NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: keyless entry, power steering, clock setting, steering wheel adjustment, keyless, fog light, check oil

Page 931 of 3051

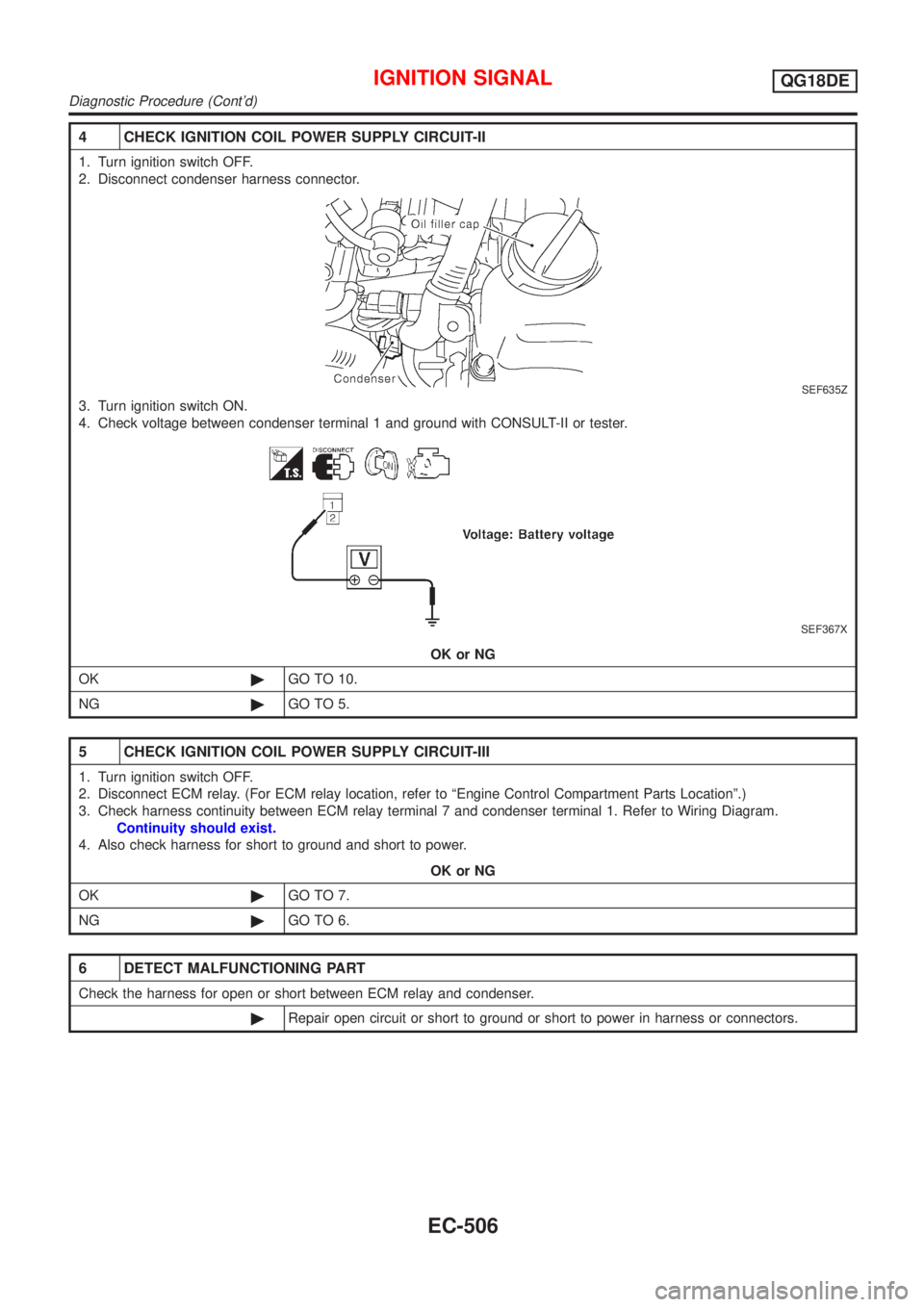

4 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

SEF635Z

3. Turn ignition switch ON.

4. Check voltage between condenser terminal 1 and ground with CONSULT-II or tester.

SEF367X

OK or NG

OK©GO TO 10.

NG©GO TO 5.

5 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Compartment Parts Locationº.)

3. Check harness continuity between ECM relay terminal 7 and condenser terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM relay and condenser.

©Repair open circuit or short to ground or short to power in harness or connectors.

IGNITION SIGNALQG18DE

Diagnostic Procedure (Cont'd)

EC-506

Page 932 of 3051

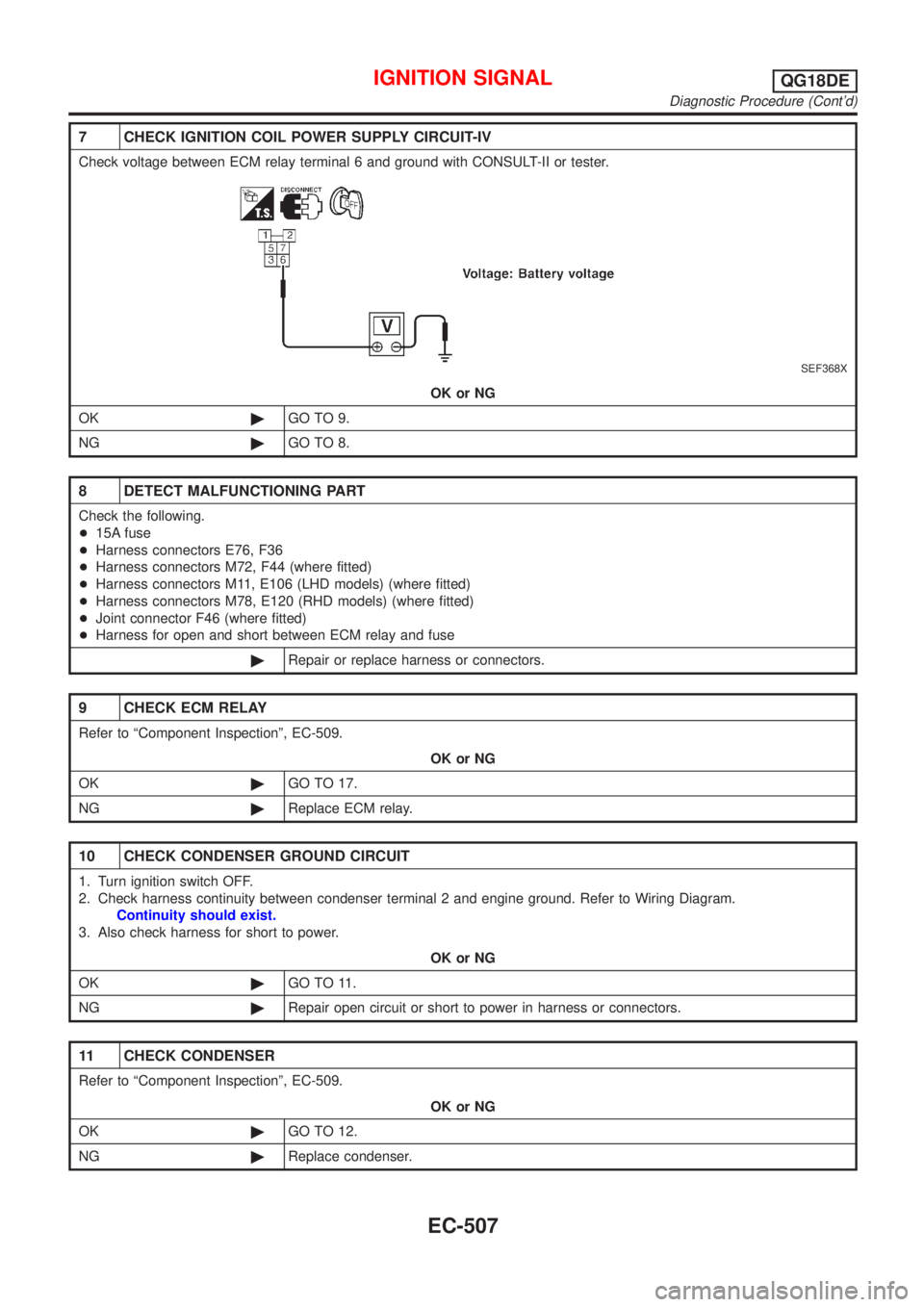

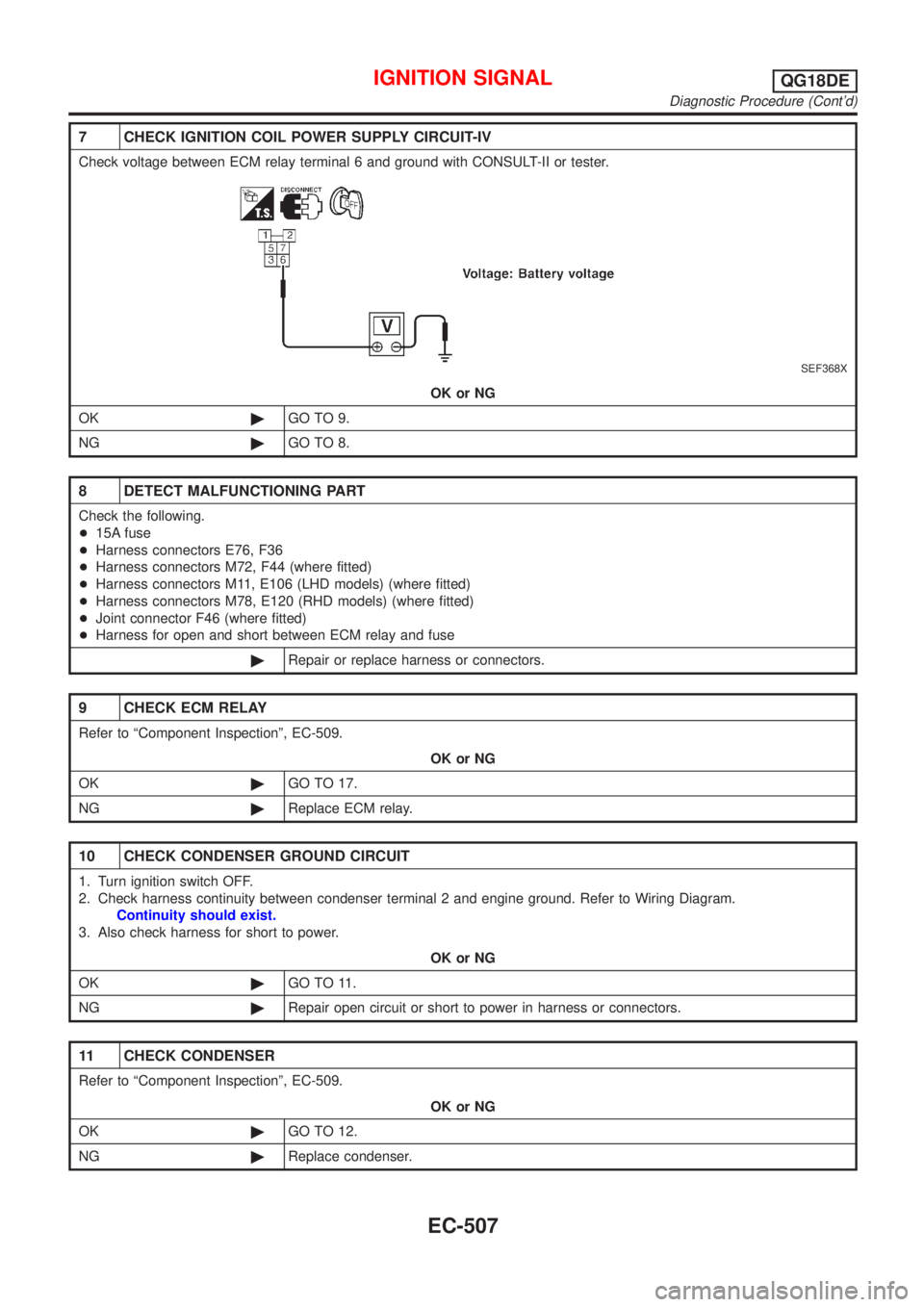

7 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-IV

Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF368X

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse

+Harness connectors E76, F36

+Harness connectors M72, F44 (where fitted)

+Harness connectors M11, E106 (LHD models) (where fitted)

+Harness connectors M78, E120 (RHD models) (where fitted)

+Joint connector F46 (where fitted)

+Harness for open and short between ECM relay and fuse

©Repair or replace harness or connectors.

9 CHECK ECM RELAY

Refer to ªComponent Inspectionº, EC-509.

OK or NG

OK©GO TO 17.

NG©Replace ECM relay.

10 CHECK CONDENSER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 11.

NG©Repair open circuit or short to power in harness or connectors.

11 CHECK CONDENSER

Refer to ªComponent Inspectionº, EC-509.

OK or NG

OK©GO TO 12.

NG©Replace condenser.

IGNITION SIGNALQG18DE

Diagnostic Procedure (Cont'd)

EC-507

Page 933 of 3051

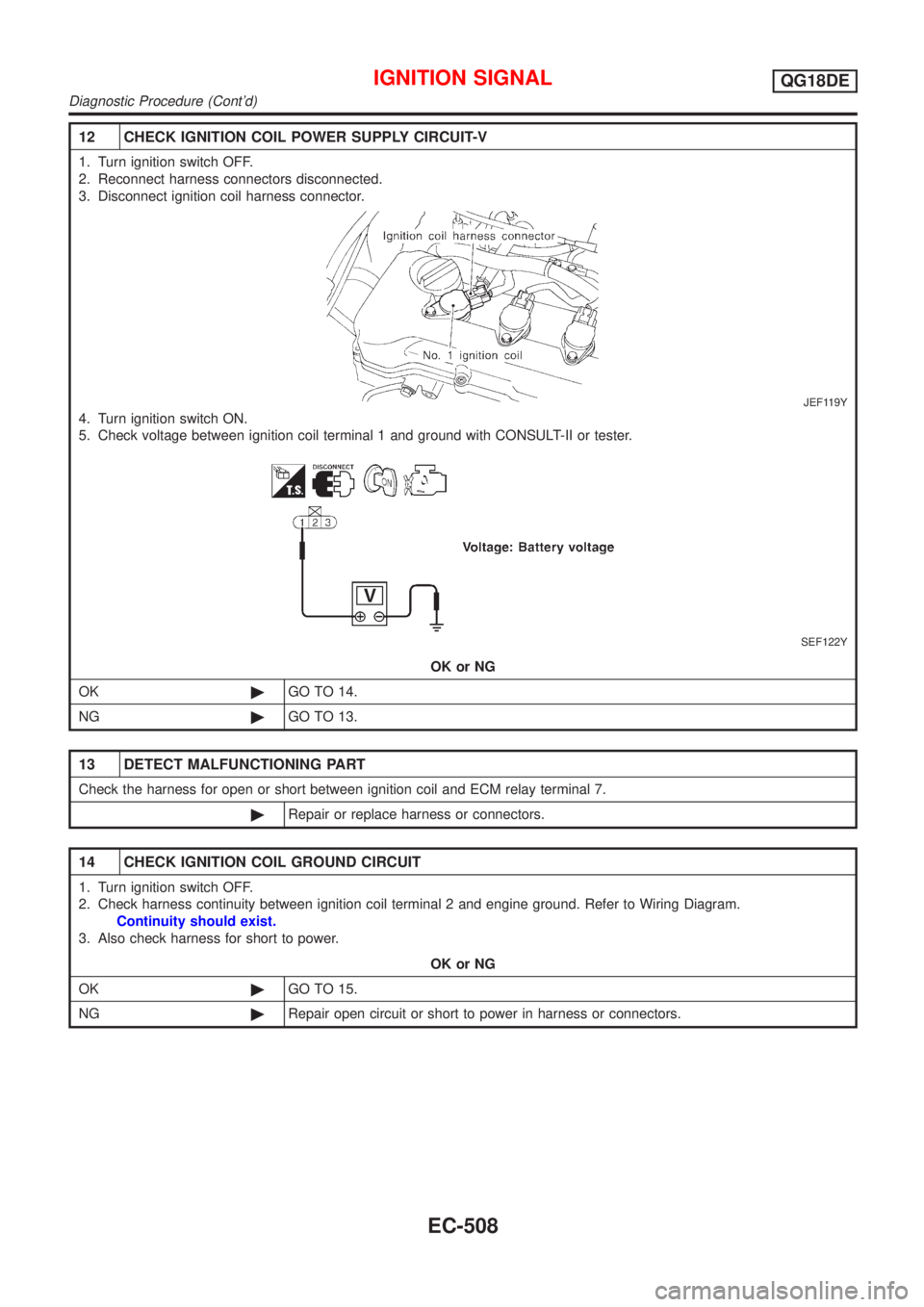

12 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-V

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect ignition coil harness connector.

JEF119Y

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 1 and ground with CONSULT-II or tester.

SEF122Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the harness for open or short between ignition coil and ECM relay terminal 7.

©Repair or replace harness or connectors.

14 CHECK IGNITION COIL GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 15.

NG©Repair open circuit or short to power in harness or connectors.

IGNITION SIGNALQG18DE

Diagnostic Procedure (Cont'd)

EC-508

Page 934 of 3051

15 CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 35, 36, 37, 38 and ignition coil terminal 3. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

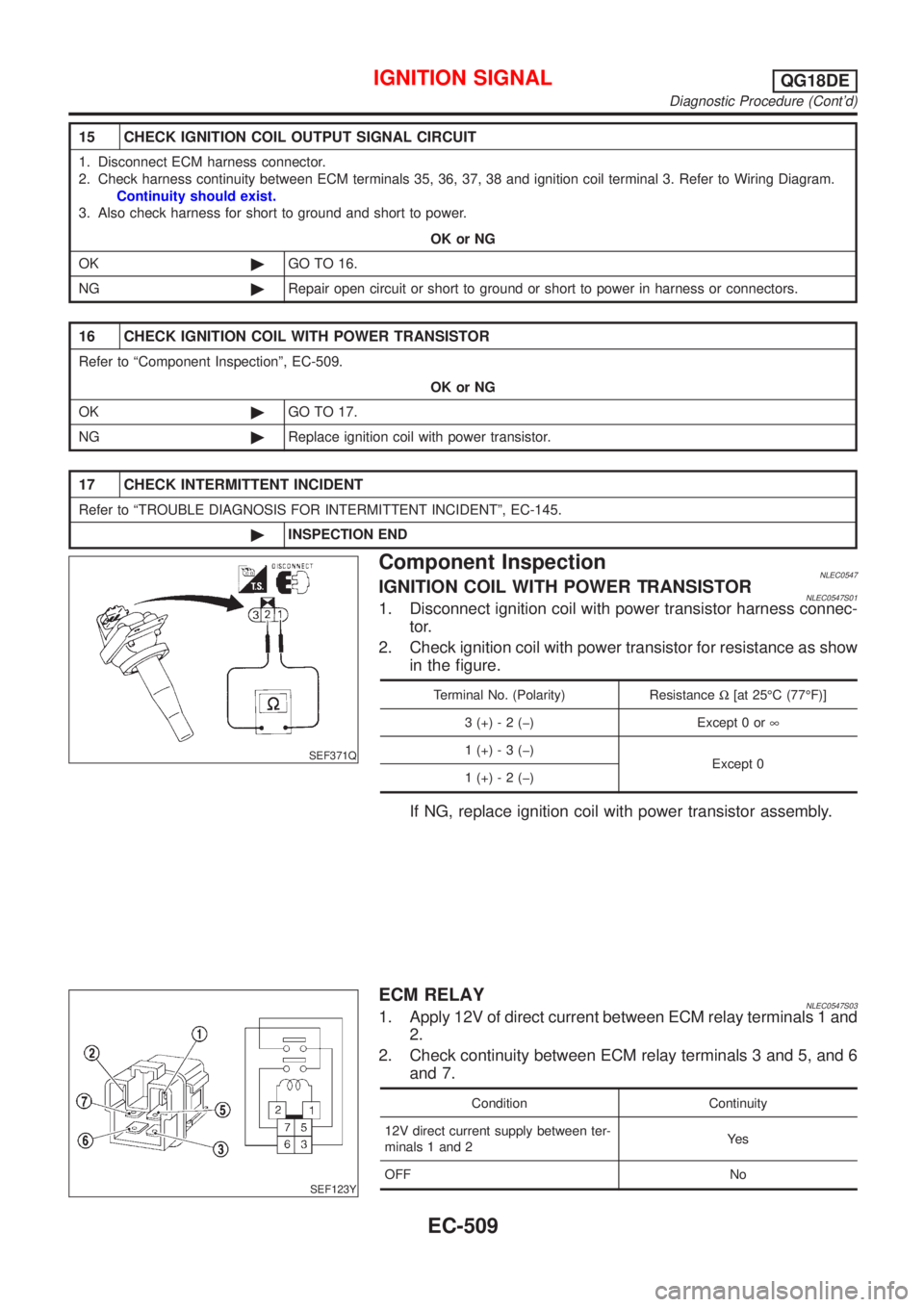

16 CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to ªComponent Inspectionº, EC-509.

OK or NG

OK©GO TO 17.

NG©Replace ignition coil with power transistor.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

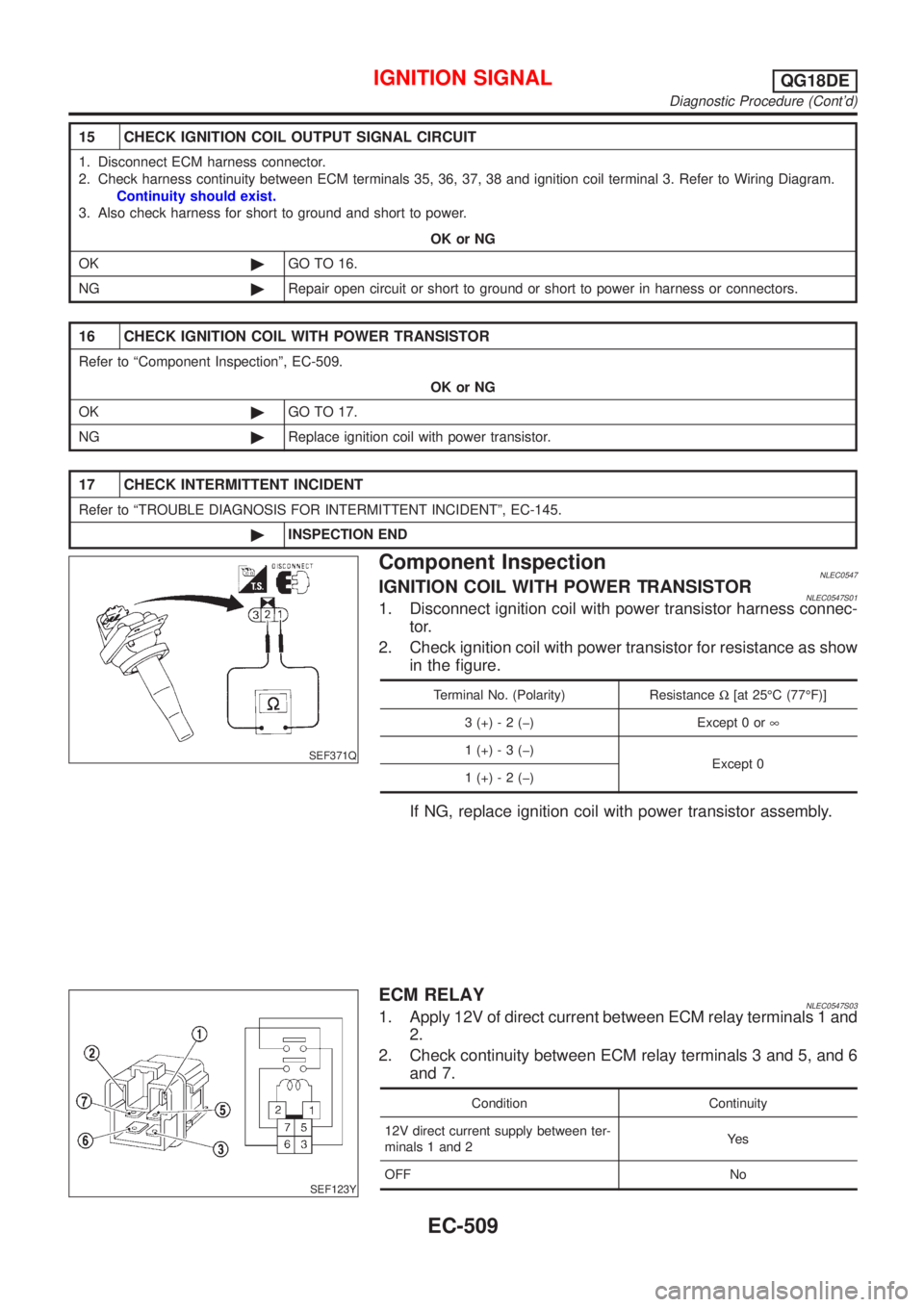

SEF371Q

Component InspectionNLEC0547IGNITION COIL WITH POWER TRANSISTORNLEC0547S011. Disconnect ignition coil with power transistor harness connec-

tor.

2. Check ignition coil with power transistor for resistance as show

in the figure.

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 2 (þ) Except 0 or¥

1 (+) - 3 (þ)

Except 0

1 (+) - 2 (þ)

If NG, replace ignition coil with power transistor assembly.

SEF123Y

ECM RELAYNLEC0547S031. Apply 12V of direct current between ECM relay terminals 1 and

2.

2. Check continuity between ECM relay terminals 3 and 5, and 6

and 7.

Condition Continuity

12V direct current supply between ter-

minals 1 and 2Ye s

OFF No

IGNITION SIGNALQG18DE

Diagnostic Procedure (Cont'd)

EC-509

Page 935 of 3051

If NG, replace ECM relay.

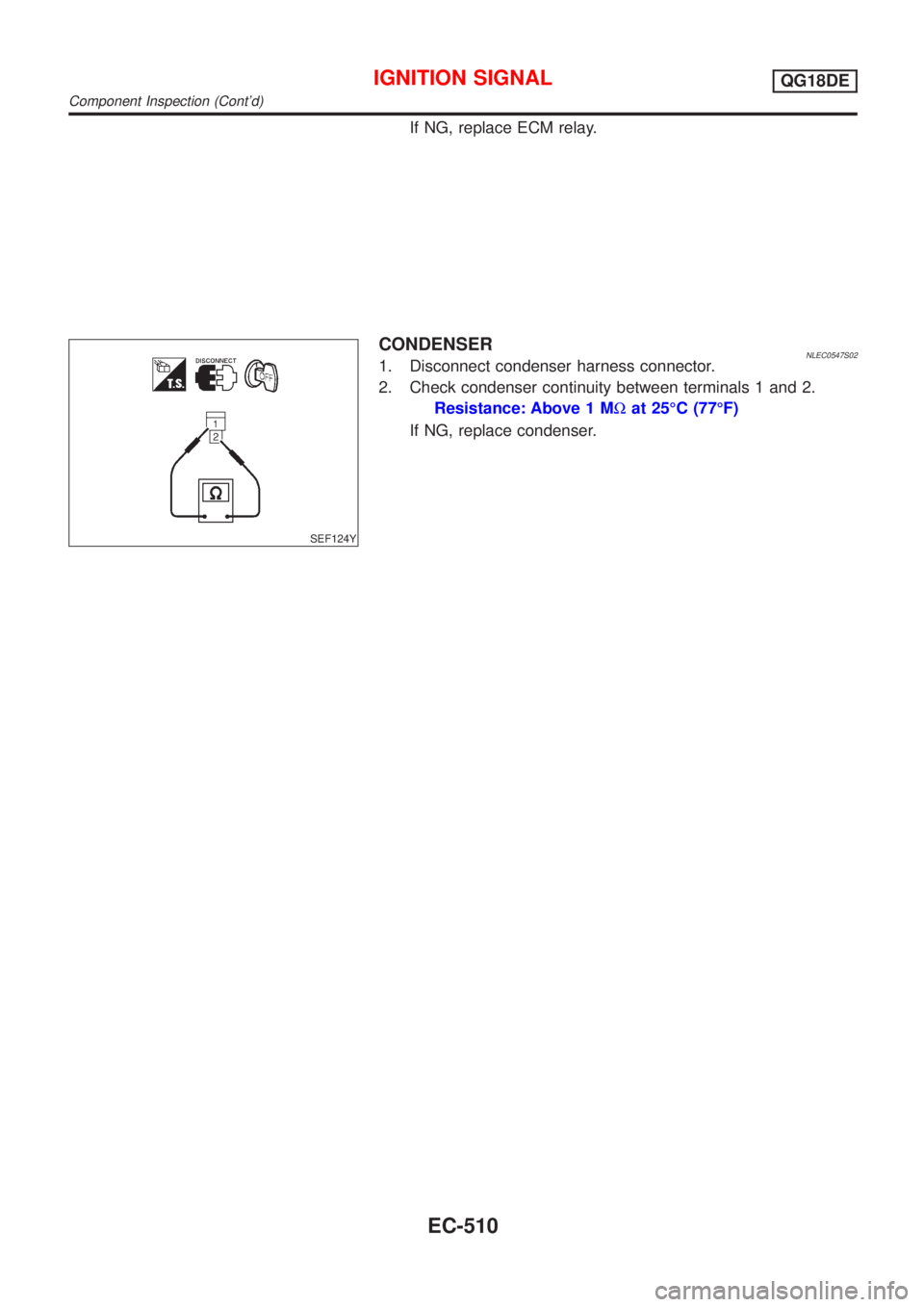

SEF124Y

CONDENSERNLEC0547S021. Disconnect condenser harness connector.

2. Check condenser continuity between terminals 1 and 2.

Resistance: Above 1 MWat 25ÉC (77ÉF)

If NG, replace condenser.

IGNITION SIGNALQG18DE

Component Inspection (Cont'd)

EC-510

Page 936 of 3051

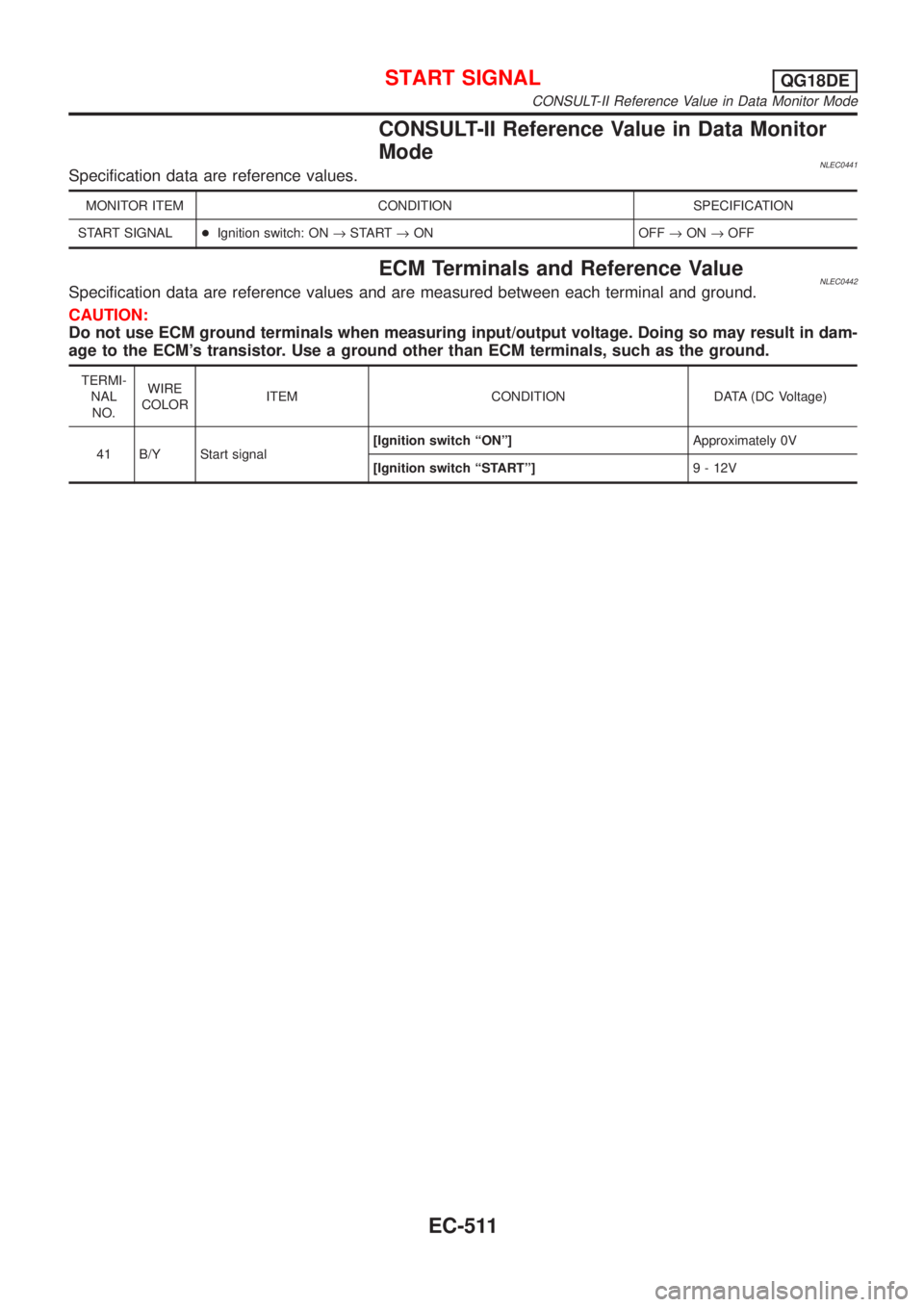

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0441Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

ECM Terminals and Reference ValueNLEC0442Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

41 B/Y Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]9 - 12V

START SIGNALQG18DE

CONSULT-II Reference Value in Data Monitor Mode

EC-511

Page 937 of 3051

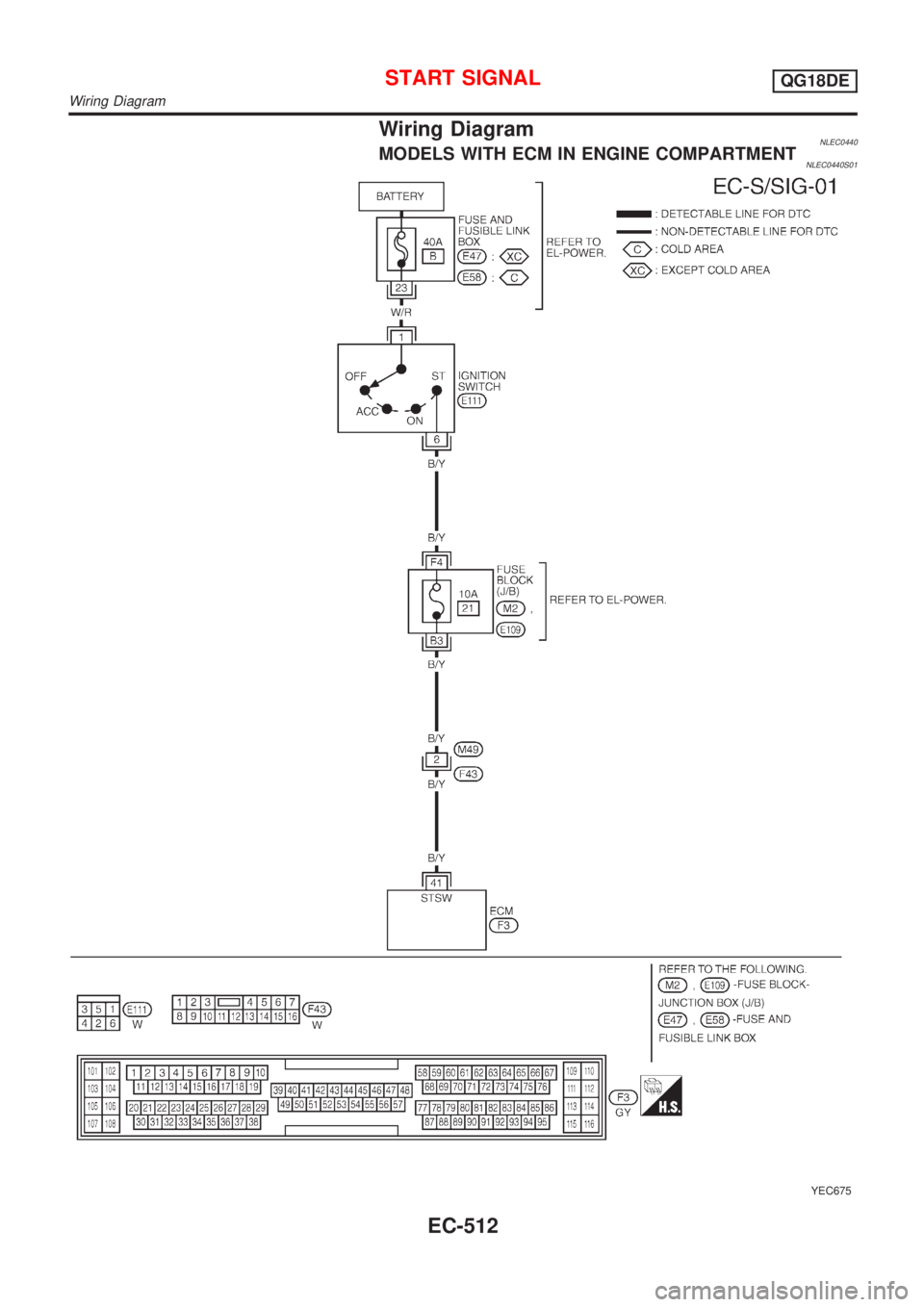

Wiring DiagramNLEC0440MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0440S01

YEC675

START SIGNALQG18DE

Wiring Diagram

EC-512

Page 938 of 3051

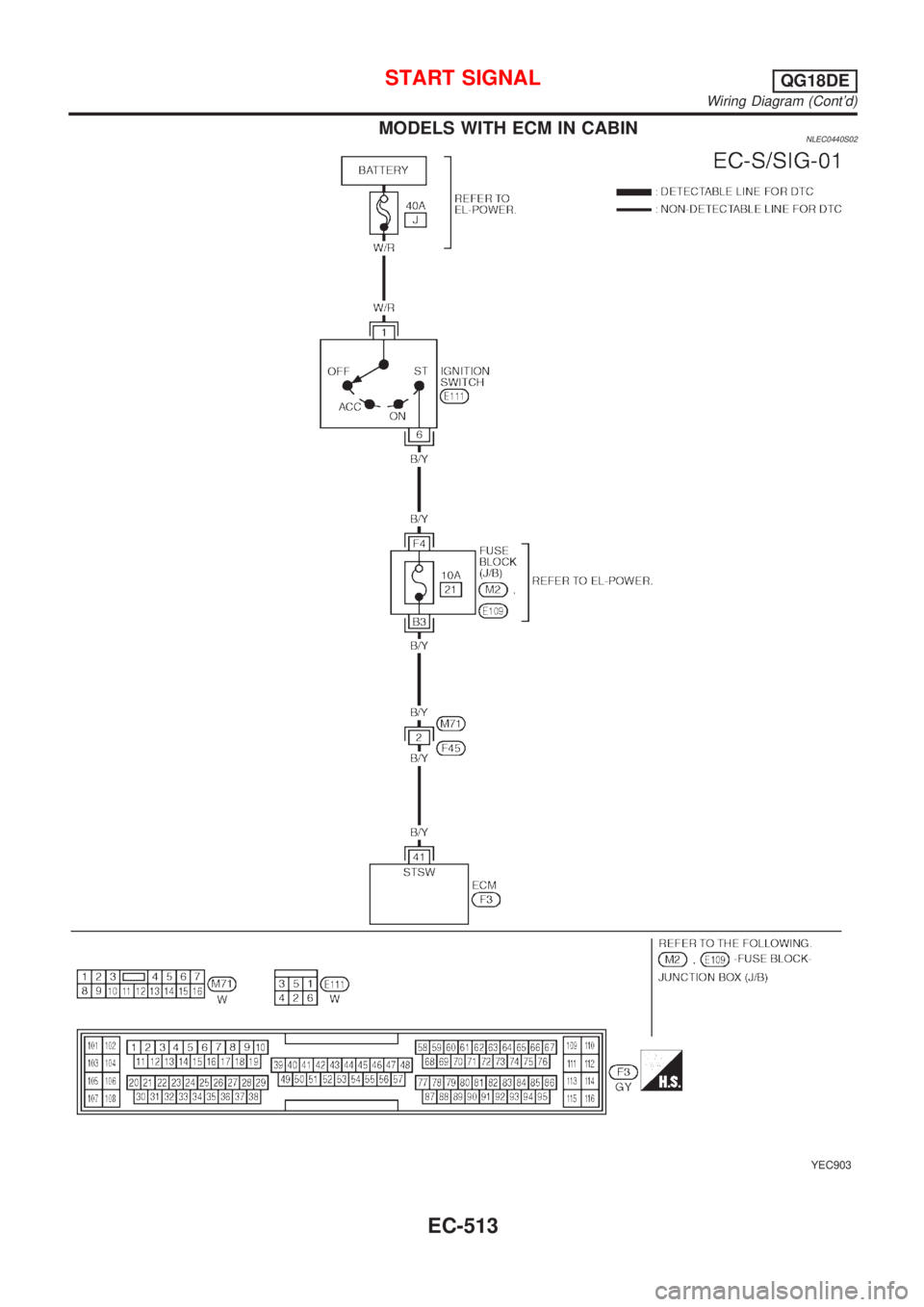

MODELS WITH ECM IN CABINNLEC0440S02

YEC903

START SIGNALQG18DE

Wiring Diagram (Cont'd)

EC-513

Page 939 of 3051

Diagnostic Procedure=NLEC0443

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

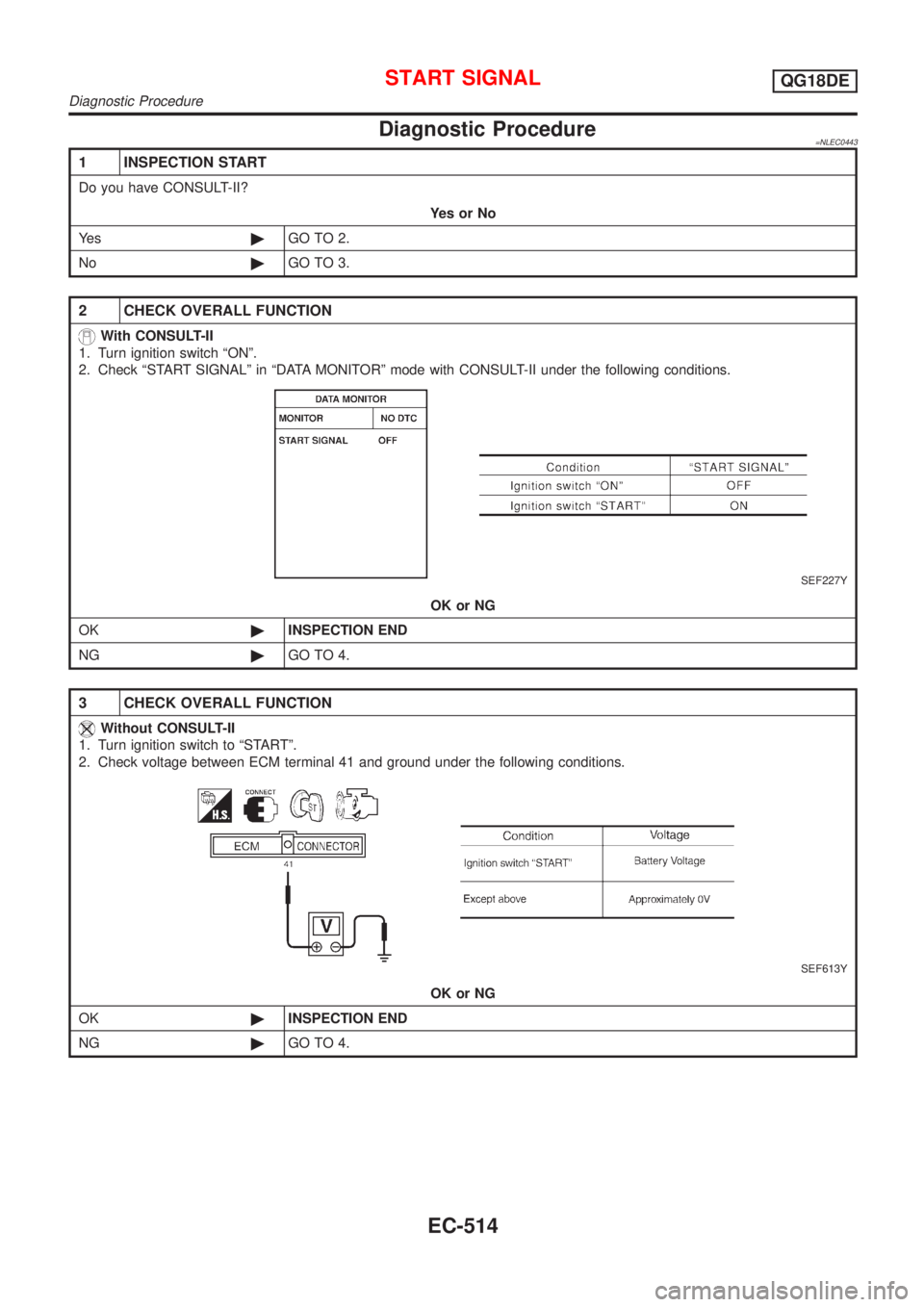

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF227Y

OK or NG

OK©INSPECTION END

NG©GO TO 4.

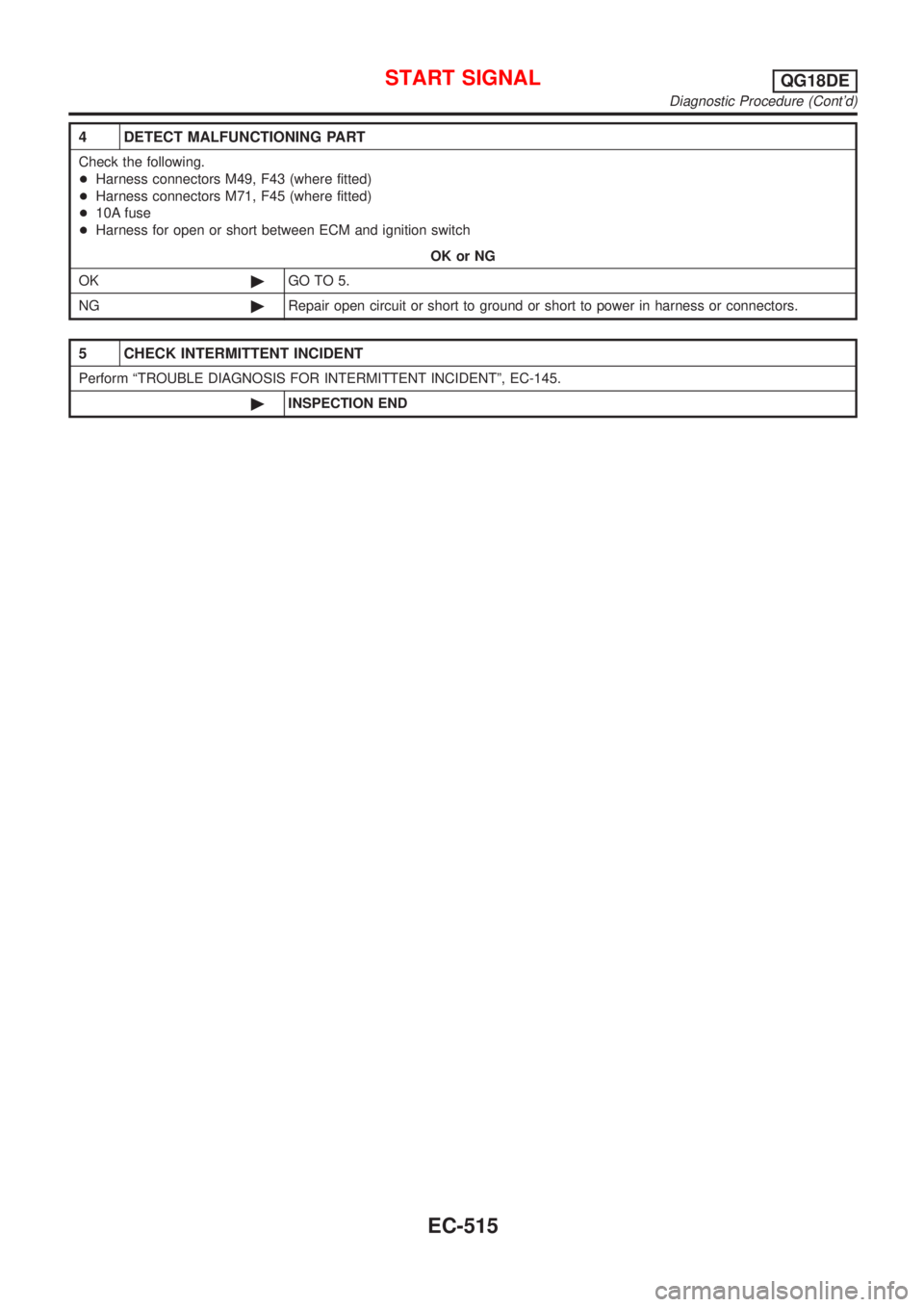

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Turn ignition switch to ªSTARTº.

2. Check voltage between ECM terminal 41 and ground under the following conditions.

SEF613Y

OK or NG

OK©INSPECTION END

NG©GO TO 4.

START SIGNALQG18DE

Diagnostic Procedure

EC-514

Page 940 of 3051

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M49, F43 (where fitted)

+Harness connectors M71, F45 (where fitted)

+10A fuse

+Harness for open or short between ECM and ignition switch

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

START SIGNALQG18DE

Diagnostic Procedure (Cont'd)

EC-515

Trending: recommended oil, radiator, change language, ground clearance, towing, air condition, remote start