NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 781 of 2493

7 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Disconnect time control unit harness connector.

3. Check harness continuity between ECM terminal 50 and time control unit harness connector terminal 14.

Refer to wiring diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK©Refer to EL-229, ªTIME CONTROL UNITº.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M63, F102

+Harness open and short between ECM and time control unit connectors

©Repair open circuit or short to ground or short to power in harness or connectors.

9 CHECK HEADLAMP FUNCTION

1. Start engine.

2. Turn the lighting switch ªONº.

3. Check that headlamps are illuminated.

Do the headlamps illuminate in both ªHighº and ªLowº positions?

YesorNo

Ye s©GO TO 11.

No©Refer to EL-40, ªHEADLAMP SYSTEMº.

10 CHECK HEADLAMP FUNCTION

1. Start engine.

2. Turn the lighting switch ªONº.

3. Check that headlamps are illuminated.

OK or NG

OK©GO TO 11.

NG©Refer to EL-40, ªHEADLAMP SYSTEMº.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

EC-485

Page 782 of 2493

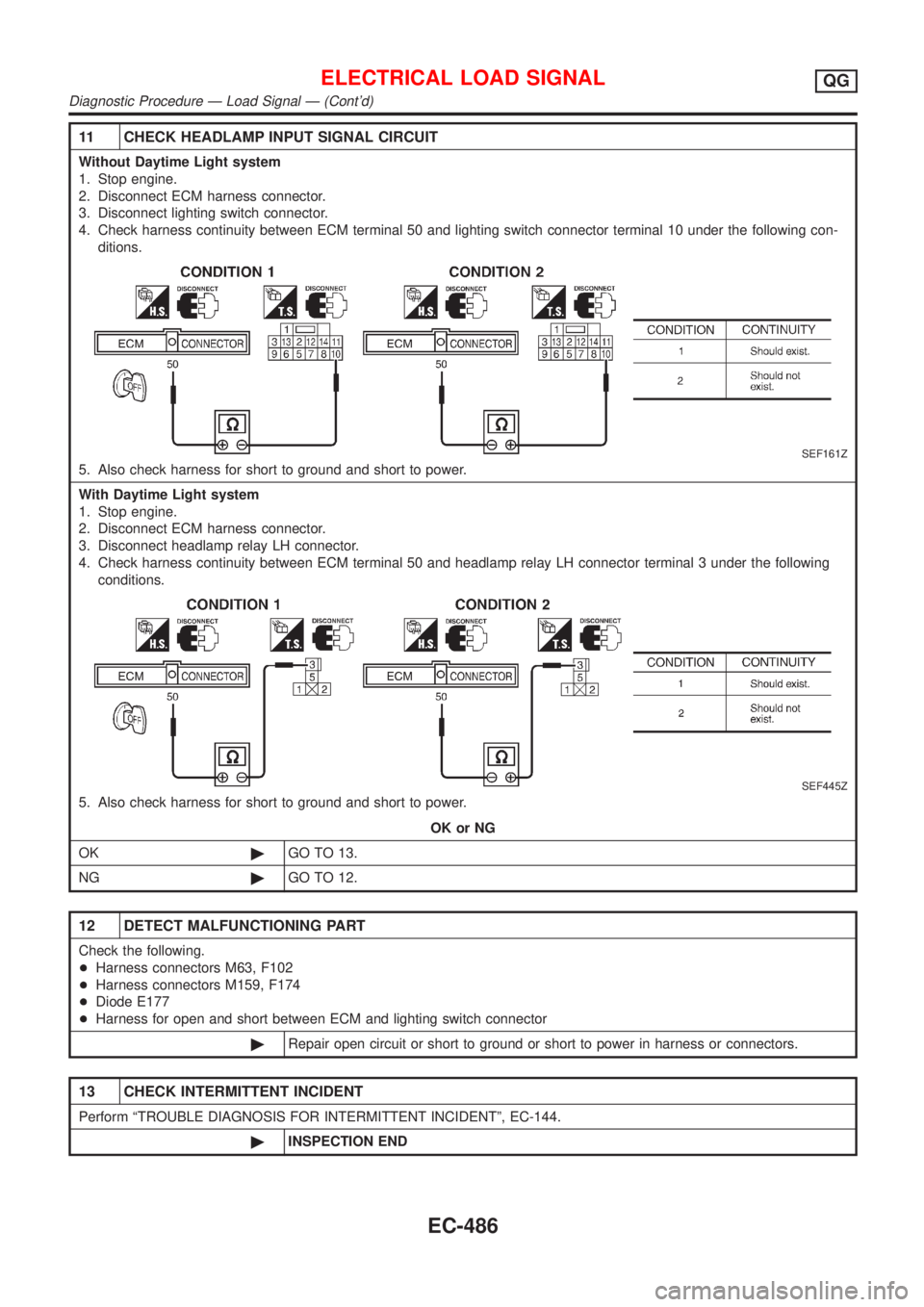

11 CHECK HEADLAMP INPUT SIGNAL CIRCUIT

Without Daytime Light system

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect lighting switch connector.

4. Check harness continuity between ECM terminal 50 and lighting switch connector terminal 10 under the following con-

ditions.

SEF161Z

5. Also check harness for short to ground and short to power.

With Daytime Light system

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect headlamp relay LH connector.

4. Check harness continuity between ECM terminal 50 and headlamp relay LH connector terminal 3 under the following

conditions.

SEF445Z

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M63, F102

+Harness connectors M159, F174

+Diode E177

+Harness for open and short between ECM and lighting switch connector

©Repair open circuit or short to ground or short to power in harness or connectors.

13 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

EC-486

Page 783 of 2493

Diagnostic Procedure Ð Heater Control Panel

(Fan Switch) Ð

NJEC0585

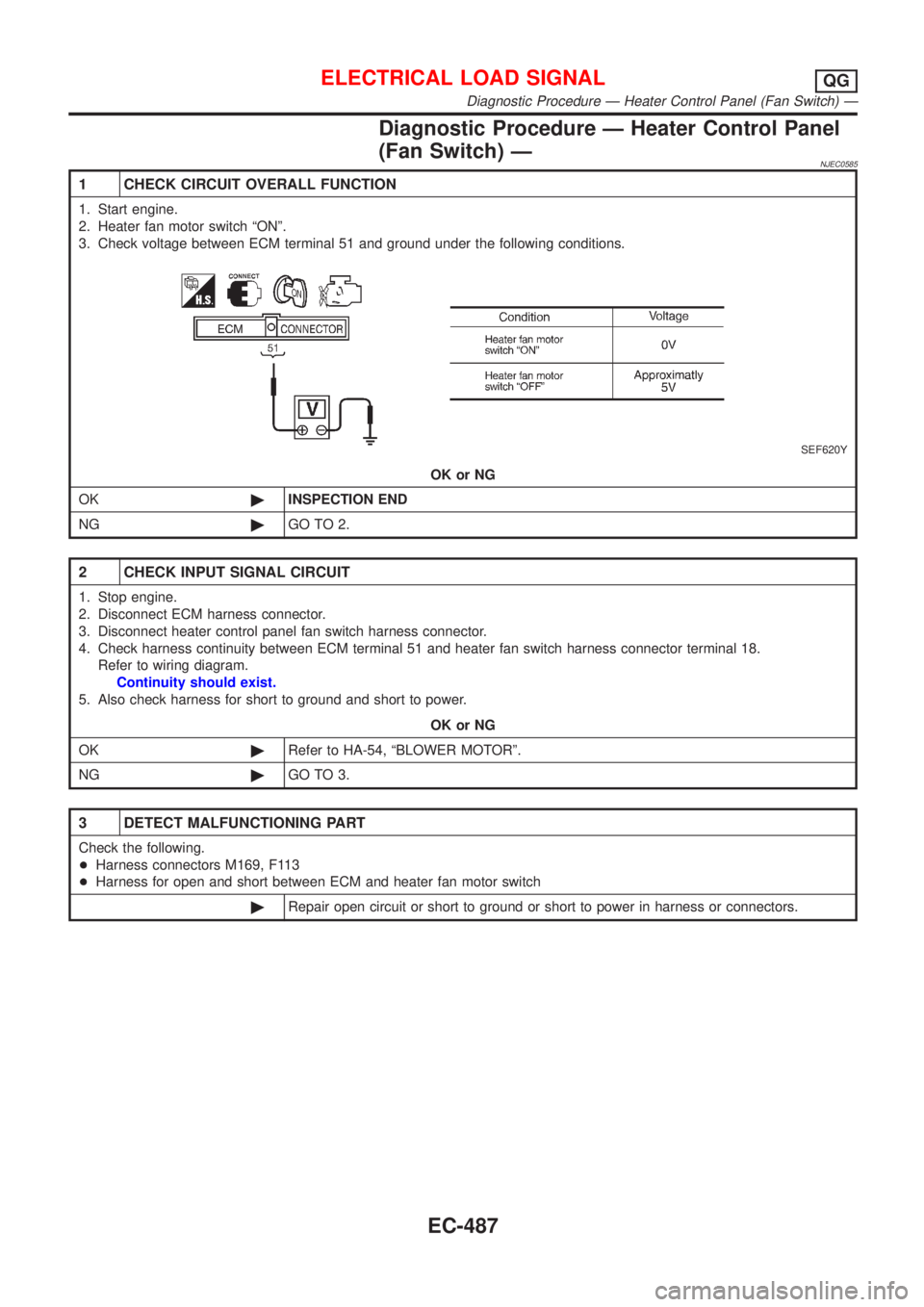

1 CHECK CIRCUIT OVERALL FUNCTION

1. Start engine.

2. Heater fan motor switch ªONº.

3. Check voltage between ECM terminal 51 and ground under the following conditions.

SEF620Y

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK INPUT SIGNAL CIRCUIT

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect heater control panel fan switch harness connector.

4. Check harness continuity between ECM terminal 51 and heater fan switch harness connector terminal 18.

Refer to wiring diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©Refer to HA-54, ªBLOWER MOTORº.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M169, F113

+Harness for open and short between ECM and heater fan motor switch

©Repair open circuit or short to ground or short to power in harness or connectors.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Heater Control Panel (Fan Switch) Ð

EC-487

Page 784 of 2493

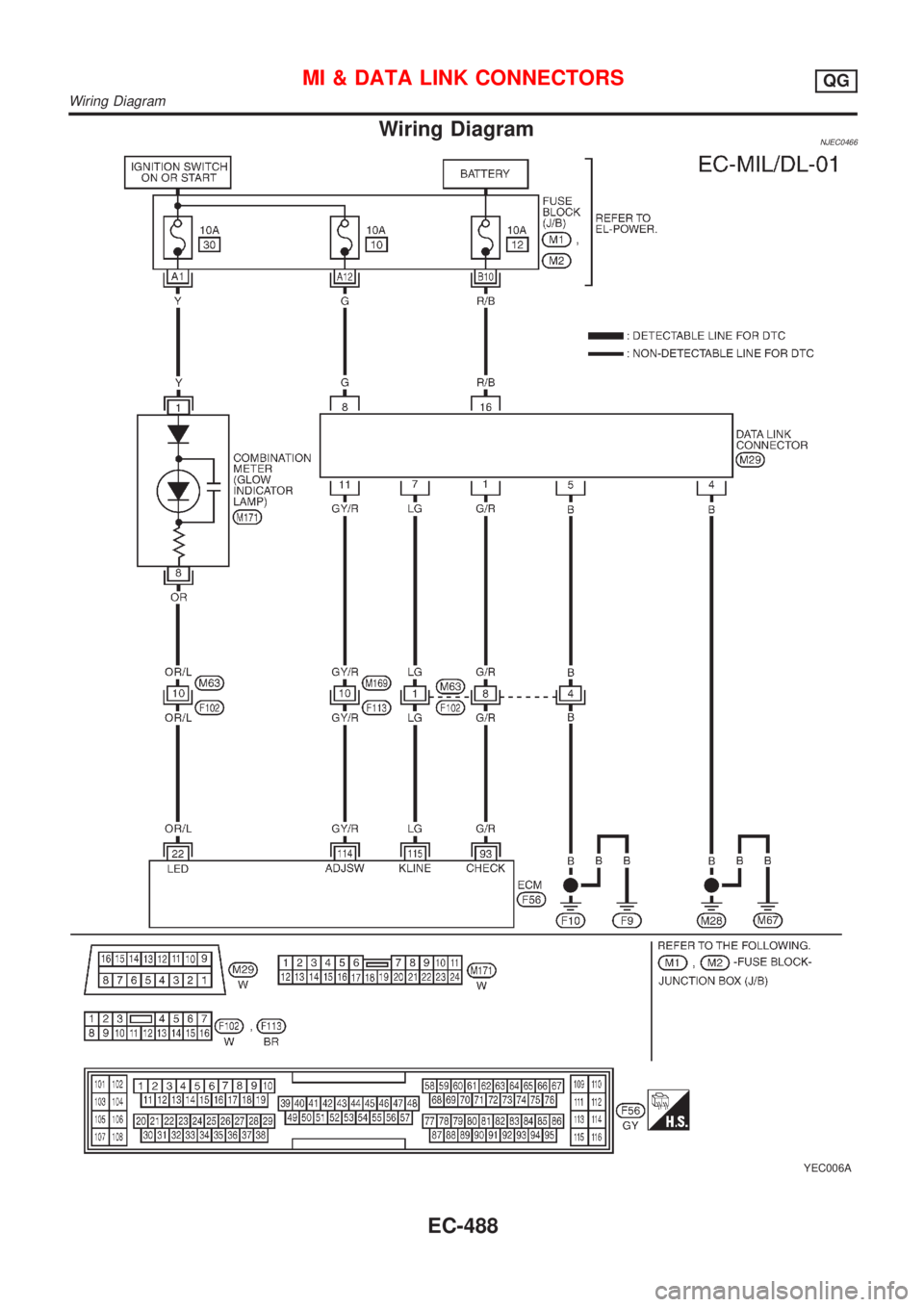

Wiring DiagramNJEC0466

YEC006A

MI & DATA LINK CONNECTORSQG

Wiring Diagram

EC-488

Page 785 of 2493

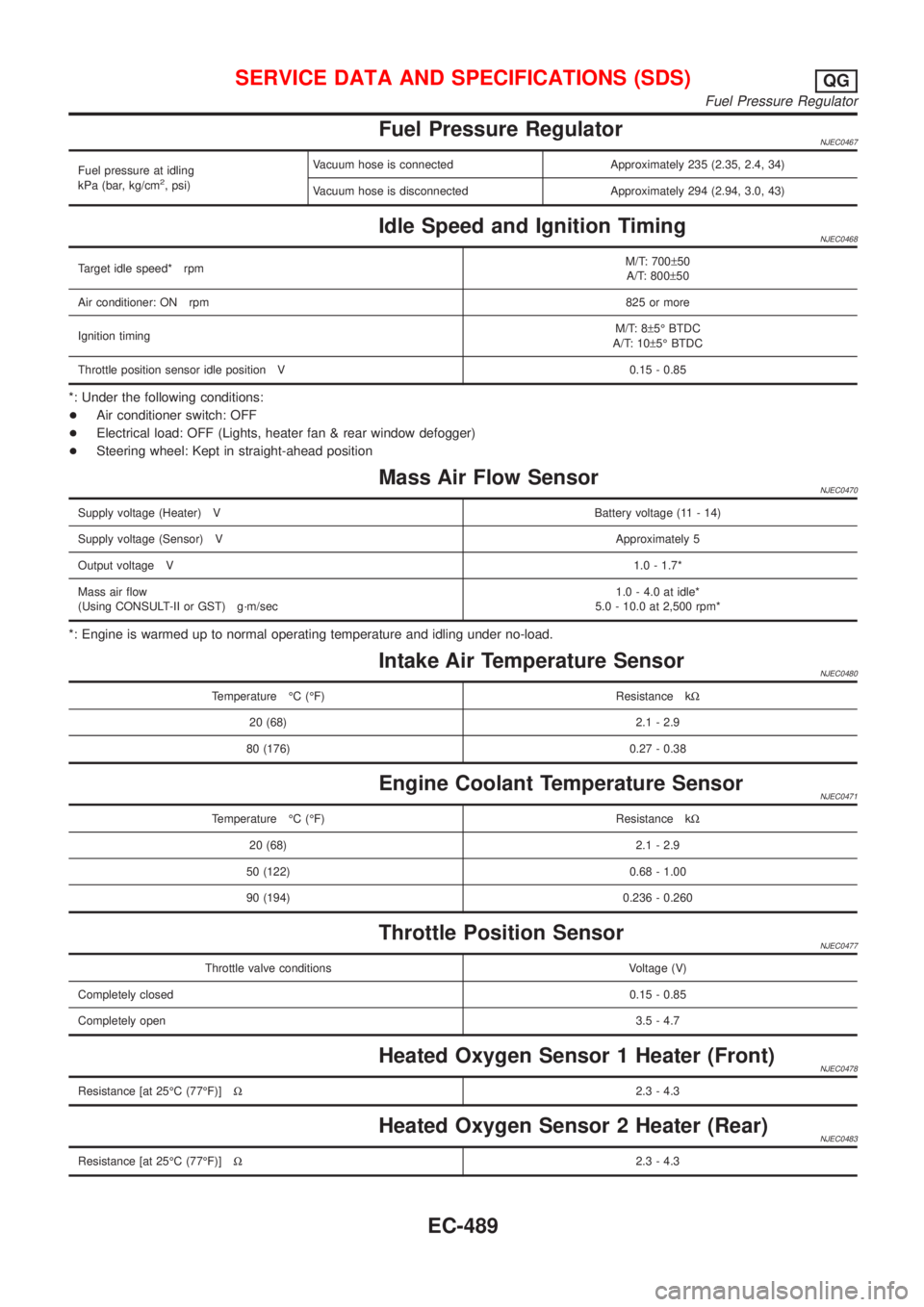

Fuel Pressure RegulatorNJEC0467

Fuel pressure at idling

kPa (bar, kg/cm2, psi)Vacuum hose is connected Approximately 235 (2.35, 2.4, 34)

Vacuum hose is disconnected Approximately 294 (2.94, 3.0, 43)

Idle Speed and Ignition TimingNJEC0468

Target idle speed* rpmM/T: 700±50

A/T: 800±50

Air conditioner: ON rpm825 or more

Ignition timingM/T: 8±5É BTDC

A/T: 10±5É BTDC

Throttle position sensor idle position V 0.15 - 0.85

*: Under the following conditions:

+Air conditioner switch: OFF

+Electrical load: OFF (Lights, heater fan & rear window defogger)

+Steering wheel: Kept in straight-ahead position

Mass Air Flow SensorNJEC0470

Supply voltage (Heater) VBattery voltage (11 - 14)

Supply voltage (Sensor) VApproximately 5

Output voltage V1.0 - 1.7*

Mass air flow

(Using CONSULT-II or GST) g´m/sec1.0 - 4.0 at idle*

5.0 - 10.0 at 2,500 rpm*

*: Engine is warmed up to normal operating temperature and idling under no-load.

Intake Air Temperature SensorNJEC0480

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

80 (176) 0.27 - 0.38

Engine Coolant Temperature SensorNJEC0471

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Throttle Position SensorNJEC0477

Throttle valve conditions Voltage (V)

Completely closed0.15 - 0.85

Completely open3.5 - 4.7

Heated Oxygen Sensor 1 Heater (Front)NJEC0478

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Heated Oxygen Sensor 2 Heater (Rear)NJEC0483

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Fuel Pressure Regulator

EC-489

Page 786 of 2493

![NISSAN ALMERA N16 2001 Electronic Repair Manual EGR Volume Control Valve (Where Fitted)NJEC0560

Terminal No. ResistanceW[at 20ÉC (68ÉF)]

1-2

20-24 2-3

4-5

5-6

EGR Temperature Sensor (Where Fitted)NJEC0472

EGR temperature

ÉC (ÉF)Voltage

VResista NISSAN ALMERA N16 2001 Electronic Repair Manual EGR Volume Control Valve (Where Fitted)NJEC0560

Terminal No. ResistanceW[at 20ÉC (68ÉF)]

1-2

20-24 2-3

4-5

5-6

EGR Temperature Sensor (Where Fitted)NJEC0472

EGR temperature

ÉC (ÉF)Voltage

VResista](/img/5/57351/w960_57351-785.png)

EGR Volume Control Valve (Where Fitted)NJEC0560

Terminal No. ResistanceW[at 20ÉC (68ÉF)]

1-2

20-24 2-3

4-5

5-6

EGR Temperature Sensor (Where Fitted)NJEC0472

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

EVAP Canister Purge Volume Control ValveNJEC0481

Resistance [at 20ÉC (68ÉF)]W31-35

IACV-AAC ValveNJEC0474

Terminal No. ResistanceW[at 20ÉC (68ÉF)]

1-2

20-24 2-3

4-5

5-6

InjectorNJEC0475

Resistance [at 25ÉC (77ÉF)]W13.5 - 17.5

Ignition Coil with Power TransistorNJEC0561

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 2 (þ) Except 0 or¥

1 (+) - 3 (þ)

Except 0

1 (+) - 2 (þ)

CondenserNJEC0587

Resistance [at 25ÉC (77ÉF)] MWAbove 1

Fuel PumpNJEC0473

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

SERVICE DATA AND SPECIFICATIONS (SDS)QG

EGR Volume Control Valve (Where Fitted)

EC-490

Page 787 of 2493

Crankshaft Position Sensor (POS)NJEC0558Refer to ªComponent Inspectionº, EC-277.

Camshaft Position Sensor (PHASE)NJEC0559Refer to ªComponent Inspectionº, EC-284.

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Crankshaft Position Sensor (POS)

EC-491

Page 788 of 2493

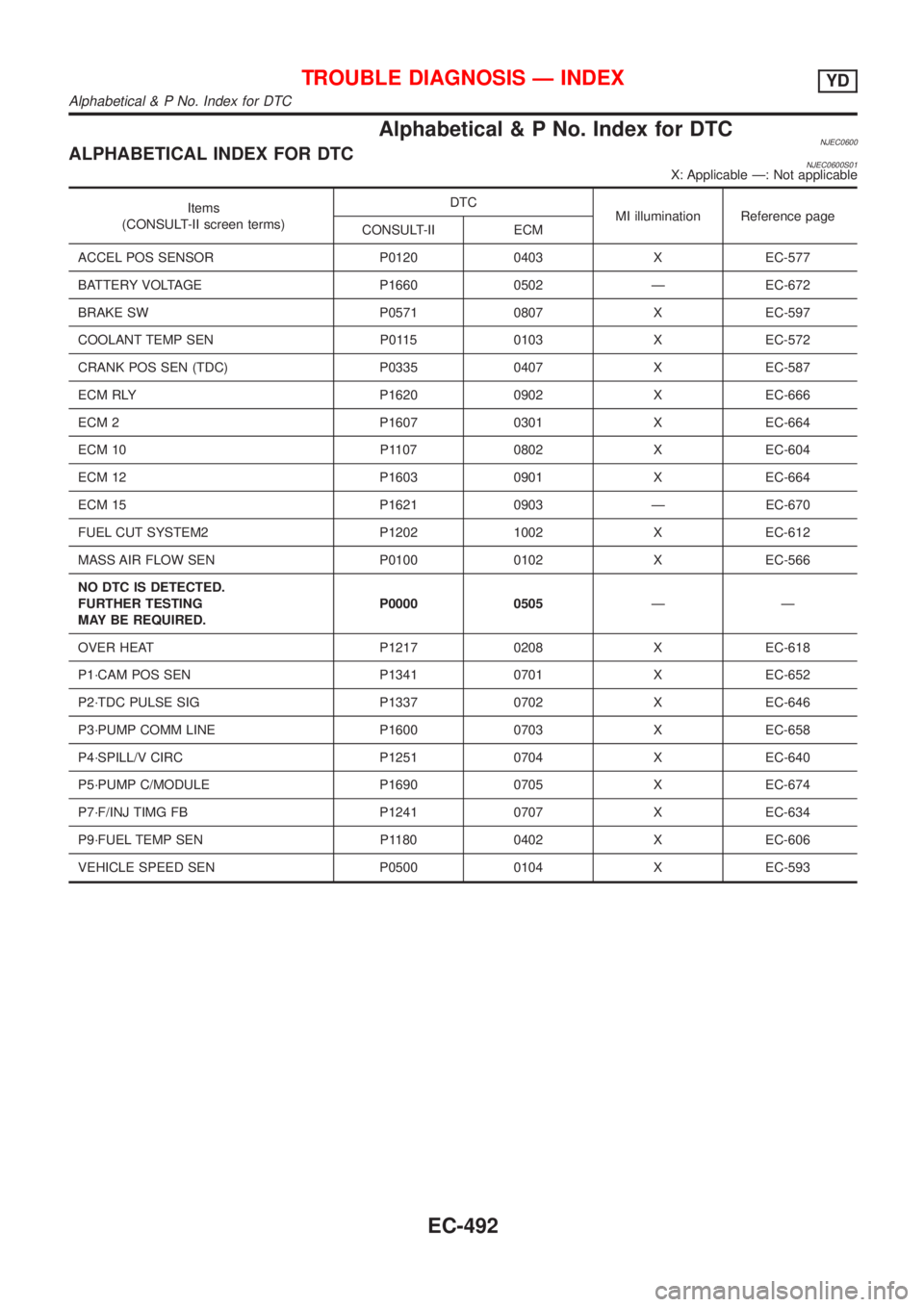

Alphabetical & P No. Index for DTCNJEC0600ALPHABETICAL INDEX FOR DTCNJEC0600S01X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC

MI illumination Reference page

CONSULT-II ECM

ACCEL POS SENSOR P0120 0403 X EC-577

BATTERY VOLTAGE P1660 0502 Ð EC-672

BRAKE SW P0571 0807 X EC-597

COOLANT TEMP SEN P0115 0103 X EC-572

CRANK POS SEN (TDC) P0335 0407 X EC-587

ECM RLY P1620 0902 X EC-666

ECM 2 P1607 0301 X EC-664

ECM 10 P1107 0802 X EC-604

ECM 12 P1603 0901 X EC-664

ECM 15 P1621 0903 Ð EC-670

FUEL CUT SYSTEM2 P1202 1002 X EC-612

MASS AIR FLOW SEN P0100 0102 X EC-566

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0505ÐÐ

OVER HEAT P1217 0208 X EC-618

P1´CAM POS SEN P1341 0701 X EC-652

P2´TDC PULSE SIG P1337 0702 X EC-646

P3´PUMP COMM LINE P1600 0703 X EC-658

P4´SPILL/V CIRC P1251 0704 X EC-640

P5´PUMP C/MODULE P1690 0705 X EC-674

P7´F/INJ TIMG FB P1241 0707 X EC-634

P9´FUEL TEMP SEN P1180 0402 X EC-606

VEHICLE SPEED SEN P0500 0104 X EC-593

TROUBLE DIAGNOSIS Ð INDEXYD

Alphabetical & P No. Index for DTC

EC-492

Page 789 of 2493

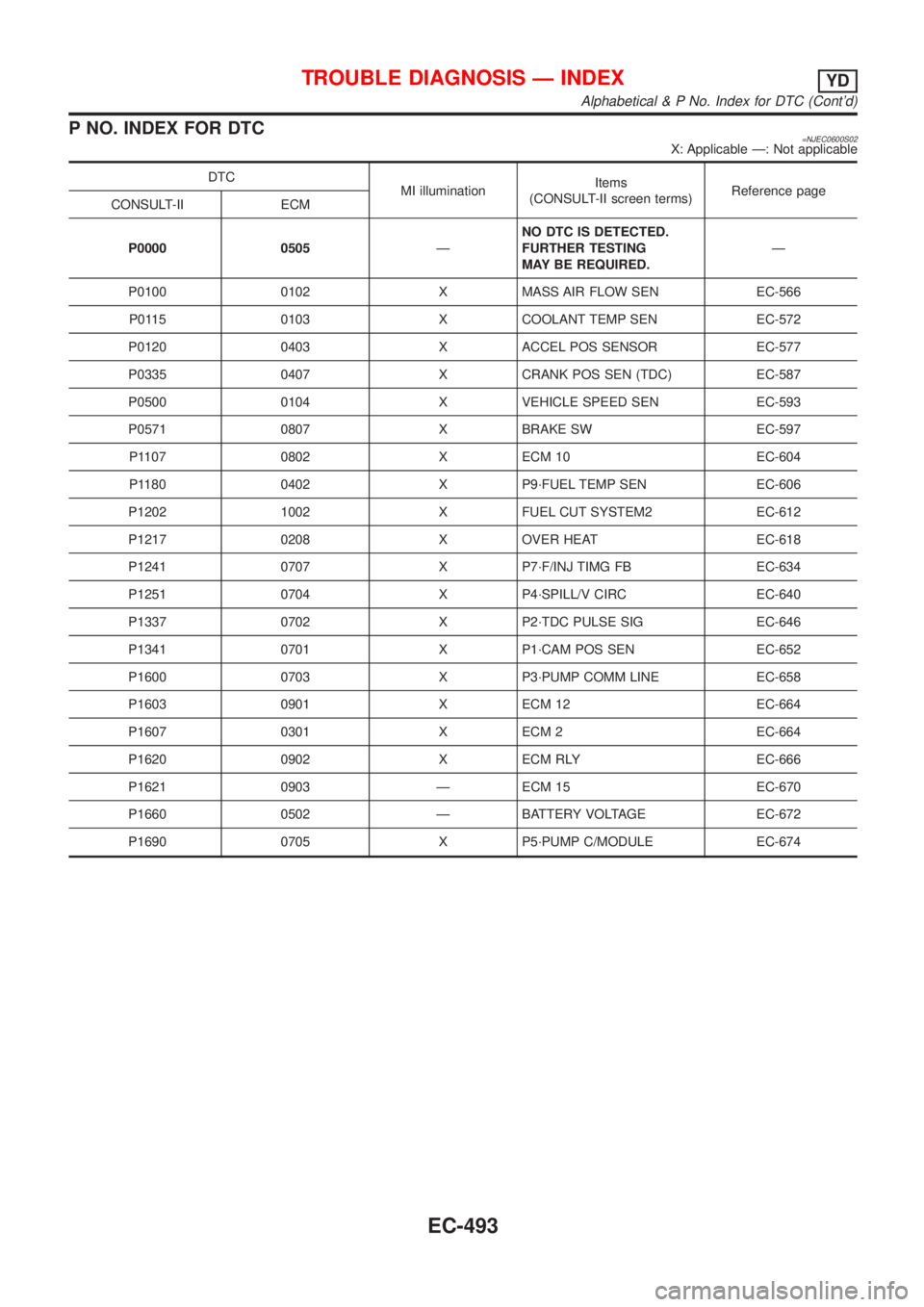

P NO. INDEX FOR DTC=NJEC0600S02X: Applicable Ð: Not applicable

DTC

MI illuminationItems

(CONSULT-II screen terms)Reference page

CONSULT-II ECM

P0000 0505ÐNO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.Ð

P0100 0102 X MASS AIR FLOW SEN EC-566

P0115 0103 X COOLANT TEMP SEN EC-572

P0120 0403 X ACCEL POS SENSOR EC-577

P0335 0407 X CRANK POS SEN (TDC) EC-587

P0500 0104 X VEHICLE SPEED SEN EC-593

P0571 0807 X BRAKE SW EC-597

P1107 0802 X ECM 10 EC-604

P1180 0402 X P9´FUEL TEMP SEN EC-606

P1202 1002 X FUEL CUT SYSTEM2 EC-612

P1217 0208 X OVER HEAT EC-618

P1241 0707 X P7´F/INJ TIMG FB EC-634

P1251 0704 X P4´SPILL/V CIRC EC-640

P1337 0702 X P2´TDC PULSE SIG EC-646

P1341 0701 X P1´CAM POS SEN EC-652

P1600 0703 X P3´PUMP COMM LINE EC-658

P1603 0901 X ECM 12 EC-664

P1607 0301 X ECM 2 EC-664

P1620 0902 X ECM RLY EC-666

P1621 0903 Ð ECM 15 EC-670

P1660 0502 Ð BATTERY VOLTAGE EC-672

P1690 0705 X P5´PUMP C/MODULE EC-674

TROUBLE DIAGNOSIS Ð INDEXYD

Alphabetical & P No. Index for DTC (Cont'd)

EC-493

Page 790 of 2493

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJEC0601The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harness can be identified by yellow harness connector.

PRECAUTIONSYD

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-494