NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: spark plugs, fuel pump, length, jump cable, sat nav, key, ignition

Page 921 of 3051

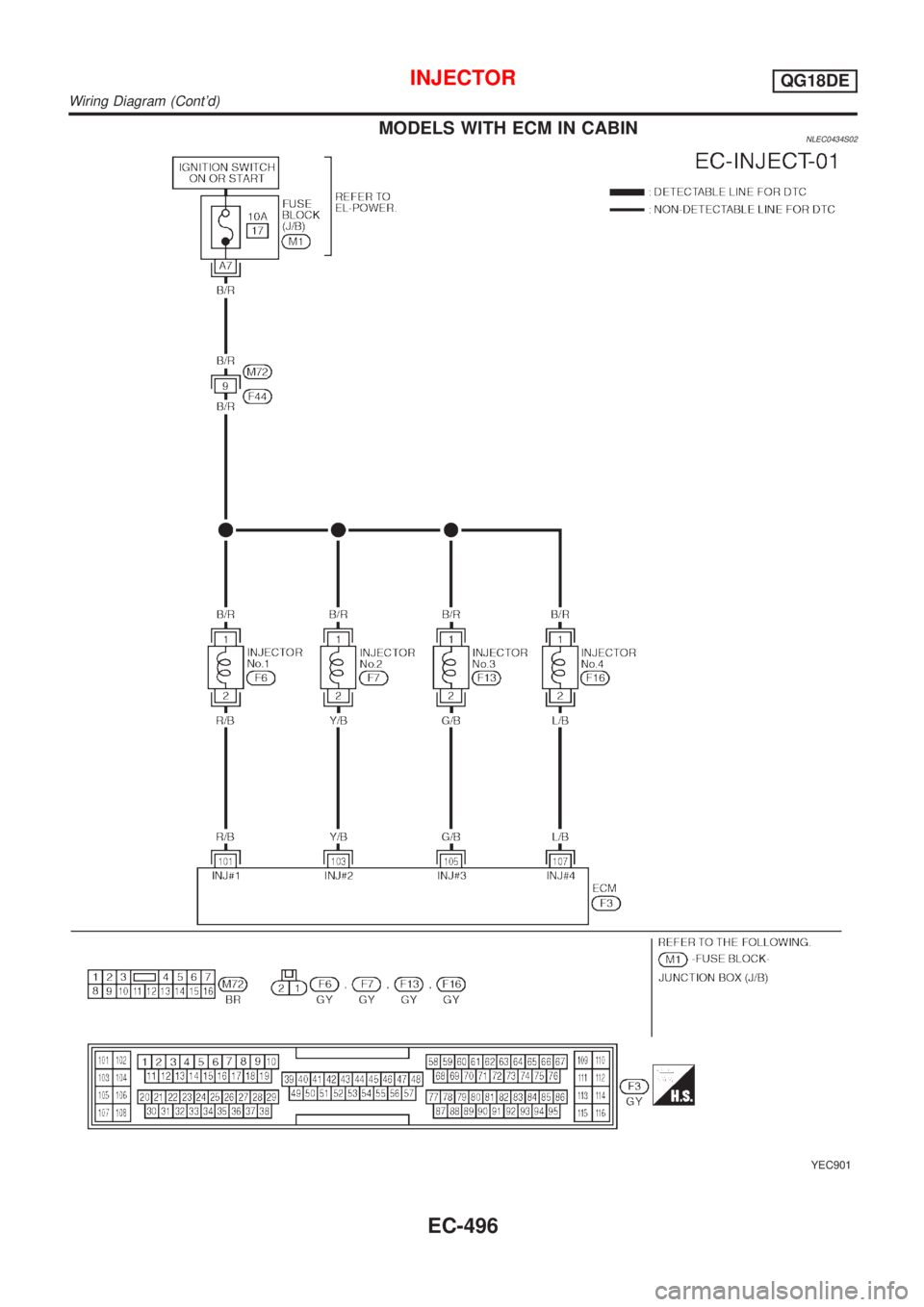

MODELS WITH ECM IN CABINNLEC0434S02

YEC901

INJECTORQG18DE

Wiring Diagram (Cont'd)

EC-496

Page 922 of 3051

Diagnostic ProcedureNLEC0438

1 CHECK OVERALL FUNCTION

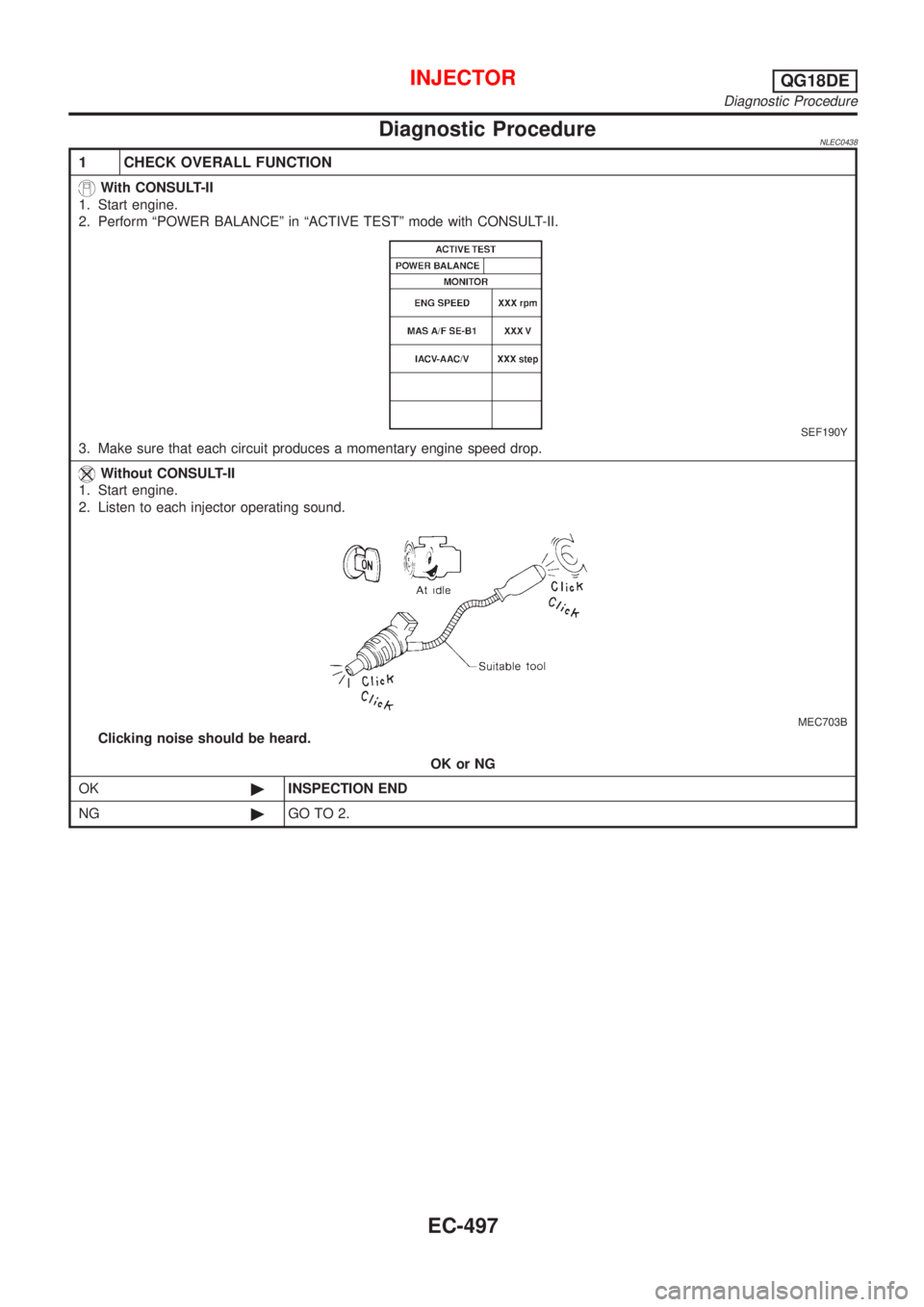

With CONSULT-II

1. Start engine.

2. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

SEF190Y

3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-II

1. Start engine.

2. Listen to each injector operating sound.

MEC703B

Clicking noise should be heard.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

INJECTORQG18DE

Diagnostic Procedure

EC-497

Page 923 of 3051

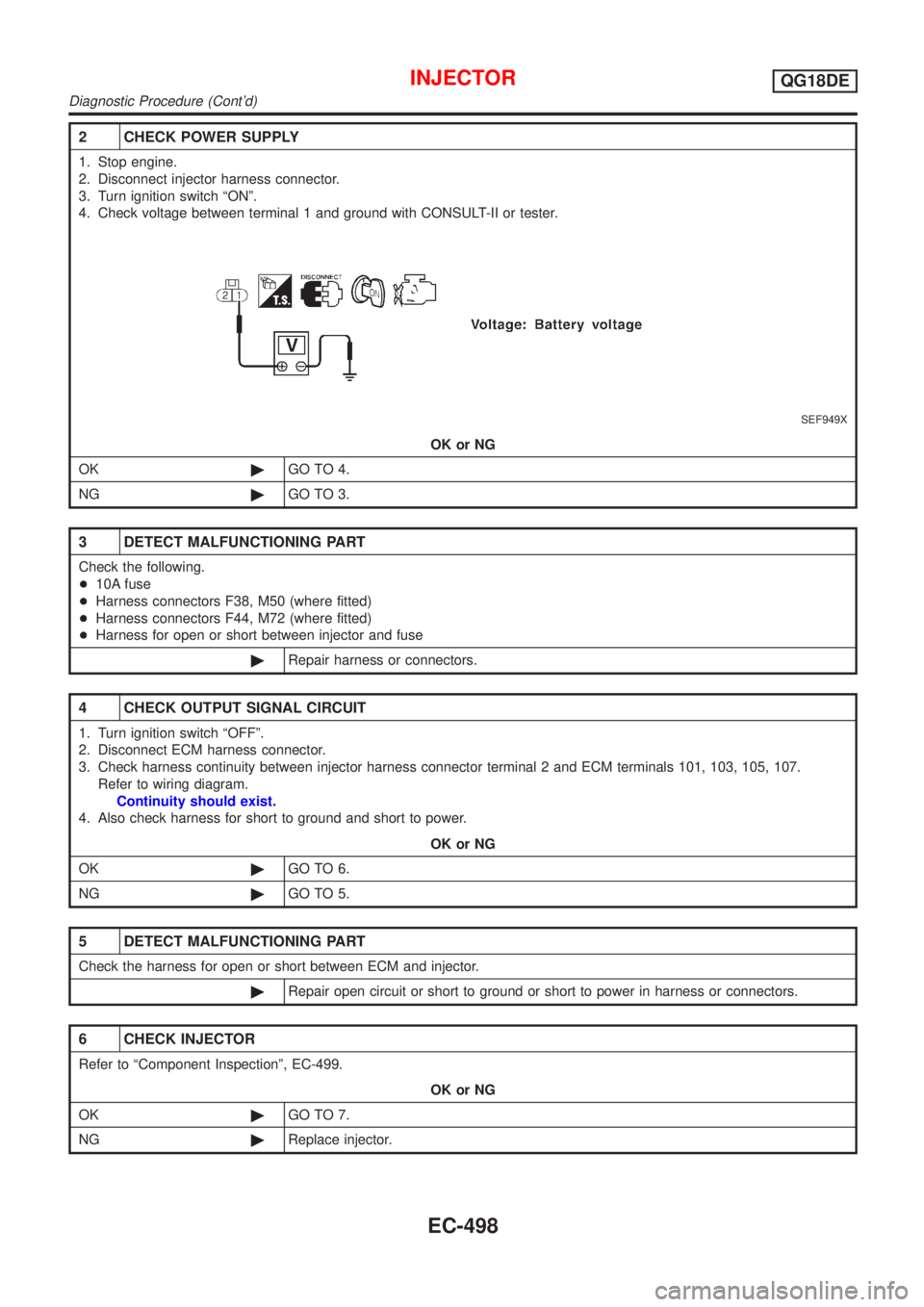

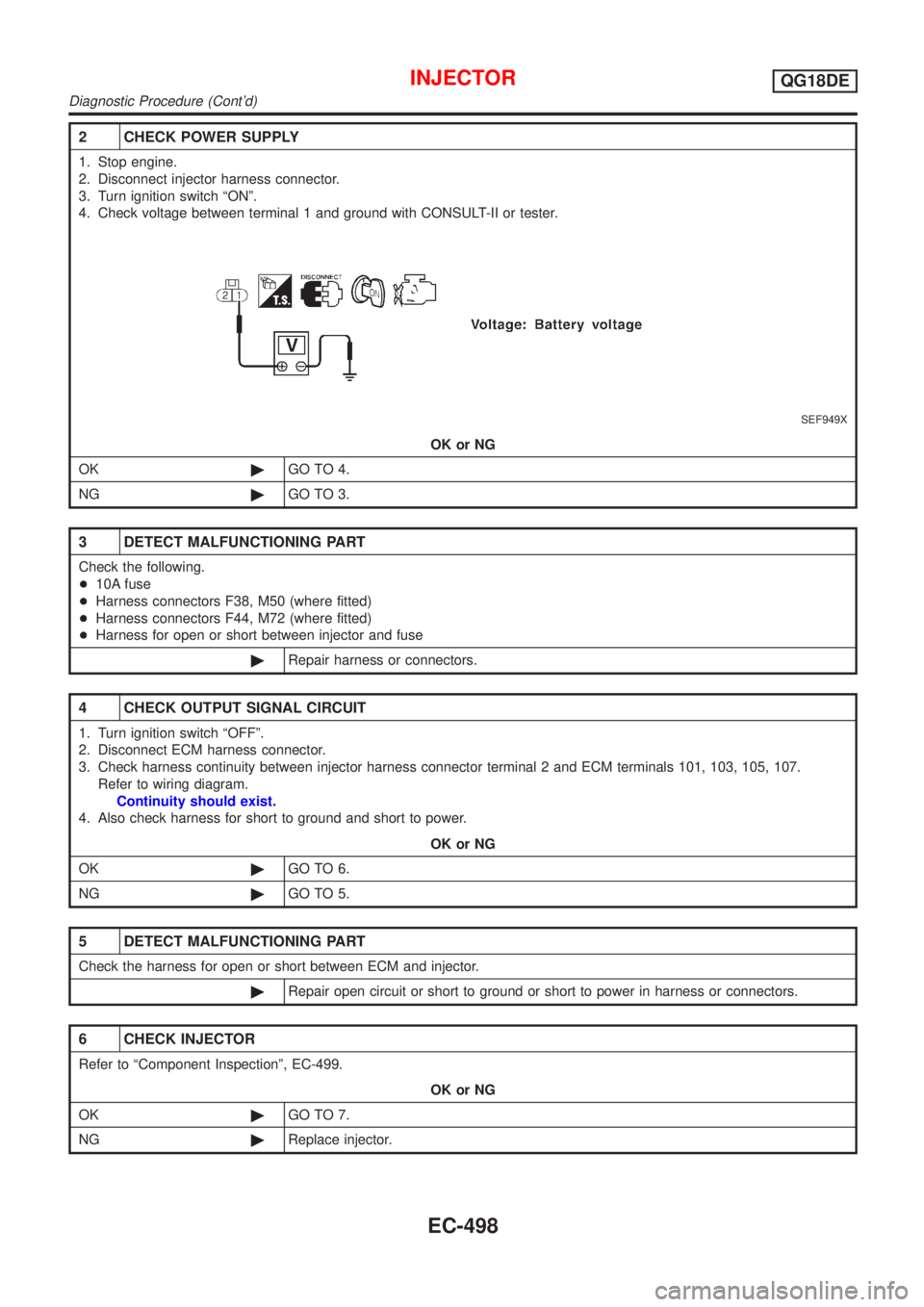

2 CHECK POWER SUPPLY

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF949X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+Harness connectors F38, M50 (where fitted)

+Harness connectors F44, M72 (where fitted)

+Harness for open or short between injector and fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector harness connector terminal 2 and ECM terminals 101, 103, 105, 107.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and injector.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INJECTOR

Refer to ªComponent Inspectionº, EC-499.

OK or NG

OK©GO TO 7.

NG©Replace injector.

INJECTORQG18DE

Diagnostic Procedure (Cont'd)

EC-498

Page 924 of 3051

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

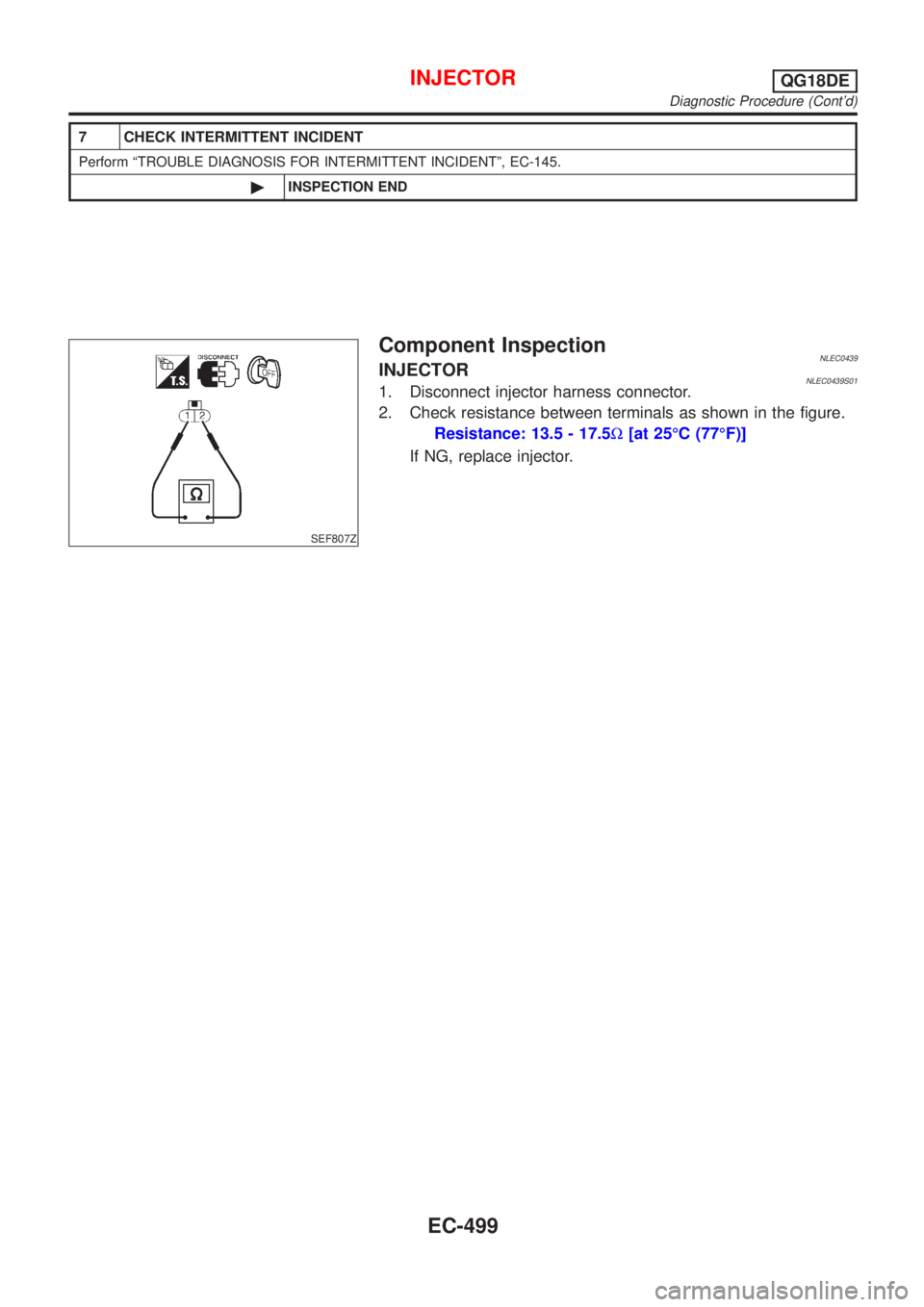

SEF807Z

Component InspectionNLEC0439INJECTORNLEC0439S011. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

Resistance: 13.5 - 17.5W[at 25ÉC (77ÉF)]

If NG, replace injector.

INJECTORQG18DE

Diagnostic Procedure (Cont'd)

EC-499

Page 925 of 3051

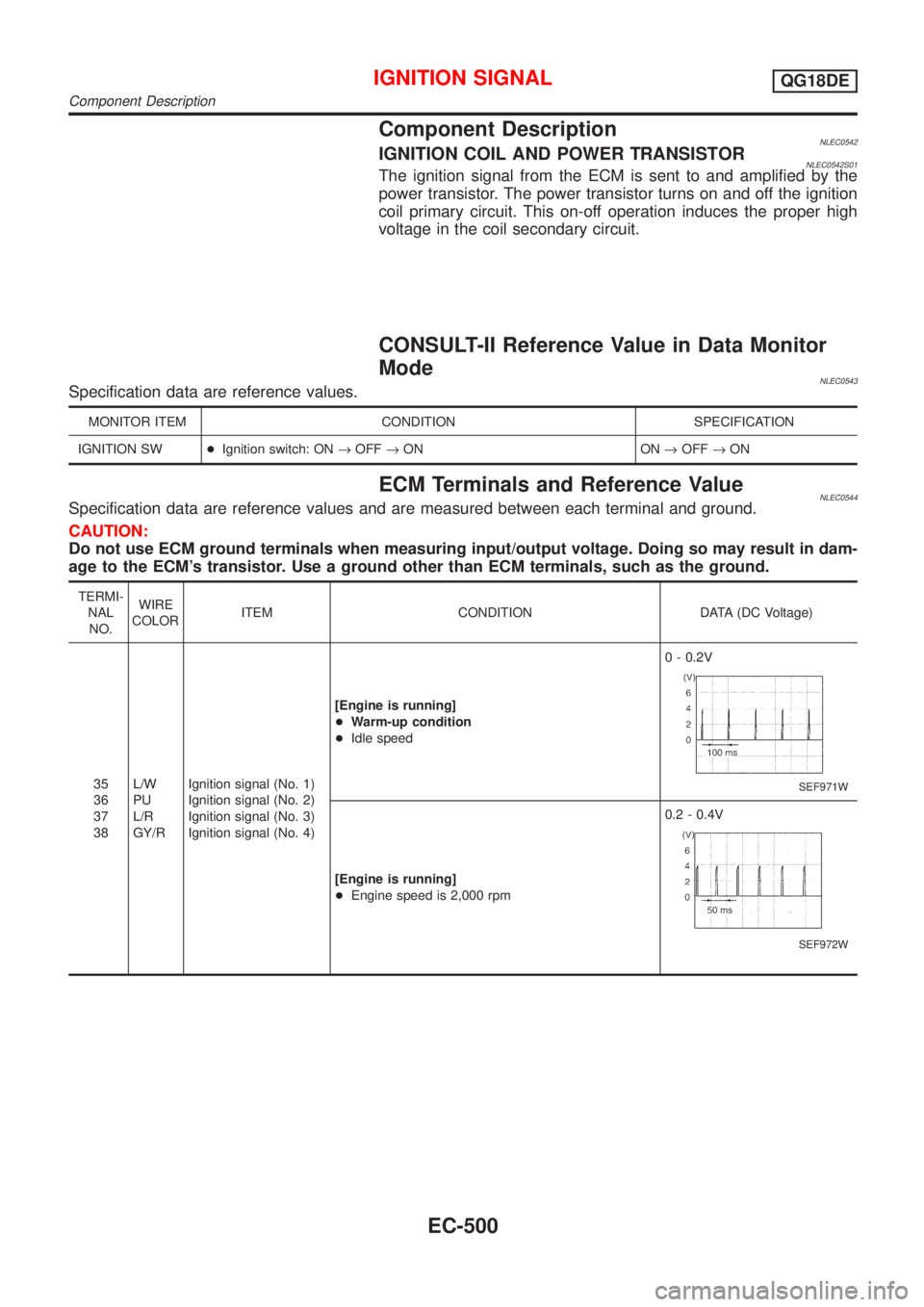

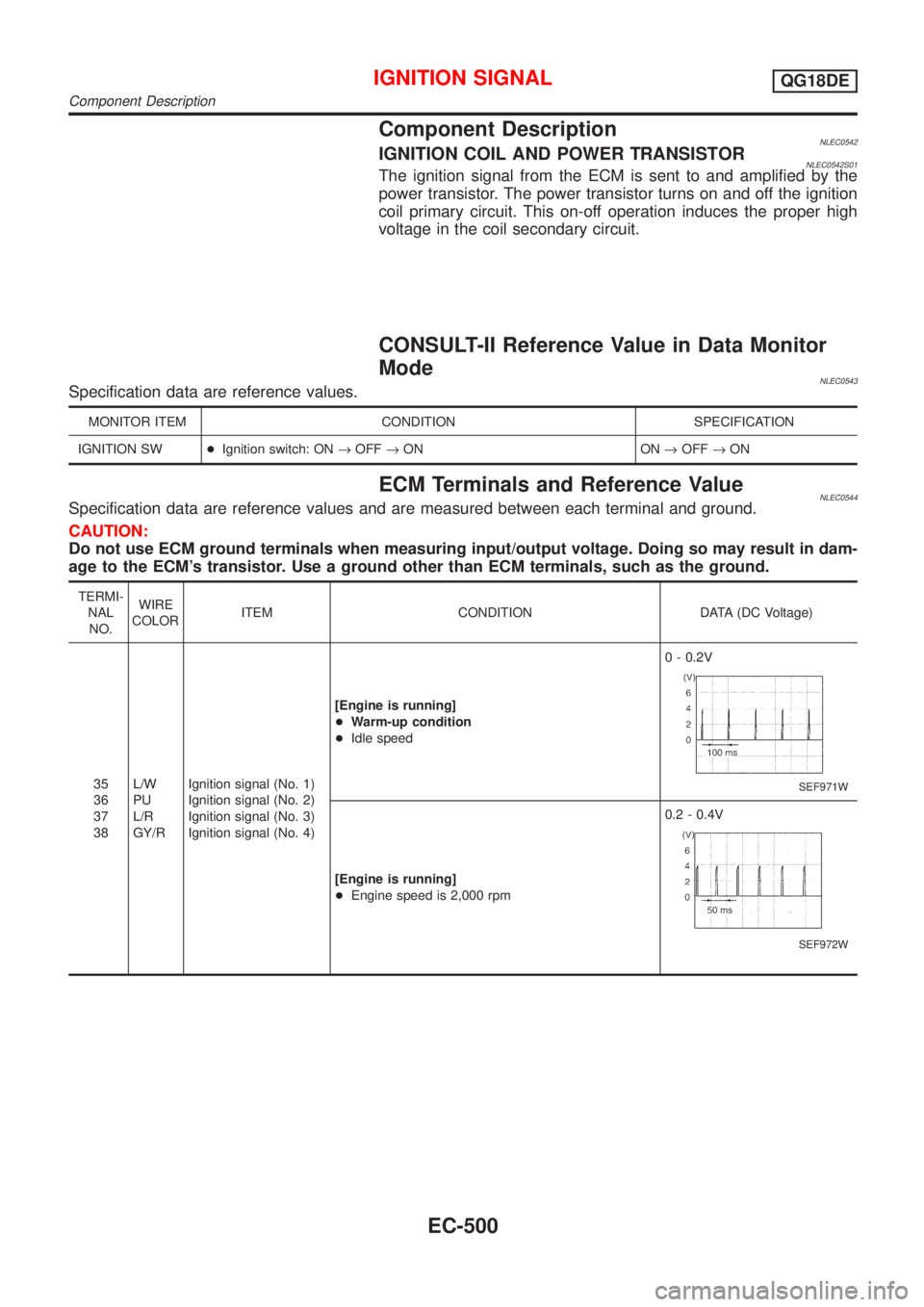

Component DescriptionNLEC0542IGNITION COIL AND POWER TRANSISTORNLEC0542S01The ignition signal from the ECM is sent to and amplified by the

power transistor. The power transistor turns on and off the ignition

coil primary circuit. This on-off operation induces the proper high

voltage in the coil secondary circuit.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0543Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

IGNITION SW+Ignition switch: ON®OFF®ON ON®OFF®ON

ECM Terminals and Reference ValueNLEC0544Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

35

36

37

38L/W

PU

L/R

GY/RIgnition signal (No. 1)

Ignition signal (No. 2)

Ignition signal (No. 3)

Ignition signal (No. 4)[Engine is running]

+Warm-up condition

+Idle speed0 - 0.2V

SEF971W

[Engine is running]

+Engine speed is 2,000 rpm0.2 - 0.4V

SEF972W

IGNITION SIGNALQG18DE

Component Description

EC-500

Page 926 of 3051

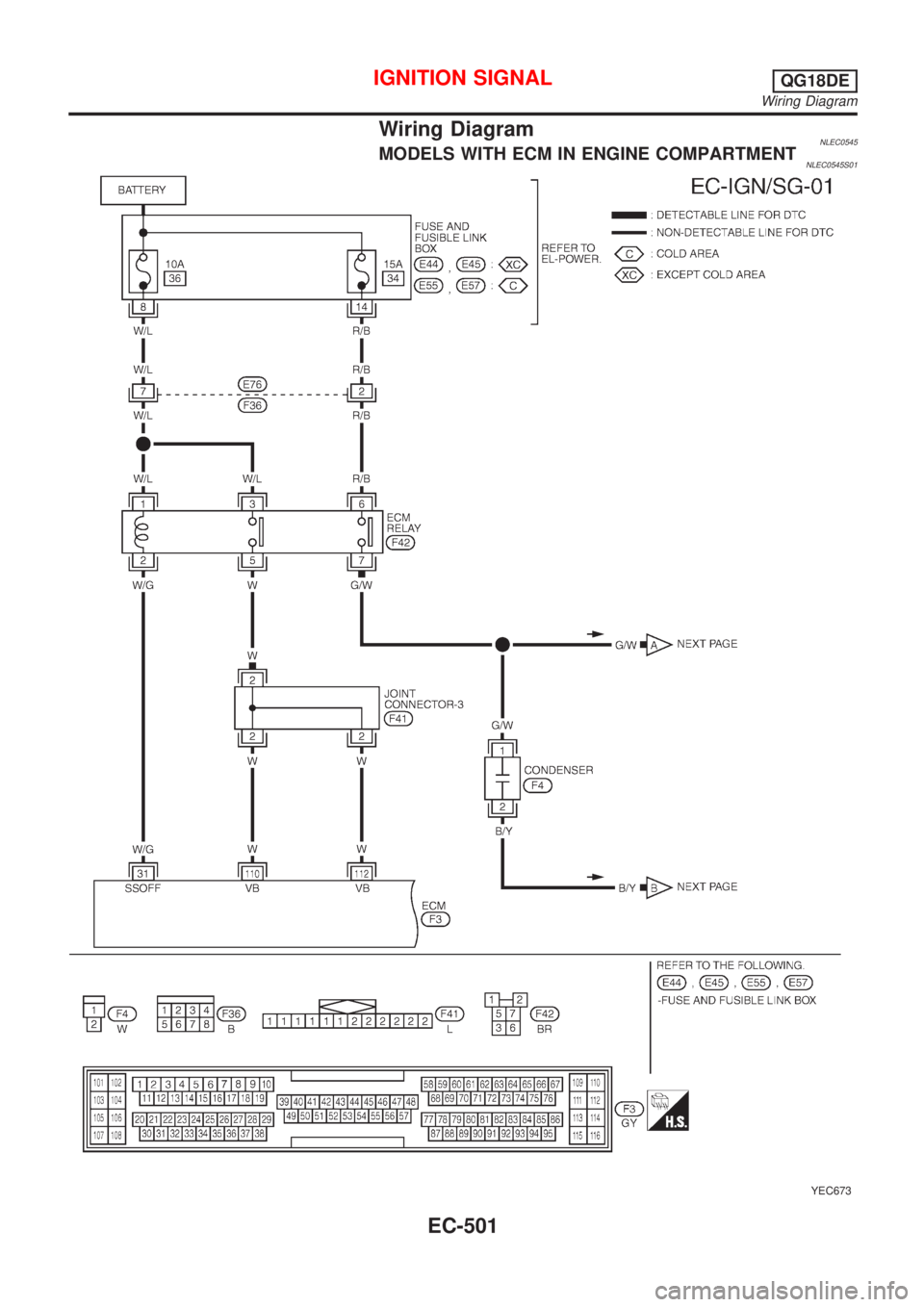

Wiring DiagramNLEC0545MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0545S01

YEC673

IGNITION SIGNALQG18DE

Wiring Diagram

EC-501

Page 927 of 3051

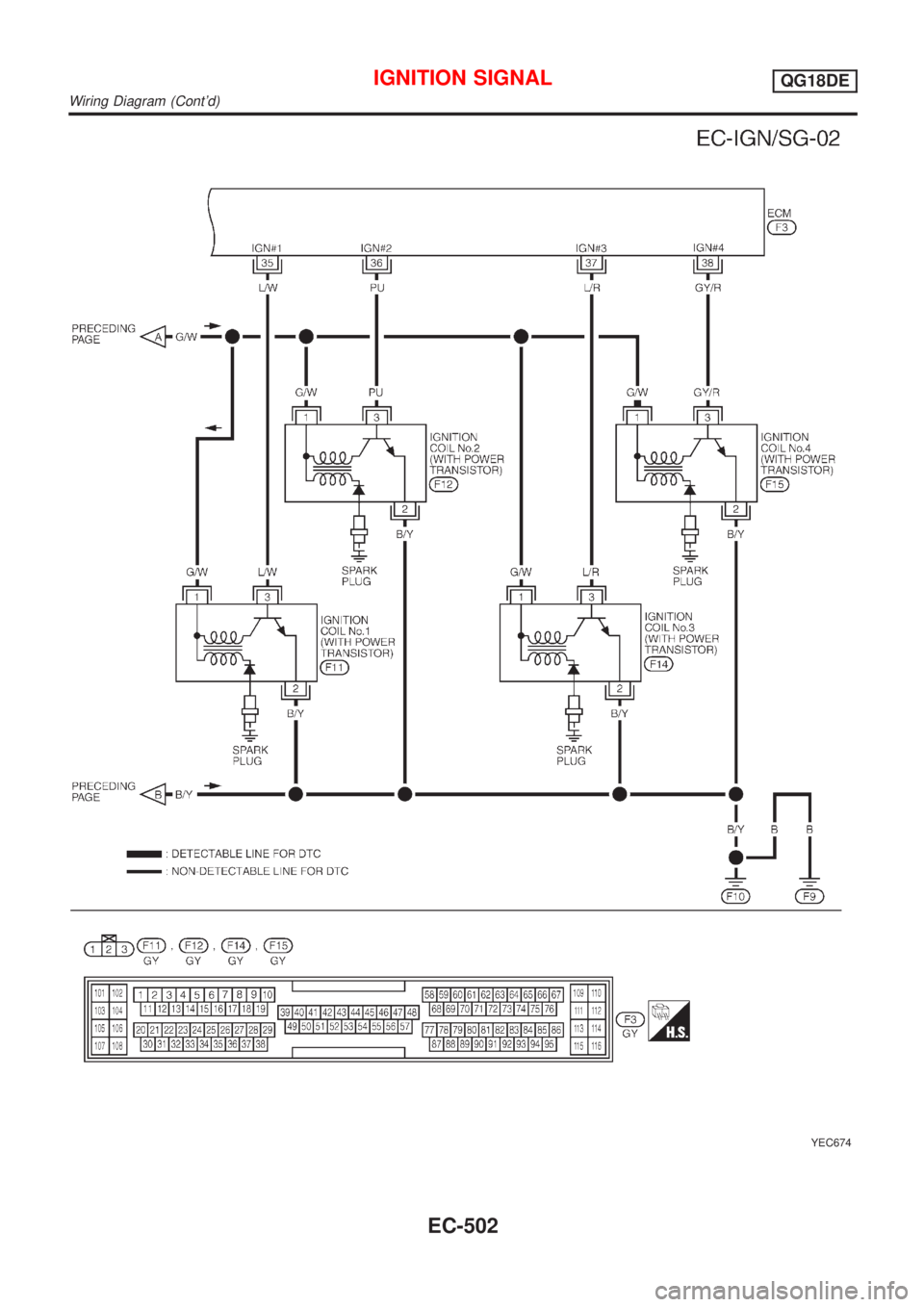

YEC674

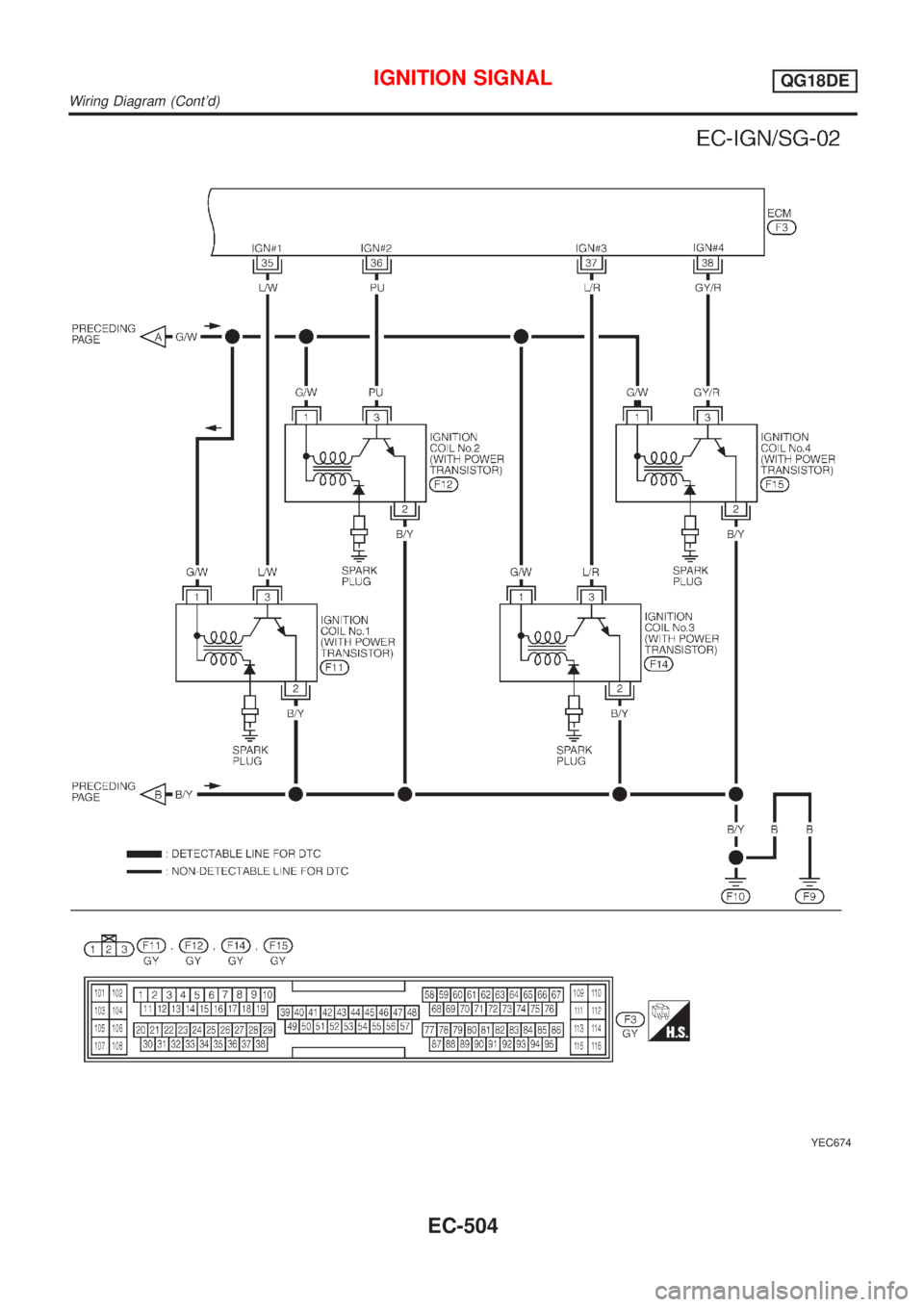

IGNITION SIGNALQG18DE

Wiring Diagram (Cont'd)

EC-502

Page 928 of 3051

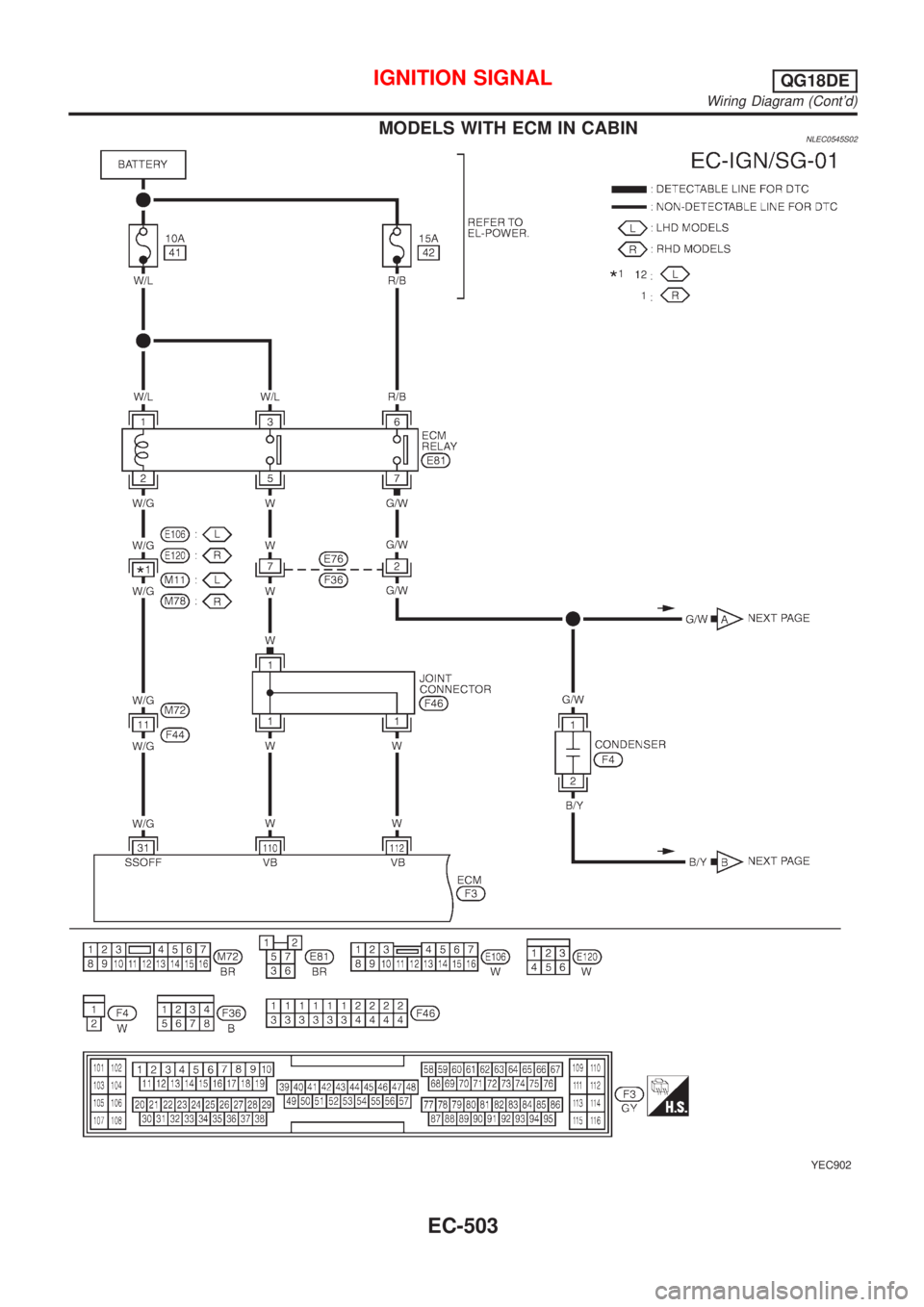

MODELS WITH ECM IN CABINNLEC0545S02

YEC902

IGNITION SIGNALQG18DE

Wiring Diagram (Cont'd)

EC-503

Page 929 of 3051

YEC674

IGNITION SIGNALQG18DE

Wiring Diagram (Cont'd)

EC-504

Page 930 of 3051

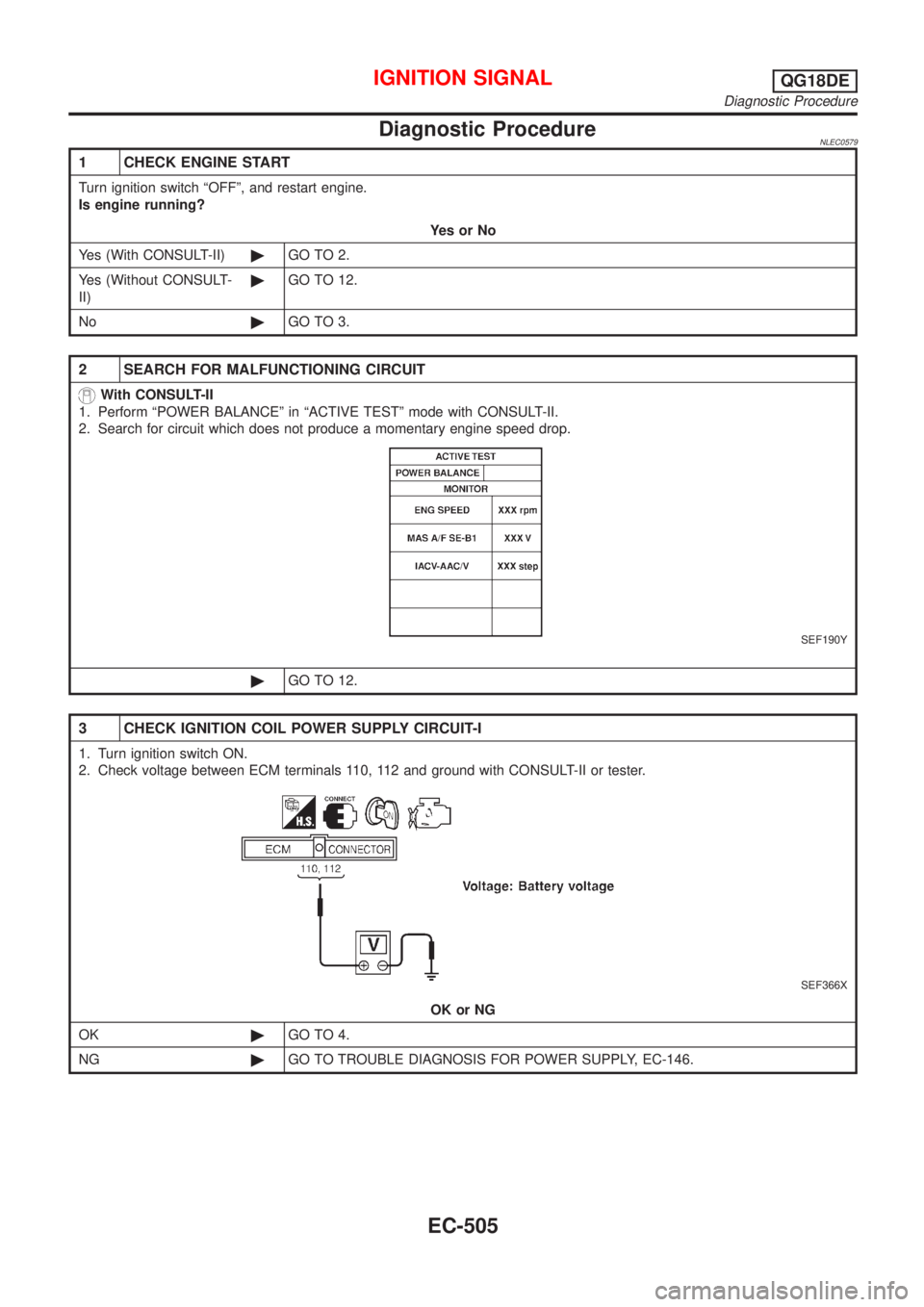

Diagnostic ProcedureNLEC0579

1 CHECK ENGINE START

Turn ignition switch ªOFFº, and restart engine.

Is engine running?

YesorNo

Yes (With CONSULT-II)©GO TO 2.

Yes (Without CONSULT-

II)©GO TO 12.

No©GO TO 3.

2 SEARCH FOR MALFUNCTIONING CIRCUIT

With CONSULT-II

1. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

2. Search for circuit which does not produce a momentary engine speed drop.

SEF190Y

©GO TO 12.

3 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF366X

OK or NG

OK©GO TO 4.

NG©GO TO TROUBLE DIAGNOSIS FOR POWER SUPPLY, EC-146.

IGNITION SIGNALQG18DE

Diagnostic Procedure

EC-505

Trending: brake rotor, Storage, sat nav, brake pads replacement, instrument, oil, fuse diagram