NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 111 of 3051

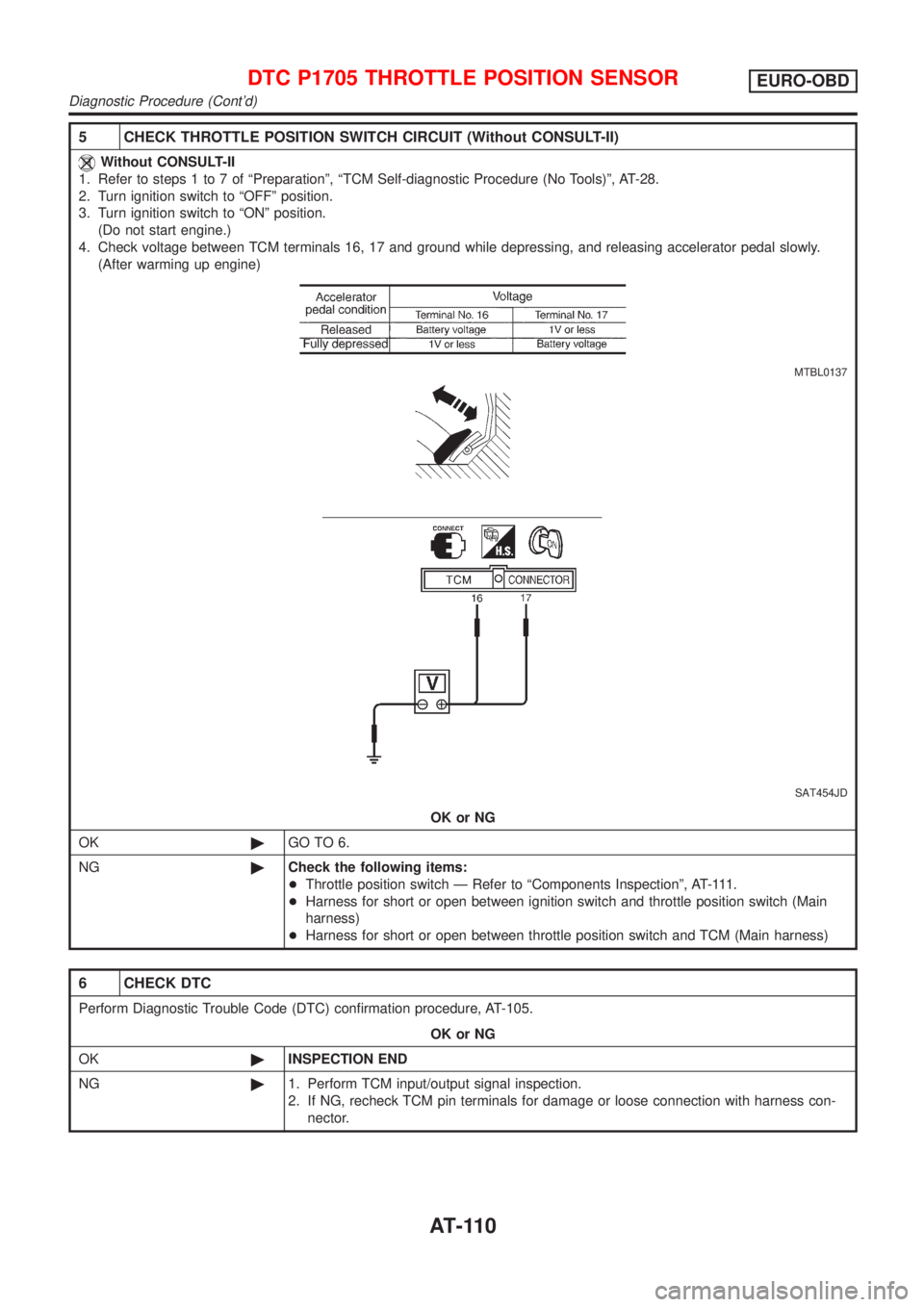

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Refer to steps 1 to 7 of ªPreparationº, ªTCM Self-diagnostic Procedure (No Tools)º, AT-28.

2. Turn ignition switch to ªOFFº position.

3. Turn ignition switch to ªONº position.

(Do not start engine.)

4. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(After warming up engine)

MTBL0137

SAT454JD

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-111.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

6 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-105.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Diagnostic Procedure (Cont'd)

AT-110

Page 112 of 3051

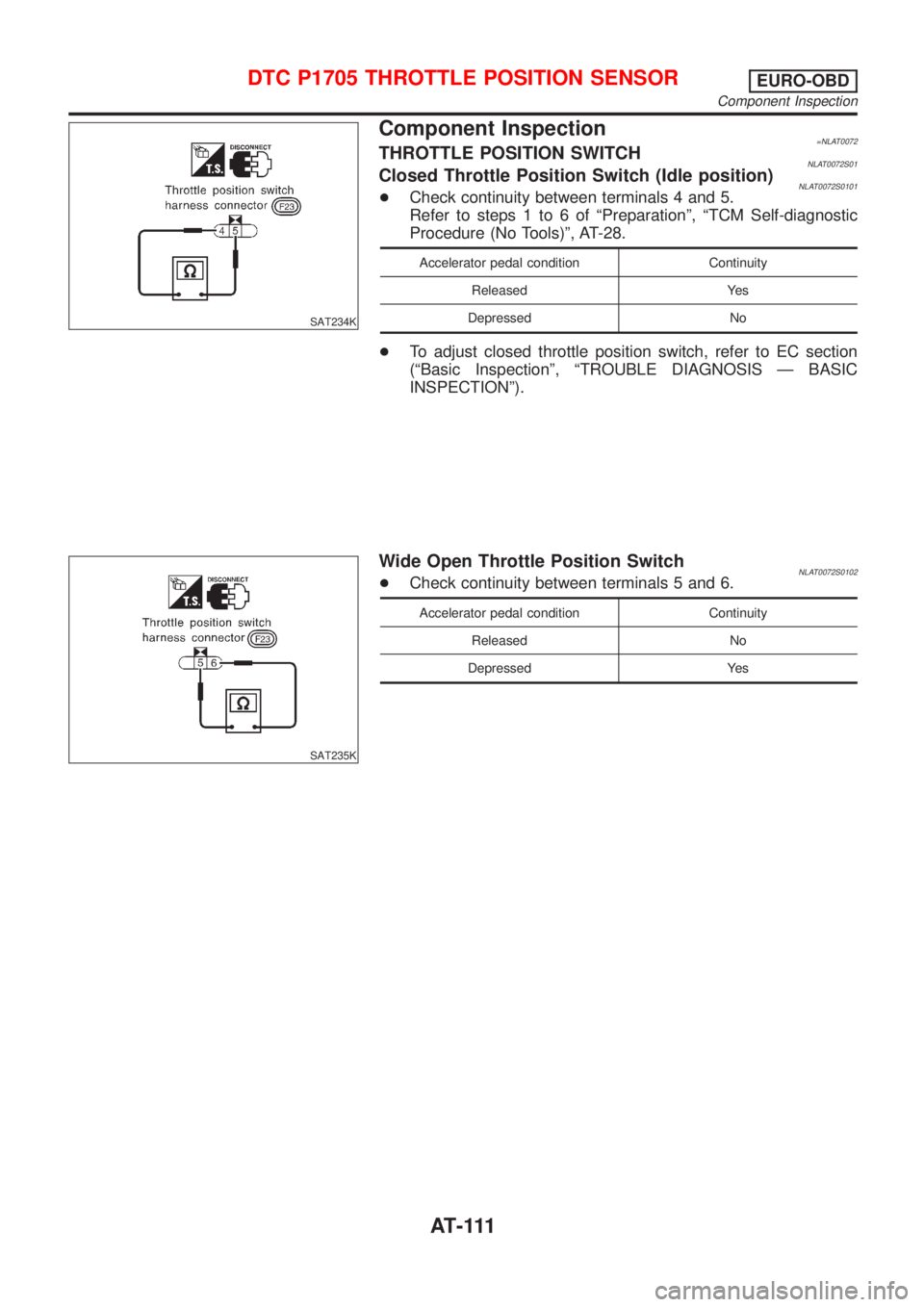

SAT234K

Component Inspection=NLAT0072THROTTLE POSITION SWITCHNLAT0072S01Closed Throttle Position Switch (Idle position)NLAT0072S0101+Check continuity between terminals 4 and 5.

Refer to steps 1 to 6 of ªPreparationº, ªTCM Self-diagnostic

Procedure (No Tools)º, AT-28.

Accelerator pedal condition Continuity

Released Yes

Depressed No

+To adjust closed throttle position switch, refer to EC section

(ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð BASIC

INSPECTIONº).

SAT235K

Wide Open Throttle Position SwitchNLAT0072S0102+Check continuity between terminals 5 and 6.

Accelerator pedal condition Continuity

Released No

Depressed Yes

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Component Inspection

AT - 111

Page 113 of 3051

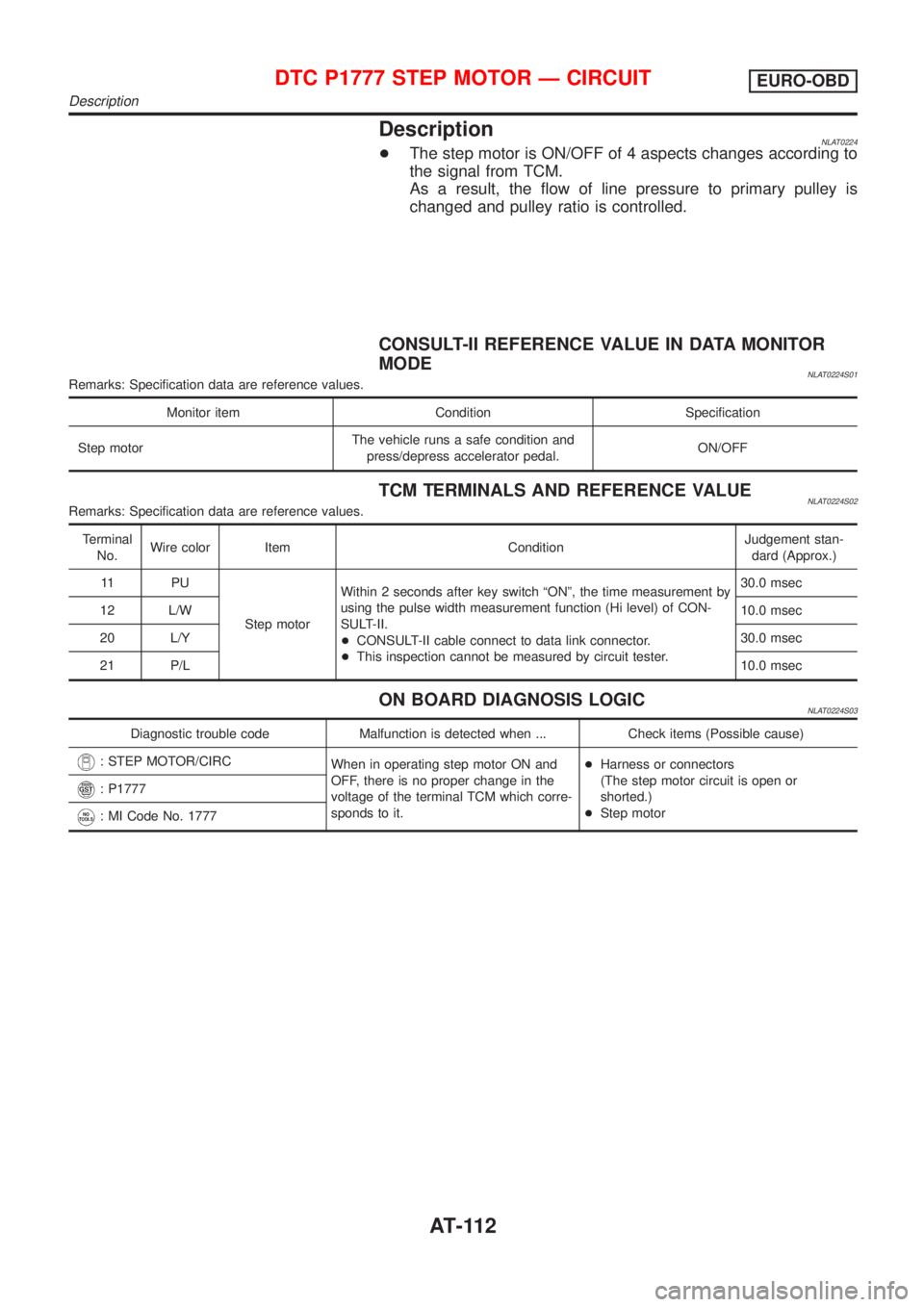

DescriptionNLAT0224+The step motor is ON/OFF of 4 aspects changes according to

the signal from TCM.

As a result, the flow of line pressure to primary pulley is

changed and pulley ratio is controlled.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0224S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Step motorThe vehicle runs a safe condition and

press/depress accelerator pedal.ON/OFF

TCM TERMINALS AND REFERENCE VALUENLAT0224S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

11 P U

Step motorWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

+CONSULT-II cable connect to data link connector.

+This inspection cannot be measured by circuit tester.30.0 msec

12 L/W10.0 msec

20 L/Y30.0 msec

21 P/L10.0 msec

ON BOARD DIAGNOSIS LOGICNLAT0224S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR/CIRC

When in operating step motor ON and

OFF, there is no proper change in the

voltage of the terminal TCM which corre-

sponds to it.+Harness or connectors

(The step motor circuit is open or

shorted.)

+Step motor

: P1777

: MI Code No. 1777

DTC P1777 STEP MOTOR Ð CIRCUITEURO-OBD

Description

AT-112

Page 114 of 3051

SAT250K

SAT255K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NLAT0224S04CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªCVTº with CONSULT-II.

2) Drive vehicle for at least 5 consecutive seconds.

If the check result is ªNGº, go to ªDiagnostic Procedureº,

AT-115.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P1777 STEP MOTOR Ð CIRCUITEURO-OBD

Description (Cont'd)

AT-113

Page 115 of 3051

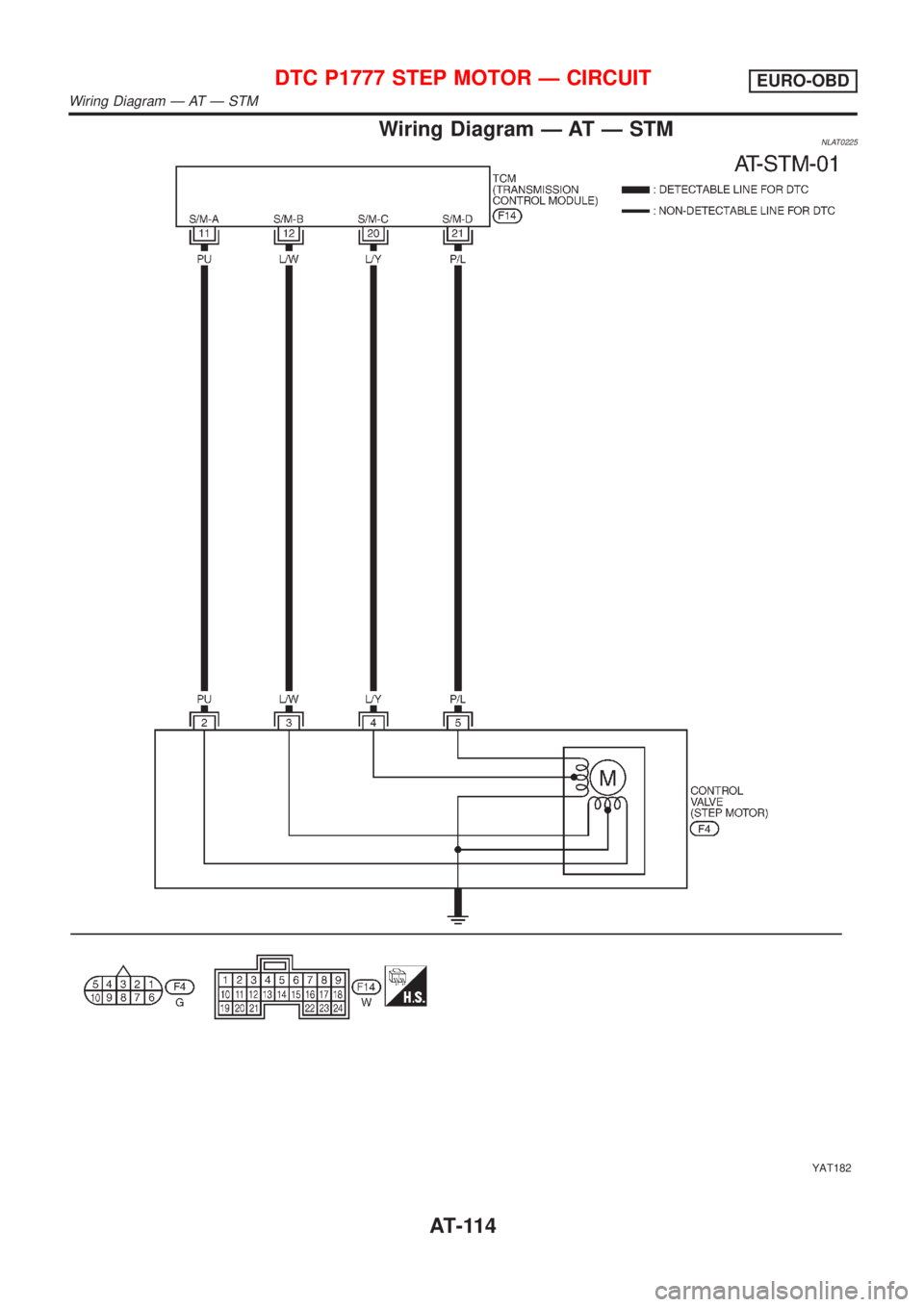

Wiring Diagram Ð AT Ð STMNLAT0225

YAT182

DTC P1777 STEP MOTOR Ð CIRCUITEURO-OBD

Wiring Diagram Ð AT Ð STM

AT-114

Page 116 of 3051

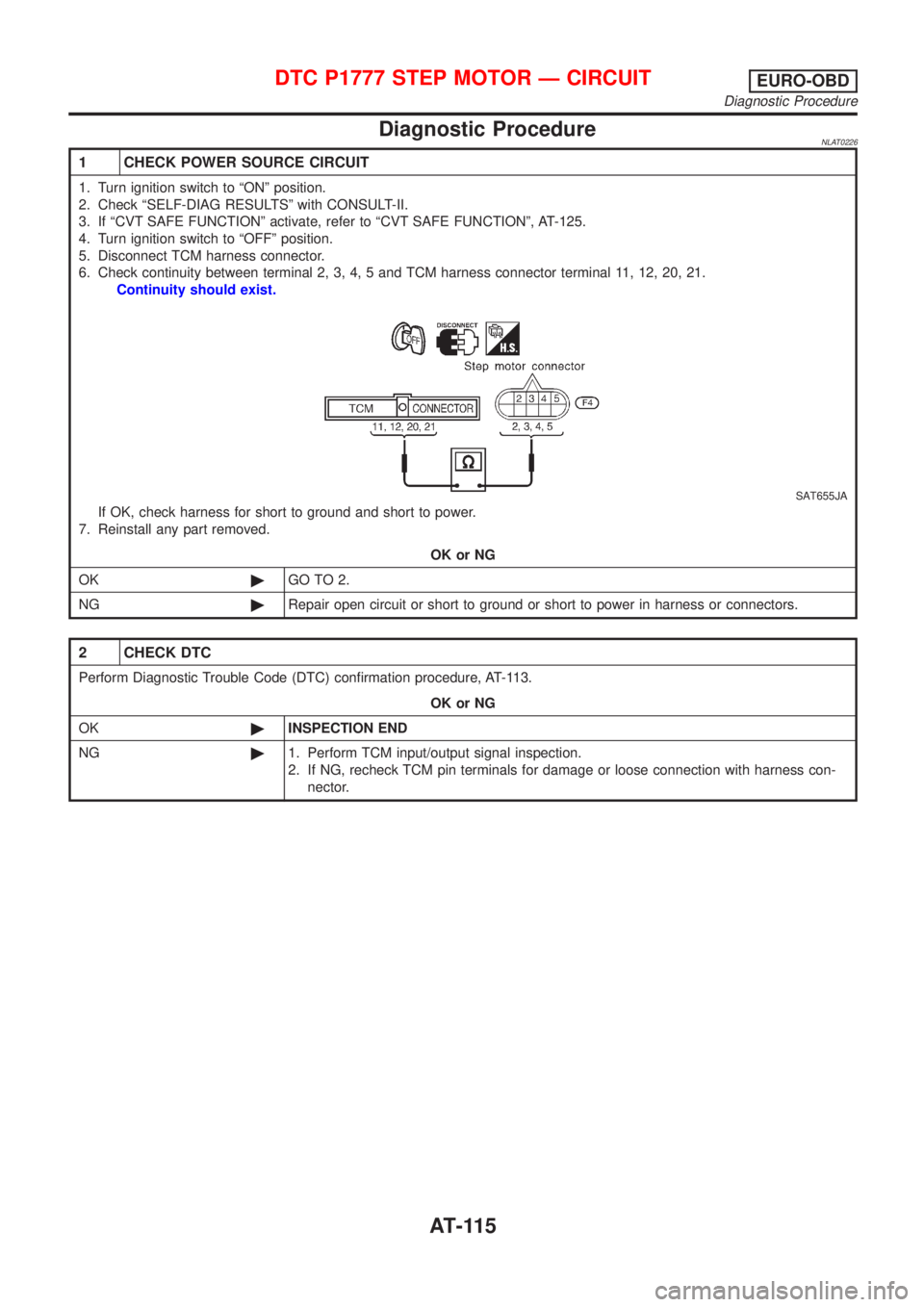

Diagnostic ProcedureNLAT0226

1 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªONº position.

2. Check ªSELF-DIAG RESULTSº with CONSULT-II.

3. If ªCVT SAFE FUNCTIONº activate, refer to ªCVT SAFE FUNCTIONº, AT-125.

4. Turn ignition switch to ªOFFº position.

5. Disconnect TCM harness connector.

6. Check continuity between terminal 2, 3, 4, 5 and TCM harness connector terminal 11, 12, 20, 21.

Continuity should exist.

SAT655JA

If OK, check harness for short to ground and short to power.

7. Reinstall any part removed.

OK or NG

OK©GO TO 2.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

2 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-113.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P1777 STEP MOTOR Ð CIRCUITEURO-OBD

Diagnostic Procedure

AT-115

Page 117 of 3051

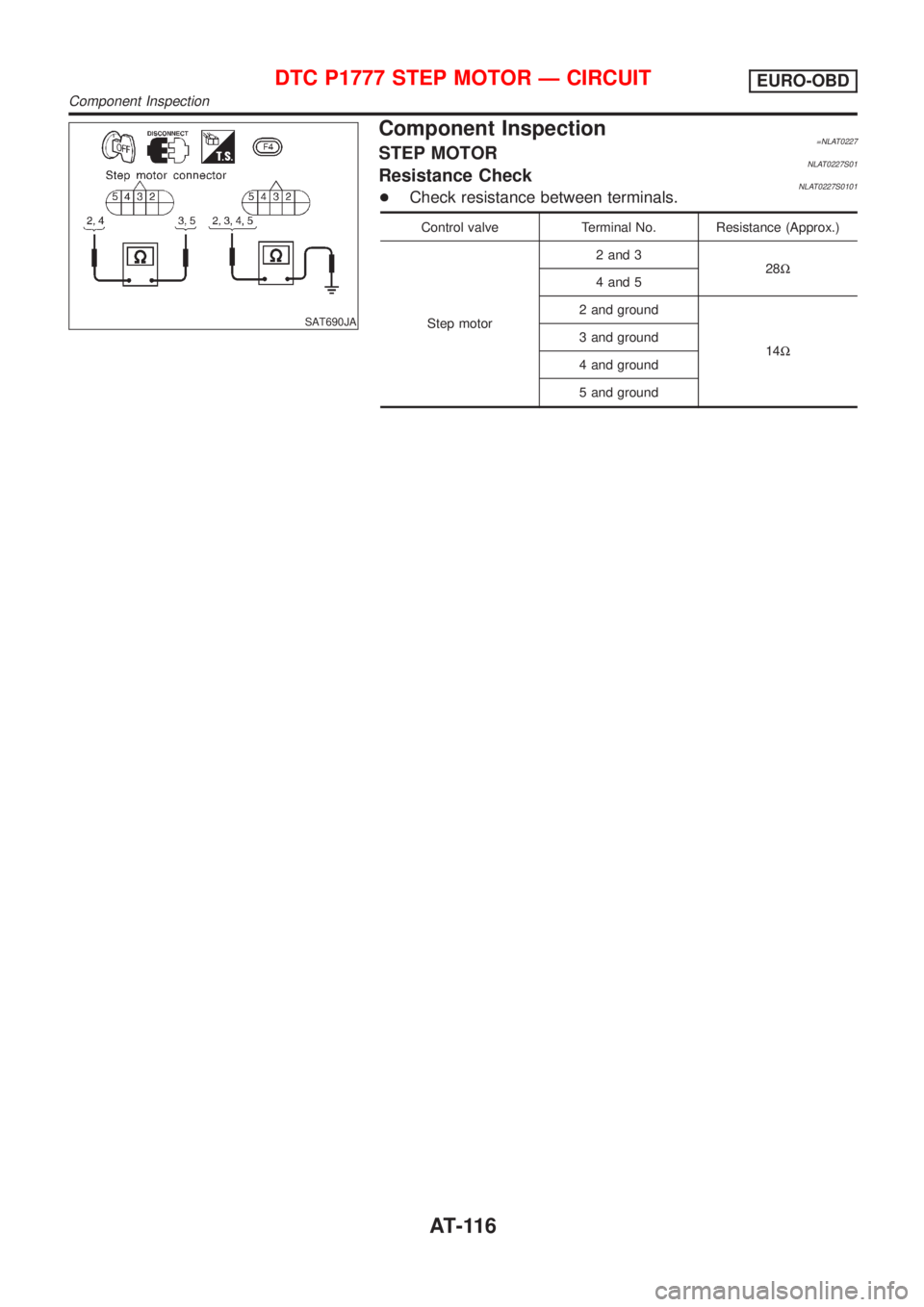

SAT690JA

Component Inspection=NLAT0227STEP MOTORNLAT0227S01Resistance CheckNLAT0227S0101+Check resistance between terminals.

Control valve Terminal No. Resistance (Approx.)

Step motor2 and 3

28W

4 and 5

2 and ground

14W 3 and ground

4 and ground

5 and ground

DTC P1777 STEP MOTOR Ð CIRCUITEURO-OBD

Component Inspection

AT-116

Page 118 of 3051

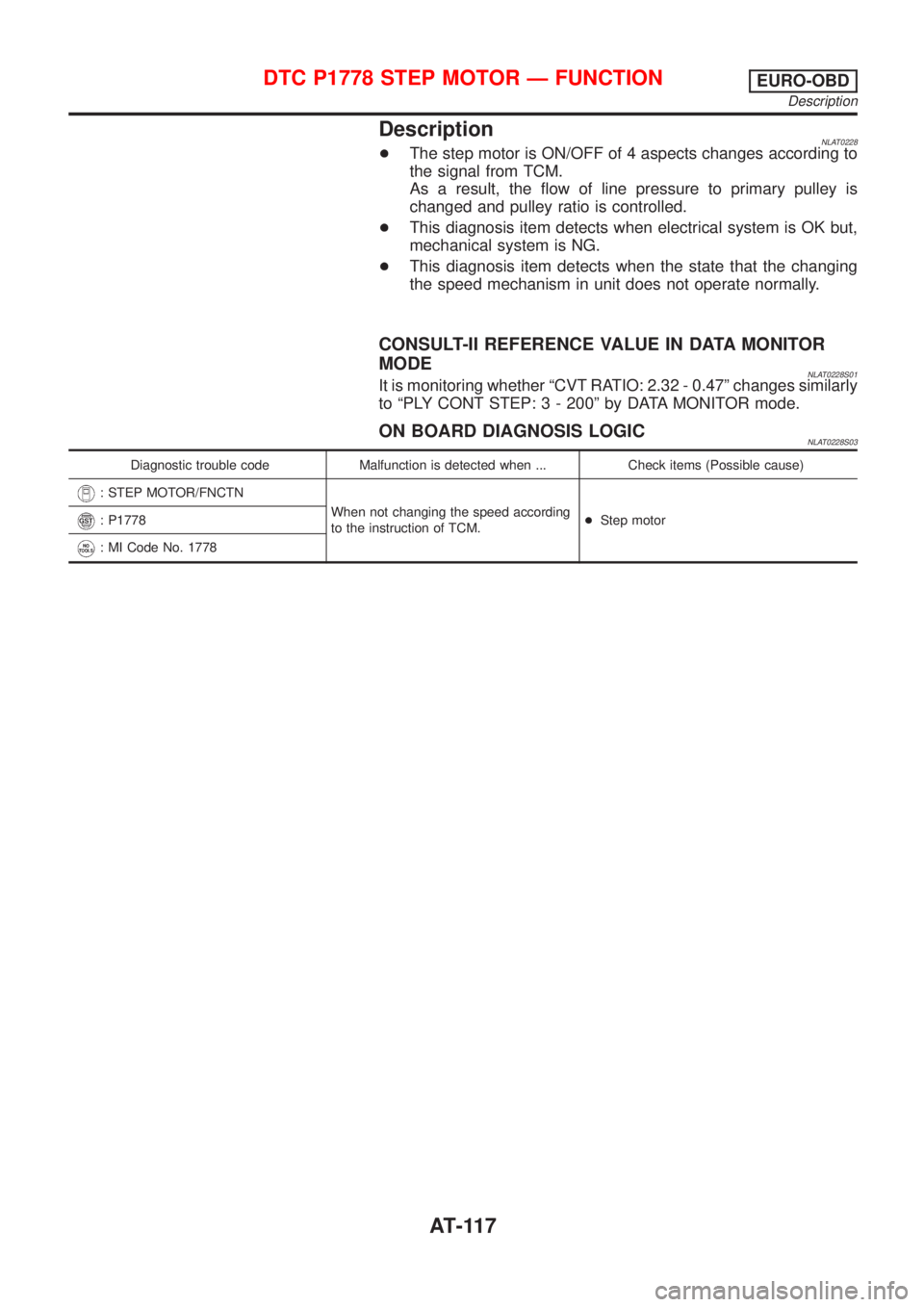

DescriptionNLAT0228+The step motor is ON/OFF of 4 aspects changes according to

the signal from TCM.

As a result, the flow of line pressure to primary pulley is

changed and pulley ratio is controlled.

+This diagnosis item detects when electrical system is OK but,

mechanical system is NG.

+This diagnosis item detects when the state that the changing

the speed mechanism in unit does not operate normally.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0228S01It is monitoring whether ªCVT RATIO: 2.32 - 0.47º changes similarly

to ªPLY CONT STEP: 3 - 200º by DATA MONITOR mode.

ON BOARD DIAGNOSIS LOGICNLAT0228S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR/FNCTN

When not changing the speed according

to the instruction of TCM.+Step motor

: P1778

: MI Code No. 1778

DTC P1778 STEP MOTOR Ð FUNCTIONEURO-OBD

Description

AT-117

Page 119 of 3051

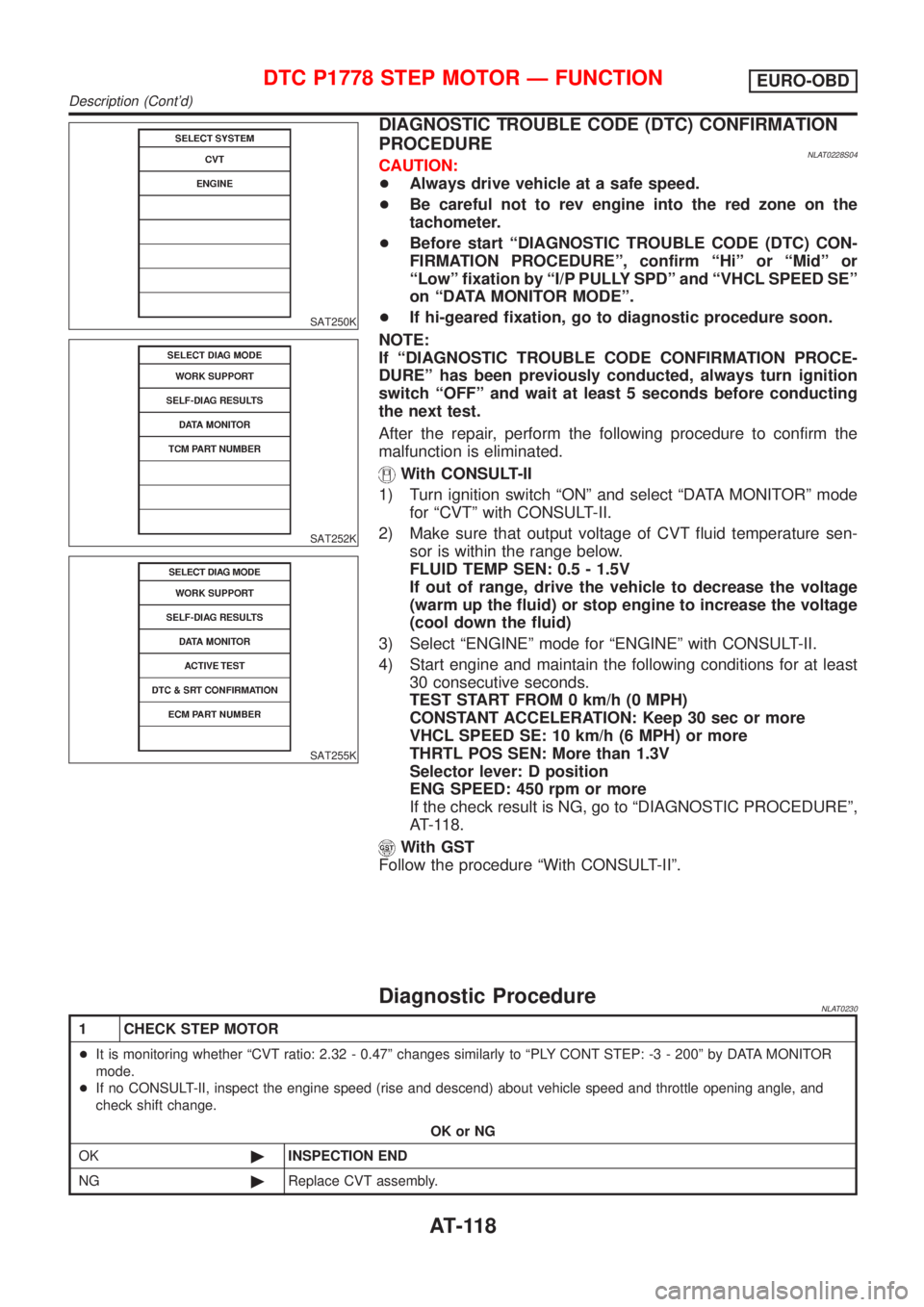

SAT250K

SAT252K

SAT255K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NLAT0228S04CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

+Before start ªDIAGNOSTIC TROUBLE CODE (DTC) CON-

FIRMATION PROCEDUREº, confirm ªHiº or ªMidº or

ªLowº fixation by ªI/P PULLY SPDº and ªVHCL SPEED SEº

on ªDATA MONITOR MODEº.

+If hi-geared fixation, go to diagnostic procedure soon.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªCVTº with CONSULT-II.

2) Make sure that output voltage of CVT fluid temperature sen-

sor is within the range below.

FLUID TEMP SEN: 0.5 - 1.5V

If out of range, drive the vehicle to decrease the voltage

(warm up the fluid) or stop engine to increase the voltage

(cool down the fluid)

3) Select ªENGINEº mode for ªENGINEº with CONSULT-II.

4) Start engine and maintain the following conditions for at least

30 consecutive seconds.

TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position

ENG SPEED: 450 rpm or more

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-118.

With GST

Follow the procedure ªWith CONSULT-IIº.

Diagnostic ProcedureNLAT0230

1 CHECK STEP MOTOR

+It is monitoring whether ªCVT ratio: 2.32 - 0.47º changes similarly to ªPLY CONT STEP: -3 - 200º by DATA MONITOR

mode.

+If no CONSULT-II, inspect the engine speed (rise and descend) about vehicle speed and throttle opening angle, and

check shift change.

OK or NG

OK©INSPECTION END

NG©Replace CVT assembly.

DTC P1778 STEP MOTOR Ð FUNCTIONEURO-OBD

Description (Cont'd)

AT-118

Page 120 of 3051

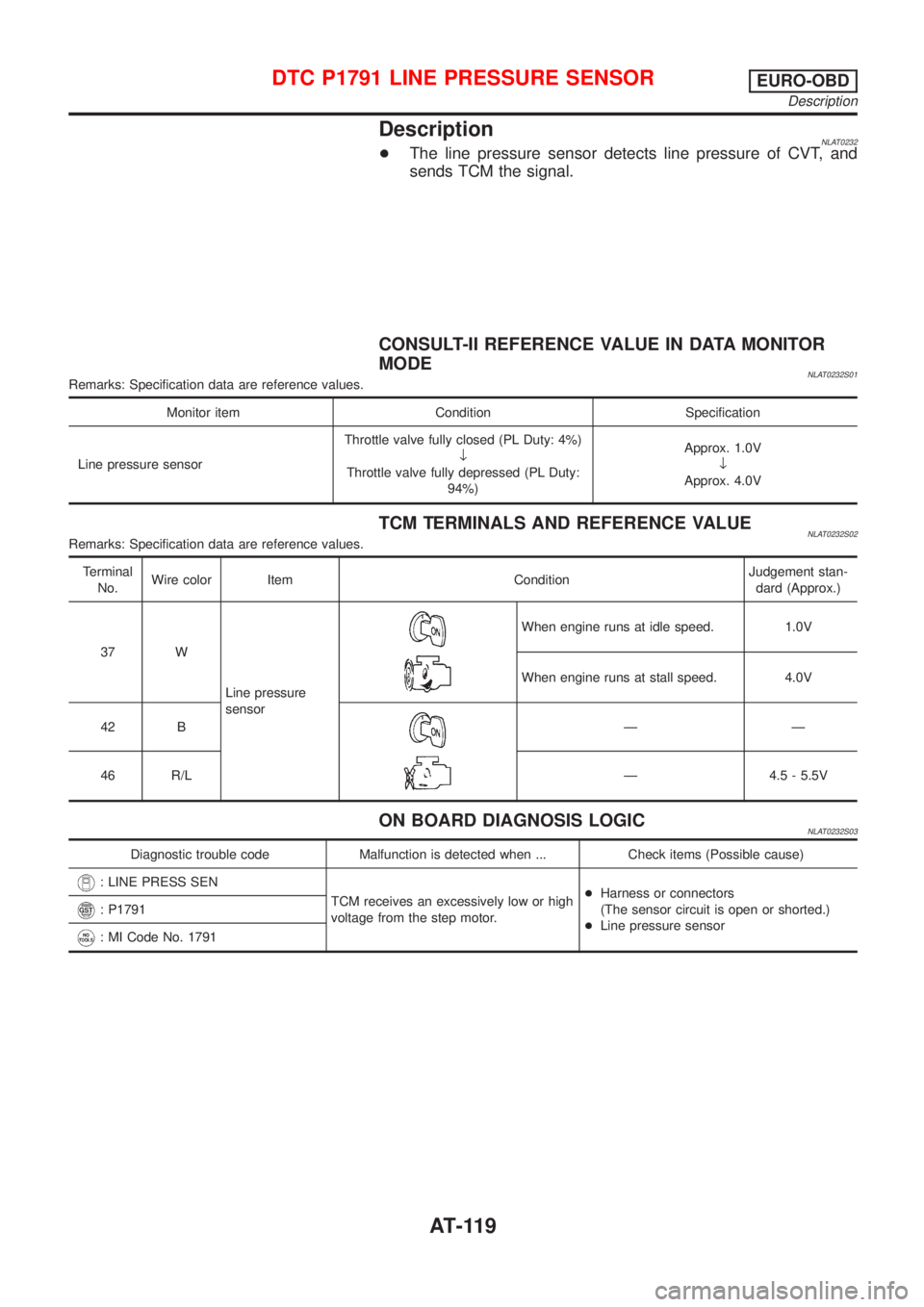

DescriptionNLAT0232+The line pressure sensor detects line pressure of CVT, and

sends TCM the signal.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0232S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure sensorThrottle valve fully closed (PL Duty: 4%)

¯

Throttle valve fully depressed (PL Duty:

94%)Approx. 1.0V

¯

Approx. 4.0V

TCM TERMINALS AND REFERENCE VALUENLAT0232S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

37 W

Line pressure

sensor

When engine runs at idle speed. 1.0V

When engine runs at stall speed. 4.0V

42 B

ÐÐ

46 R/LÐ 4.5 - 5.5V

ON BOARD DIAGNOSIS LOGICNLAT0232S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: LINE PRESS SEN

TCM receives an excessively low or high

voltage from the step motor.+Harness or connectors

(The sensor circuit is open or shorted.)

+Line pressure sensor

: P1791

: MI Code No. 1791

DTC P1791 LINE PRESSURE SENSOREURO-OBD

Description

AT-119