NISSAN ALMERA TINO 2001 Service Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 41 of 3051

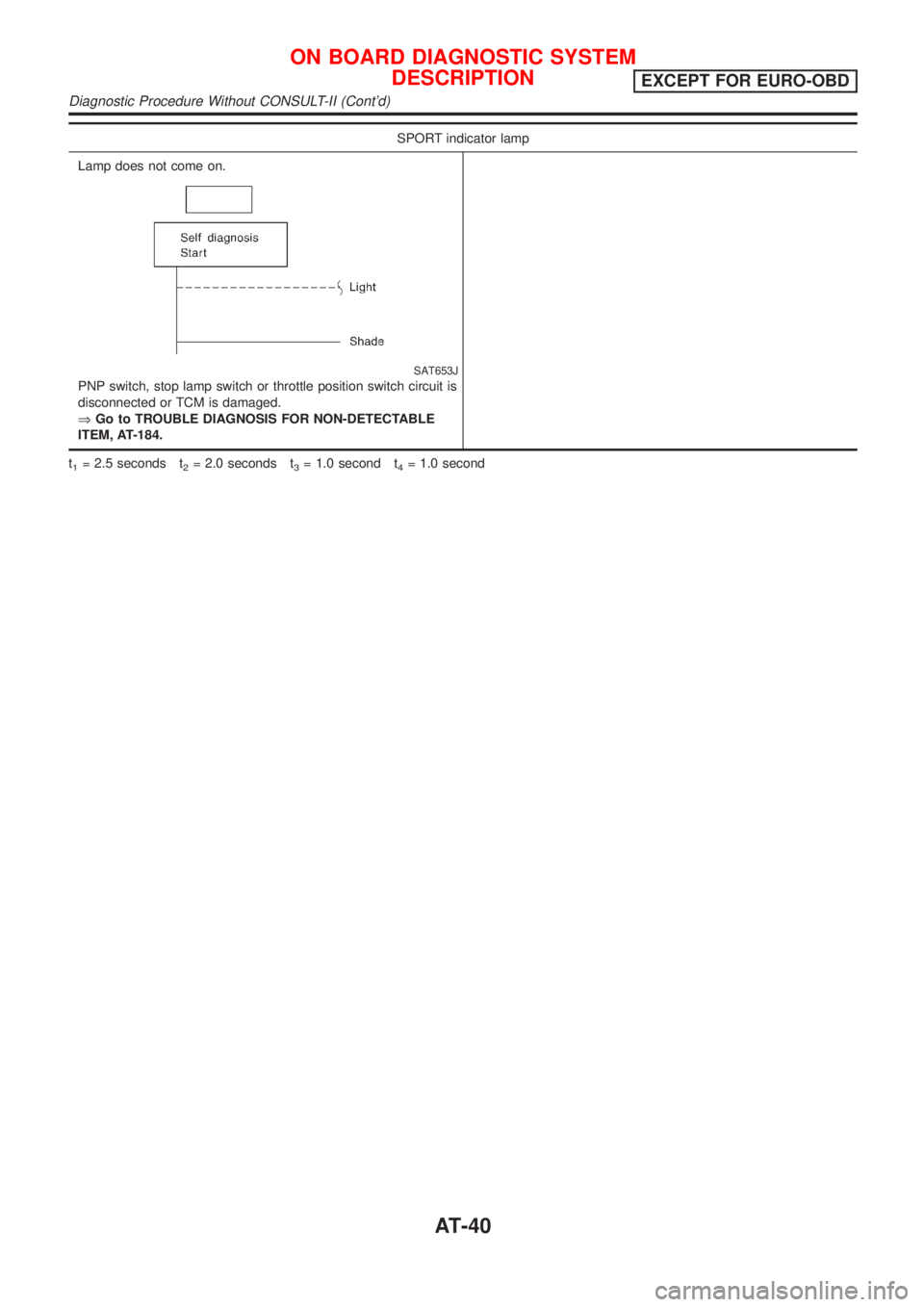

SPORT indicator lamp

Lamp does not come on.

SAT653J

PNP switch, stop lamp switch or throttle position switch circuit is

disconnected or TCM is damaged.

ÞGo to TROUBLE DIAGNOSIS FOR NON-DETECTABLE

ITEM, AT-184.

t

1= 2.5 seconds t2= 2.0 seconds t3= 1.0 second t4= 1.0 second

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

EXCEPT FOR EURO-OBD

Diagnostic Procedure Without CONSULT-II (Cont'd)

AT-40

Page 42 of 3051

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0023The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via step motor and CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the EURO-OBD-related

parts of the CVT system for malfunction-diagnostic purposes. The

TCM is capable of diagnosing malfunctioning parts while the ECM

can store malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº. Refer to AT-44.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-43) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

AT-41

Page 43 of 3051

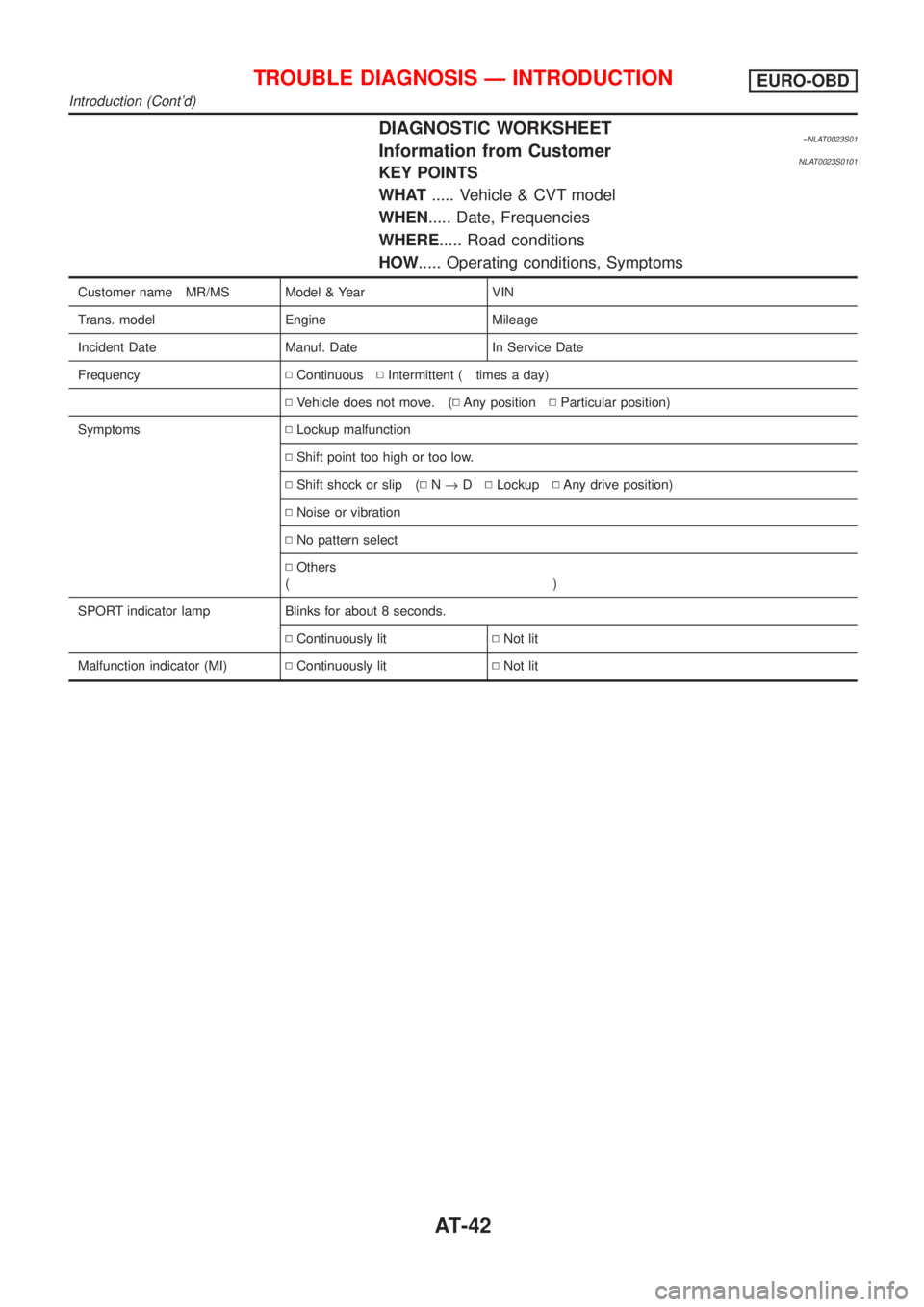

DIAGNOSTIC WORKSHEET=NLAT0023S01Information from CustomerNLAT0023S0101KEY POINTS

WHAT..... Vehicle & CVT model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencyNContinuousNIntermittent ( times a day)

NVehicle does not move. (NAny positionNParticular position)

SymptomsNLockup malfunction

NShift point too high or too low.

NShift shock or slip (NN®DNLockupNAny drive position)

NNoise or vibration

NNo pattern select

NOthers

()

SPORT indicator lamp Blinks for about 8 seconds.

NContinuously litNNot lit

Malfunction indicator (MI)NContinuously litNNot lit

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Introduction (Cont'd)

AT-42

Page 44 of 3051

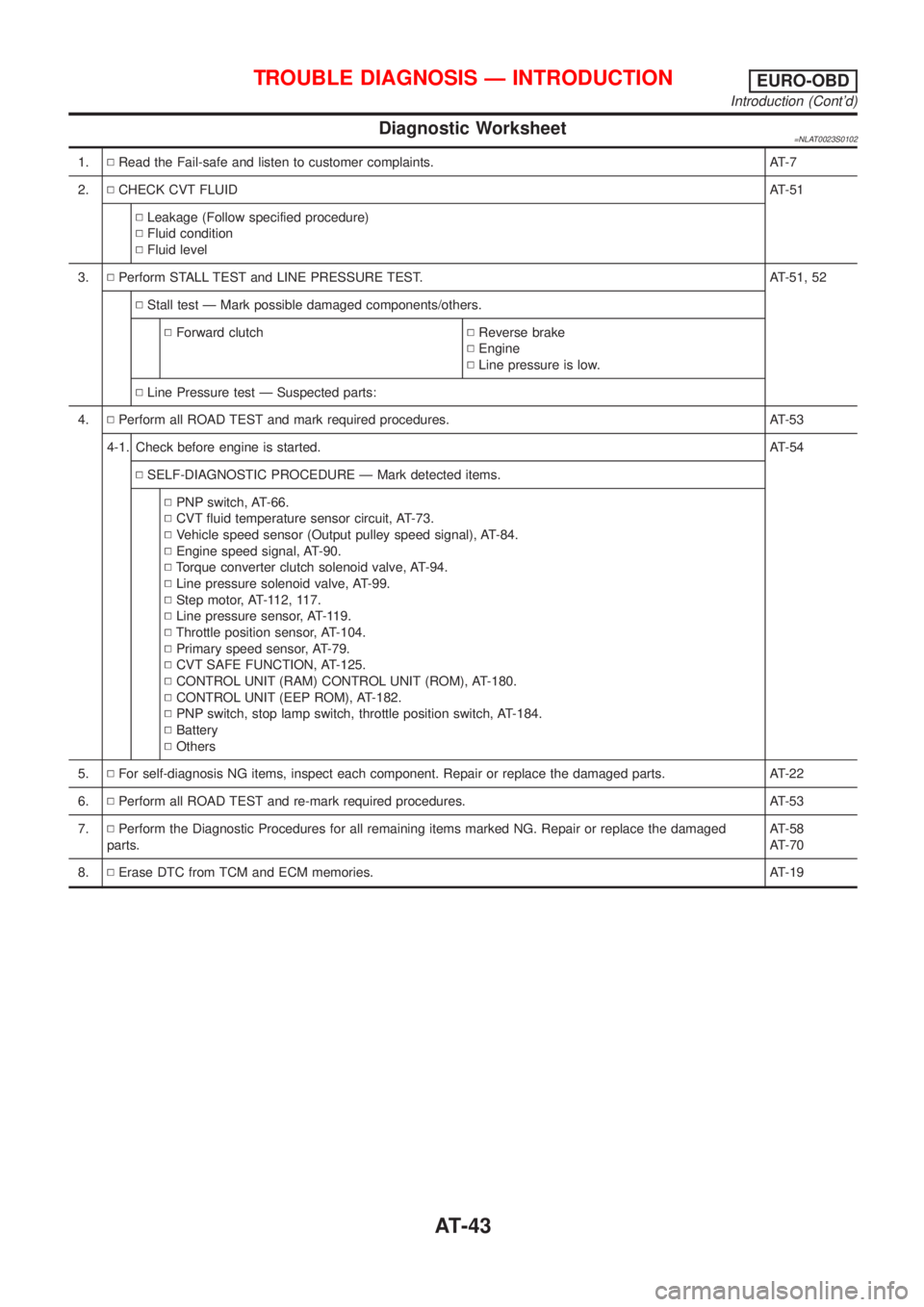

Diagnostic Worksheet=NLAT0023S0102

1.NRead the Fail-safe and listen to customer complaints. AT-7

2.NCHECK CVT FLUIDAT-51

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-51, 52

NStall test Ð Mark possible damaged components/others.

NForward clutchNReverse brake

NEngine

NLine pressure is low.

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-53

4-1. Check before engine is started.AT-54

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NPNP switch, AT-66.

NCVT fluid temperature sensor circuit, AT-73.

NVehicle speed sensor (Output pulley speed signal), AT-84.

NEngine speed signal, AT-90.

NTorque converter clutch solenoid valve, AT-94.

NLine pressure solenoid valve, AT-99.

NStep motor, AT-112, 117.

NLine pressure sensor, AT-119.

NThrottle position sensor, AT-104.

NPrimary speed sensor, AT-79.

NCVT SAFE FUNCTION, AT-125.

NCONTROL UNIT (RAM) CONTROL UNIT (ROM), AT-180.

NCONTROL UNIT (EEP ROM), AT-182.

NPNP switch, stop lamp switch, throttle position switch, AT-184.

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-22

6.NPerform all ROAD TEST and re-mark required procedures. AT-53

7.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.AT-58

AT-70

8.NErase DTC from TCM and ECM memories. AT-19

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Introduction (Cont'd)

AT-43

Page 45 of 3051

Work Flow=NLAT0024HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIRNLAT0024S01A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a problem. It is important to fully understand the symptoms or

conditions for a customer complaint.

Make good use of the two sheets provided, ªINFORMATION FROM CUSTOMERº (AT-42) and ªDIAGNOS-

TIC WORKSHEETº (AT-43), to perform the best troubleshooting possible.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Work Flow

AT-44

Page 46 of 3051

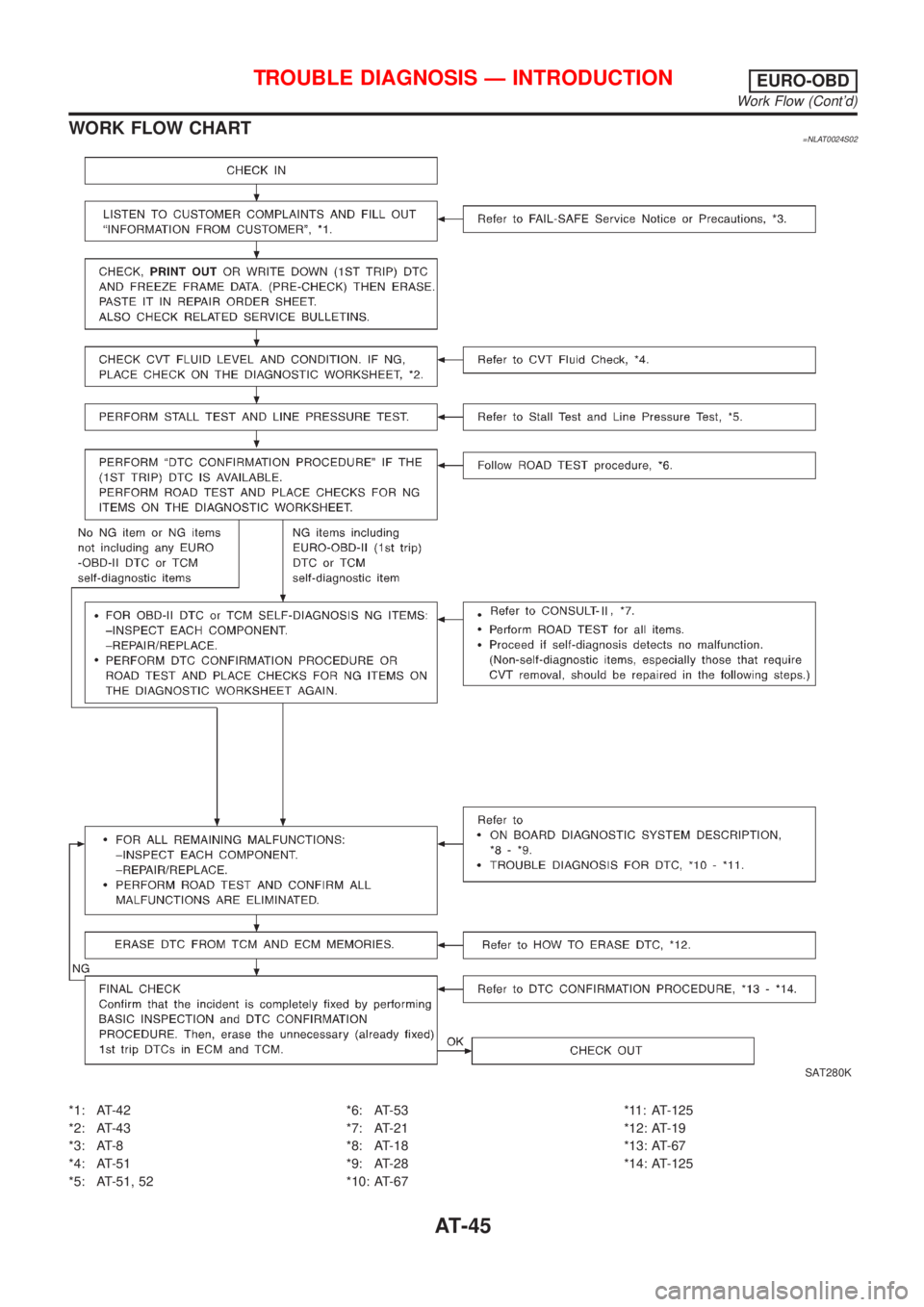

WORK FLOW CHART=NLAT0024S02

SAT280K

*1: AT-42

*2: AT-43

*3: AT-8

*4: AT-51

*5: AT-51, 52*6: AT-53

*7: AT-21

*8: AT-18

*9: AT-28

*10: AT-67*11: AT-125

*12: AT-19

*13: AT-67

*14: AT-125

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Work Flow (Cont'd)

AT-45

Page 47 of 3051

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0247The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº. Refer to AT-49.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-48) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

AT-46

Page 48 of 3051

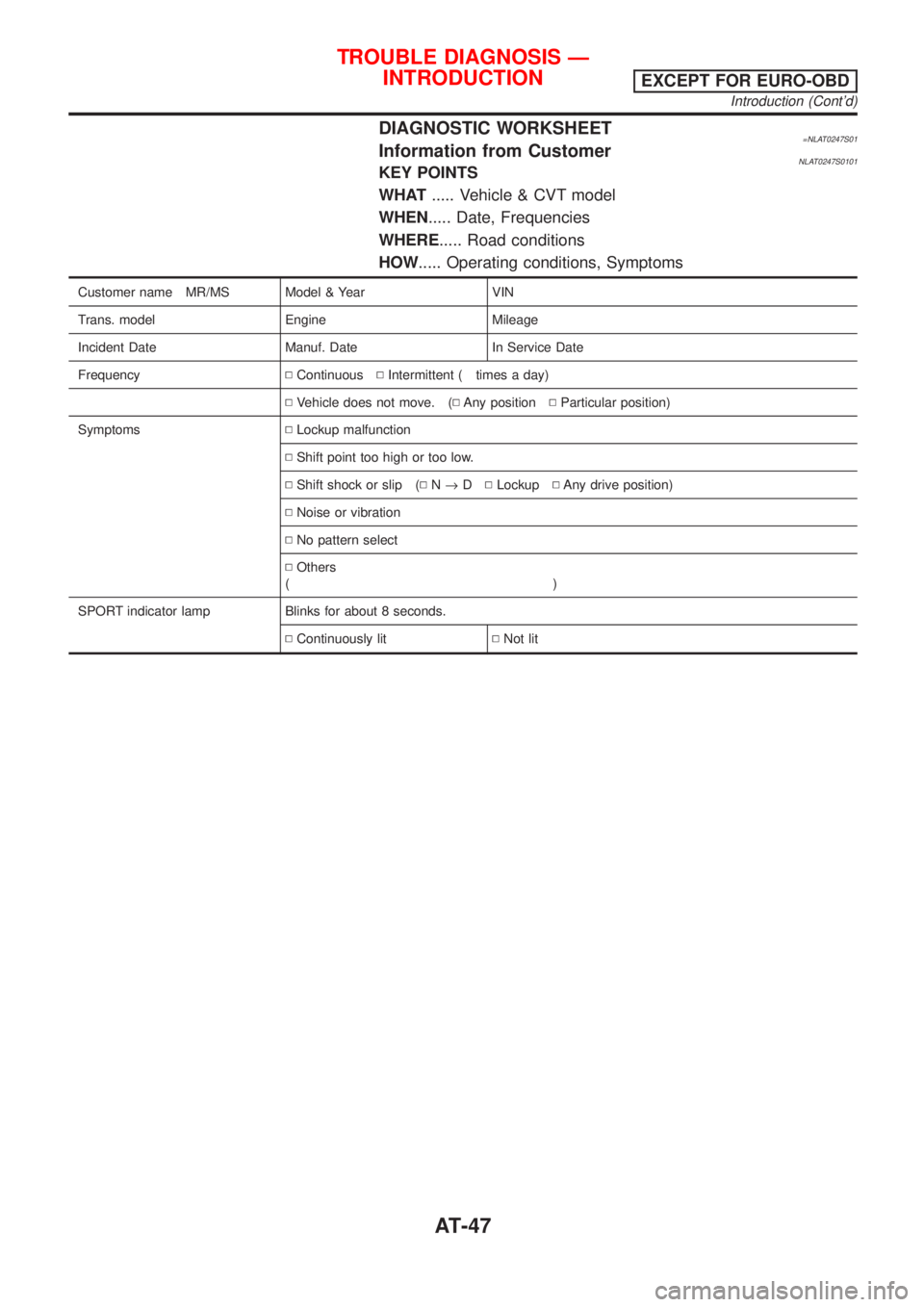

DIAGNOSTIC WORKSHEET=NLAT0247S01Information from CustomerNLAT0247S0101KEY POINTS

WHAT..... Vehicle & CVT model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencyNContinuousNIntermittent ( times a day)

NVehicle does not move. (NAny positionNParticular position)

SymptomsNLockup malfunction

NShift point too high or too low.

NShift shock or slip (NN®DNLockupNAny drive position)

NNoise or vibration

NNo pattern select

NOthers

()

SPORT indicator lamp Blinks for about 8 seconds.

NContinuously litNNot lit

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Introduction (Cont'd)

AT-47

Page 49 of 3051

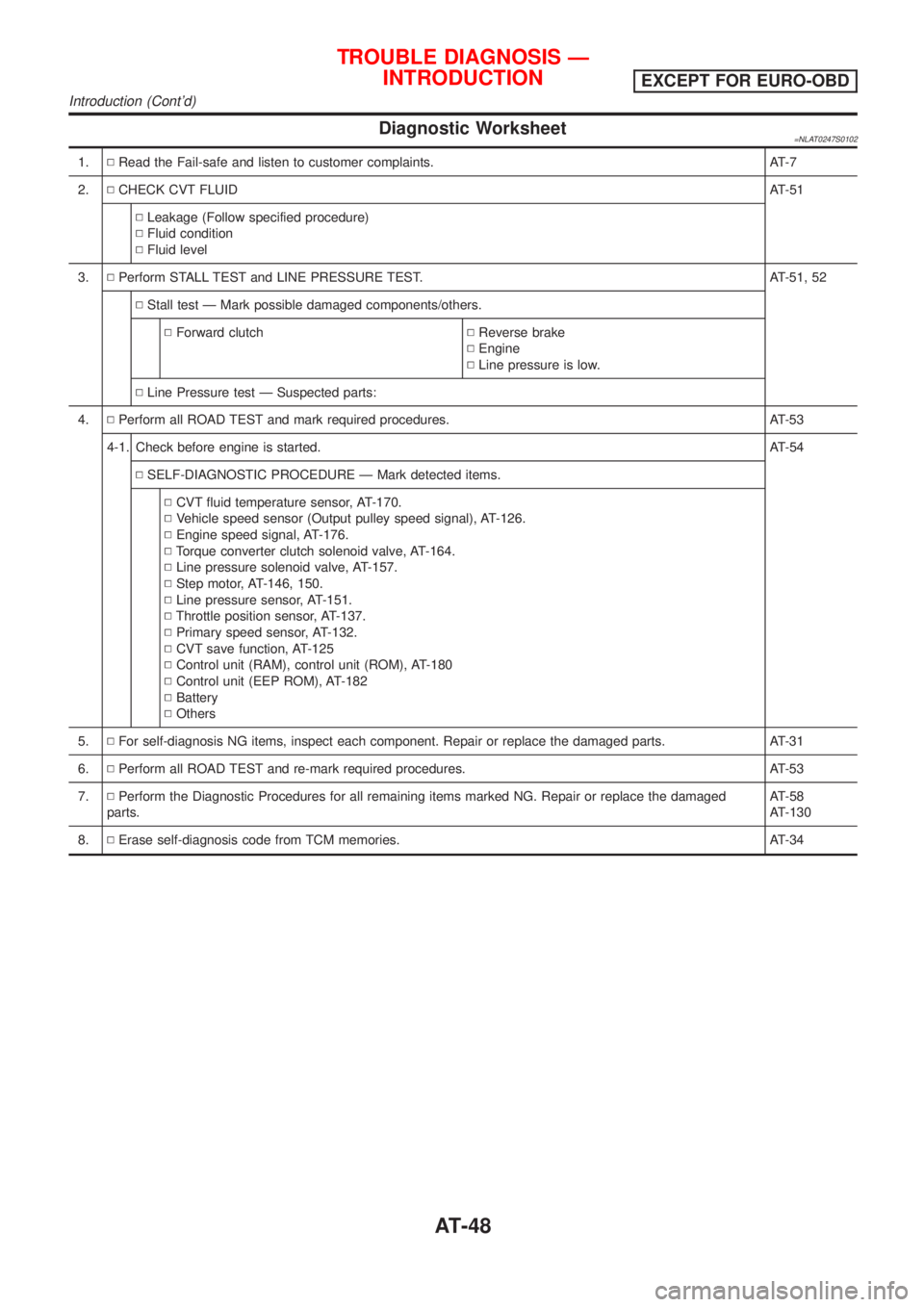

Diagnostic Worksheet=NLAT0247S0102

1.NRead the Fail-safe and listen to customer complaints. AT-7

2.NCHECK CVT FLUIDAT-51

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-51, 52

NStall test Ð Mark possible damaged components/others.

NForward clutchNReverse brake

NEngine

NLine pressure is low.

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-53

4-1. Check before engine is started.AT-54

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NCVT fluid temperature sensor, AT-170.

NVehicle speed sensor (Output pulley speed signal), AT-126.

NEngine speed signal, AT-176.

NTorque converter clutch solenoid valve, AT-164.

NLine pressure solenoid valve, AT-157.

NStep motor, AT-146, 150.

NLine pressure sensor, AT-151.

NThrottle position sensor, AT-137.

NPrimary speed sensor, AT-132.

NCVT save function, AT-125

NControl unit (RAM), control unit (ROM), AT-180

NControl unit (EEP ROM), AT-182

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-31

6.NPerform all ROAD TEST and re-mark required procedures. AT-53

7.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.AT-58

AT-130

8.NErase self-diagnosis code from TCM memories. AT-34

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Introduction (Cont'd)

AT-48

Page 50 of 3051

Work Flow=NLAT0248HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIRNLAT0248S01A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a problem. It is important to fully understand the symptoms or

conditions for a customer complaint.

Make good use of the two sheets provided, ªINFORMATION FROM CUSTOMERº (AT-47) and ªDIAGNOS-

TIC WORKSHEETº (AT-48), to perform the best troubleshooting possible.

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Work Flow

AT-49