EL page 71 NISSAN ALMERA N16 2001 Electronic Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 843 of 2493

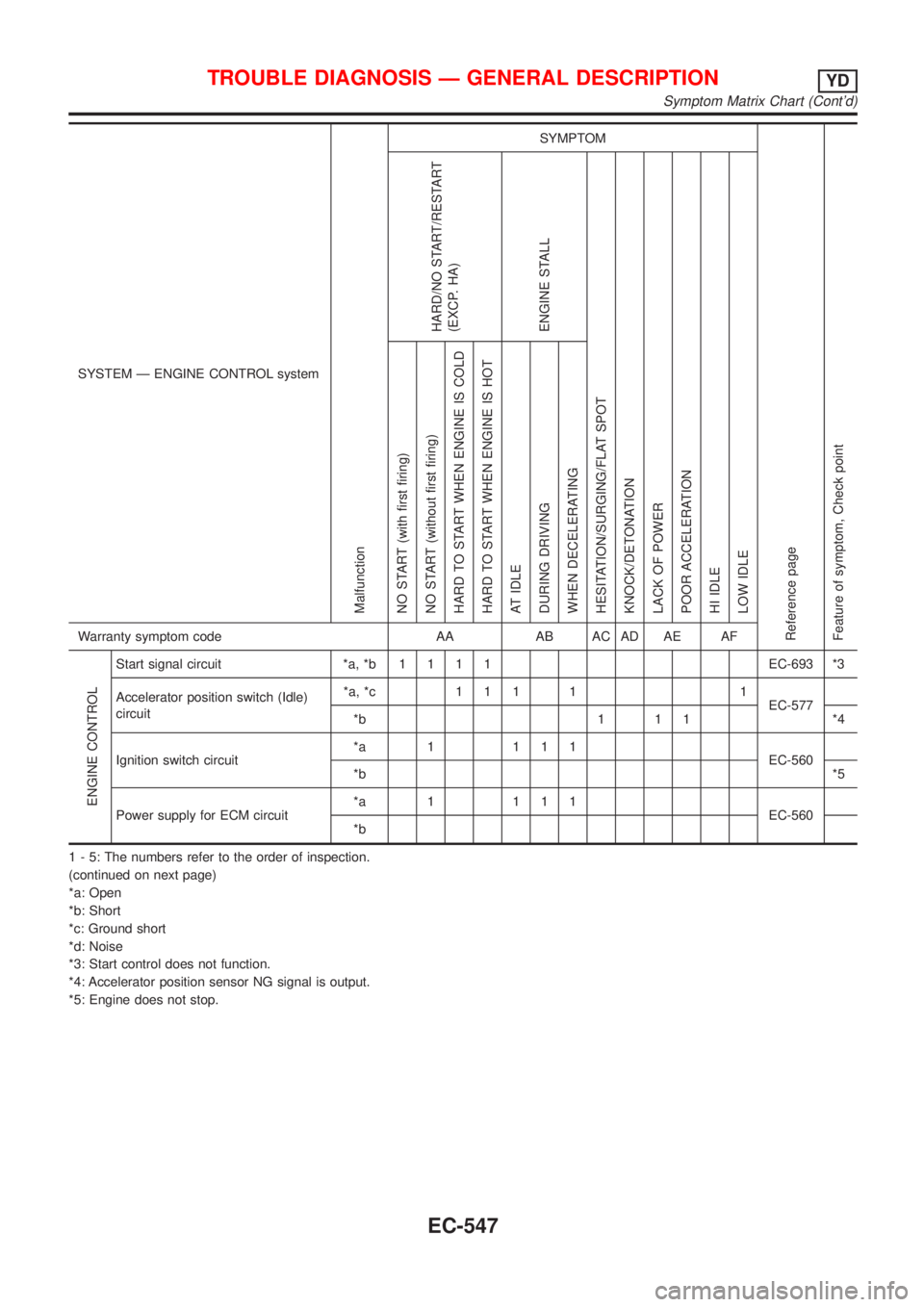

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART

(EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGWarranty symptom code AA AB AC AD AE AF

ENGINE CONTROL

Start signal circuit *a, *b1111EC-693 *3

Accelerator position switch (Idle)

circuit*a, *c 1 1 1 1 1

EC-577

*b 1 1 1 *4

Ignition switch circuit*a 1 111

EC-560

*b*5

Power supply for ECM circuit*a 1 111

EC-560

*b

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*3: Start control does not function.

*4: Accelerator position sensor NG signal is output.

*5: Engine does not stop.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont'd)

EC-547

Page 844 of 2493

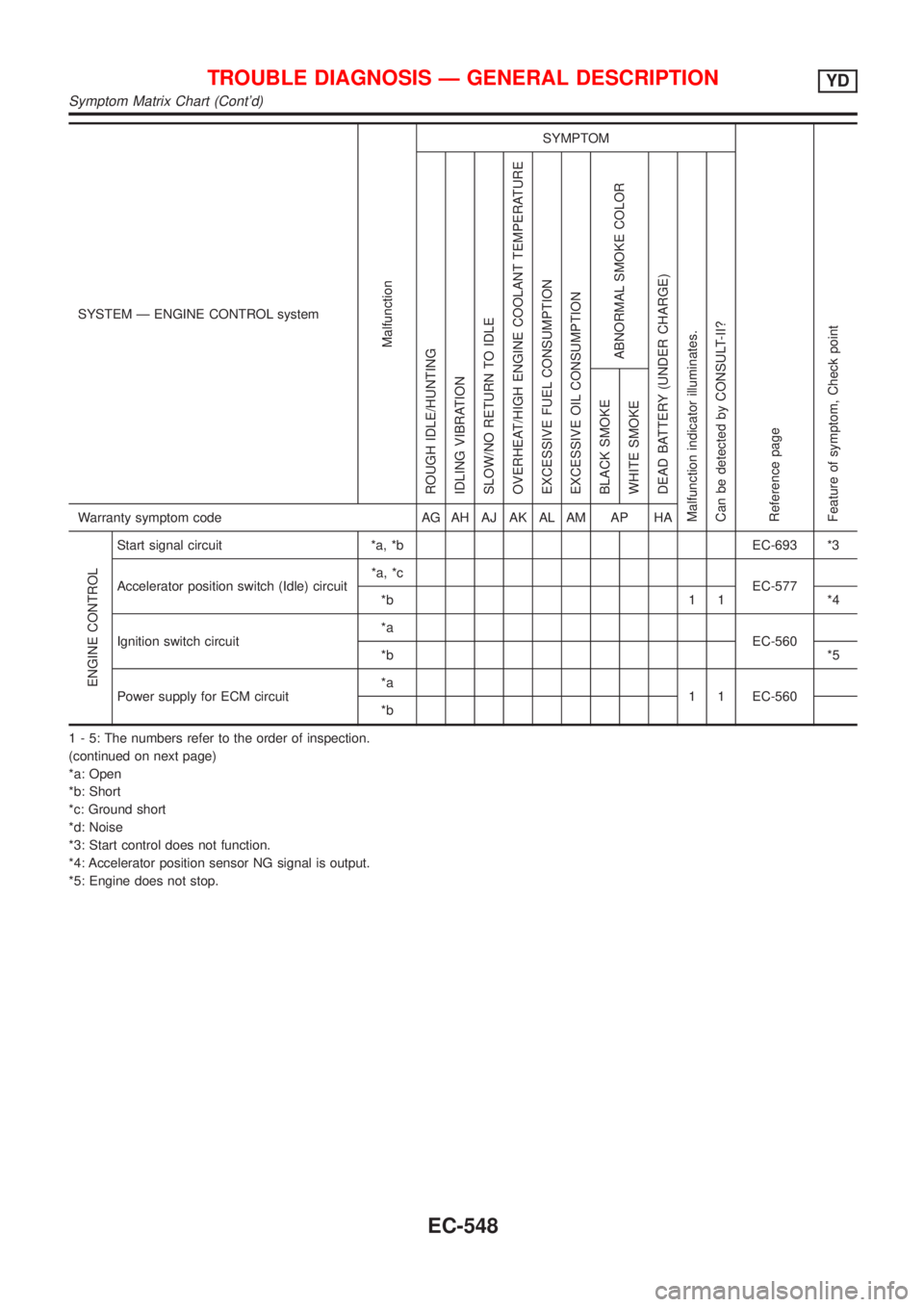

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?BLACK SMOKE

WHITE SMOKEWarranty symptom code AG AH AJ AK AL AM AP HA

ENGINE CONTROL

Start signal circuit *a, *b EC-693 *3

Accelerator position switch (Idle) circuit*a, *c

EC-577

*b 1 1 *4

Ignition switch circuit*a

EC-560

*b*5

Power supply for ECM circuit*a

1 1 EC-560

*b

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*3: Start control does not function.

*4: Accelerator position sensor NG signal is output.

*5: Engine does not stop.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont'd)

EC-548

Page 845 of 2493

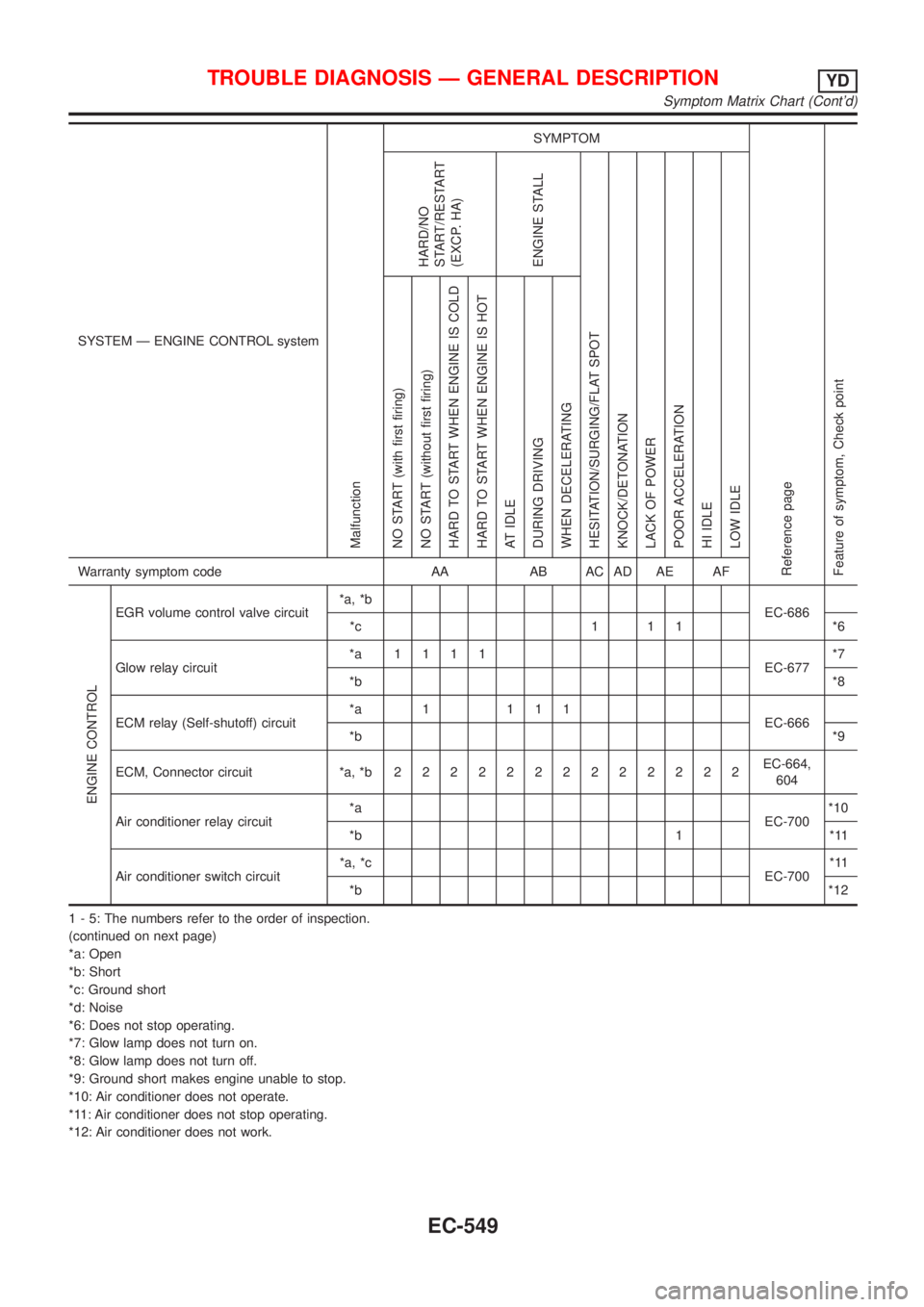

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO

START/RESTART

(EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGWarranty symptom code AA AB AC AD AE AF

ENGINE CONTROL

EGR volume control valve circuit*a, *b

EC-686

*c 1 1 1 *6

Glow relay circuit*a 1111

EC-677*7

*b*8

ECM relay (Self-shutoff) circuit*a 1 111

EC-666

*b*9

ECM, Connector circuit *a, *b2222222222222EC-664,

604

Air conditioner relay circuit*a

EC-700*10

*b 1 *11

Air conditioner switch circuit*a, *c

EC-700*11

*b*12

1 - 5: The numbers refer to the order of inspection.

(continued on next page)

*a: Open

*b: Short

*c: Ground short

*d: Noise

*6: Does not stop operating.

*7: Glow lamp does not turn on.

*8: Glow lamp does not turn off.

*9: Ground short makes engine unable to stop.

*10: Air conditioner does not operate.

*11: Air conditioner does not stop operating.

*12: Air conditioner does not work.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont'd)

EC-549

Page 846 of 2493

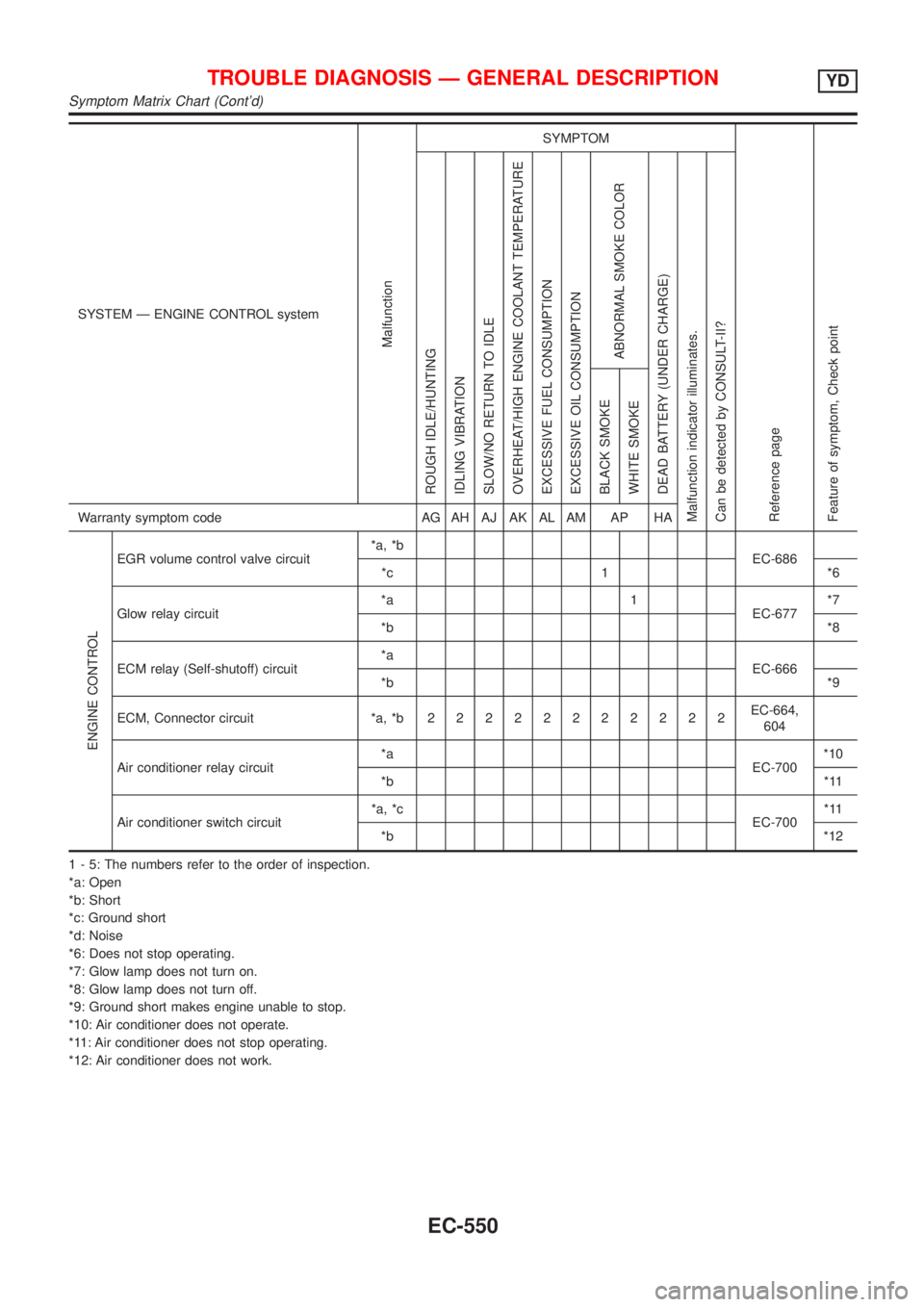

SYSTEM Ð ENGINE CONTROL system

Malfunction

SYMPTOM

Reference page

Feature of symptom, Check pointROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?BLACK SMOKE

WHITE SMOKEWarranty symptom code AG AH AJ AK AL AM AP HA

ENGINE CONTROL

EGR volume control valve circuit*a, *b

EC-686

*c 1 *6

Glow relay circuit*a 1

EC-677*7

*b*8

ECM relay (Self-shutoff) circuit*a

EC-666

*b*9

ECM, Connector circuit *a, *b22222222222EC-664,

604

Air conditioner relay circuit*a

EC-700*10

*b*11

Air conditioner switch circuit*a, *c

EC-700*11

*b*12

1 - 5: The numbers refer to the order of inspection.

*a: Open

*b: Short

*c: Ground short

*d: Noise

*6: Does not stop operating.

*7: Glow lamp does not turn on.

*8: Glow lamp does not turn off.

*9: Ground short makes engine unable to stop.

*10: Air conditioner does not operate.

*11: Air conditioner does not stop operating.

*12: Air conditioner does not work.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

Symptom Matrix Chart (Cont'd)

EC-550

Page 929 of 2493

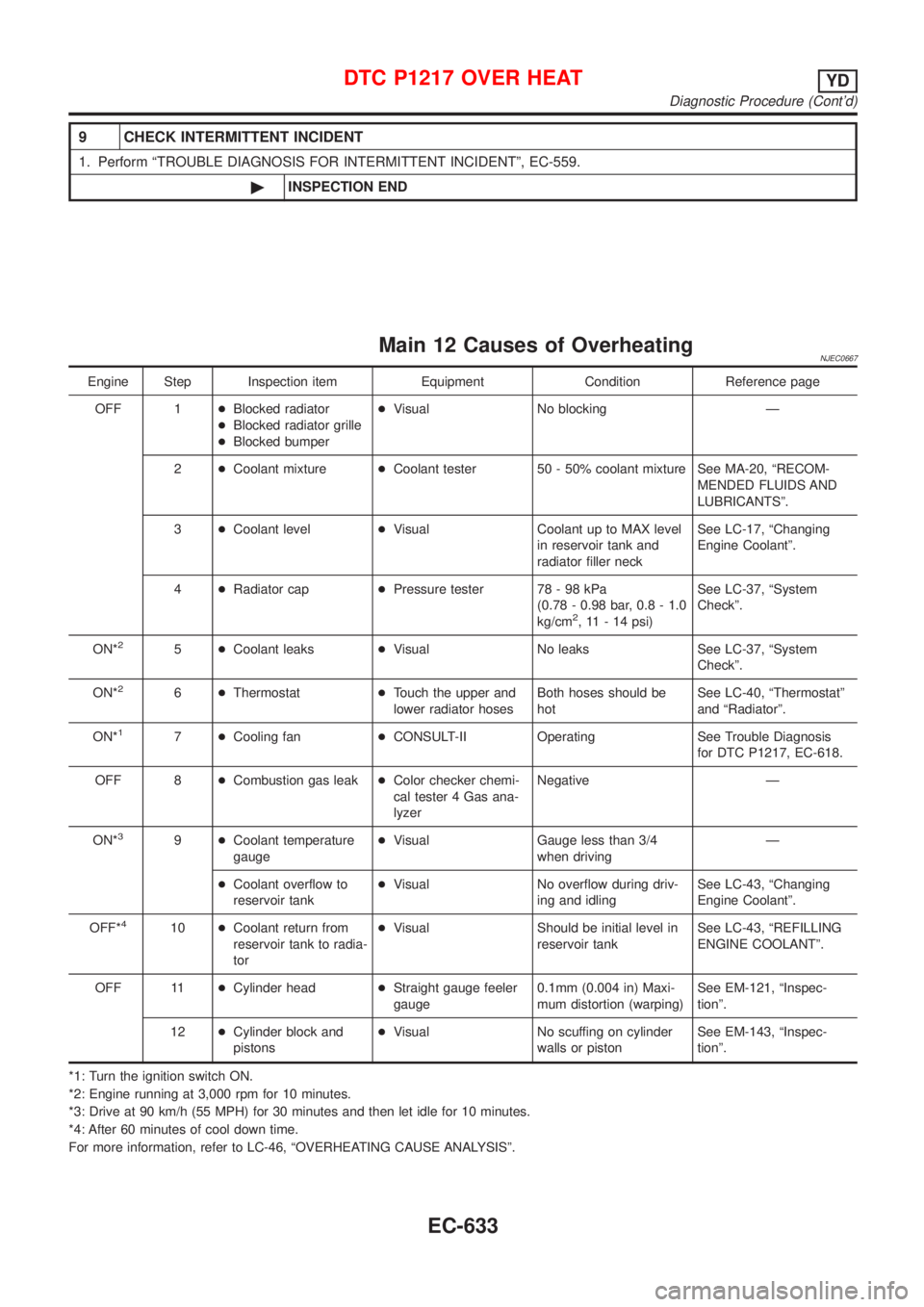

9 CHECK INTERMITTENT INCIDENT

1. Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-559.

©INSPECTION END

Main 12 Causes of OverheatingNJEC0667

Engine Step Inspection item Equipment Condition Reference page

OFF 1+Blocked radiator

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mixture See MA-20, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee LC-17, ªChanging

Engine Coolantº.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)See LC-37, ªSystem

Checkº.

ON*

25+Coolant leaks+Visual No leaks See LC-37, ªSystem

Checkº.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-40, ªThermostatº

and ªRadiatorº.

ON*

17+Cooling fan+CONSULT-II Operating See Trouble Diagnosis

for DTC P1217, EC-618.

OFF 8+Combustion gas leak+Color checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to

reservoir tank+Visual No overflow during driv-

ing and idlingSee LC-43, ªChanging

Engine Coolantº.

OFF*

410+Coolant return from

reservoir tank to radia-

tor+Visual Should be initial level in

reservoir tankSee LC-43, ªREFILLING

ENGINE COOLANTº.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1mm (0.004 in) Maxi-

mum distortion (warping)See EM-121, ªInspec-

tionº.

12+Cylinder block and

pistons+Visual No scuffing on cylinder

walls or pistonSee EM-143, ªInspec-

tionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC-46, ªOVERHEATING CAUSE ANALYSISº.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont'd)

EC-633

Page 1030 of 2493

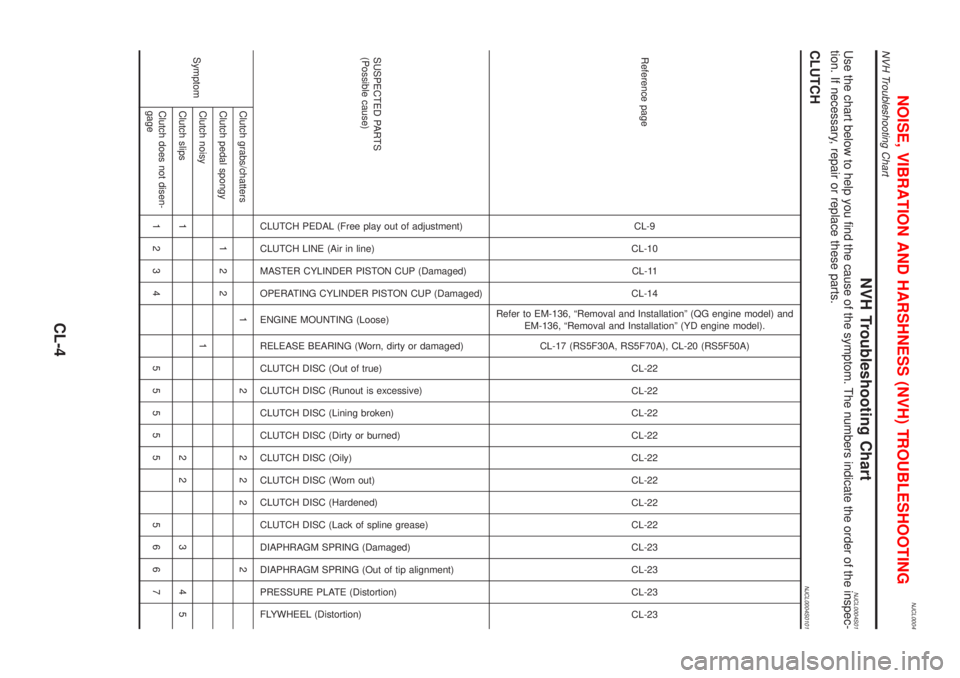

NJCL0004

NVH Troubleshooting ChartNJCL0004S01Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

CLUTCHNJCL0004S0101

Reference pageCL-9

CL-10

CL-11

CL-14

Refer to EM-136, ªRemoval and Installationº (QG engine model) and

EM-136, ªRemoval and Installationº (YD engine model).

CL-17 (RS5F30A, RS5F70A), CL-20 (RS5F50A)

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-23

CL-23

CL-23

CL-23

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disen-

gage1234 55555 5667

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

CL-4

Page 1063 of 2493

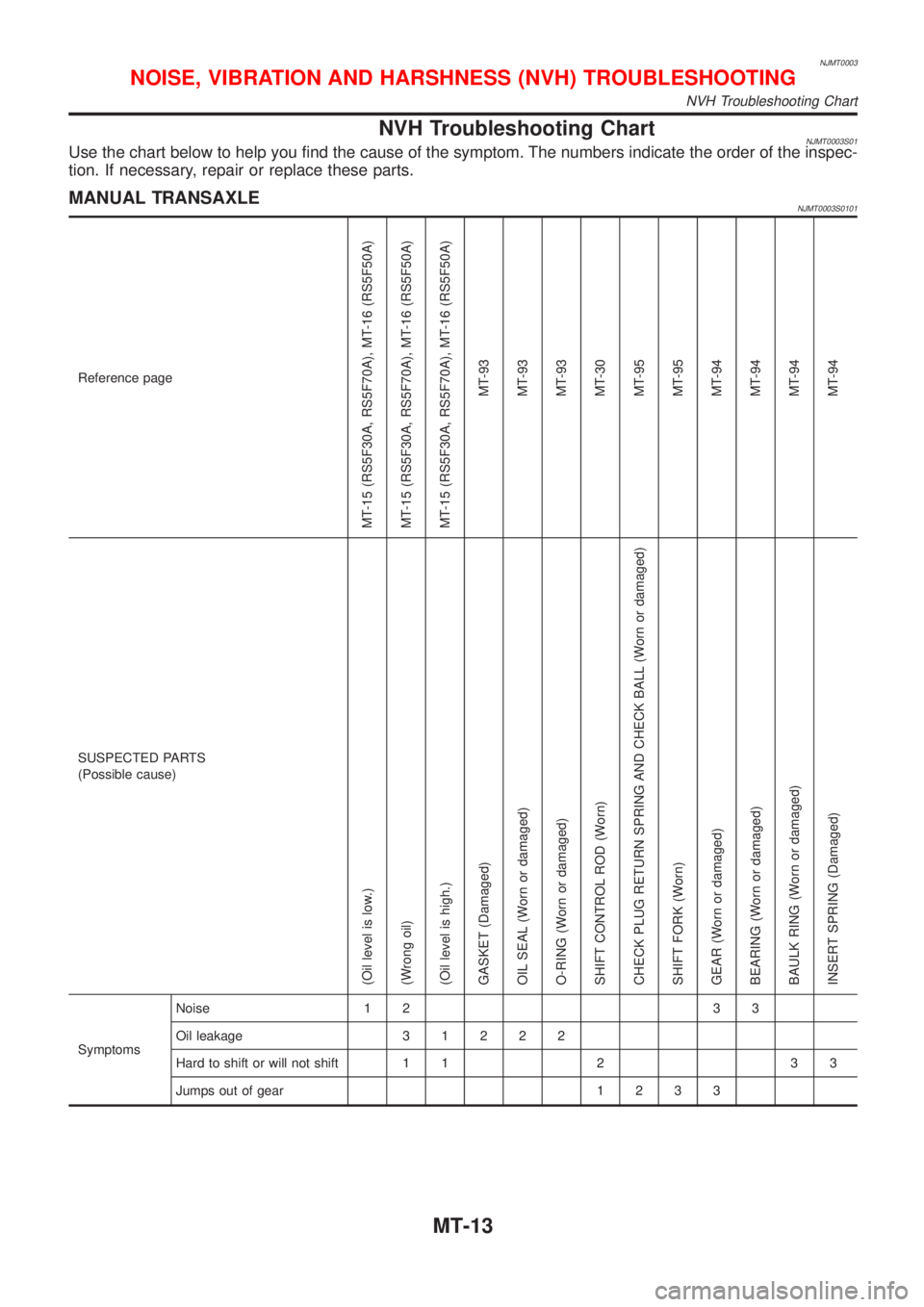

NJMT0003

NVH Troubleshooting ChartNJMT0003S01Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

MANUAL TRANSAXLENJMT0003S0101

Reference page

MT-15 (RS5F30A, RS5F70A), MT-16 (RS5F50A)

MT-15 (RS5F30A, RS5F70A), MT-16 (RS5F50A)

MT-15 (RS5F30A, RS5F70A), MT-16 (RS5F50A)

MT-93

MT-93

MT-93

MT-30

MT-95

MT-95

MT-94

MT-94

MT-94

MT-94

SUSPECTED PARTS

(Possible cause)

(Oil level is low.)

(Wrong oil)

(Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

SHIFT CONTROL ROD (Worn)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomsNoise 1 2 3 3

Oil leakage31222

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear1233

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

MT-13

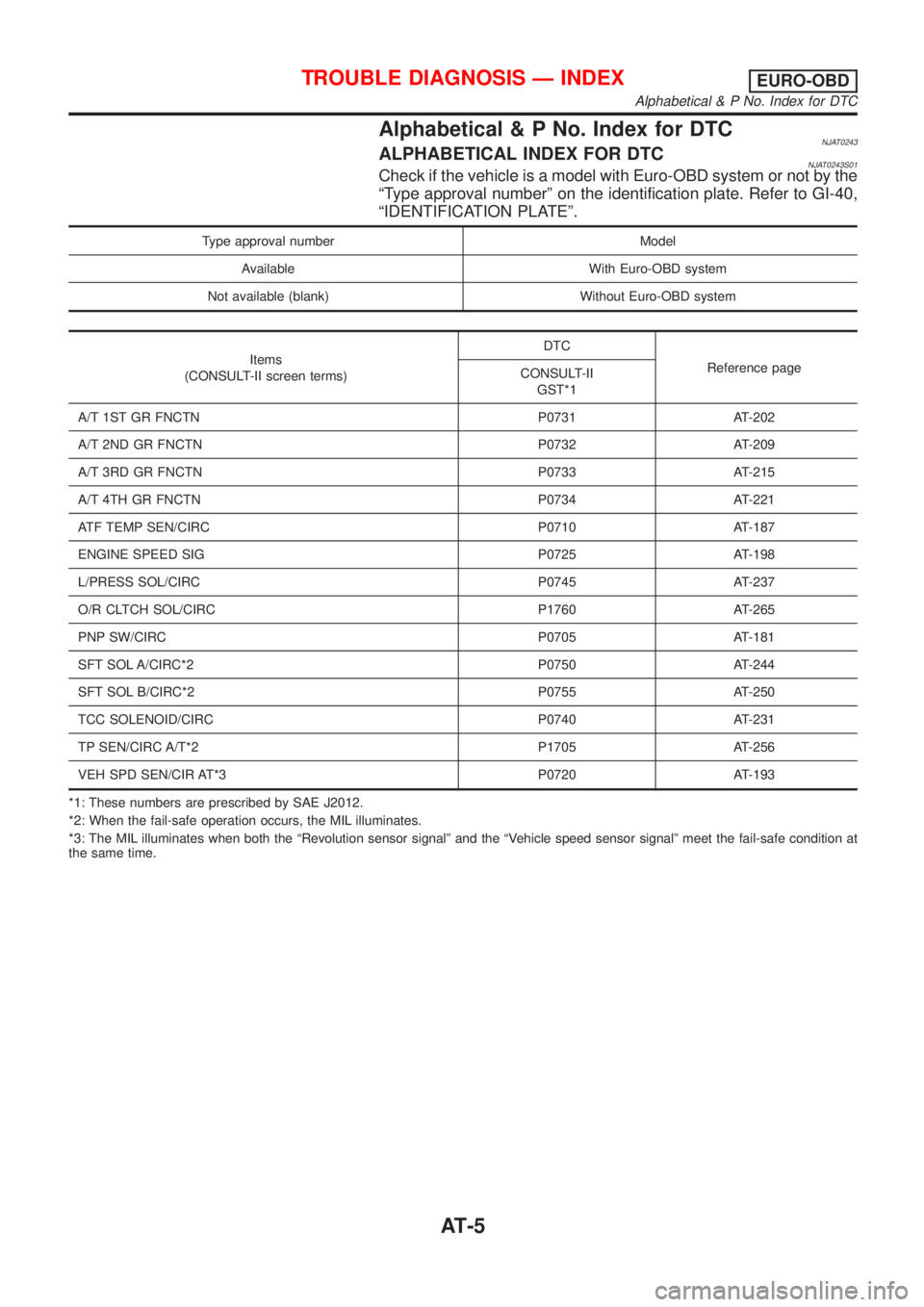

Page 1191 of 2493

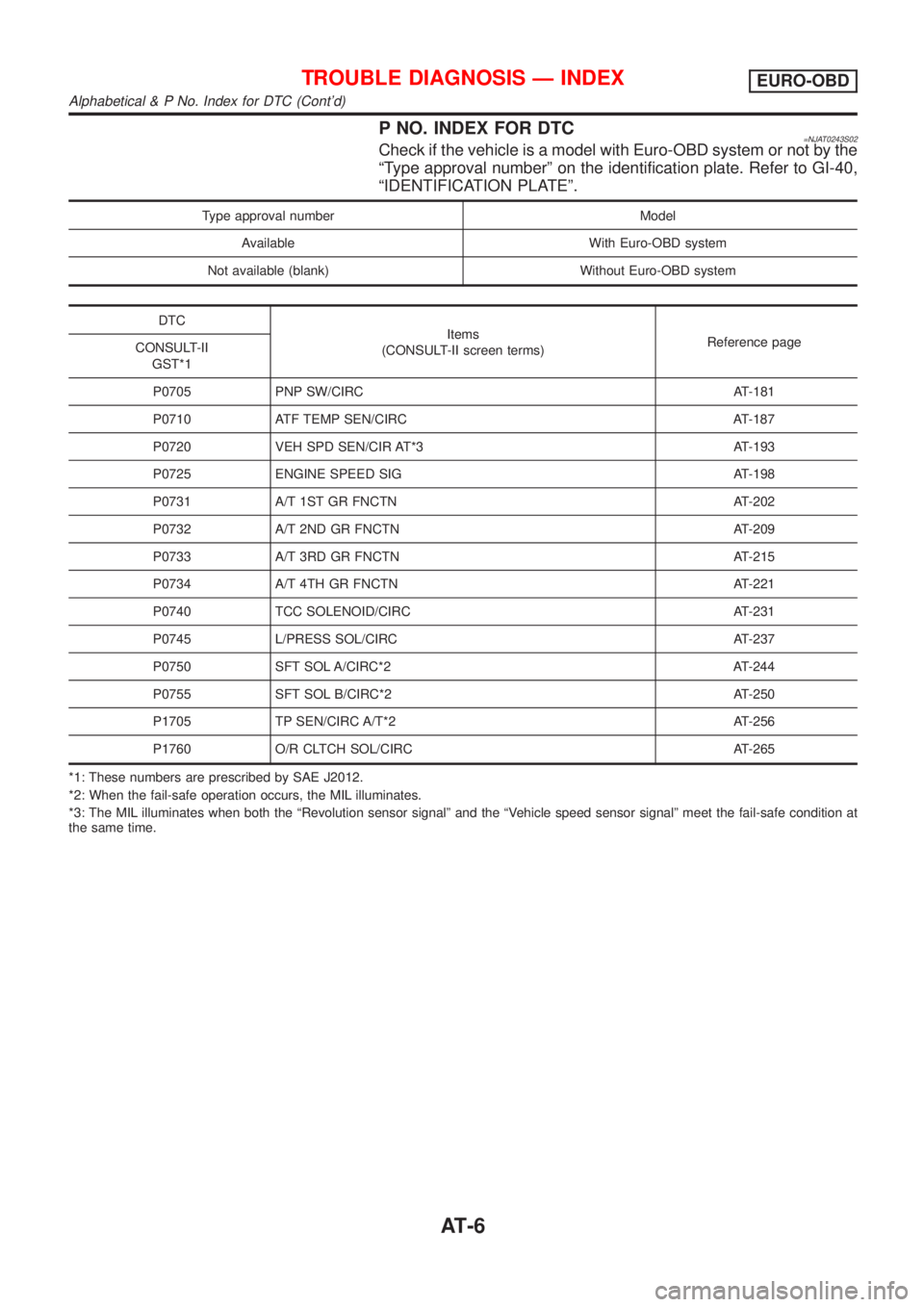

Alphabetical & P No. Index for DTCNJAT0243ALPHABETICAL INDEX FOR DTCNJAT0243S01Check if the vehicle is a model with Euro-OBD system or not by the

ªType approval numberº on the identification plate. Refer to GI-40,

ªIDENTIFICATION PLATEº.

Type approval number Model

Available With Euro-OBD system

Not available (blank) Without Euro-OBD system

Items

(CONSULT-II screen terms)DTC

Reference page

CONSULT-II

GST*1

A/T 1ST GR FNCTN P0731 AT-202

A/T 2ND GR FNCTN P0732 AT-209

A/T 3RD GR FNCTN P0733 AT-215

A/T 4TH GR FNCTN P0734 AT-221

ATF TEMP SEN/CIRC P0710 AT-187

ENGINE SPEED SIG P0725 AT-198

L/PRESS SOL/CIRC P0745 AT-237

O/R CLTCH SOL/CIRC P1760 AT-265

PNP SW/CIRC P0705 AT-181

SFT SOL A/CIRC*2 P0750 AT-244

SFT SOL B/CIRC*2 P0755 AT-250

TCC SOLENOID/CIRC P0740 AT-231

TP SEN/CIRC A/T*2 P1705 AT-256

VEH SPD SEN/CIR AT*3 P0720 AT-193

*1: These numbers are prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at

the same time.

TROUBLE DIAGNOSIS Ð INDEXEURO-OBD

Alphabetical & P No. Index for DTC

AT-5

Page 1192 of 2493

P NO. INDEX FOR DTC=NJAT0243S02Check if the vehicle is a model with Euro-OBD system or not by the

ªType approval numberº on the identification plate. Refer to GI-40,

ªIDENTIFICATION PLATEº.

Type approval number Model

Available With Euro-OBD system

Not available (blank) Without Euro-OBD system

DTC

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*1

P0705 PNP SW/CIRC AT-181

P0710 ATF TEMP SEN/CIRC AT-187

P0720 VEH SPD SEN/CIR AT*3 AT-193

P0725 ENGINE SPEED SIG AT-198

P0731 A/T 1ST GR FNCTN AT-202

P0732 A/T 2ND GR FNCTN AT-209

P0733 A/T 3RD GR FNCTN AT-215

P0734 A/T 4TH GR FNCTN AT-221

P0740 TCC SOLENOID/CIRC AT-231

P0745 L/PRESS SOL/CIRC AT-237

P0750 SFT SOL A/CIRC*2 AT-244

P0755 SFT SOL B/CIRC*2 AT-250

P1705 TP SEN/CIRC A/T*2 AT-256

P1760 O/R CLTCH SOL/CIRC AT-265

*1: These numbers are prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at

the same time.

TROUBLE DIAGNOSIS Ð INDEXEURO-OBD

Alphabetical & P No. Index for DTC (Cont'd)

AT-6

Page 1194 of 2493

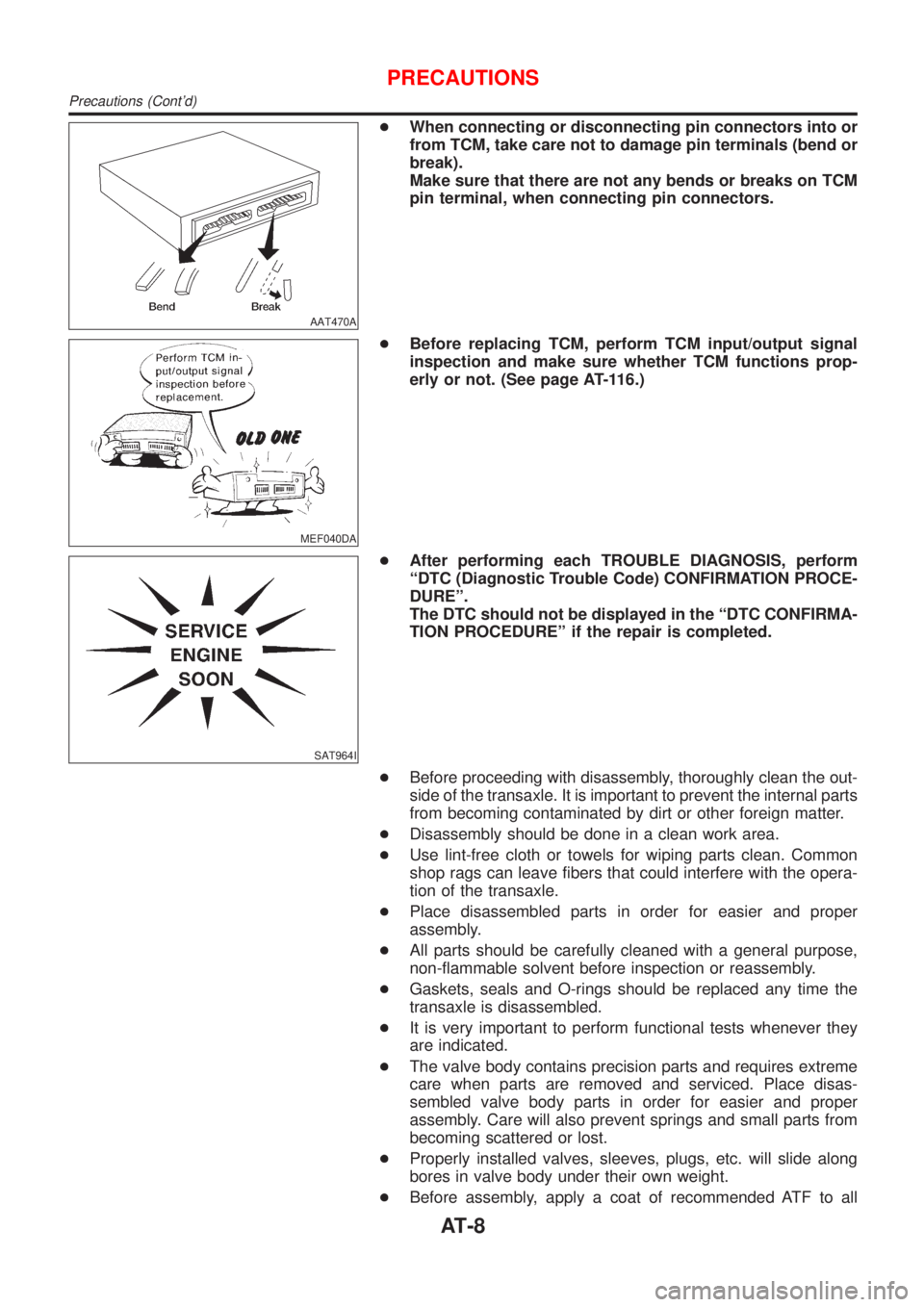

AAT470A

+When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

MEF040DA

+Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (See page AT-116.)

SAT964I

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

+Before proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

+Disassembly should be done in a clean work area.

+Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the opera-

tion of the transaxle.

+Place disassembled parts in order for easier and proper

assembly.

+All parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

+Gaskets, seals and O-rings should be replaced any time the

transaxle is disassembled.

+It is very important to perform functional tests whenever they

are indicated.

+The valve body contains precision parts and requires extreme

care when parts are removed and serviced. Place disas-

sembled valve body parts in order for easier and proper

assembly. Care will also prevent springs and small parts from

becoming scattered or lost.

+Properly installed valves, sleeves, plugs, etc. will slide along

bores in valve body under their own weight.

+Before assembly, apply a coat of recommended ATF to all

PRECAUTIONS

Precautions (Cont'd)

AT-8