NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: service reset, bulb, sunroof, mileage, check transmission fluid, airbag off, coolant capacity

Page 861 of 3051

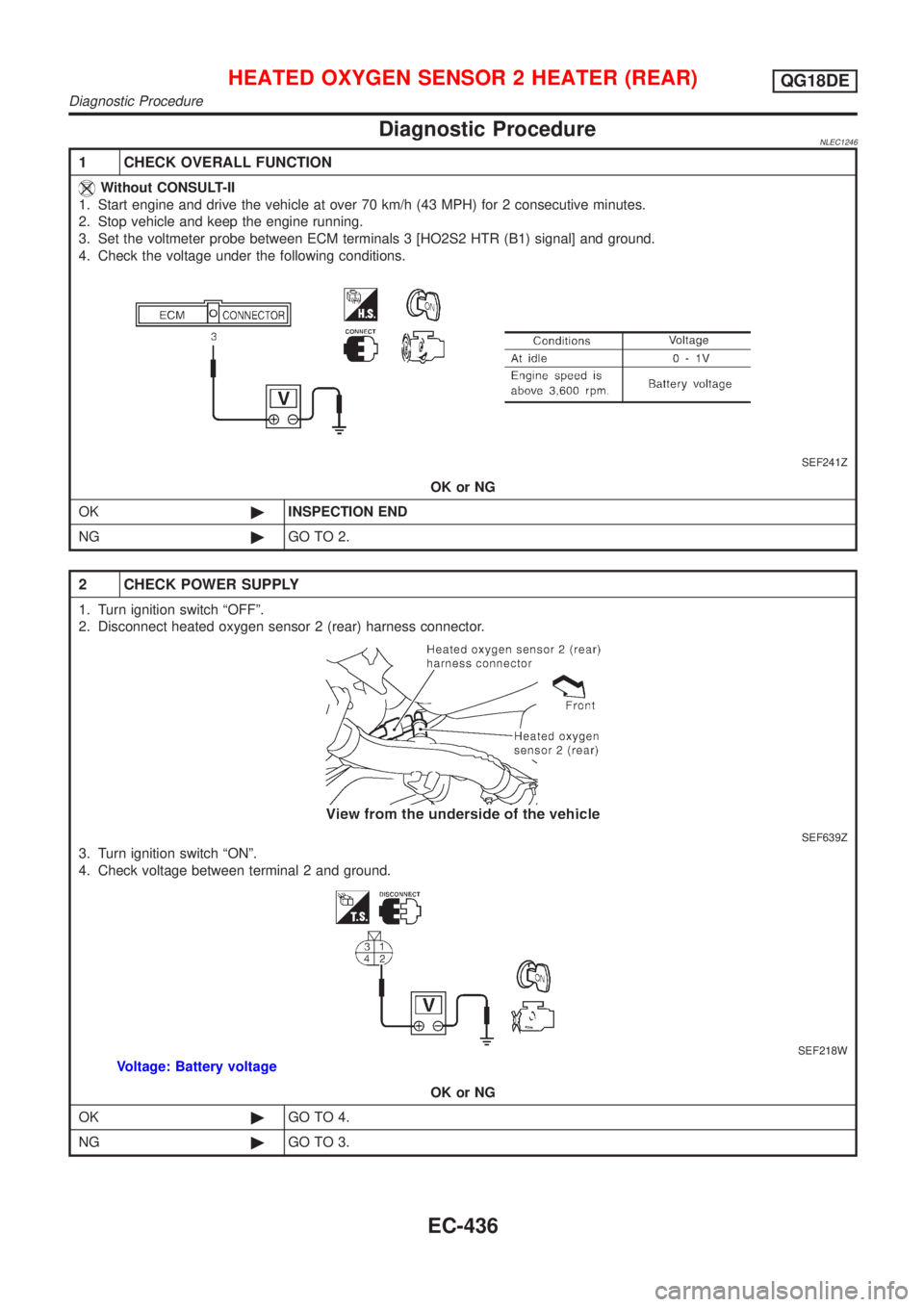

Diagnostic ProcedureNLEC1246

1 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine and drive the vehicle at over 70 km/h (43 MPH) for 2 consecutive minutes.

2. Stop vehicle and keep the engine running.

3. Set the voltmeter probe between ECM terminals 3 [HO2S2 HTR (B1) signal] and ground.

4. Check the voltage under the following conditions.

SEF241Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector.

SEF639Z

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground.

SEF218W

Voltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

HEATED OXYGEN SENSOR 2 HEATER (REAR)QG18DE

Diagnostic Procedure

EC-436

Page 862 of 3051

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F38, M50 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness for open or short between heated oxygen sensor 2 (rear) and fuse

+10A fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 3 and ECM terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 heater (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK HEATED OXYGEN SENSOR 2 HEATER (REAR)

Refer to ªComponent Inspectionº, EC-438.

OK or NG

OK©GO TO 7.

NG©Replace heated oxygen sensor 2 (rear).

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

HEATED OXYGEN SENSOR 2 HEATER (REAR)QG18DE

Diagnostic Procedure (Cont'd)

EC-437

Page 863 of 3051

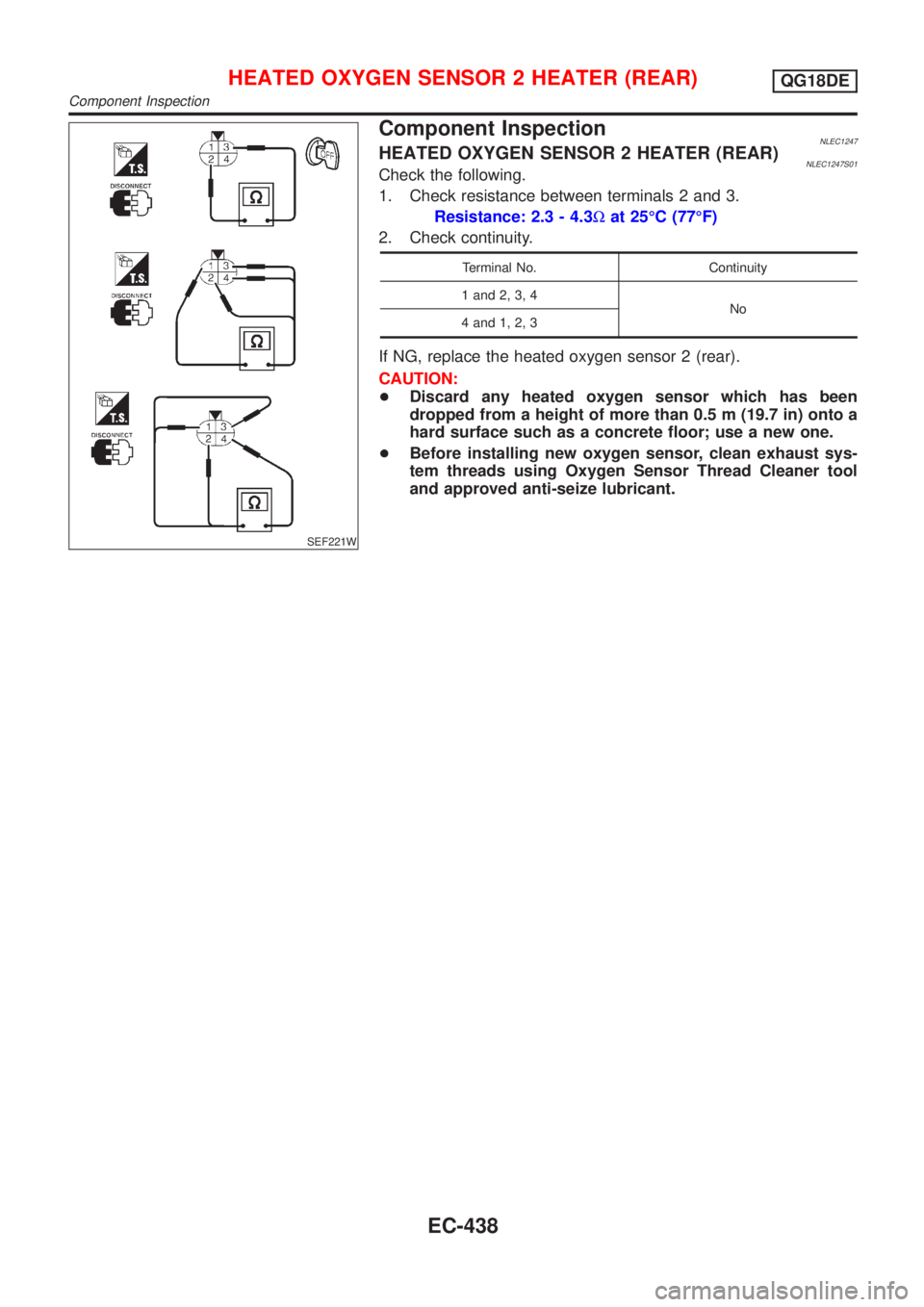

SEF221W

Component InspectionNLEC1247HEATED OXYGEN SENSOR 2 HEATER (REAR)NLEC1247S01Check the following.

1. Check resistance between terminals 2 and 3.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

2. Check continuity.

Terminal No. Continuity

1 and 2, 3, 4

No

4 and 1, 2, 3

If NG, replace the heated oxygen sensor 2 (rear).

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

HEATED OXYGEN SENSOR 2 HEATER (REAR)QG18DE

Component Inspection

EC-438

Page 864 of 3051

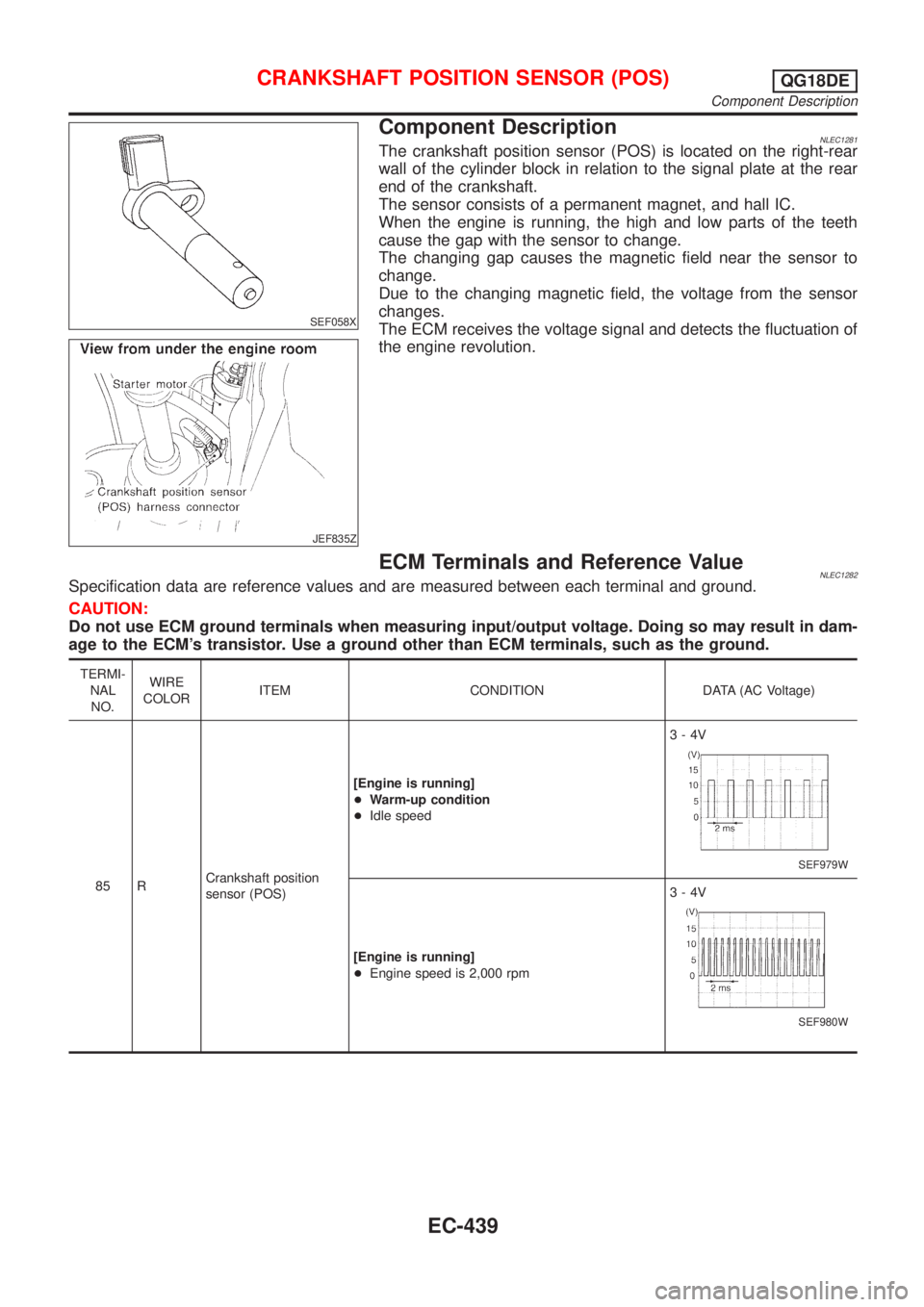

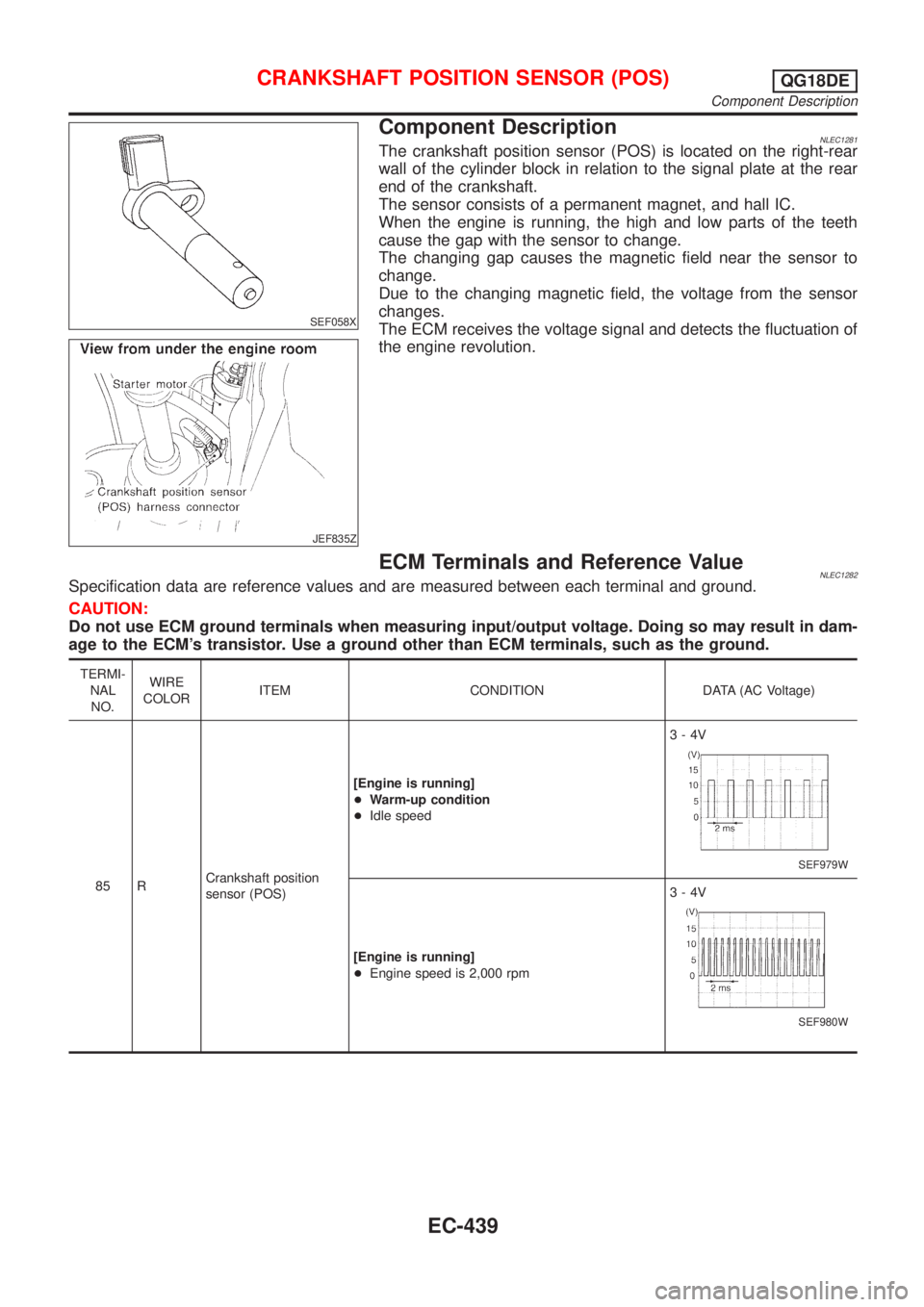

SEF058X

JEF835Z

Component DescriptionNLEC1281The crankshaft position sensor (POS) is located on the right-rear

wall of the cylinder block in relation to the signal plate at the rear

end of the crankshaft.

The sensor consists of a permanent magnet, and hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

ECM Terminals and Reference ValueNLEC1282Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (AC Voltage)

85 RCrankshaft position

sensor (POS)[Engine is running]

+Warm-up condition

+Idle speed3-4V

SEF979W

[Engine is running]

+Engine speed is 2,000 rpm3-4V

SEF980W

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Component Description

EC-439

Page 865 of 3051

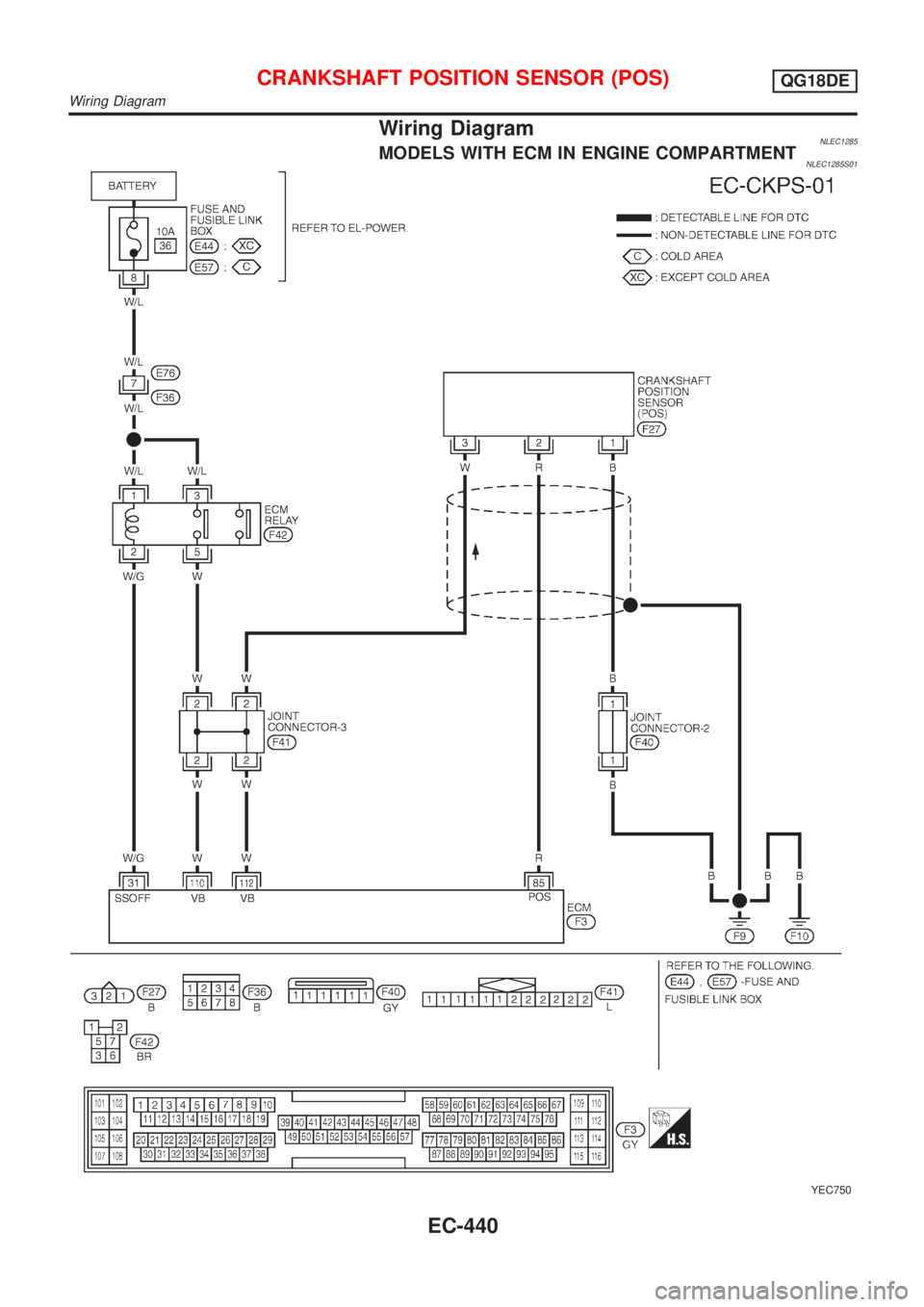

Wiring DiagramNLEC1285MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1285S01

YEC750

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Wiring Diagram

EC-440

Page 866 of 3051

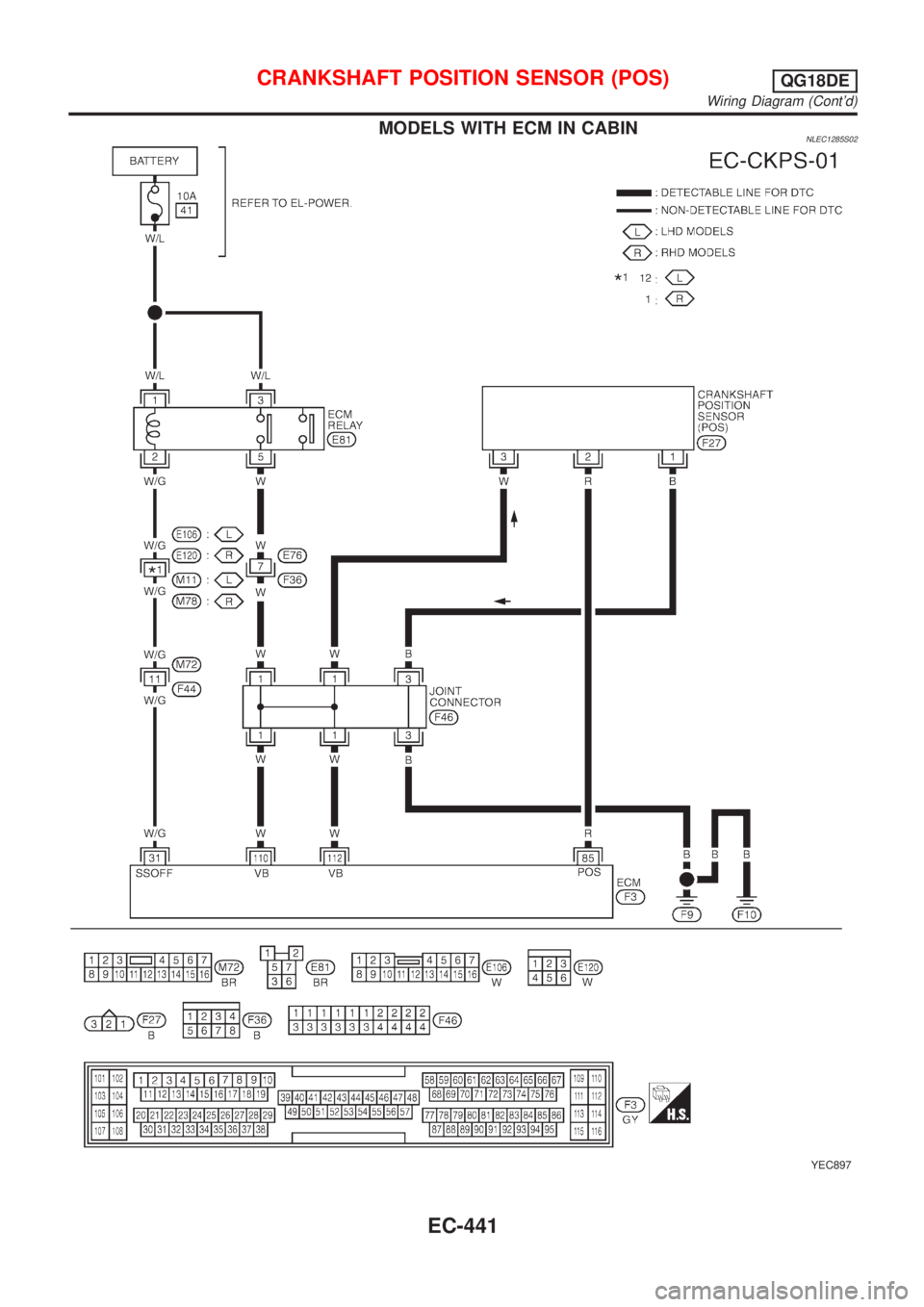

MODELS WITH ECM IN CABINNLEC1285S02

YEC897

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Wiring Diagram (Cont'd)

EC-441

Page 867 of 3051

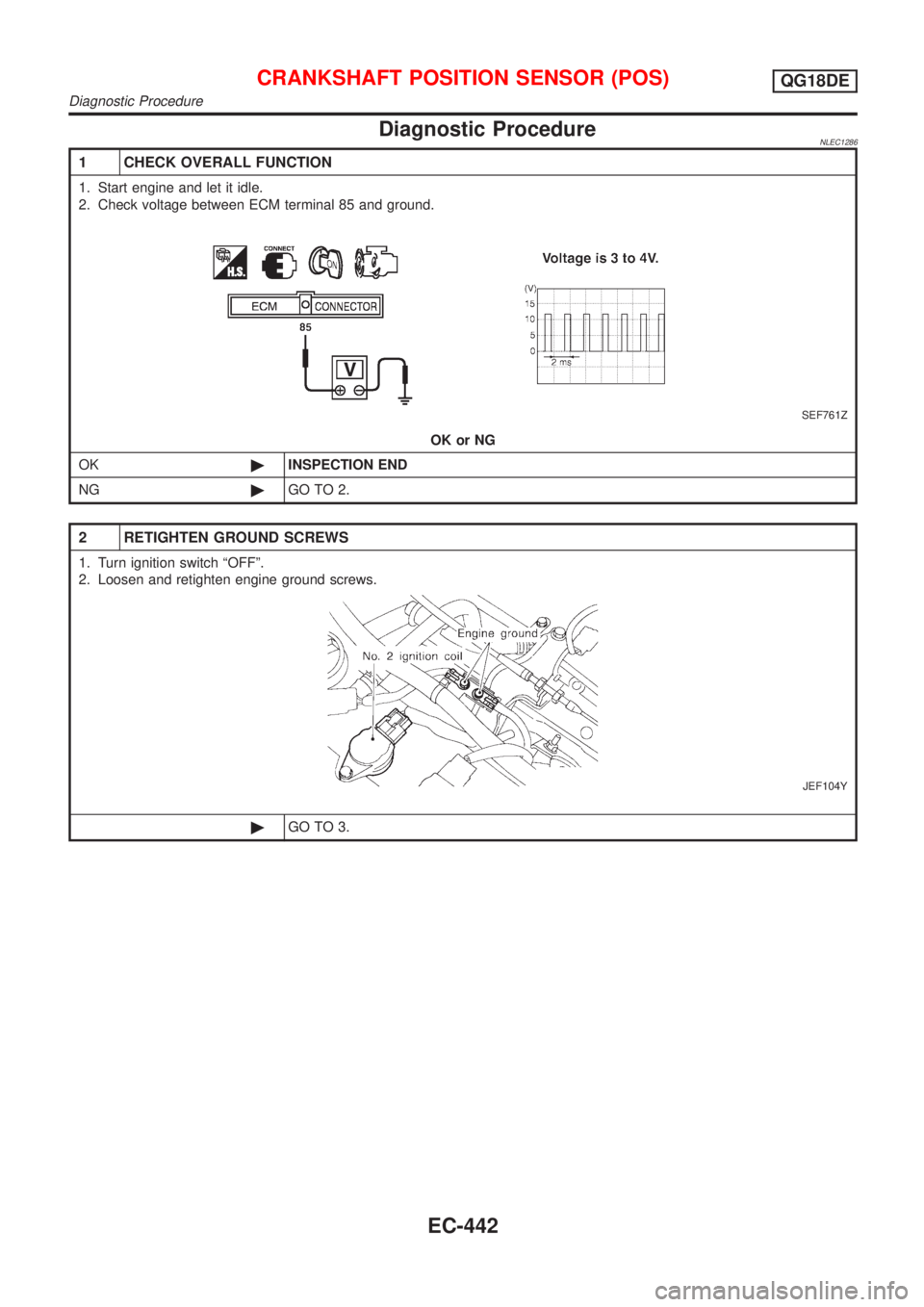

Diagnostic ProcedureNLEC1286

1 CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Check voltage between ECM terminal 85 and ground.

SEF761Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

©GO TO 3.

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Diagnostic Procedure

EC-442

Page 868 of 3051

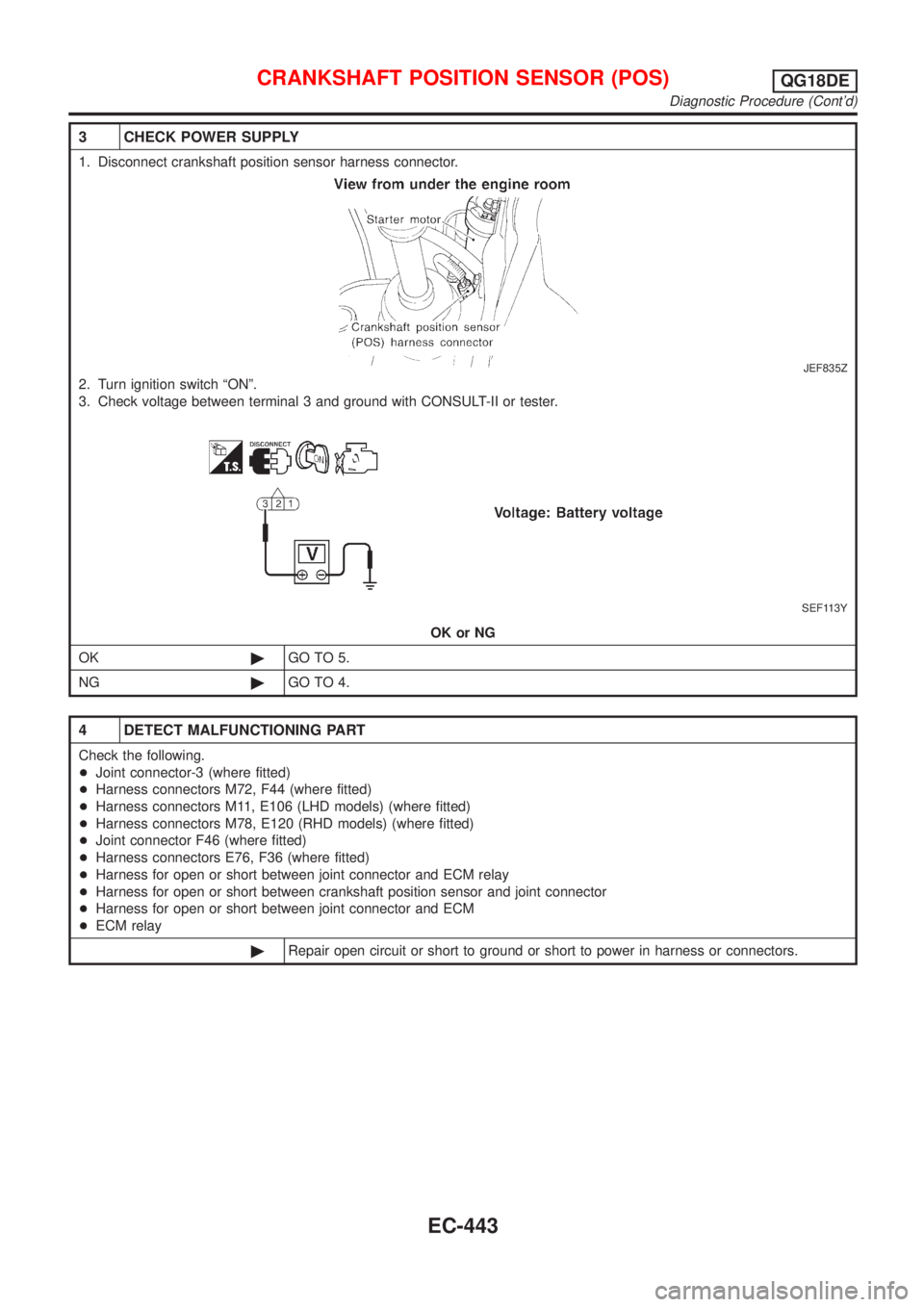

3 CHECK POWER SUPPLY

1. Disconnect crankshaft position sensor harness connector.

JEF835Z

2. Turn ignition switch ªONº.

3. Check voltage between terminal 3 and ground with CONSULT-II or tester.

SEF113Y

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-3 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Harness connectors M11, E106 (LHD models) (where fitted)

+Harness connectors M78, E120 (RHD models) (where fitted)

+Joint connector F46 (where fitted)

+Harness connectors E76, F36 (where fitted)

+Harness for open or short between joint connector and ECM relay

+Harness for open or short between crankshaft position sensor and joint connector

+Harness for open or short between joint connector and ECM

+ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Diagnostic Procedure (Cont'd)

EC-443

Page 869 of 3051

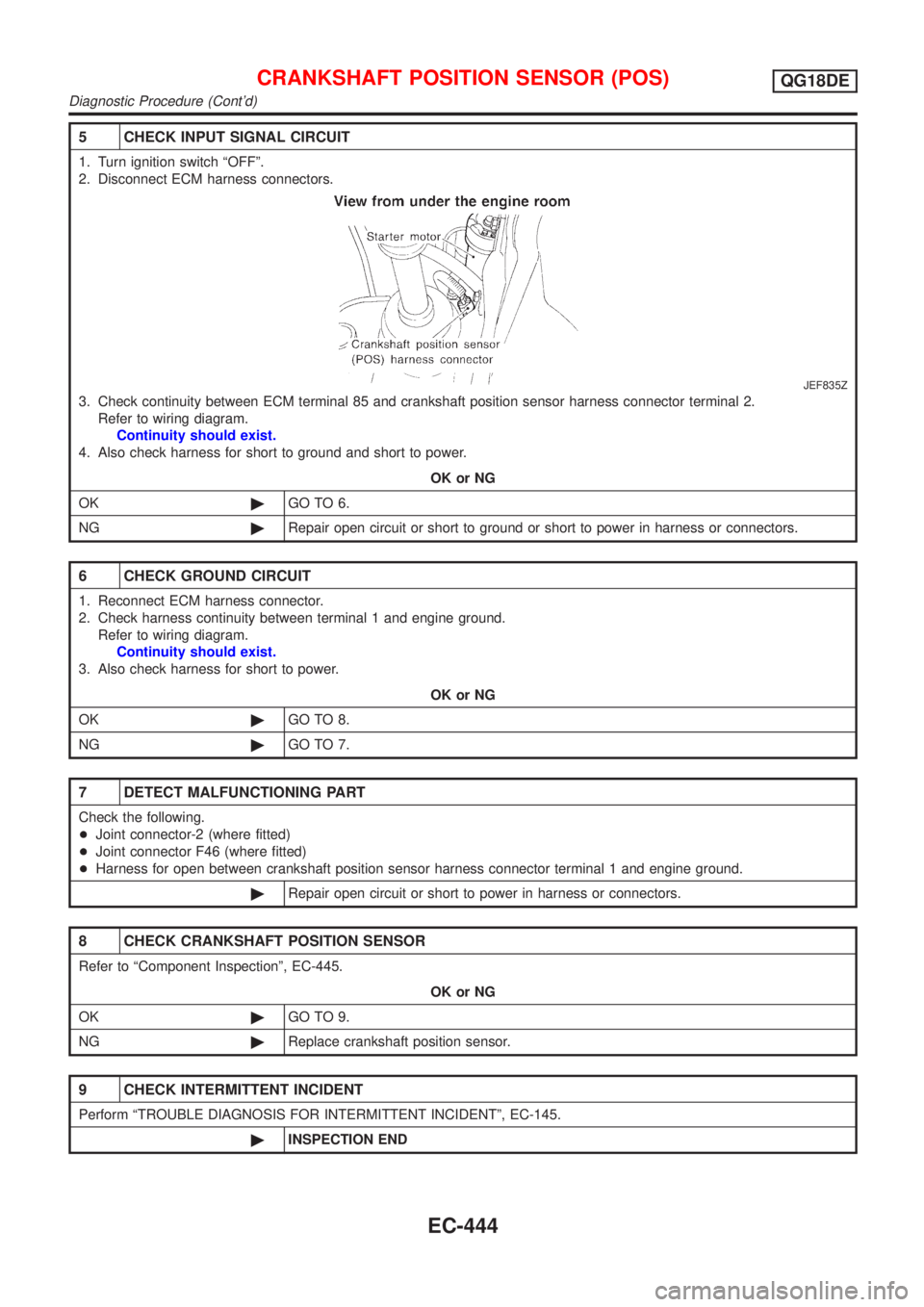

5 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connectors.

JEF835Z

3. Check continuity between ECM terminal 85 and crankshaft position sensor harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connector.

2. Check harness continuity between terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-2 (where fitted)

+Joint connector F46 (where fitted)

+Harness for open between crankshaft position sensor harness connector terminal 1 and engine ground.

©Repair open circuit or short to power in harness or connectors.

8 CHECK CRANKSHAFT POSITION SENSOR

Refer to ªComponent Inspectionº, EC-445.

OK or NG

OK©GO TO 9.

NG©Replace crankshaft position sensor.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Diagnostic Procedure (Cont'd)

EC-444

Page 870 of 3051

SEF121X

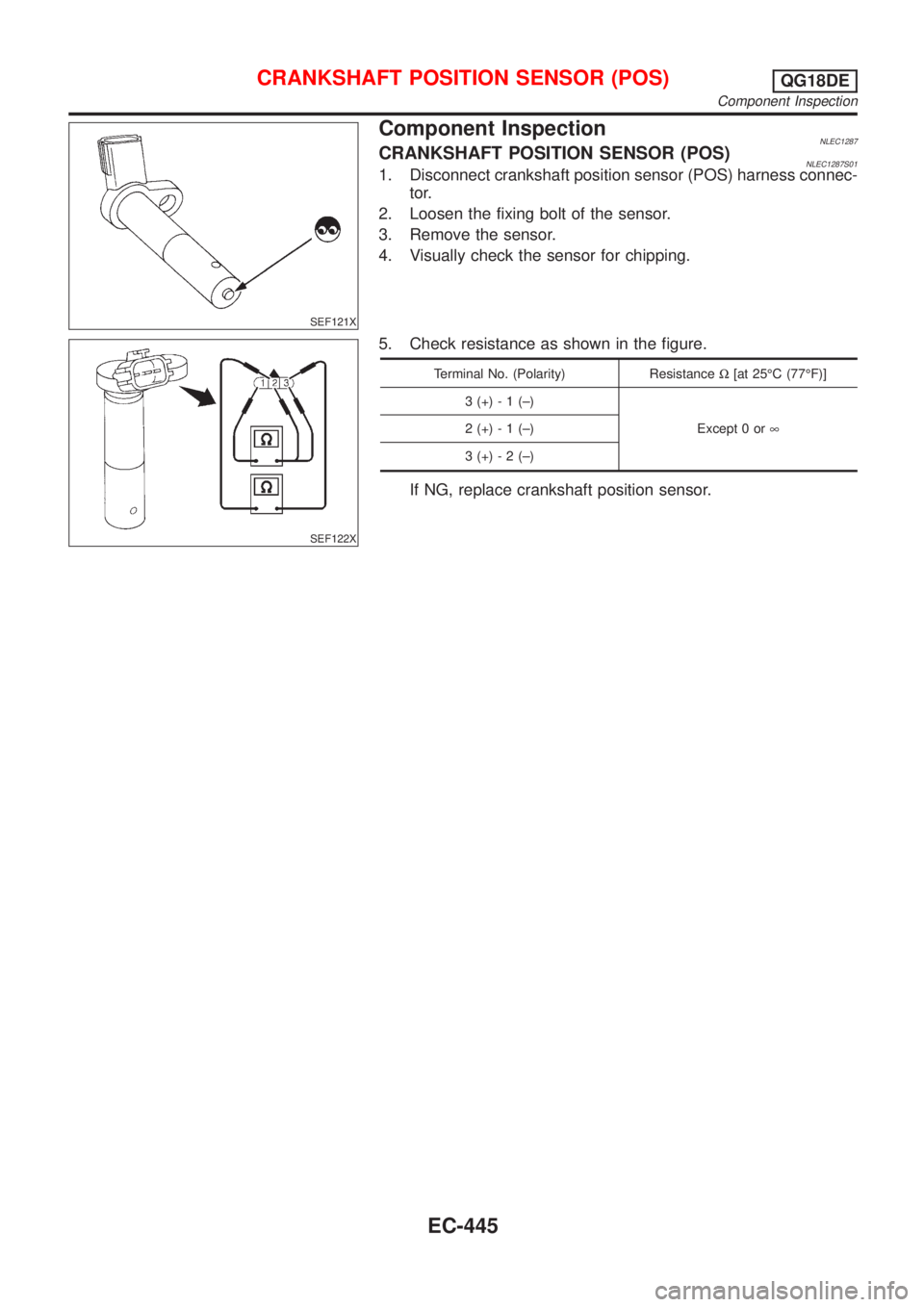

Component InspectionNLEC1287CRANKSHAFT POSITION SENSOR (POS)NLEC1287S011. Disconnect crankshaft position sensor (POS) harness connec-

tor.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

SEF122X

5. Check resistance as shown in the figure.

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (±)

Except 0 or¥ 2 (+) - 1 (±)

3 (+) - 2 (±)

If NG, replace crankshaft position sensor.

CRANKSHAFT POSITION SENSOR (POS)QG18DE

Component Inspection

EC-445

Trending: inflation pressure, wheel, steering wheel, instrument, brakes, engine oil capacity, brake pads