fuse box NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2769 of 3051

NLMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 2809 of 3051

NLMT0090

SMT928D

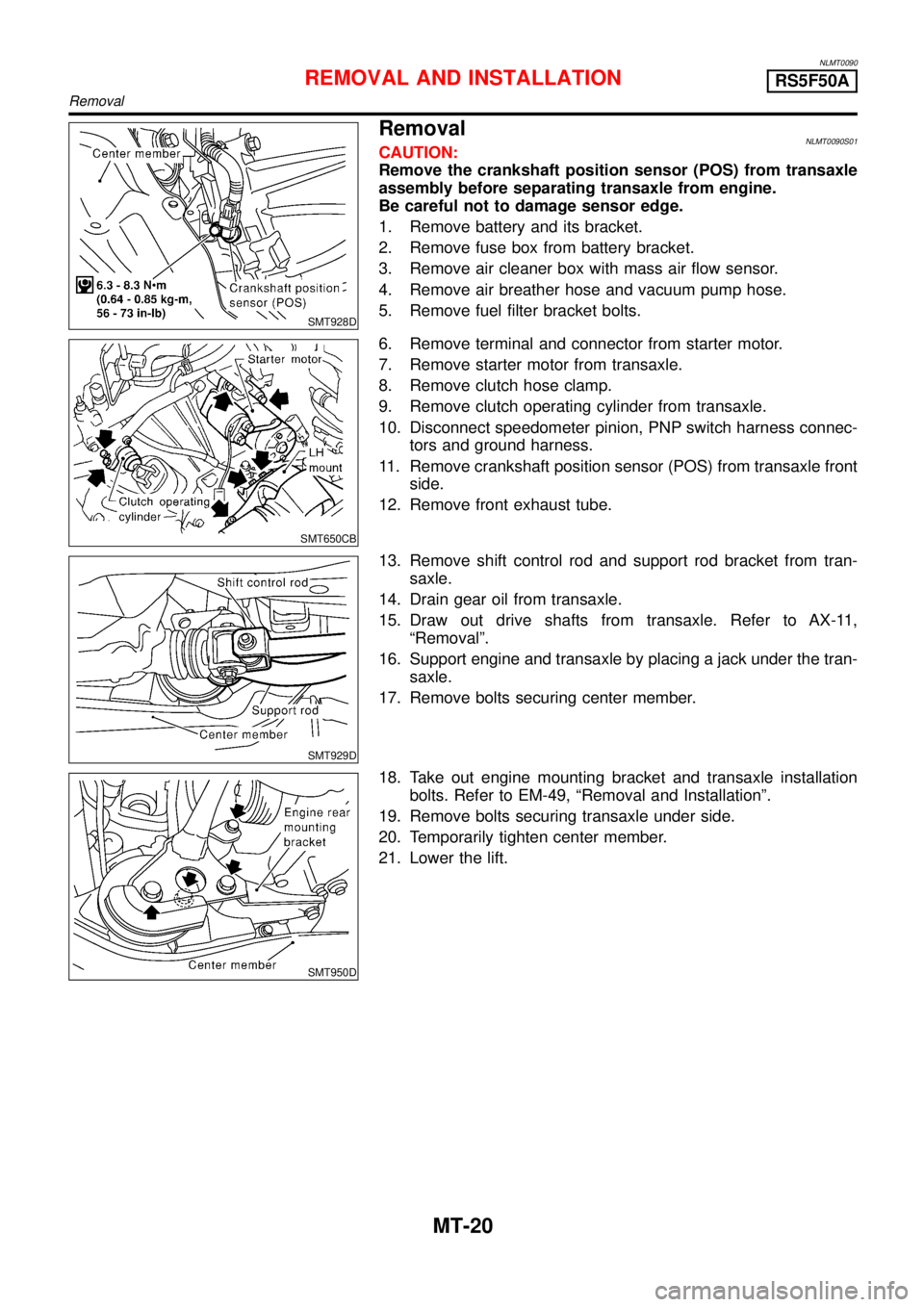

RemovalNLMT0090S01CAUTION:

Remove the crankshaft position sensor (POS) from transaxle

assembly before separating transaxle from engine.

Be careful not to damage sensor edge.

1. Remove battery and its bracket.

2. Remove fuse box from battery bracket.

3. Remove air cleaner box with mass air flow sensor.

4. Remove air breather hose and vacuum pump hose.

5. Remove fuel filter bracket bolts.

SMT650CB

6. Remove terminal and connector from starter motor.

7. Remove starter motor from transaxle.

8. Remove clutch hose clamp.

9. Remove clutch operating cylinder from transaxle.

10. Disconnect speedometer pinion, PNP switch harness connec-

tors and ground harness.

11. Remove crankshaft position sensor (POS) from transaxle front

side.

12. Remove front exhaust tube.

SMT929D

13. Remove shift control rod and support rod bracket from tran-

saxle.

14. Drain gear oil from transaxle.

15. Draw out drive shafts from transaxle. Refer to AX-11,

“Removal”.

16. Support engine and transaxle by placing a jack under the tran-

saxle.

17. Remove bolts securing center member.

SMT950D

18. Take out engine mounting bracket and transaxle installation

bolts. Refer to EM-49,“Removal and Installation”.

19. Remove bolts securing transaxle under side.

20. Temporarily tighten center member.

21. Lower the lift.

REMOVAL AND INSTALLATIONRS5F50A

Removal

MT-20

Page 2962 of 3051

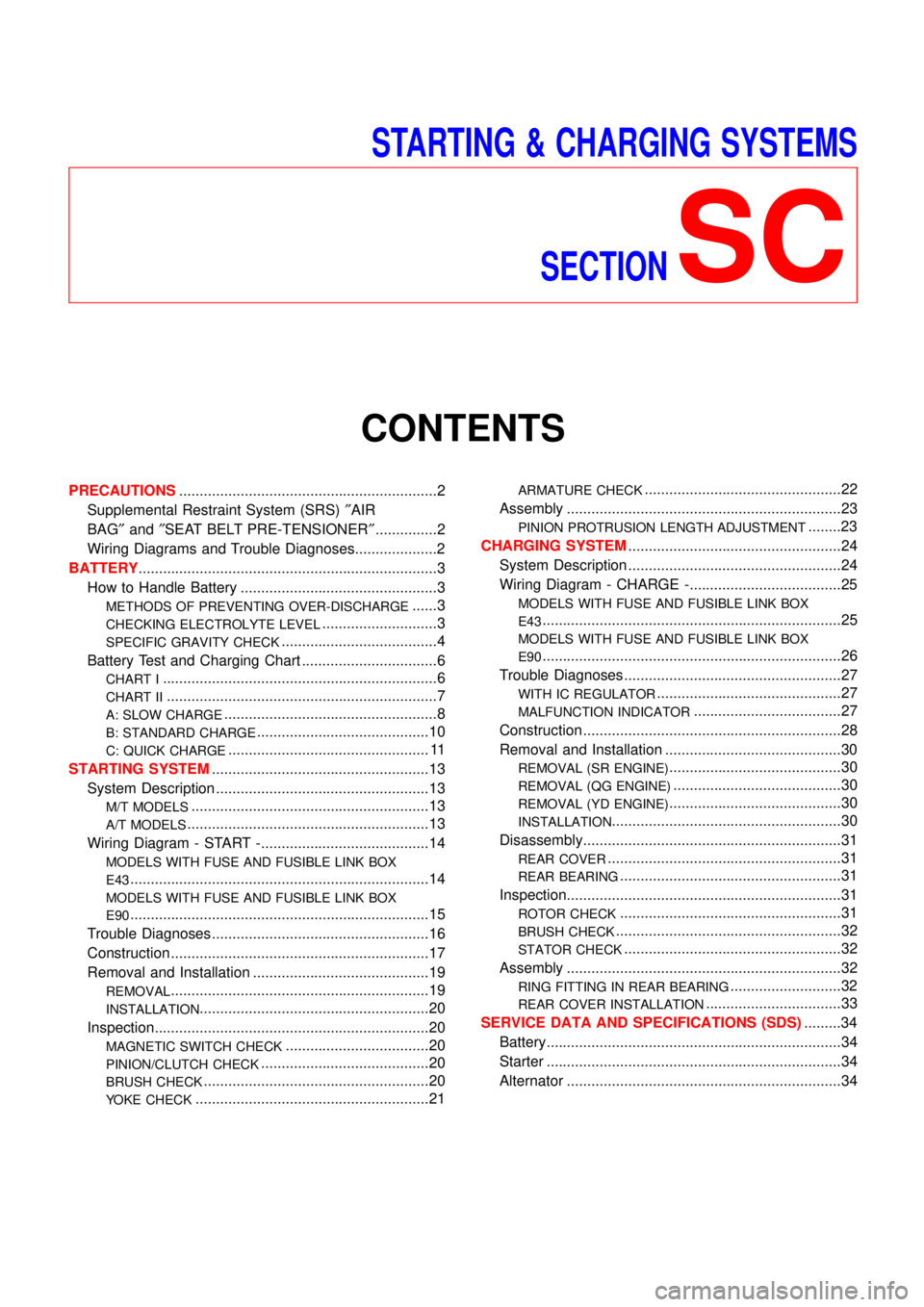

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)″AIR

BAG″and″SEAT BELT PRE-TENSIONER″...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

METHODS OF PREVENTING OVER-DISCHARGE......3

CHECKING ELECTROLYTE LEVEL............................3

SPECIFIC GRAVITY CHECK......................................4

Battery Test and Charging Chart .................................6

CHART I...................................................................6

CHART II..................................................................7

A: SLOW CHARGE....................................................8

B: STANDARD CHARGE..........................................10

C: QUICK CHARGE................................................. 11

STARTING SYSTEM.....................................................13

System Description ....................................................13

M/T MODELS..........................................................13

A/T MODELS...........................................................13

Wiring Diagram - START -.........................................14

MODELS WITH FUSE AND FUSIBLE LINK BOX

E43

.........................................................................14

MODELS WITH FUSE AND FUSIBLE LINK BOX

E90

.........................................................................15

Trouble Diagnoses.....................................................16

Construction ...............................................................17

Removal and Installation ...........................................19

REMOVAL...............................................................19

INSTALLATION........................................................20

Inspection...................................................................20

MAGNETIC SWITCH CHECK...................................20

PINION/CLUTCH CHECK.........................................20

BRUSH CHECK.......................................................20

YOKE CHECK.........................................................21

ARMATURE CHECK................................................22

Assembly ...................................................................23

PINION PROTRUSION LENGTH ADJUSTMENT........23

CHARGING SYSTEM....................................................24

System Description ....................................................24

Wiring Diagram - CHARGE -.....................................25

MODELS WITH FUSE AND FUSIBLE LINK BOX

E43

.........................................................................25

MODELS WITH FUSE AND FUSIBLE LINK BOX

E90

.........................................................................26

Trouble Diagnoses.....................................................27

WITH IC REGULATOR.............................................27

MALFUNCTION INDICATOR....................................27

Construction ...............................................................28

Removal and Installation ...........................................30

REMOVAL (SR ENGINE)..........................................30

REMOVAL (QG ENGINE).........................................30

REMOVAL (YD ENGINE)..........................................30

INSTALLATION........................................................30

Disassembly...............................................................31

REAR COVER.........................................................31

REAR BEARING......................................................31

Inspection...................................................................31

ROTOR CHECK......................................................31

BRUSH CHECK.......................................................32

STATOR CHECK.....................................................32

Assembly ...................................................................32

RING FITTING IN REAR BEARING...........................32

REAR COVER INSTALLATION.................................33

SERVICE DATA AND SPECIFICATIONS (SDS).........34

Battery........................................................................34

Starter ........................................................................34

Alternator ...................................................................34

Page 2974 of 3051

System DescriptionNLSC0004M/T MODELSNLSC0004S01Power is supplied at all times

+through 40A fusible link (letterB, located in the fuse and fusible link box)

+to ignition switch terminal 1.

With the ignition switch in START position, power is supplied

+from ignition switch terminal 5

+to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

A/T MODELSNLSC0004S02Power is supplied at all times

+through 40A fusible link (letterB, located in the fuse and fusible link box)

+to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

+from ignition switch terminal 5

+to park/neutral position relay terminal 5.

With the ignition switch ON or START position, power is supplied

+through 10A fuse [No. 20, located in the fuse block (J/B)]

+to park/neutral position (PNP) relay terminal 1.

With the selector lever in the P or N position, ground is supplied

+to park/neutral position relay terminal 2 through the park/neutral position switch

+from body grounds, F9 and F10.

Then park/neutral position relay is energized and power is supplied

+from park/neutral position relay terminal 3

+to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

STARTING SYSTEM

System Description

SC-13

Page 2975 of 3051

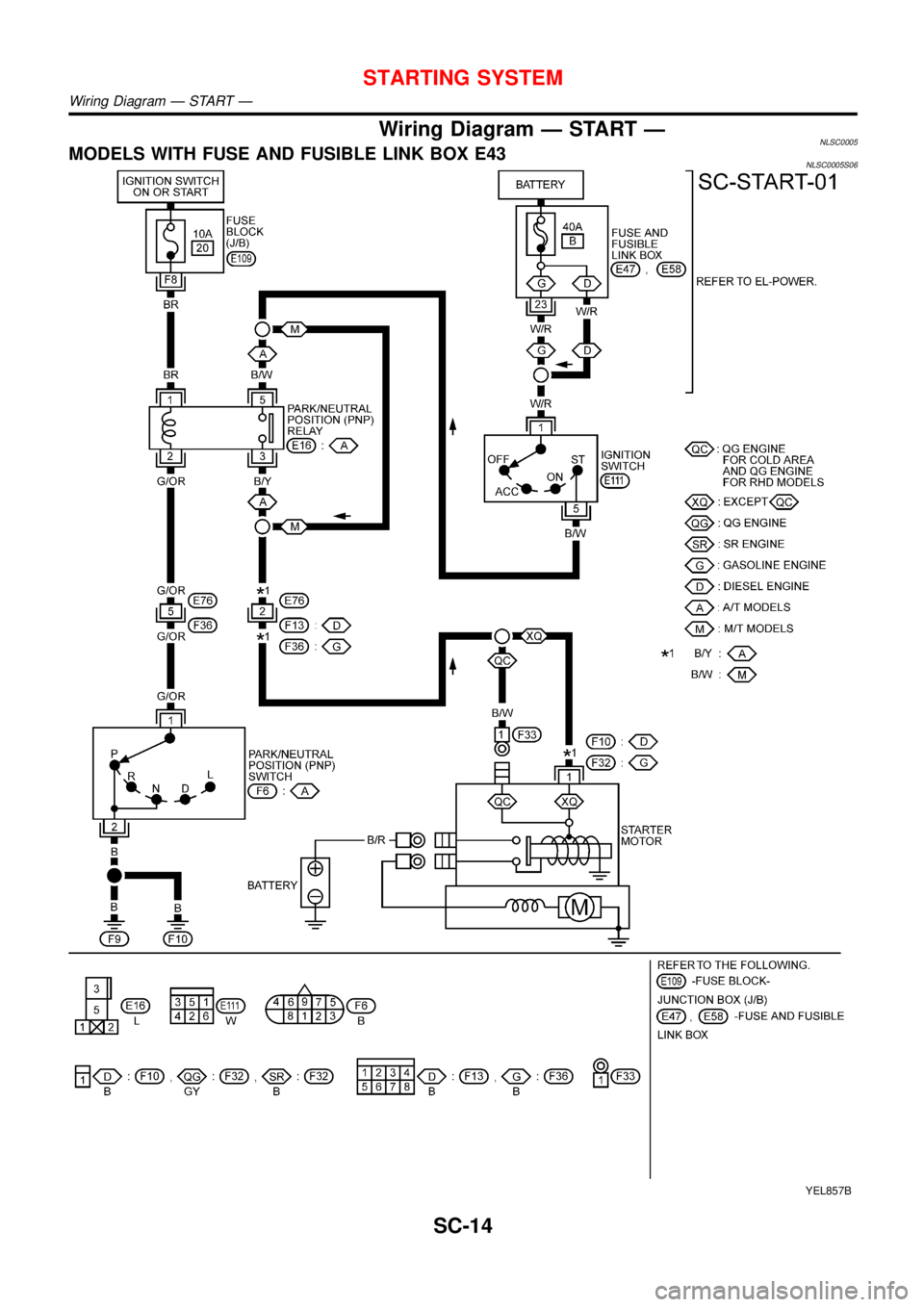

Wiring Diagram—START—NLSC0005MODELS WITH FUSE AND FUSIBLE LINK BOX E43NLSC0005S06

YEL857B

STARTING SYSTEM

Wiring Diagram—START—

SC-14

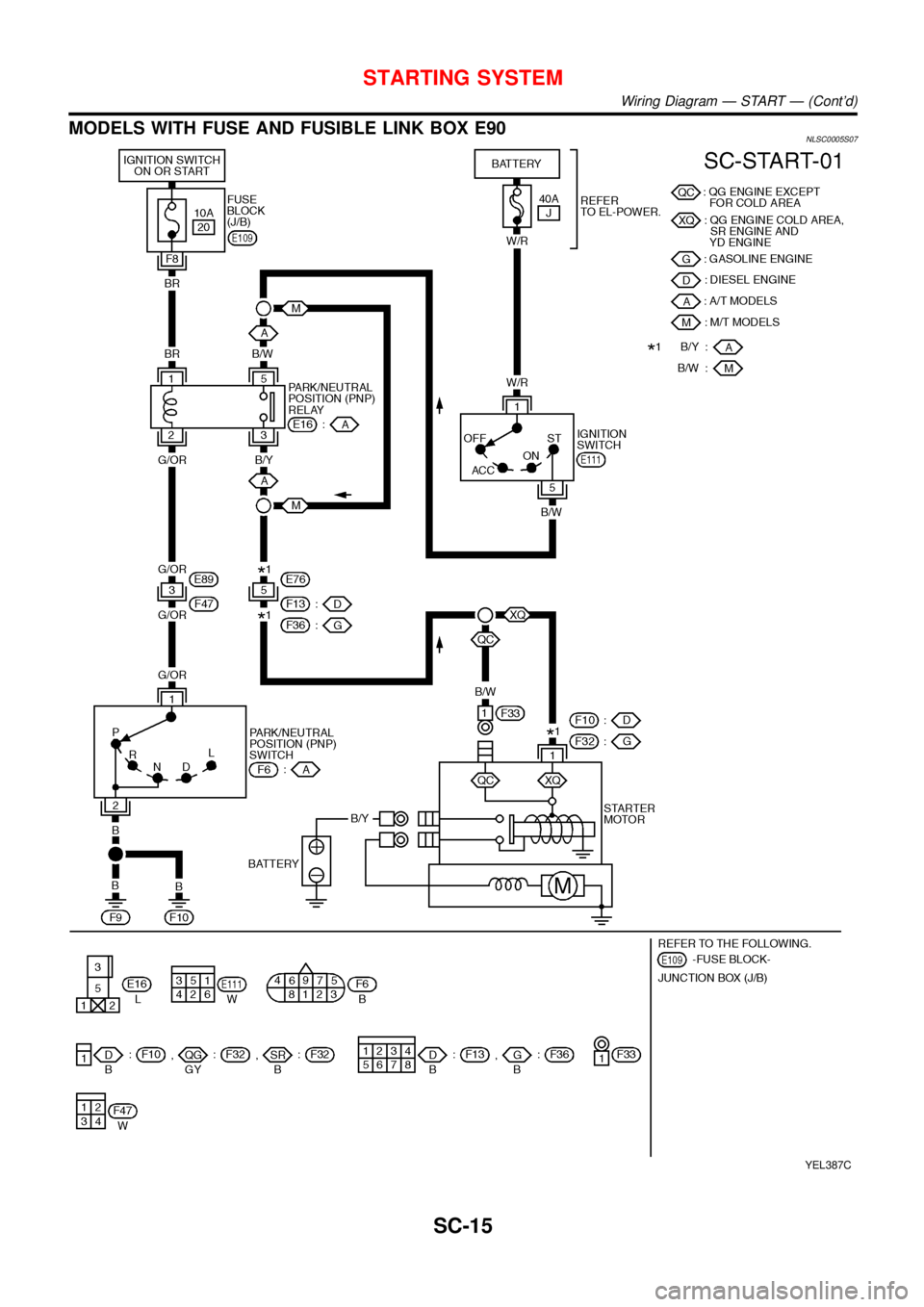

Page 2976 of 3051

MODELS WITH FUSE AND FUSIBLE LINK BOX E90NLSC0005S07

YEL387C

STARTING SYSTEM

Wiring Diagram—START—(Cont’d)

SC-15

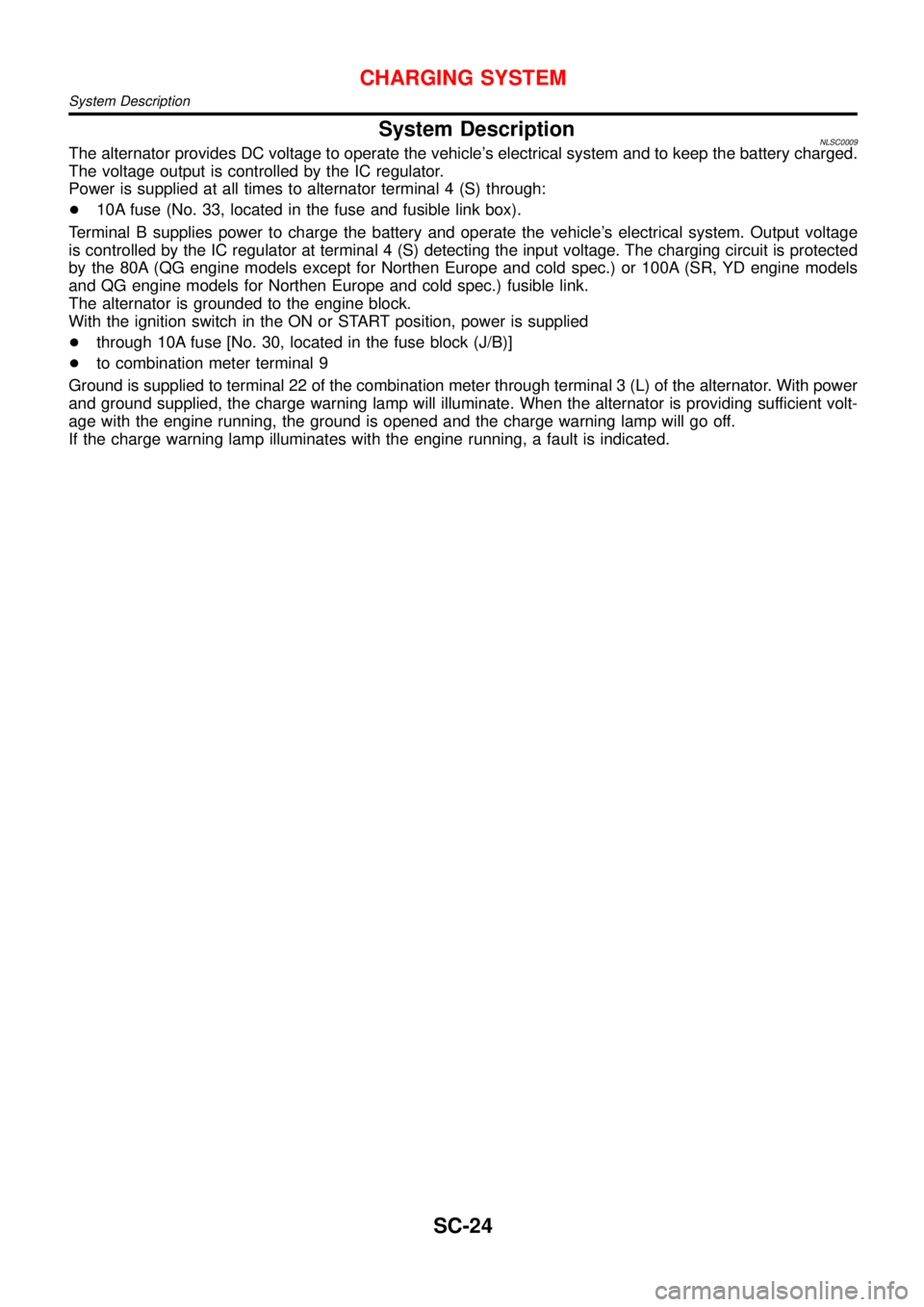

Page 2985 of 3051

System DescriptionNLSC0009The alternator provides DC voltage to operate the vehicle’s electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle’s electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (QG engine models except for Northen Europe and cold spec.) or 100A (SR, YD engine models

and QG engine models for Northen Europe and cold spec.) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 9

Ground is supplied to terminal 22 of the combination meter through terminal 3 (L) of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

CHARGING SYSTEM

System Description

SC-24

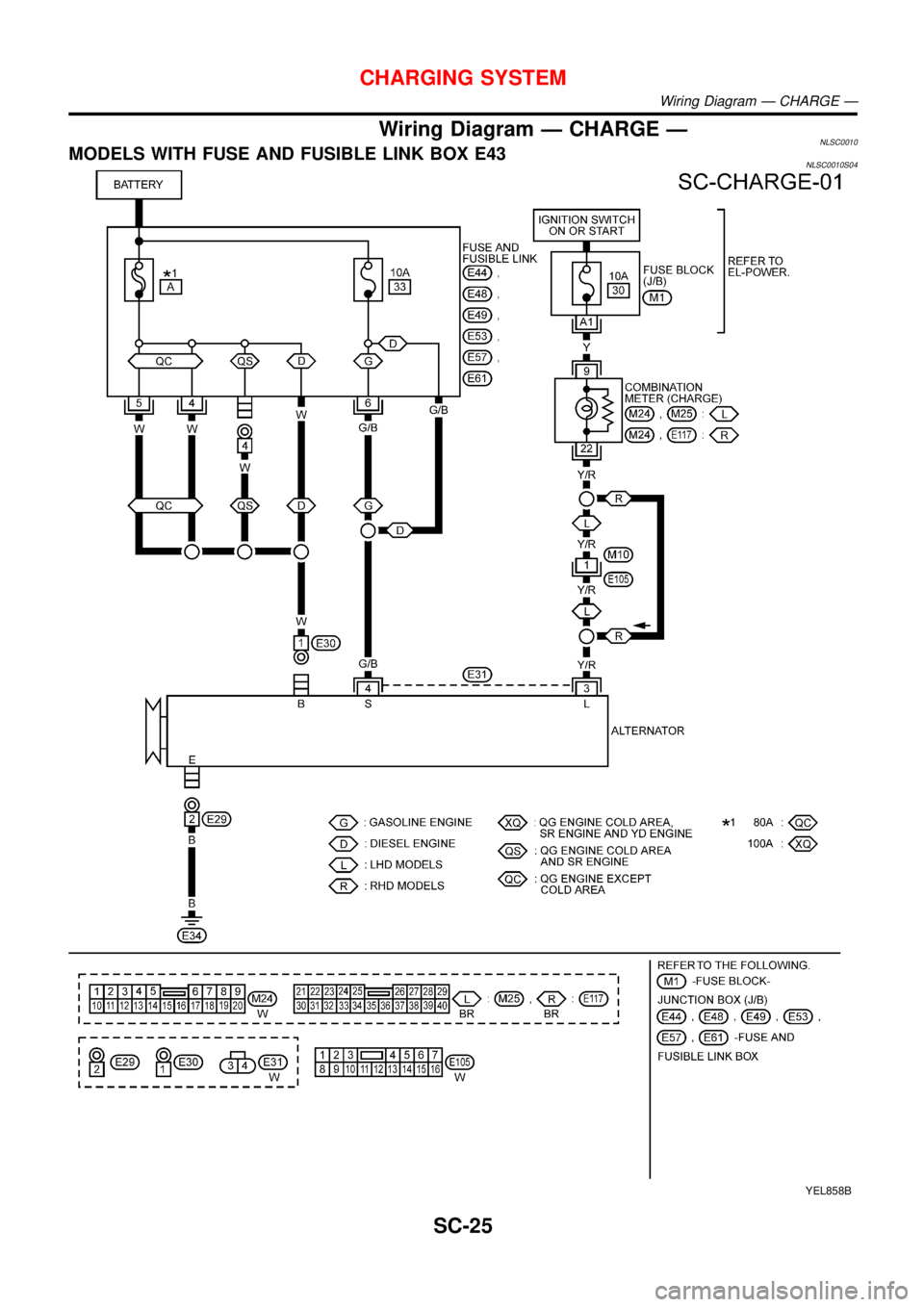

Page 2986 of 3051

Wiring Diagram—CHARGE—NLSC0010MODELS WITH FUSE AND FUSIBLE LINK BOX E43NLSC0010S04

YEL858B

CHARGING SYSTEM

Wiring Diagram—CHARGE—

SC-25

Page 2987 of 3051

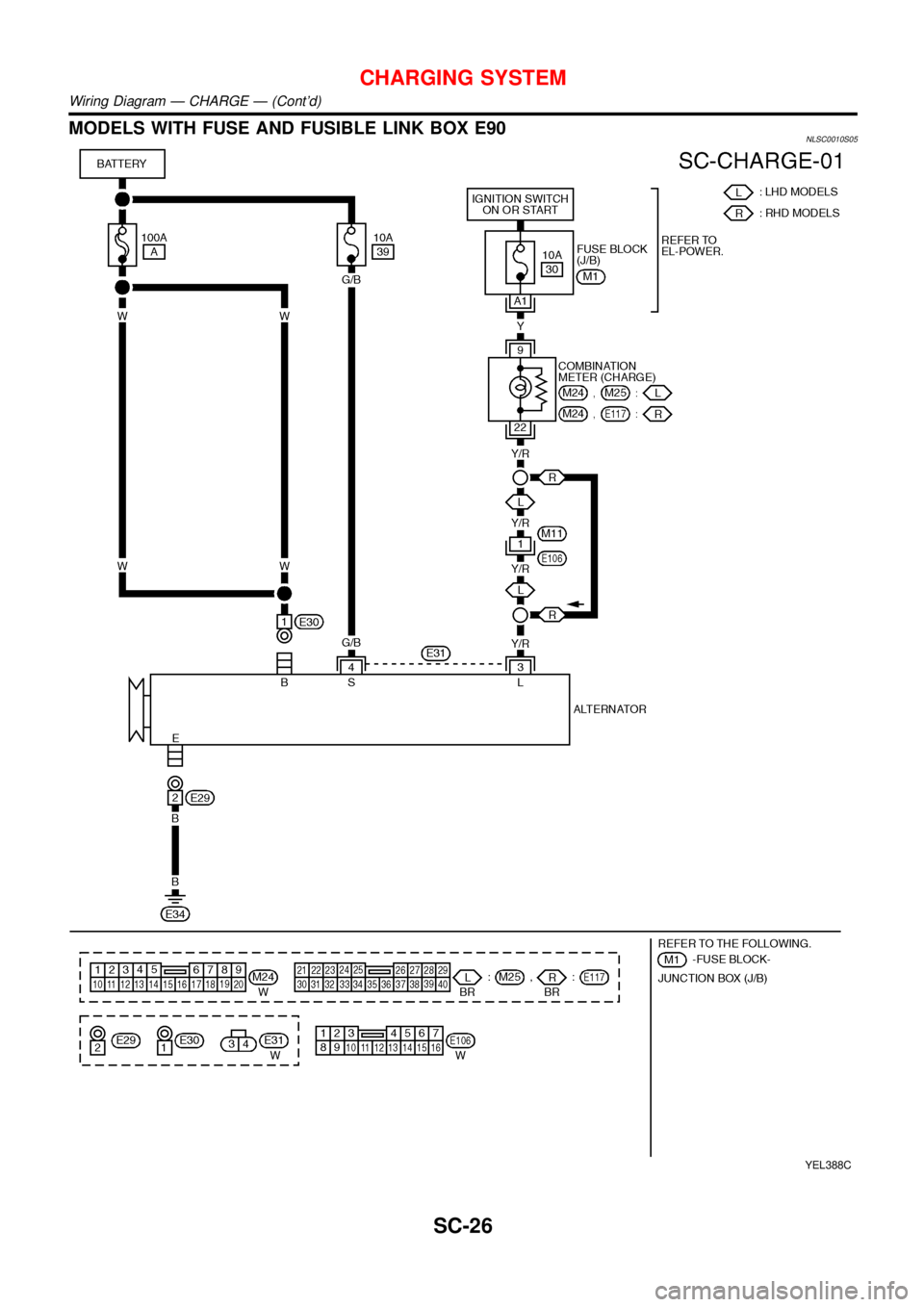

MODELS WITH FUSE AND FUSIBLE LINK BOX E90NLSC0010S05

YEL388C

CHARGING SYSTEM

Wiring Diagram—CHARGE—(Cont’d)

SC-26