NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 911 of 3051

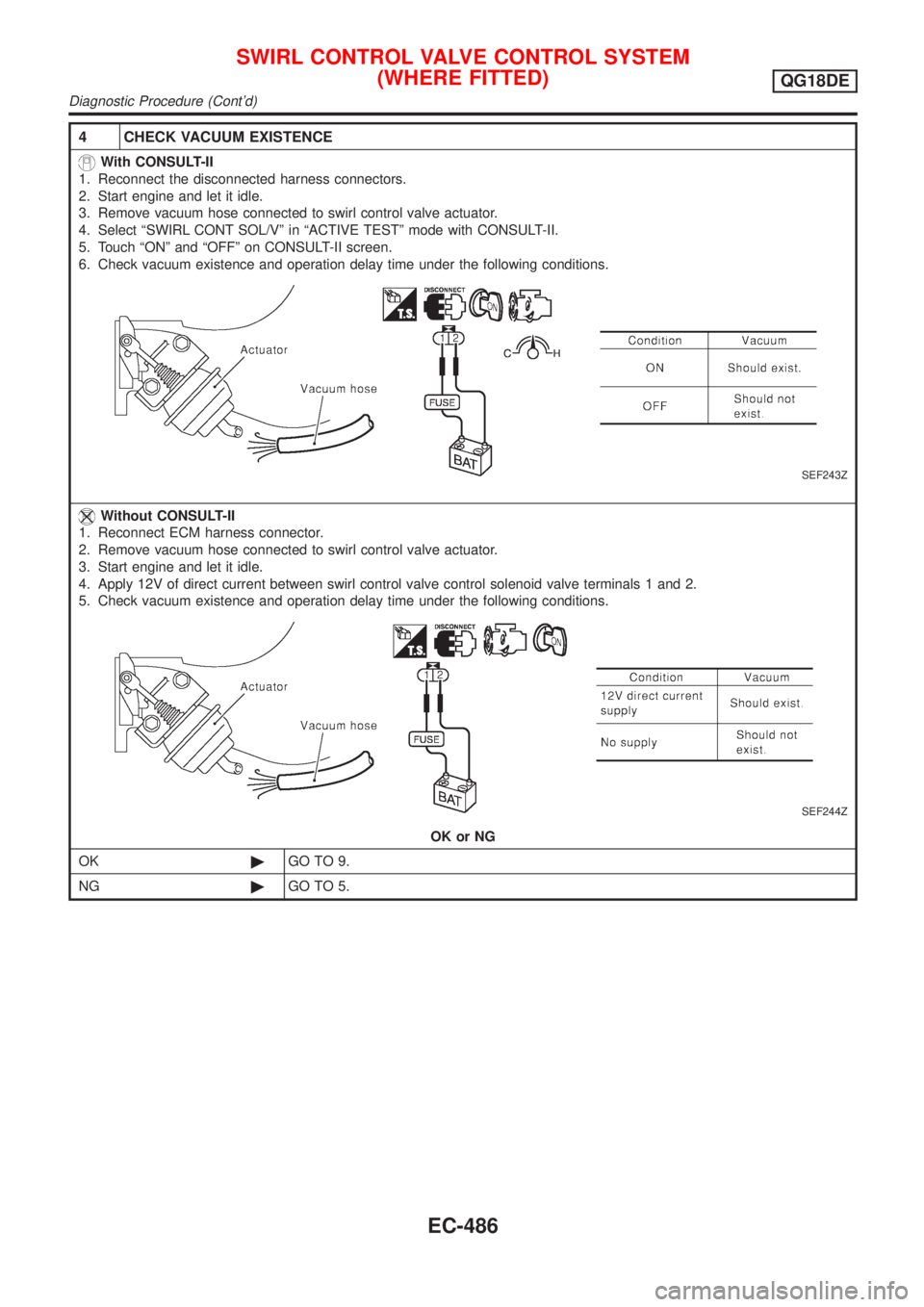

4 CHECK VACUUM EXISTENCE

With CONSULT-II

1. Reconnect the disconnected harness connectors.

2. Start engine and let it idle.

3. Remove vacuum hose connected to swirl control valve actuator.

4. Select ÂȘSWIRL CONT SOL/VÂș in ÂȘACTIVE TESTÂș mode with CONSULT-II.

5. Touch ÂȘONÂș and ÂȘOFFÂș on CONSULT-II screen.

6. Check vacuum existence and operation delay time under the following conditions.

SEF243Z

Without CONSULT-II

1. Reconnect ECM harness connector.

2. Remove vacuum hose connected to swirl control valve actuator.

3. Start engine and let it idle.

4. Apply 12V of direct current between swirl control valve control solenoid valve terminals 1 and 2.

5. Check vacuum existence and operation delay time under the following conditions.

SEF244Z

OK or NG

OK©GO TO 9.

NG©GO TO 5.

SWIRL CONTROL VALVE CONTROL SYSTEM

(WHERE FITTED)

QG18DE

Diagnostic Procedure (Cont'd)

EC-486

Page 912 of 3051

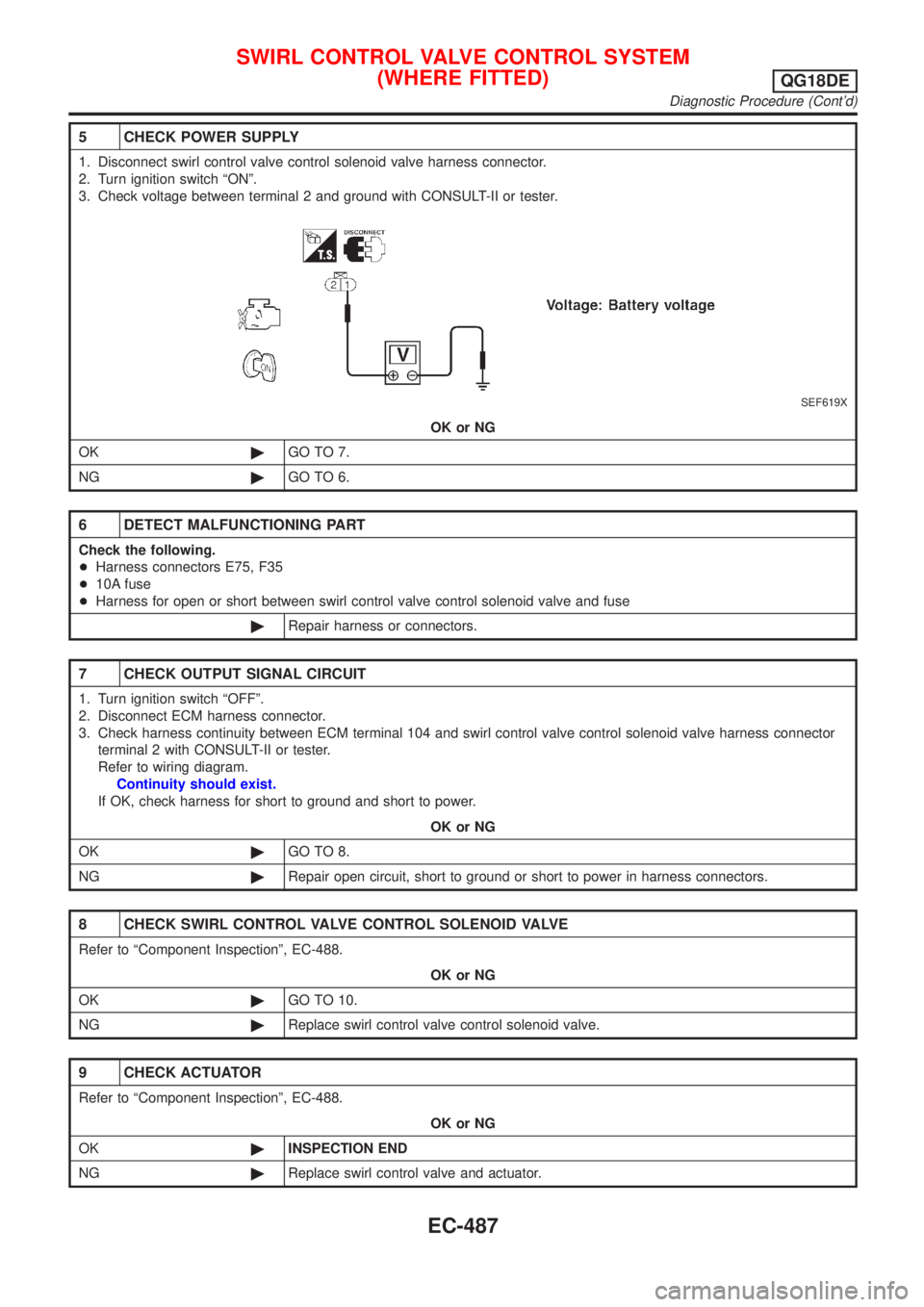

5 CHECK POWER SUPPLY

1. Disconnect swirl control valve control solenoid valve harness connector.

2. Turn ignition switch ÂȘONÂș.

3. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF619X

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F35

+10A fuse

+Harness for open or short between swirl control valve control solenoid valve and fuse

©Repair harness or connectors.

7 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 104 and swirl control valve control solenoid valve harness connector

terminal 2 with CONSULT-II or tester.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit, short to ground or short to power in harness connectors.

8 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Refer to ÂȘComponent InspectionÂș, EC-488.

OK or NG

OK©GO TO 10.

NG©Replace swirl control valve control solenoid valve.

9 CHECK ACTUATOR

Refer to ÂȘComponent InspectionÂș, EC-488.

OK or NG

OK©INSPECTION END

NG©Replace swirl control valve and actuator.

SWIRL CONTROL VALVE CONTROL SYSTEM

(WHERE FITTED)

QG18DE

Diagnostic Procedure (Cont'd)

EC-487

Page 913 of 3051

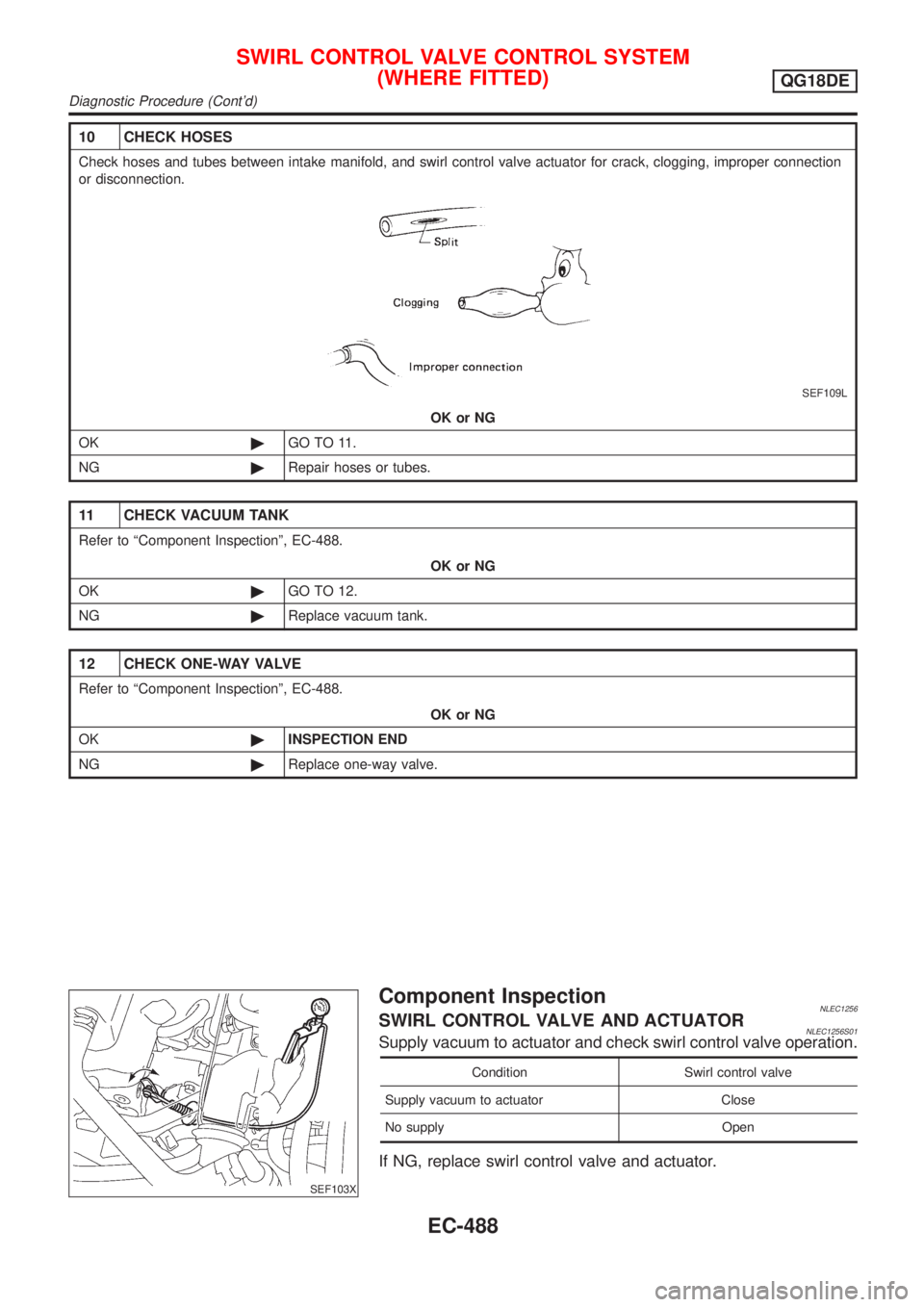

10 CHECK HOSES

Check hoses and tubes between intake manifold, and swirl control valve actuator for crack, clogging, improper connection

or disconnection.

SEF109L

OK or NG

OK©GO TO 11.

NG©Repair hoses or tubes.

11 CHECK VACUUM TANK

Refer to ÂȘComponent InspectionÂș, EC-488.

OK or NG

OK©GO TO 12.

NG©Replace vacuum tank.

12 CHECK ONE-WAY VALVE

Refer to ÂȘComponent InspectionÂș, EC-488.

OK or NG

OK©INSPECTION END

NG©Replace one-way valve.

SEF103X

Component InspectionNLEC1256SWIRL CONTROL VALVE AND ACTUATORNLEC1256S01Supply vacuum to actuator and check swirl control valve operation.

Condition Swirl control valve

Supply vacuum to actuator Close

No supply Open

If NG, replace swirl control valve and actuator.

SWIRL CONTROL VALVE CONTROL SYSTEM

(WHERE FITTED)

QG18DE

Diagnostic Procedure (Cont'd)

EC-488

Page 914 of 3051

SEF105X

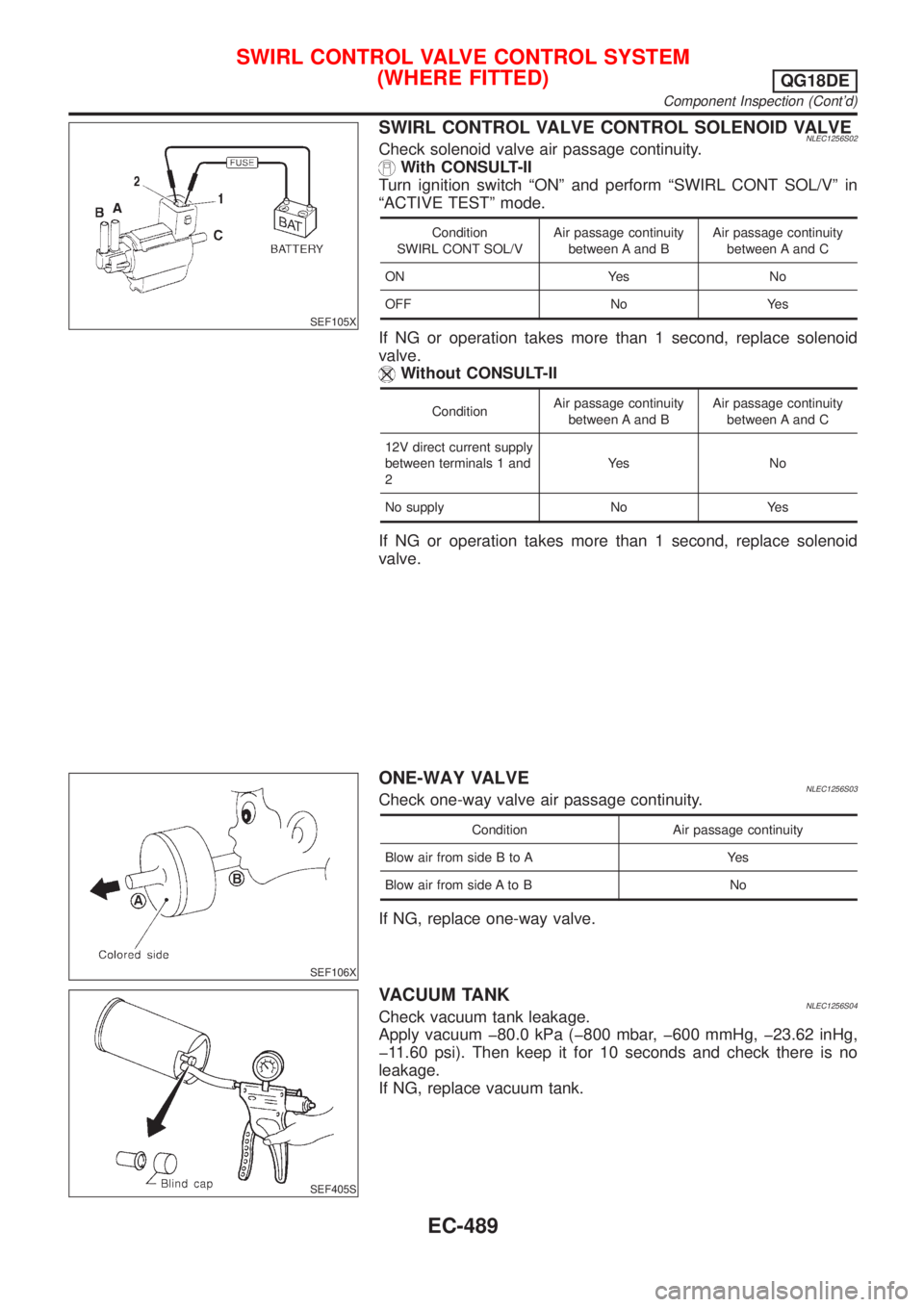

SWIRL CONTROL VALVE CONTROL SOLENOID VALVENLEC1256S02Check solenoid valve air passage continuity.

With CONSULT-II

Turn ignition switch ÂȘONÂș and perform ÂȘSWIRL CONT SOL/VÂș in

ÂȘACTIVE TESTÂș mode.

Condition

SWIRL CONT SOL/VAir passage continuity

between A and BAir passage continuity

between A and C

ON Yes No

OFF No Yes

If NG or operation takes more than 1 second, replace solenoid

valve.

Without CONSULT-II

ConditionAir passage continuity

between A and BAir passage continuity

between A and C

12V direct current supply

between terminals 1 and

2Ye s N o

No supply No Yes

If NG or operation takes more than 1 second, replace solenoid

valve.

SEF106X

ONE-WAY VALVENLEC1256S03Check one-way valve air passage continuity.

Condition Air passage continuity

Blow air from side B to A Yes

Blow air from side A to B No

If NG, replace one-way valve.

SEF405S

VACUUM TANKNLEC1256S04Check vacuum tank leakage.

Apply vacuum ĂŸ80.0 kPa (ĂŸ800 mbar, ĂŸ600 mmHg, ĂŸ23.62 inHg,

ĂŸ11.60 psi). Then keep it for 10 seconds and check there is no

leakage.

If NG, replace vacuum tank.

SWIRL CONTROL VALVE CONTROL SYSTEM

(WHERE FITTED)

QG18DE

Component Inspection (Cont'd)

EC-489

Page 915 of 3051

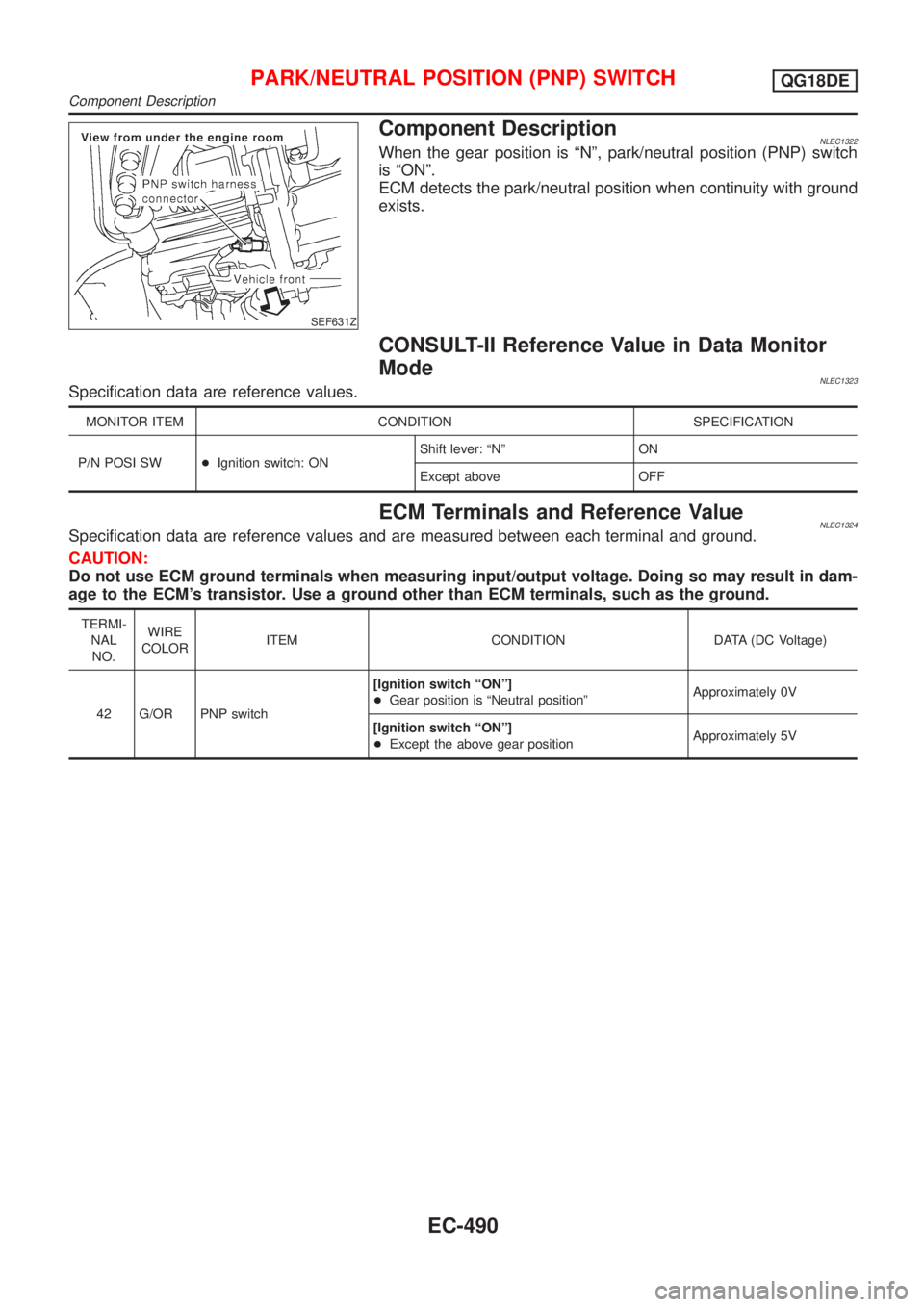

SEF631Z

Component DescriptionNLEC1322When the gear position is ÂȘNÂș, park/neutral position (PNP) switch

is ÂȘONÂș.

ECM detects the park/neutral position when continuity with ground

exists.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC1323Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW+Ignition switch: ONShift lever: ÂȘNÂș ON

Except above OFF

ECM Terminals and Reference ValueNLEC1324Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 G/OR PNP switch[Ignition switch ÂȘONÂș]

+Gear position is ÂȘNeutral positionÂșApproximately 0V

[Ignition switch ÂȘONÂș]

+Except the above gear positionApproximately 5V

PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Component Description

EC-490

Page 916 of 3051

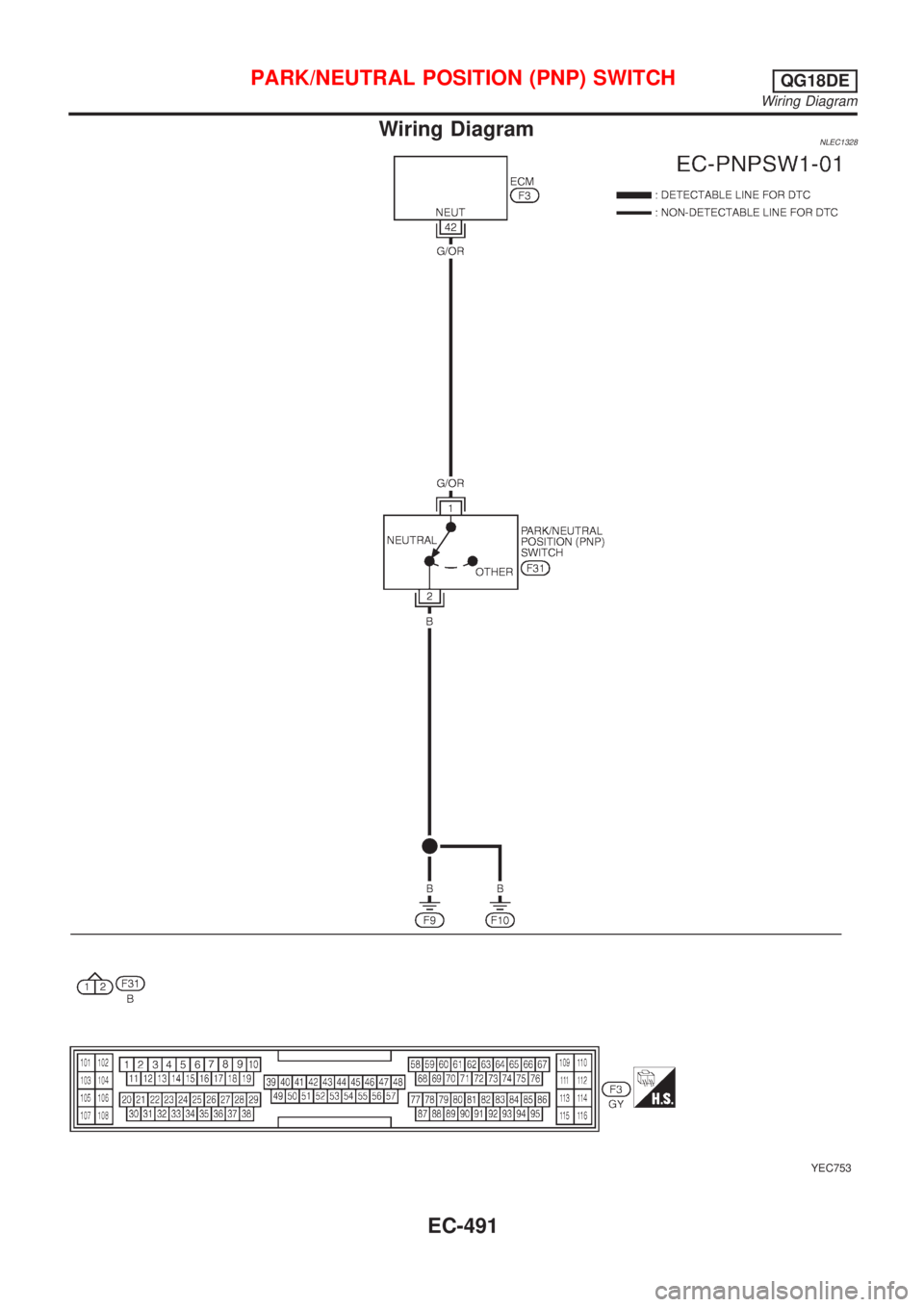

Wiring DiagramNLEC1328

YEC753

PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Wiring Diagram

EC-491

Page 917 of 3051

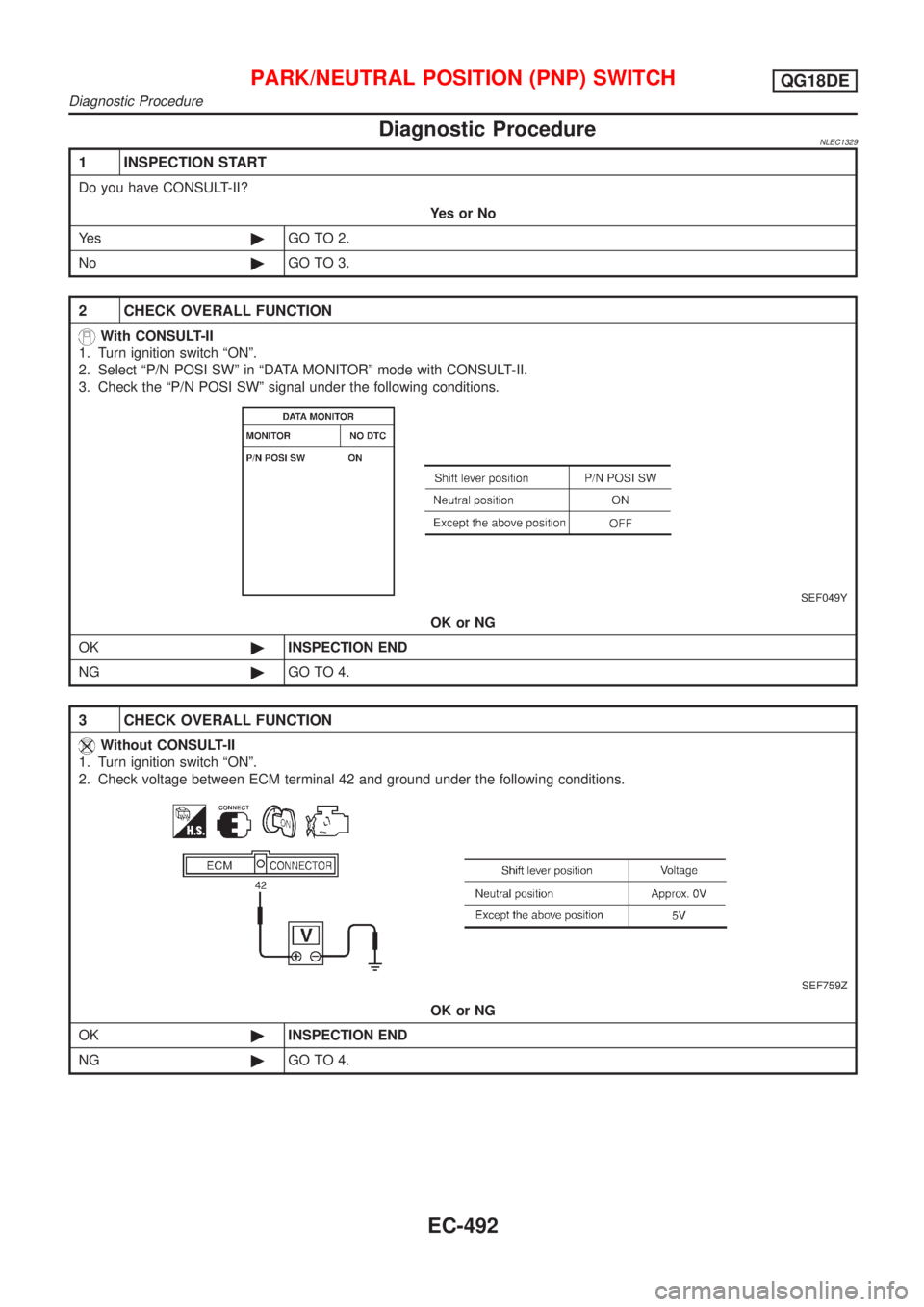

Diagnostic ProcedureNLEC1329

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ÂȘONÂș.

2. Select ÂȘP/N POSI SWÂș in ÂȘDATA MONITORÂș mode with CONSULT-II.

3. Check the ÂȘP/N POSI SWÂș signal under the following conditions.

SEF049Y

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Turn ignition switch ÂȘONÂș.

2. Check voltage between ECM terminal 42 and ground under the following conditions.

SEF759Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Diagnostic Procedure

EC-492

Page 918 of 3051

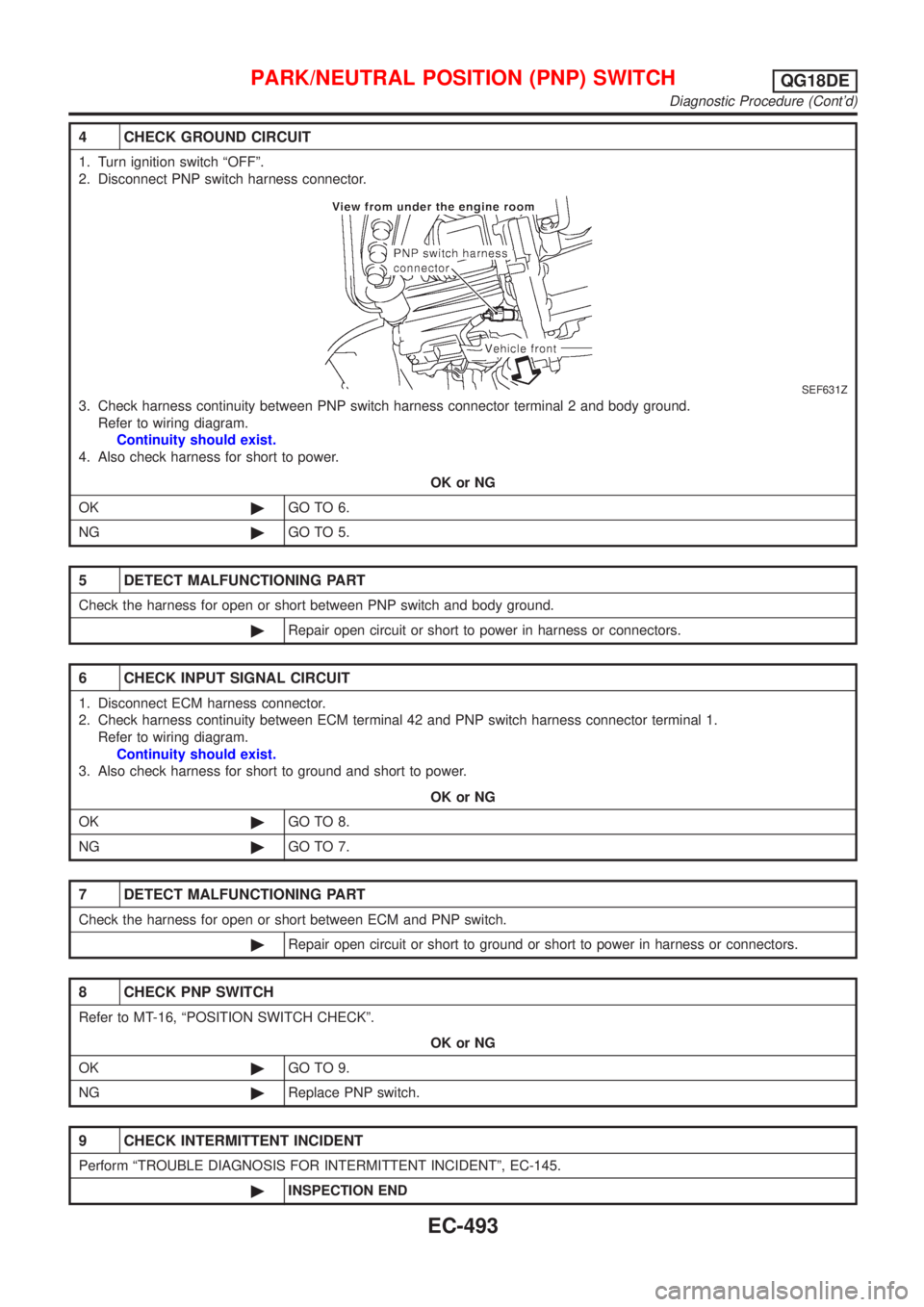

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect PNP switch harness connector.

SEF631Z

3. Check harness continuity between PNP switch harness connector terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between PNP switch and body ground.

©Repair open circuit or short to power in harness or connectors.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 42 and PNP switch harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and PNP switch.

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK PNP SWITCH

Refer to MT-16, ÂȘPOSITION SWITCH CHECKÂș.

OK or NG

OK©GO TO 9.

NG©Replace PNP switch.

9 CHECK INTERMITTENT INCIDENT

Perform ÂȘTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTÂș, EC-145.

©INSPECTION END

PARK/NEUTRAL POSITION (PNP) SWITCHQG18DE

Diagnostic Procedure (Cont'd)

EC-493

Page 919 of 3051

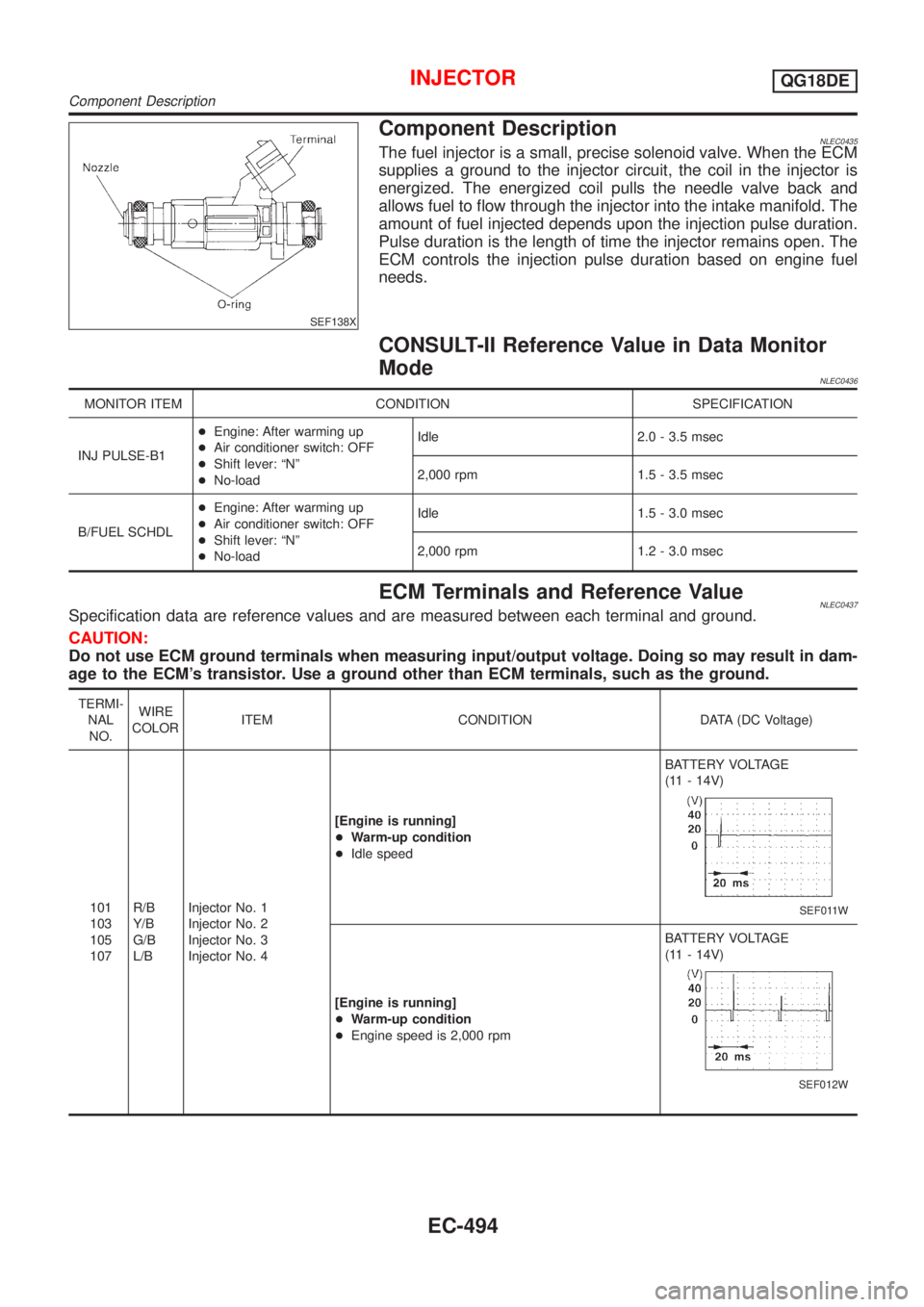

SEF138X

Component DescriptionNLEC0435The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the injector circuit, the coil in the injector is

energized. The energized coil pulls the needle valve back and

allows fuel to flow through the injector into the intake manifold. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the injector remains open. The

ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0436

MONITOR ITEM CONDITION SPECIFICATION

INJ PULSE-B1+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ÂȘNÂș

+No-loadIdle 2.0 - 3.5 msec

2,000 rpm 1.5 - 3.5 msec

B/FUEL SCHDL+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ÂȘNÂș

+No-loadIdle 1.5 - 3.0 msec

2,000 rpm 1.2 - 3.0 msec

ECM Terminals and Reference ValueNLEC0437Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

101

103

105

107R/B

Y/B

G/B

L/BInjector No. 1

Injector No. 2

Injector No. 3

Injector No. 4[Engine is running]

+Warm-up condition

+Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF011W

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

SEF012W

INJECTORQG18DE

Component Description

EC-494

Page 920 of 3051

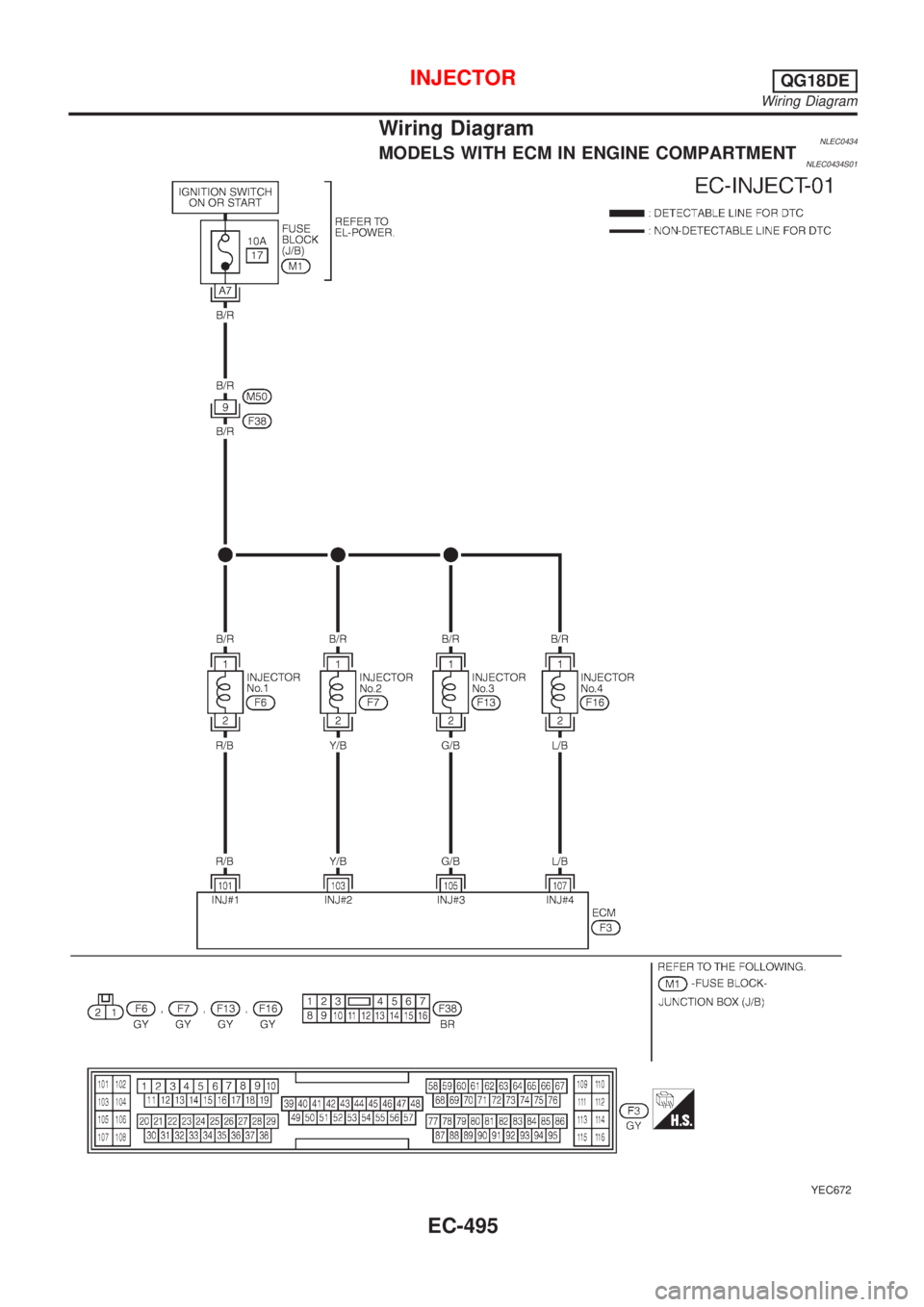

Wiring DiagramNLEC0434MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0434S01

YEC672

INJECTORQG18DE

Wiring Diagram

EC-495