Time NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2 of 3189

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

ALMERA, model N16 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

fications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not specifically recommended by NISSAN must

first completely satisfy himself that neither his safety nor the vehicle’s

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering Section

Paris, France

Page 6 of 3189

The security indicator is located on the combi meter. The indicator

blinks when the ignition switch is in “OFF” or “ACC” position.

Therefore, NATS warns outsiders that the vehicle is equipped with

the anti-theft system.

When NATS detects trouble, the security indicator lamp lights

up while ignition switch is in “ON” position.

This lighting up indicates that the anti-theft is not functioning,

so prompt service is required.

When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs),

CONSULT-II hardware and CONSULT-II NATS software is

necessary.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner. A

maximum of five key IDs can be registered into NATS.

When failing to start the engine first time using the key of

NATS, start as follows.

a) Leave the ignition key in “ON” position for approximately 5

seconds.

b) Turn ignition key to “OFF” or “LOCK” position and wait approxi-

mately 5 seconds.

c) Repeat step 1 and 2 again.

d) Restart the engine while keeping the key separate from any

others on key-chain.

SGI285

GENERAL PRECAUTIONSNJGI0001S03Do not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or

transaxle, be careful not to lose your balance and drop them.

Also, do not allow them to strike adjacent parts, especially the

brake tubes and master cylinder.

PRECAUTIONS

Precautions (Cont’d)

GI-4

Page 11 of 3189

fuels in your diesel engine. The use of those can cause

engine damage.

Do not use summer fuel at temperatures below −7°C

(20°F). The cold temperatures will cause wax to form in the

fuel. As a result, it may prevent the engine from running

smoothly.

Do not add gasoline or other alternate fuels to diesel fuel.

PRECAUTIONS FOR AIR CONDITIONINGNJGI0001S09Use an approved refrigerant recovery unit any time the air condi-

tioning system must be discharged. Refer to HA-77 (Manual) or

ATC-132 (Auto), “HFC-134a (R-134a) Service Procedure” for spe-

cific instructions.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions (Cont’d)

GI-9

Page 24 of 3189

NJGI0005

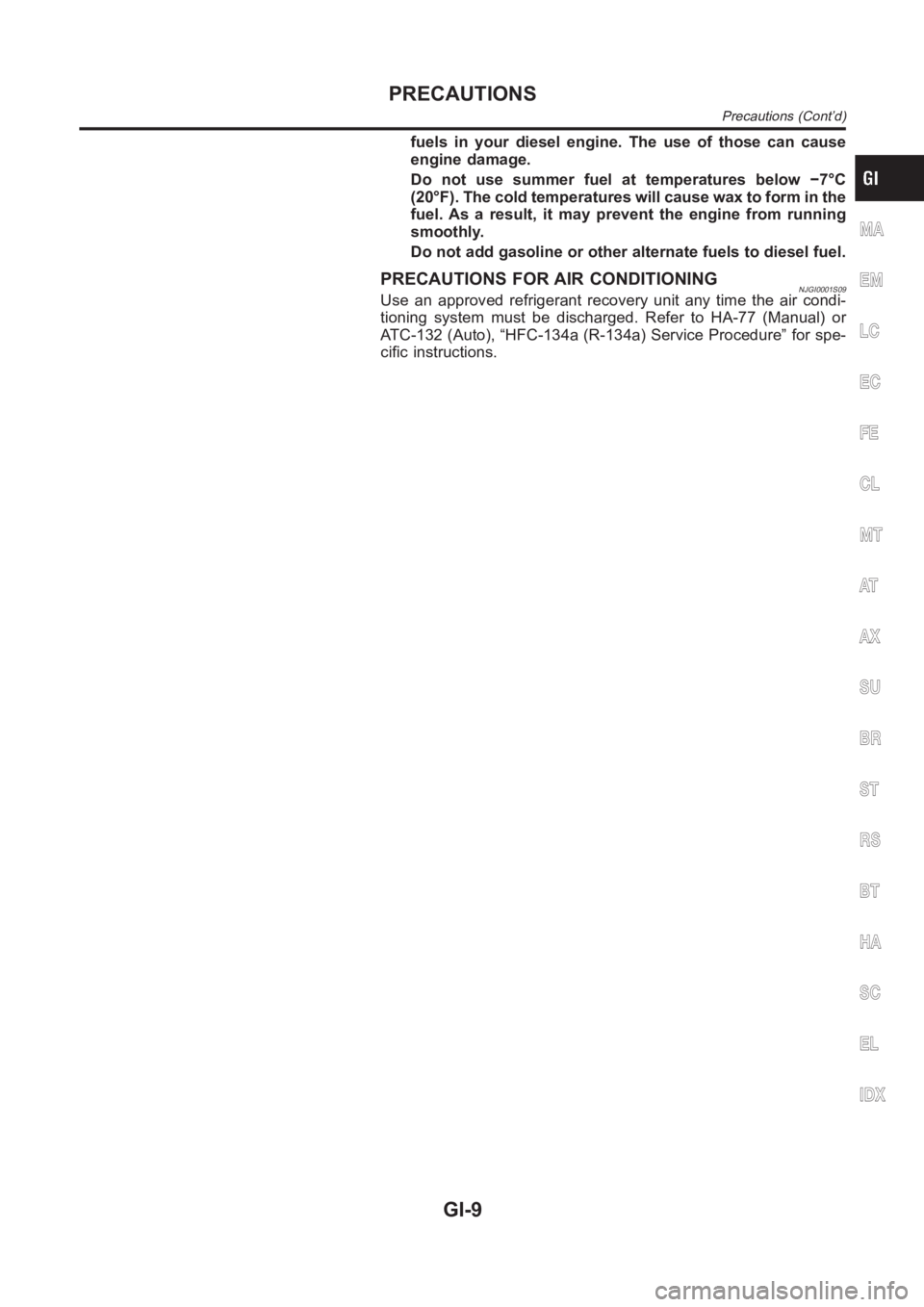

Work FlowNJGI0005S01

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem can not be duplicated, refer to “Incident Simulation Tests”next page.

STEP 3 Get the proper diagnoses materials together including:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnoses based upon your knowledge of the system operation and the cus-

tomer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing

and Harness Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you

have not inadvertently created a new incident during your diagnoses or repair steps.

HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT

Work Flow

GI-22

Page 25 of 3189

Incident Simulation TestsNJGI0005S02INTRODUCTIONNJGI0005S0201Sometimes the symptom is not present when the vehicle is brought

in for service. If possible, re-create the conditions present at the

time of the incident. Doing so may help avoid a No Trouble Found

Diagnoses. The following section illustrates ways to simulate the

conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

Vehicle vibration

Heat sensitive

Freezing

Water intrusion

Electrical load

Cold or hot start up

Get a thorough description of the incident from the customer. It is

important for simulating the conditions of the problem.

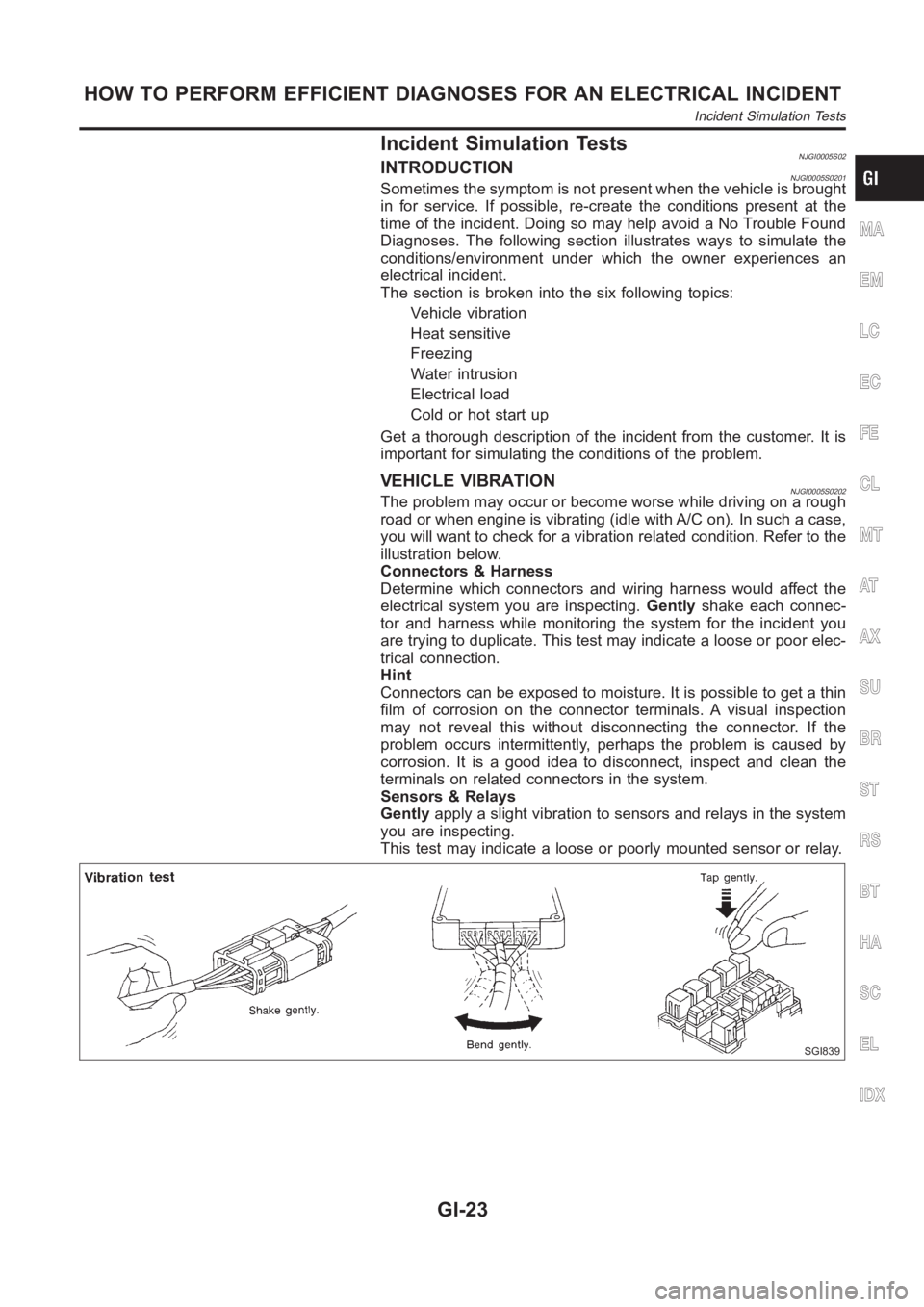

VEHICLE VIBRATIONNJGI0005S0202The problem may occur or become worse while driving on a rough

road or when engine is vibrating (idle with A/C on). In such a case,

you will want to check for a vibration related condition. Refer to the

illustration below.

Connectors & Harness

Determine which connectors and wiring harness would affect the

electrical system you are inspecting.Gentlyshake each connec-

tor and harness while monitoring the system for the incident you

are trying to duplicate. This test may indicate a loose or poor elec-

trical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin

film of corrosion on the connector terminals. A visual inspection

may not reveal this without disconnecting the connector. If the

problem occurs intermittently, perhaps the problem is caused by

corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensors & Relays

Gentlyapply a slight vibration to sensors and relays in the system

you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests

GI-23

Page 26 of 3189

Engine Compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

Connectors not fully seated.

Wiring harness not long enough and is being stressed due to

engine vibrations or rocking.

Wires laying across brackets or moving components.

Loose, dirty or corroded ground wires.

Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection bygently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind The Instrument Panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

SGI842

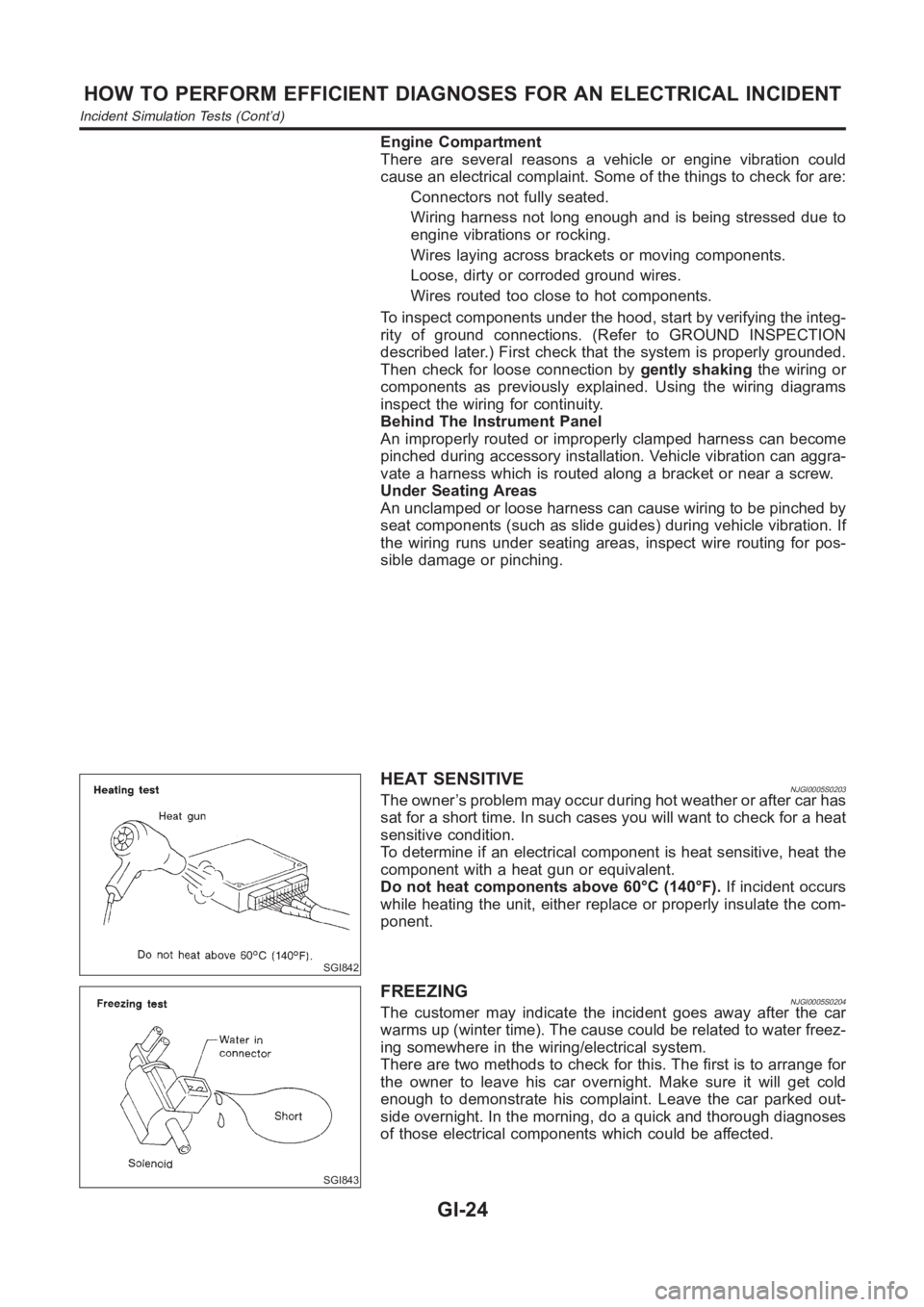

HEAT SENSITIVENJGI0005S0203The owner’s problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60°C (140°F).If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI843

FREEZINGNJGI0005S0204The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnoses

of those electrical components which could be affected.

HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont’d)

GI-24

Page 28 of 3189

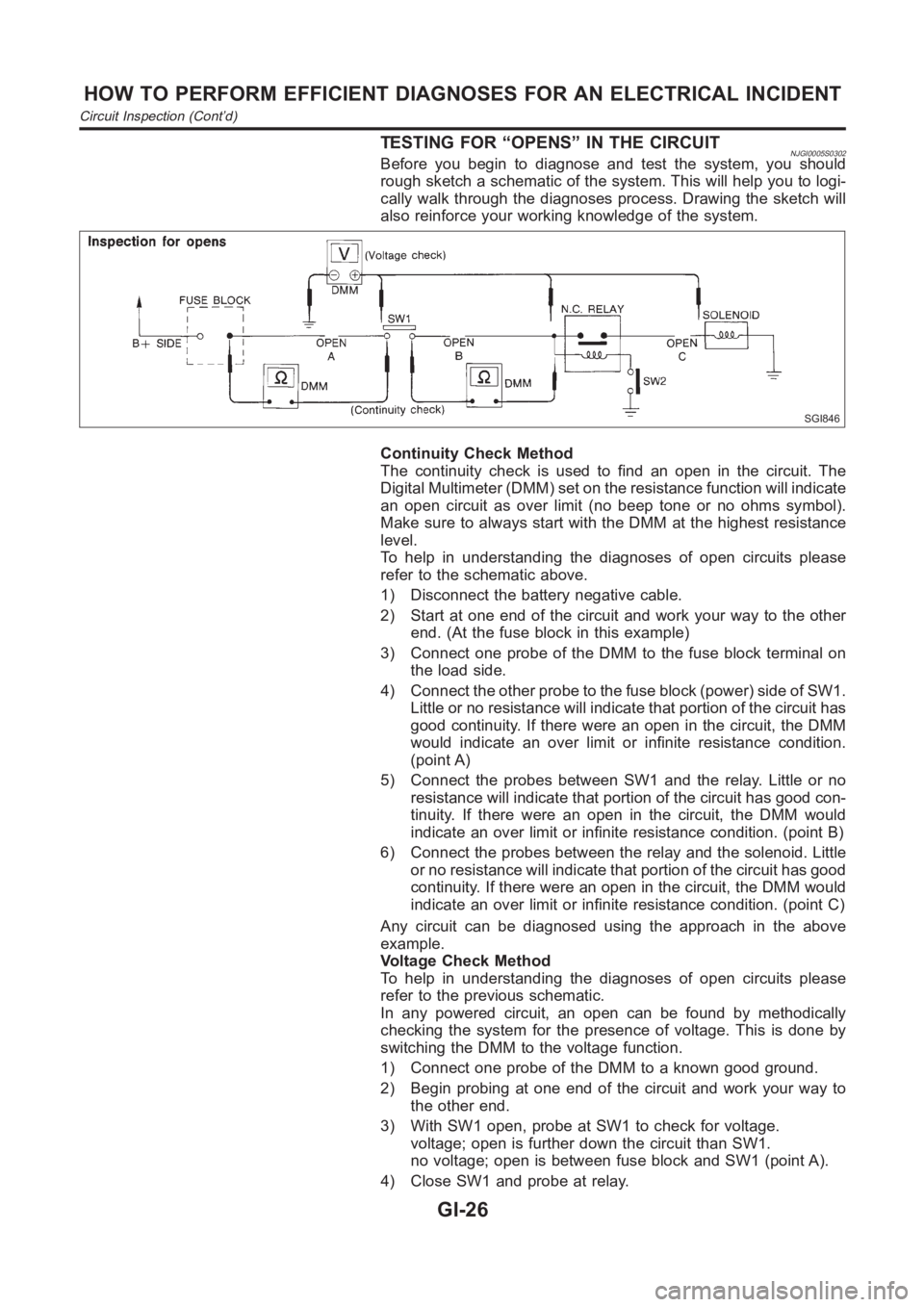

TESTING FOR “OPENS” IN THE CIRCUITNJGI0005S0302Before you begin to diagnose and test the system, you should

rough sketch a schematic of the system. This will help you to logi-

cally walk through the diagnoses process. Drawing the sketch will

also reinforce your working knowledge of the system.

SGI846

Continuity Check Method

The continuity check is used to find an open in the circuit. The

Digital Multimeter (DMM) set on the resistance function will indicate

an open circuit as over limit (no beep tone or no ohms symbol).

Make sure to always start with the DMM at the highest resistance

level.

To help in understanding the diagnoses of open circuits please

refer to the schematic above.

1) Disconnect the battery negative cable.

2) Start at one end of the circuit and work your way to the other

end. (At the fuse block in this example)

3) Connect one probe of the DMM to the fuse block terminal on

the load side.

4) Connect the other probe to the fuse block (power) side of SW1.

Little or no resistance will indicate that portion of the circuit has

good continuity. If there were an open in the circuit, the DMM

would indicate an over limit or infinite resistance condition.

(point A)

5) Connect the probes between SW1 and the relay. Little or no

resistance will indicate that portion of the circuit has good con-

tinuity. If there were an open in the circuit, the DMM would

indicate an over limit or infinite resistance condition. (point B)

6) Connect the probes between the relay and the solenoid. Little

or no resistance will indicate that portion of the circuit has good

continuity. If there were an open in the circuit, the DMM would

indicate an over limit or infinite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the above

example.

Voltage Check Method

To help in understanding the diagnoses of open circuits please

refer to the previous schematic.

In any powered circuit, an open can be found by methodically

checking the system for the presence of voltage. This is done by

switching the DMM to the voltage function.

1) Connect one probe of the DMM to a known good ground.

2) Begin probing at one end of the circuit and work your way to

the other end.

3) With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

4) Close SW1 and probe at relay.

HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont’d)

GI-26

Page 38 of 3189

NJGI0007

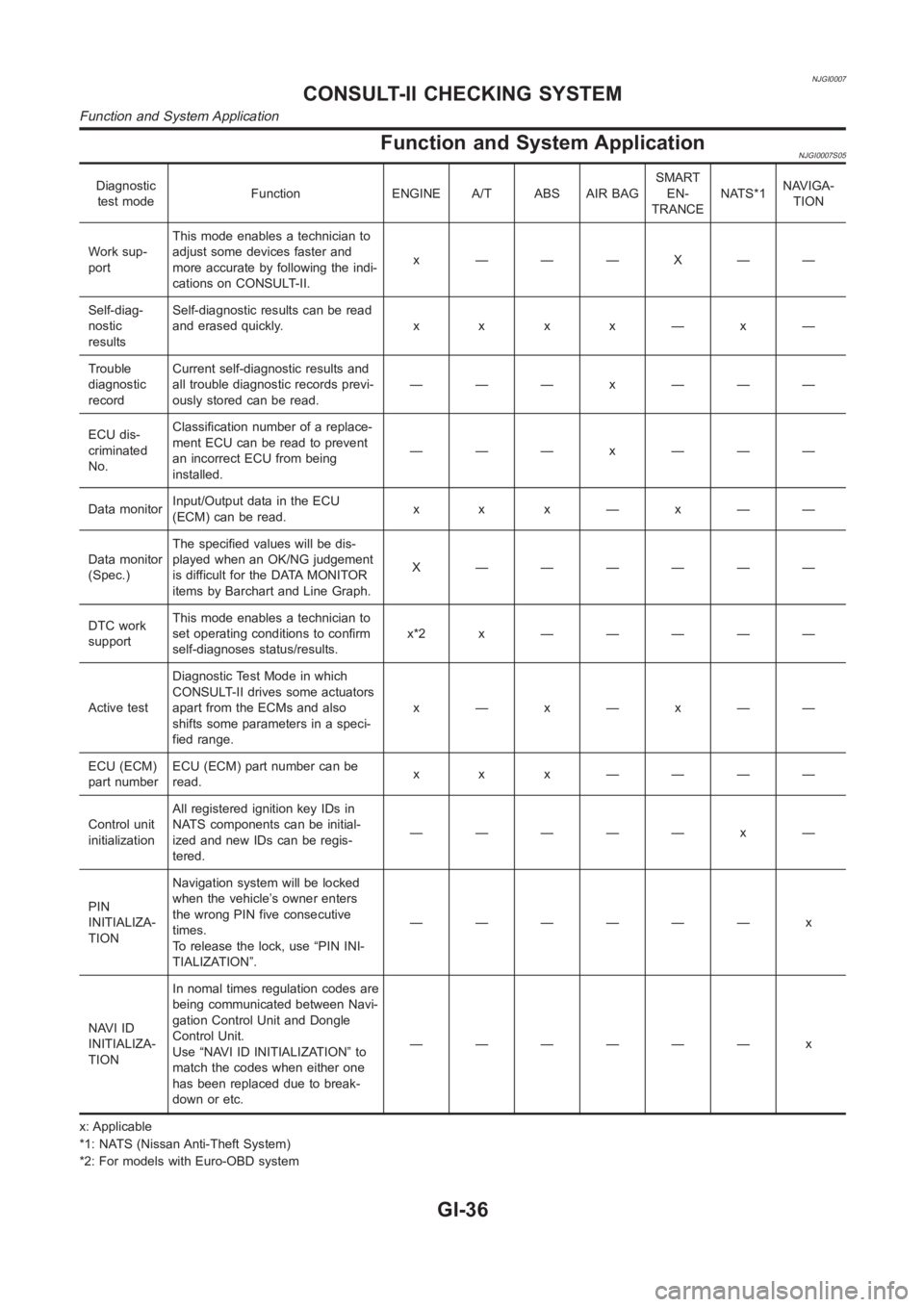

Function and System ApplicationNJGI0007S05

Diagnostic

test modeFunction ENGINE A/T ABS AIR BAGSMART

EN-

TRANCENATS*1NAVIGA-

TION

Work sup-

portThis mode enables a technician to

adjust some devices faster and

more accurate by following the indi-

cations on CONSULT-II.x ———X——

Self-diag-

nostic

resultsSelf-diagnostic results can be read

anderasedquickly. x x x x—x—

Trouble

diagnostic

recordCurrent self-diagnostic results and

all trouble diagnostic records previ-

ously stored can be read.——— x ———

ECU dis-

criminated

No.Classification number of a replace-

ment ECU can be read to prevent

an incorrect ECU from being

installed.——— x ———

Data monitorInput/Output data in the ECU

(ECM) can be read.x x x—x——

Data monitor

(Spec.)The specified values will be dis-

played when an OK/NG judgement

is difficult for the DATA MONITOR

items by Barchart and Line Graph.X ——————

DTC work

supportThis mode enables a technician to

set operating conditions to confirm

self-diagnoses status/results.x*2x —————

Active testDiagnostic Test Mode in which

CONSULT-II drives some actuators

apart from the ECMs and also

shifts some parameters in a speci-

fied range.x—x—x——

ECU (ECM)

part numberECU (ECM) part number can be

read.x x x ————

Control unit

initializationAll registered ignition key IDs in

NATS components can be initial-

ized and new IDs can be regis-

tered.————— x —

PIN

INITIALIZA-

TIONNavigation system will be locked

when the vehicle’s owner enters

the wrong PIN five consecutive

times.

To release the lock, use “PIN INI-

TIALIZATION”.—————— x

NAVI ID

INITIALIZA-

TIONIn nomal times regulation codes are

being communicated between Navi-

gation Control Unit and Dongle

Control Unit.

Use “NAVI ID INITIALIZATION” to

match the codes when either one

has been replaced due to break-

down or etc.—————— x

x: Applicable

*1: NATS (Nissan Anti-Theft System)

*2: For models with Euro-OBD system

CONSULT-II CHECKING SYSTEM

Function and System Application

GI-36

Page 59 of 3189

NJMA0004

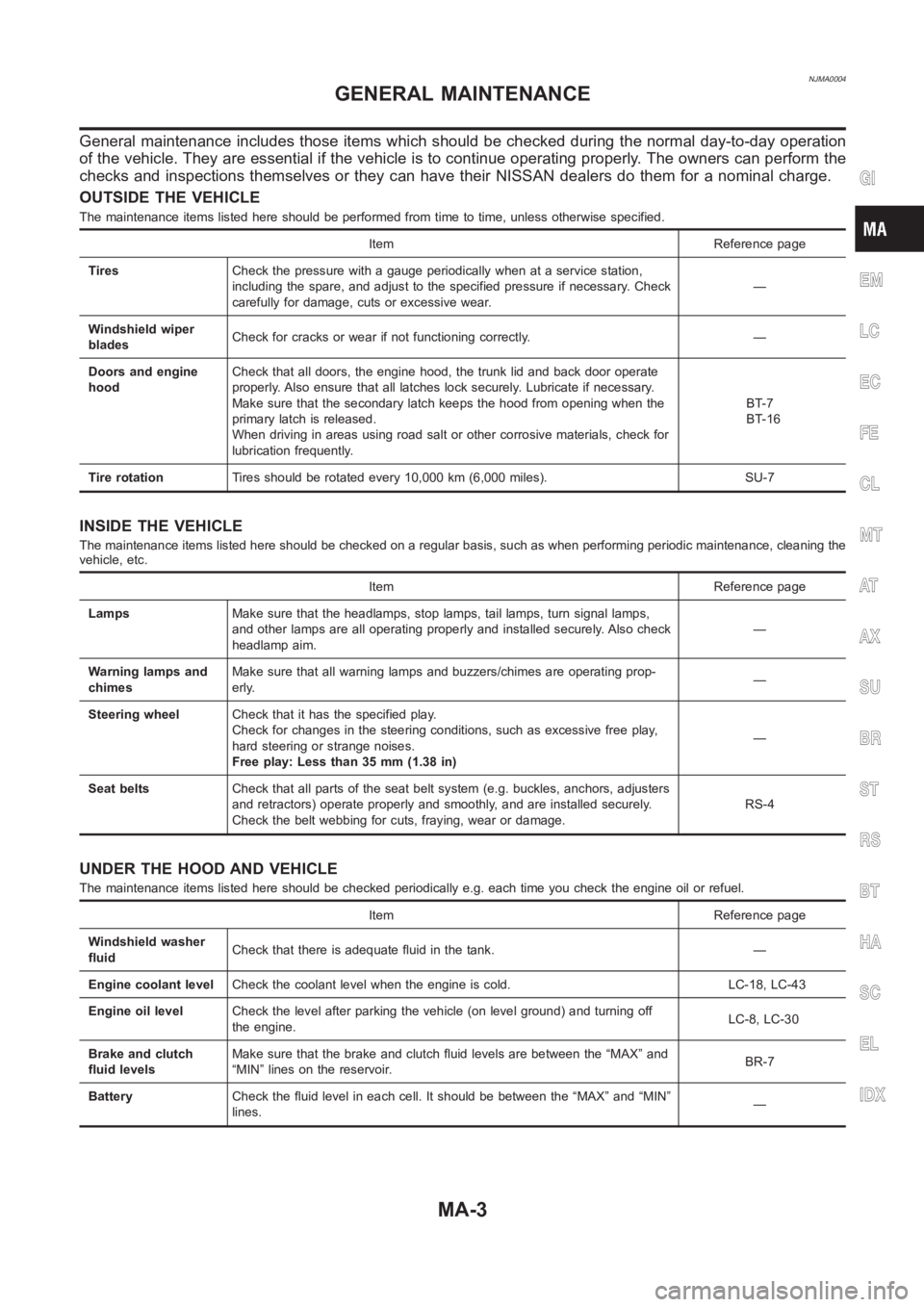

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers dothem for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-16

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-7

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-4

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-18, LC-43

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-30

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

GENERAL MAINTENANCE

MA-3

Page 88 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-10

[QG]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS00LPX

1. Locate the area where noise occurs.

2. Confirm the type of n NISSAN ALMERA N16 2003 Electronic Repair Manual EM-10

[QG]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS00LPX

1. Locate the area where noise occurs.

2. Confirm the type of n](/img/5/57350/w960_57350-87.png)

EM-10

[QG]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS00LPX

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseTy p e o f

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

Top of

engine

Rocker

cover

Cylinder

headTick in g o r

clickingCA—AB—Tappet

noise

●Valve clearanceEM-42

Rattle C A — A B CCamshaft

bearing

noise

●Camshaft journal

clearance

●Camshaft runoutEM-39EM-39

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock—A—B B—Piston pin

noise

●Piston and piston pin

clearance

●Connecting rod

bushing clearanceEM-84EM-87

Slap or

rapA——B B APiston

slap noise

●Piston-to-bore clear-

ance

●Piston ring side

clearance

●Piston ring end gap

●Connecting rod bend

and torsionEM-88

EM-85

EM-86

EM-86

Knock A B C B B BConnect-

ing rod

bearing

noise

●Connecting rod

bushing clearance

(Small end)

●Connecting rod bear-

ing clearance (Big

end)EM-87EM-87

Knock A B — A B CMain

bearing

noise

●Main bearing oil

clearance

●Crankshaft runoutEM-91EM-90

Front of

engine

Timing

chain

coverTapping or

tickingAA—BBBTiming

chain and

chain ten-

sioner

noise●Timing chain cracks

and wear

●Timing chain ten-

sioner operationEM-51EM-47

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belts

(Sticking

or slip-

ping)

●Drive belts deflection

EM-11

CreakingABABABDrive belts

(Slipping)●Idler pulley bearing

operation

Squall

CreakAB—BABWater

pump

noise

●Water pump opera-

tionLC-14