NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 881 of 3051

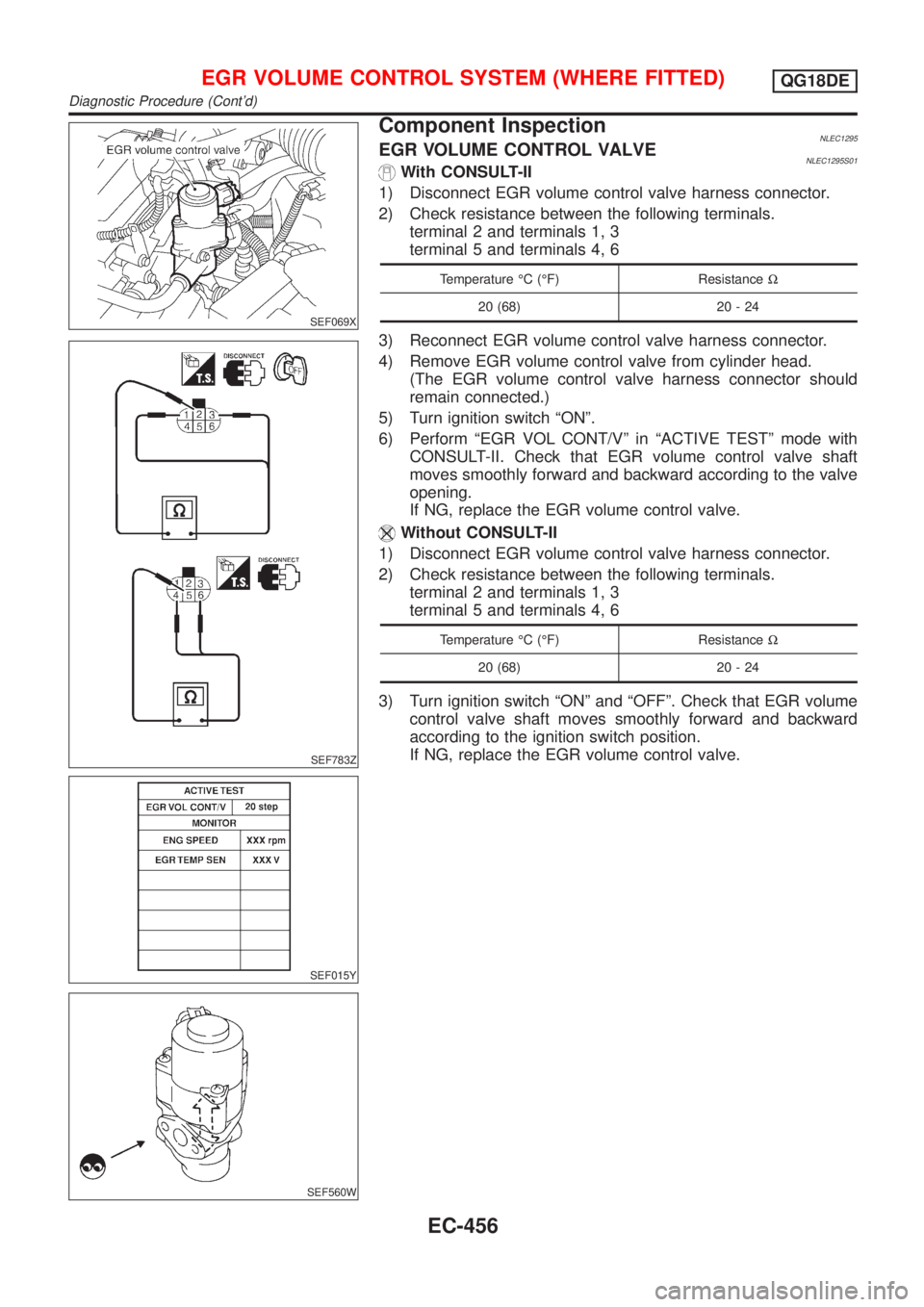

SEF069X

SEF783Z

SEF015Y

SEF560W

Component InspectionNLEC1295EGR VOLUME CONTROL VALVENLEC1295S01With CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Reconnect EGR volume control valve harness connector.

4) Remove EGR volume control valve from cylinder head.

(The EGR volume control valve harness connector should

remain connected.)

5) Turn ignition switch ªONº.

6) Perform ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT-II. Check that EGR volume control valve shaft

moves smoothly forward and backward according to the valve

opening.

If NG, replace the EGR volume control valve.

Without CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Turn ignition switch ªONº and ªOFFº. Check that EGR volume

control valve shaft moves smoothly forward and backward

according to the ignition switch position.

If NG, replace the EGR volume control valve.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG18DE

Diagnostic Procedure (Cont'd)

EC-456

Page 882 of 3051

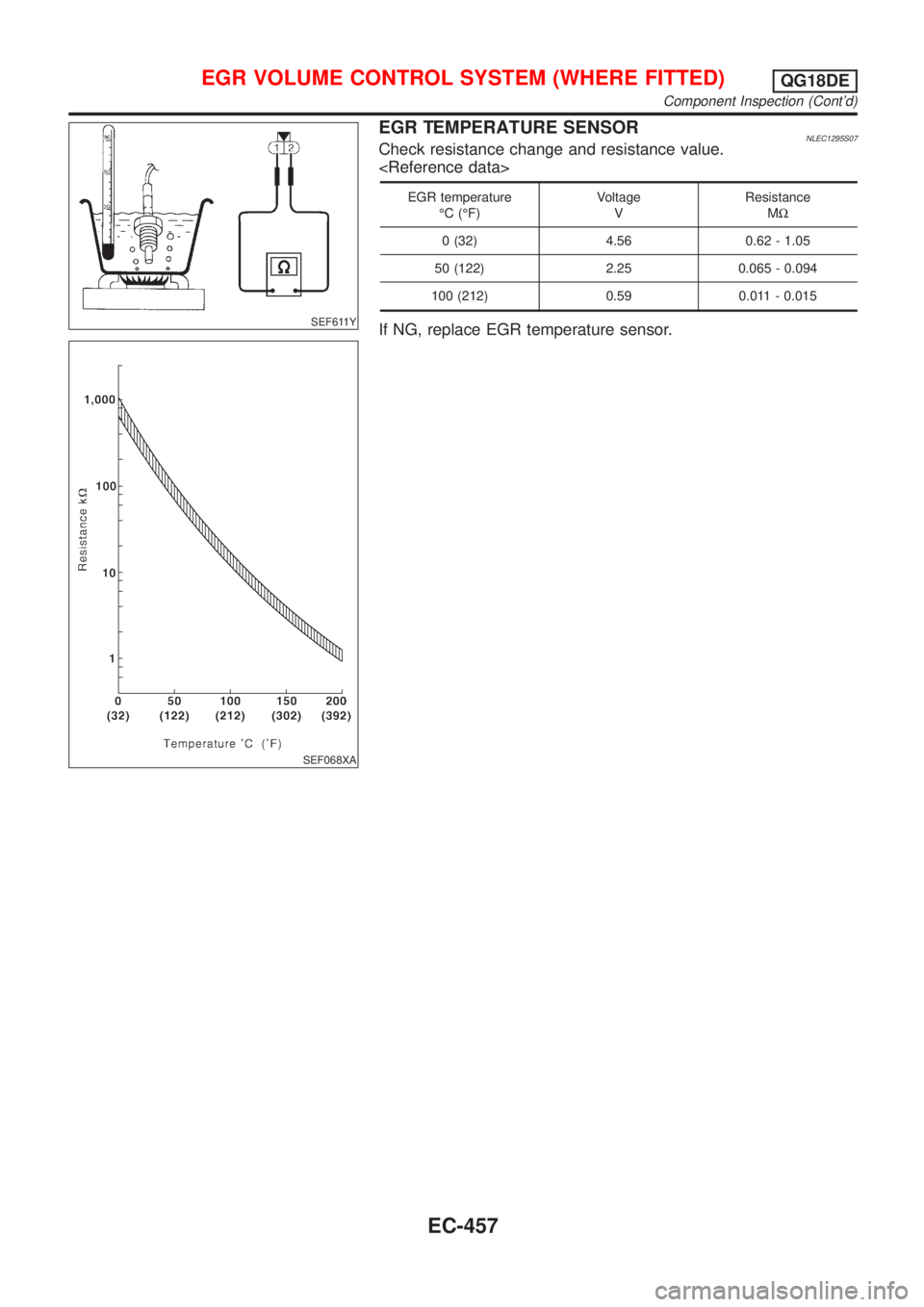

SEF611Y

SEF068XA

EGR TEMPERATURE SENSORNLEC1295S07Check resistance change and resistance value.

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

If NG, replace EGR temperature sensor.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG18DE

Component Inspection (Cont'd)

EC-457

Page 883 of 3051

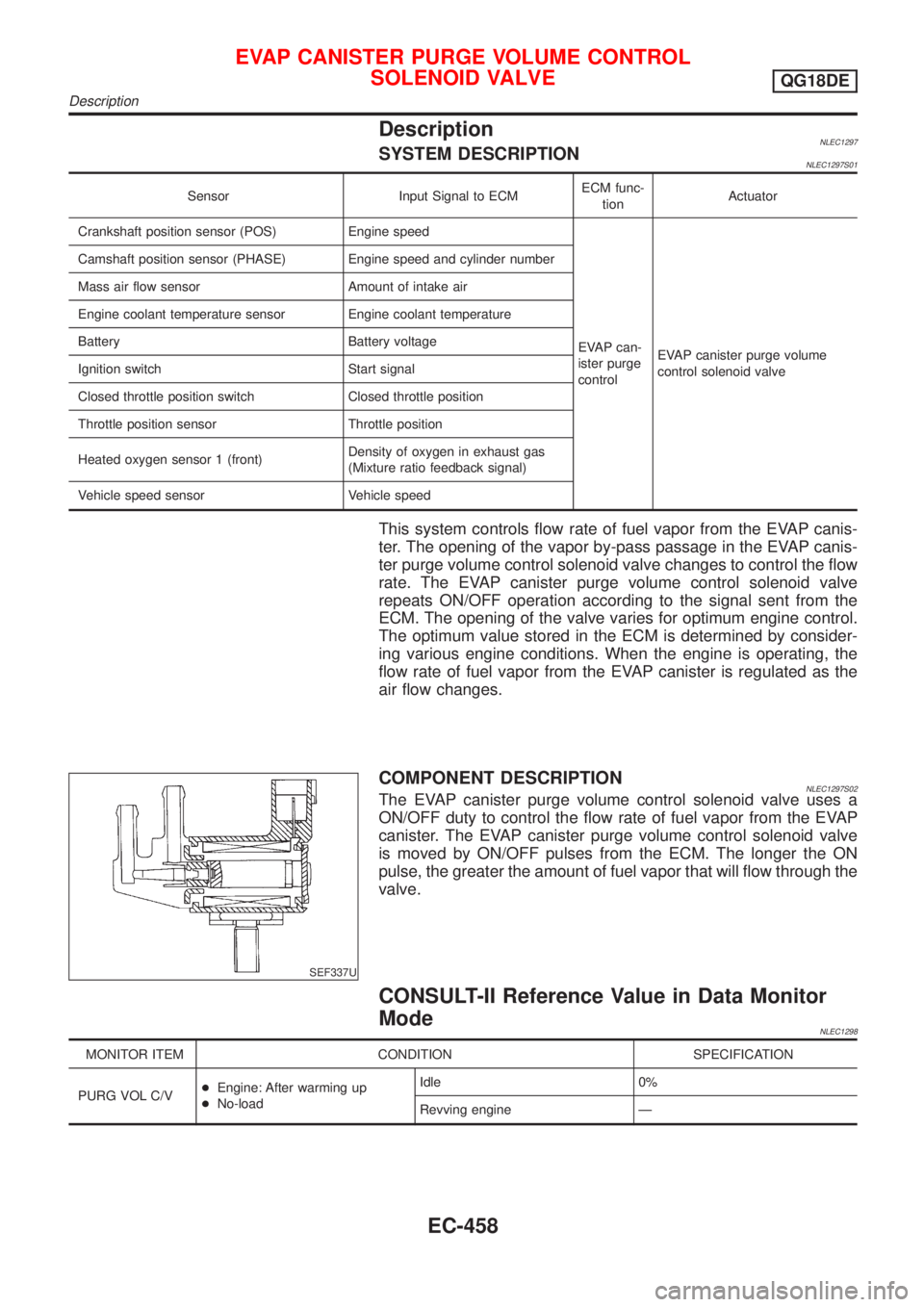

DescriptionNLEC1297SYSTEM DESCRIPTIONNLEC1297S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EVAP can-

ister purge

controlEVAP canister purge volume

control solenoid valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Battery Battery voltage

Ignition switch Start signal

Closed throttle position switch Closed throttle position

Throttle position sensor Throttle position

Heated oxygen sensor 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Vehicle speed sensor Vehicle speed

This system controls flow rate of fuel vapor from the EVAP canis-

ter. The opening of the vapor by-pass passage in the EVAP canis-

ter purge volume control solenoid valve changes to control the flow

rate. The EVAP canister purge volume control solenoid valve

repeats ON/OFF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engine control.

The optimum value stored in the ECM is determined by consider-

ing various engine conditions. When the engine is operating, the

flow rate of fuel vapor from the EVAP canister is regulated as the

air flow changes.

SEF337U

COMPONENT DESCRIPTIONNLEC1297S02The EVAP canister purge volume control solenoid valve uses a

ON/OFF duty to control the flow rate of fuel vapor from the EVAP

canister. The EVAP canister purge volume control solenoid valve

is moved by ON/OFF pulses from the ECM. The longer the ON

pulse, the greater the amount of fuel vapor that will flow through the

valve.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC1298

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/V+Engine: After warming up

+No-loadIdle 0%

Revving engine Ð

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Description

EC-458

Page 884 of 3051

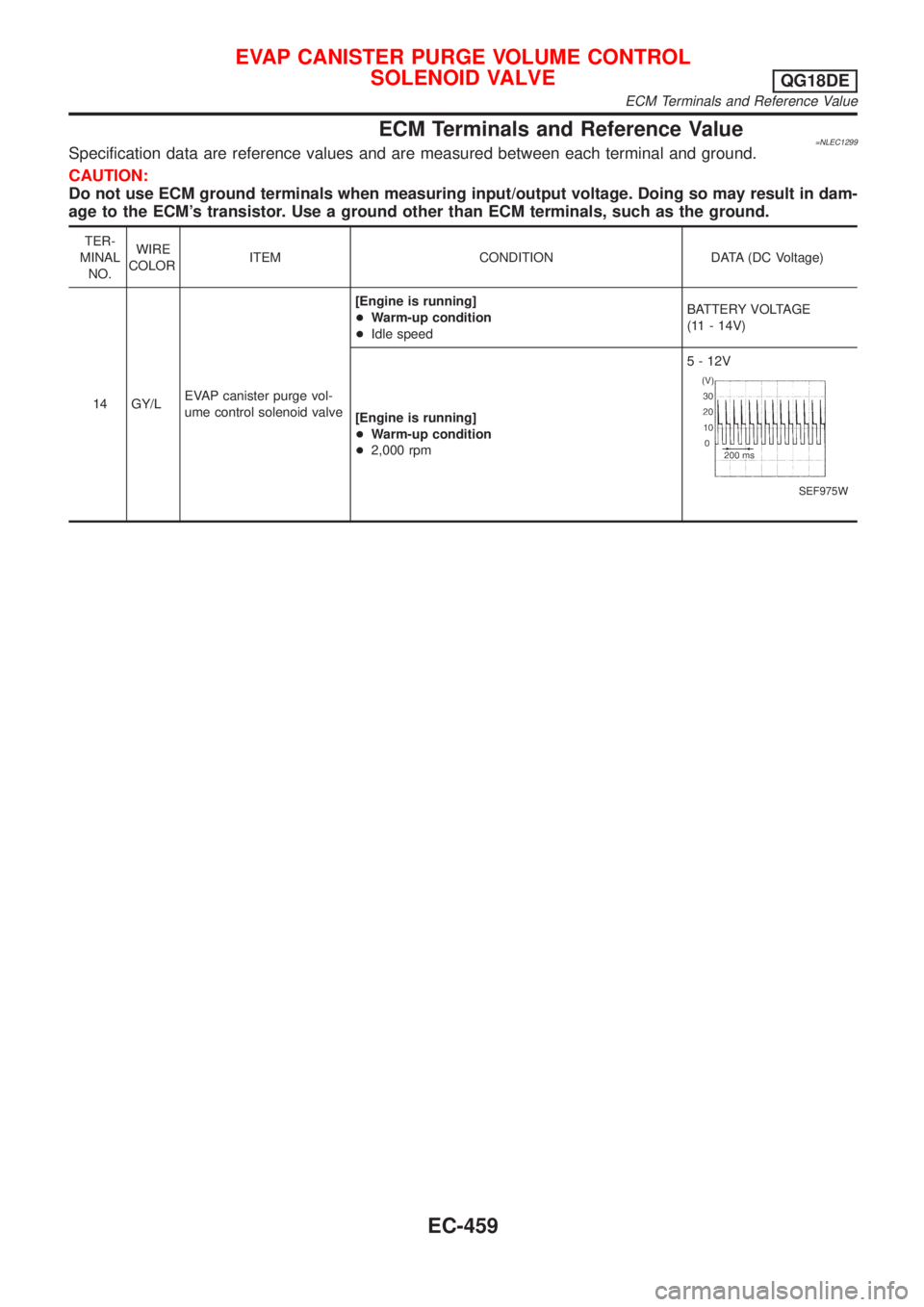

ECM Terminals and Reference Value=NLEC1299Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 GY/LEVAP canister purge vol-

ume control solenoid valve[Engine is running]

+Warm-up condition

+Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Warm-up condition

+2,000 rpm5 - 12V

SEF975W

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

ECM Terminals and Reference Value

EC-459

Page 885 of 3051

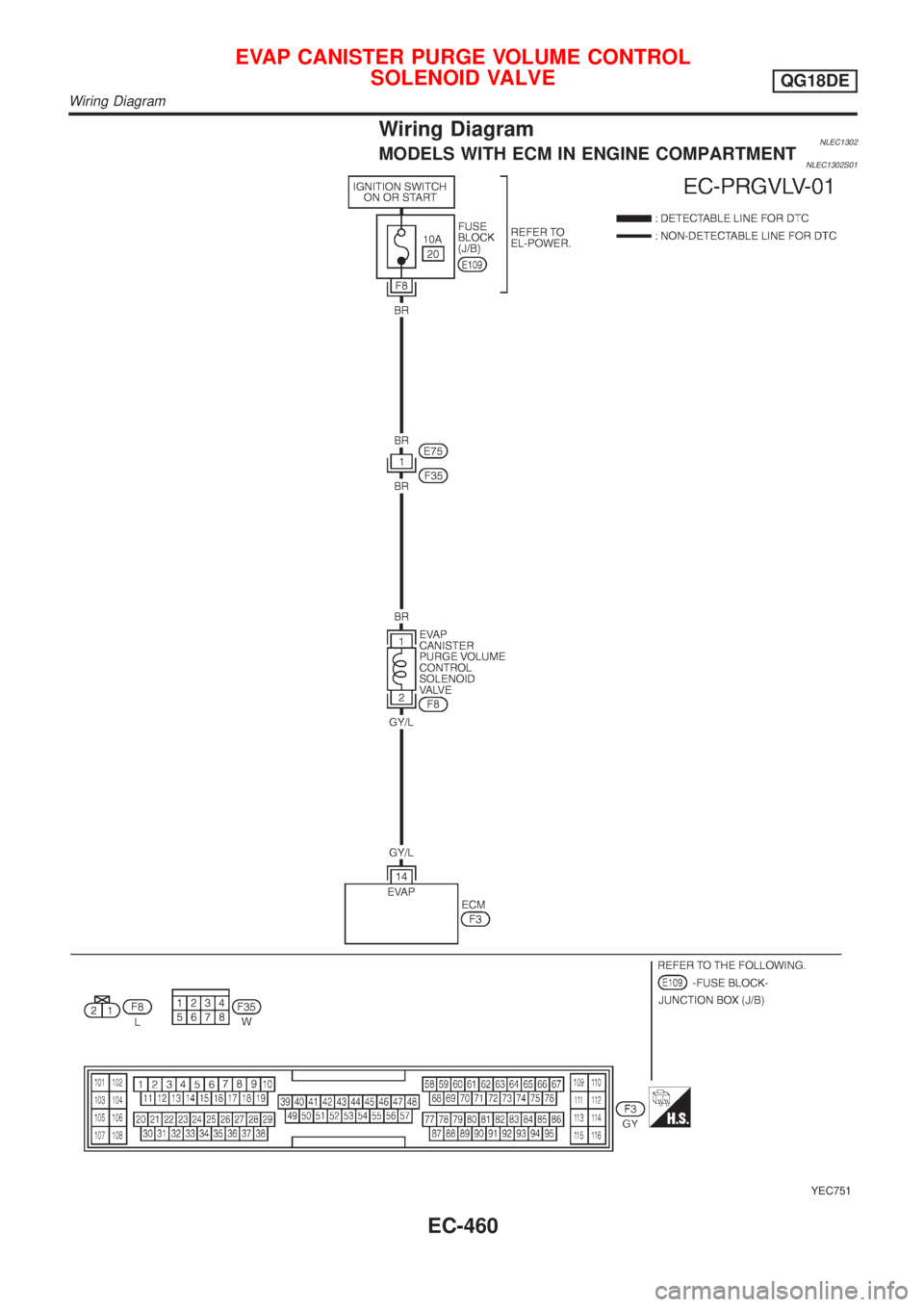

Wiring DiagramNLEC1302MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1302S01

YEC751

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Wiring Diagram

EC-460

Page 886 of 3051

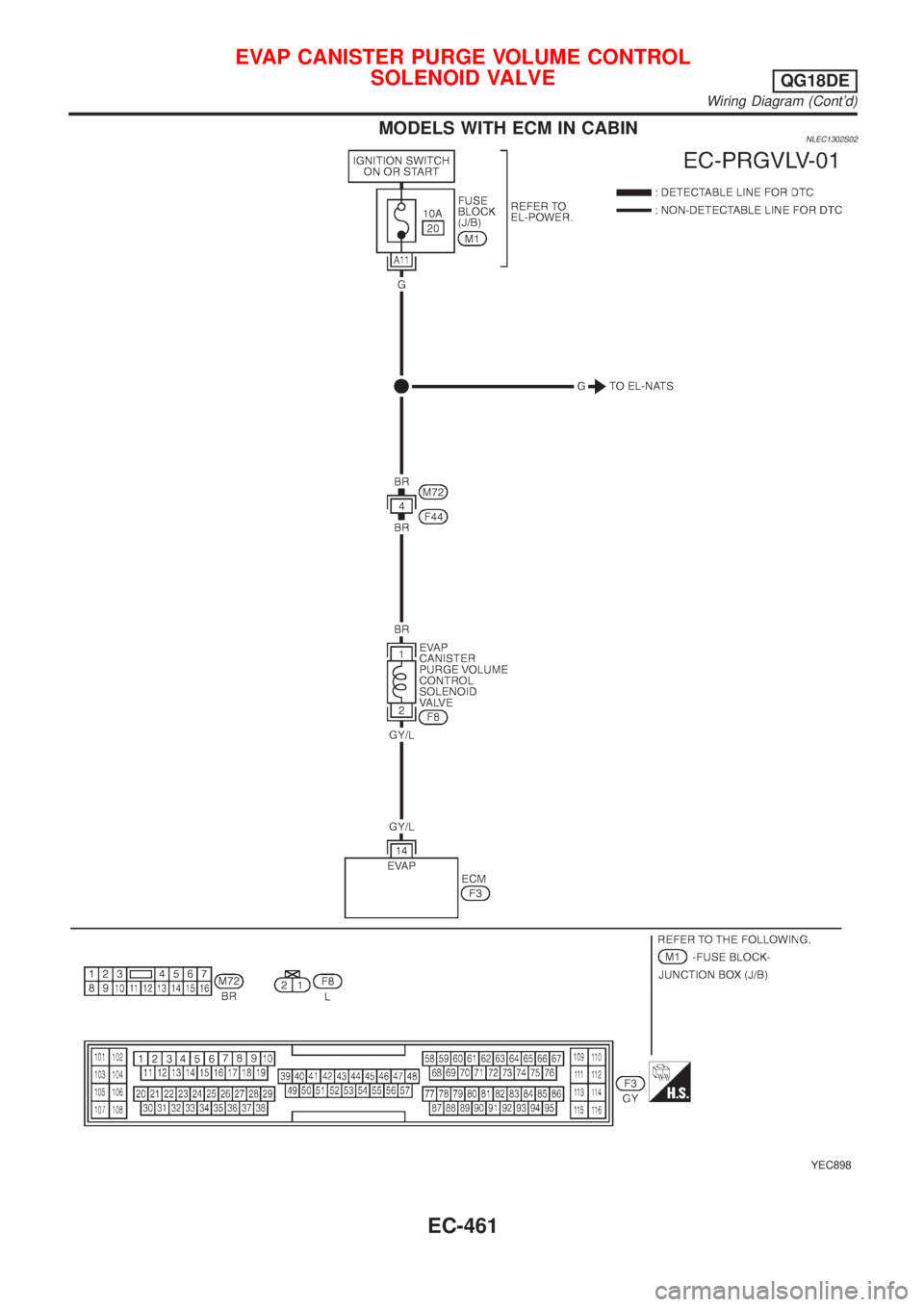

MODELS WITH ECM IN CABINNLEC1302S02

YEC898

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Wiring Diagram (Cont'd)

EC-461

Page 887 of 3051

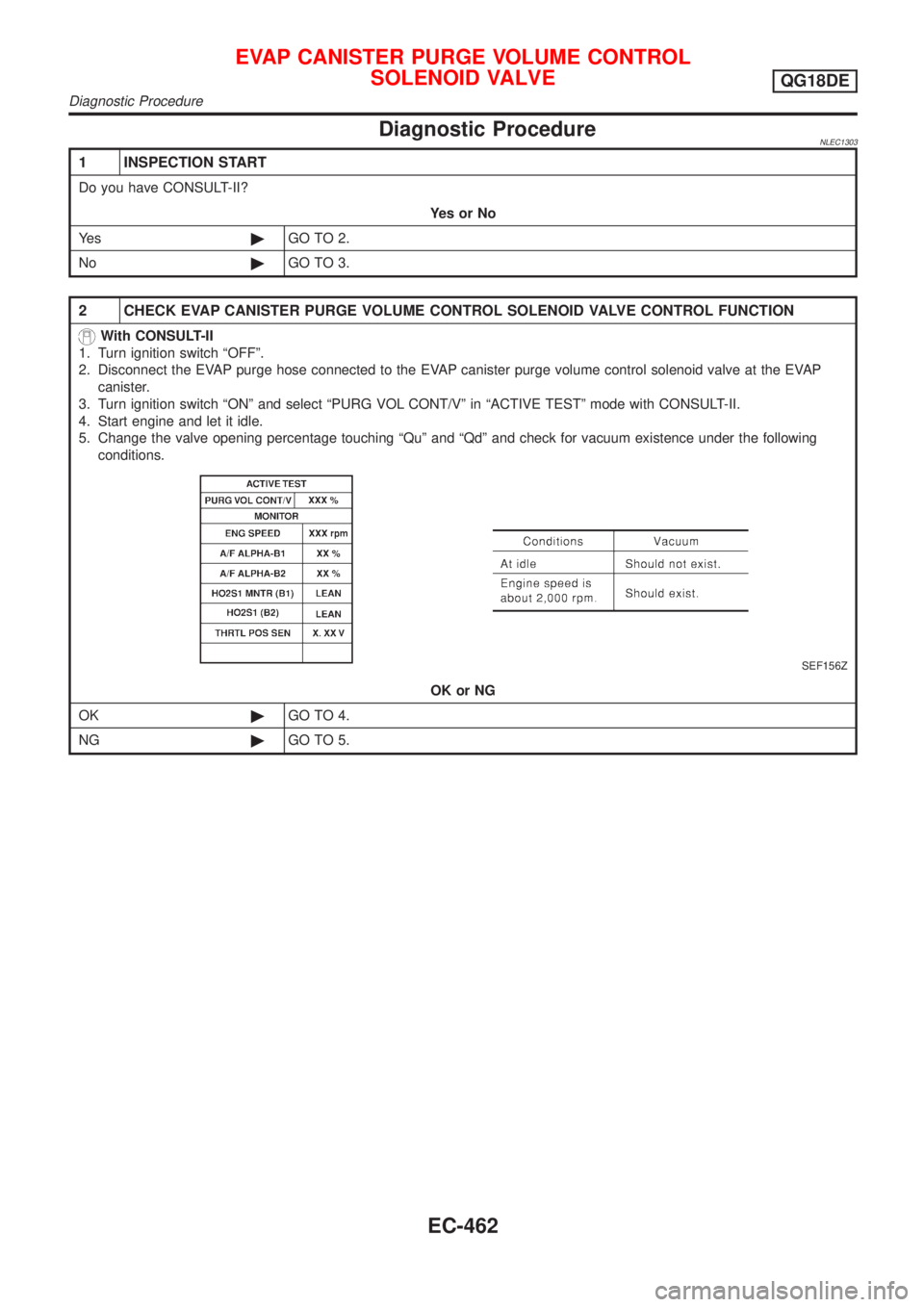

Diagnostic ProcedureNLEC1303

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE CONTROL FUNCTION

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect the EVAP purge hose connected to the EVAP canister purge volume control solenoid valve at the EVAP

canister.

3. Turn ignition switch ªONº and select ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II.

4. Start engine and let it idle.

5. Change the valve opening percentage touching ªQuº and ªQdº and check for vacuum existence under the following

conditions.

SEF156Z

OK or NG

OK©GO TO 4.

NG©GO TO 5.

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Diagnostic Procedure

EC-462

Page 888 of 3051

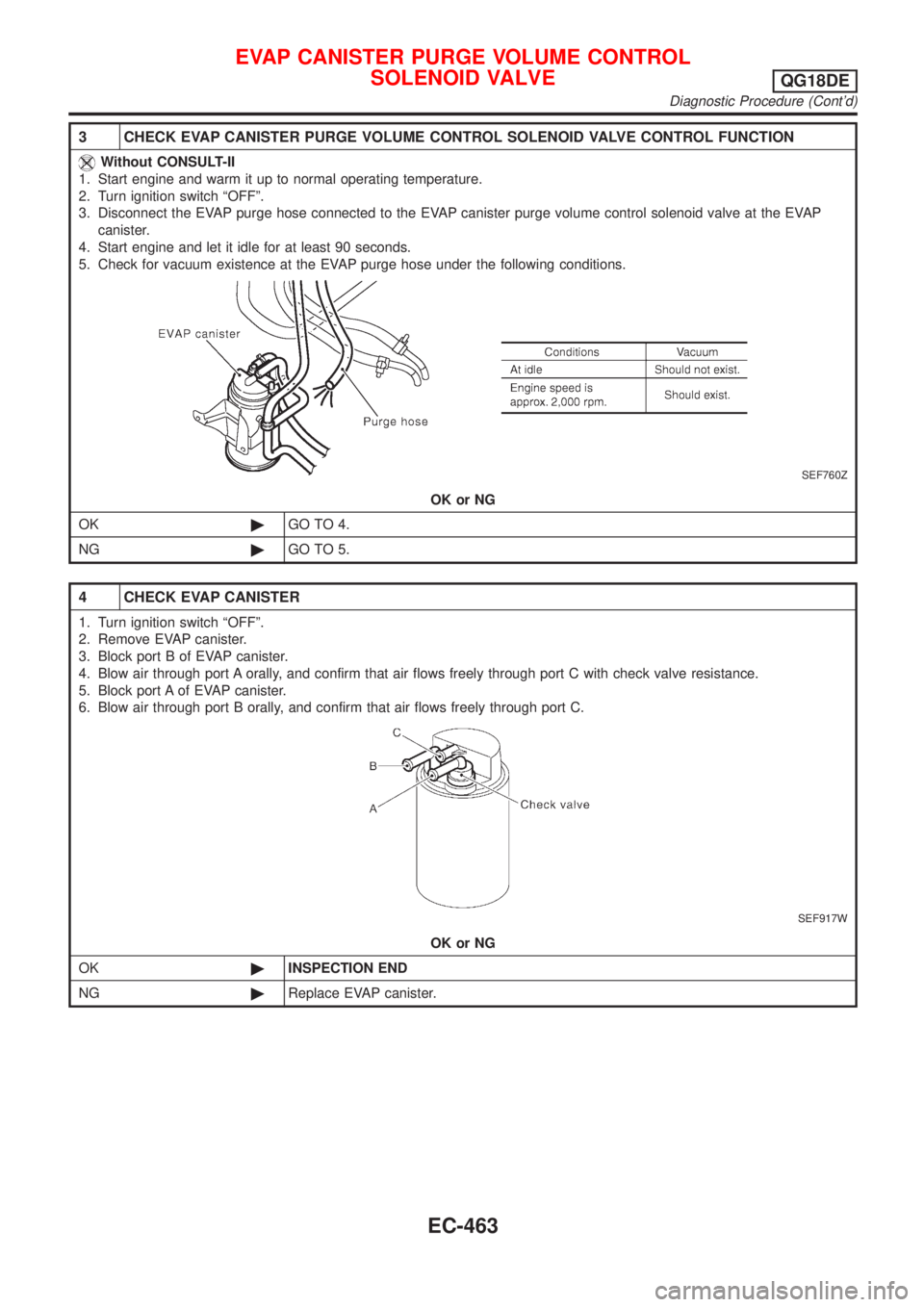

3 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE CONTROL FUNCTION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Disconnect the EVAP purge hose connected to the EVAP canister purge volume control solenoid valve at the EVAP

canister.

4. Start engine and let it idle for at least 90 seconds.

5. Check for vacuum existence at the EVAP purge hose under the following conditions.

SEF760Z

OK or NG

OK©GO TO 4.

NG©GO TO 5.

4 CHECK EVAP CANISTER

1. Turn ignition switch ªOFFº.

2. Remove EVAP canister.

3. Block port B of EVAP canister.

4. Blow air through port A orally, and confirm that air flows freely through port C with check valve resistance.

5. Block port A of EVAP canister.

6. Blow air through port B orally, and confirm that air flows freely through port C.

SEF917W

OK or NG

OK©INSPECTION END

NG©Replace EVAP canister.

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Diagnostic Procedure (Cont'd)

EC-463

Page 889 of 3051

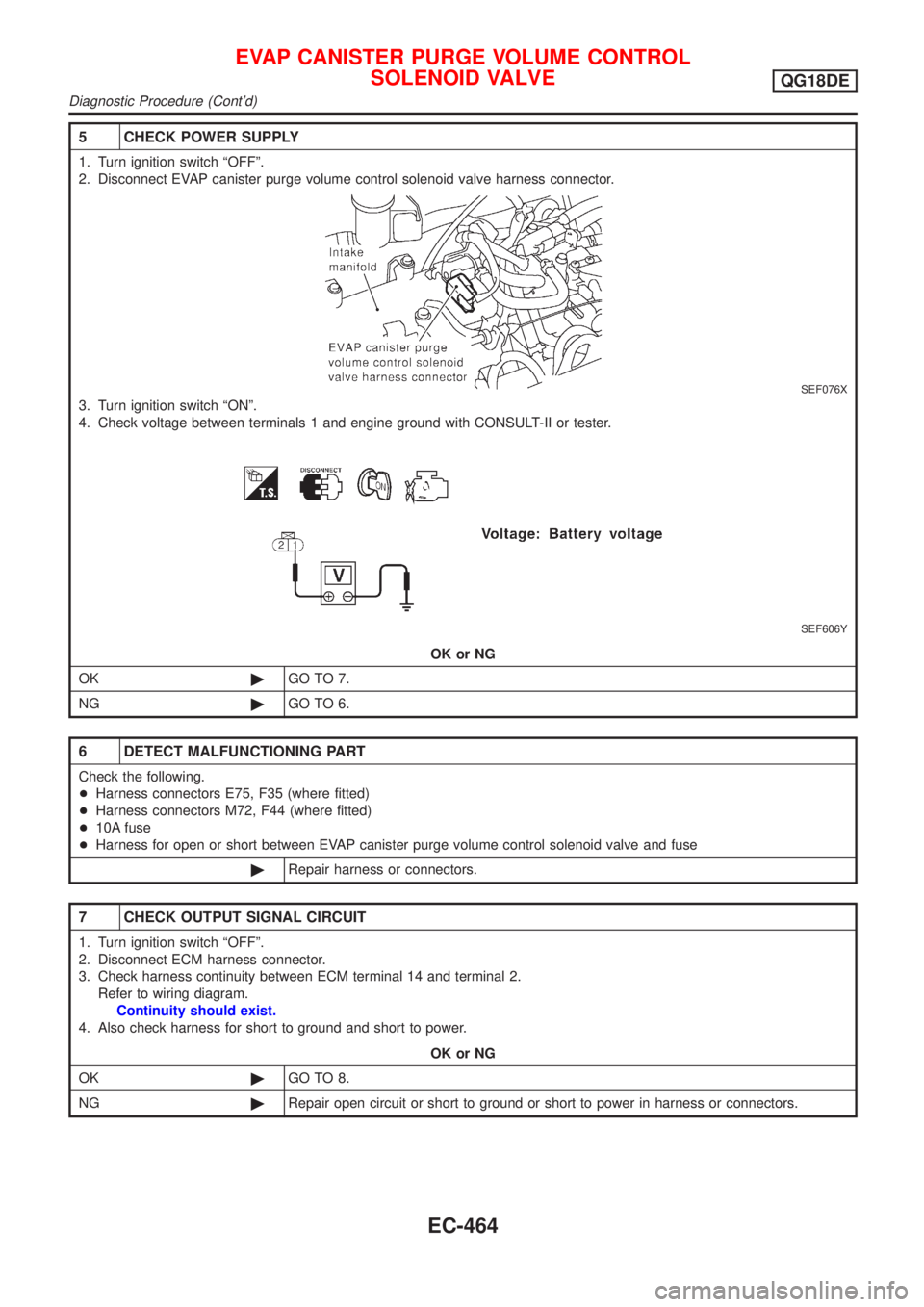

5 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect EVAP canister purge volume control solenoid valve harness connector.

SEF076X

3. Turn ignition switch ªONº.

4. Check voltage between terminals 1 and engine ground with CONSULT-II or tester.

SEF606Y

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F35 (where fitted)

+Harness connectors M72, F44 (where fitted)

+10A fuse

+Harness for open or short between EVAP canister purge volume control solenoid valve and fuse

©Repair harness or connectors.

7 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 14 and terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Diagnostic Procedure (Cont'd)

EC-464

Page 890 of 3051

8 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to ªComponent Inspectionº EC-465.

OK or NG

OK©GO TO 9.

NG©Replace EVAP canister purge volume control solenoid valve.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

SEF677Y

SEF661U

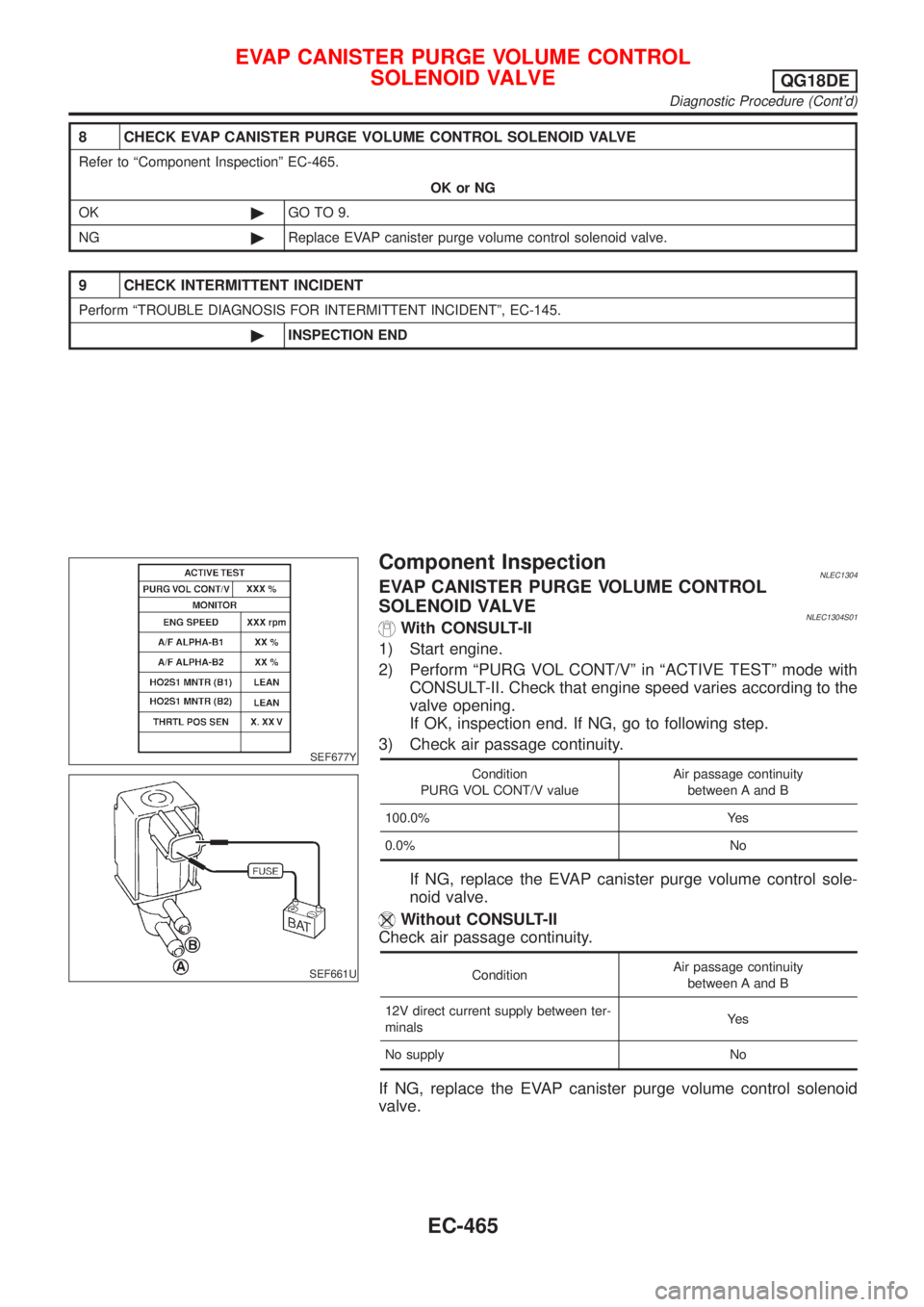

Component InspectionNLEC1304EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

NLEC1304S01With CONSULT-II

1) Start engine.

2) Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT-II. Check that engine speed varies according to the

valve opening.

If OK, inspection end. If NG, go to following step.

3) Check air passage continuity.

Condition

PURG VOL CONT/V valueAir passage continuity

between A and B

100.0% Yes

0.0% No

If NG, replace the EVAP canister purge volume control sole-

noid valve.

Without CONSULT-II

Check air passage continuity.

ConditionAir passage continuity

between A and B

12V direct current supply between ter-

minalsYe s

No supply No

If NG, replace the EVAP canister purge volume control solenoid

valve.

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

QG18DE

Diagnostic Procedure (Cont'd)

EC-465