NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2491 of 3189

DIAGNOSTIC PROCEDURE 3 (DOOR UNLOCK SENSOR

CHECK)

NJEL0455S05

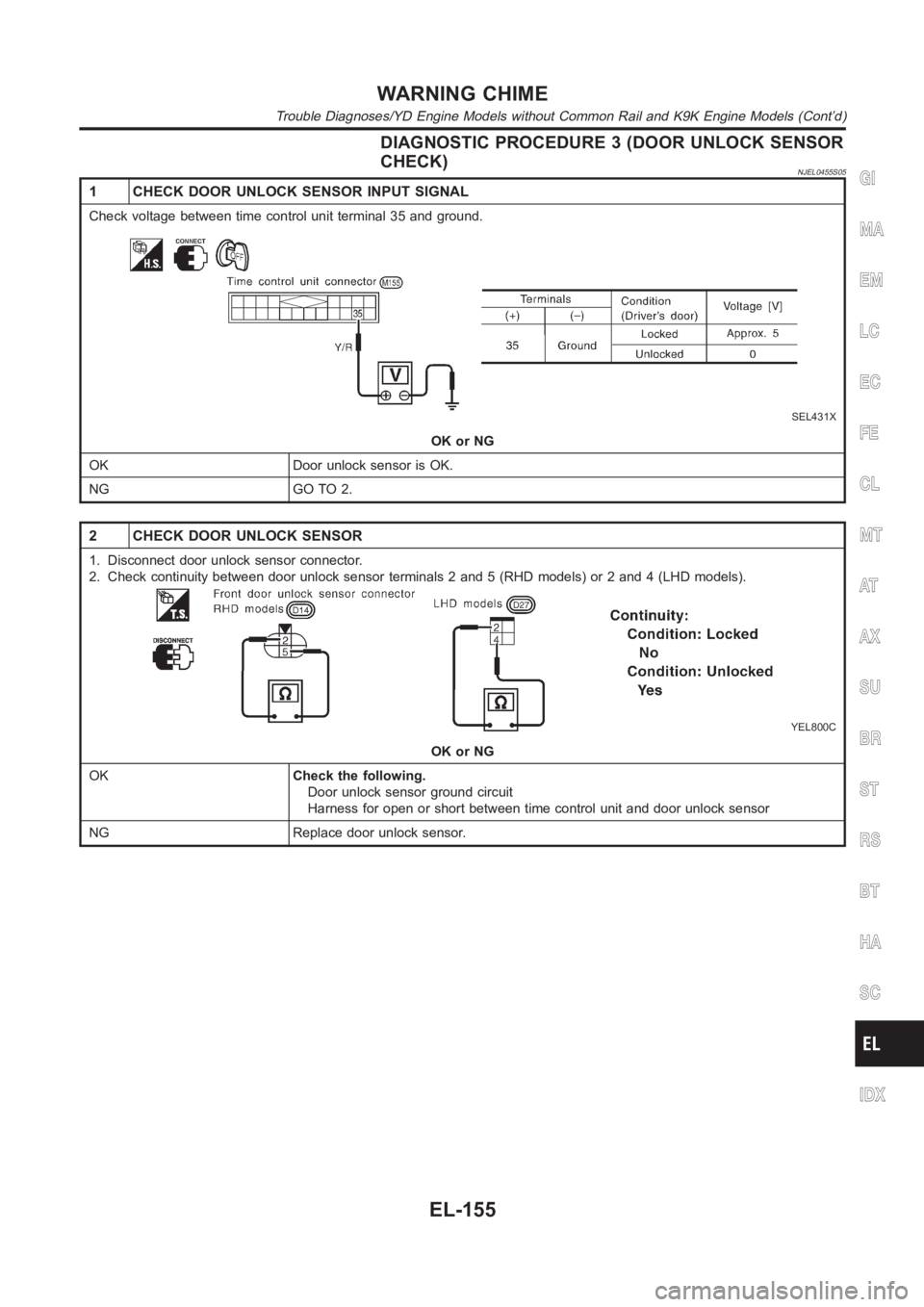

1 CHECK DOOR UNLOCK SENSOR INPUT SIGNAL

Check voltage between time control unit terminal 35 and ground.

SEL431X

OK or NG

OK Door unlock sensor is OK.

NG GO TO 2.

2 CHECK DOOR UNLOCK SENSOR

1. Disconnect door unlock sensor connector.

2. Check continuity between door unlock sensor terminals 2 and 5 (RHD models) or 2 and 4 (LHD models).

YEL800C

OK or NG

OKCheck the following.

Door unlock sensor ground circuit

Harness for open or short between time control unit and door unlock sensor

NG Replace door unlock sensor.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WARNING CHIME

Trouble Diagnoses/YD Engine Models without Common Rail and K9K Engine Models (Cont’d)

EL-155

Page 2492 of 3189

DIAGNOSTIC PROCEDURE 4=NJEL0455S06

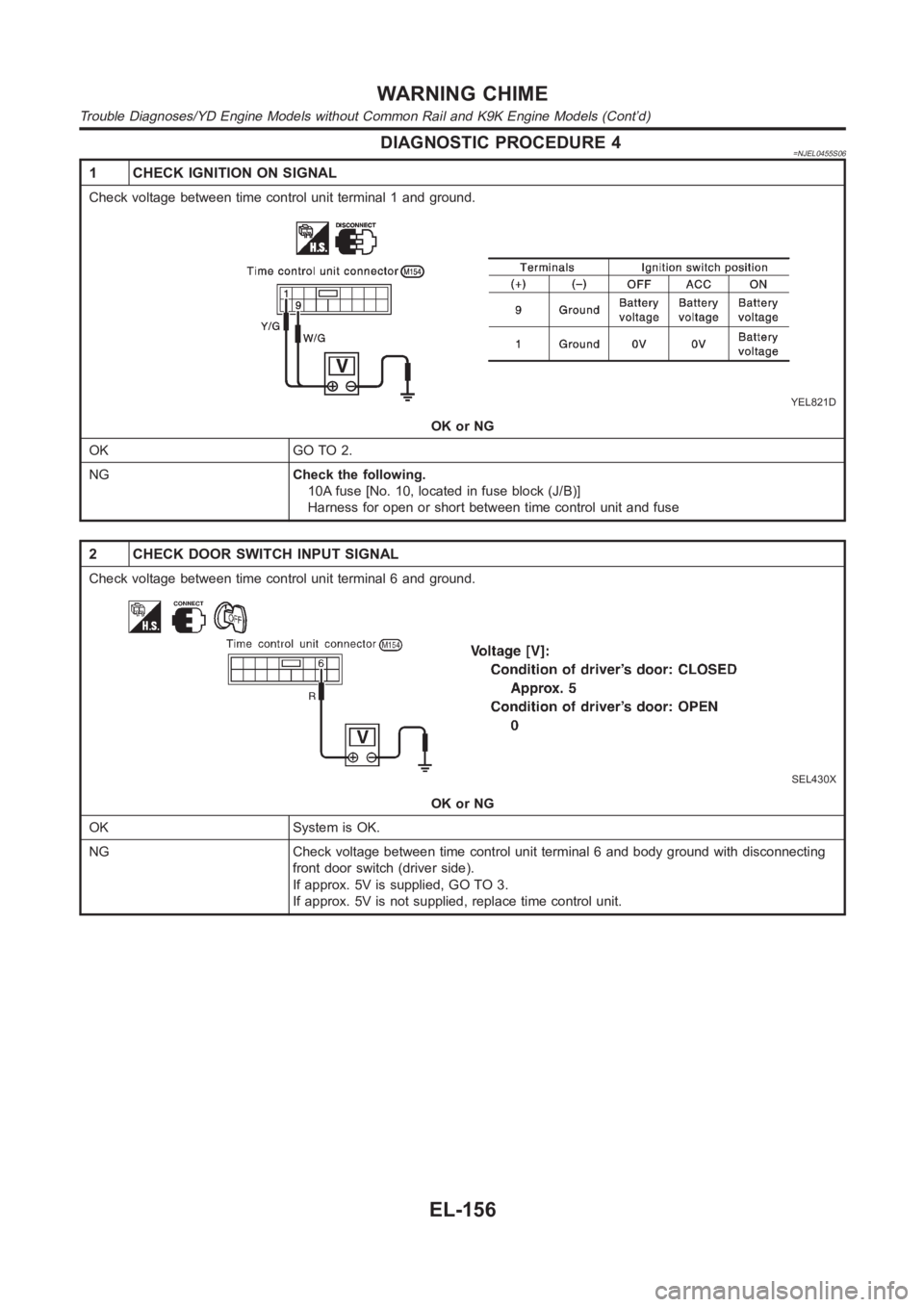

1 CHECK IGNITION ON SIGNAL

Check voltage between time control unit terminal 1 and ground.

YEL821D

OK or NG

OK GO TO 2.

NGCheck the following.

10A fuse [No. 10, located in fuse block (J/B)]

Harness for open or short between time control unit and fuse

2 CHECK DOOR SWITCH INPUT SIGNAL

Check voltage between time control unit terminal 6 and ground.

SEL430X

OK or NG

OK System is OK.

NG Check voltage between time control unit terminal 6 and body ground with disconnecting

front door switch (driver side).

If approx. 5V is supplied, GO TO 3.

If approx. 5V is not supplied, replace time control unit.

WARNING CHIME

Trouble Diagnoses/YD Engine Models without Common Rail and K9K Engine Models (Cont’d)

EL-156

Page 2493 of 3189

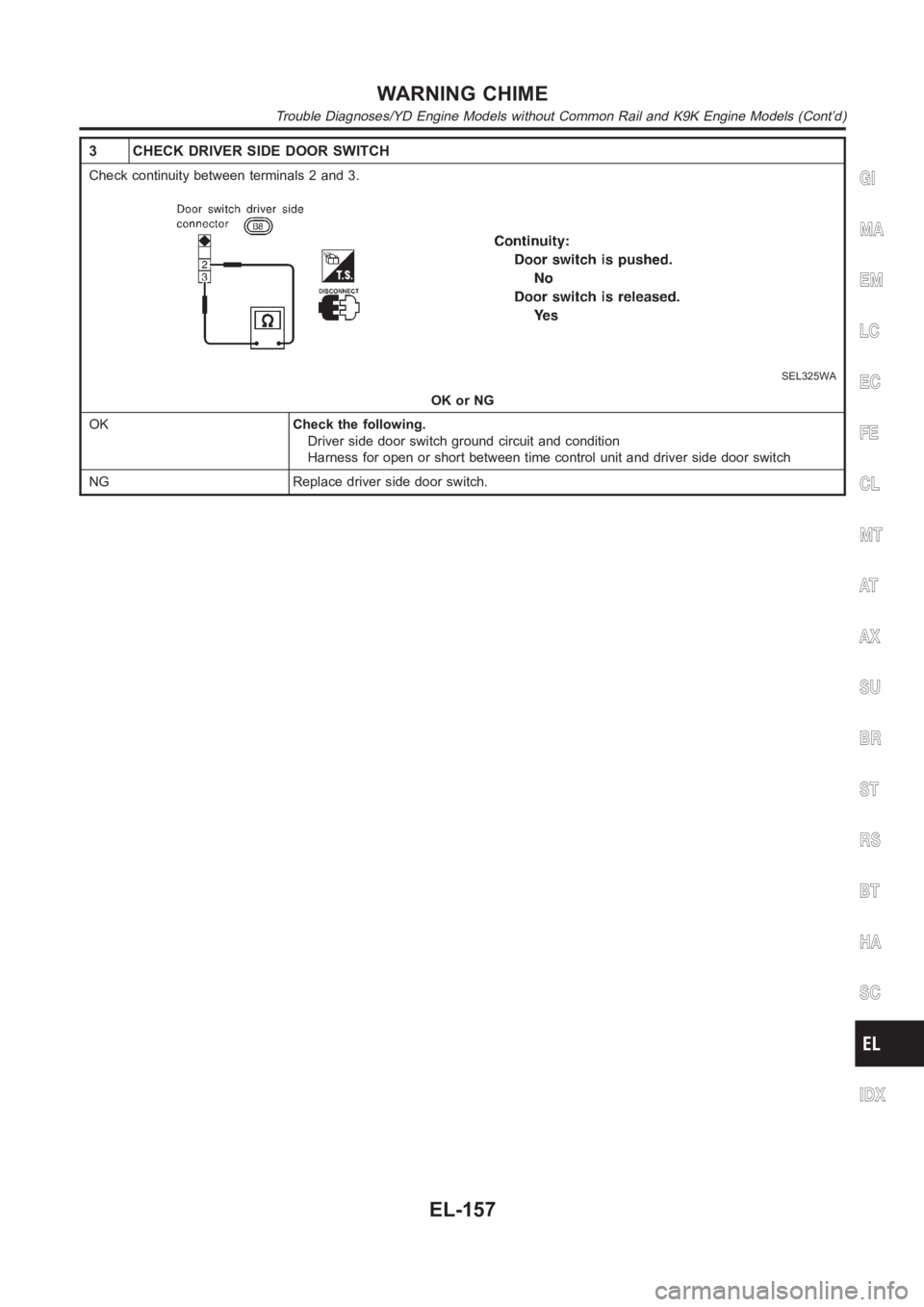

3 CHECK DRIVER SIDE DOOR SWITCH

Check continuity between terminals 2 and 3.

SEL325WA

OK or NG

OKCheck the following.

Driver side door switch ground circuit and condition

Harness for open or short between time control unit and driver side door switch

NG Replace driver side door switch.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WARNING CHIME

Trouble Diagnoses/YD Engine Models without Common Rail and K9K Engine Models (Cont’d)

EL-157

Page 2494 of 3189

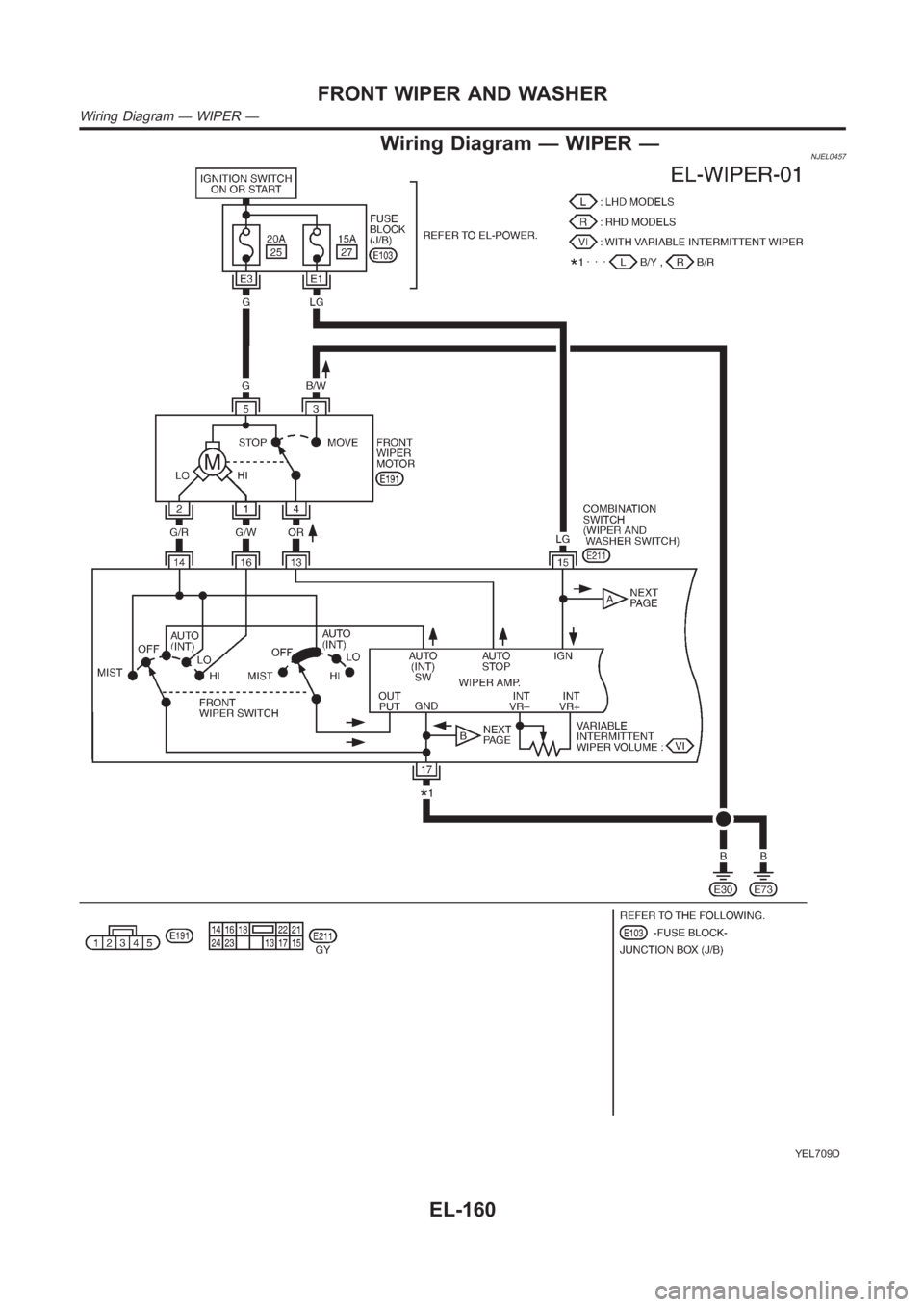

System DescriptionNJEL0456WIPER OPERATIONNJEL0456S01The wiper switch is controlled by a lever built into the combination switch.

There are three wiper switch positions:

LO speed

HI speed

INT (Intermittent)

With the ignition switch in the ON or START position, power is supplied

through 20A fuse [No. 25, located in the fuse block (J/B)]

to front wiper motor terminal 5.

Low and High Speed Wiper OperationNJEL0456S0101Ground is supplied to wiper and washer switch terminal 17 through body grounds E30 and E73.

When the wiper switch is placed in the LO position, ground is supplied

through terminal 14 of the front wiper and washer switch

to front wiper motor terminal 2.

With power and ground supplied, the wiper motor operates at low speed.

When the wiper switch is placed in the HI position, ground is supplied

through terminal 16 of the front wiper and washer switch

to wiper motor terminal 1.

With power and ground supplied, the wiper motor operates at high speed.

Auto Stop OperationNJEL0456S0102With wiper switch turned OFF, wiper motor will continue to operate until wiper arms reach windshield base.

When wiper arms are not located at base of windshield with wiper switch OFF,ground is provided

from terminal 14 of the front wiper and washer switch

to front wiper motor terminal 2, in order to continue wiper motor operationat low speed.

Ground is also supplied

through terminal 13 of the front wiper and washer switch

to front wiper motor terminal 4

through terminal 3 of front wiper motor

through body grounds E30 and E73.

When wiper arms reach base of windshield, front wiper motor terminals 4 and5 are connected instead of ter-

minals 4 and 3. Wiper motor will then stop wiper arms at the STOP position.

Intermittent OperationNJEL0456S0103The front wiper motor operates the wiper arms one time at low speed at a set interval of approximately 1 to

13 seconds. This feature is controlled by the wiper amplifier (INT SW) combined with front wiper switch.

When the wiper switch is placed in the INT position, ground is supplied to wiper amplifier (WIPER SW INT)

and (ACC).

The desired interval time is input to wiper amplifier (INT VR) from wiper volume switch combined with front

wiper and washer switch.

When the wiper switch is placed in the INT position, intermittent ground issupplied

through wiper amplifier (OUTPUT) and

through terminal 14 of front wiper and washer switch

to front wiper motor terminal 5.

The wiper motor operates at low speed at the desired interval.

When the lever is pulled to the WASH position for one second or more, the wiper motor operates at low speed

for approximately 3 seconds to clean windshield. This feature is controlled by the wiper amplifier in the same

manner as the intermittent operation.

WASHER OPERATIONNJEL0456S02With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 27, located in the fuse block (J/B)]

through front wiper switch terminals 15 and 18.

to front washer motor terminal 1.

FRONT WIPER AND WASHER

System Description

EL-158

Page 2495 of 3189

When the lever is pulled to the WASHER/FRONT position, ground is supplied

from body grounds E30 and E73,

through terminal 17 of the front wiper switch, and

through terminal 22 of the front wiper switch

to front washer motor terminal 2.

With power and ground supplied, the washer motor operates.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

FRONT WIPER AND WASHER

System Description (Cont’d)

EL-159

Page 2496 of 3189

Wiring Diagram — WIPER —NJEL0457

YEL709D

FRONT WIPER AND WASHER

Wiring Diagram — WIPER —

EL-160

Page 2497 of 3189

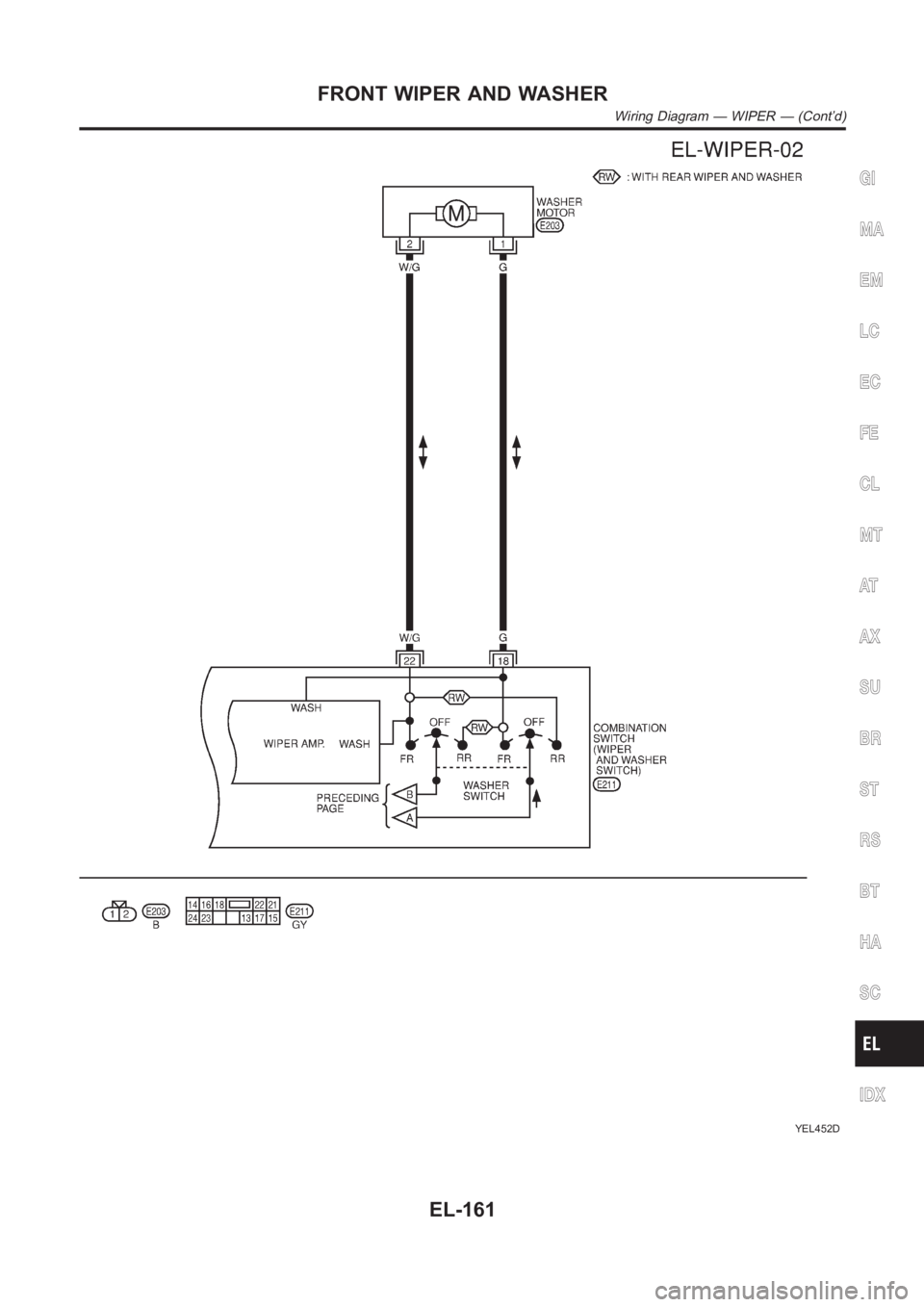

YEL452D

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

FRONT WIPER AND WASHER

Wiring Diagram — WIPER — (Cont’d)

EL-161

Page 2498 of 3189

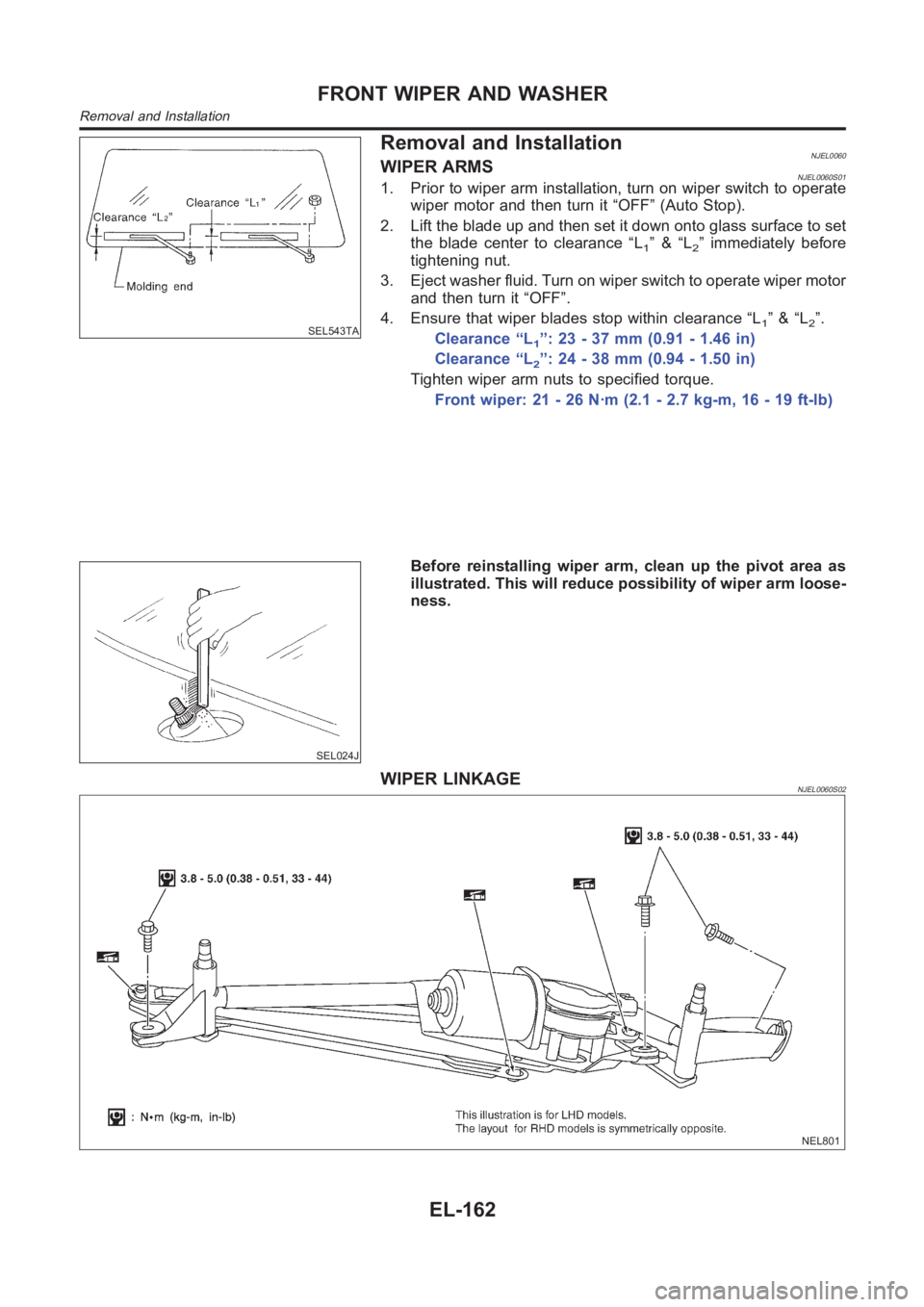

SEL543TA

Removal and InstallationNJEL0060WIPER ARMSNJEL0060S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it “OFF” (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to set

the blade center to clearance “L

1”&“L2” immediately before

tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it “OFF”.

4. Ensure that wiper blades stop within clearance “L

1”&“L2”.

Clearance “L1”:23-37mm(0.91-1.46in)

Clearance “L

2”:24-38mm(0.94-1.50in)

Tighten wiper arm nuts to specified torque.

Front wiper: 21 - 26 N·m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

SEL024J

Before reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

WIPER LINKAGENJEL0060S02

NEL801

FRONT WIPER AND WASHER

Removal and Installation

EL-162

Page 2499 of 3189

RemovalNJEL0060S02011. Remove cowl top seal rubber and cowl top cover.

2. Remove wiper motor connector.

3. Remove 3 screws that secure wiper motor and wiper frame.

4. Detach wiper motor from wiper linkage at ball joint.

5. Remove wiper linkage.

Be careful not to break ball joint rubber boot.

InstallationNJEL0060S0202Grease ball joint portion before installation.

1. Installation is the reverse order of removal.

YEL822D

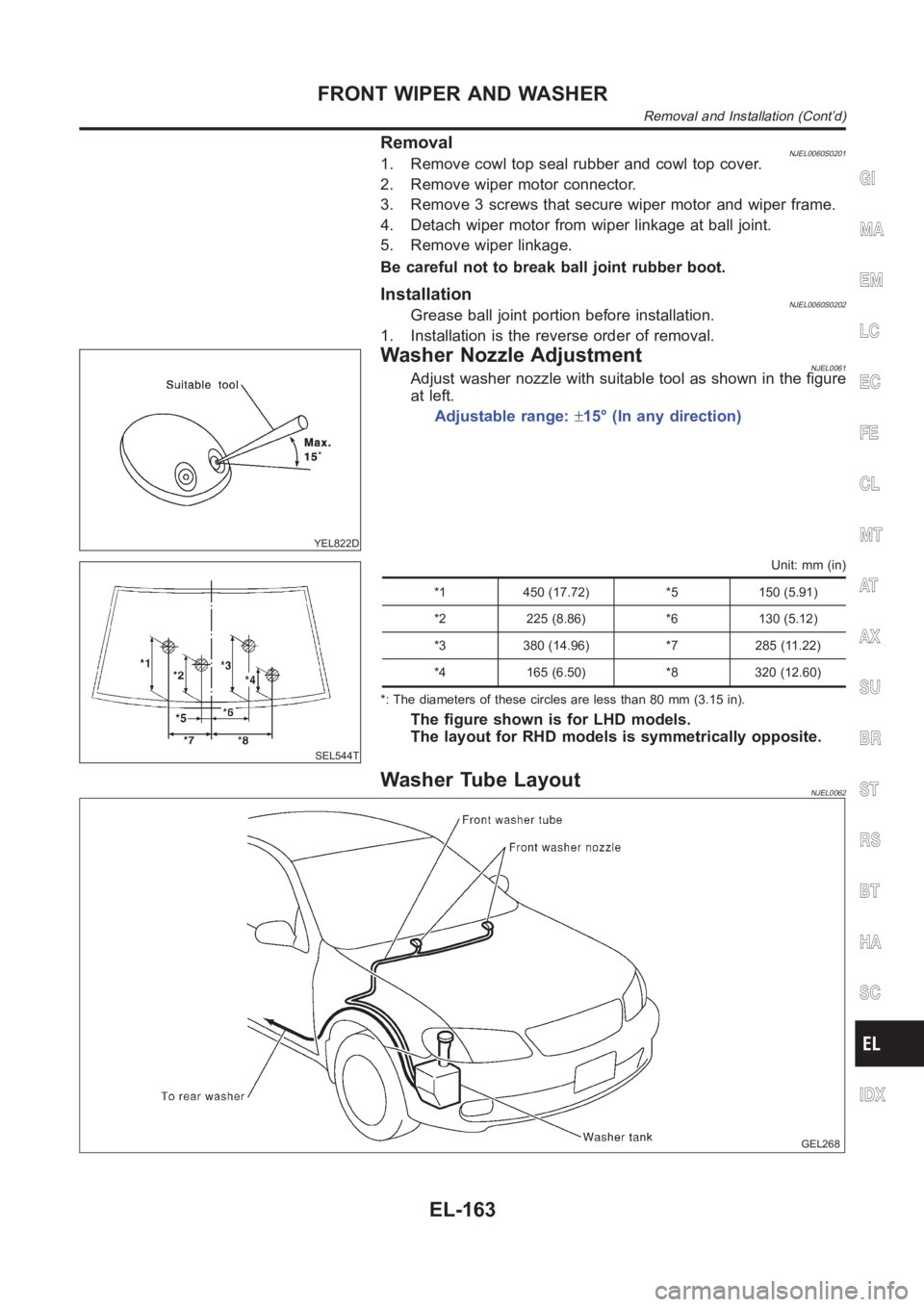

Washer Nozzle AdjustmentNJEL0061Adjust washer nozzle with suitable tool as shown in the figure

at left.

Adjustable range:±15° (In any direction)

SEL544T

Unit: mm (in)

*1 450 (17.72) *5 150 (5.91)

*2 225 (8.86) *6 130 (5.12)

*3 380 (14.96) *7 285 (11.22)

*4 165 (6.50) *8 320 (12.60)

*: The diameters of these circles are less than 80 mm (3.15 in).

The figure shown is for LHD models.

The layout for RHD models is symmetrically opposite.

Washer Tube LayoutNJEL0062

GEL268

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

FRONT WIPER AND WASHER

Removal and Installation (Cont’d)

EL-163

Page 2500 of 3189

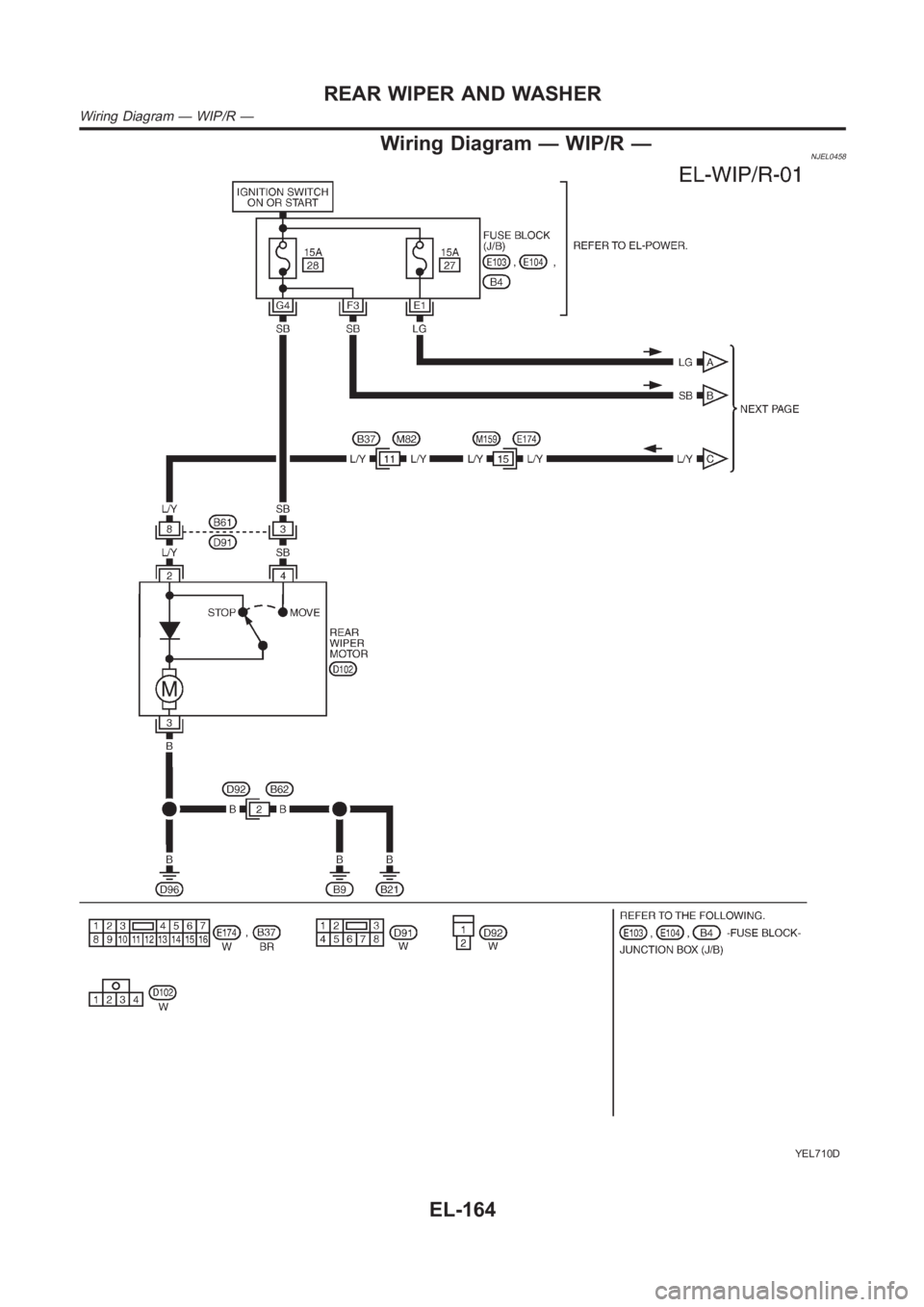

Wiring Diagram — WIP/R —NJEL0458

YEL710D

REAR WIPER AND WASHER

Wiring Diagram — WIP/R —

EL-164