NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 321 of 3051

NOTE:

Stopping distance may be longer than vehicles without ABS when

road condition is slippery.

4. ABS Does Not WorkNLBR0107

1 CHECK WARNING LAMP INDICATION

Does the ABS warning lamp activate?

Ye s©Carry out self-diagnosis. Refer to BR-56, BR-58.

No©Go to“3. CHECK WARNING LAMP INDICATION”in“2. Unexpected Pedal Action”,

BR-82.

NOTE:

ABS does not work when vehicle speed is under 10 km/h (6 MPH).

TROUBLE DIAGNOSES FOR SYMPTOMSABS

4. ABS Does Not Work

BR-84

Page 322 of 3051

5. Pedal Vibration and Noise=NLBR0108

1 INSPECTION START

Pedal vibration and noise inspection

SAT797A

©GO TO 2.

2 CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom appear only when engine is started?

Ye s©Carry out self-diagnosis. Refer to BR-56, BR-58.

No©GO TO 3.

3 RECHECK SYMPTOM

Does the symptom appear when electrical equipment switches (such as headlamp) are operated?

Ye s©GO TO 4.

No©Go to“3. CHECK WARNING LAMP INDICATION”in“2. Unexpected Pedal Action”,

BR-82.

4 CHECK WHEEL SENSOR

Check wheel sensor shield ground. For location of shield ground, refer to wiring diagram and“HARNESS LAYOUT”in EL

section.

Is wheel sensor shield grounded properly?

Ye s©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

No©Repair.

NOTE:

ABS may operate and cause vibration under any of the following

conditions.

+Applying brake gradually when shifting or operating clutch.

+Low friction (slippery) road.

+High speed cornering.

+Driving over bumps and pot holes.

+Engine speed is over 5,000 rpm with vehicle stopped.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise

BR-85

Page 323 of 3051

6. ABS Warning Lamp Does Not Come On

When Ignition Switch Is Turned On

=NLBR0109

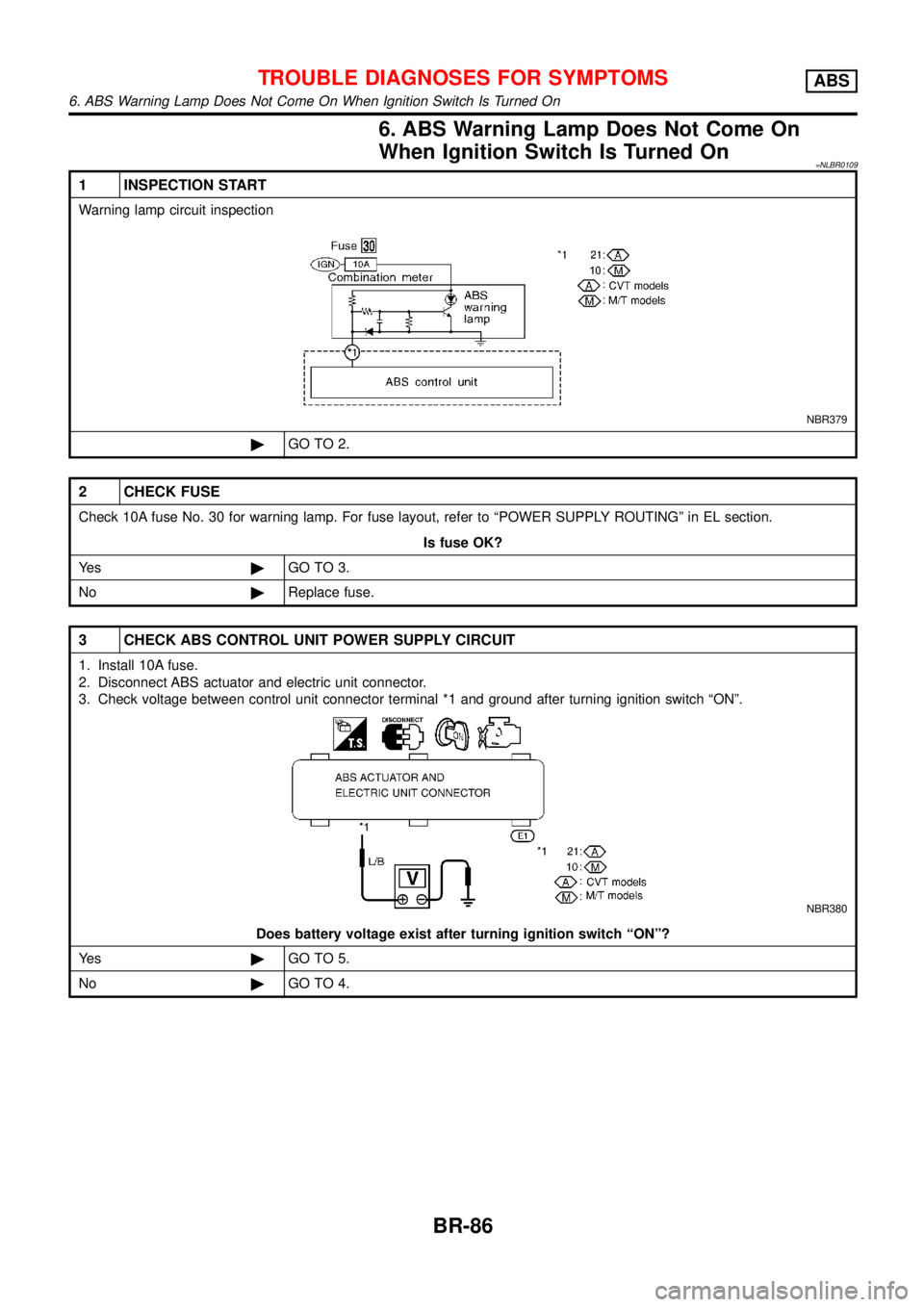

1 INSPECTION START

Warning lamp circuit inspection

NBR379

©GO TO 2.

2 CHECK FUSE

Check 10A fuse No. 30 for warning lamp. For fuse layout, refer to“POWER SUPPLY ROUTING”in EL section.

Is fuse OK?

Ye s©GO TO 3.

No©Replace fuse.

3 CHECK ABS CONTROL UNIT POWER SUPPLY CIRCUIT

1. Install 10A fuse.

2. Disconnect ABS actuator and electric unit connector.

3. Check voltage between control unit connector terminal *1 and ground after turning ignition switch“ON”.

NBR380

Does battery voltage exist after turning ignition switch“ON”?

Ye s©GO TO 5.

No©GO TO 4.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

6. ABS Warning Lamp Does Not Come On When Ignition Switch Is Turned On

BR-86

Page 324 of 3051

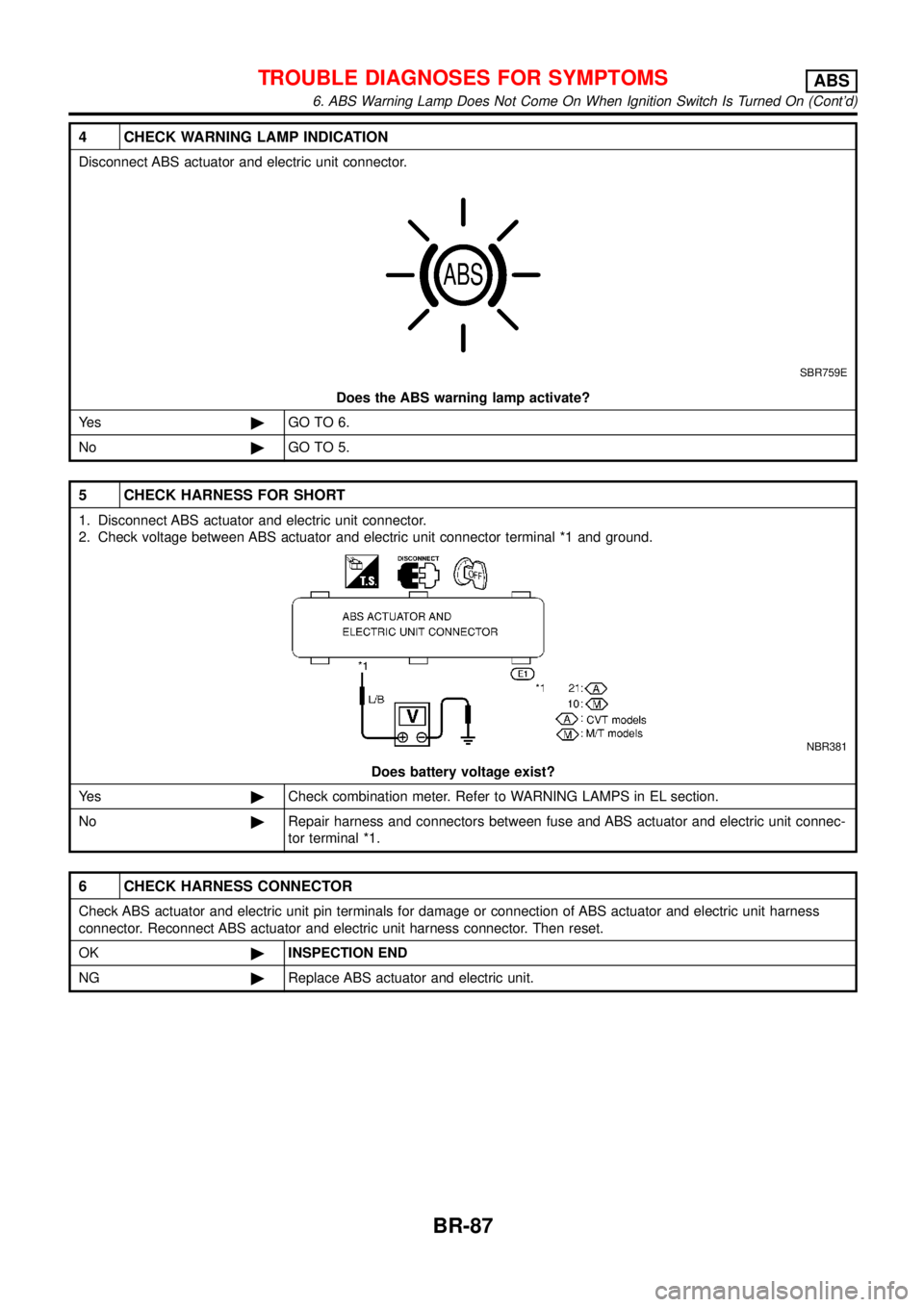

4 CHECK WARNING LAMP INDICATION

Disconnect ABS actuator and electric unit connector.

SBR759E

Does the ABS warning lamp activate?

Ye s©GO TO 6.

No©GO TO 5.

5 CHECK HARNESS FOR SHORT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal *1 and ground.

NBR381

Does battery voltage exist?

Ye s©Check combination meter. Refer to WARNING LAMPS in EL section.

No©Repair harness and connectors between fuse and ABS actuator and electric unit connec-

tor terminal *1.

6 CHECK HARNESS CONNECTOR

Check ABS actuator and electric unit pin terminals for damage or connection of ABS actuator and electric unit harness

connector. Reconnect ABS actuator and electric unit harness connector. Then reset.

OK©INSPECTION END

NG©Replace ABS actuator and electric unit.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

6. ABS Warning Lamp Does Not Come On When Ignition Switch Is Turned On (Cont’d)

BR-87

Page 325 of 3051

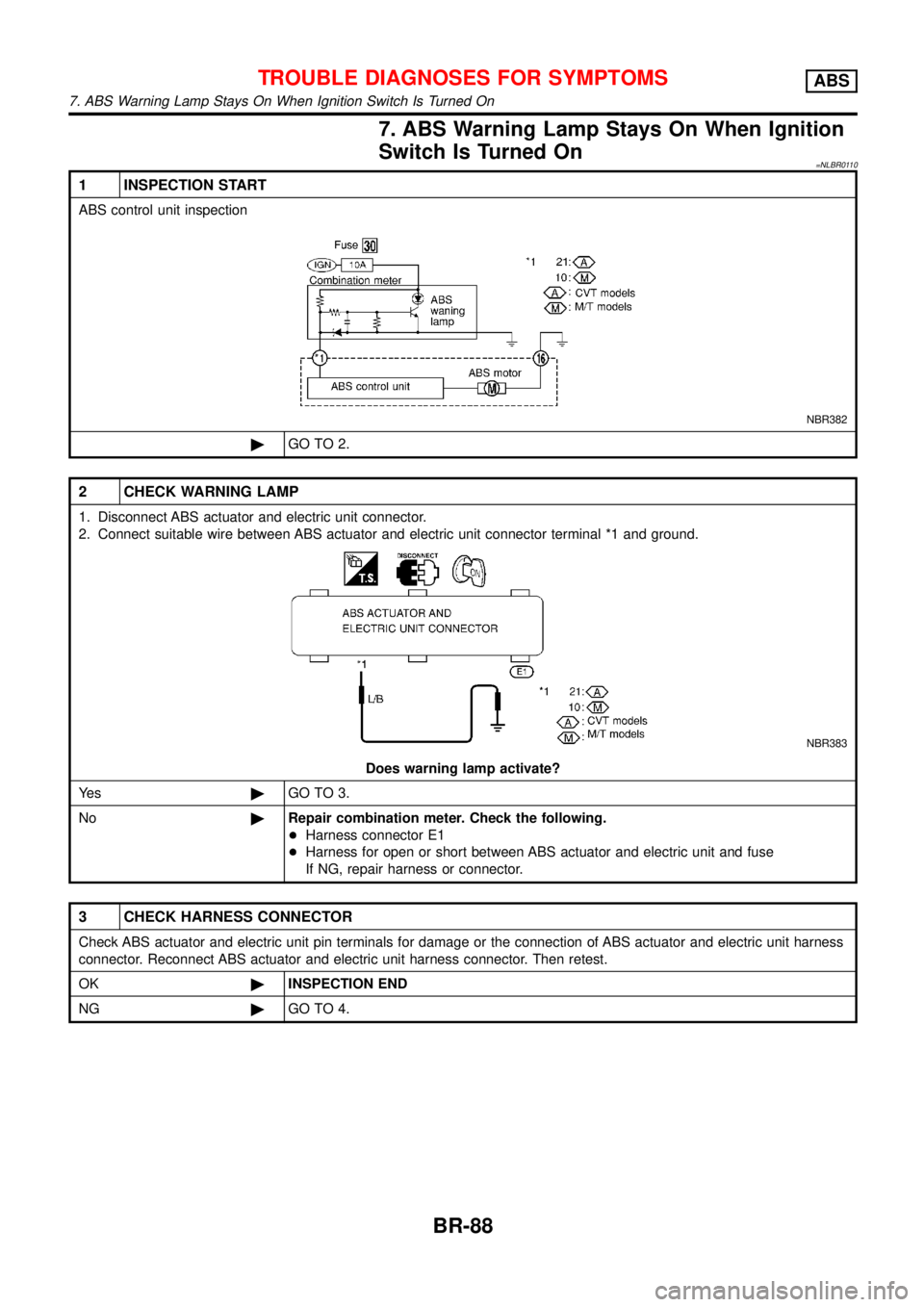

7. ABS Warning Lamp Stays On When Ignition

Switch Is Turned On

=NLBR0110

1 INSPECTION START

ABS control unit inspection

NBR382

©GO TO 2.

2 CHECK WARNING LAMP

1. Disconnect ABS actuator and electric unit connector.

2. Connect suitable wire between ABS actuator and electric unit connector terminal *1 and ground.

NBR383

Does warning lamp activate?

Ye s©GO TO 3.

No©Repair combination meter. Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fuse

If NG, repair harness or connector.

3 CHECK HARNESS CONNECTOR

Check ABS actuator and electric unit pin terminals for damage or the connection of ABS actuator and electric unit harness

connector. Reconnect ABS actuator and electric unit harness connector. Then retest.

OK©INSPECTION END

NG©GO TO 4.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

7. ABS Warning Lamp Stays On When Ignition Switch Is Turned On

BR-88

Page 326 of 3051

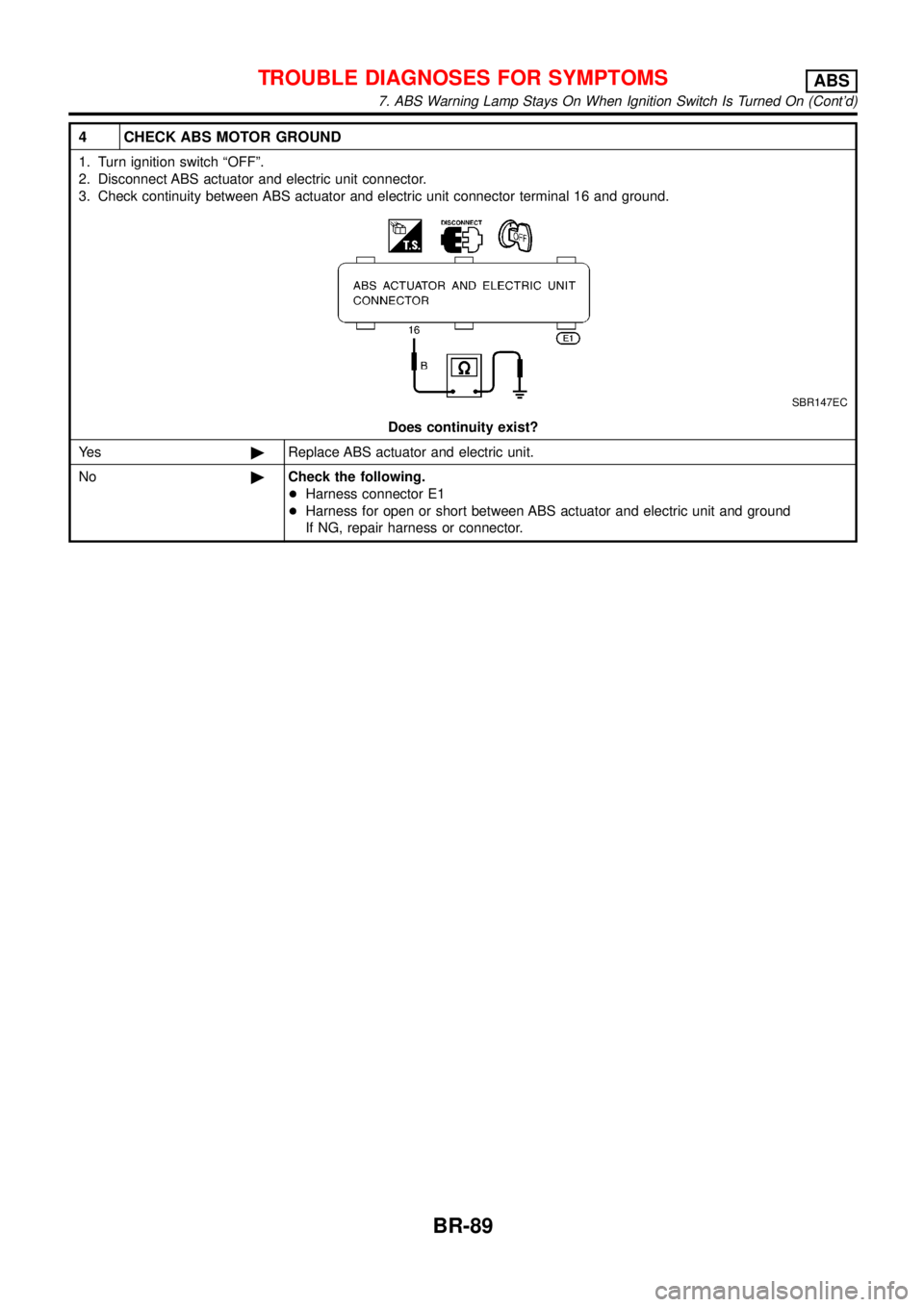

4 CHECK ABS MOTOR GROUND

1. Turn ignition switch“OFF”.

2. Disconnect ABS actuator and electric unit connector.

3. Check continuity between ABS actuator and electric unit connector terminal 16 and ground.

SBR147EC

Does continuity exist?

Ye s©Replace ABS actuator and electric unit.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and ground

If NG, repair harness or connector.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

7. ABS Warning Lamp Stays On When Ignition Switch Is Turned On (Cont’d)

BR-89

Page 327 of 3051

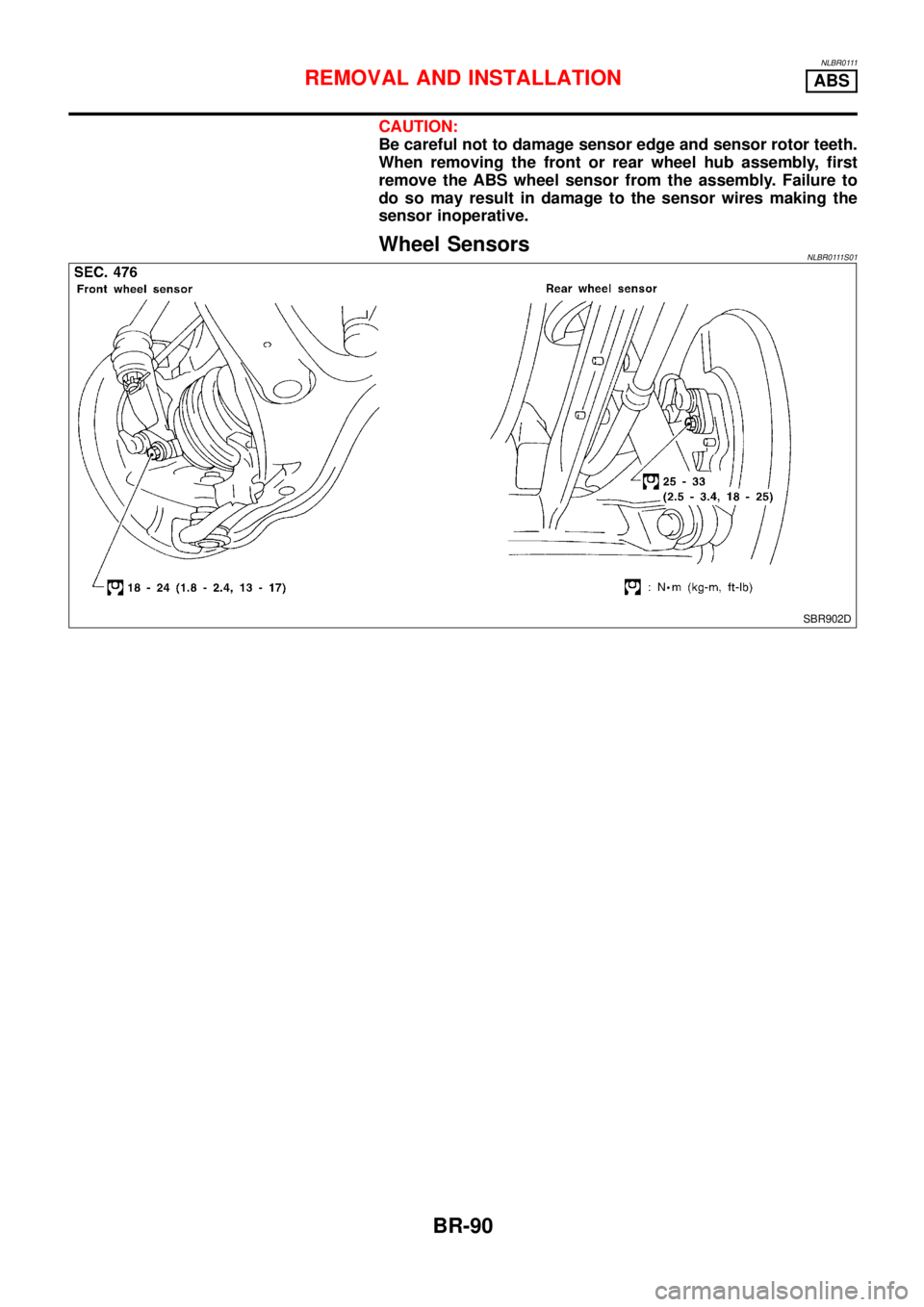

NLBR0111

CAUTION:

Be careful not to damage sensor edge and sensor rotor teeth.

When removing the front or rear wheel hub assembly, first

remove the ABS wheel sensor from the assembly. Failure to

do so may result in damage to the sensor wires making the

sensor inoperative.

Wheel SensorsNLBR0111S01

SBR902D

REMOVAL AND INSTALLATIONABS

BR-90

Page 328 of 3051

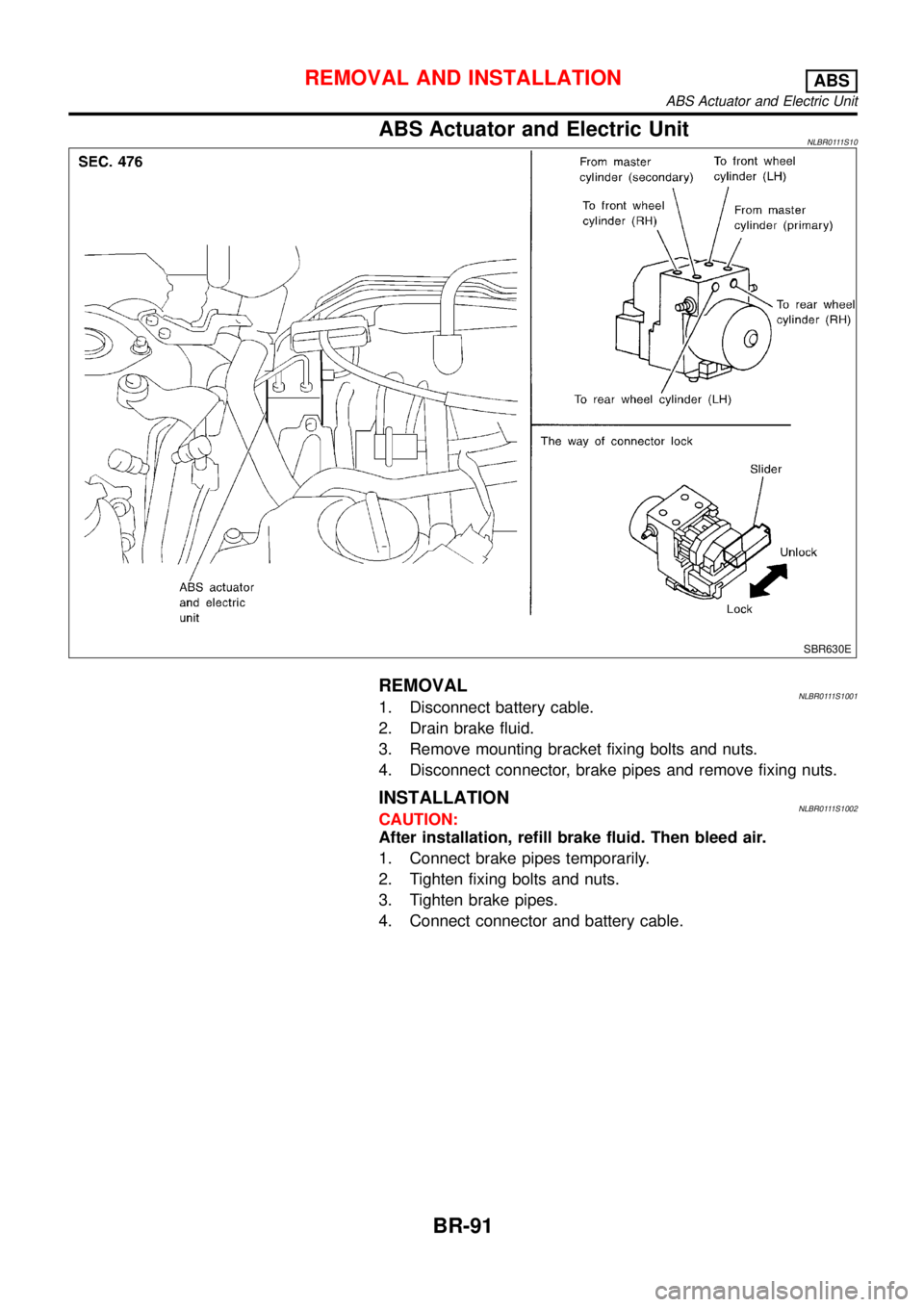

ABS Actuator and Electric UnitNLBR0111S10

SBR630E

REMOVALNLBR0111S10011. Disconnect battery cable.

2. Drain brake fluid.

3. Remove mounting bracket fixing bolts and nuts.

4. Disconnect connector, brake pipes and remove fixing nuts.

INSTALLATIONNLBR0111S1002CAUTION:

After installation, refill brake fluid. Then bleed air.

1. Connect brake pipes temporarily.

2. Tighten fixing bolts and nuts.

3. Tighten brake pipes.

4. Connect connector and battery cable.

REMOVAL AND INSTALLATIONABS

ABS Actuator and Electric Unit

BR-91

Page 329 of 3051

SBR984C

SBR873CA

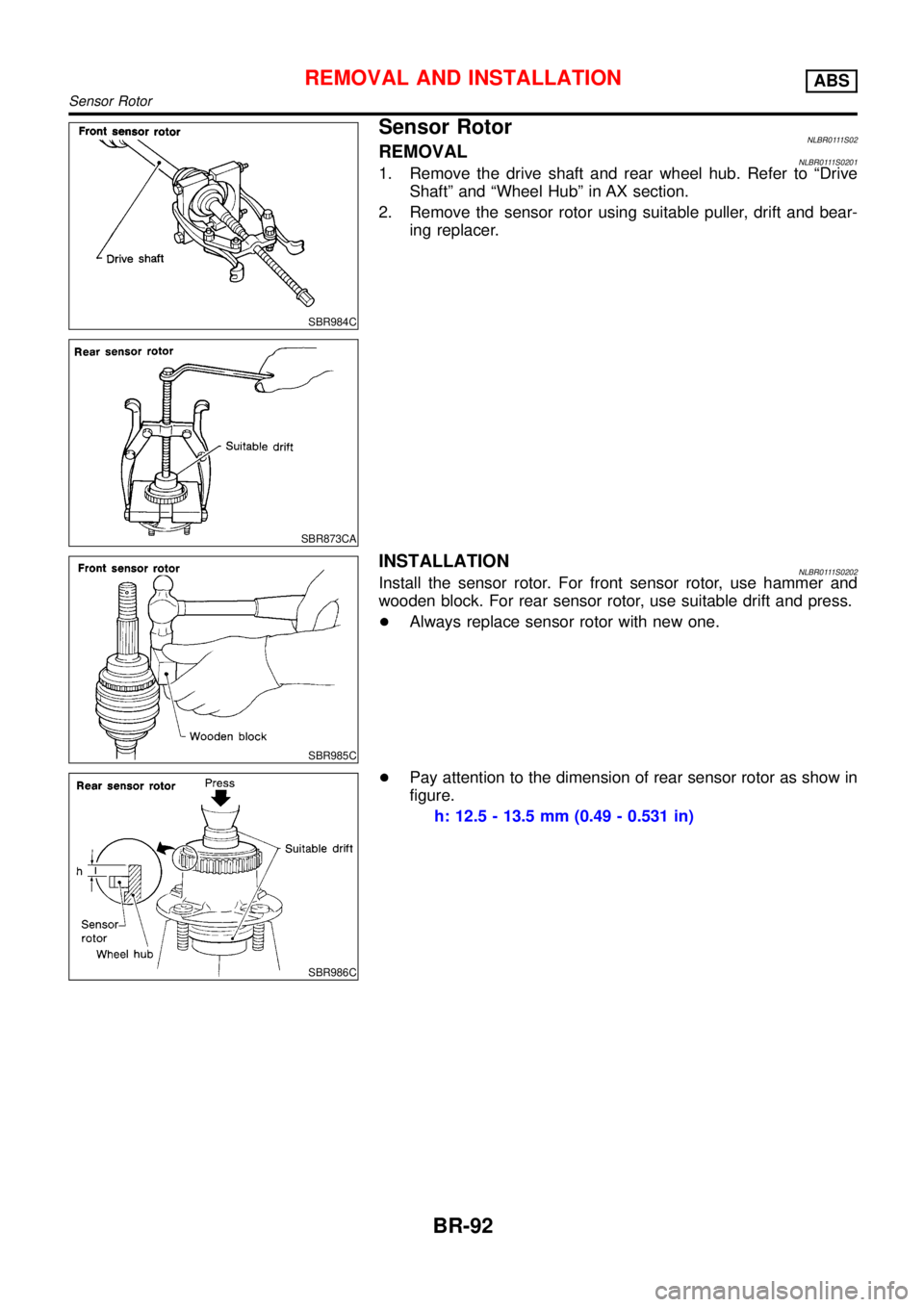

Sensor RotorNLBR0111S02REMOVALNLBR0111S02011. Remove the drive shaft and rear wheel hub. Refer to“Drive

Shaft”and“Wheel Hub”in AX section.

2. Remove the sensor rotor using suitable puller, drift and bear-

ing replacer.

SBR985C

INSTALLATIONNLBR0111S0202Install the sensor rotor. For front sensor rotor, use hammer and

wooden block. For rear sensor rotor, use suitable drift and press.

+Always replace sensor rotor with new one.

SBR986C

+Pay attention to the dimension of rear sensor rotor as show in

figure.

h: 12.5 - 13.5 mm (0.49 - 0.531 in)

REMOVAL AND INSTALLATIONABS

Sensor Rotor

BR-92

Page 330 of 3051

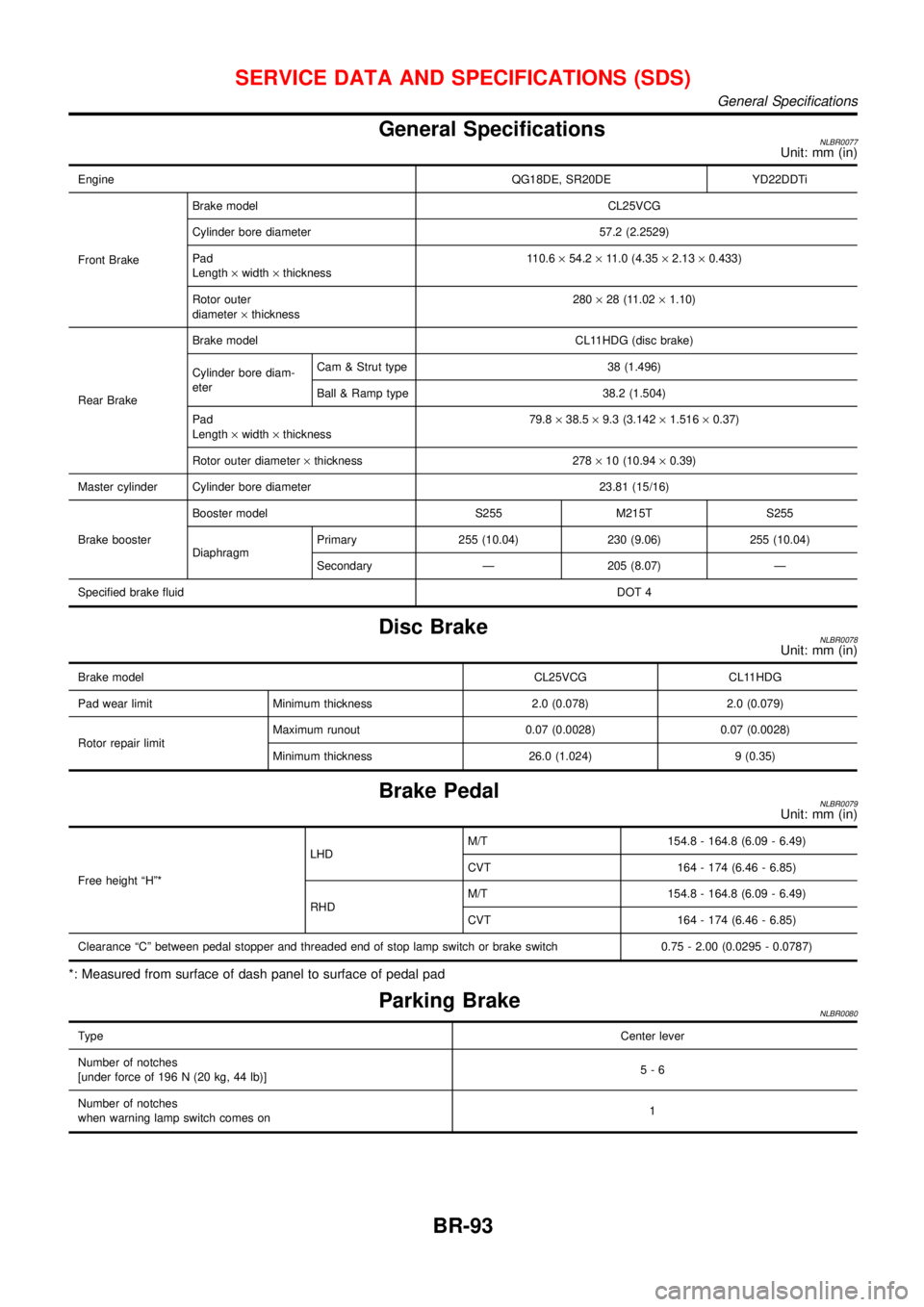

General SpecificationsNLBR0077Unit: mm (in)

EngineQG18DE, SR20DE YD22DDTi

Front BrakeBrake model CL25VCG

Cylinder bore diameter 57.2 (2.2529)

Pad

Length×width×thickness110.6×54.2×11.0 (4.35×2.13×0.433)

Rotor outer

diameter×thickness280×28 (11.02×1.10)

Rear BrakeBrake model CL11HDG (disc brake)

Cylinder bore diam-

eterCam & Strut type 38 (1.496)

Ball & Ramp type 38.2 (1.504)

Pad

Length×width×thickness79.8×38.5×9.3 (3.142×1.516×0.37)

Rotor outer diameter×thickness 278×10 (10.94×0.39)

Master cylinder Cylinder bore diameter 23.81 (15/16)

Brake boosterBooster model S255 M215T S255

DiaphragmPrimary 255 (10.04) 230 (9.06) 255 (10.04)

Secondary—205 (8.07)—

Specified brake fluidDOT 4

Disc BrakeNLBR0078Unit: mm (in)

Brake modelCL25VCG CL11HDG

Pad wear limit Minimum thickness 2.0 (0.078) 2.0 (0.079)

Rotor repair limitMaximum runout 0.07 (0.0028) 0.07 (0.0028)

Minimum thickness 26.0 (1.024) 9 (0.35)

Brake PedalNLBR0079Unit: mm (in)

Free height“H”*LHDM/T 154.8 - 164.8 (6.09 - 6.49)

CVT 164 - 174 (6.46 - 6.85)

RHDM/T 154.8 - 164.8 (6.09 - 6.49)

CVT 164 - 174 (6.46 - 6.85)

Clearance“C”between pedal stopper and threaded end of stop lamp switch or brake switch 0.75 - 2.00 (0.0295 - 0.0787)

*: Measured from surface of dash panel to surface of pedal pad

Parking BrakeNLBR0080

TypeCenter lever

Number of notches

[under force of 196 N (20 kg, 44 lb)]5-6

Number of notches

when warning lamp switch comes on1

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

BR-93