oil pressure NISSAN ALMERA TINO 2001 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 459 of 3051

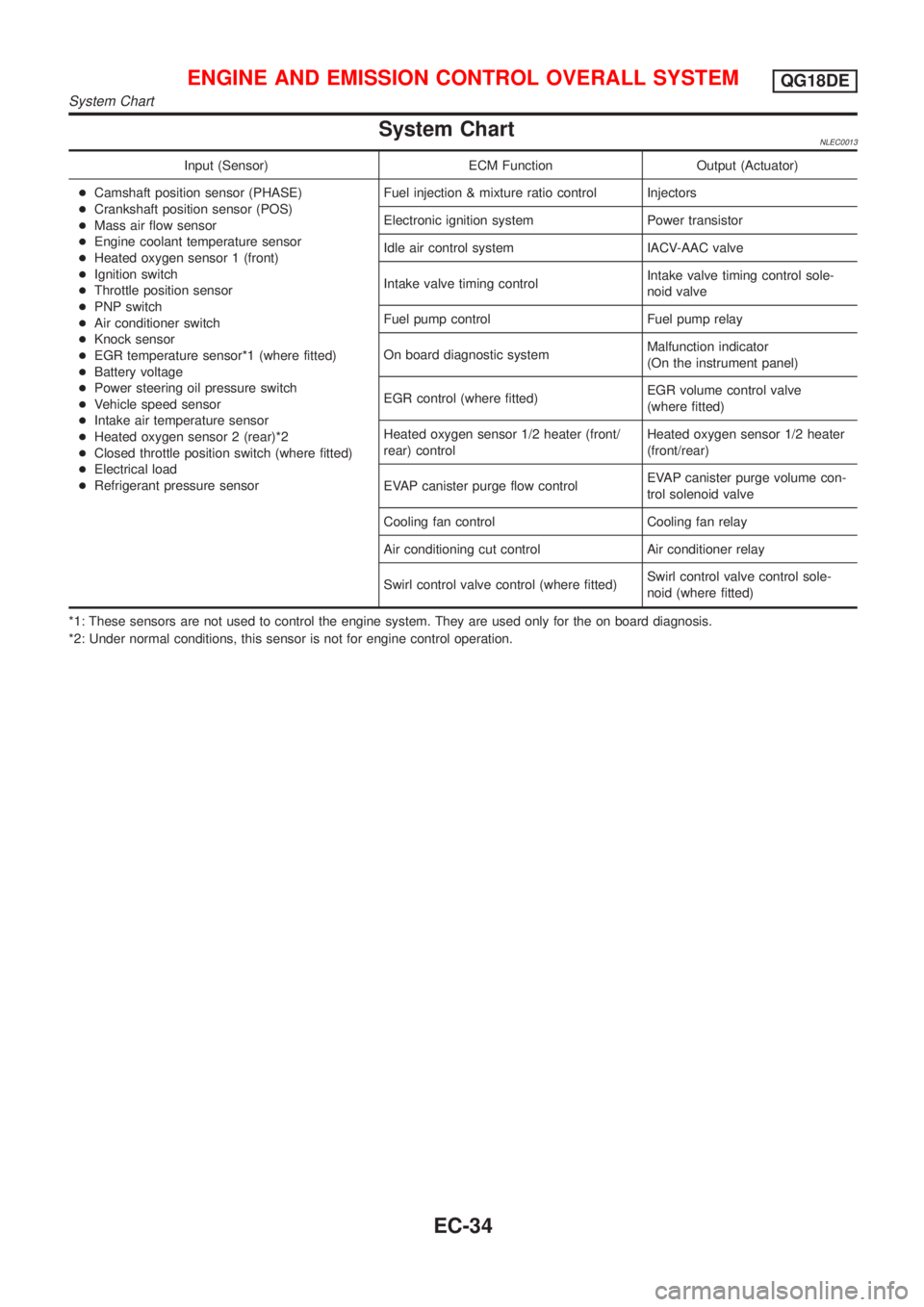

System ChartNLEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor (PHASE)

+Crankshaft position sensor (POS)

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1 (front)

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+EGR temperature sensor*1 (where fitted)

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2 (rear)*2

+Closed throttle position switch (where fitted)

+Electrical load

+Refrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Intake valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

On board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control (where fitted)EGR volume control valve

(where fitted)

Heated oxygen sensor 1/2 heater (front/

rear) controlHeated oxygen sensor 1/2 heater

(front/rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Swirl control valve control (where fitted)Swirl control valve control sole-

noid (where fitted)

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG18DE

System Chart

EC-34

Page 460 of 3051

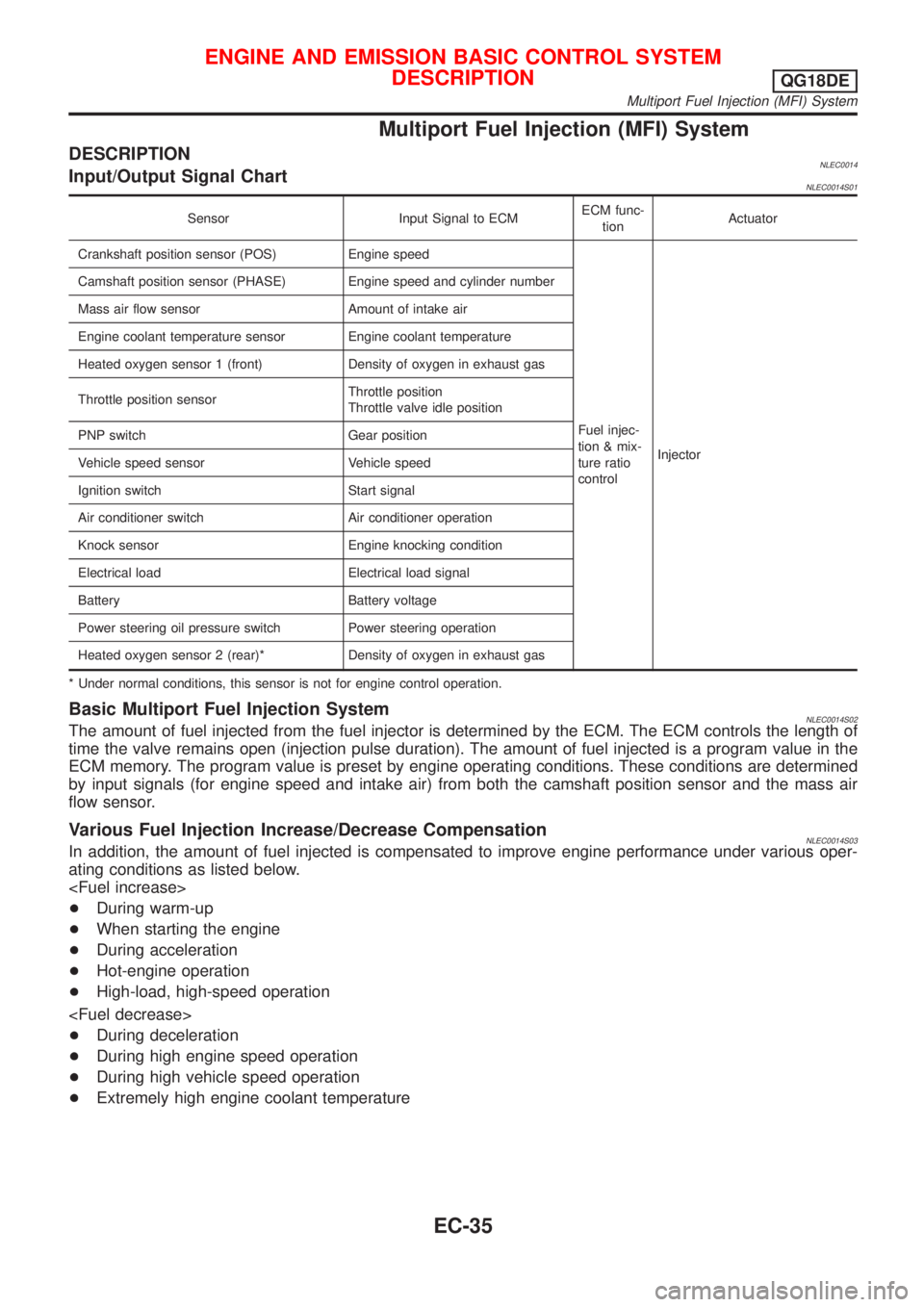

Multiport Fuel Injection (MFI) System

DESCRIPTIONNLEC0014Input/Output Signal ChartNLEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Fuel injec-

tion & mix-

ture ratio

controlInjector Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Electrical load Electrical load signal

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNLEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNLEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

+During warm-up

+When starting the engine

+During acceleration

+Hot-engine operation

+High-load, high-speed operation

+During deceleration

+During high engine speed operation

+During high vehicle speed operation

+Extremely high engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System

EC-35

Page 463 of 3051

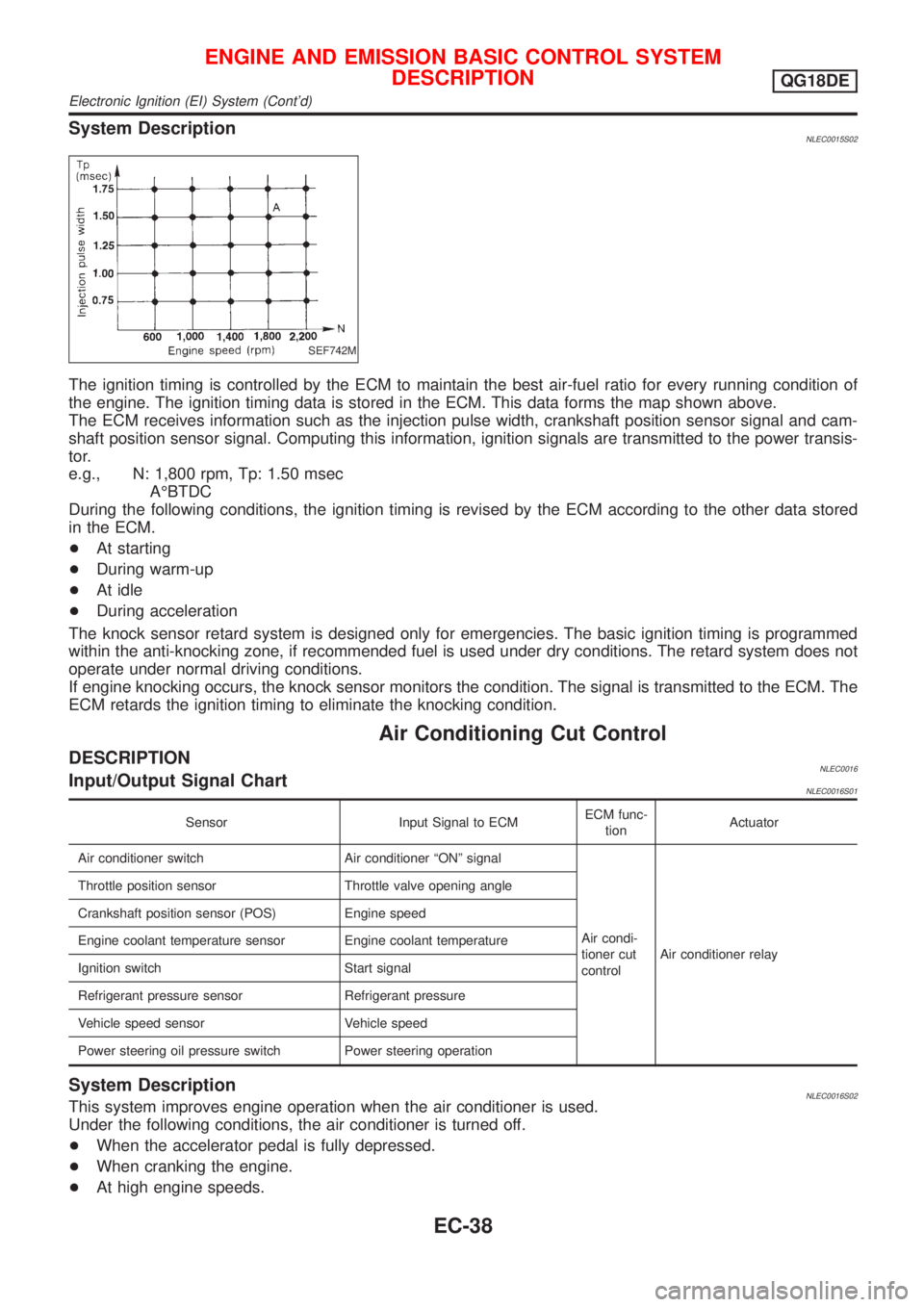

System DescriptionNLEC0015S02

SEF742M

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width, crankshaft position sensor signal and cam-

shaft position sensor signal. Computing this information, ignition signals are transmitted to the power transis-

tor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

+At starting

+During warm-up

+At idle

+During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNLEC0016Input/Output Signal ChartNLEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNLEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

+When the accelerator pedal is fully depressed.

+When cranking the engine.

+At high engine speeds.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Electronic Ignition (EI) System (Cont'd)

EC-38

Page 469 of 3051

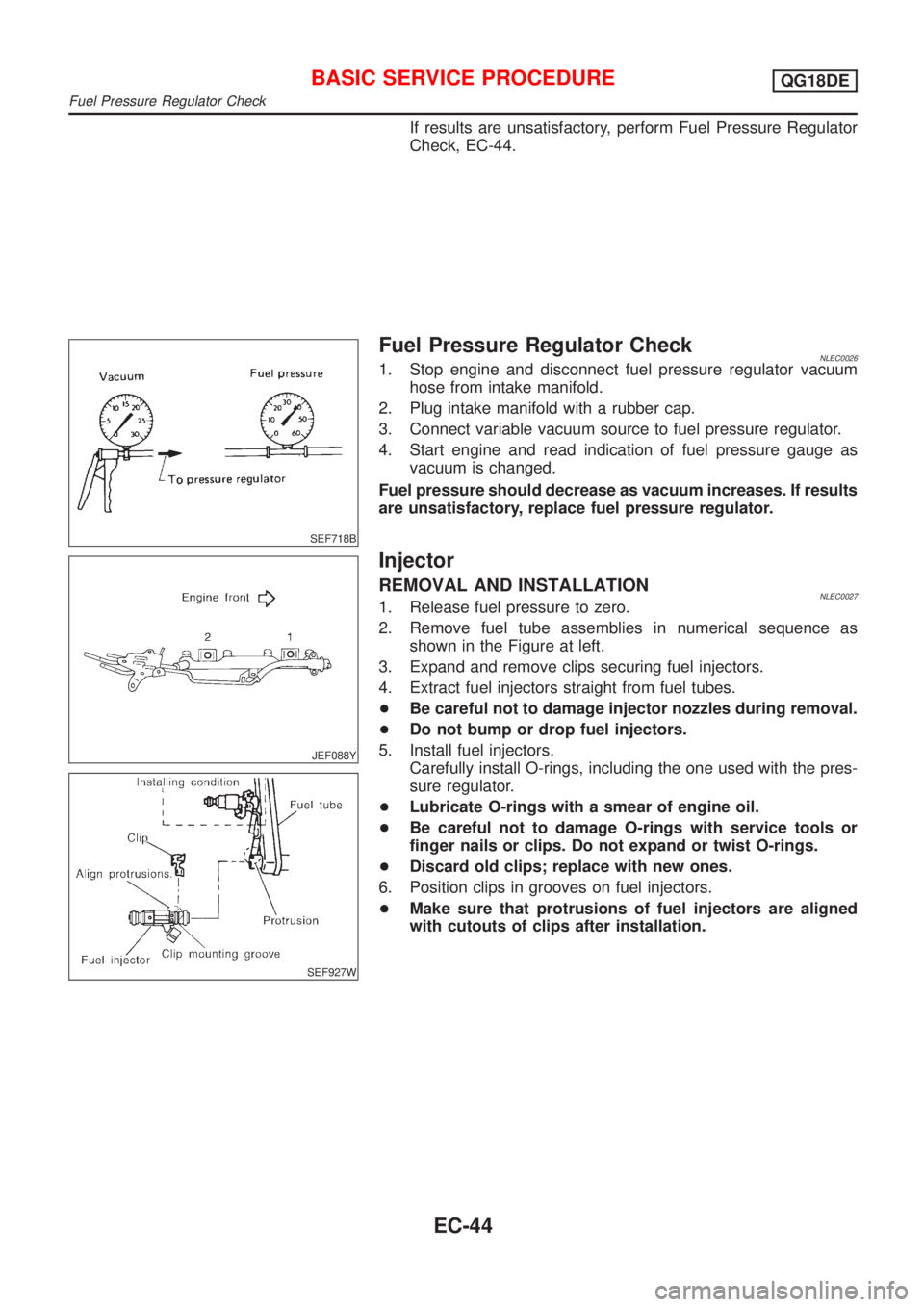

If results are unsatisfactory, perform Fuel Pressure Regulator

Check, EC-44.

SEF718B

Fuel Pressure Regulator CheckNLEC00261. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

2. Plug intake manifold with a rubber cap.

3. Connect variable vacuum source to fuel pressure regulator.

4. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If results

are unsatisfactory, replace fuel pressure regulator.

JEF088Y

SEF927W

Injector

REMOVAL AND INSTALLATIONNLEC00271. Release fuel pressure to zero.

2. Remove fuel tube assemblies in numerical sequence as

shown in the Figure at left.

3. Expand and remove clips securing fuel injectors.

4. Extract fuel injectors straight from fuel tubes.

+Be careful not to damage injector nozzles during removal.

+Do not bump or drop fuel injectors.

5. Install fuel injectors.

Carefully install O-rings, including the one used with the pres-

sure regulator.

+Lubricate O-rings with a smear of engine oil.

+Be careful not to damage O-rings with service tools or

finger nails or clips. Do not expand or twist O-rings.

+Discard old clips; replace with new ones.

6. Position clips in grooves on fuel injectors.

+Make sure that protrusions of fuel injectors are aligned

with cutouts of clips after installation.

BASIC SERVICE PROCEDUREQG18DE

Fuel Pressure Regulator Check

EC-44

Page 472 of 3051

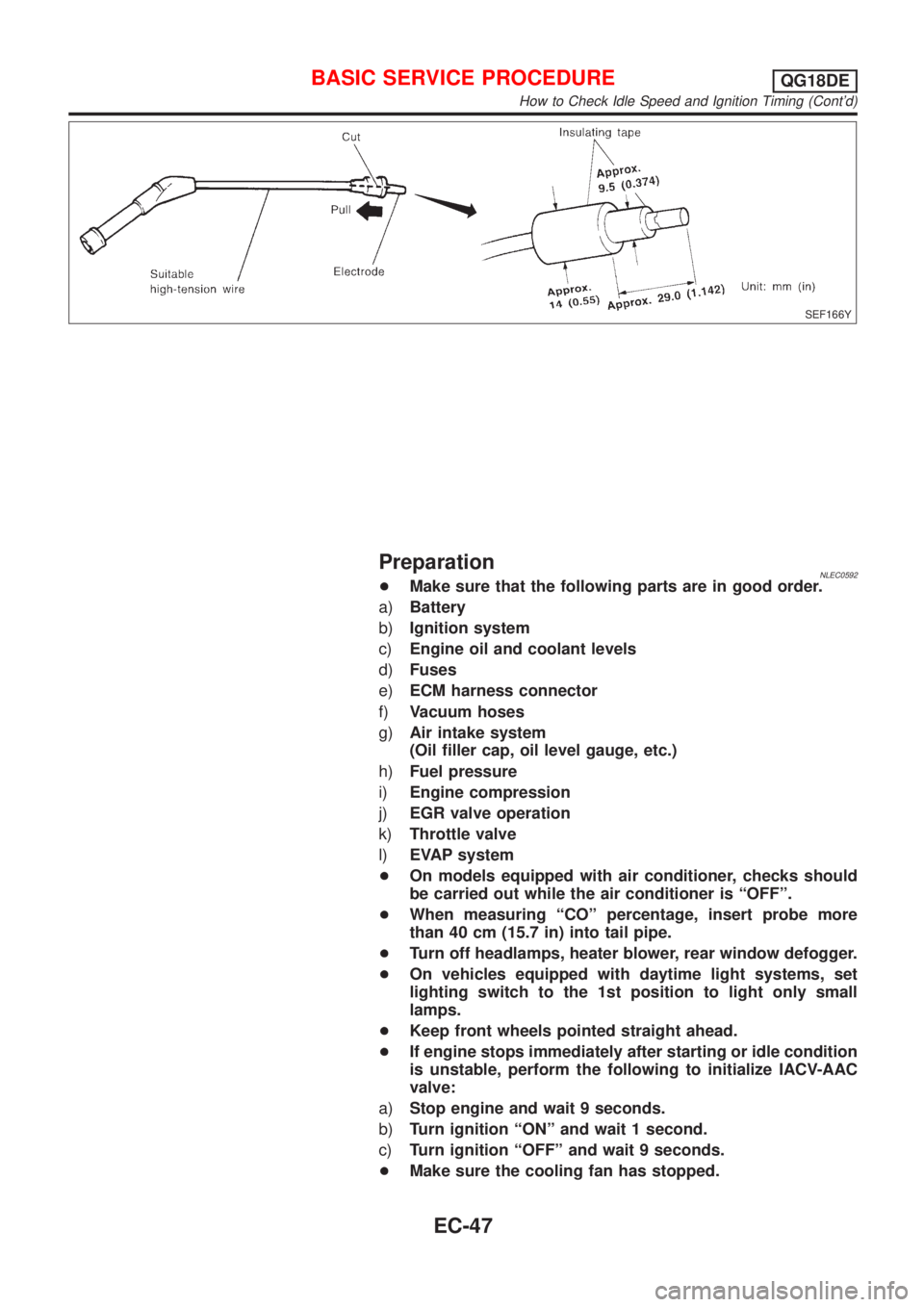

SEF166Y

PreparationNLEC0592+Make sure that the following parts are in good order.

a)Battery

b)Ignition system

c)Engine oil and coolant levels

d)Fuses

e)ECM harness connector

f)Vacuum hoses

g)Air intake system

(Oil filler cap, oil level gauge, etc.)

h)Fuel pressure

i)Engine compression

j)EGR valve operation

k)Throttle valve

l)EVAP system

+On models equipped with air conditioner, checks should

be carried out while the air conditioner is ªOFFº.

+When measuring ªCOº percentage, insert probe more

than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower, rear window defogger.

+On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

+Keep front wheels pointed straight ahead.

+If engine stops immediately after starting or idle condition

is unstable, perform the following to initialize IACV-AAC

valve:

a)Stop engine and wait 9 seconds.

b)Turn ignition ªONº and wait 1 second.

c)Turn ignition ªOFFº and wait 9 seconds.

+Make sure the cooling fan has stopped.

BASIC SERVICE PROCEDUREQG18DE

How to Check Idle Speed and Ignition Timing (Cont'd)

EC-47

Page 508 of 3051

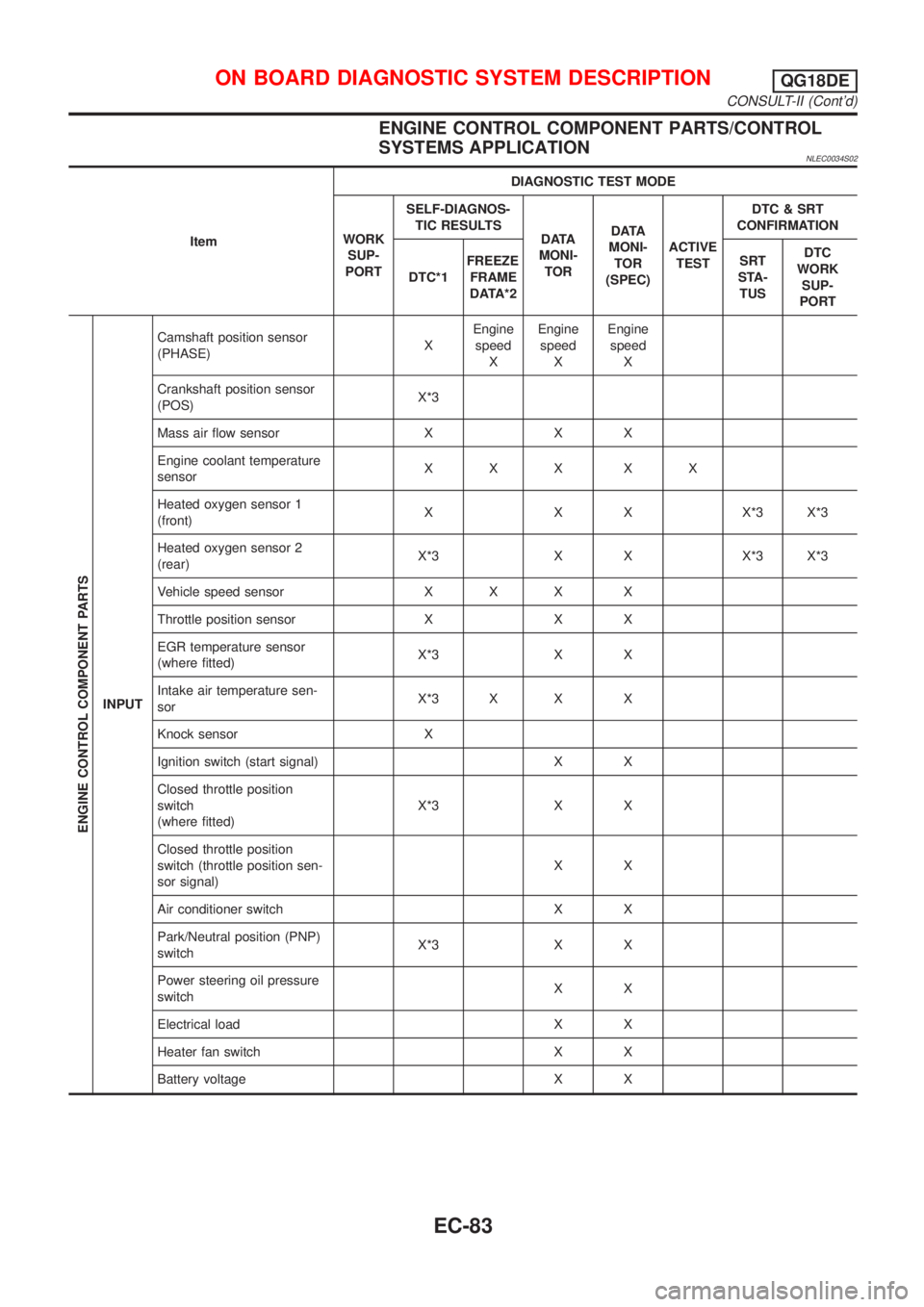

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

NLEC0034S02

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOS-

TIC RESULTS

D ATA

MONI-

TORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STA-

TUSDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

INPUTCamshaft position sensor

(PHASE)XEngine

speed

XEngine

speed

XEngine

speed

X

Crankshaft position sensor

(POS)X*3

Mass air flow sensor X X X

Engine coolant temperature

sensorXXX XX

Heated oxygen sensor 1

(front)X X X X*3 X*3

Heated oxygen sensor 2

(rear)X*3 X X X*3 X*3

Vehicle speed sensor X X X X

Throttle position sensor X X X

EGR temperature sensor

(where fitted)X*3 X X

Intake air temperature sen-

sorX*3 X X X

Knock sensor X

Ignition switch (start signal) X X

Closed throttle position

switch

(where fitted)X*3 X X

Closed throttle position

switch (throttle position sen-

sor signal)XX

Air conditioner switch X X

Park/Neutral position (PNP)

switchX*3 X X

Power steering oil pressure

switchXX

Electrical load X X

Heater fan switch X X

Battery voltage X X

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-83

Page 512 of 3051

![NISSAN ALMERA TINO 2001 Service User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three wa NISSAN ALMERA TINO 2001 Service User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three wa](/img/5/57352/w960_57352-511.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three way catalyst is relatively small.

LEAN ... means the amount of oxygen after

three way catalyst is relatively large.+When the engine is stopped, a cer-

tain value is indicated.

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the vehicle

speed sensor signal is displayed.

BATTERY VOLT [V]j+The power supply voltage of ECM is dis-

played.

THRTL POS SEN [V]jj+The throttle position sensor signal voltage is

displayed.

INT/A TEMP SE

[ÉC] or [ÉF]j+The intake air temperature determined by the

signal voltage of the intake air temperature

sensor is indicated.

EGR TEMP SEN [V]

(where fitted)jj+The signal voltage of the EGR temperature

sensor is displayed.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the starter

signal.+After starting the engine, [OFF] is

displayed regardless of the starter

signal.

CLSD THL POS

[ON/OFF]jj+Indicates idle position [ON/OFF] computed by

ECM according to the throttle position sensor

signal.

CLSD THL/P SW

[ON/OFF]

(where fitted)j+Indicates mechanical contact [ON/OFF] con-

dition of the closed throttle position switch.

AIR COND SIG

[ON/OFF]jj+Indicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condi-

tioning signal.

P/N POSI SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the PNP

switch signal.

PW/ST SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition of the power

steering oil pressure switch determined by

the power steering oil pressure switch signal.

LOAD SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the electri-

cal load signal and/or lighting switch.

ON ... rear defogger is operating and/or light-

ing switch is on.

OFF ... rear defogger is not operating and

lighting switch is not on.

IGNITION SW

[ON/OFF]j+Indicates [ON/OFF] condition from ignition

switch.

HEATER FAN SW

[ON/OFF]j+Indicates [ON/OFF] condition from the heater

fan switch.

INJ PULSE-B1

[msec]j+Indicates the actual fuel injection pulse width

compensated by ECM according to the input

signals.+When the engine is stopped, a cer-

tain computed value is indicated.

IGN TIMING [BTDC]j+Indicates the ignition timing computed by

ECM according to the input signals.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-87

Page 549 of 3051

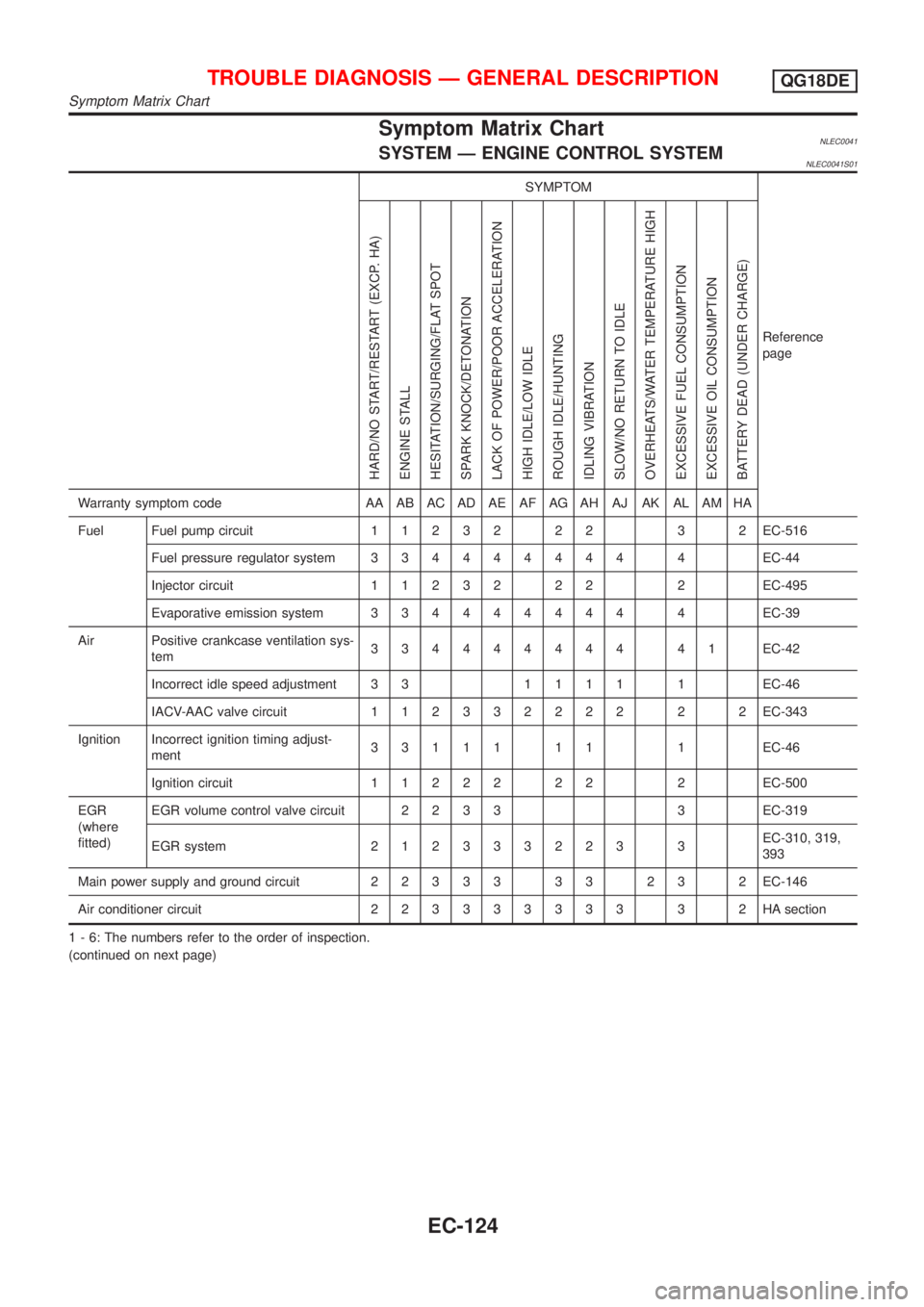

Symptom Matrix ChartNLEC0041SYSTEM Ð ENGINE CONTROL SYSTEMNLEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 22 3 2EC-516

Fuel pressure regulator system334444444 4EC-44

Injector circuit11232 22 2EC-495

Evaporative emission system334444444 4EC-39

Air Positive crankcase ventilation sys-

tem334444444 41EC-42

Incorrect idle speed adjustment 3 31111 1EC-46

IACV-AAC valve circuit112332222 2 2EC-343

Ignition Incorrect ignition timing adjust-

ment33111 11 1EC-46

Ignition circuit11222 22 2EC-500

EGR

(where

fitted)EGR volume control valve circuit2233 3EC-319

EGR system212333223 3EC-310, 319,

393

Main power supply and ground circuit22333 33 23 2EC-146

Air conditioner circuit223333333 3 2HAsection

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG18DE

Symptom Matrix Chart

EC-124

Page 550 of 3051

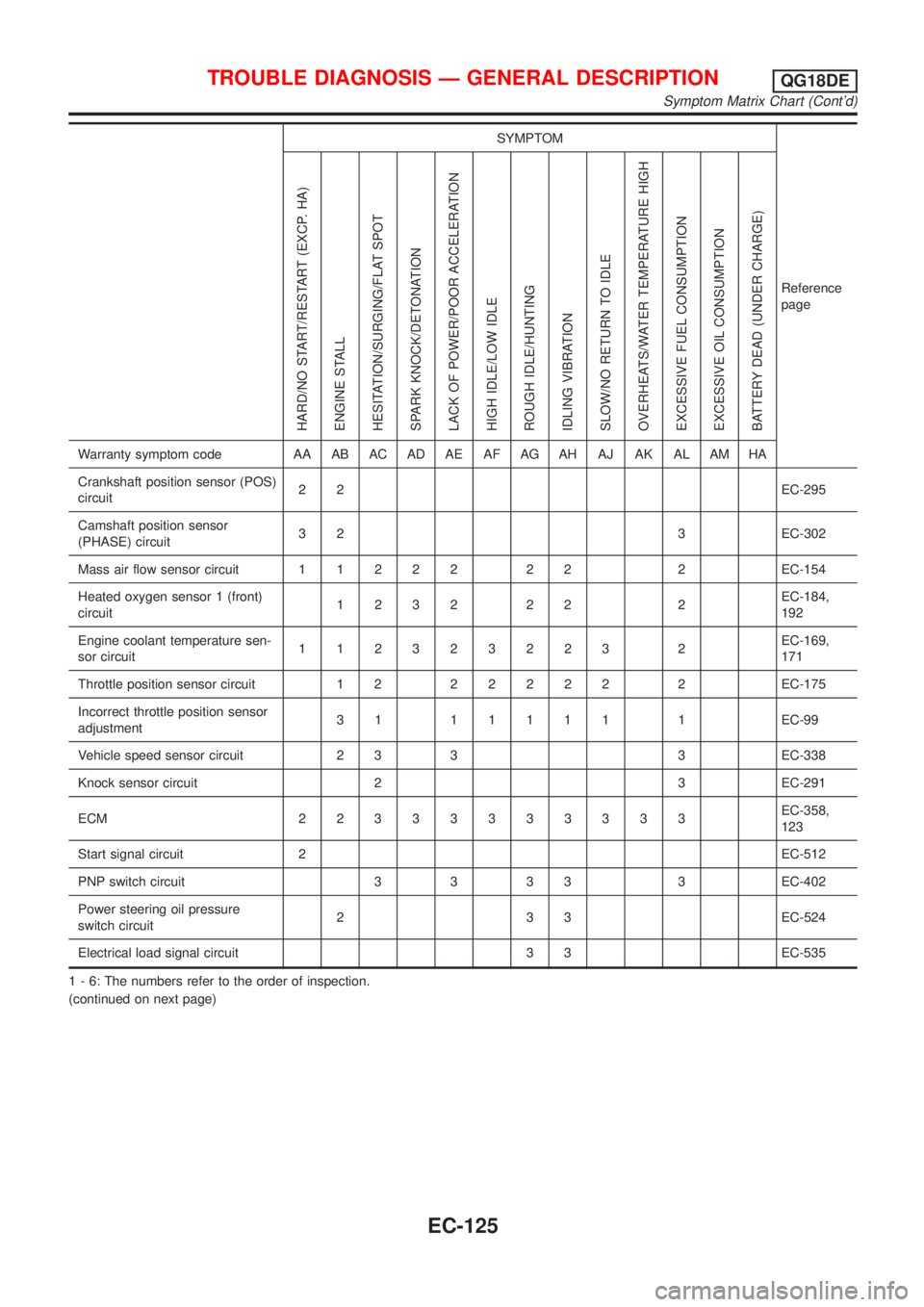

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Crankshaft position sensor (POS)

circuit22EC-295

Camshaft position sensor

(PHASE) circuit3 2 3 EC-302

Mass air flow sensor circuit11222 22 2EC-154

Heated oxygen sensor 1 (front)

circuit1232 22 2EC-184,

192

Engine coolant temperature sen-

sor circuit112323223 2EC-169,

171

Throttle position sensor circuit 1 222222 2EC-175

Incorrect throttle position sensor

adjustment31 11111 1EC-99

Vehicle speed sensor circuit 2 3 3 3 EC-338

Knock sensor circuit 2 3 EC-291

ECM 22333333333EC-358,

123

Start signal circuit 2EC-512

PNP switch circuit 3 3 3 3 3 EC-402

Power steering oil pressure

switch circuit2 3 3 EC-524

Electrical load signal circuit 3 3 EC-535

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG18DE

Symptom Matrix Chart (Cont'd)

EC-125

Page 713 of 3051

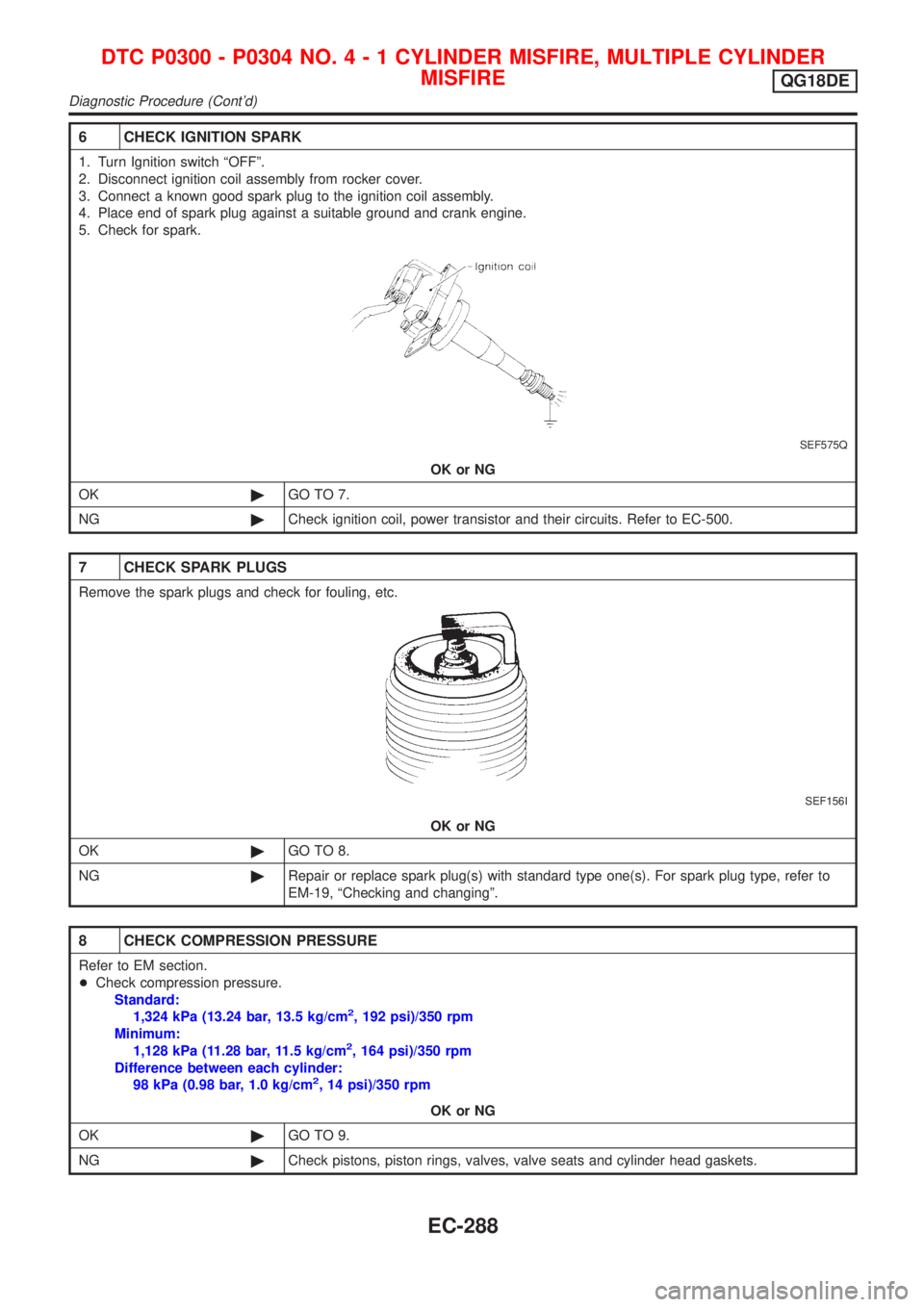

6 CHECK IGNITION SPARK

1. Turn Ignition switch ªOFFº.

2. Disconnect ignition coil assembly from rocker cover.

3. Connect a known good spark plug to the ignition coil assembly.

4. Place end of spark plug against a suitable ground and crank engine.

5. Check for spark.

SEF575Q

OK or NG

OK©GO TO 7.

NG©Check ignition coil, power transistor and their circuits. Refer to EC-500.

7 CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

SEF156I

OK or NG

OK©GO TO 8.

NG©Repair or replace spark plug(s) with standard type one(s). For spark plug type, refer to

EM-19, ªChecking and changingº.

8 CHECK COMPRESSION PRESSURE

Refer to EM section.

+Check compression pressure.

Standard:

1,324 kPa (13.24 bar, 13.5 kg/cm

2, 192 psi)/350 rpm

Minimum:

1,128 kPa (11.28 bar, 11.5 kg/cm

2, 164 psi)/350 rpm

Difference between each cylinder:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)/350 rpm

OK or NG

OK©GO TO 9.

NG©Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

QG18DE

Diagnostic Procedure (Cont'd)

EC-288