NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 101 of 3051

SAT250K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

=NLAT0061S04NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

SAT255K

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Depress accelerator pedal completely and wait at least 5 sec-

onds.

If the check result is ªNGº, go to ªDiagnostic Procedureº,

AT-102.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0745 LINE PRESSURE SOLENOID VALVEEURO-OBD

Description (Cont'd)

AT-100

Page 102 of 3051

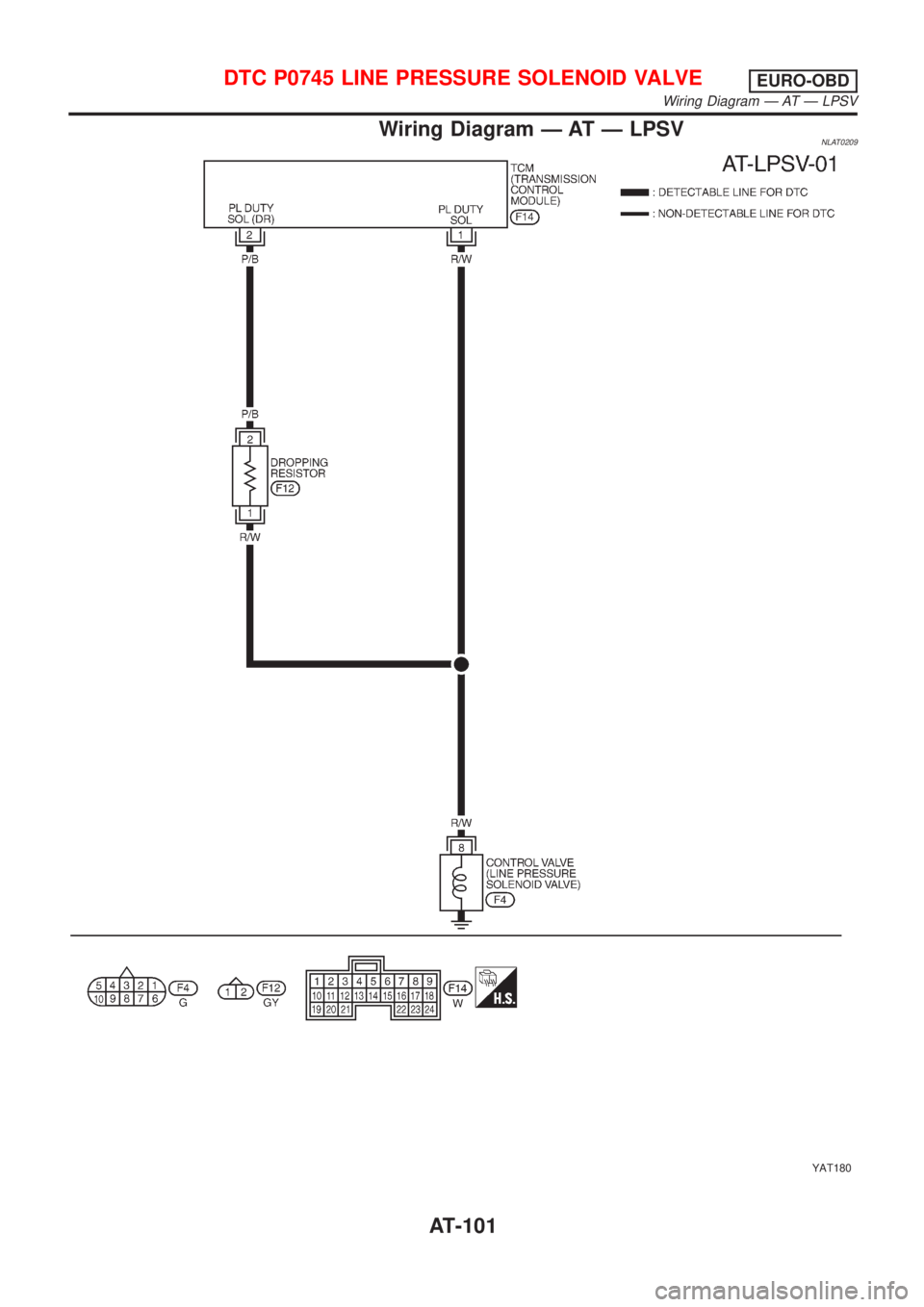

Wiring Diagram Ð AT Ð LPSVNLAT0209

YAT180

DTC P0745 LINE PRESSURE SOLENOID VALVEEURO-OBD

Wiring Diagram Ð AT Ð LPSV

AT-101

Page 103 of 3051

Diagnostic ProcedureNLAT0062

1 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 8 and ground.

Resistance:

2.5-5W

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Line pressure solenoid valve

Refer to ªComponent Inspectionº, AT-103.

+Harness of terminal cord assembly for short or open

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 8 and TCM harness connector terminal 2.

Resistance:

11.2 - 12.8W

OK or NG

OK©GO TO 3.

NG©Check the following items:

+Dropping resistor

Refer to ªComponent Inspectionº, AT-103.

+Harness for short or open between TCM terminal 2 and terminal cord assembly (Main

harness)

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Check continuity between terminal 8 and TCM harness connector terminal 1.

Continuity should exist.

If OK, check harness for short to ground and short to power.

3. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-100.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0745 LINE PRESSURE SOLENOID VALVEEURO-OBD

Diagnostic Procedure

AT-102

Page 104 of 3051

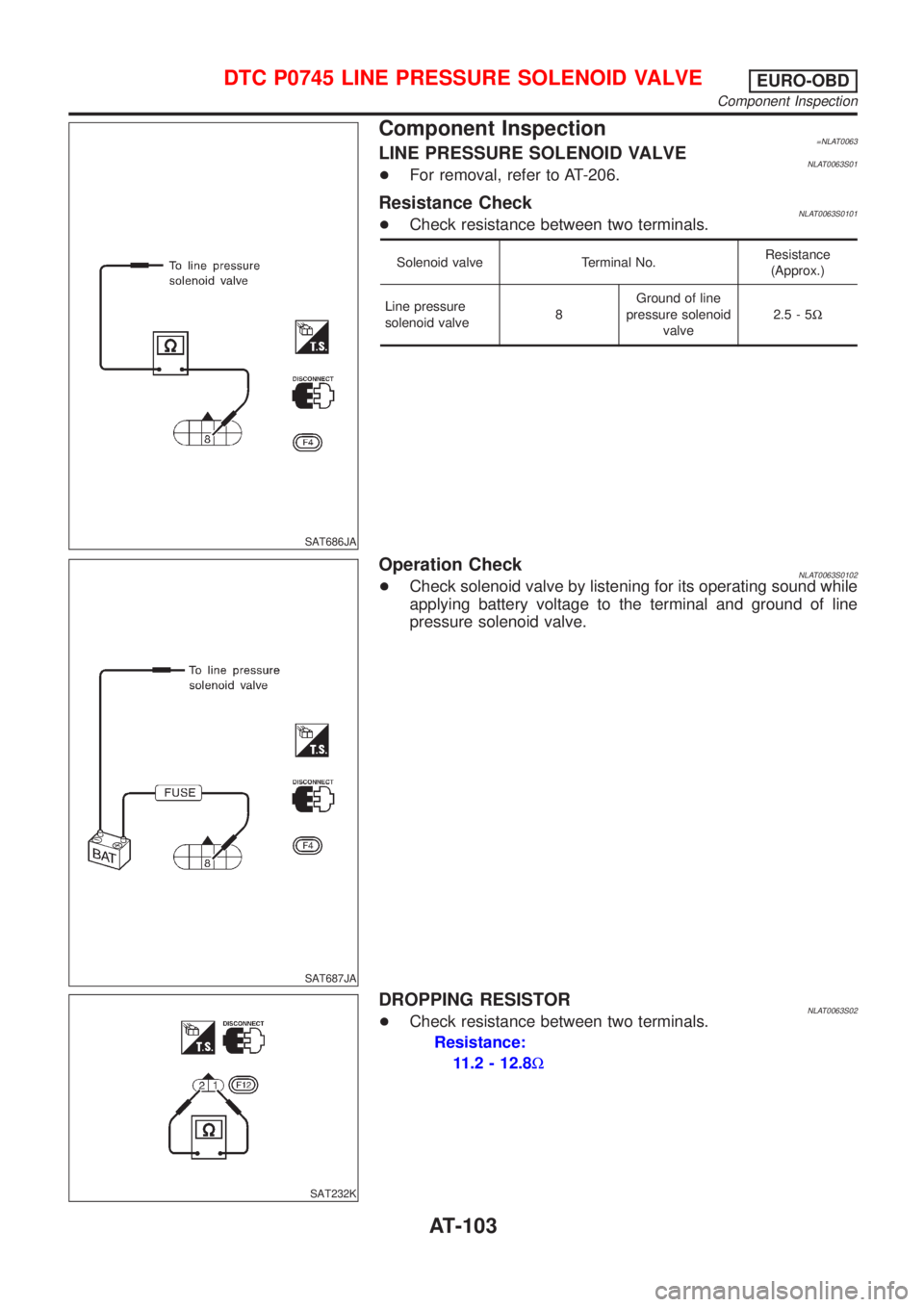

SAT686JA

Component Inspection=NLAT0063LINE PRESSURE SOLENOID VALVENLAT0063S01+For removal, refer to AT-206.

Resistance CheckNLAT0063S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Line pressure

solenoid valve8Ground of line

pressure solenoid

valve2.5-5W

SAT687JA

Operation CheckNLAT0063S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground of line

pressure solenoid valve.

SAT232K

DROPPING RESISTORNLAT0063S02+Check resistance between two terminals.

Resistance:

11.2 - 12.8W

DTC P0745 LINE PRESSURE SOLENOID VALVEEURO-OBD

Component Inspection

AT-103

Page 105 of 3051

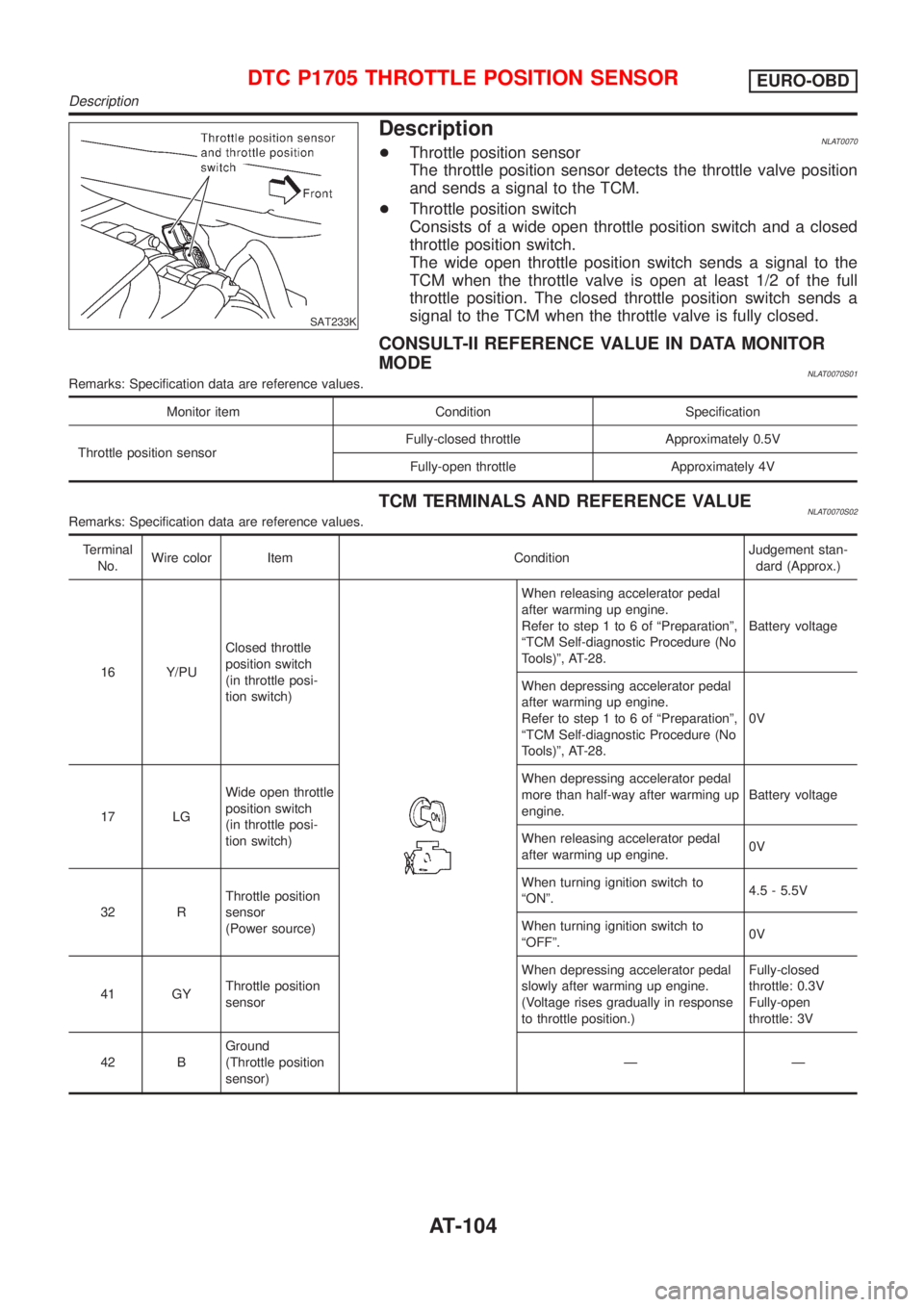

SAT233K

DescriptionNLAT0070+Throttle position sensor

The throttle position sensor detects the throttle valve position

and sends a signal to the TCM.

+Throttle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0070S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Throttle position sensorFully-closed throttle Approximately 0.5V

Fully-open throttle Approximately 4V

TCM TERMINALS AND REFERENCE VALUENLAT0070S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

16 Y/PUClosed throttle

position switch

(in throttle posi-

tion switch)

When releasing accelerator pedal

after warming up engine.

Refer to step 1 to 6 of ªPreparationº,

ªTCM Self-diagnostic Procedure (No

Tools)º, AT-28.Battery voltage

When depressing accelerator pedal

after warming up engine.

Refer to step 1 to 6 of ªPreparationº,

ªTCM Self-diagnostic Procedure (No

Tools)º, AT-28.0V

17 LGWide open throttle

position switch

(in throttle posi-

tion switch)When depressing accelerator pedal

more than half-way after warming up

engine.Battery voltage

When releasing accelerator pedal

after warming up engine.0V

32 RThrottle position

sensor

(Power source)When turning ignition switch to

ªONº.4.5 - 5.5V

When turning ignition switch to

ªOFFº.0V

41 GYThrottle position

sensorWhen depressing accelerator pedal

slowly after warming up engine.

(Voltage rises gradually in response

to throttle position.)Fully-closed

throttle: 0.3V

Fully-open

throttle: 3V

42 BGround

(Throttle position

sensor)ÐÐ

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Description

AT-104

Page 106 of 3051

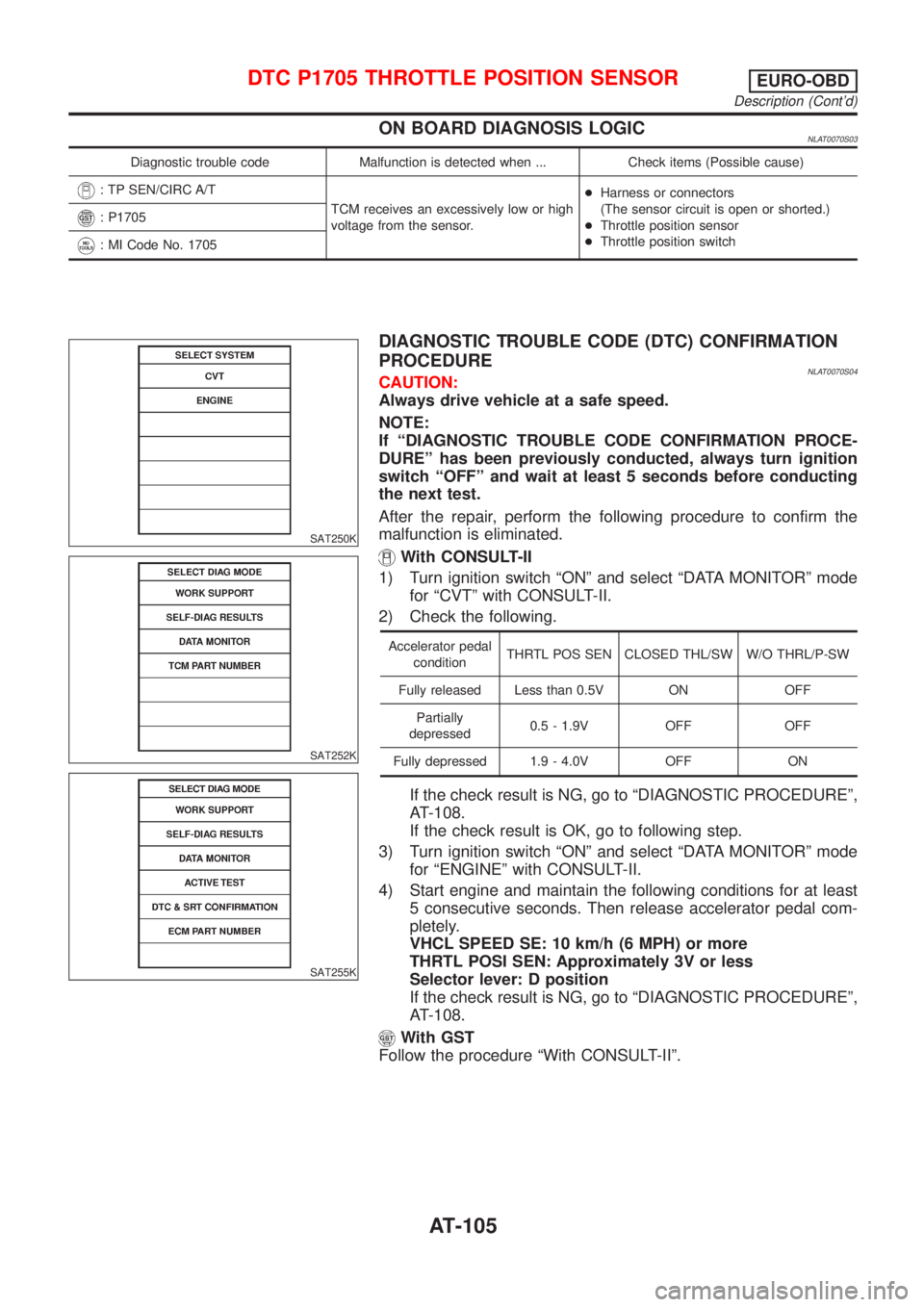

ON BOARD DIAGNOSIS LOGICNLAT0070S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TP SEN/CIRC A/T

TCM receives an excessively low or high

voltage from the sensor.+Harness or connectors

(The sensor circuit is open or shorted.)

+Throttle position sensor

+Throttle position switch

: P1705

: MI Code No. 1705

SAT250K

SAT252K

SAT255K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NLAT0070S04CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªCVTº with CONSULT-II.

2) Check the following.

Accelerator pedal

conditionTHRTL POS SEN CLOSED THL/SW W/O THRL/P-SW

Fully released Less than 0.5V ON OFF

Partially

depressed0.5 - 1.9V OFF OFF

Fully depressed 1.9 - 4.0V OFF ON

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-108.

If the check result is OK, go to following step.

3) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

4) Start engine and maintain the following conditions for at least

5 consecutive seconds. Then release accelerator pedal com-

pletely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POSI SEN: Approximately 3V or less

Selector lever: D position

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-108.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Description (Cont'd)

AT-105

Page 107 of 3051

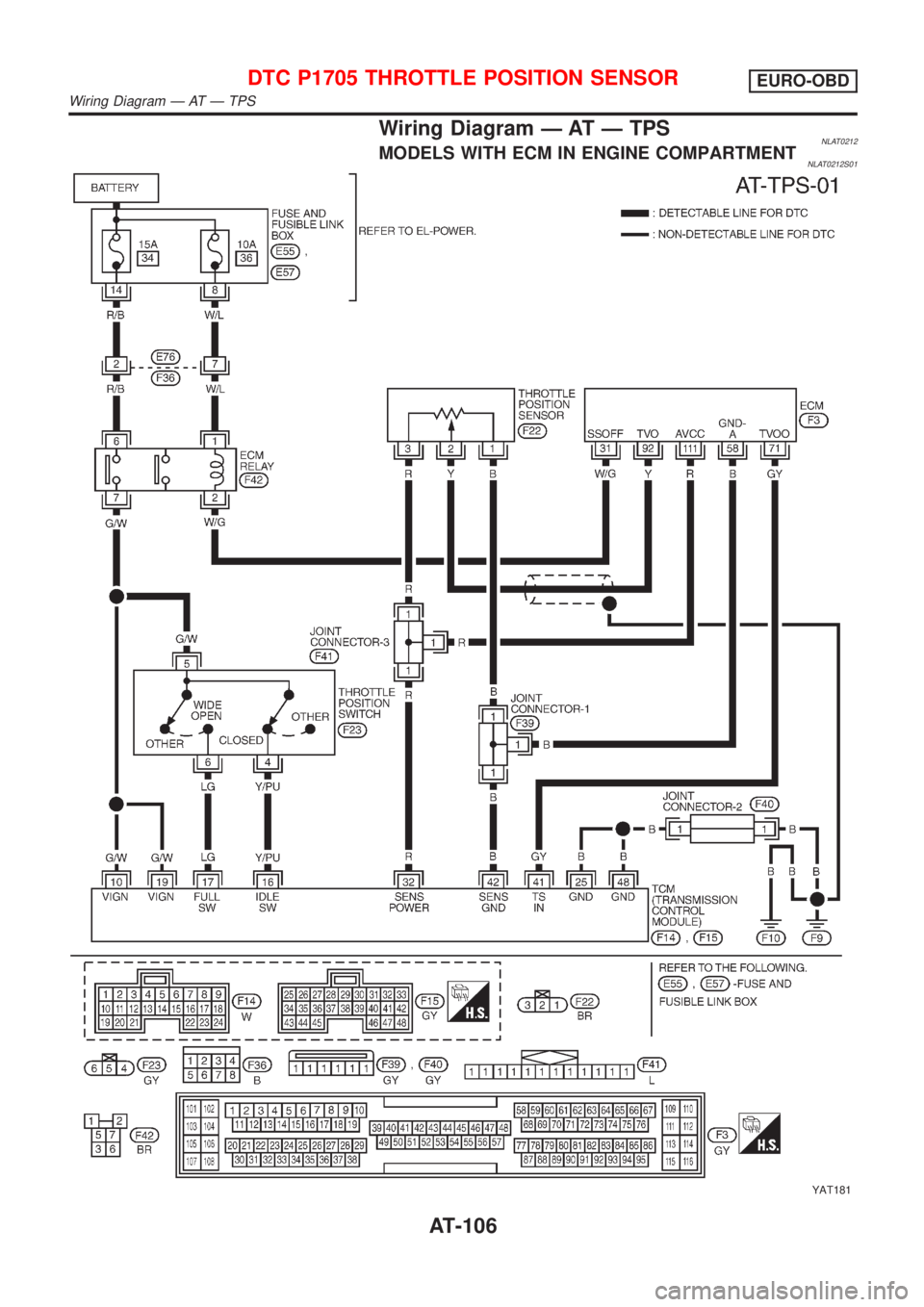

Wiring Diagram Ð AT Ð TPSNLAT0212MODELS WITH ECM IN ENGINE COMPARTMENTNLAT0212S01

YAT181

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Wiring Diagram Ð AT Ð TPS

AT-106

Page 108 of 3051

MODELS WITH ECM IN CABINNLAT0212S02

YAT217

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Wiring Diagram Ð AT Ð TPS (Cont'd)

AT-107

Page 109 of 3051

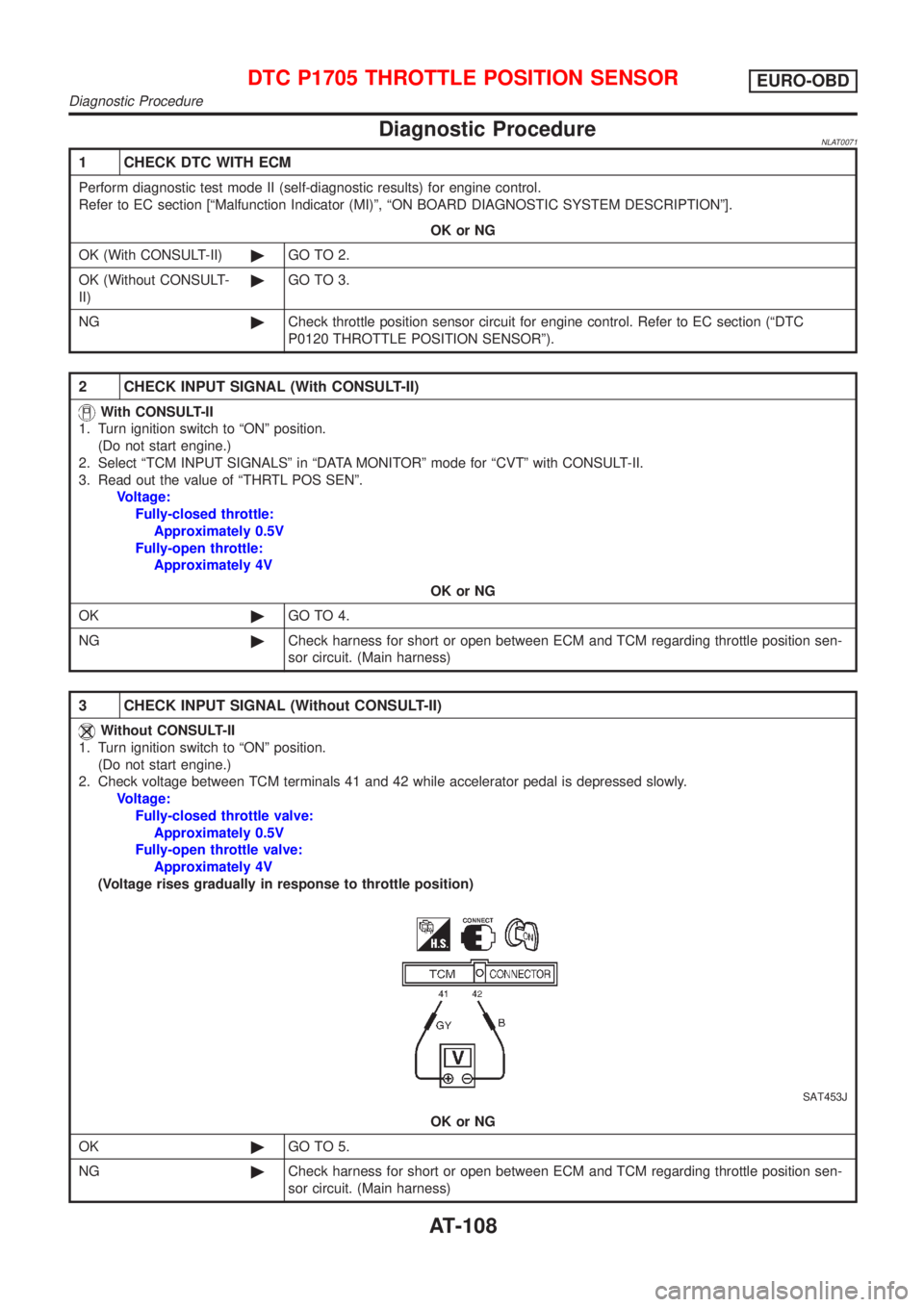

Diagnostic ProcedureNLAT0071

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº].

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Check throttle position sensor circuit for engine control. Refer to EC section (ªDTC

P0120 THROTTLE POSITION SENSORº).

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªTHRTL POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

OK or NG

OK©GO TO 4.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

3 CHECK INPUT SIGNAL (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 41 and 42 while accelerator pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in response to throttle position)

SAT453J

OK or NG

OK©GO TO 5.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Diagnostic Procedure

AT-108

Page 110 of 3051

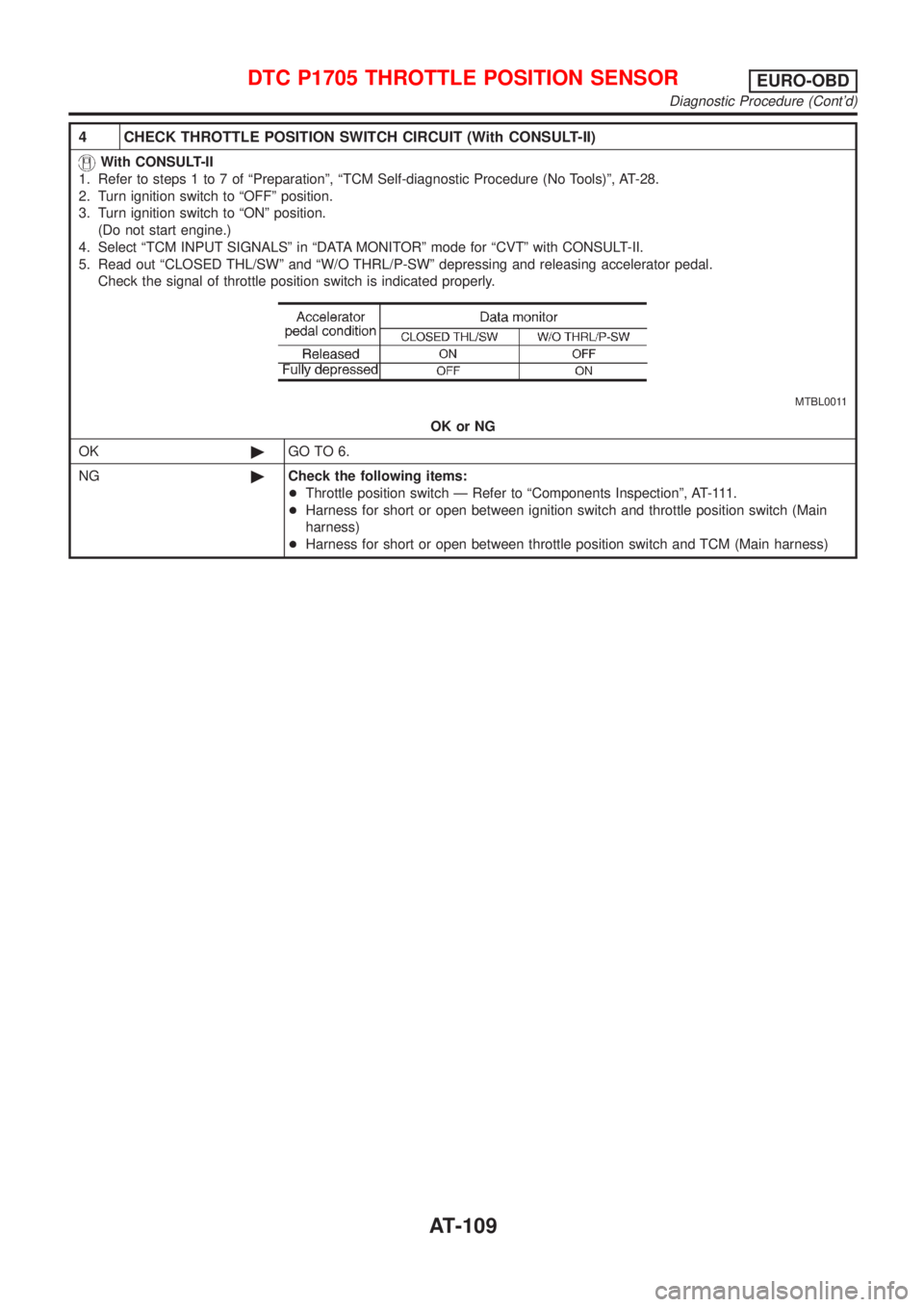

4 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Refer to steps 1 to 7 of ªPreparationº, ªTCM Self-diagnostic Procedure (No Tools)º, AT-28.

2. Turn ignition switch to ªOFFº position.

3. Turn ignition switch to ªONº position.

(Do not start engine.)

4. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

5. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-111.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Diagnostic Procedure (Cont'd)

AT-109