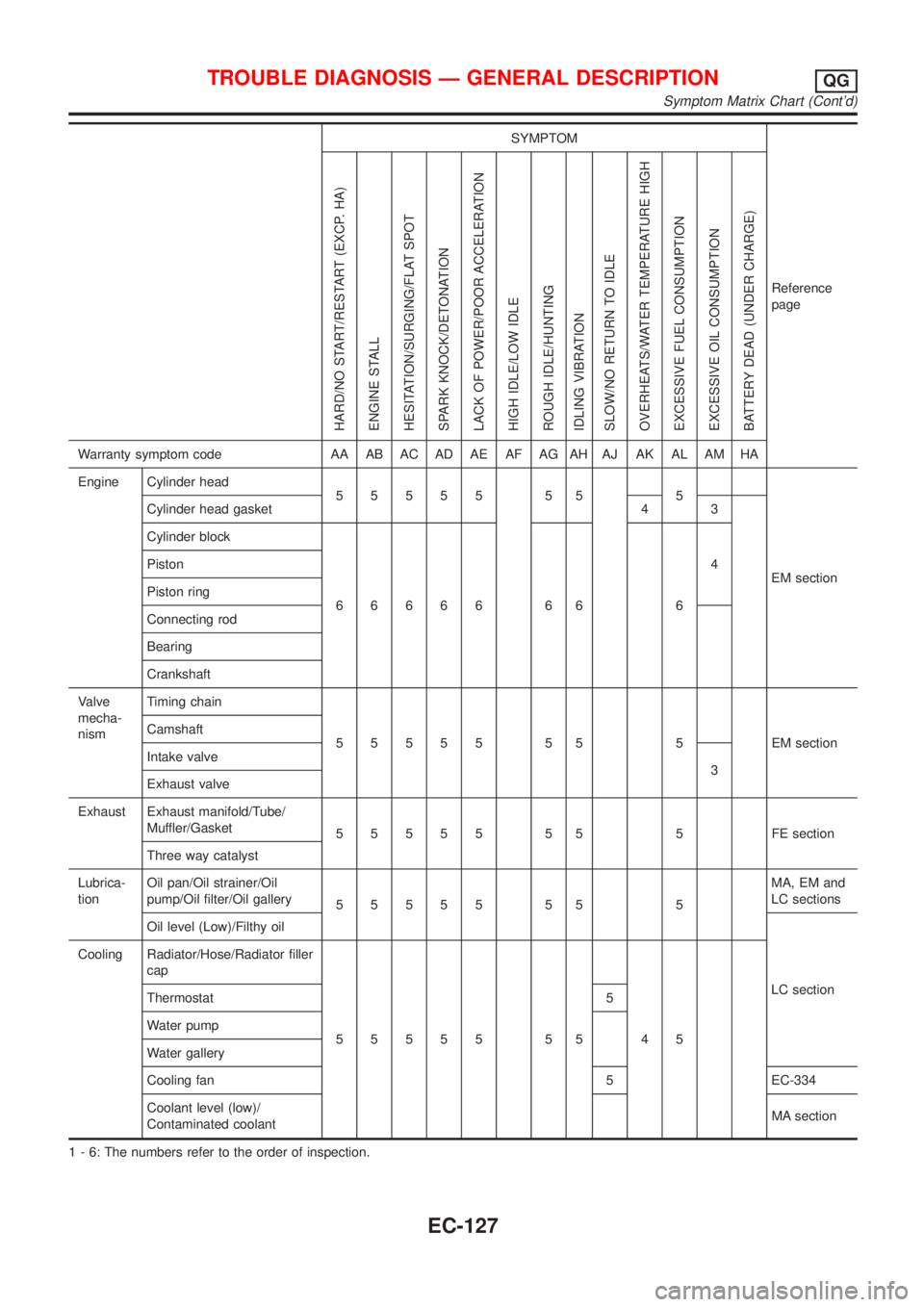

Page 423 of 2493

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 55 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 66 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nismTiming chain

55555 55 5 EMsection Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/

Muffler/Gasket

55555 55 5 FEsection

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil

pump/Oil filter/Oil gallery

55555 55 5MA, EM and

LC sections

Oil level (Low)/Filthy oil

LC section Cooling Radiator/Hose/Radiator filler

cap

55555 55 45 Thermostat 5

Water pump

Water gallery

Cooling fan 5 EC-334

Coolant level (low)/

Contaminated coolantMA section

1 - 6: The numbers refer to the order of inspection.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-127