NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 141 of 3051

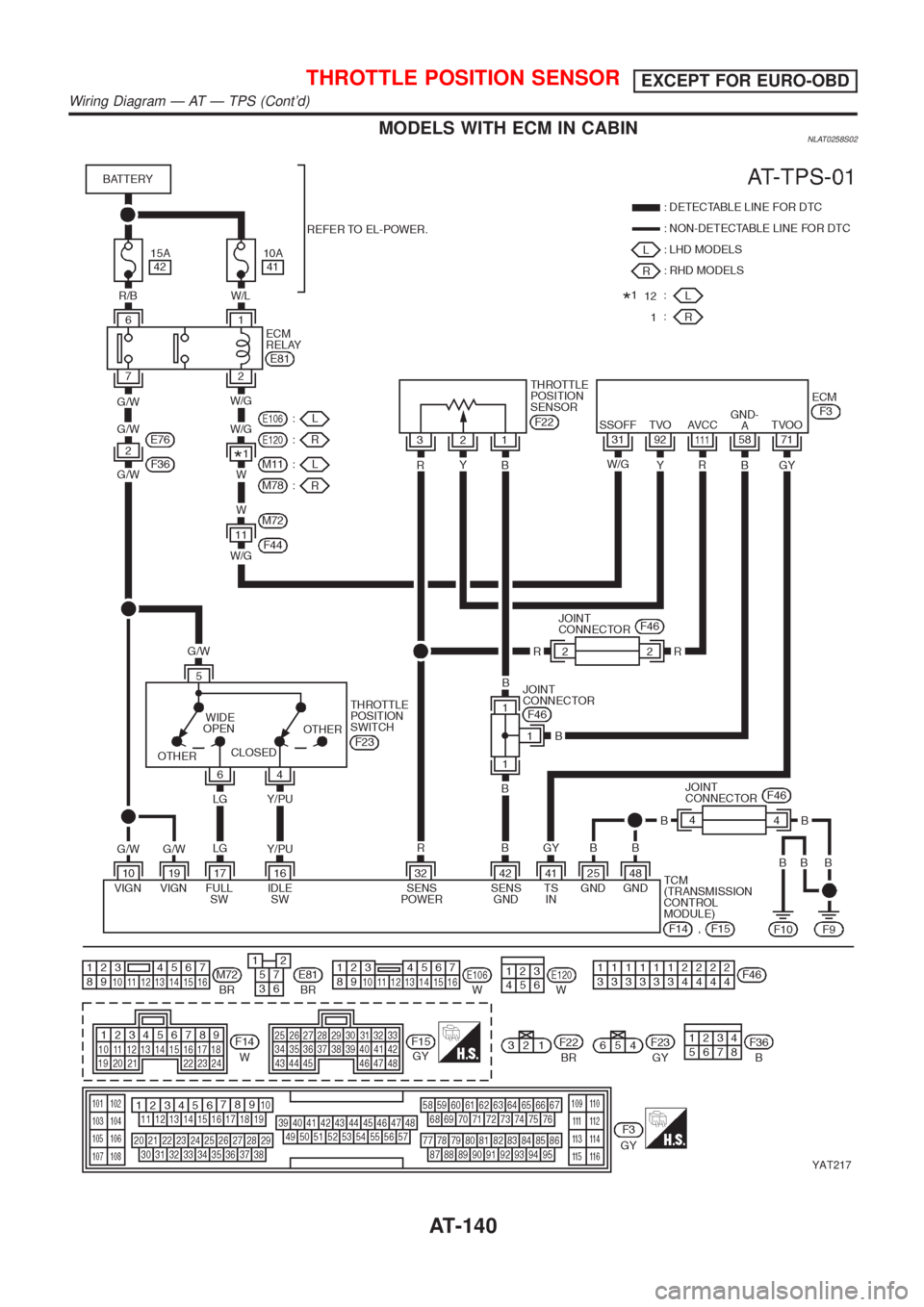

MODELS WITH ECM IN CABINNLAT0258S02

YAT217

THROTTLE POSITION SENSOREXCEPT FOR EURO-OBD

Wiring Diagram Ð AT Ð TPS (Cont'd)

AT-140

Page 142 of 3051

Diagnostic ProcedureNLAT0259

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control.

Refer to EC SECTION , ªMalfunction Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Check throttle position sensor circuit for engine control. Refer to EC section , ªDTC

P0120 THROTTLE POSITION SENSORº.

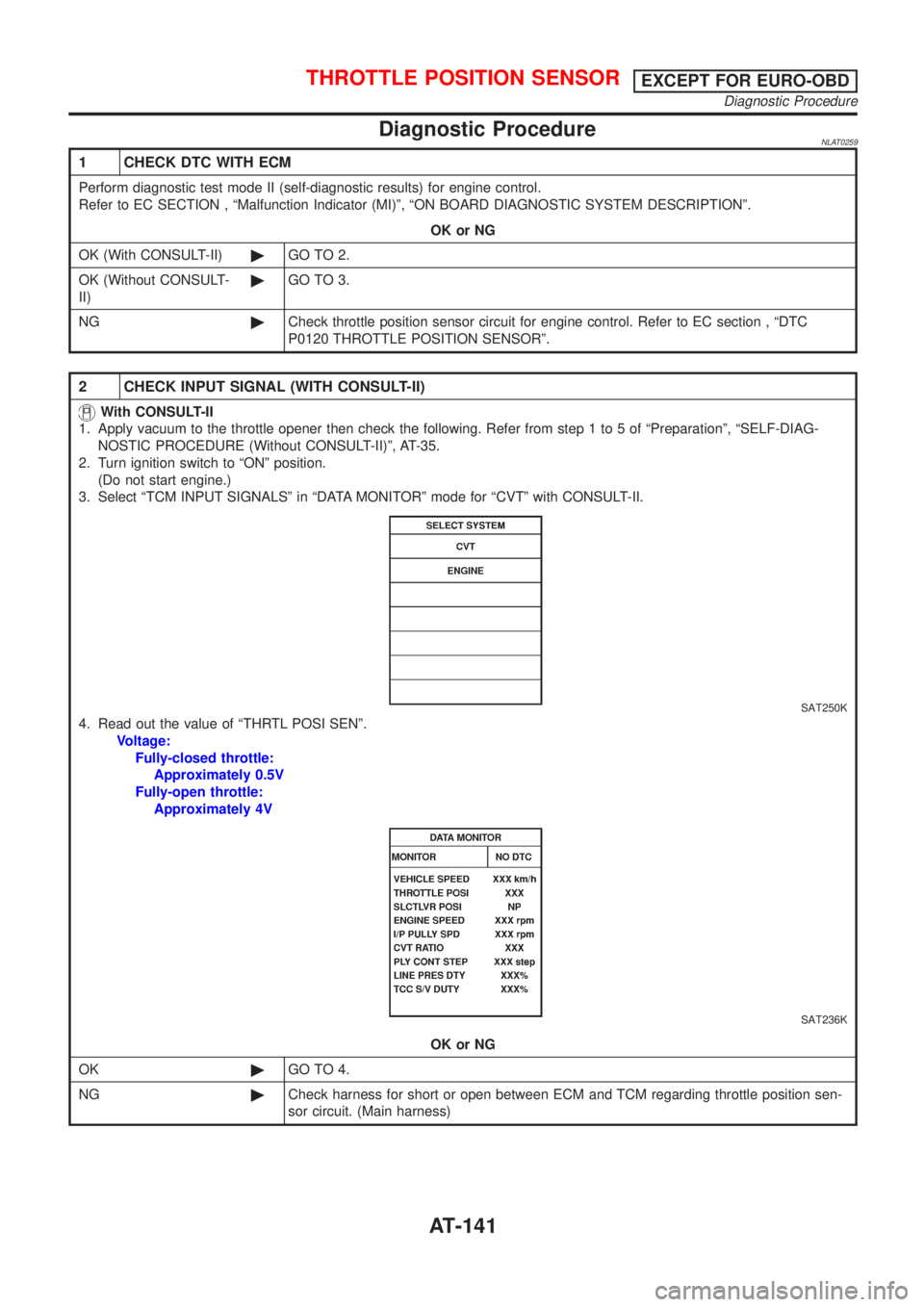

2 CHECK INPUT SIGNAL (WITH CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener then check the following. Refer from step 1 to 5 of ªPreparationº, ªSELF-DIAG-

NOSTIC PROCEDURE (Without CONSULT-II)º, AT-35.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

4. Read out the value of ªTHRTL POSI SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

SAT236K

OK or NG

OK©GO TO 4.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

THROTTLE POSITION SENSOREXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-141

Page 143 of 3051

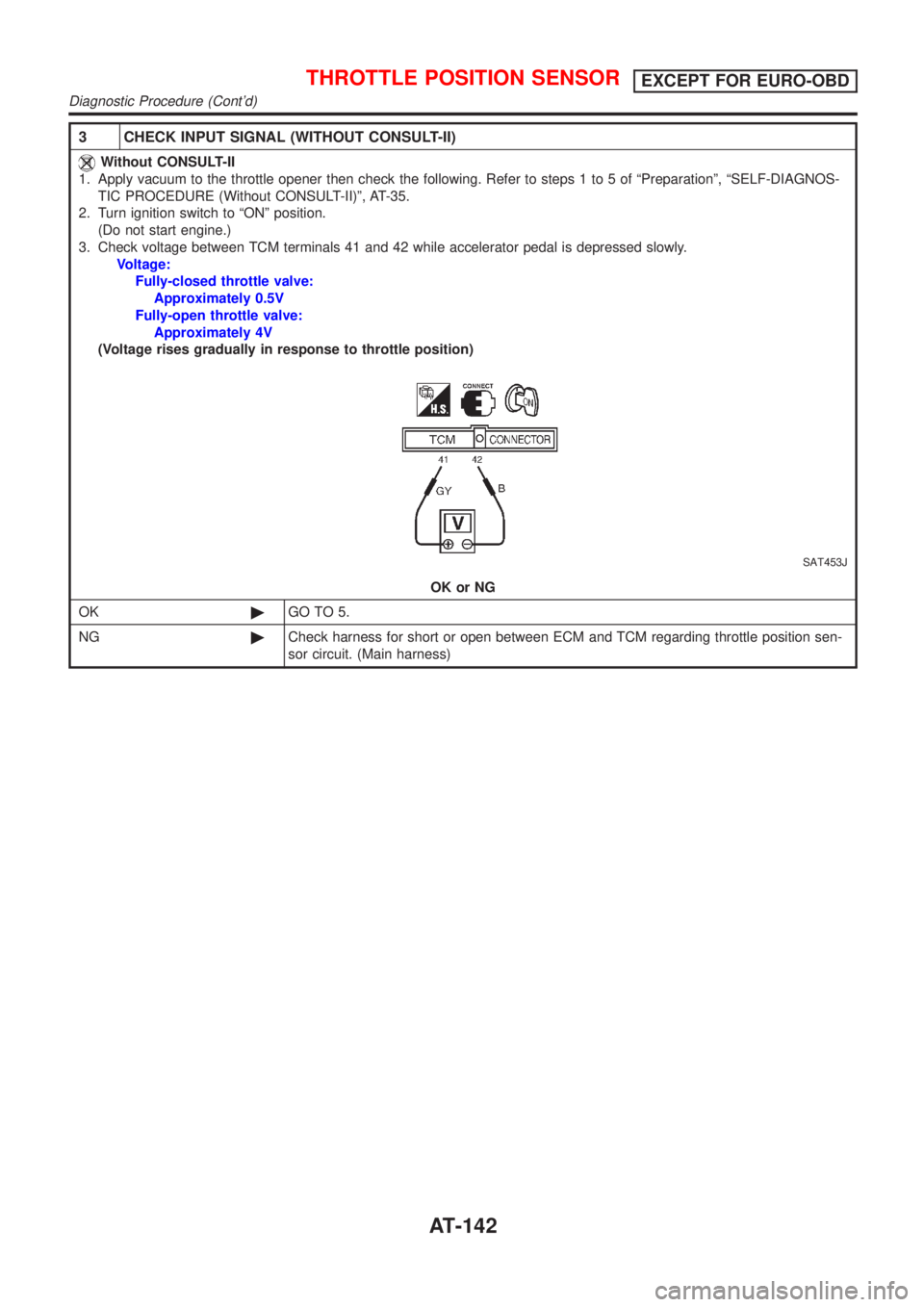

3 CHECK INPUT SIGNAL (WITHOUT CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener then check the following. Refer to steps 1 to 5 of ªPreparationº, ªSELF-DIAGNOS-

TIC PROCEDURE (Without CONSULT-II)º, AT-35.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 41 and 42 while accelerator pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in response to throttle position)

SAT453J

OK or NG

OK©GO TO 5.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

THROTTLE POSITION SENSOREXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-142

Page 144 of 3051

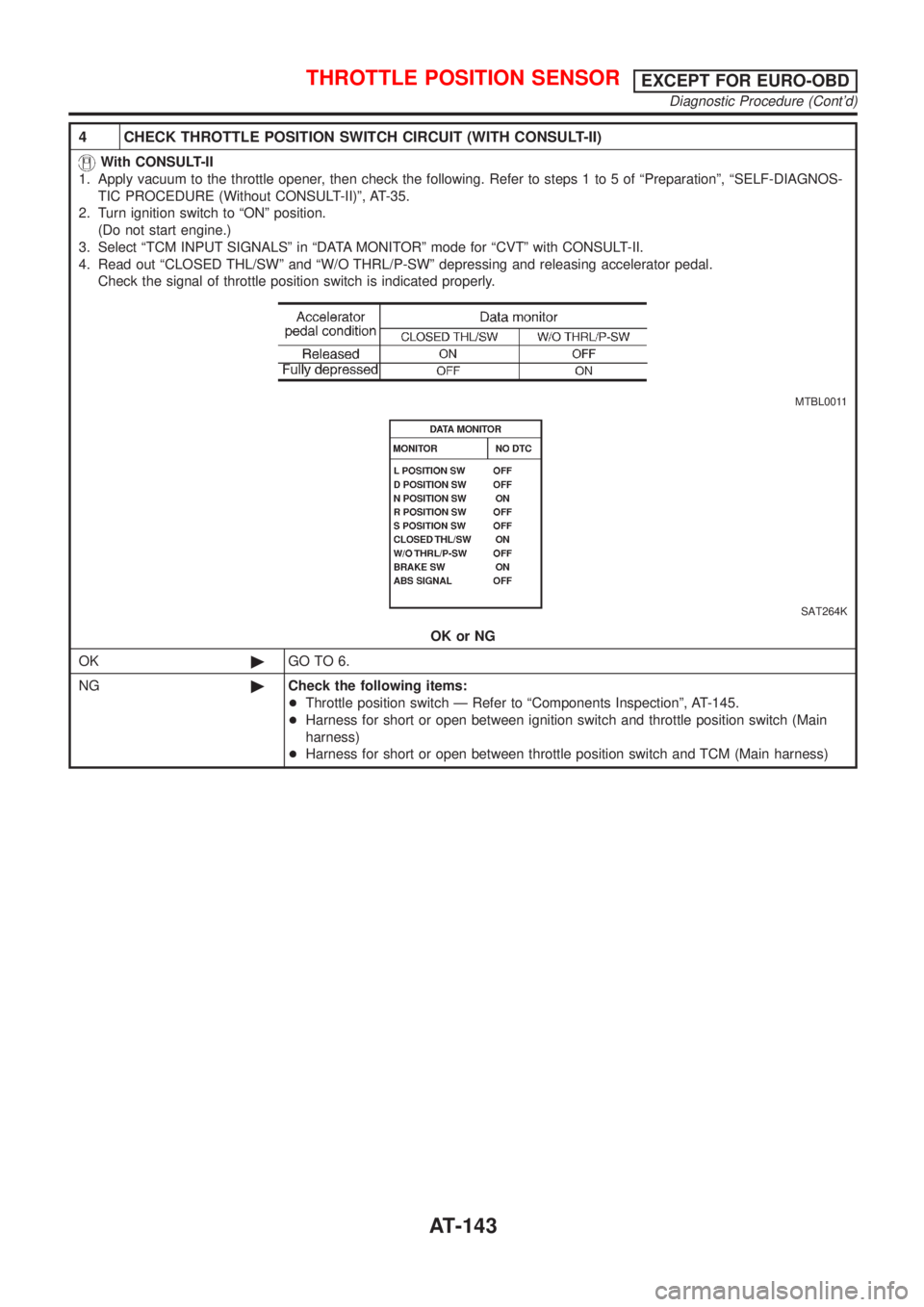

4 CHECK THROTTLE POSITION SWITCH CIRCUIT (WITH CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 to 5 of ªPreparationº, ªSELF-DIAGNOS-

TIC PROCEDURE (Without CONSULT-II)º, AT-35.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT264K

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-145.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

THROTTLE POSITION SENSOREXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-143

Page 145 of 3051

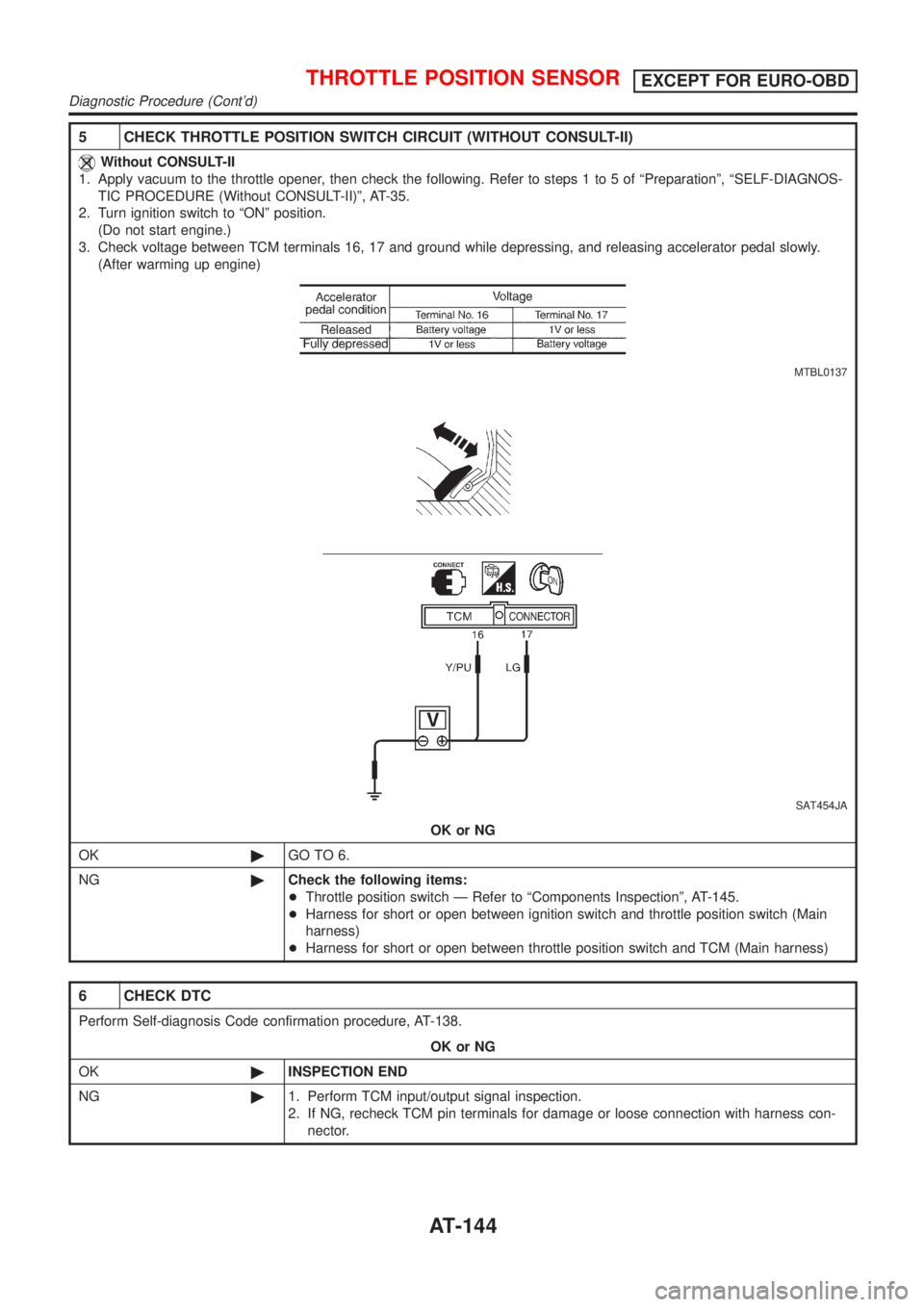

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (WITHOUT CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 to 5 of ªPreparationº, ªSELF-DIAGNOS-

TIC PROCEDURE (Without CONSULT-II)º, AT-35.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(After warming up engine)

MTBL0137

SAT454JA

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-145.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

6 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-138.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

THROTTLE POSITION SENSOREXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-144

Page 146 of 3051

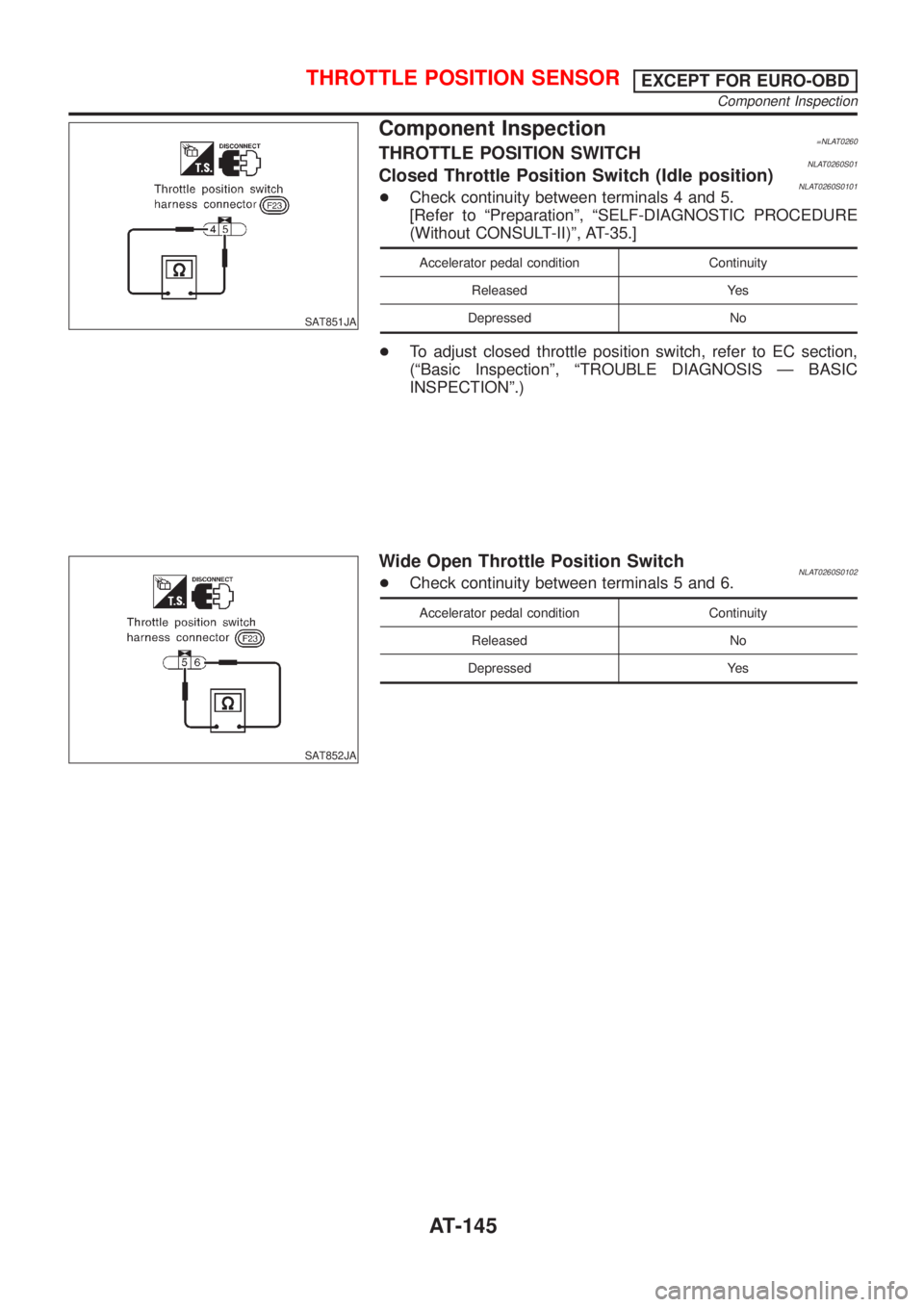

SAT851JA

Component Inspection=NLAT0260THROTTLE POSITION SWITCHNLAT0260S01Closed Throttle Position Switch (Idle position)NLAT0260S0101+Check continuity between terminals 4 and 5.

[Refer to ªPreparationº, ªSELF-DIAGNOSTIC PROCEDURE

(Without CONSULT-II)º, AT-35.]

Accelerator pedal condition Continuity

Released Yes

Depressed No

+To adjust closed throttle position switch, refer to EC section,

(ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð BASIC

INSPECTIONº.)

SAT852JA

Wide Open Throttle Position SwitchNLAT0260S0102+Check continuity between terminals 5 and 6.

Accelerator pedal condition Continuity

Released No

Depressed Yes

THROTTLE POSITION SENSOREXCEPT FOR EURO-OBD

Component Inspection

AT-145

Page 147 of 3051

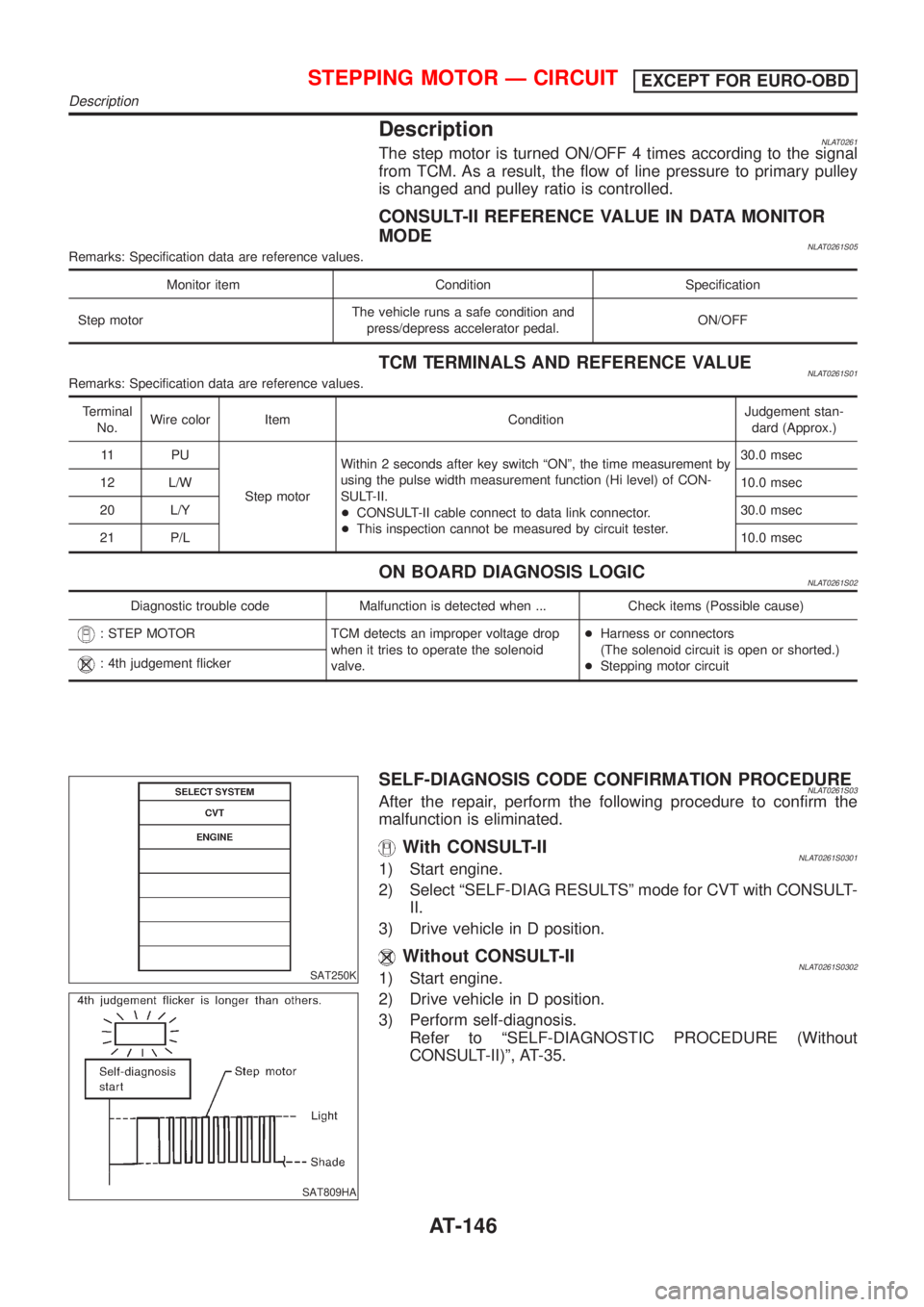

DescriptionNLAT0261The step motor is turned ON/OFF 4 times according to the signal

from TCM. As a result, the flow of line pressure to primary pulley

is changed and pulley ratio is controlled.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0261S05Remarks: Specification data are reference values.

Monitor item Condition Specification

Step motorThe vehicle runs a safe condition and

press/depress accelerator pedal.ON/OFF

TCM TERMINALS AND REFERENCE VALUENLAT0261S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

11 P U

Step motorWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

+CONSULT-II cable connect to data link connector.

+This inspection cannot be measured by circuit tester.30.0 msec

12 L/W10.0 msec

20 L/Y30.0 msec

21 P/L10.0 msec

ON BOARD DIAGNOSIS LOGICNLAT0261S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Stepping motor circuit

: 4th judgement flicker

SAT250K

SAT809HA

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENLAT0261S03After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINLAT0261S03011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for CVT with CONSULT-

II.

3) Drive vehicle in D position.

Without CONSULT-IINLAT0261S03021) Start engine.

2) Drive vehicle in D position.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-35.

STEPPING MOTOR Ð CIRCUITEXCEPT FOR EURO-OBD

Description

AT-146

Page 148 of 3051

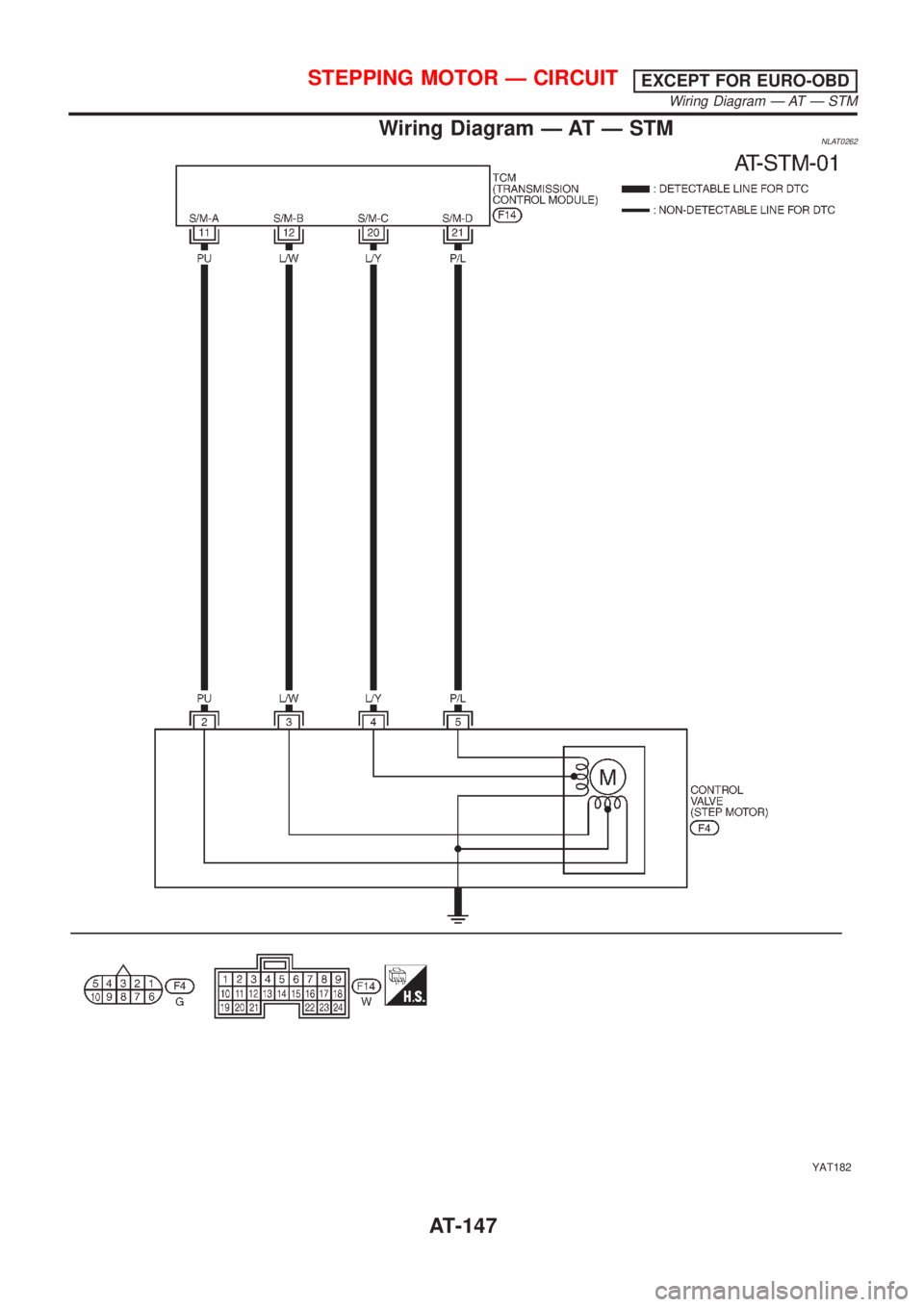

Wiring Diagram Ð AT Ð STMNLAT0262

YAT182

STEPPING MOTOR Ð CIRCUITEXCEPT FOR EURO-OBD

Wiring Diagram Ð AT Ð STM

AT-147

Page 149 of 3051

Diagnostic ProcedureNLAT0265

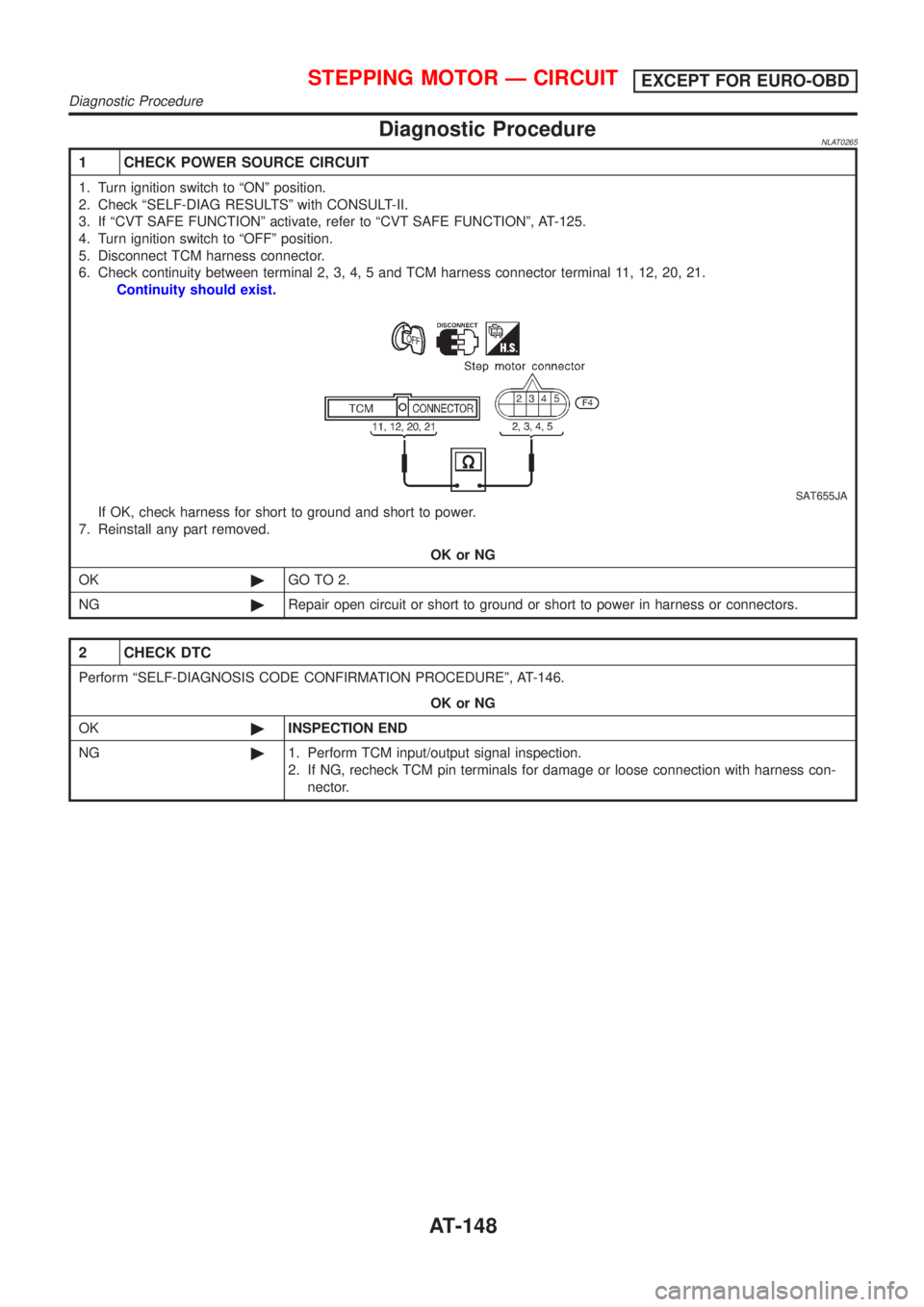

1 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªONº position.

2. Check ªSELF-DIAG RESULTSº with CONSULT-II.

3. If ªCVT SAFE FUNCTIONº activate, refer to ªCVT SAFE FUNCTIONº, AT-125.

4. Turn ignition switch to ªOFFº position.

5. Disconnect TCM harness connector.

6. Check continuity between terminal 2, 3, 4, 5 and TCM harness connector terminal 11, 12, 20, 21.

Continuity should exist.

SAT655JA

If OK, check harness for short to ground and short to power.

7. Reinstall any part removed.

OK or NG

OK©GO TO 2.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

2 CHECK DTC

Perform ªSELF-DIAGNOSIS CODE CONFIRMATION PROCEDUREº, AT-146.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

STEPPING MOTOR Ð CIRCUITEXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-148

Page 150 of 3051

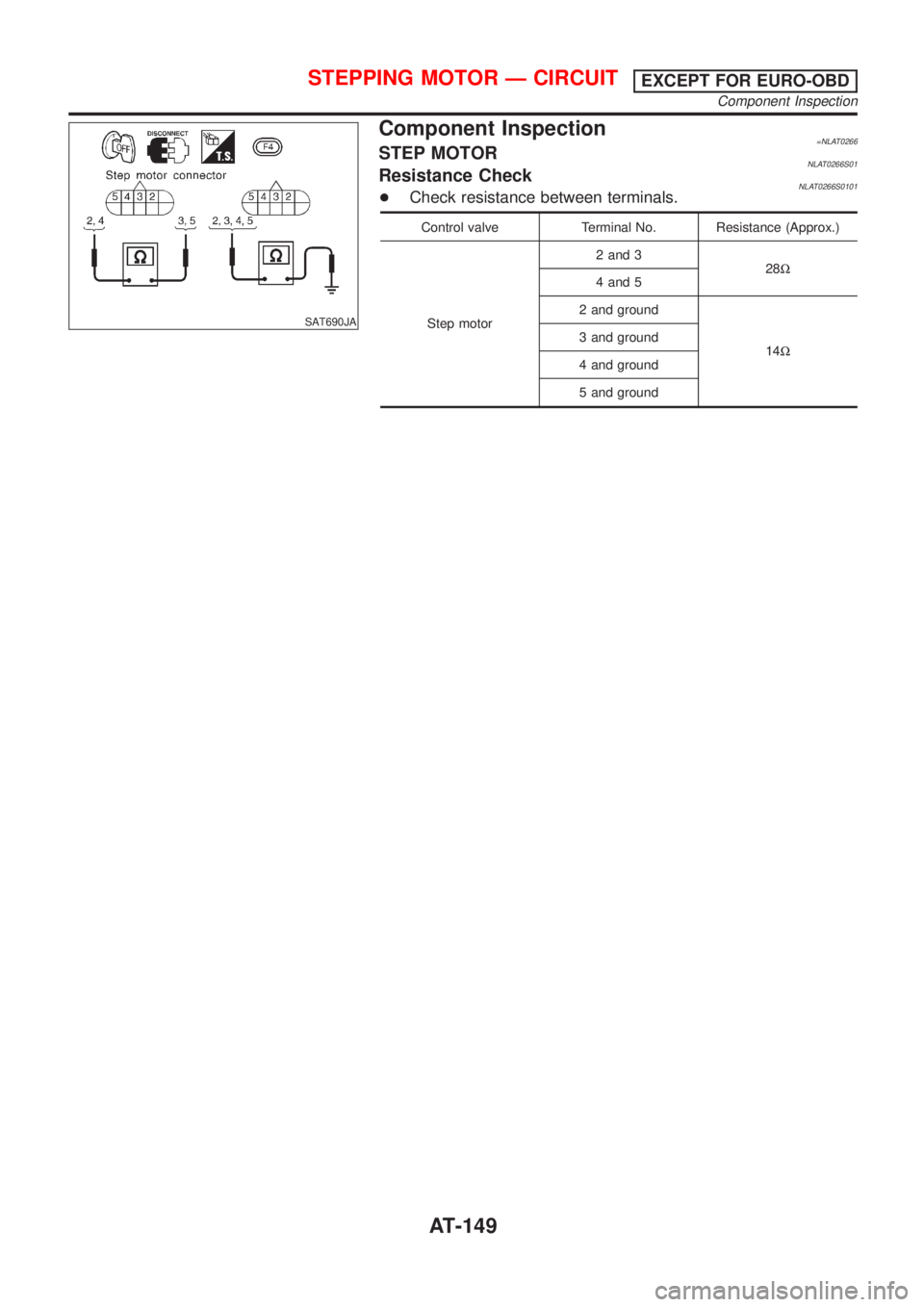

SAT690JA

Component Inspection=NLAT0266STEP MOTORNLAT0266S01Resistance CheckNLAT0266S0101+Check resistance between terminals.

Control valve Terminal No. Resistance (Approx.)

Step motor2 and 3

28W

4 and 5

2 and ground

14W 3 and ground

4 and ground

5 and ground

STEPPING MOTOR Ð CIRCUITEXCEPT FOR EURO-OBD

Component Inspection

AT-149