NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1631 of 3051

Diagnostic ProcedureNLEC0666

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 4.

2 CHECK COOLING FAN LOW SPEED OPERATION

With CONSULT-II

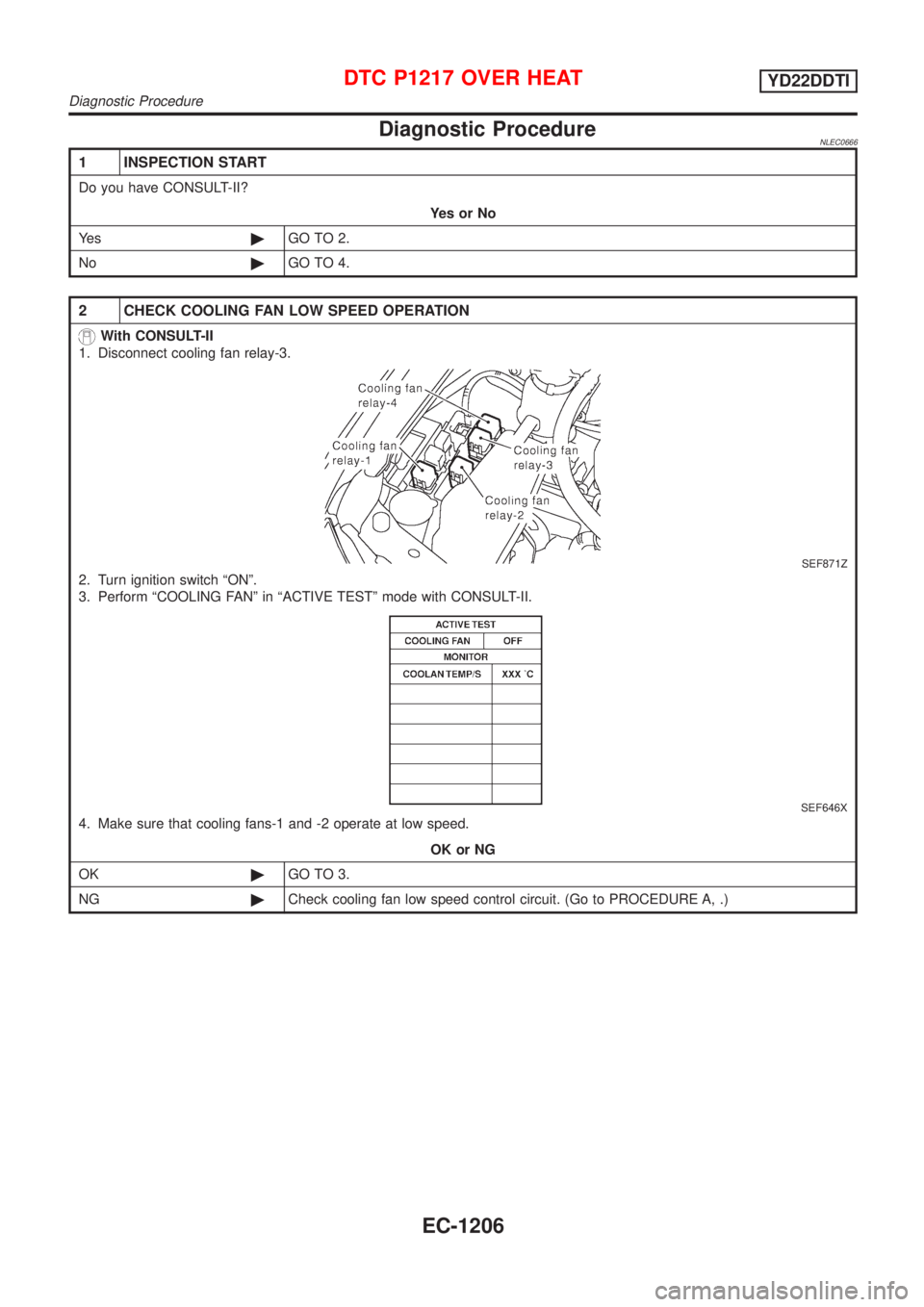

1. Disconnect cooling fan relay-3.

SEF871Z

2. Turn ignition switch ªONº.

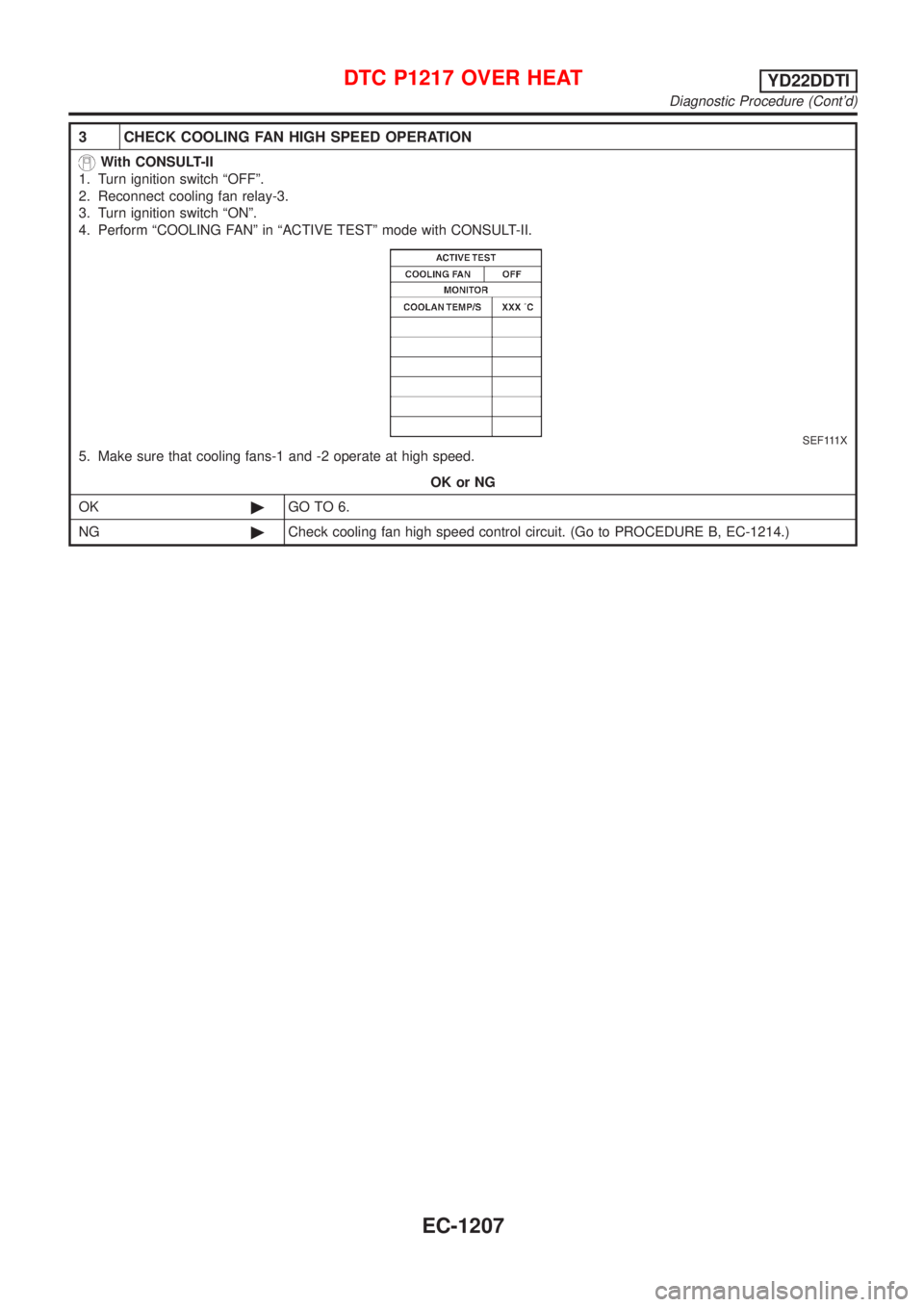

3. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF646X

4. Make sure that cooling fans-1 and -2 operate at low speed.

OK or NG

OK©GO TO 3.

NG©Check cooling fan low speed control circuit. (Go to PROCEDURE A, .)

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure

EC-1206

Page 1632 of 3051

3 CHECK COOLING FAN HIGH SPEED OPERATION

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Reconnect cooling fan relay-3.

3. Turn ignition switch ªONº.

4. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

SEF111X

5. Make sure that cooling fans-1 and -2 operate at high speed.

OK or NG

OK©GO TO 6.

NG©Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-1214.)

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1207

Page 1633 of 3051

4 CHECK COOLING FAN LOW SPEED OPERATION

Without CONSULT-II

1. Disconnect cooling fan relay-3.

SEF871Z

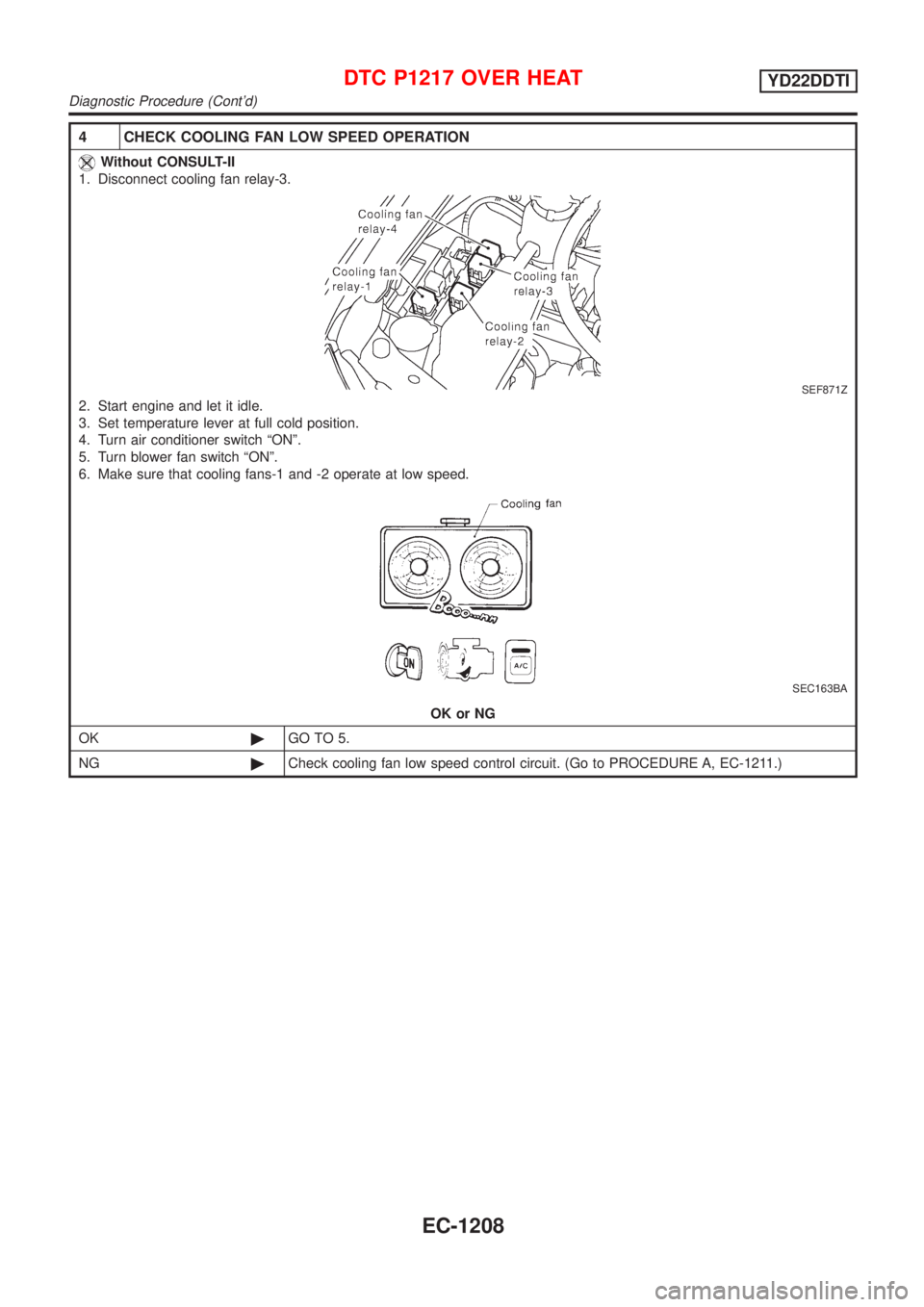

2. Start engine and let it idle.

3. Set temperature lever at full cold position.

4. Turn air conditioner switch ªONº.

5. Turn blower fan switch ªONº.

6. Make sure that cooling fans-1 and -2 operate at low speed.

SEC163BA

OK or NG

OK©GO TO 5.

NG©Check cooling fan low speed control circuit. (Go to PROCEDURE A, EC-1211.)

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1208

Page 1634 of 3051

5 CHECK COOLING FAN HIGH SPEED OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Reconnect cooling fan relay-3.

3. Turn air conditioner switch and blower fan switch ªOFFº.

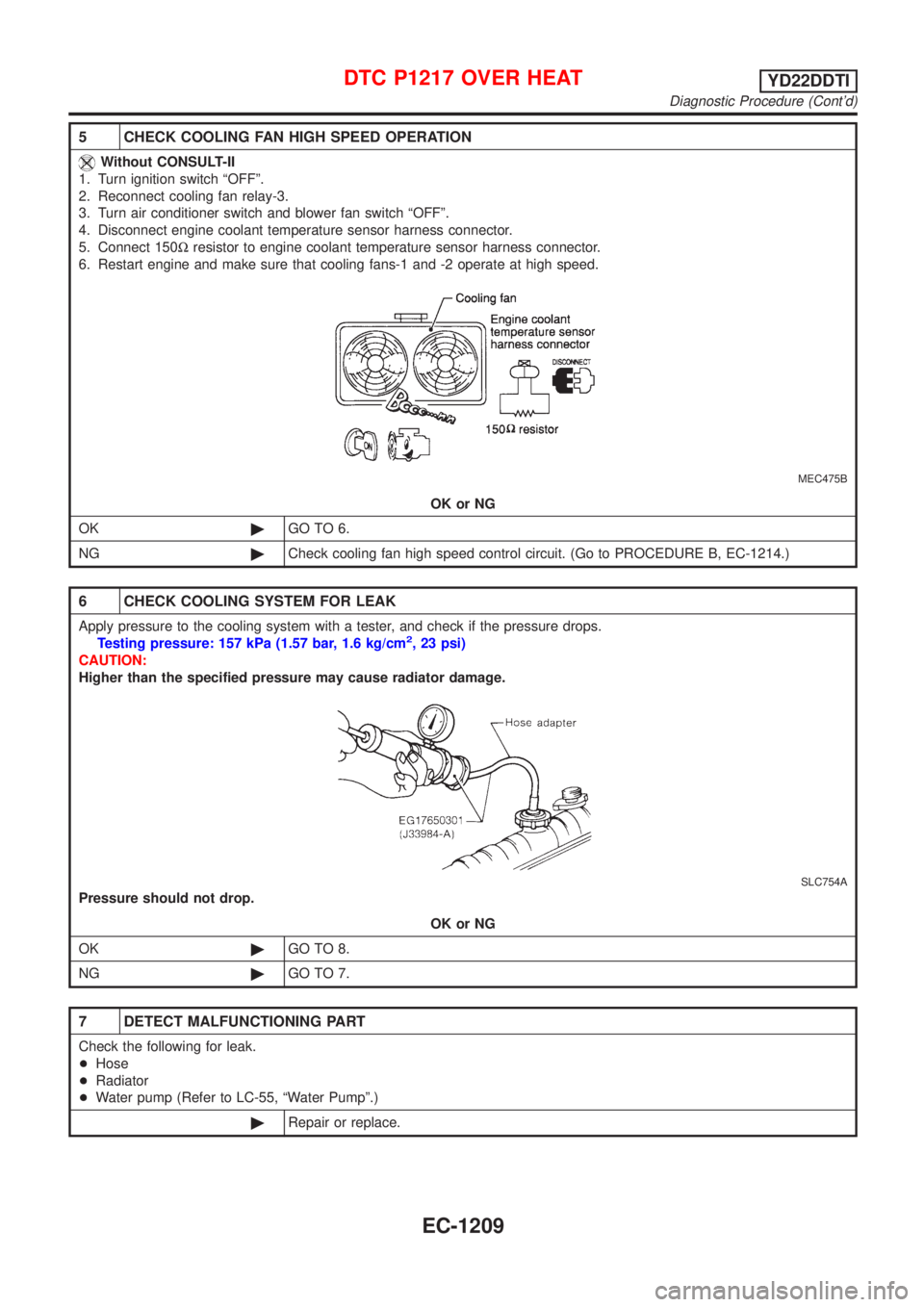

4. Disconnect engine coolant temperature sensor harness connector.

5. Connect 150Wresistor to engine coolant temperature sensor harness connector.

6. Restart engine and make sure that cooling fans-1 and -2 operate at high speed.

MEC475B

OK or NG

OK©GO TO 6.

NG©Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-1214.)

6 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following for leak.

+Hose

+Radiator

+Water pump (Refer to LC-55, ªWater Pumpº.)

©Repair or replace.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1209

Page 1635 of 3051

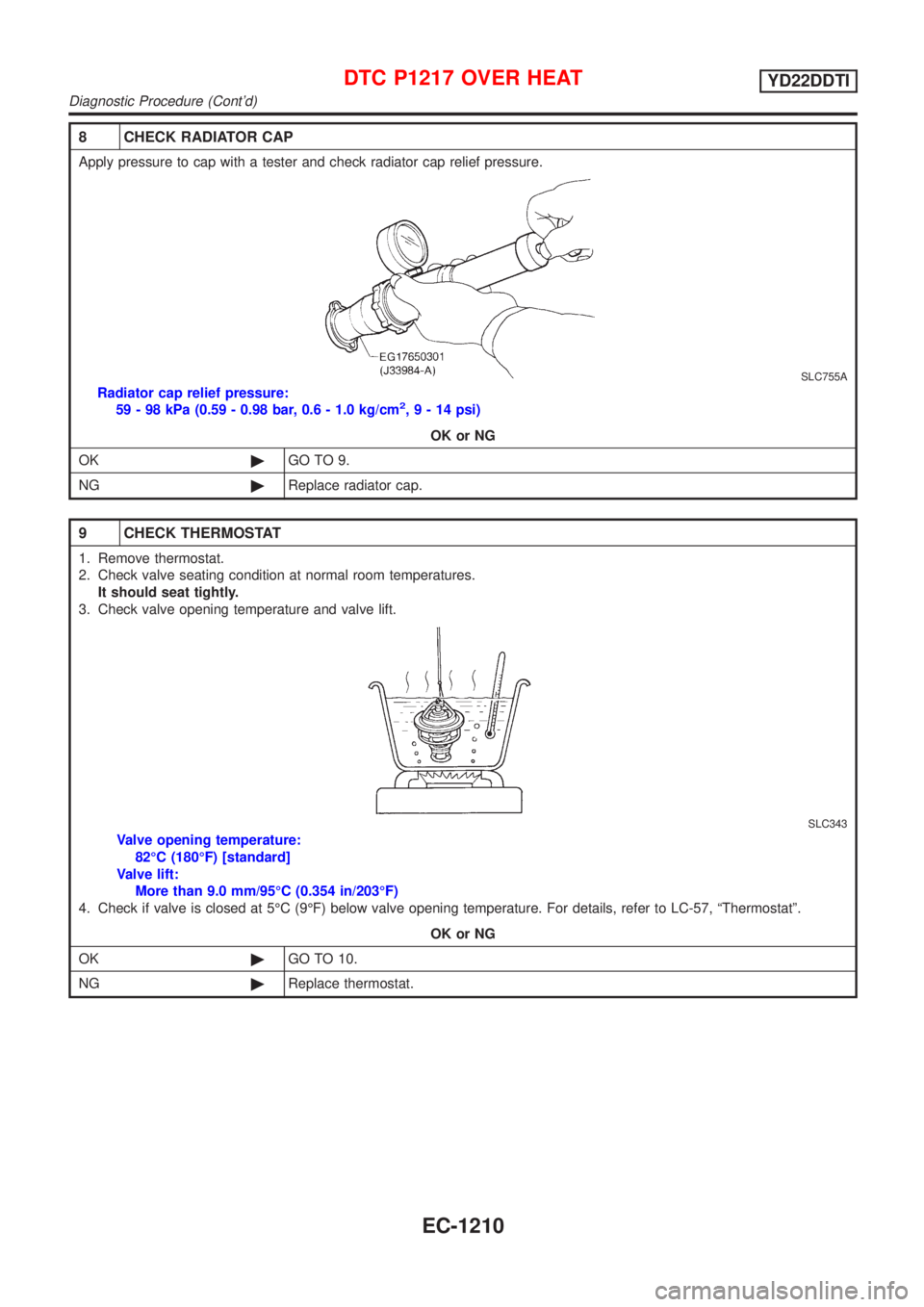

8 CHECK RADIATOR CAP

Apply pressure to cap with a tester and check radiator cap relief pressure.

SLC755A

Radiator cap relief pressure:

59 - 98 kPa (0.59 - 0.98 bar, 0.6 - 1.0 kg/cm2,9-14psi)

OK or NG

OK©GO TO 9.

NG©Replace radiator cap.

9 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard]

Valve lift:

More than 9.0 mm/95ÉC (0.354 in/203ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC-57, ªThermostatº.

OK or NG

OK©GO TO 10.

NG©Replace thermostat.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1210

Page 1636 of 3051

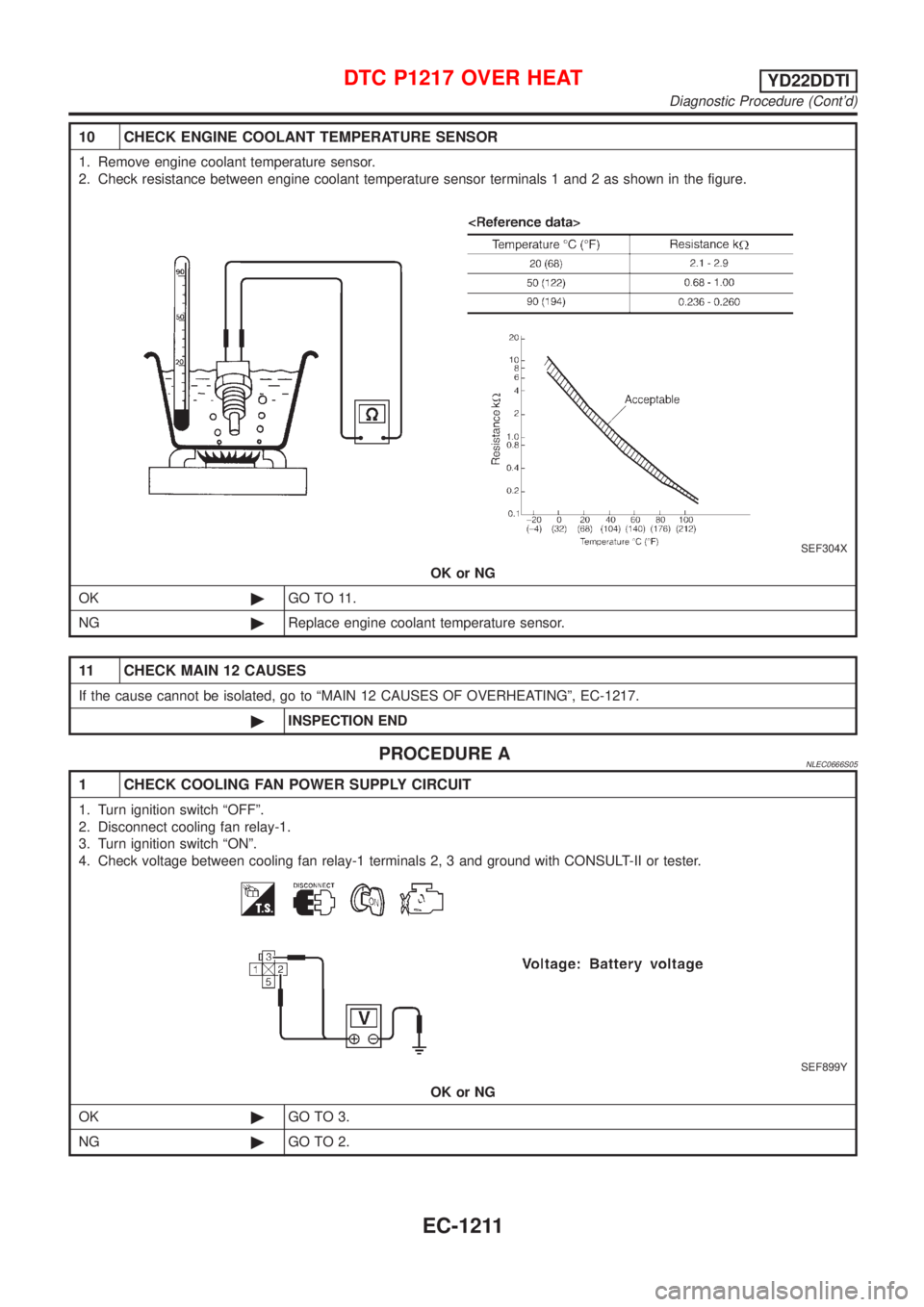

10 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor.

2. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OK©GO TO 11.

NG©Replace engine coolant temperature sensor.

11 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-1217.

©INSPECTION END

PROCEDURE ANLEC0666S05

1 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay-1.

3. Turn ignition switch ªONº.

4. Check voltage between cooling fan relay-1 terminals 2, 3 and ground with CONSULT-II or tester.

SEF899Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1211

Page 1637 of 3051

2 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector E109

+10A fuse

+40A fusible link

+Harness for open or short between cooling fan relay-1 and fuse

+Harness for open or short between cooling fan relay-1 and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

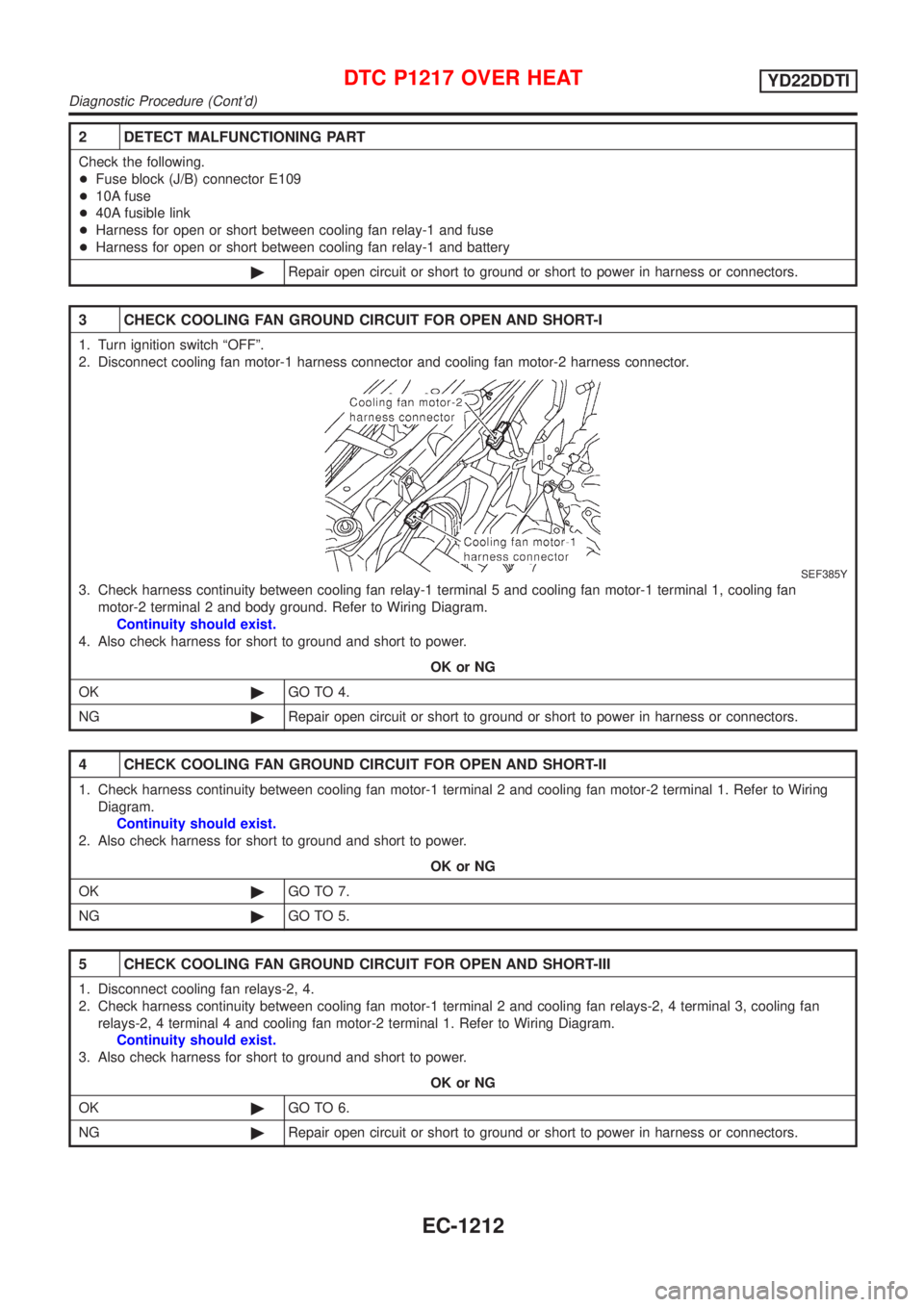

3 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor-1 harness connector and cooling fan motor-2 harness connector.

SEF385Y

3. Check harness continuity between cooling fan relay-1 terminal 5 and cooling fan motor-1 terminal 1, cooling fan

motor-2 terminal 2 and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Check harness continuity between cooling fan motor-1 terminal 2 and cooling fan motor-2 terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 5.

5 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-III

1. Disconnect cooling fan relays-2, 4.

2. Check harness continuity between cooling fan motor-1 terminal 2 and cooling fan relays-2, 4 terminal 3, cooling fan

relays-2, 4 terminal 4 and cooling fan motor-2 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1212

Page 1638 of 3051

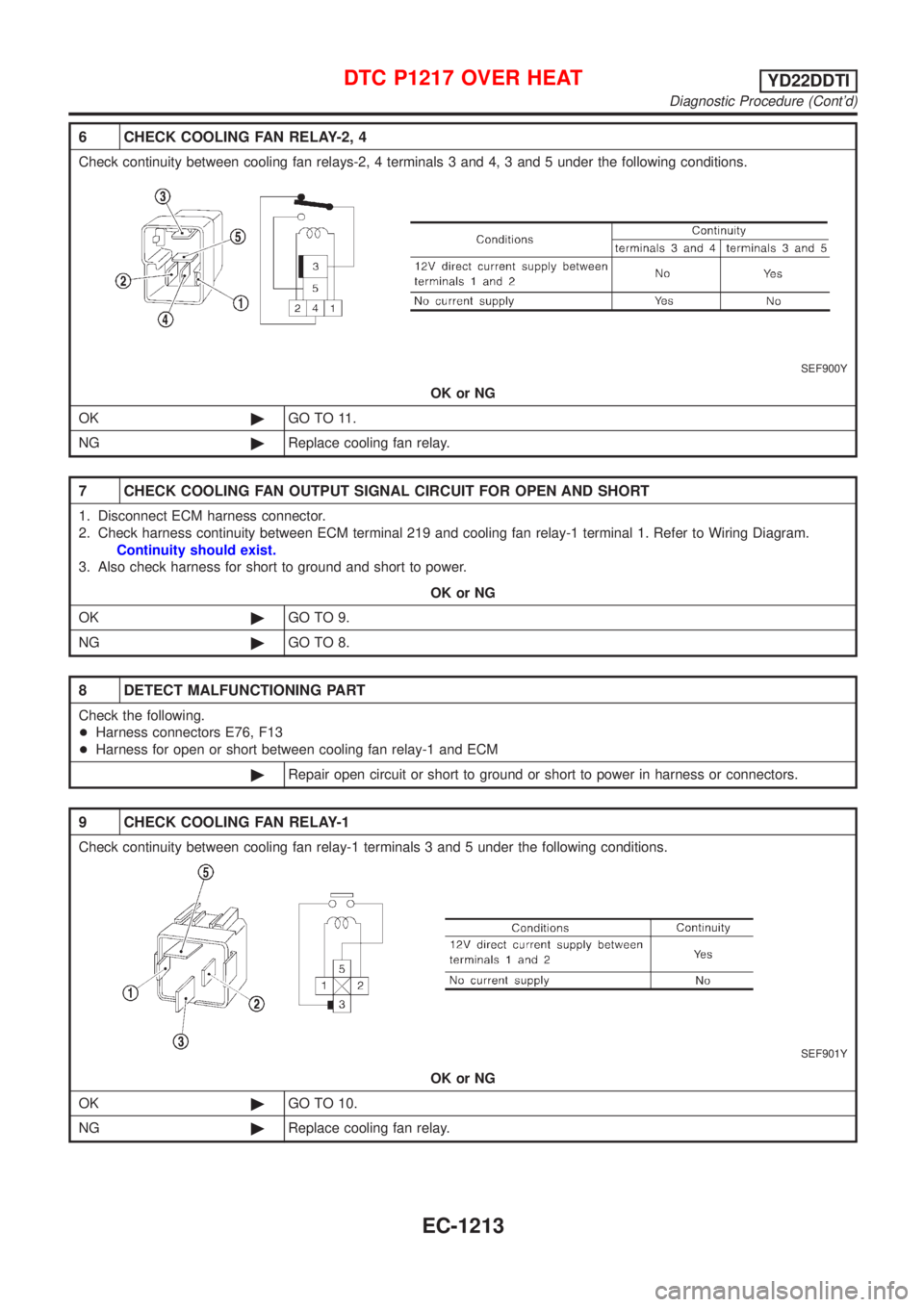

6 CHECK COOLING FAN RELAY-2, 4

Check continuity between cooling fan relays-2, 4 terminals 3 and 4, 3 and 5 under the following conditions.

SEF900Y

OK or NG

OK©GO TO 11.

NG©Replace cooling fan relay.

7 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 219 and cooling fan relay-1 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E76, F13

+Harness for open or short between cooling fan relay-1 and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

9 CHECK COOLING FAN RELAY-1

Check continuity between cooling fan relay-1 terminals 3 and 5 under the following conditions.

SEF901Y

OK or NG

OK©GO TO 10.

NG©Replace cooling fan relay.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1213

Page 1639 of 3051

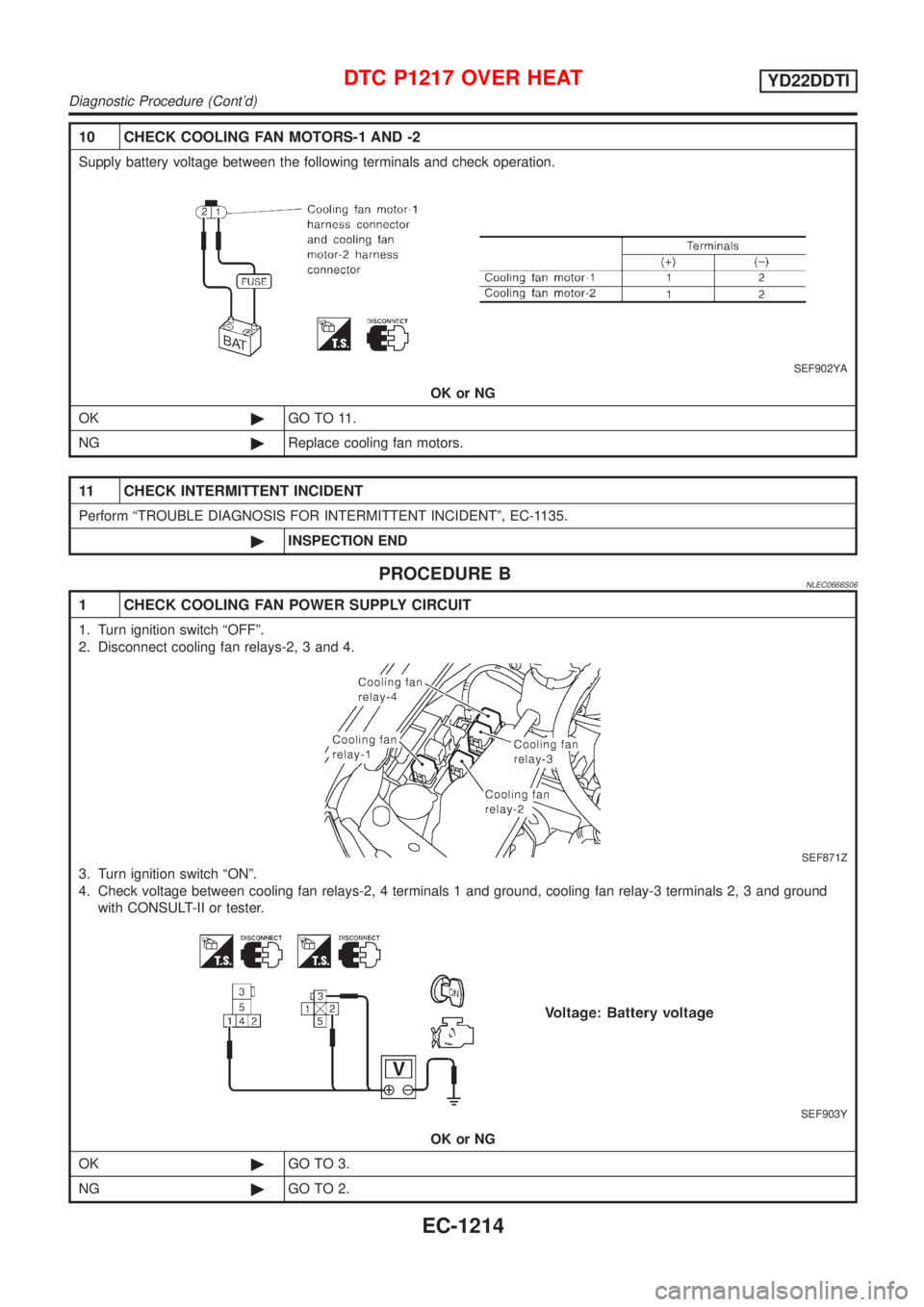

10 CHECK COOLING FAN MOTORS-1 AND -2

Supply battery voltage between the following terminals and check operation.

SEF902YA

OK or NG

OK©GO TO 11.

NG©Replace cooling fan motors.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

©INSPECTION END

PROCEDURE BNLEC0666S06

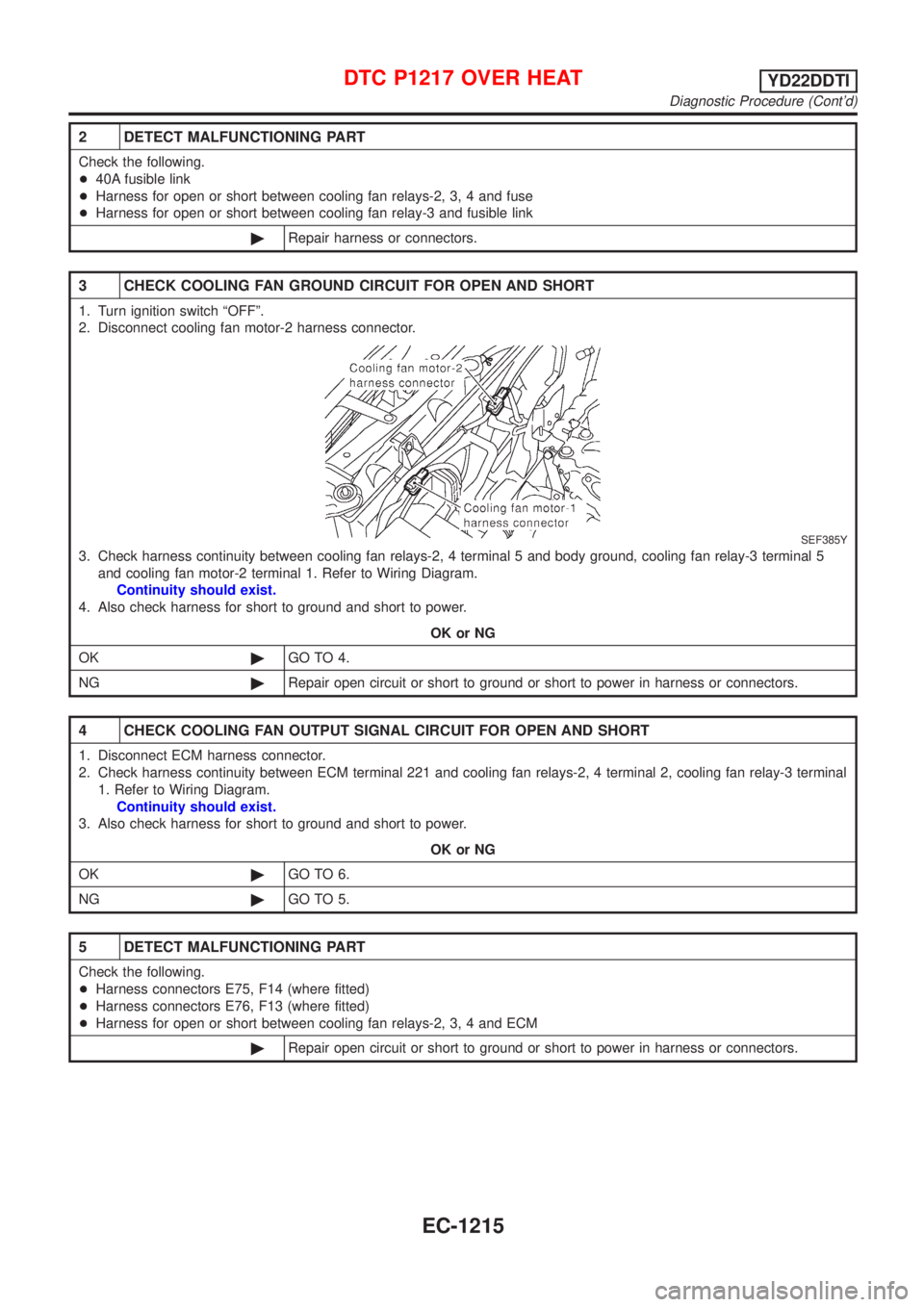

1 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relays-2, 3 and 4.

SEF871Z

3. Turn ignition switch ªONº.

4. Check voltage between cooling fan relays-2, 4 terminals 1 and ground, cooling fan relay-3 terminals 2, 3 and ground

with CONSULT-II or tester.

SEF903Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1214

Page 1640 of 3051

2 DETECT MALFUNCTIONING PART

Check the following.

+40A fusible link

+Harness for open or short between cooling fan relays-2, 3, 4 and fuse

+Harness for open or short between cooling fan relay-3 and fusible link

©Repair harness or connectors.

3 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor-2 harness connector.

SEF385Y

3. Check harness continuity between cooling fan relays-2, 4 terminal 5 and body ground, cooling fan relay-3 terminal 5

and cooling fan motor-2 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 221 and cooling fan relays-2, 4 terminal 2, cooling fan relay-3 terminal

1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F14 (where fitted)

+Harness connectors E76, F13 (where fitted)

+Harness for open or short between cooling fan relays-2, 3, 4 and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1217 OVER HEATYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1215