NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: exhaust manifold, fuse box diagram, audio, bulb, oil viscosity, gas mileage, service schedule

Page 2981 of 3051

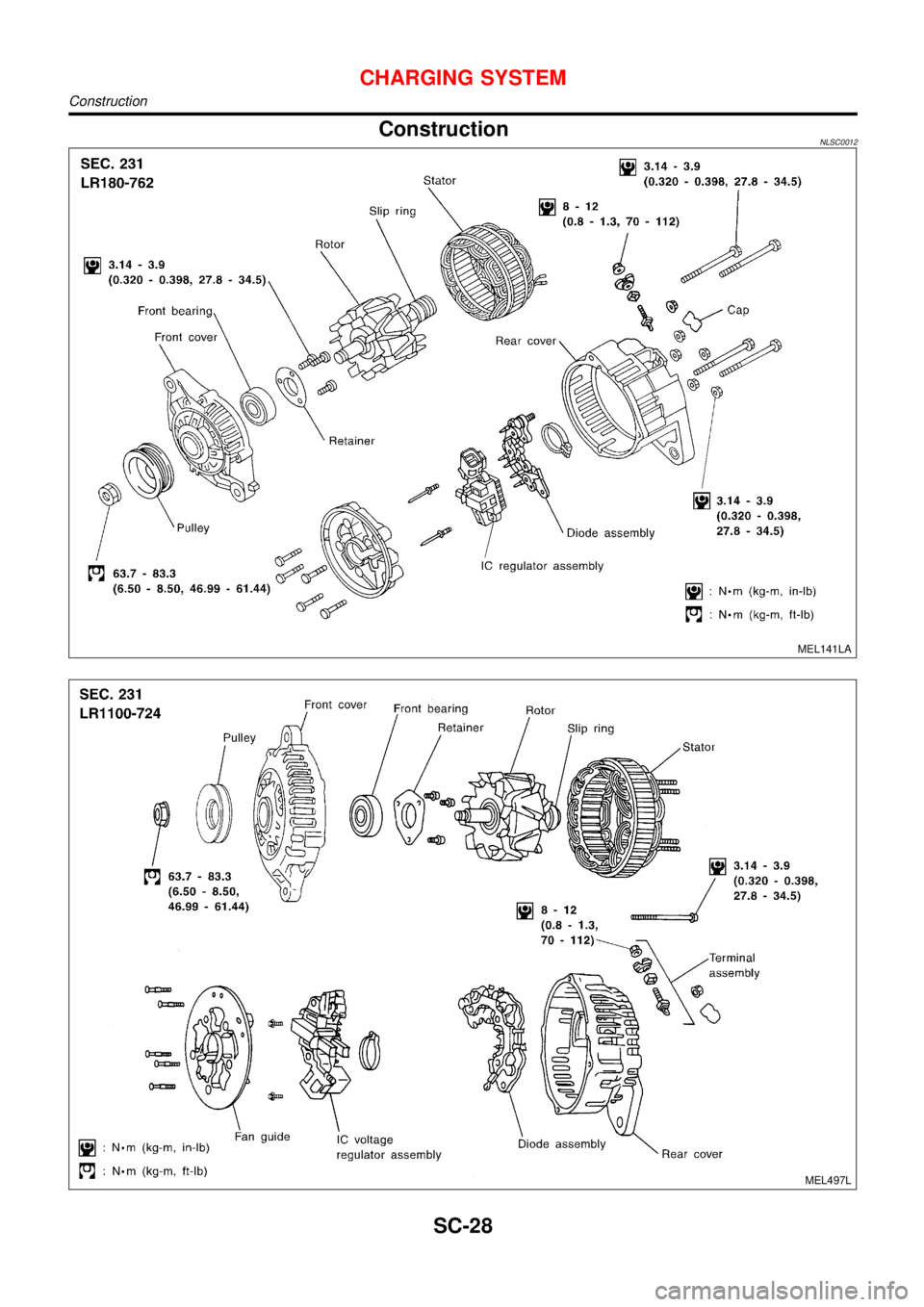

NEL644

INSTALLATIONNLSC0007S02To install, reverse the removal procedure.

MEL138L

InspectionNLSC0019MAGNETIC SWITCH CHECKNLSC0019S01+Before starting to check, disconnect battery ground cable.

+Disconnect“M”terminal of starter motor.

1. Continuity test (between“S”terminal and switch body).

+No continuity ... Replace.

2. Continuity test (between“S”terminal and“M”terminal).

+No continuity ... Replace.

MEL139L

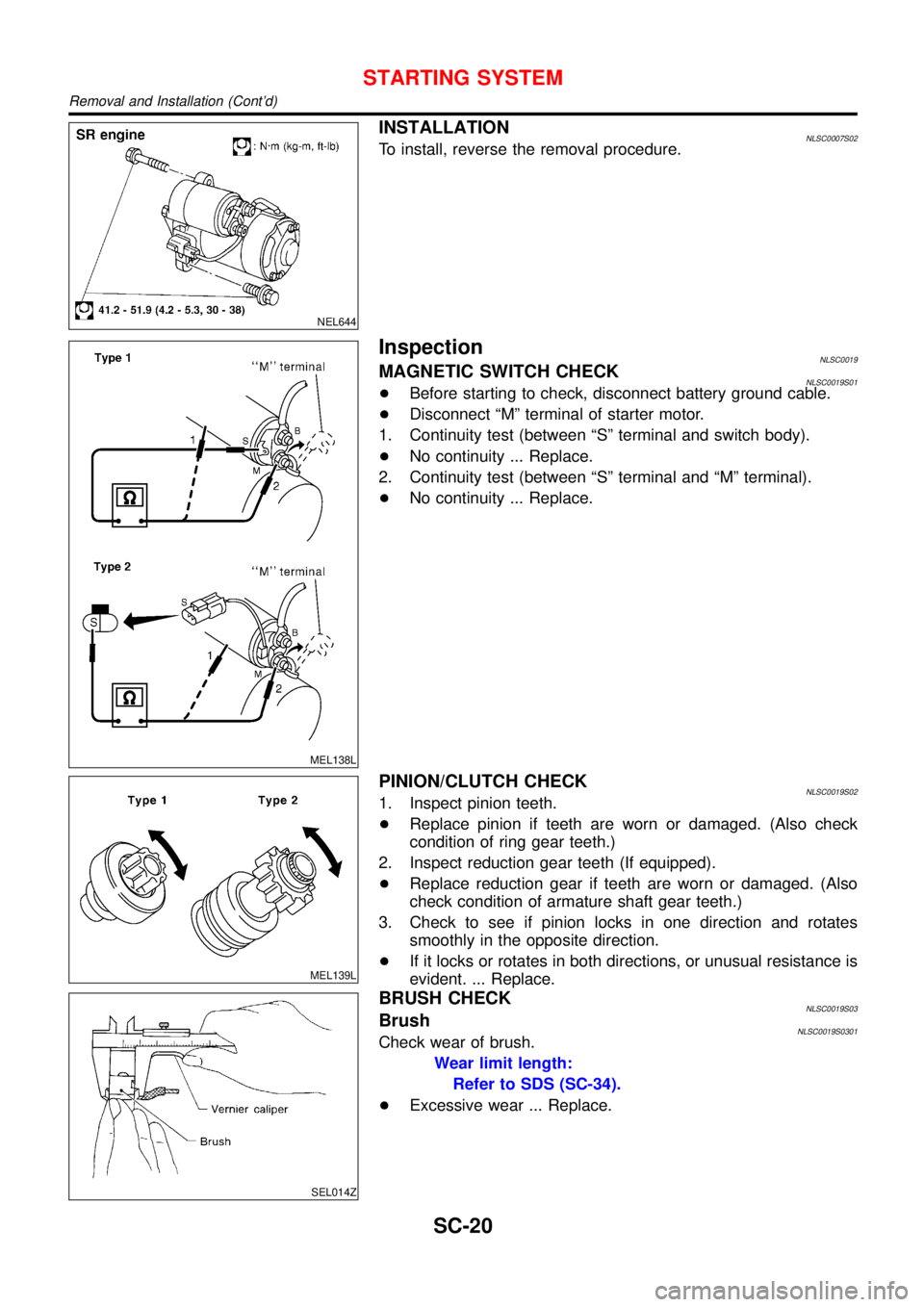

PINION/CLUTCH CHECKNLSC0019S021. Inspect pinion teeth.

+Replace pinion if teeth are worn or damaged. (Also check

condition of ring gear teeth.)

2. Inspect reduction gear teeth (If equipped).

+Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

+If it locks or rotates in both directions, or unusual resistance is

evident. ... Replace.

SEL014Z

BRUSH CHECKNLSC0019S03BrushNLSC0019S0301Check wear of brush.

Wear limit length:

Refer to SDS (SC-34).

+Excessive wear ... Replace.

STARTING SYSTEM

Removal and Installation (Cont’d)

SC-20

Page 2982 of 3051

SEL015Z

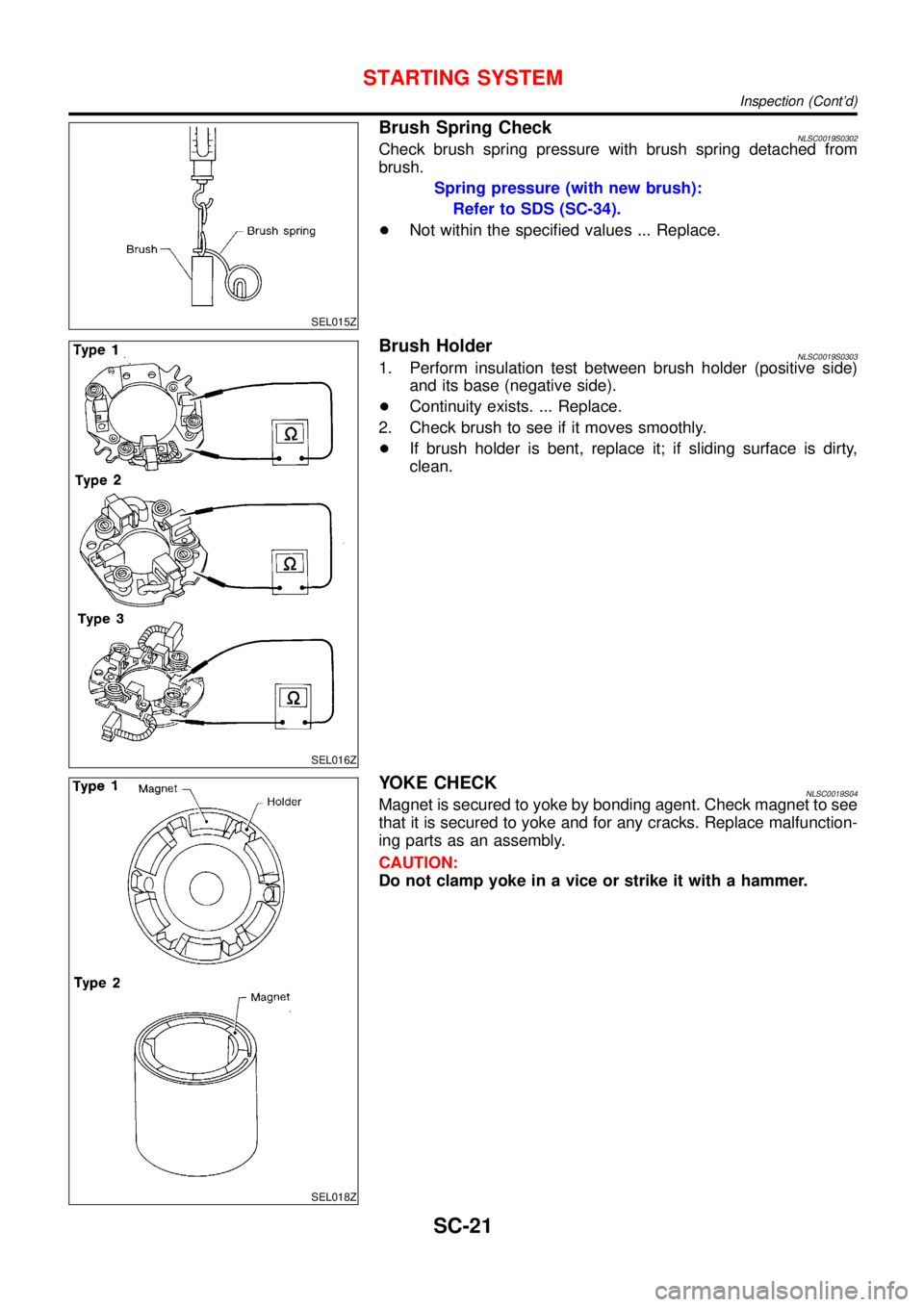

Brush Spring CheckNLSC0019S0302Check brush spring pressure with brush spring detached from

brush.

Spring pressure (with new brush):

Refer to SDS (SC-34).

+Not within the specified values ... Replace.

SEL016Z

Brush HolderNLSC0019S03031. Perform insulation test between brush holder (positive side)

and its base (negative side).

+Continuity exists. ... Replace.

2. Check brush to see if it moves smoothly.

+If brush holder is bent, replace it; if sliding surface is dirty,

clean.

SEL018Z

YOKE CHECKNLSC0019S04Magnet is secured to yoke by bonding agent. Check magnet to see

that it is secured to yoke and for any cracks. Replace malfunction-

ing parts as an assembly.

CAUTION:

Do not clamp yoke in a vice or strike it with a hammer.

STARTING SYSTEM

Inspection (Cont’d)

SC-21

Page 2983 of 3051

SEL019Z

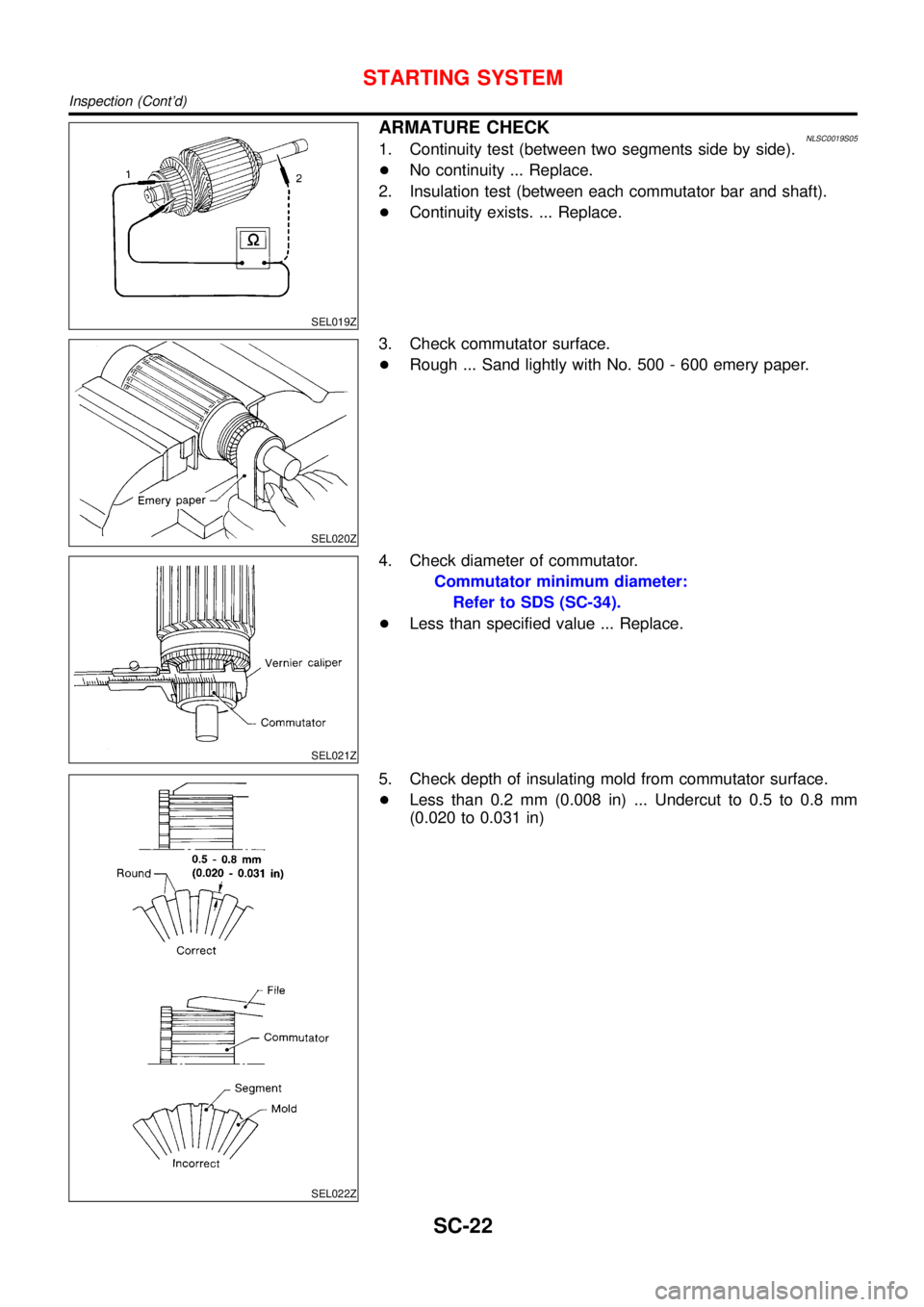

ARMATURE CHECKNLSC0019S051. Continuity test (between two segments side by side).

+No continuity ... Replace.

2. Insulation test (between each commutator bar and shaft).

+Continuity exists. ... Replace.

SEL020Z

3. Check commutator surface.

+Rough ... Sand lightly with No. 500 - 600 emery paper.

SEL021Z

4. Check diameter of commutator.

Commutator minimum diameter:

Refer to SDS (SC-34).

+Less than specified value ... Replace.

SEL022Z

5. Check depth of insulating mold from commutator surface.

+Less than 0.2 mm (0.008 in) ... Undercut to 0.5 to 0.8 mm

(0.020 to 0.031 in)

STARTING SYSTEM

Inspection (Cont’d)

SC-22

Page 2984 of 3051

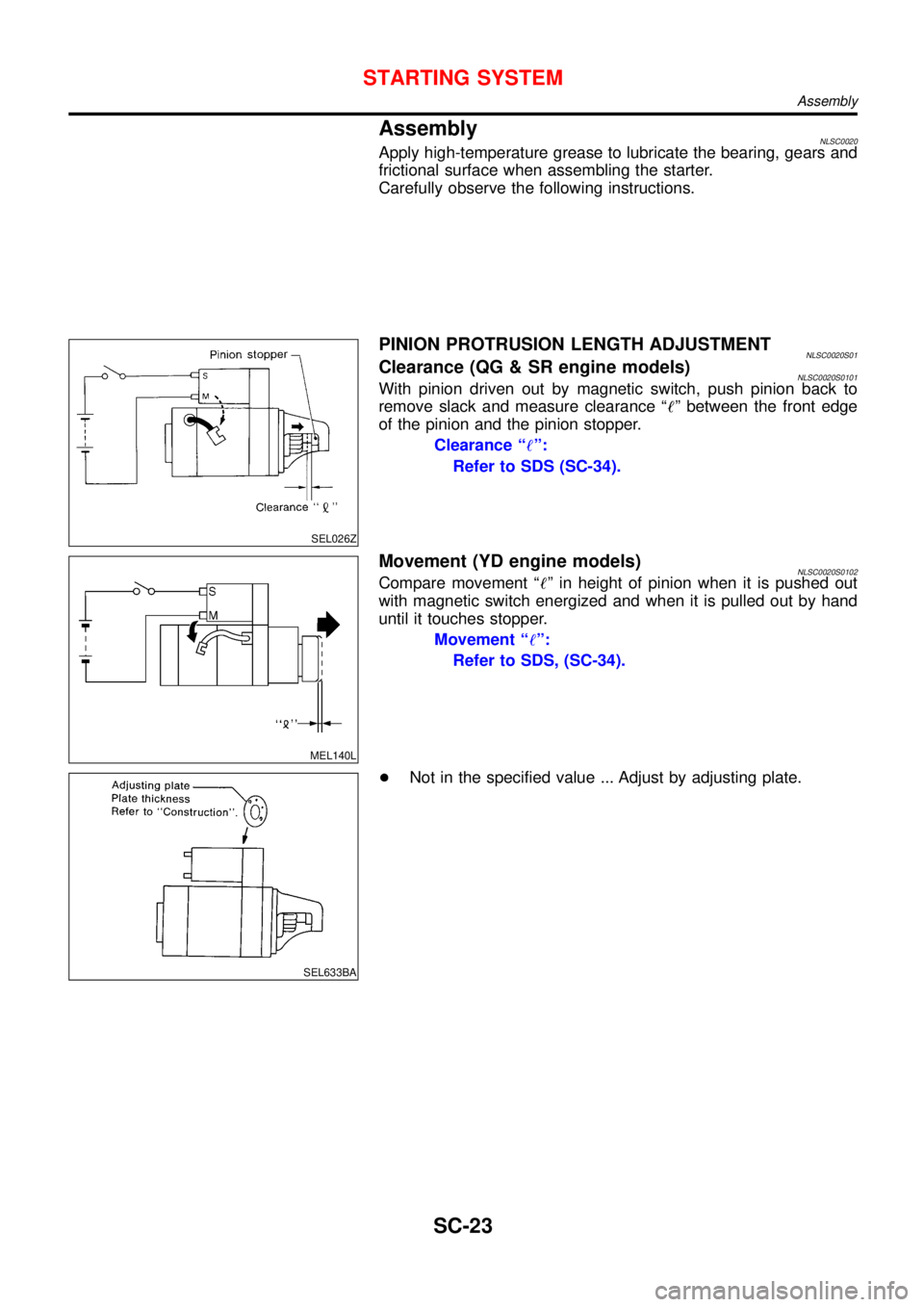

AssemblyNLSC0020Apply high-temperature grease to lubricate the bearing, gears and

frictional surface when assembling the starter.

Carefully observe the following instructions.

SEL026Z

PINION PROTRUSION LENGTH ADJUSTMENTNLSC0020S01Clearance (QG & SR engine models)NLSC0020S0101With pinion driven out by magnetic switch, push pinion back to

remove slack and measure clearance“!”between the front edge

of the pinion and the pinion stopper.

Clearance“!”:

Refer to SDS (SC-34).

MEL140L

Movement (YD engine models)NLSC0020S0102Compare movement“!”in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

Movement“!”:

Refer to SDS, (SC-34).

SEL633BA

+Not in the specified value ... Adjust by adjusting plate.

STARTING SYSTEM

Assembly

SC-23

Page 2985 of 3051

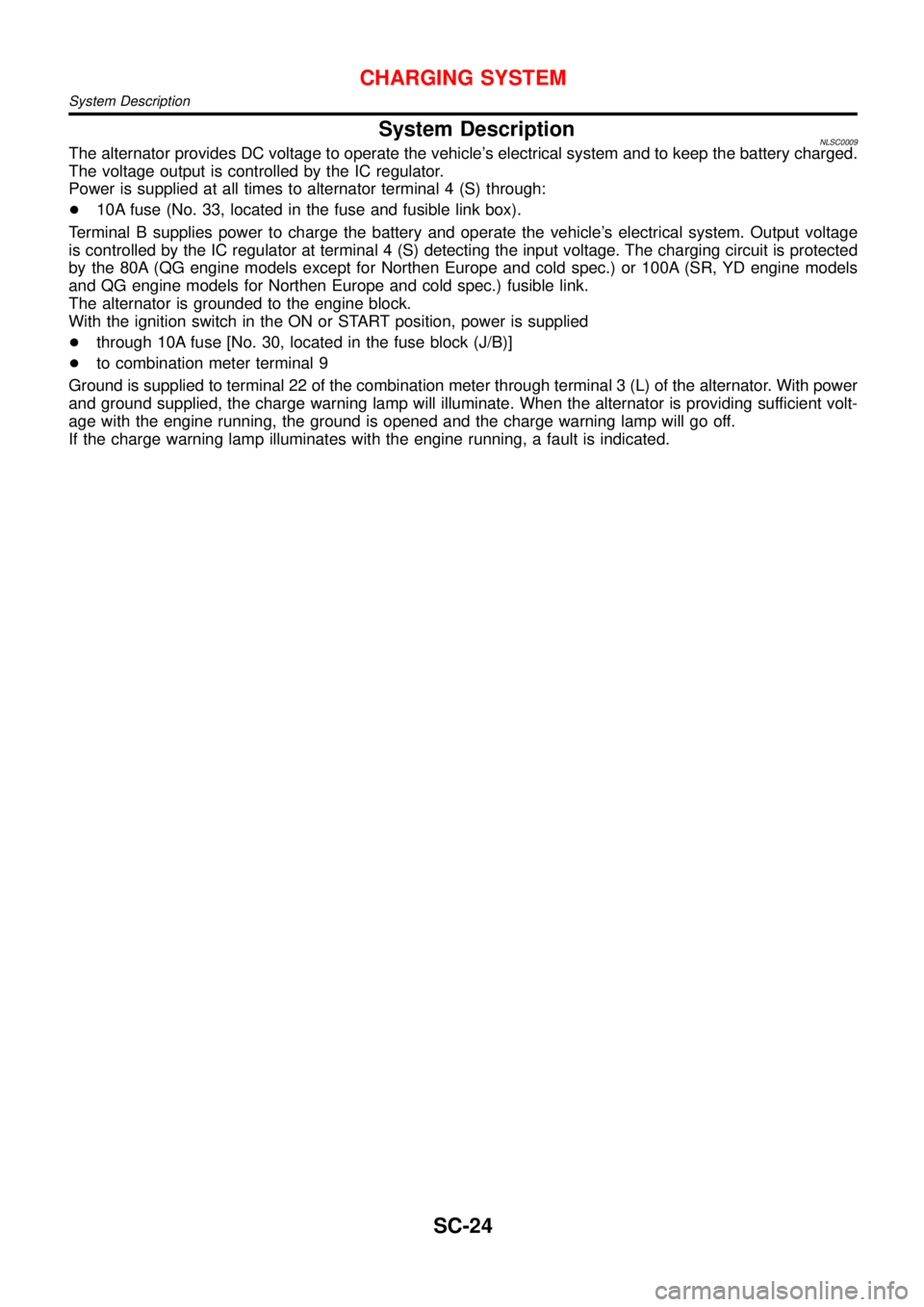

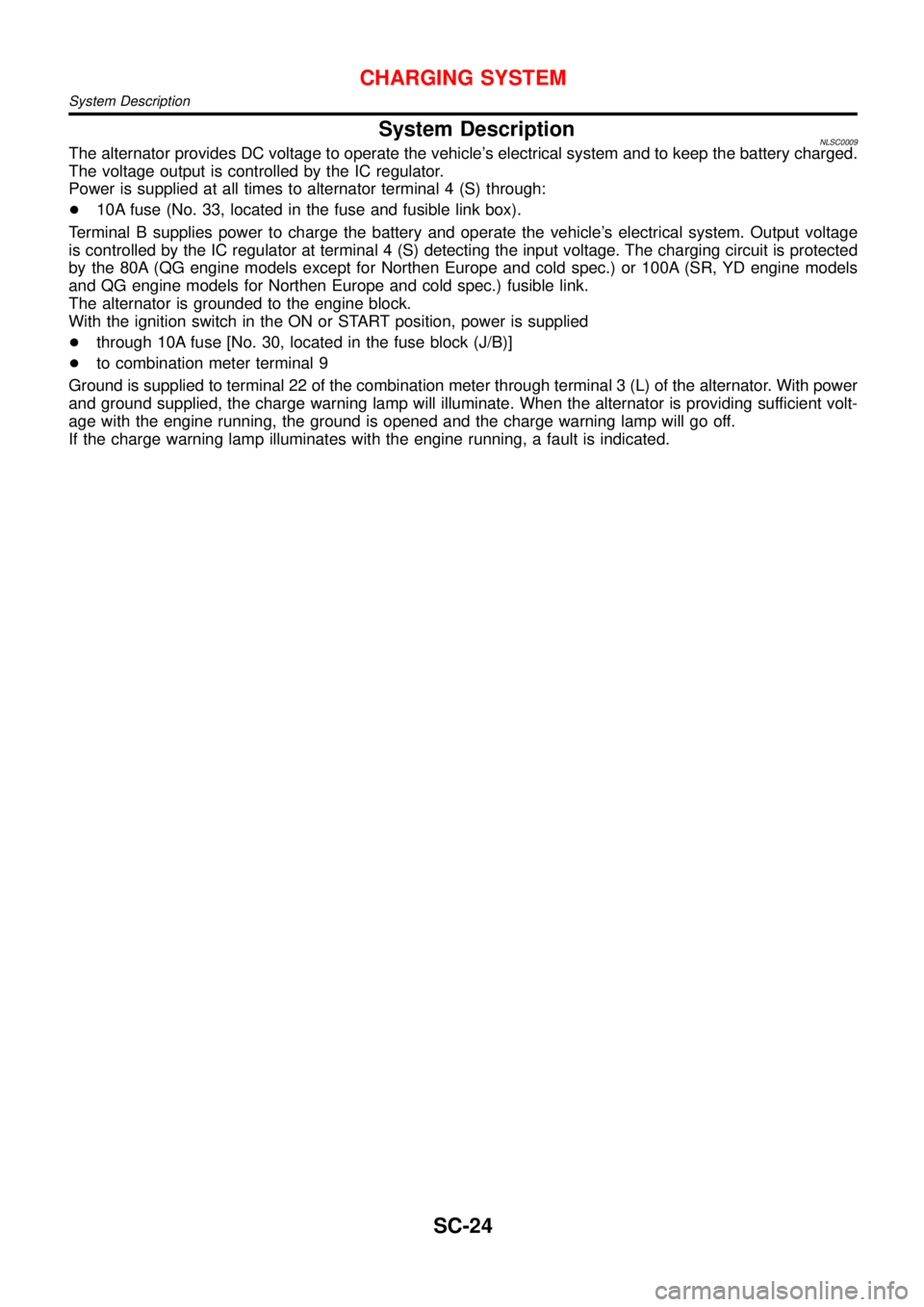

System DescriptionNLSC0009The alternator provides DC voltage to operate the vehicle’s electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle’s electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (QG engine models except for Northen Europe and cold spec.) or 100A (SR, YD engine models

and QG engine models for Northen Europe and cold spec.) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 9

Ground is supplied to terminal 22 of the combination meter through terminal 3 (L) of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

CHARGING SYSTEM

System Description

SC-24

Page 2986 of 3051

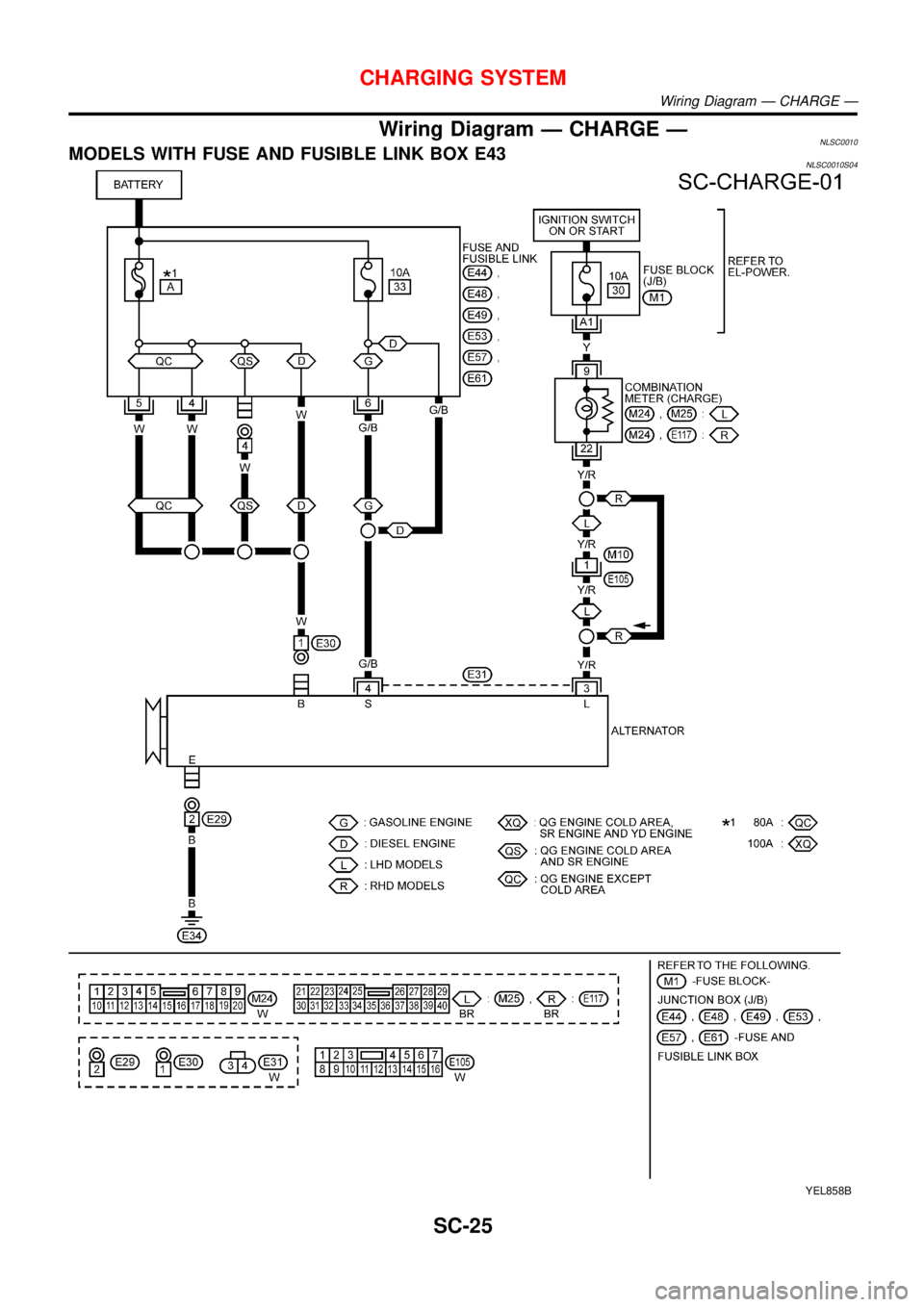

Wiring Diagram—CHARGE—NLSC0010MODELS WITH FUSE AND FUSIBLE LINK BOX E43NLSC0010S04

YEL858B

CHARGING SYSTEM

Wiring Diagram—CHARGE—

SC-25

Page 2987 of 3051

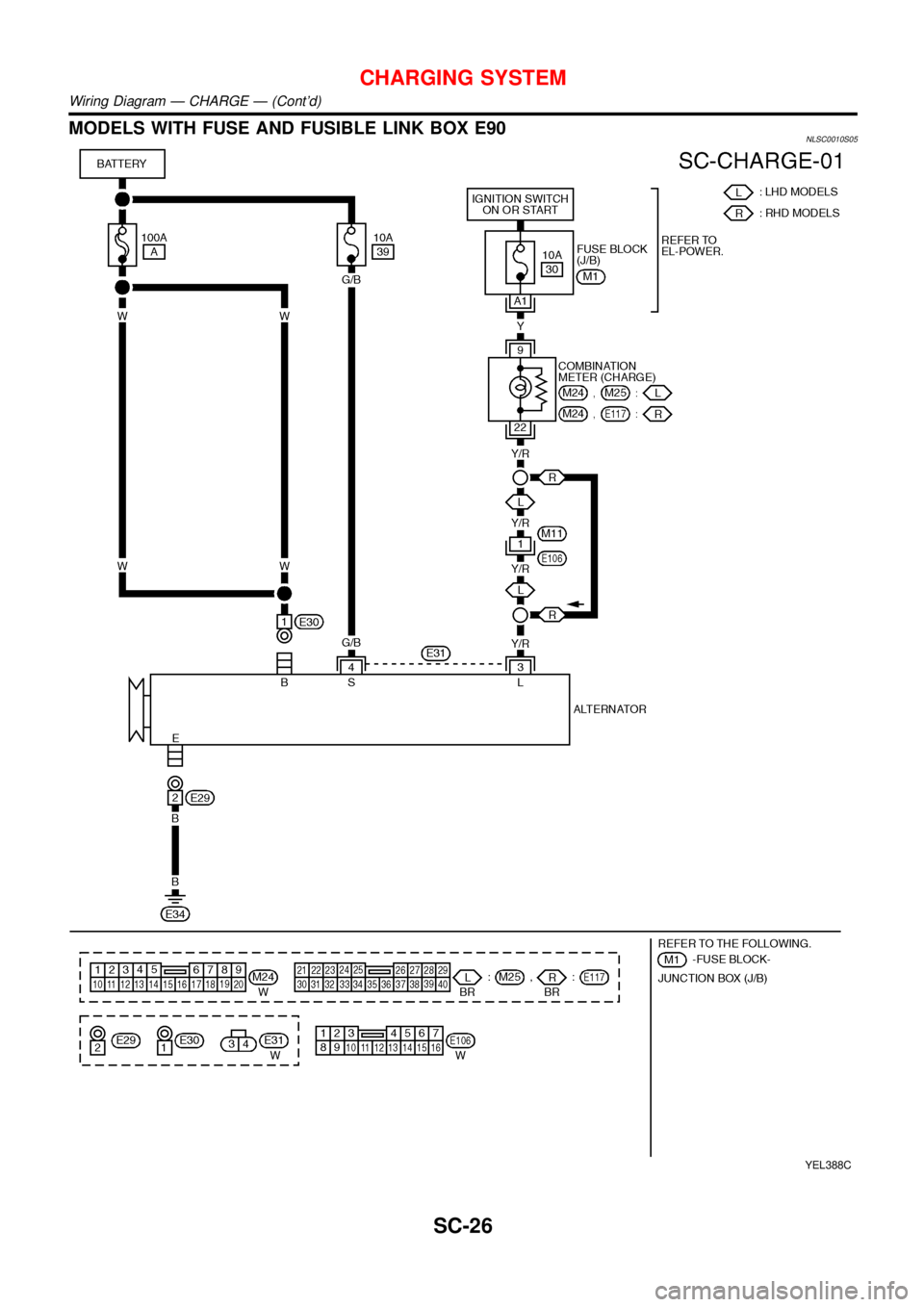

MODELS WITH FUSE AND FUSIBLE LINK BOX E90NLSC0010S05

YEL388C

CHARGING SYSTEM

Wiring Diagram—CHARGE—(Cont’d)

SC-26

Page 2988 of 3051

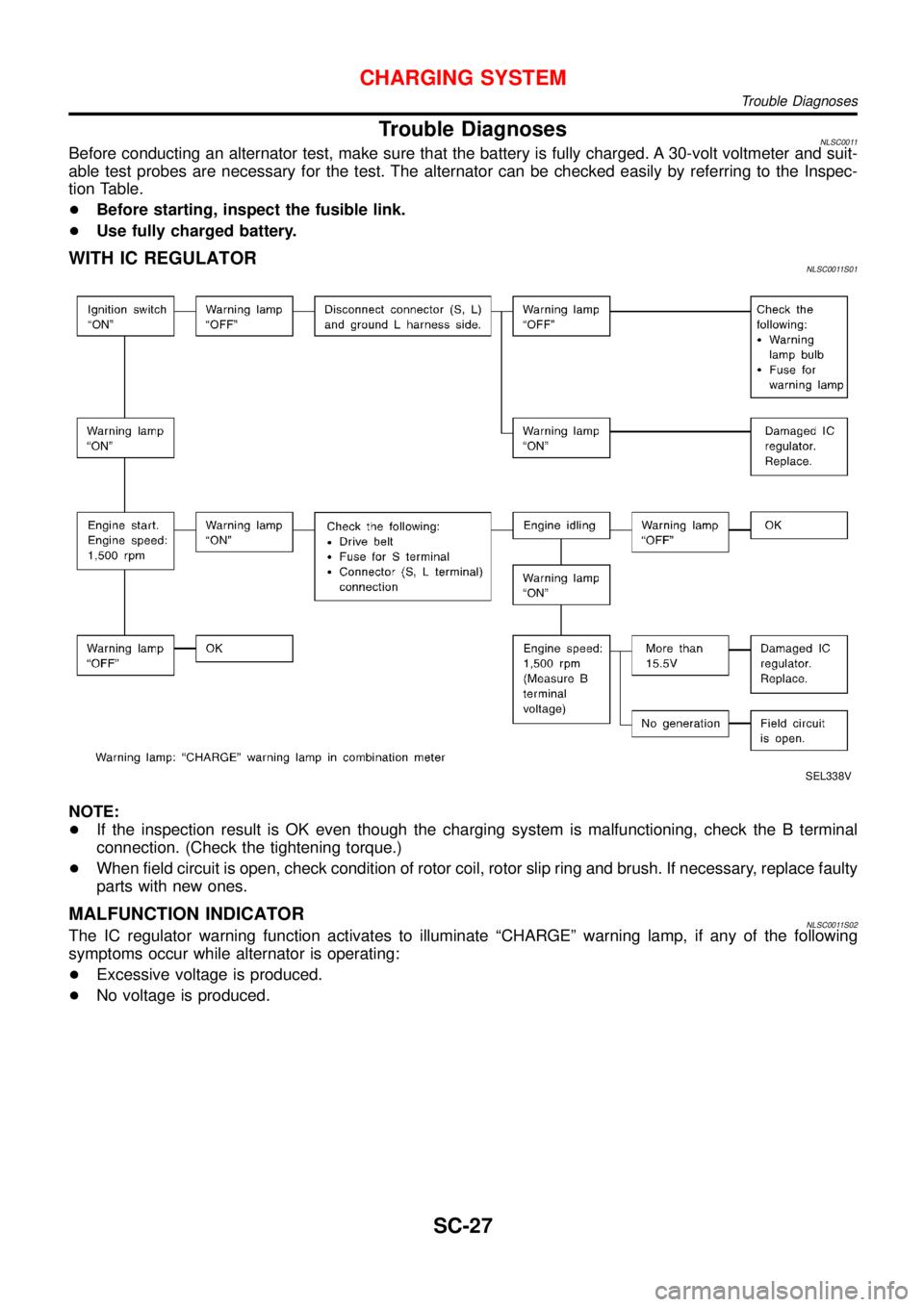

Trouble DiagnosesNLSC0011Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and suit-

able test probes are necessary for the test. The alternator can be checked easily by referring to the Inspec-

tion Table.

+Before starting, inspect the fusible link.

+Use fully charged battery.

WITH IC REGULATORNLSC0011S01

SEL338V

NOTE:

+If the inspection result is OK even though the charging system is malfunctioning, check the B terminal

connection. (Check the tightening torque.)

+When field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary, replace faulty

parts with new ones.

MALFUNCTION INDICATORNLSC0011S02The IC regulator warning function activates to illuminate“CHARGE”warning lamp, if any of the following

symptoms occur while alternator is operating:

+Excessive voltage is produced.

+No voltage is produced.

CHARGING SYSTEM

Trouble Diagnoses

SC-27

Page 2989 of 3051

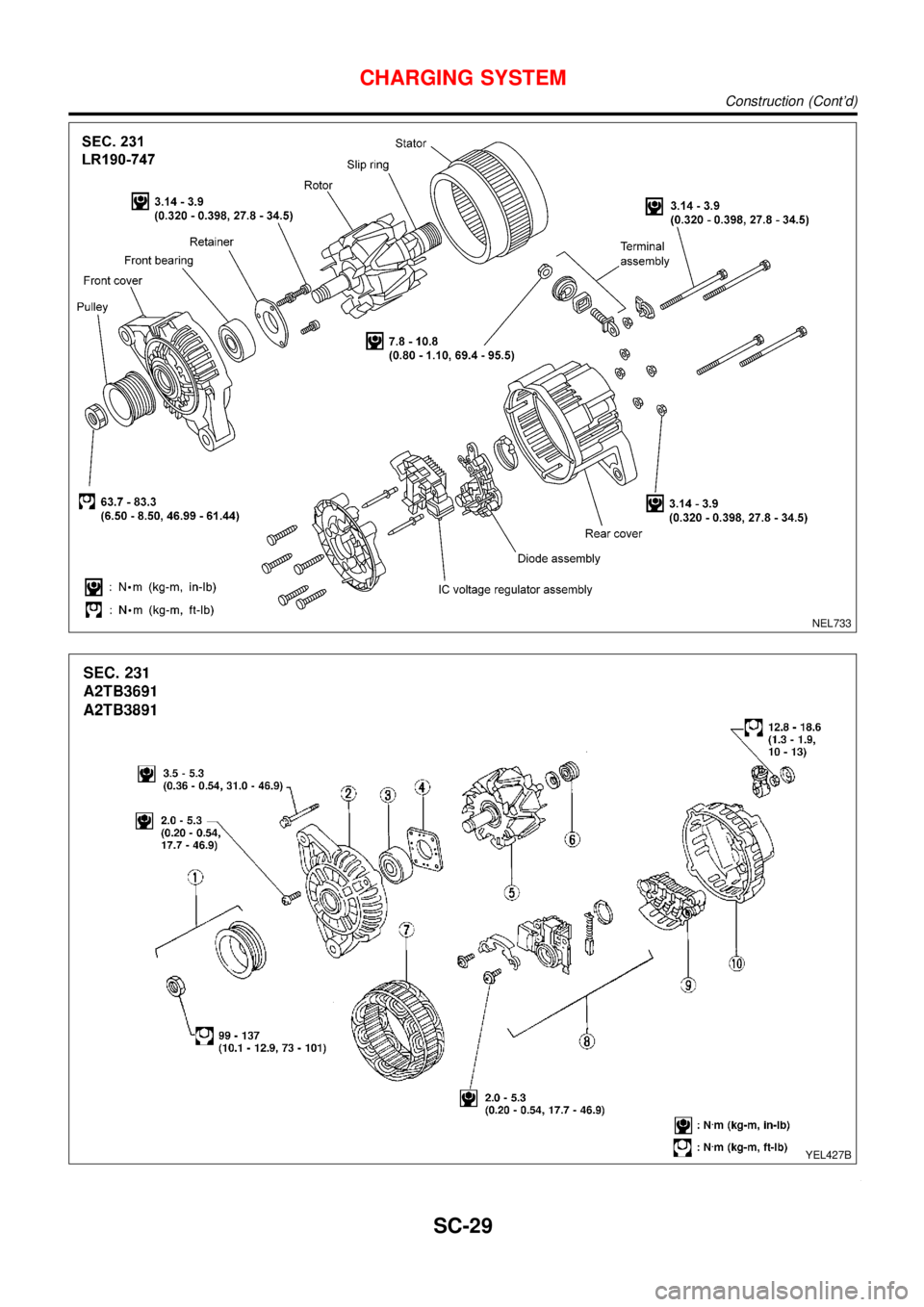

ConstructionNLSC0012

MEL141LA

MEL497L

CHARGING SYSTEM

Construction

SC-28

Page 2990 of 3051

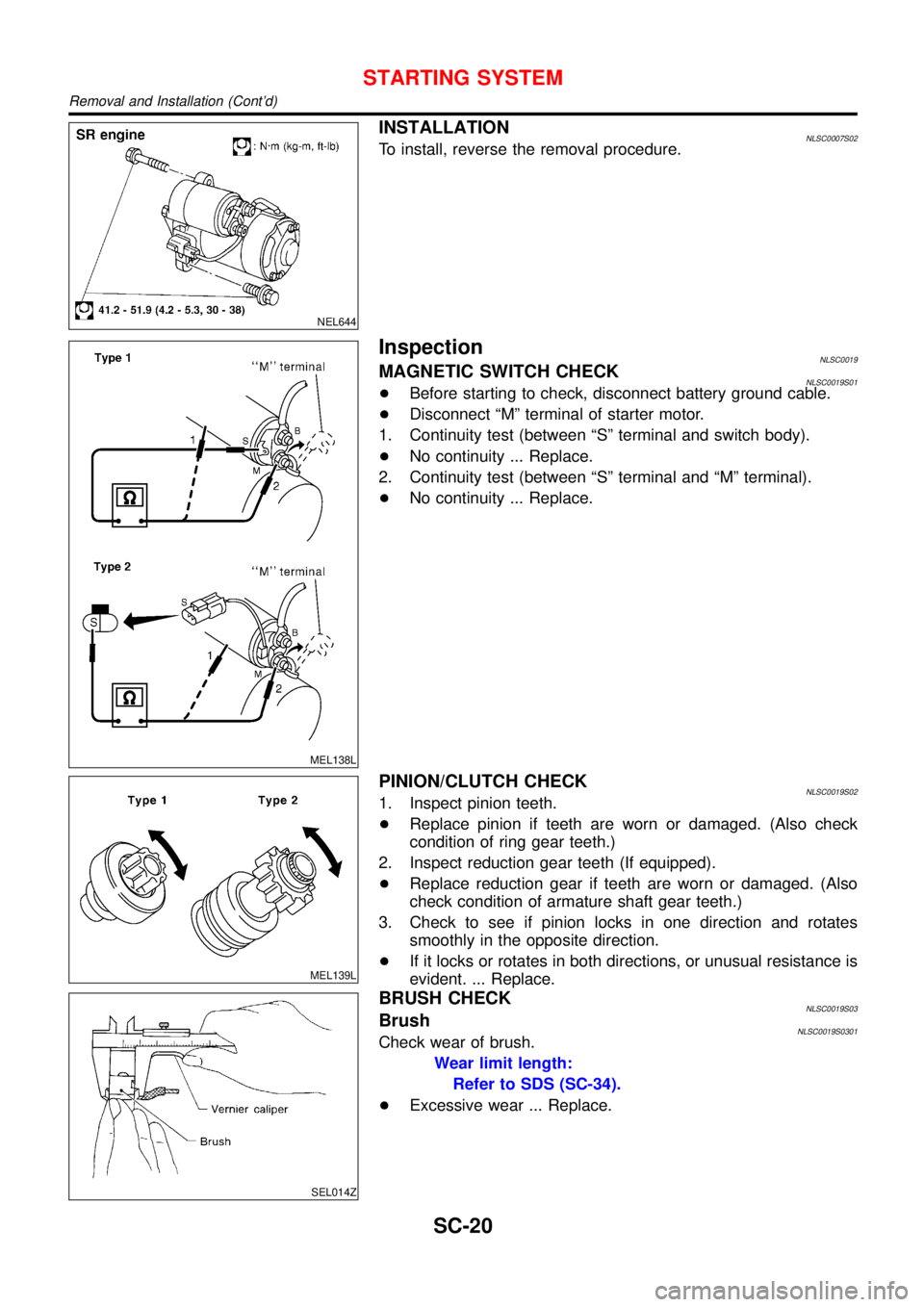

NEL733

YEL427B

CHARGING SYSTEM

Construction (Cont’d)

SC-29

Trending: high beam, navigation, belt, ESP inoperative, jacking, BT-20, cooling