NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: wheel alignment, rims, change language, fuses, wiring, interior lights, bulb

Page 941 of 3051

System DescriptionNLEC0444

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Fuel pump

controlFuel pump relay Camshaft position sensor (PHASE) Engine speed and cylinder number

Ignition switch Ignition signal and start signal

The ECM activates the fuel pump for several seconds after the ignition switch is turned on to improve engine

startability. If the ECM receives a 180É signal from the camshaft position sensor, it knows that the engine is

rotating, and causes the pump to perform. If the 180É signal is not received when the ignition switch is on, the

engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving safety. The

ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump relay, which in turn controls the

fuel pump.

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second

Engine running and cranking Operates

When engine is stopped (Signal is not sent from crankshaft position sensor

and camshaft position sensor.)Stops in 1.5 seconds

Except as shown aboveStops

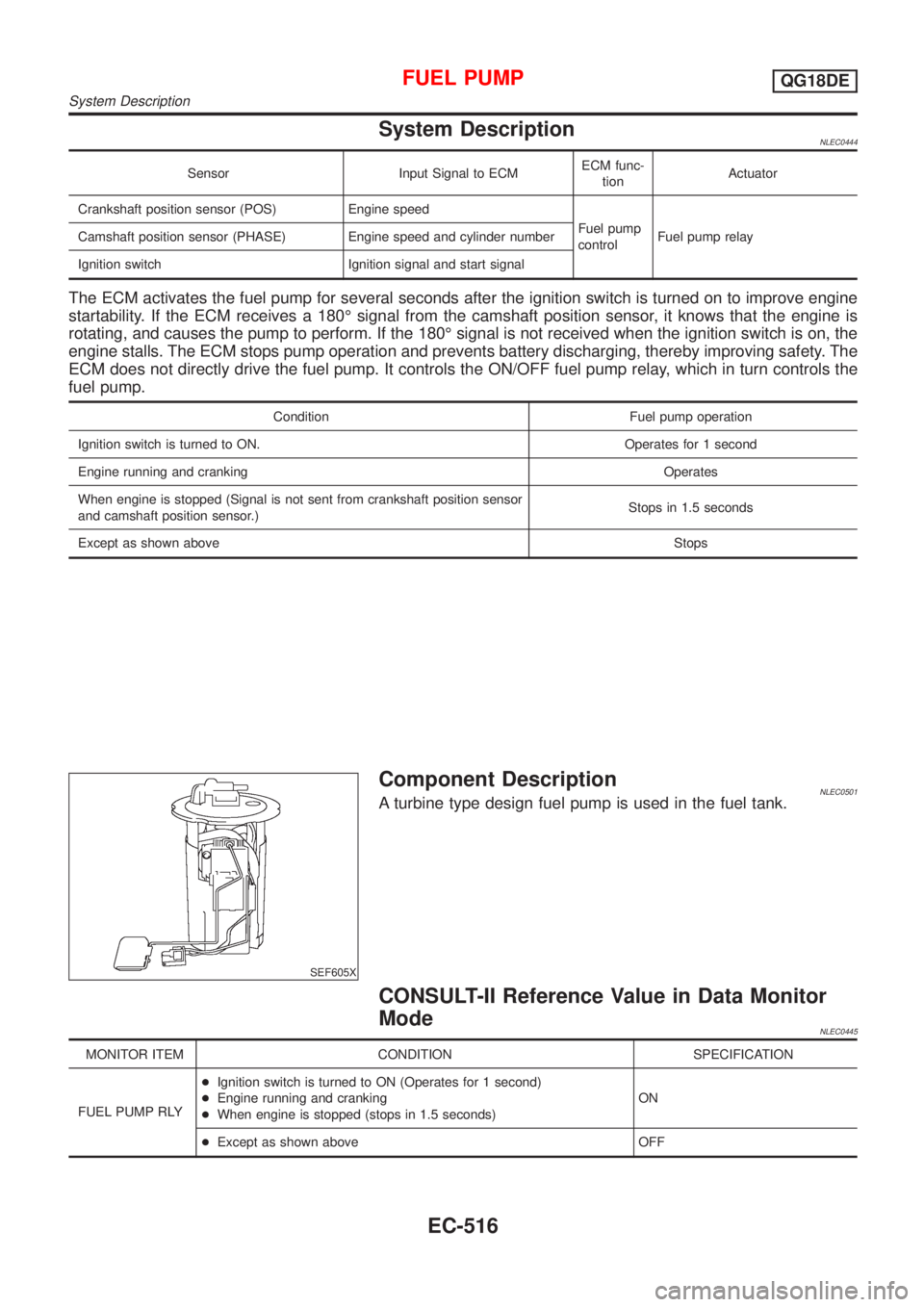

SEF605X

Component DescriptionNLEC0501A turbine type design fuel pump is used in the fuel tank.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0445

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY+Ignition switch is turned to ON (Operates for 1 second)

+Engine running and cranking

+When engine is stopped (stops in 1.5 seconds)ON

+Except as shown above OFF

FUEL PUMPQG18DE

System Description

EC-516

Page 942 of 3051

ECM Terminals and Reference Value=NLEC0446Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

21 B/P Fuel pump relay[Ignition switch ªONº]

+For 1 second after turning ignition switch ªONº

[Engine is running]0-1V

[Ignition switch ªONº]

+More than 1 second after turning ignition switch

ªONºBATTERY VOLTAGE

(11 - 14V)

FUEL PUMPQG18DE

ECM Terminals and Reference Value

EC-517

Page 943 of 3051

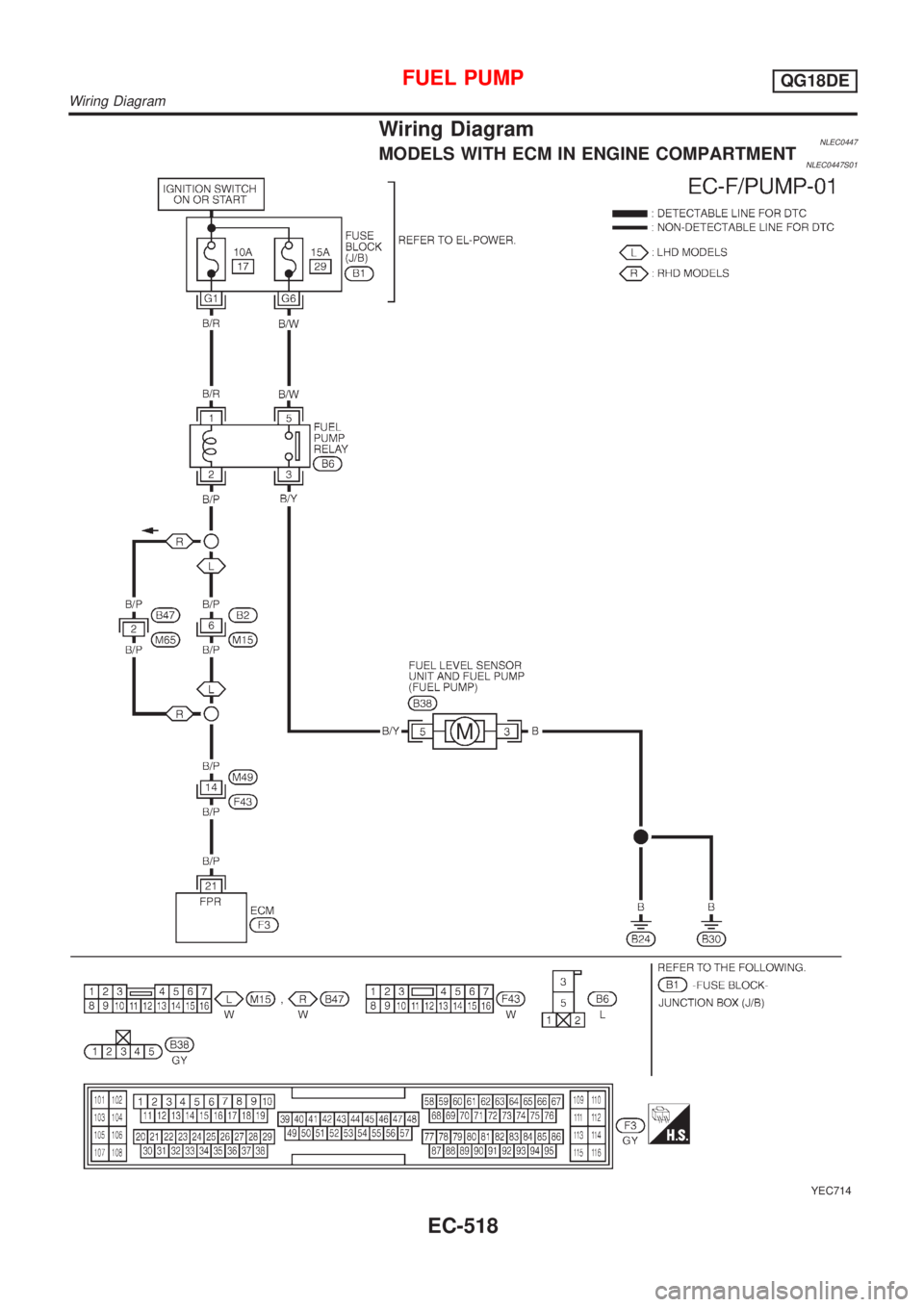

Wiring DiagramNLEC0447MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0447S01

YEC714

FUEL PUMPQG18DE

Wiring Diagram

EC-518

Page 944 of 3051

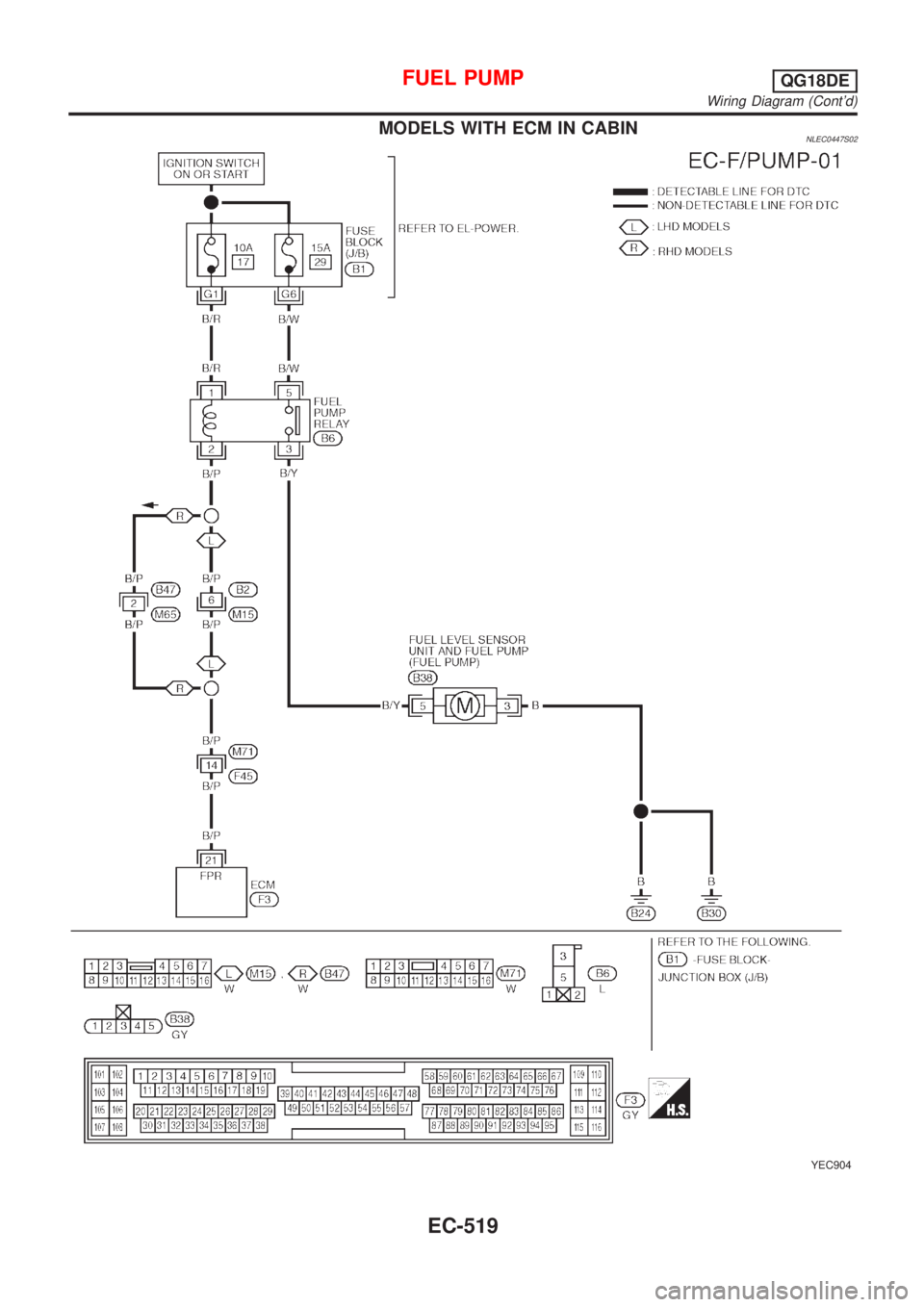

MODELS WITH ECM IN CABINNLEC0447S02

YEC904

FUEL PUMPQG18DE

Wiring Diagram (Cont'd)

EC-519

Page 945 of 3051

Diagnostic ProcedureNLEC0448

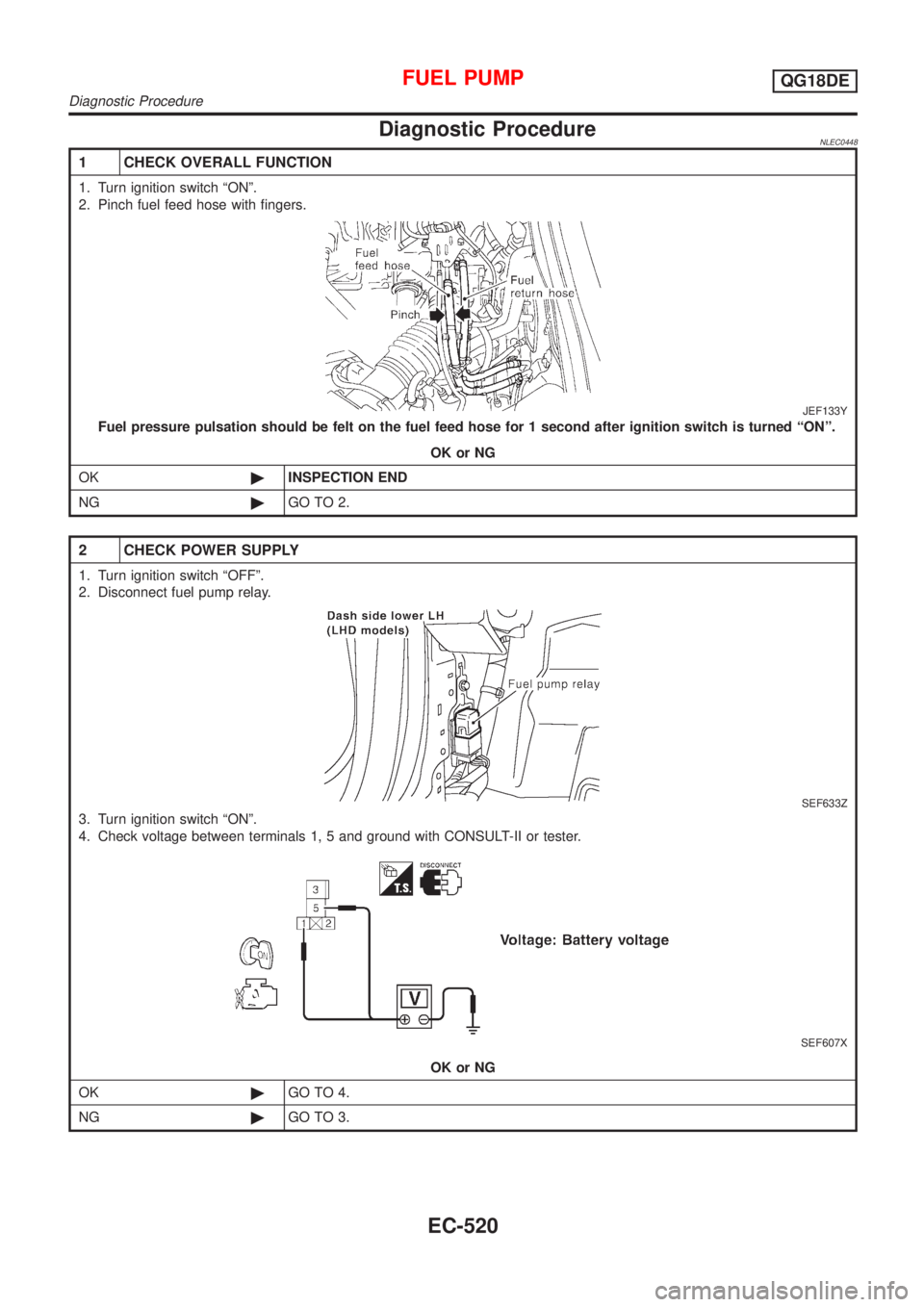

1 CHECK OVERALL FUNCTION

1. Turn ignition switch ªONº.

2. Pinch fuel feed hose with fingers.

JEF133Y

Fuel pressure pulsation should be felt on the fuel feed hose for 1 second after ignition switch is turned ªONº.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect fuel pump relay.

SEF633Z

3. Turn ignition switch ªONº.

4. Check voltage between terminals 1, 5 and ground with CONSULT-II or tester.

SEF607X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

FUEL PUMPQG18DE

Diagnostic Procedure

EC-520

Page 946 of 3051

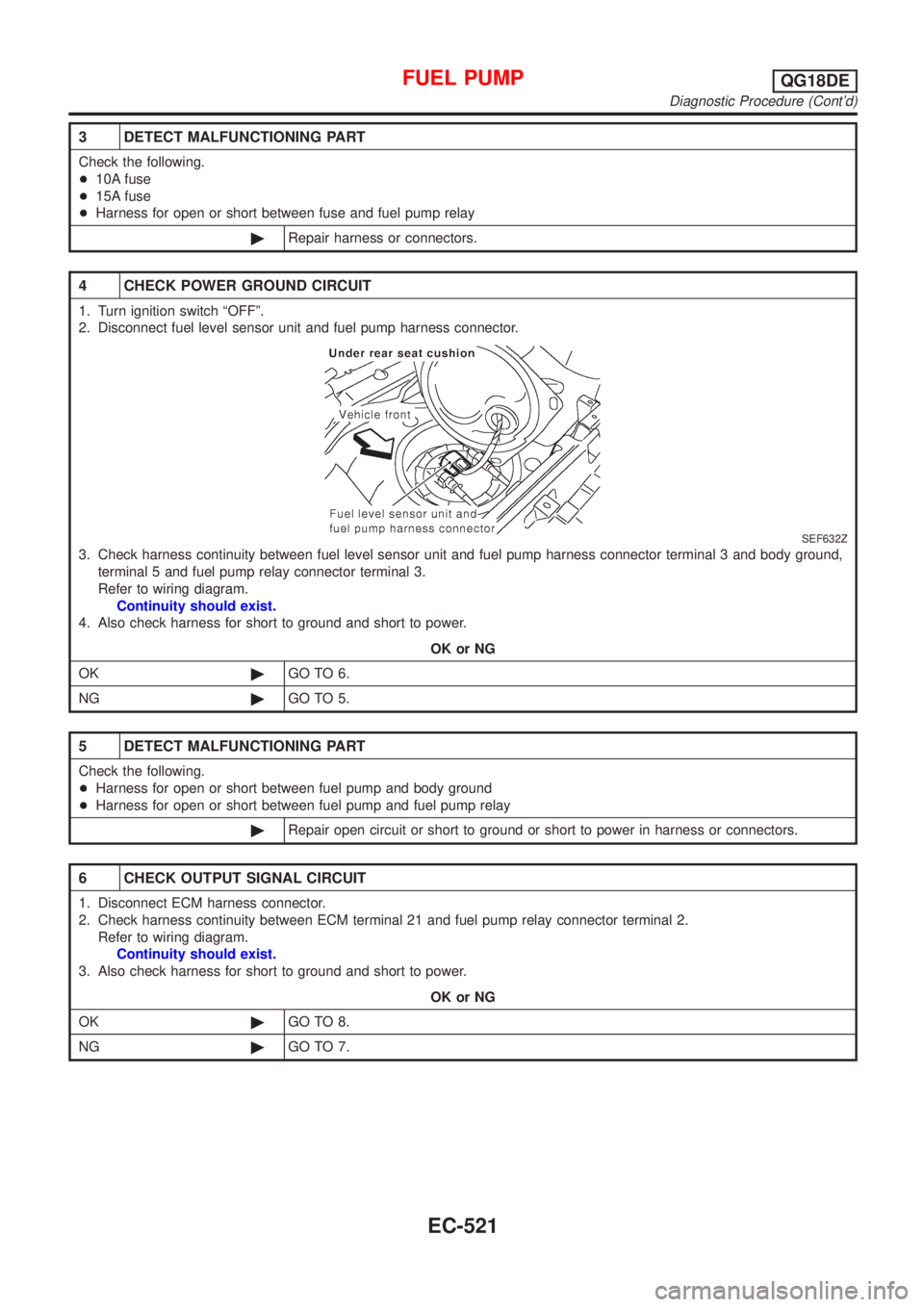

3 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+15A fuse

+Harness for open or short between fuse and fuel pump relay

©Repair harness or connectors.

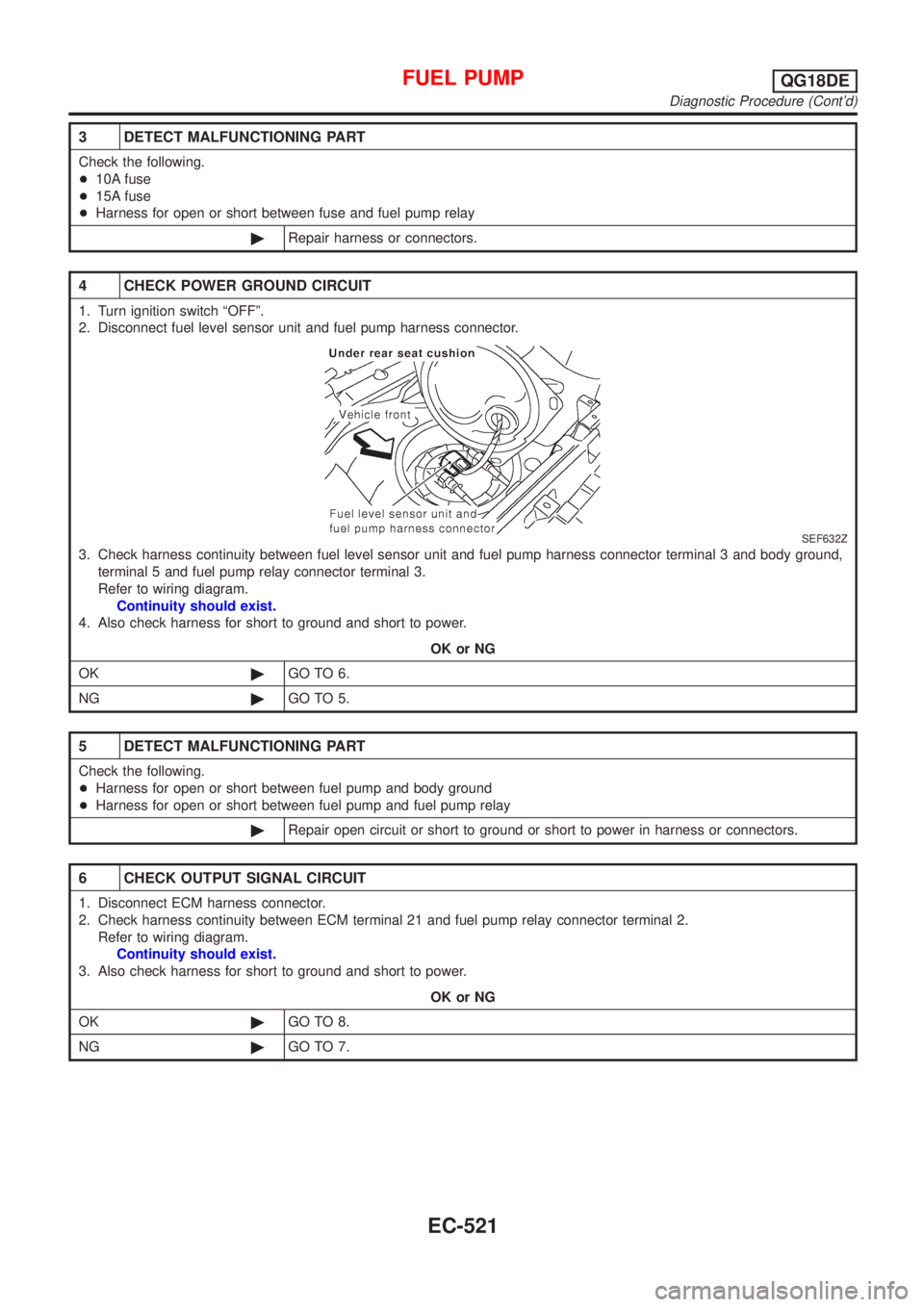

4 CHECK POWER GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect fuel level sensor unit and fuel pump harness connector.

SEF632Z

3. Check harness continuity between fuel level sensor unit and fuel pump harness connector terminal 3 and body ground,

terminal 5 and fuel pump relay connector terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness for open or short between fuel pump and body ground

+Harness for open or short between fuel pump and fuel pump relay

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK OUTPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 21 and fuel pump relay connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

FUEL PUMPQG18DE

Diagnostic Procedure (Cont'd)

EC-521

Page 947 of 3051

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors B2, M15 (LHD models), B47, M65 (RHD models)

+Harness connectors M49, F43 (where fitted)

+Harness connectors M71, F45 (where fitted)

+Harness for open or short between ECM and fuel pump relay

NG©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK FUEL PUMP RELAY

Refer to ªComponent Inspectionº, EC-522.

OK or NG

OK©GO TO 9.

NG©Replace fuel pump relay.

9 CHECK FUEL PUMP

Refer to ªComponent Inspectionº, EC-522.

OK or NG

OK©GO TO 10.

NG©Replace fuel pump.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

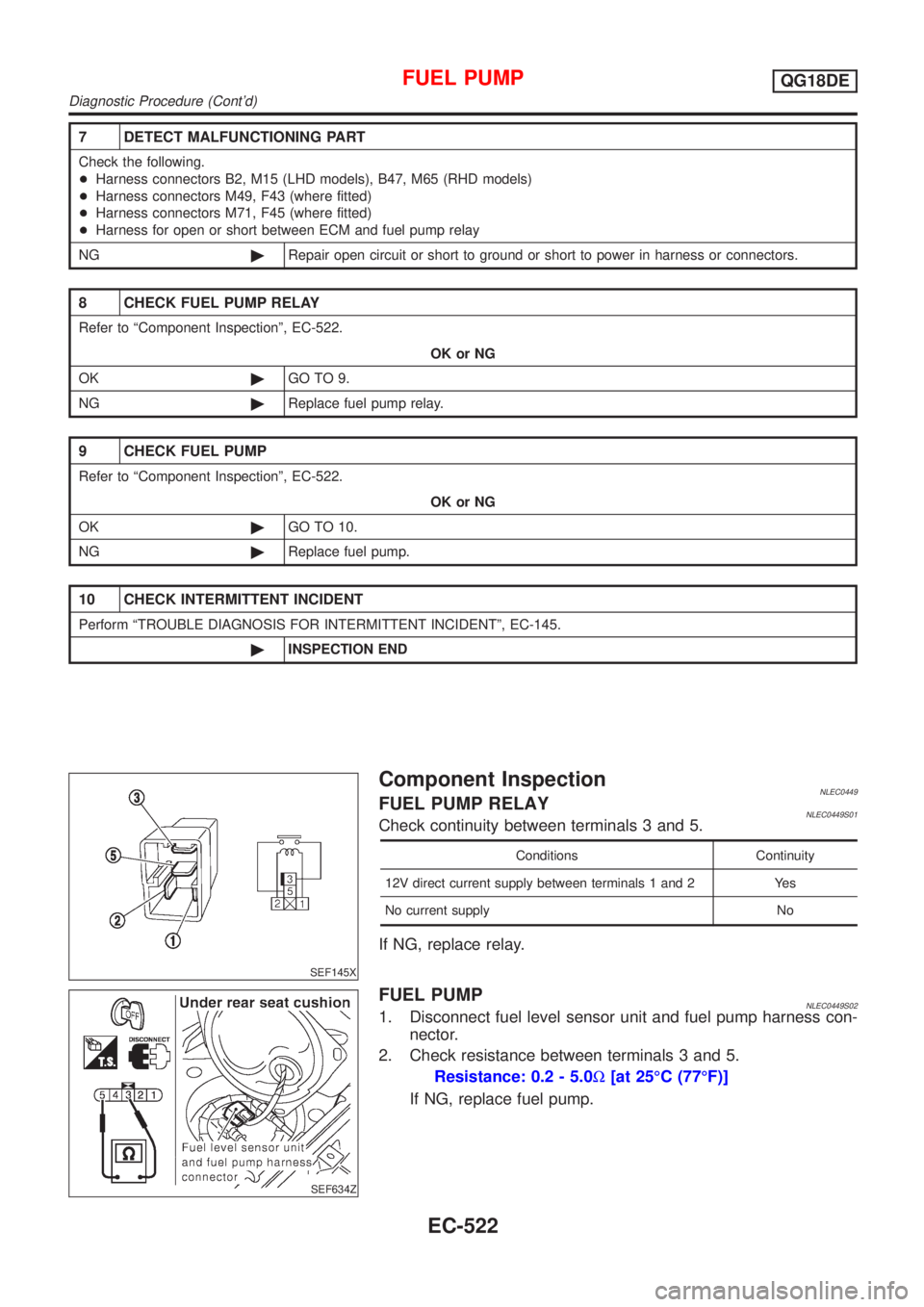

SEF145X

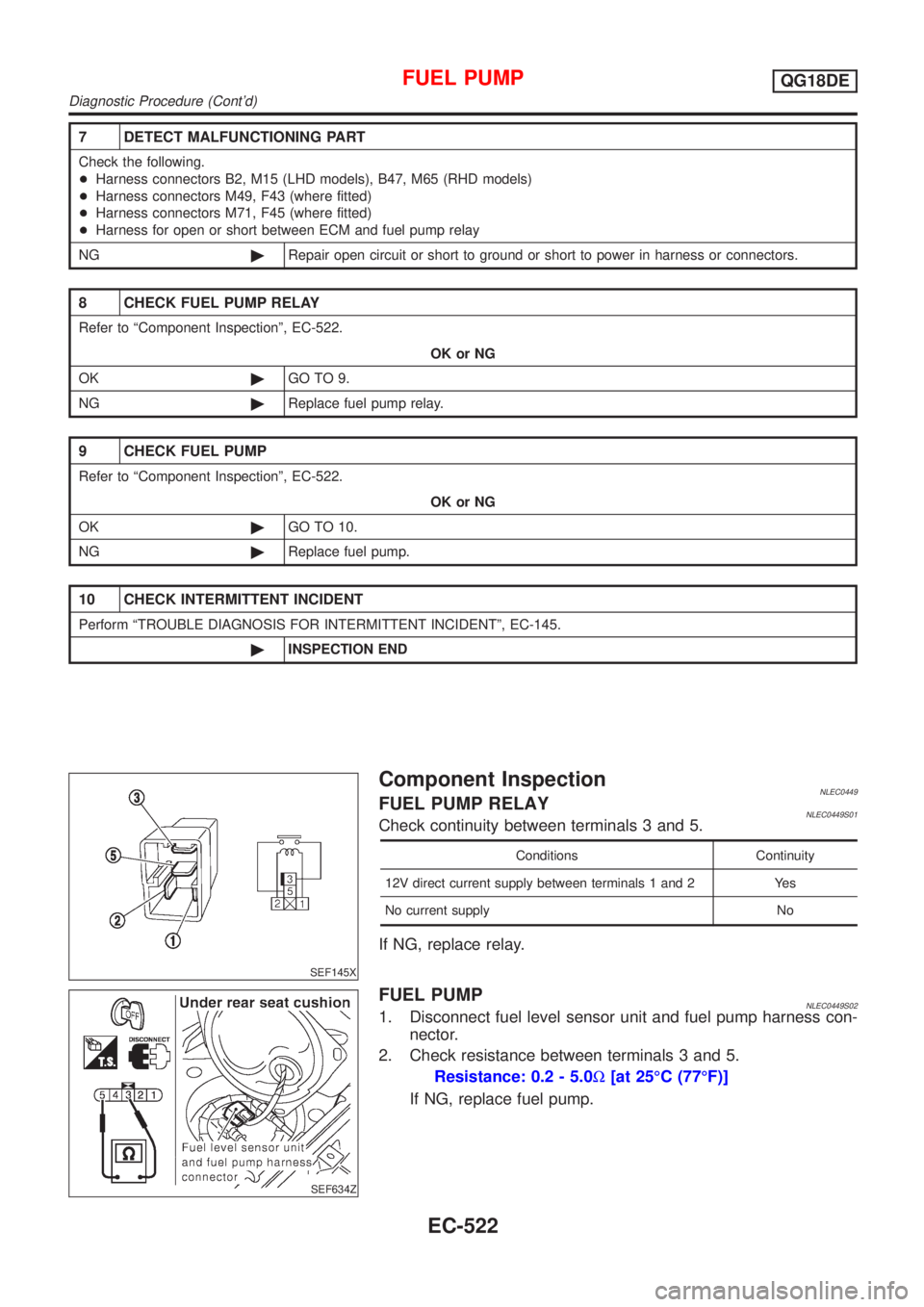

Component InspectionNLEC0449FUEL PUMP RELAYNLEC0449S01Check continuity between terminals 3 and 5.

Conditions Continuity

12V direct current supply between terminals 1 and 2 Yes

No current supply No

If NG, replace relay.

SEF634Z

FUEL PUMPNLEC0449S021. Disconnect fuel level sensor unit and fuel pump harness con-

nector.

2. Check resistance between terminals 3 and 5.

Resistance: 0.2 - 5.0W[at 25ÉC (77ÉF)]

If NG, replace fuel pump.

FUEL PUMPQG18DE

Diagnostic Procedure (Cont'd)

EC-522

Page 948 of 3051

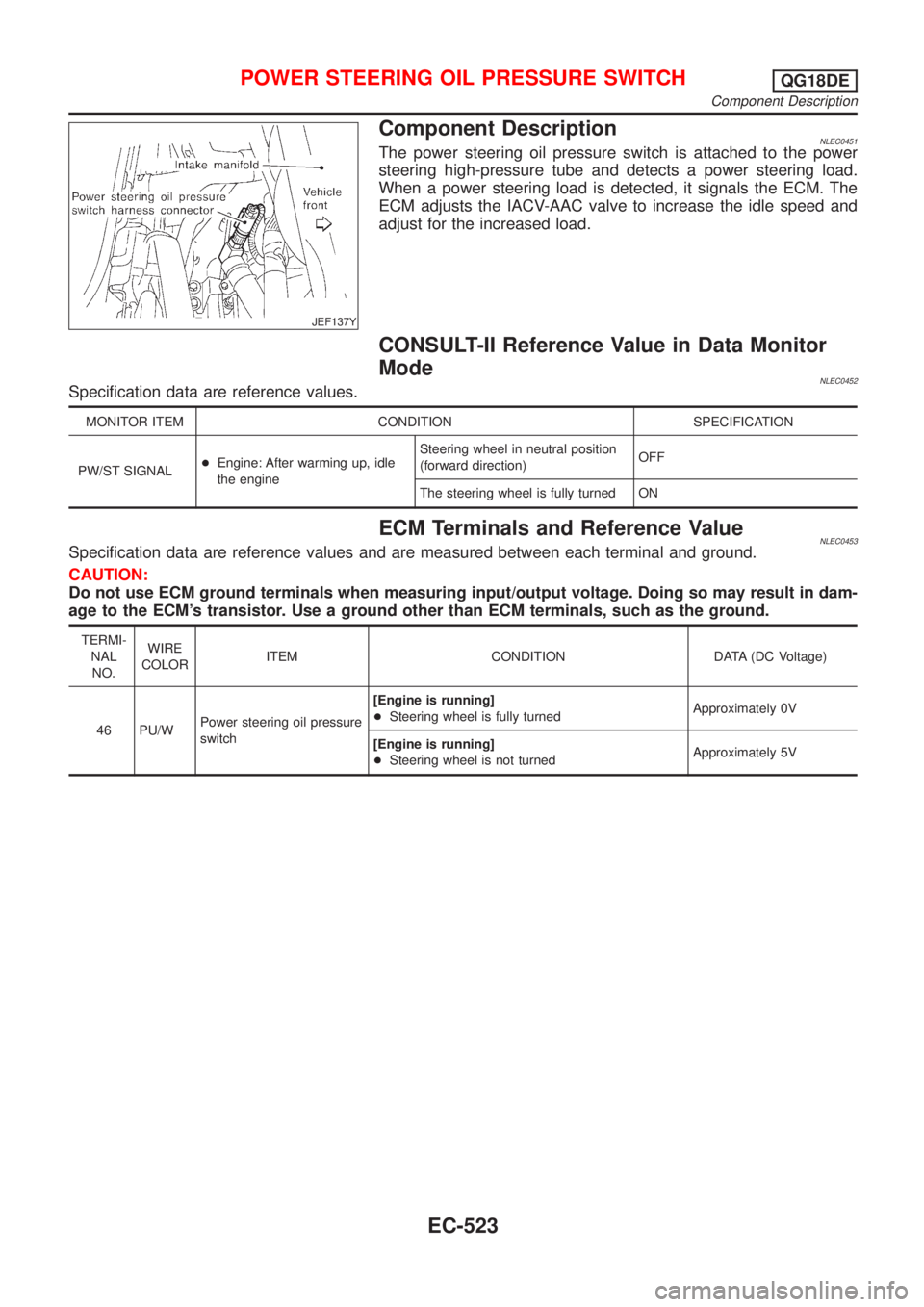

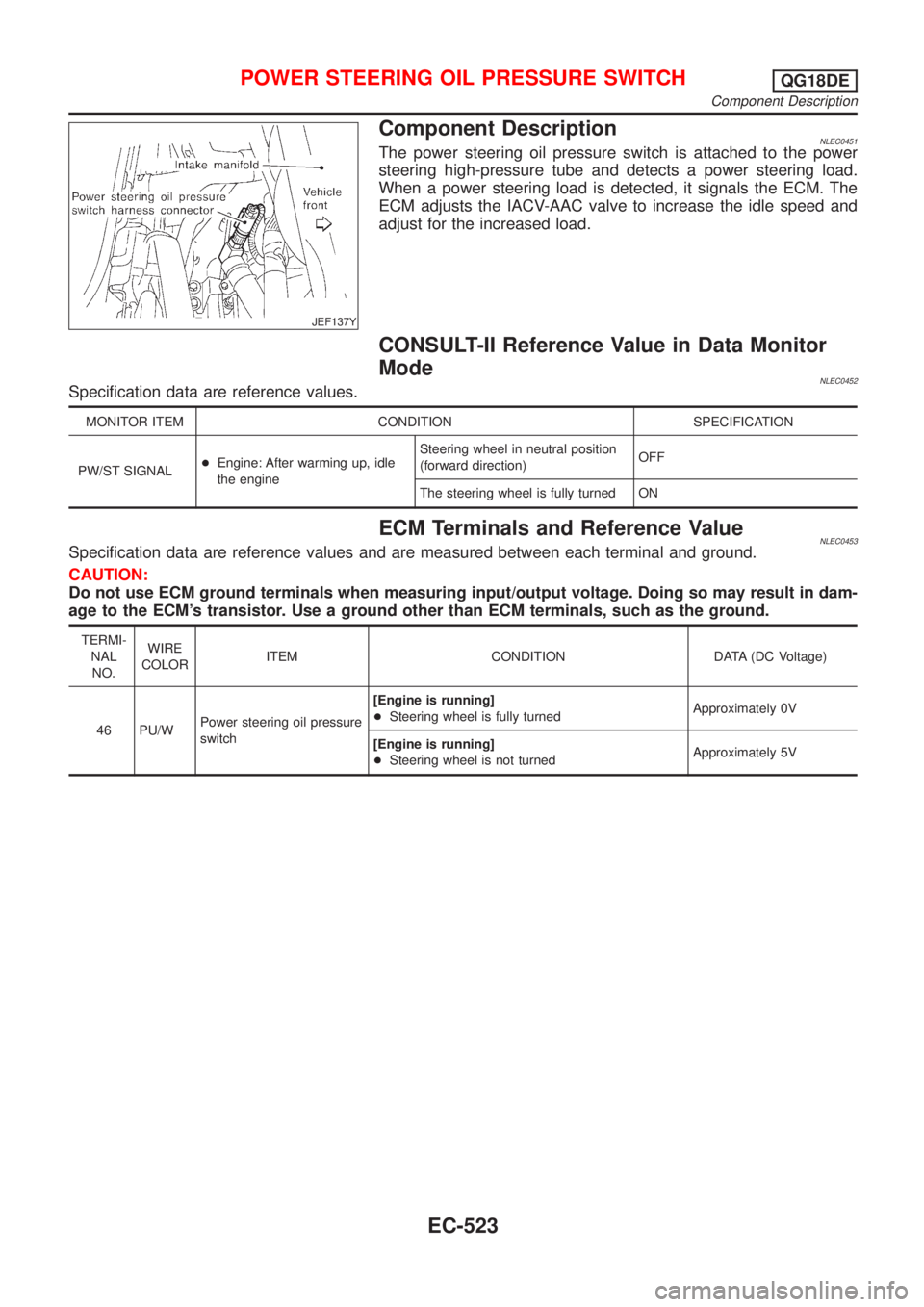

JEF137Y

Component DescriptionNLEC0451The power steering oil pressure switch is attached to the power

steering high-pressure tube and detects a power steering load.

When a power steering load is detected, it signals the ECM. The

ECM adjusts the IACV-AAC valve to increase the idle speed and

adjust for the increased load.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0452Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PW/ST SIGNAL+Engine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is fully turned ON

ECM Terminals and Reference ValueNLEC0453Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

46 PU/WPower steering oil pressure

switch[Engine is running]

+Steering wheel is fully turnedApproximately 0V

[Engine is running]

+Steering wheel is not turnedApproximately 5V

POWER STEERING OIL PRESSURE SWITCHQG18DE

Component Description

EC-523

Page 949 of 3051

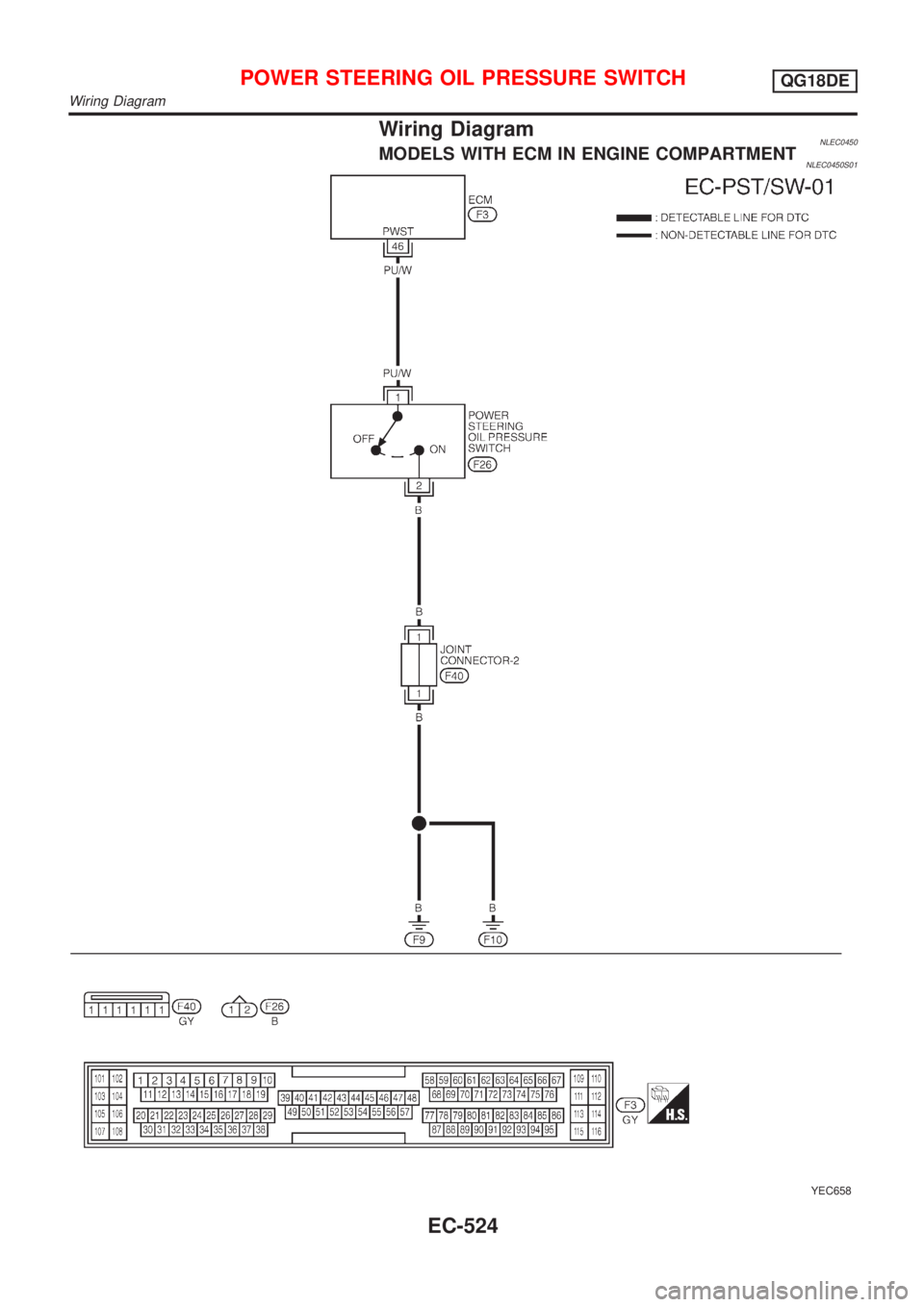

Wiring DiagramNLEC0450MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0450S01

YEC658

POWER STEERING OIL PRESSURE SWITCHQG18DE

Wiring Diagram

EC-524

Page 950 of 3051

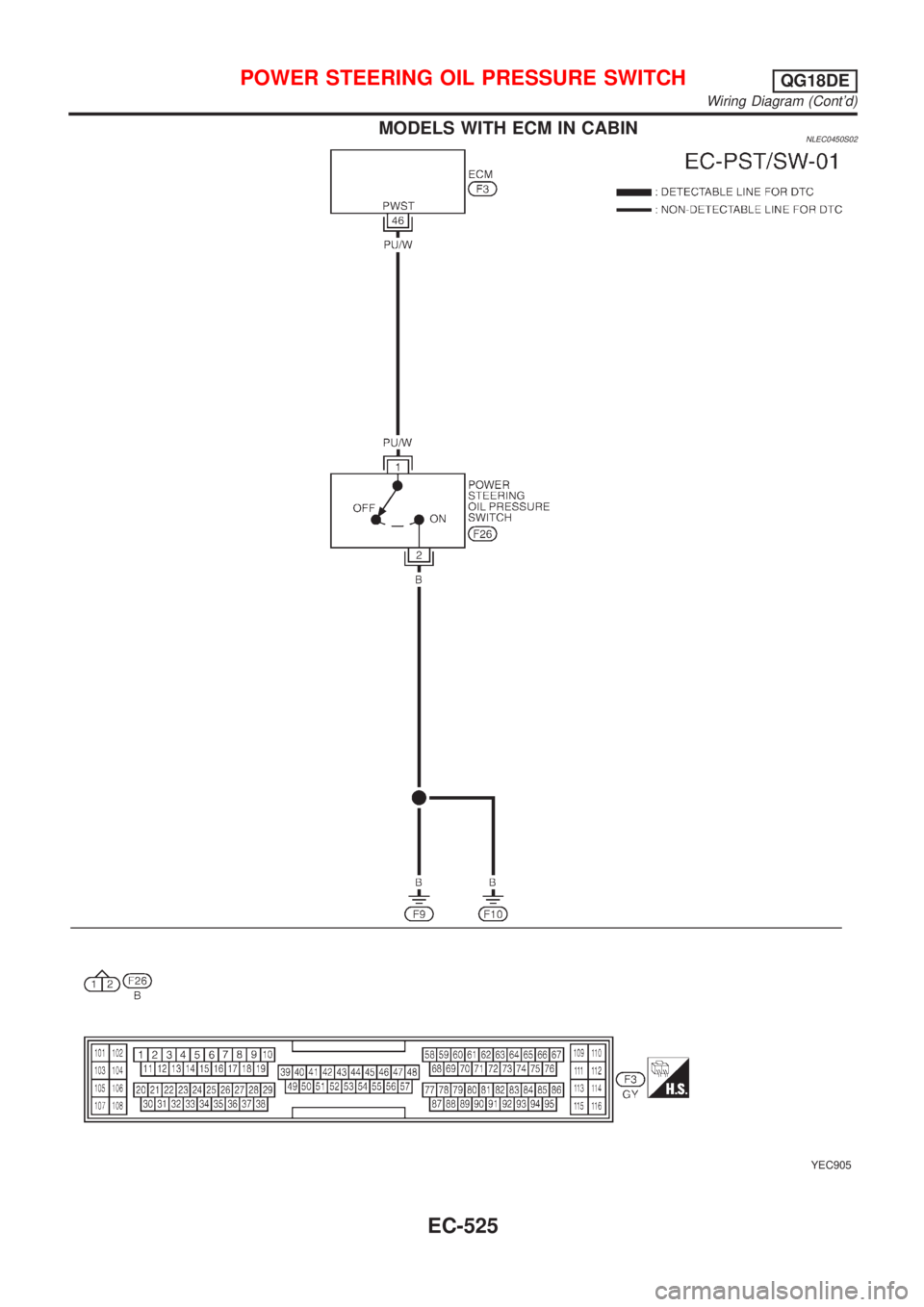

MODELS WITH ECM IN CABINNLEC0450S02

YEC905

POWER STEERING OIL PRESSURE SWITCHQG18DE

Wiring Diagram (Cont'd)

EC-525

Trending: power steering fluid, service indicator, fuel filter location, sensor, height adjustment, air filter, warning lights