NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2721 of 3051

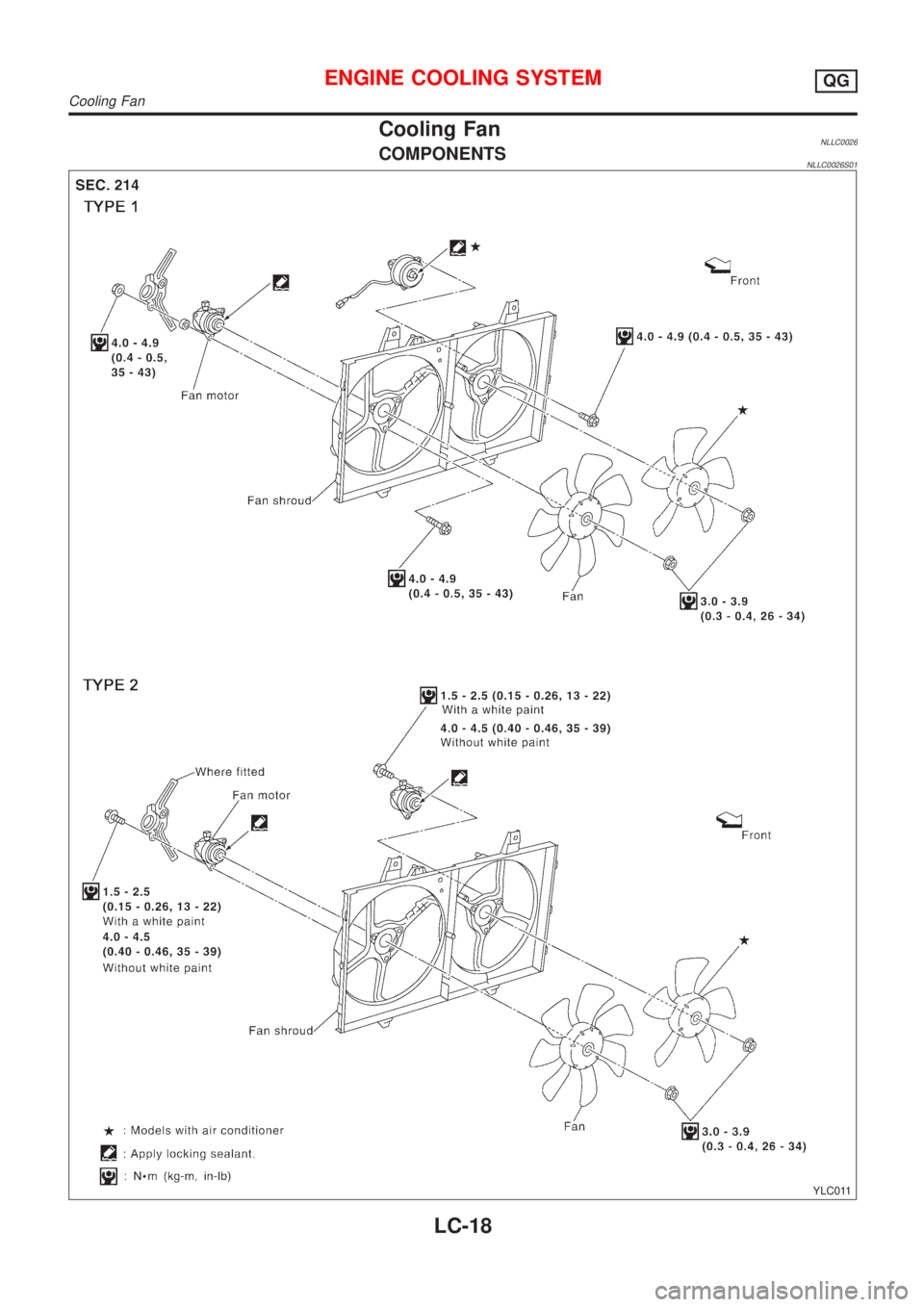

Cooling FanNLLC0026COMPONENTSNLLC0026S01

YLC011

ENGINE COOLING SYSTEMQG

Cooling Fan

LC-18

Page 2722 of 3051

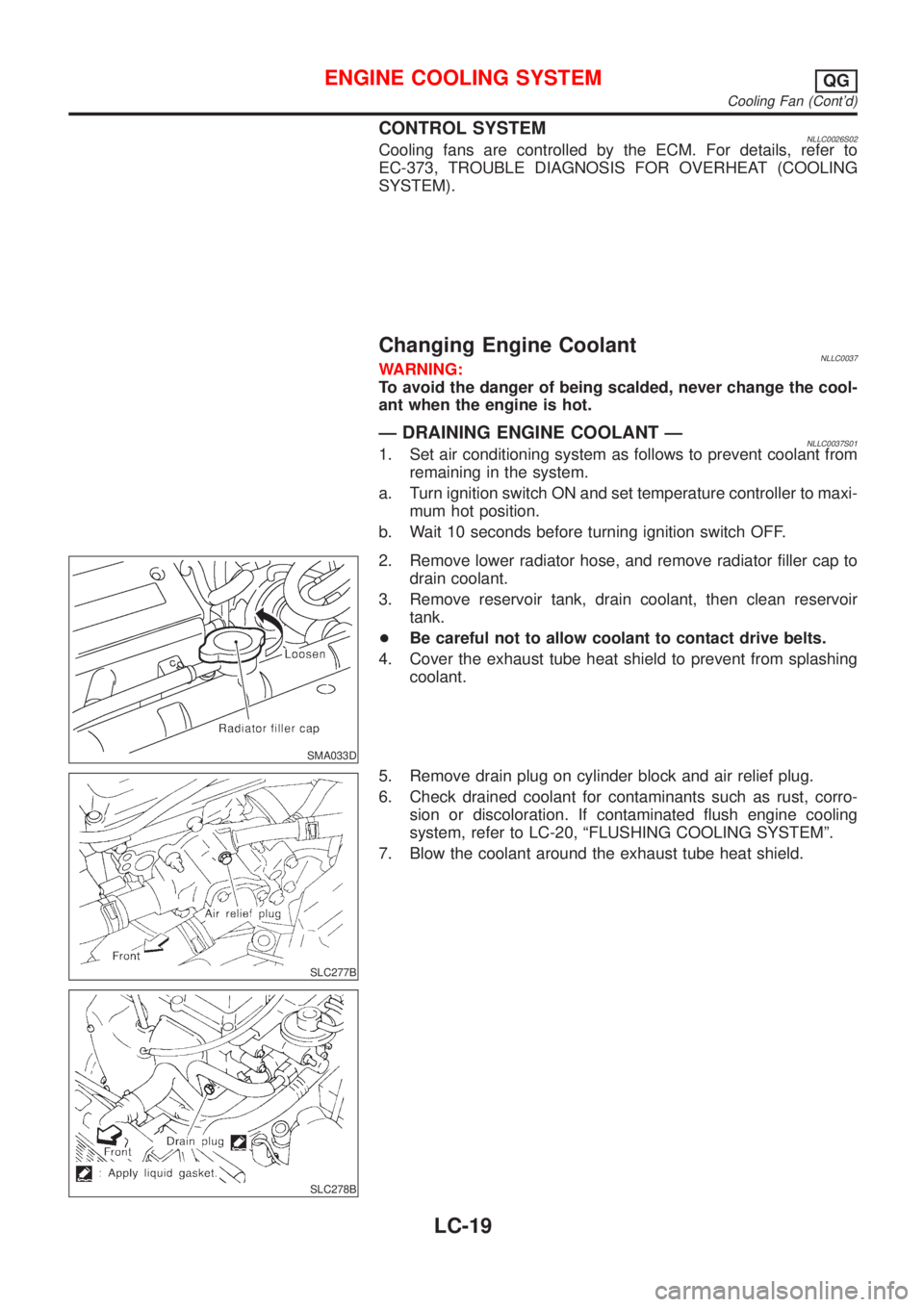

CONTROLSYSTEM

SMA033D

SLC277B

SLC278B

Cooling Fan (Cont'd)

Page 2723 of 3051

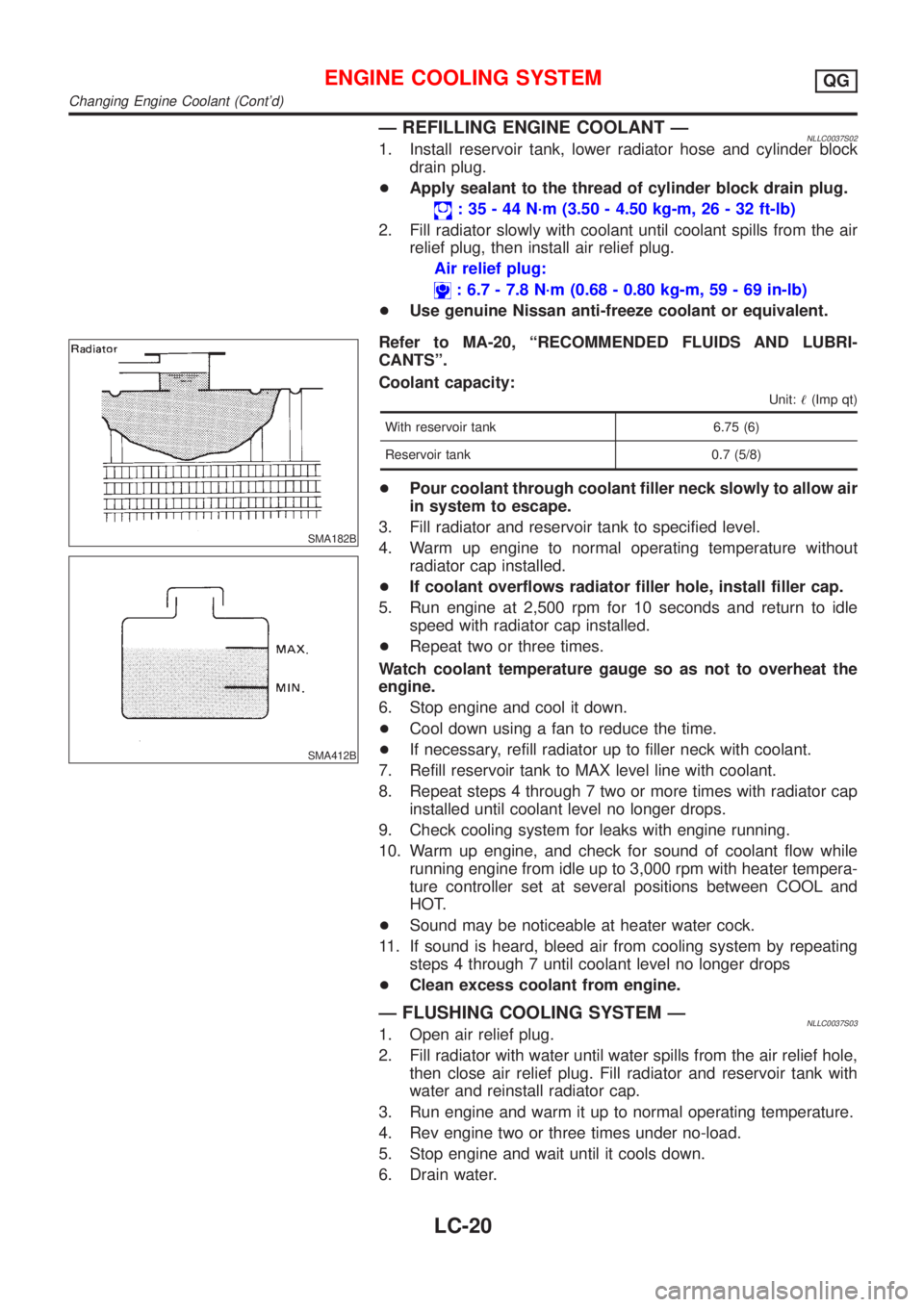

Ð REFILLING ENGINE COOLANT ÐNLLC0037S021. Install reservoir tank, lower radiator hose and cylinder block

drain plug.

+Apply sealant to the thread of cylinder block drain plug.

: 35 - 44 N´m (3.50 - 4.50 kg-m, 26 - 32 ft-lb)

2. Fill radiator slowly with coolant until coolant spills from the air

relief plug, then install air relief plug.

Air relief plug:

: 6.7 - 7.8 N´m (0.68 - 0.80 kg-m, 59 - 69 in-lb)

+Use genuine Nissan anti-freeze coolant or equivalent.

SMA182B

SMA412B

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Coolant capacity:

Unit:!(Imp qt)

With reservoir tank 6.75 (6)

Reservoir tank 0.7 (5/8)

+Pour coolant through coolant filler neck slowly to allow air

in system to escape.

3. Fill radiator and reservoir tank to specified level.

4. Warm up engine to normal operating temperature without

radiator cap installed.

+If coolant overflows radiator filler hole, install filler cap.

5. Run engine at 2,500 rpm for 10 seconds and return to idle

speed with radiator cap installed.

+Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

6. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

+If necessary, refill radiator up to filler neck with coolant.

7. Refill reservoir tank to MAX level line with coolant.

8. Repeat steps 4 through 7 two or more times with radiator cap

installed until coolant level no longer drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater tempera-

ture controller set at several positions between COOL and

HOT.

+Sound may be noticeable at heater water cock.

11. If sound is heard, bleed air from cooling system by repeating

steps 4 through 7 until coolant level no longer drops

+Clean excess coolant from engine.

Ð FLUSHING COOLING SYSTEM ÐNLLC0037S031. Open air relief plug.

2. Fill radiator with water until water spills from the air relief hole,

then close air relief plug. Fill radiator and reservoir tank with

water and reinstall radiator cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

ENGINE COOLING SYSTEMQG

Changing Engine Coolant (Cont'd)

LC-20

Page 2724 of 3051

7. Repeat steps 1 through 6 until clear water begins to drain from

radiator.

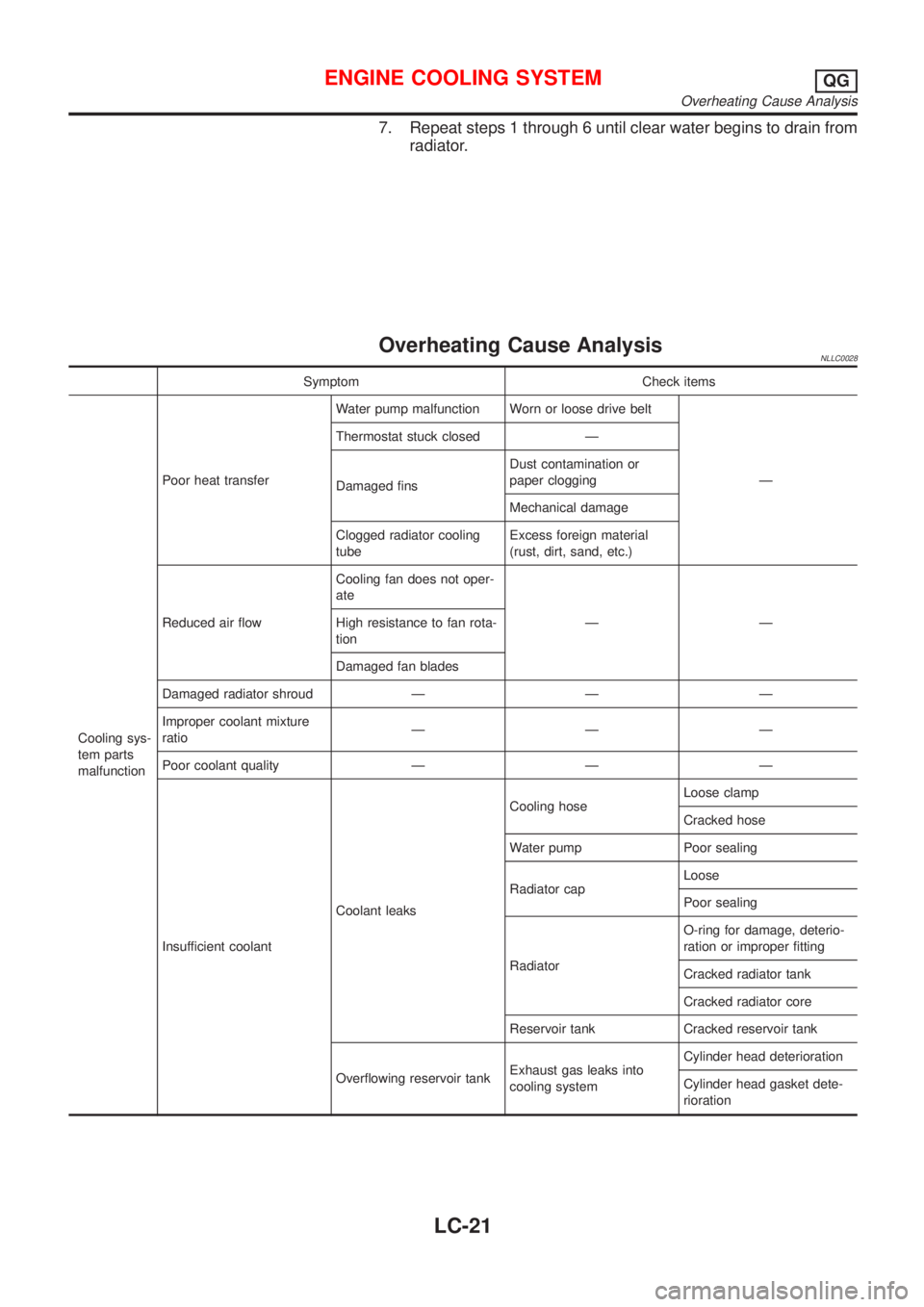

Overheating Cause AnalysisNLLC0028

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis

LC-21

Page 2725 of 3051

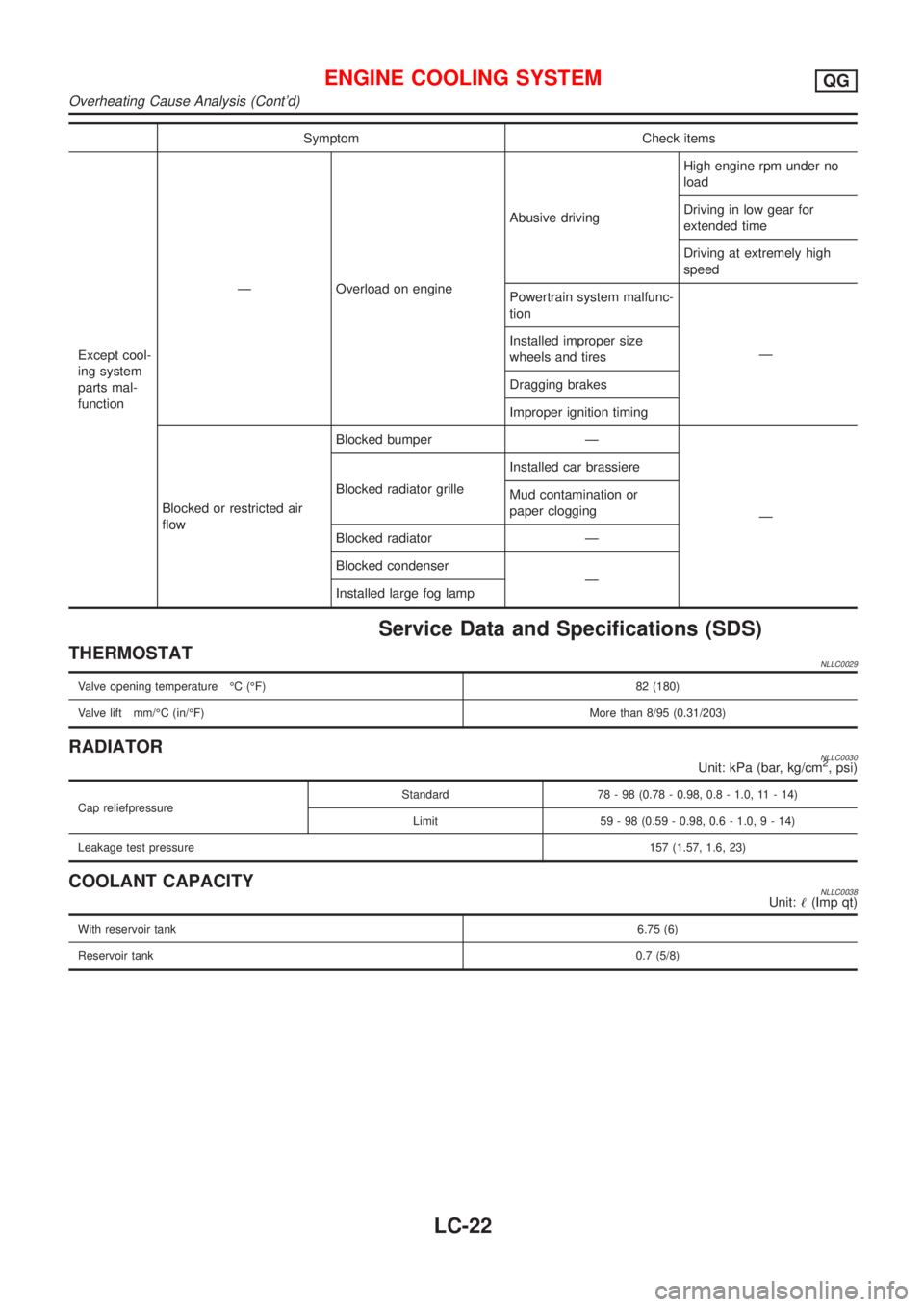

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNLLC0029

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/95 (0.31/203)

RADIATORNLLC0030Unit: kPa (bar, kg/cm2, psi)

Cap reliefpressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

COOLANT CAPACITYNLLC0038Unit:!(Imp qt)

With reservoir tank6.75 (6)

Reservoir tank0.7 (5/8)

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis (Cont'd)

LC-22

Page 2726 of 3051

SEM164F

AEM080

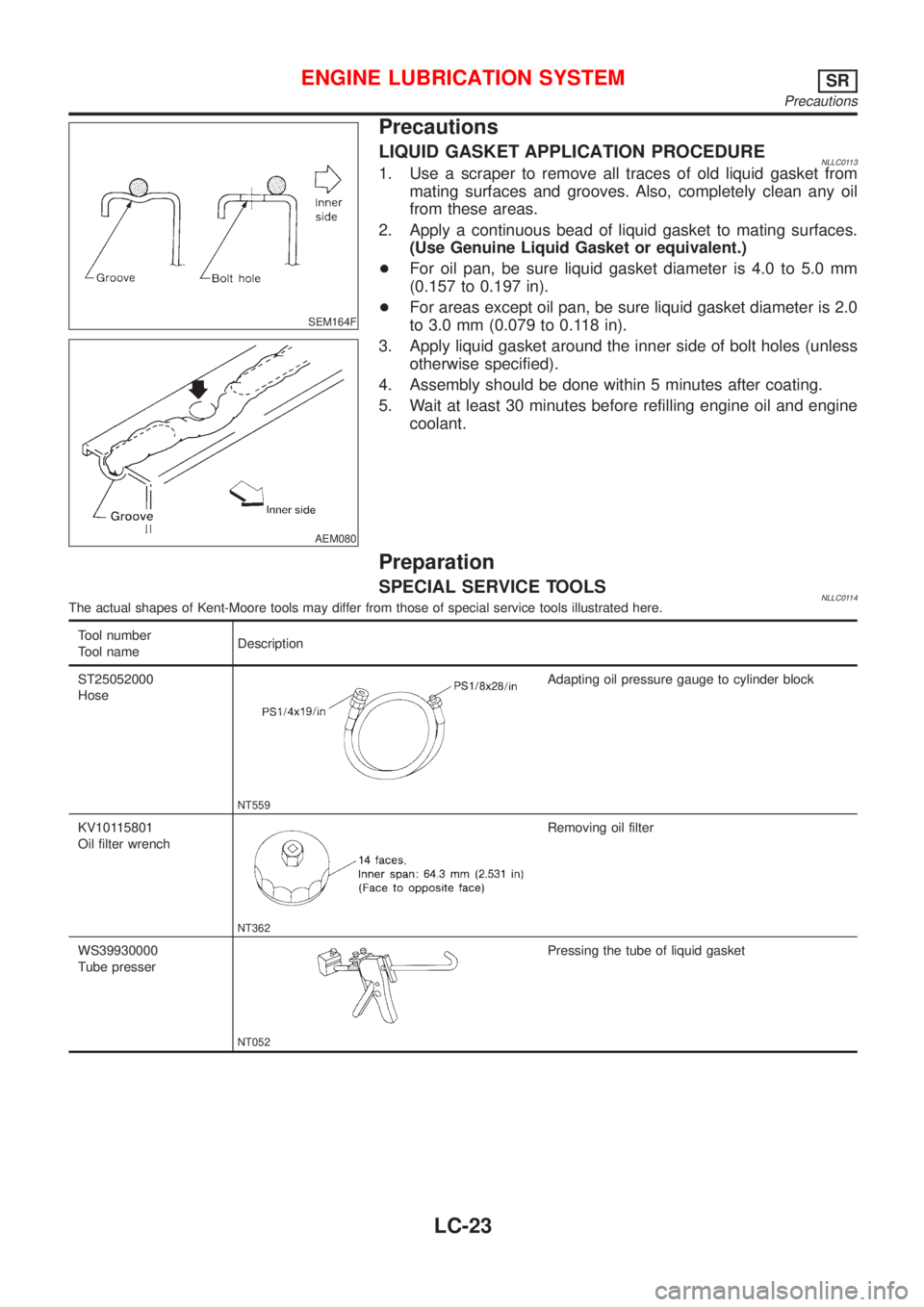

Precautions

LIQUID GASKET APPLICATION PROCEDURENLLC01131. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 4.0 to 5.0 mm

(0.157 to 0.197 in).

+For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

Preparation

SPECIAL SERVICE TOOLSNLLC0114The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

Tool nameDescription

ST25052000

Hose

NT559

Adapting oil pressure gauge to cylinder block

KV10115801

Oil filter wrench

NT362

Removing oil filter

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

ENGINE LUBRICATION SYSTEMSR

Precautions

LC-23

Page 2727 of 3051

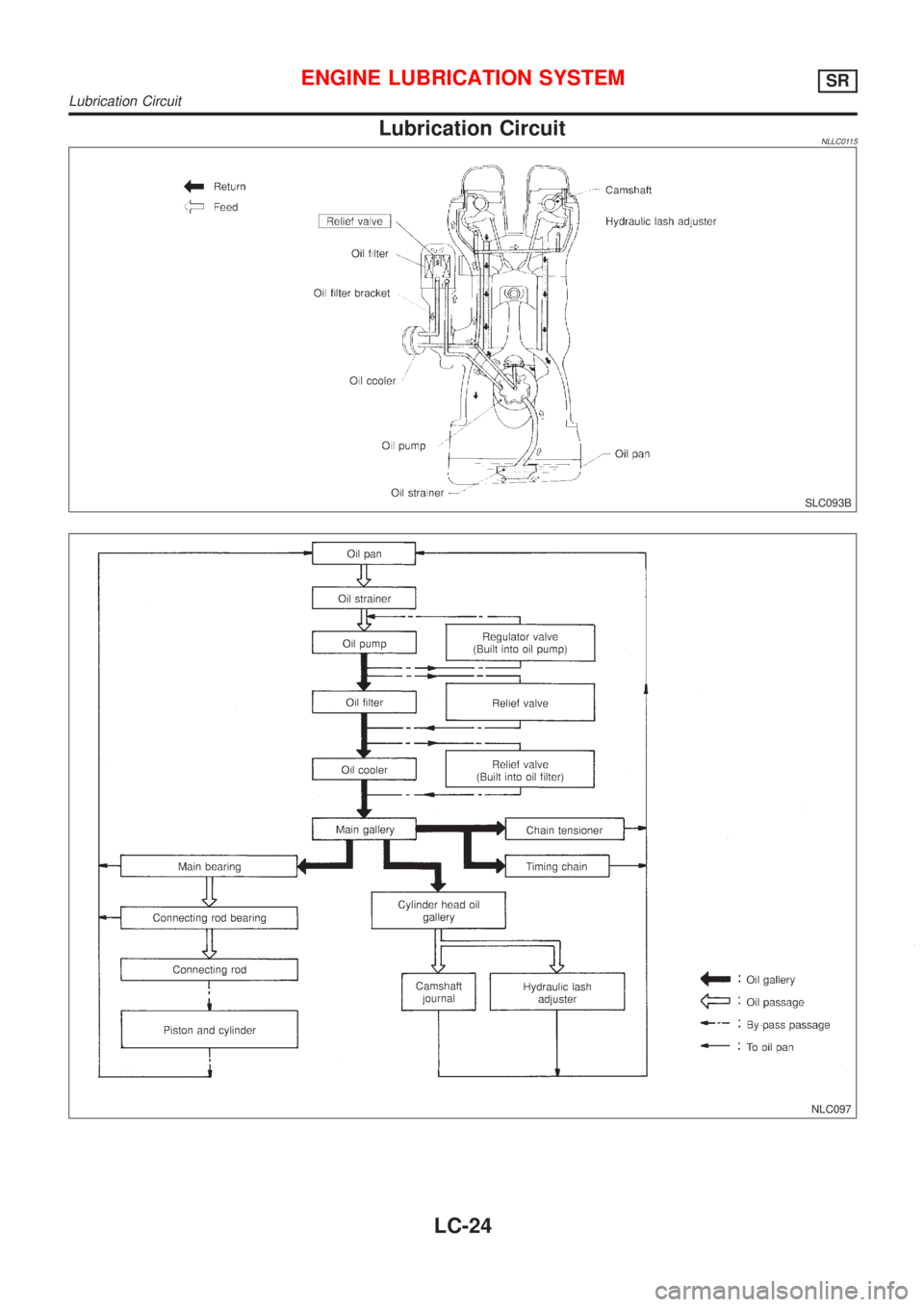

Lubrication CircuitNLLC0115

SLC093B

NLC097

ENGINE LUBRICATION SYSTEMSR

Lubrication Circuit

LC-24

Page 2728 of 3051

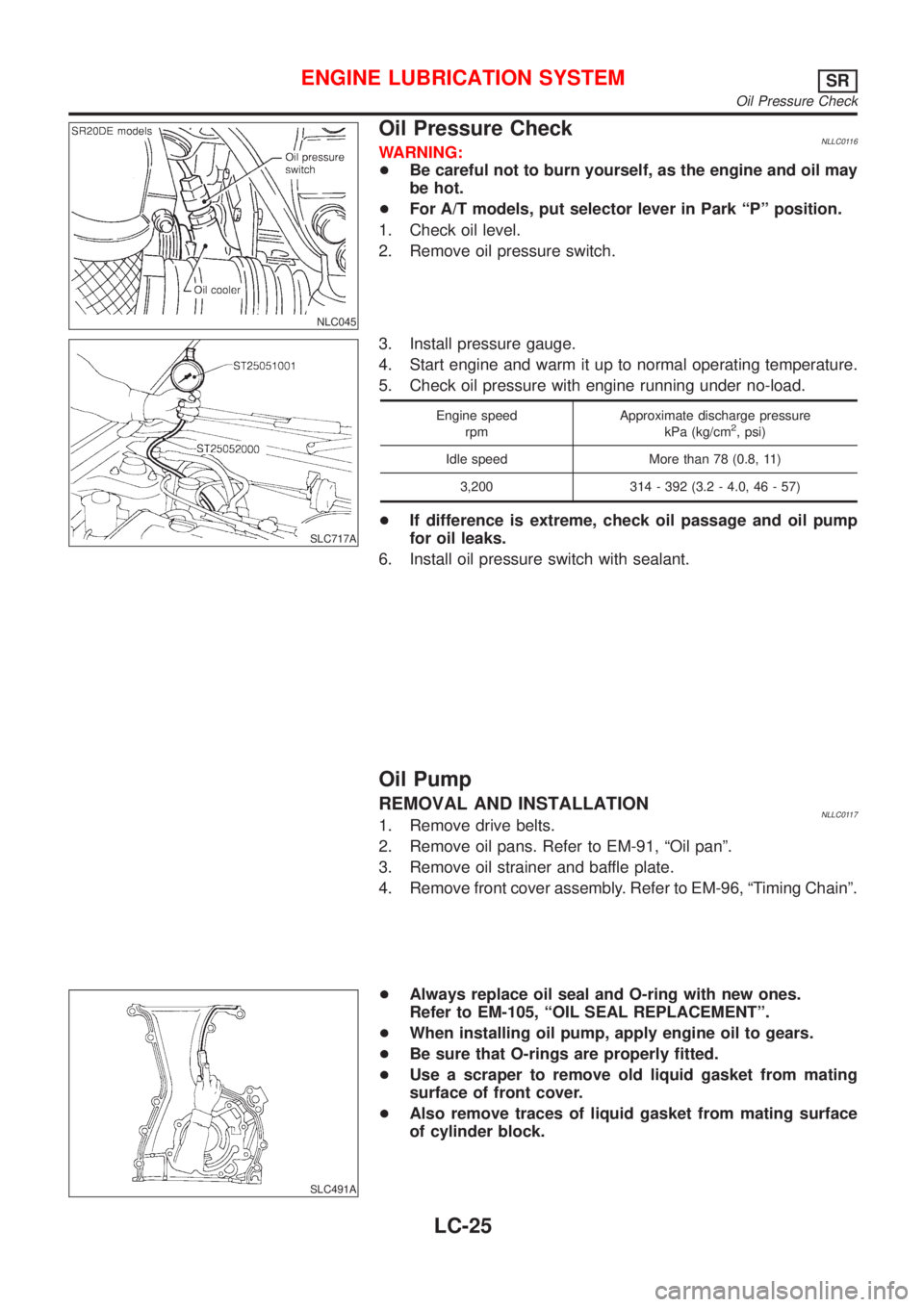

NLC045

Oil Pressure CheckNLLC0116WARNING:

+Be careful not to burn yourself, as the engine and oil may

be hot.

+For A/T models, put selector lever in Park ªPº position.

1. Check oil level.

2. Remove oil pressure switch.

SLC717A

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (kg/cm2, psi)

Idle speed More than 78 (0.8, 11)

3,200 314 - 392 (3.2 - 4.0, 46 - 57)

+If difference is extreme, check oil passage and oil pump

for oil leaks.

6. Install oil pressure switch with sealant.

Oil Pump

REMOVAL AND INSTALLATIONNLLC01171. Remove drive belts.

2. Remove oil pans. Refer to EM-91, ªOil panº.

3. Remove oil strainer and baffle plate.

4. Remove front cover assembly. Refer to EM-96, ªTiming Chainº.

SLC491A

+Always replace oil seal and O-ring with new ones.

Refer to EM-105, ªOIL SEAL REPLACEMENTº.

+When installing oil pump, apply engine oil to gears.

+Be sure that O-rings are properly fitted.

+Use a scraper to remove old liquid gasket from mating

surface of front cover.

+Also remove traces of liquid gasket from mating surface

of cylinder block.

ENGINE LUBRICATION SYSTEMSR

Oil Pressure Check

LC-25

Page 2729 of 3051

SLC492AA

5. Apply a continuous bead of liquid gasket to mating surface of

front cover assembly.

+Use Genuine Liquid Gasket or equivalent.

6. Installation is in the reverse order of removal.

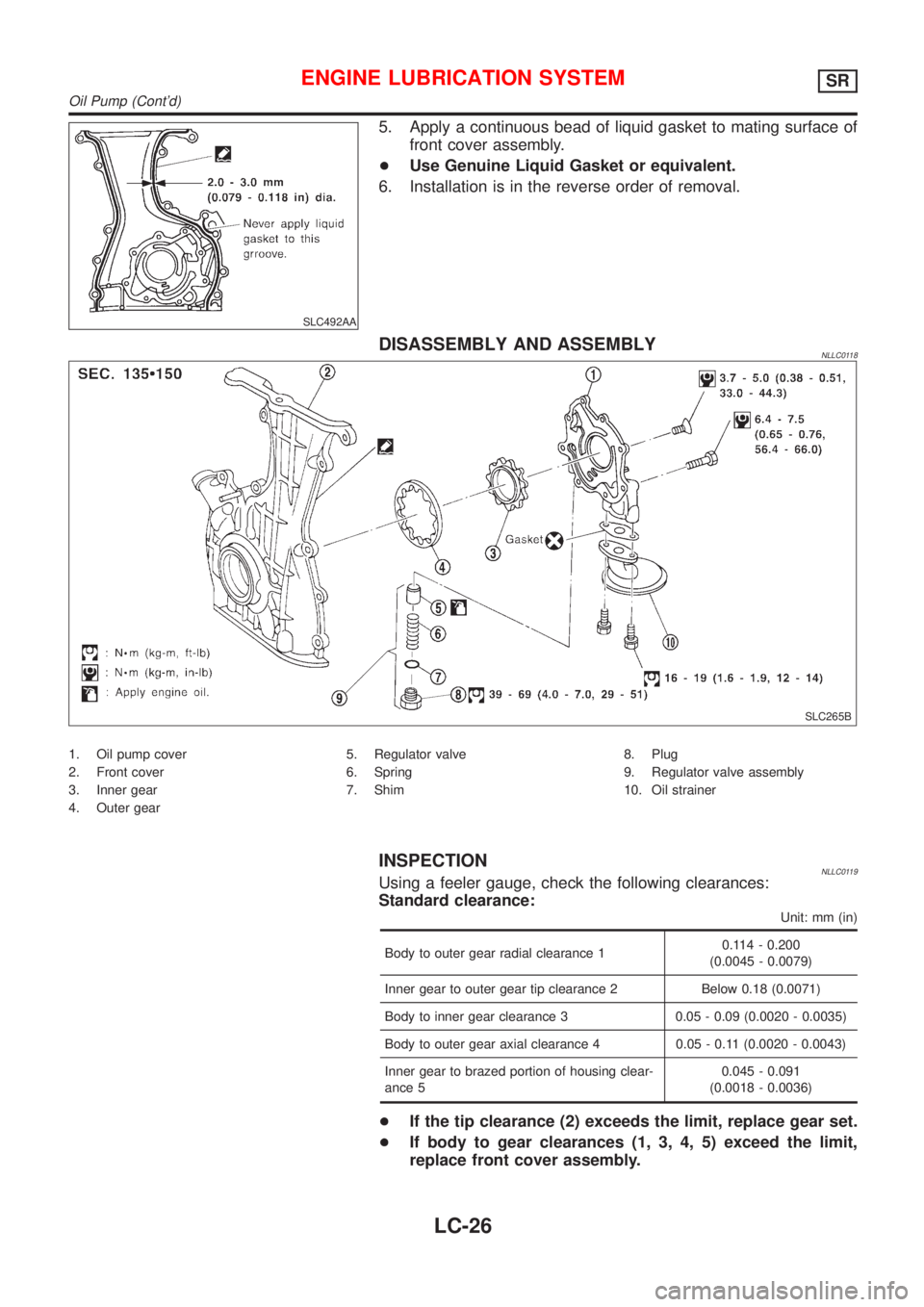

DISASSEMBLY AND ASSEMBLYNLLC0118

SLC265B

1. Oil pump cover

2. Front cover

3. Inner gear

4. Outer gear5. Regulator valve

6. Spring

7. Shim8. Plug

9. Regulator valve assembly

10. Oil strainer

INSPECTIONNLLC0119Using a feeler gauge, check the following clearances:

Standard clearance:

Unit: mm (in)

Body to outer gear radial clearance 10.114 - 0.200

(0.0045 - 0.0079)

Inner gear to outer gear tip clearance 2 Below 0.18 (0.0071)

Body to inner gear clearance 3 0.05 - 0.09 (0.0020 - 0.0035)

Body to outer gear axial clearance 4 0.05 - 0.11 (0.0020 - 0.0043)

Inner gear to brazed portion of housing clear-

ance 50.045 - 0.091

(0.0018 - 0.0036)

+If the tip clearance (2) exceeds the limit, replace gear set.

+If body to gear clearances (1, 3, 4, 5) exceed the limit,

replace front cover assembly.

ENGINE LUBRICATION SYSTEMSR

Oil Pump (Cont'd)

LC-26

Page 2730 of 3051

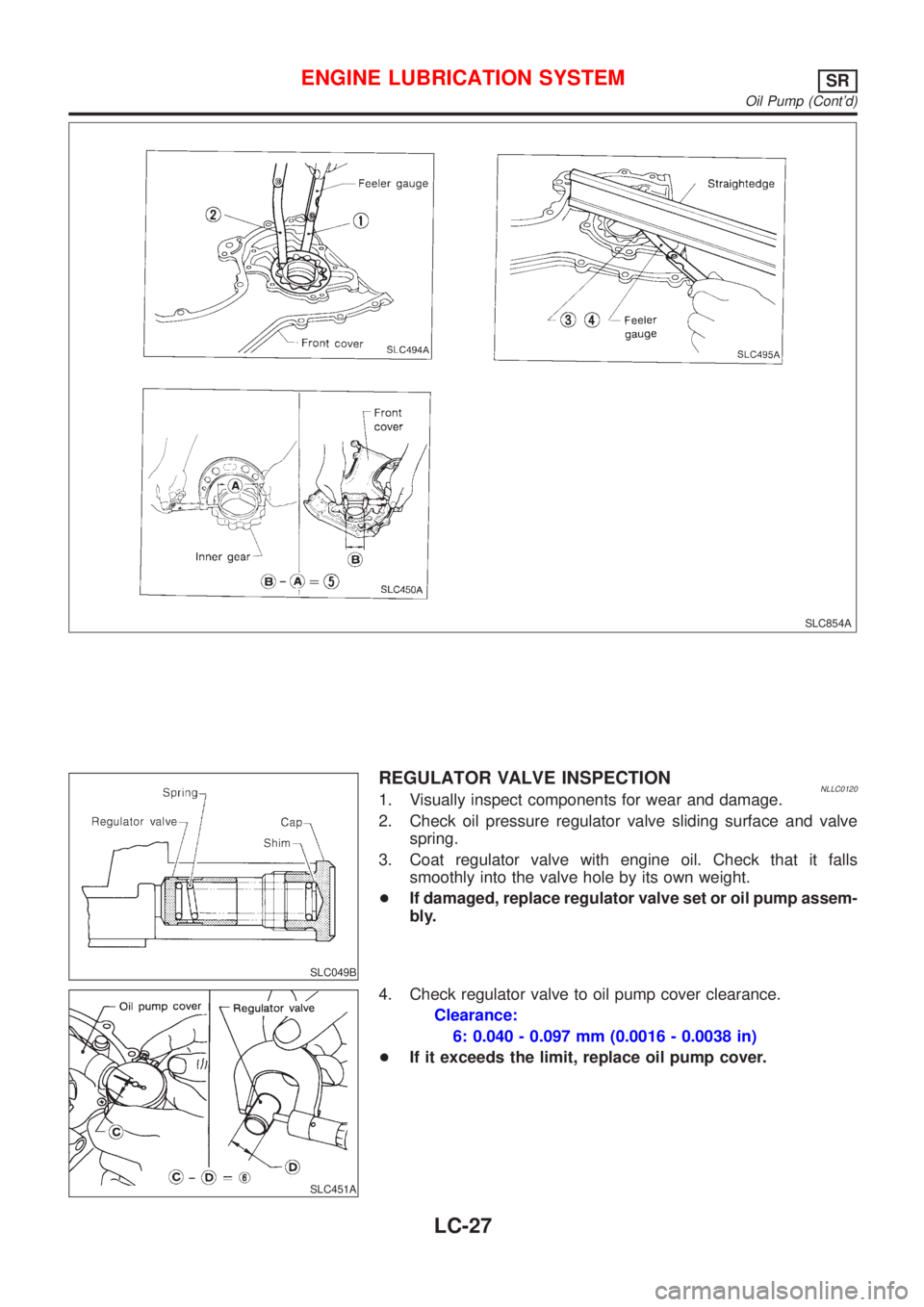

SLC854A

SLC049B

REGULATOR VALVE INSPECTIONNLLC01201. Visually inspect components for wear and damage.

2. Check oil pressure regulator valve sliding surface and valve

spring.

3. Coat regulator valve with engine oil. Check that it falls

smoothly into the valve hole by its own weight.

+If damaged, replace regulator valve set or oil pump assem-

bly.

SLC451A

4. Check regulator valve to oil pump cover clearance.

Clearance:

6: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

+If it exceeds the limit, replace oil pump cover.

ENGINE LUBRICATION SYSTEMSR

Oil Pump (Cont'd)

LC-27