ignition NISSAN GT-R 1998 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 76 of 230

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

\ I1 // \ 11 // =-I= or =mj= // 11 \ // 11 \

1, = 2.5 sec. t, = 2.0 sec. t, = 1.0 sec.

RB20DE 10 judgement flashes.

Stan signal Malfunctioning unit and circuit I

Except RBPODE 13 judgement flashes.

signal Malfunctioning unit and circuit I

POWER INDICATOR LAMP OR DUAL MATIC A/T

WARNING LAMP INDICATION

If malfunction occurs in electrical system, indicator lamp stays on

longer at corresponding circuit.

Flashing

order

t5 1 Overrun clutch solenoid

1

2

3

4

5

7 1 Lock-up solenoid

Malfunctioning

unit and circuit

Vehicle speed sensor

1

Vehicle speed sensor 2

Throttle position sensor

Shift solenoid

A

Shift solenoid B

I

W fluid temperature sensor, TCM power supply, or throttle posi-

tion sensor power supply

RB20DE

9 1 Engine speed

signal Except

RB20DE

10 1 Line

pressure solenoid I Turbine sensor

I - I Line pressure solenoid

12 1 - I Total control signal

When indicator lamp repeats flashing in 4 Hz, the following malfunctions

may exist: (Insufficient memory backup

powerflCM repiacement1Battery

has been disconnected for prolonged

periodllow battery power)

13

No flashes

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

To facilitate cause investigation of malfunction that is less likely to

reappear, the TCM always stores self-diagnostic results during cus-

tomer operation. This memory cannot be erased even if ignition

switch

is turned ON and OFF repeatedly. To erase the seif-diag-

nostic

results, turn ignition switch

OFF after self-diagnosis has

been performed, or use

"ERASE" function of CONSULT.

- - - - Shift control unit

PNP switch, idle

switch/full switch

Overdrive control switch Stop lamp switch

Page 77 of 230

TROUBLE DIAGNOSES

Symptom Chart

Sharp shock in Engine brake

applied

Shifting

Malfunctions

Slip

(Racing)

hifting

.- erator pedal

Shifting

Shifting

inspection item

Fluid level and status

Control linkage

PNP switch (short/open circuit)

Throttle ~osition sensor (installed)

I Vehicle weed sensor

I Enaine meed sensor

A/T fluid temperature sensor

Engine idle speed

Line

Dressure

Control valve assembly

Shift solenoid

A

Shift solenoid B

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

Accumulator N-D

Accumulator

1-2

Accumulator 2-3

Accumulator 3-4 (N-R) Ignition coil and starter motor

Overdrive control switch

I AfT mode switch (AUTO)

Torque converter

1 Oil pump

I Reverse clutch

I High clutch

I Forward clutch

I Forward one-wav clutch

I Overrun ciutch

1 Low one-wav clutch

I Low reverse brake

Brake. band (including servo)

Parking linkage

Page 78 of 230

Symptom Chart (Cont'd)

Greater noise

Malfunctions

Inspection item No shifting

I Shifting I

Fluid level

and status 11

Control linkage

-

(I) C 0 .- c. .- (I) 0 a

v

-CU

n - 1

PNP switch

(shortlopen

circuit)

Throttle position sensor (installed)

2 2

Vehicle speed sensor

I Engine speed sensor -

-T

L o 1 Control valve assembly .- - -- Shift solenoid A 4 3

. ' Shift solenoid 6 4 cut I1

--, Line pressure solenoid .- 5 -t Lock-up solenoid ?

6 Overrun clutch solenoid 3

Accumulator N-D

1 Accumulator 1-2 I 1-

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition coil and starter motor

I Overdrive control switch I 1-

A/T mode switch (AUTO)

A/T mode switch (POWER) I - I Ail mode switch (SNOW) I

I Torque converter I I

1 Oil pump I I -- - - Reverse clutch 0 -

'g High clutch a 4 6

%I Forward clutch I I - .- a Forward one-way clutch -

$ Overrun clutch a, 8

Low one-way clutch

O Low reverse brake 7

Brake band (including servo) 7

Parking linkage

Page 79 of 230

TROUBLE DIAGNOSES

Symptom Chart (Cont'd)

xi - - ([I C V) a, C .- cn C W

t 0 .- .L 2 a, - 8 0 ([I L 0 0 Q

& 0 a, a, Q V)

5 E .- X

i! L a

zl -I - 1 -

- 2 -

-

-

-

-

-

5 - 3 - 4 -

-

-

-

-

-

-

-

-

-

-

-

-

I1 - 0 - 6 - 7 -

-

-

-

-

9 - 8 -

-

vj c 0 .- - .- V) 0 n

Q 7J C ([I

t C .- r ([I c. V) c. 0 C V) a 0 7J 0, C .- 0 C W -

- 2 - 3 -

-

- -

-

1 -

-

-

-

- - a +- ([I a a, 2 0 c. 0 C V) a, 0 u a, - 0 2

8 - 1 -

-

-

-

-

-

-

-

2 - 3 -

-

-

-

-

-

-

-

-

-

-

- I

i

g

- 4 -

-

-

-

-

-

-

B- ; 2 to a =? - 0,

2 5.j c 2.z 2 a0 - 0- z & 5 0 gE V) V)o C 02 .s nu 5 ng %-([I C O c --t .- V) a V) r aa ([I z gz a, a- c 50 -6 s

6 $2

11

2

I

I

Malfunctions

Inspection item

I I I Fluid level and status I I Control linkage 2

PNP switch (shortfopen circuit) 1 I I I Throttle position sensor (installed) 111213

Vehicle speed sensor

214

Engine speed sensor L -

AIT fluid temperature sensor

Engine idle weed

Line pressure

Control valve assembly

Shift solenoid A 3

3

Shift solenoid B 4 4

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

u I I I -

Accumulator N-D I I 1 I Accumulator 1-2

Accumulator 2-3 I Accumulator 3-4 (N-R)

Ignition coil and starter motor

Overdrive control switch

Torque converter

tg Reverse clutch .- High clutch

2 Forward clutch C .- a Forward one-way clutch -.

$ Overrun clutch 0, 8

? Low one-way clutch 3= O Low reverse brake 9

Brake band (including servo)

Parking linkage

Page 84 of 230

ANTI-LOCK BRAKE SYSTEM

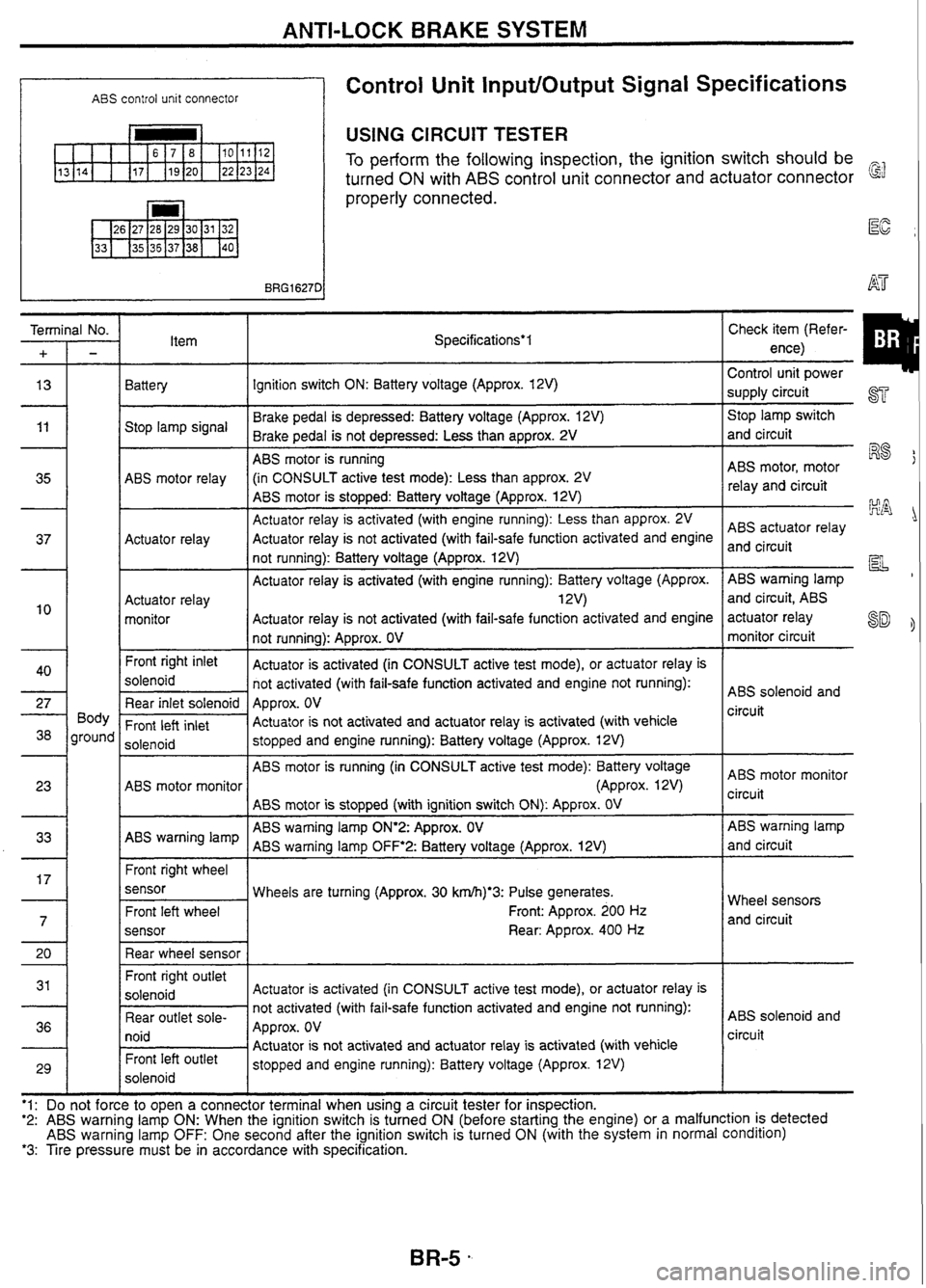

ABS control unit connector

Terminal No.

Control Unit InputlOutput Signal Specifications

USING CIRCUIT TESTER

To perform the following inspection, the ignition switch should be

turned

ON with ABS control unit connector and actuator connector

properly connected.

Item Specifications*l

Battery Ignition switch ON: Battery voltage (Approx. 12V)

Brake pedal is depressed: Battery voltage (Approx. 12V)

Stop lamp signal

Brake pedal is not depressed: Less than approx.

2V

ABS motor is running

ABS motor relay (in

CONSULT active test mode): Less than approx.

2V

ABS motor is stopped: Battery voltage (Approx.

12V)

Actuator relay is activated (with engine running): Less than approx. 2V

Actuator relay Actuator

relay is not activated (with fail-safe function activated and engine

not running): Battery voltage (Approx. 12V)

Actuator relay is activated (with engine running): Battery voltage (Approx.

Actuator relay 1 2V)

monitor Actuator

relay is not activated (with fail-safe function activated and engine

not running): Approx. OV

Front

right inlet

Actuator is activated (in CONSULT active test mode), or actuator relay is

solenoid not activated (with fail-safe function activated and engine not running):

Rear inlet solenoid Approx. OV

Front

left inlet Actuator

is not activated and actuator relay is activated (with vehicle

solenoid stopped

and engine running): Battery voltage (Approx. 12V)

ABS motor is running (in CONSULT active test mode): Battery voltage

ABS motor monitor (Approx. 12V)

ABS motor is stopped (with ignition switch

ON): Approx. OV

ABS warning lamp

ON'2:

Approx. OV

ABS warning lamp

ABS warning lamp

OFF'2:

Battery voltage (Approx. 12V)

Front right wheel

sensor Wheels are turning (Approx. 30

krn/h)*3: Pulse generates.

Front: Approx. 200

Hz

sensor

Rear: Approx. 400 Hz

Front right outlet

Actuator is activated (in CONSULT active test mode), or actuator relay is

not activated (with fail-safe function activated and engine not running):

Rear outlet

sole-

Approx. OV

I lUlU / Actuator is not activated and actuator relay is activated (with vehicle Front left Outlet stopped and engine running): Battery voltage (Approx. 12V)

solenoid

'1:e

to

tooen

a connector terminal when

using a circuit tester for inspection. Control

I

unit

power

supply circuit

ST

Stop lamp switch

and circuit

ABS motor, motor

R8

relay and circuit

ABS actuator relay

and circuit

pL

ABS warning lamp

and circuit, ABS

actuator relay

SD monitor circuit

ABS solenoid and

circuit

ABS motor monitor

circuit

ABS warning lamp

and circuit

Wheel sensors and circuit

ABS solenoid and

circuit

'2: ABS warning lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected ABS warning lamp OFF: One second after the ignition switch is turned ON (with the system in normal condition) *3: Tire pressure must be in accordance with specification.

Page 85 of 230

ANTI-LOCK BRAKE SYSTEM

Control Unit InputfOutput Signal Specifications

(Cont'd)

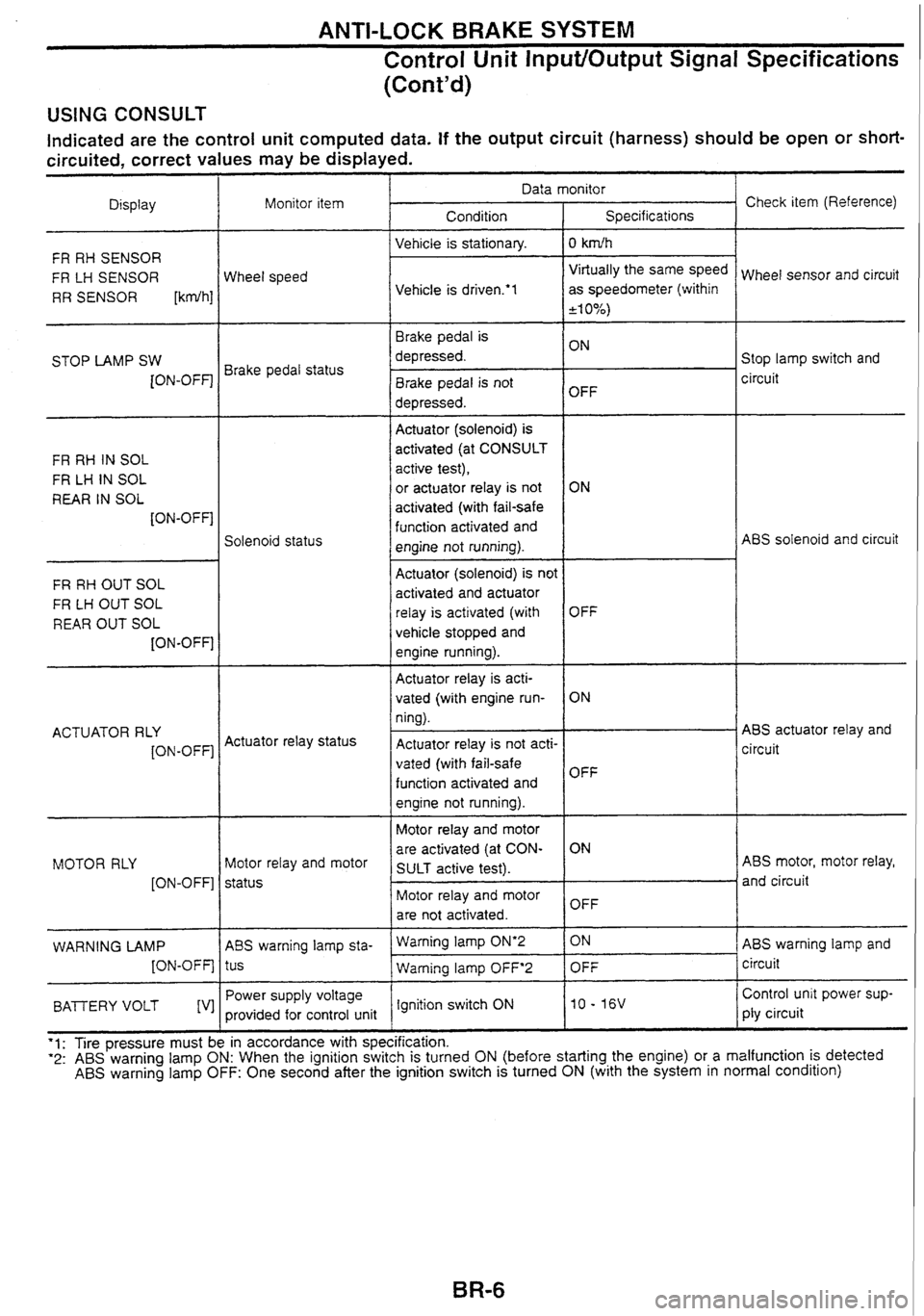

USING CONSULT

Indicated are the control unit computed data. If the output circuit (harness) should be open or short-

circuited, correct values may be displayed.

Check item (Reference)

Data monitor

Display Condition

Monitor

item

Specifications

Vehicle is stationary.

I 0 kdh

FR RH SENSOR

FR LH SENSOR

RR SENSOR

[kdh]

Virtually the same speed

as speedometer (within

+I 0%)

Wheel sensor and circuit

Wheel speed

Vehicle is

drivem'l

Brake pedal is

depressed. Stop lamp switch and

circuit

STOP

LAMP SW

[ON-OFF] Brake pedal status

Brake pedal is not

depressed. OFF

-- --

Actuator (solenoid)

is

activated (at CONSULT

active test),

or

actuator relay is not

activated (with fail-safe

function activated and

engine not running).

FR

RH IN SOL

FR

LH IN SOL

REAR IN SOL

[ON-OFF]

ABS solenoid and circuit

Solenoid status

FR RH OUT SOL

FR

LH OUT SOL

REAR OUT SOL

[ON-OFF]

-- -- - -- -

Actuator (solenoid) is not

activated and actuator

relay is activated (with

vehicle stopped and

engine running).

Actuator relay is acti-

vated (with engine run-

ning).

Actuator relay is not acti-

vated (with fail-safe

function activated and

engine not running).

ABS actuator relay and

circuit

OFF

ON

OFF

ACTUATOR

RLY

[ON-OFF] Actuator

relay status

Motor relay and motor

are activated (at CON-

SULT active test). ABS

motor, motor relay,

and circuit

MOTOR

RLY

[ON-OFF] Motor

relay and motor

status Motor relay and motor

are not activated. OFF

ABS warning lamp and

circuit

- -

Waming lamp ON'2 1 ON

WARNING LAMP

[ON-OFF] ABS

warning lamp sta-

tus

Power supply voltage

provided for control unit -- -

Warning lamp OFF'2 1 OFF

Control unit power sup-

ply circuit - -

BAlTERY VOLT [V] Ignition switch

ON

'1: Tire pressure must be in accordance with specification. "2: ABS warning lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected ABS warning lamp OFF: One second after the ignition switch is turned ON (with the system in normal condition)

Page 86 of 230

ANTI-LOCK BRAKE SYSTEM

Precautions for Trouble Diagnosis

After performing trouble diagnosis, be sure to erase trouble stored in memory. Refer to "CONSULT' (next

page) or "SELF-DIAGNOSIS"

(BR-15).

As for the concerns that are difficult to duplicate, move harnesses or harness connectors by hand to check

if there is any poor mating of connector halves or faulty connection.

Do not force to open a connector terminal when using a circuit tester for inspection.

Read GI section thoroughly in advance and make sure of all the general precautions.

Basic Inspection

BASIC INSPECTION 1 - Brake fluid level and leakage AT

1. Check brake fluid level in reservoir tank. Replenish brake fluid if necessary.

2. Check for leakage at or around brake piping and ABS actuator. If leakage or seepage is noted, proceed

as follows:

If ABS actuator connectors are loose, tighten to specified torque. Recheck to ensure that leakage is no

longer present.

If flare nut threads at piping connectors or actuator threads are damaged, replace faulty parts with new 87

ones. Recheck to ensure that leakage is no longer present.

If brake fluid leaks through areas other than actuator connectors, wipe off using a clean cloth. Recheck

for leakage or seepage. If necessary, replace faulty parts with new ones.

R8

If brake fluid leaks at or seeps through ABS actuator, wipe off using a clean cloth. Recheck for leakage

or seepage. If necessary, replace

ABS actuator with new one.

CAUTION: HA

ABS actuator cannot be disassembled. Do not attempt to disassemble it.

BASIC INSPECTION 2 - Loose power line terminal

Check battery terminals (positive and negative) and battery mounting (ground) for looseness.

BASIC INSPECTION 3 - ABS warning lamp

1. Turn ignition switch "ON" to ensure that ABS warning lamp lights up for approximately 1 second. If ABS

warning lamp does not light, check ABS warning lamp circuit.

2. After driving vehicle at approx. 30 km/h for approx. 1 minute, check to ensure that ABS warning lamp

remains off. If ABS warning lamp lights, perform self-diagnosis procedures.

3. After performing self-diagnosis procedures, be sure to erase trouble stored in memory.

Page 87 of 230

ANTI-LOCK BRAKE SYSTEM

CONSULT

CONTROL UNIT PART NUMBER

The part number that is shown on the control unit label and CON-

SULT 47850 AAOOO

- SELF-DIAGNOSIS PROCEDURE

Coliect information on the concern from the customer, and then

perform basic inspections.

Turn ignition switch

OFF and connect CONSULT connector to

data link connector for CONSULT on the vehicle.

Start engine and drive vehicle at approx.

30 km/b for approx.

1 minute.

Stop vehicle and touch "START",

"ABS" and "SELF-DIAG

RESULTS" sequentially on the CONSULT screen with engine

running.

If "START" is touched immediately after engine is started

or ignition switch is turned on,

"ABS" may not be dis-

played on "SELECT

SYSTEM" screen. To display "ABS",

repeat the self-diagnosis procedure from the beginning.

Self-diagnosis results are displayed on the screen. (Touch

"PRINT" to print out the self-diagnosis results, if necessary.)

If

"NO FAIL" is displayed, inspect ABS warning lamp. Refer to

the previous page.

Perform appropriate inspection from the self-diagnostic results

mode and repair or replace faulty parts.

Start engine and drive vehicle at approx. 30

km/b for approx.

1 minute.

Recheck to ensure that there is no other malfunction.

Turn ignition switch OFF to prepare for erasing the trouble

stored in memory.

Start engine and touch "START",

"ABS", "SELF-DIAG

RESULTS" and "ERASE" sequentially on the CONSULT

screen to erase the trouble stored in memory.

If the trouble stored in memory is not erased, repeat step

6.

10. Drive vehicle at approx. 30 km/h for approx. 1 minute and then

confirm that ABS warning lamp is

off.

Page 89 of 230

![NISSAN GT-R 1998 Workshop Manual

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost NISSAN GT-R 1998 Workshop Manual

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost](/img/5/57354/w960_57354-88.png)

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnostic

item is detected when

...

Control unit,

control

unit

power supply

and ground

circuit

Check item

ABS control unit battery voltage

is abnormally high.

ABS control unit battery voltage is abnormally low.

. ABS MOTOR

[LOCK FAILURE] Control

unit

power supply

circuit ABS motor speed is abnormally low. AES motor,

motor relay

and circuit

1 I

'1 : ABS warning lamp turns on if a wheel or wheels spin for I0 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow. ice, or mud. This is a normal condition.

'2: After repairing short-circuited sensor, turning ignition switch ON lights up ABS warning lamp. Check that ABS warning lamp

turns

off when the vehicle is driven at approx. 30 krnh for approx. 1 minute as shown in the self-diagnosis procedure. NOTE: If "ABSn is not displayed on "SELECT SYSTEM" screen, check ABS control unit and data link connector circuit, and make sure

of the CONSULT card number.

DATA MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector for CON-

SULT.

3. Turn ignition switch ON.

4. Touch "START' on CONSULT screen.

5. Touch "ABS" on CONSULT screen.

If "START" is touched immediately after engine is started

or ignition switch is turned on,

"ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS",

repeat the data monitor procedure from the beginning.

6. Touch "DATA MONITORn.

7. Touch "SETTING" to set recording condition.

8. Touch "AUTO TRIG", "LONG TIME" and then "ENTER".

9. Return to "SELECT MONITOR ITEM" screen and touch "CIU

INPUT ITEM", "ALL SIGNALS" or 'SELECTION FROM

MENU". Refer to "DATA MONITOR MODE" on the next page.

10. Touch "START'.

11. Display data monitor.

12. If necessary, sequentially touch "REC START, "REC STOP",

"DATA DISPLAY", "NUMBER PRINT' and "PRINT' to print out

the data.

Page 90 of 230

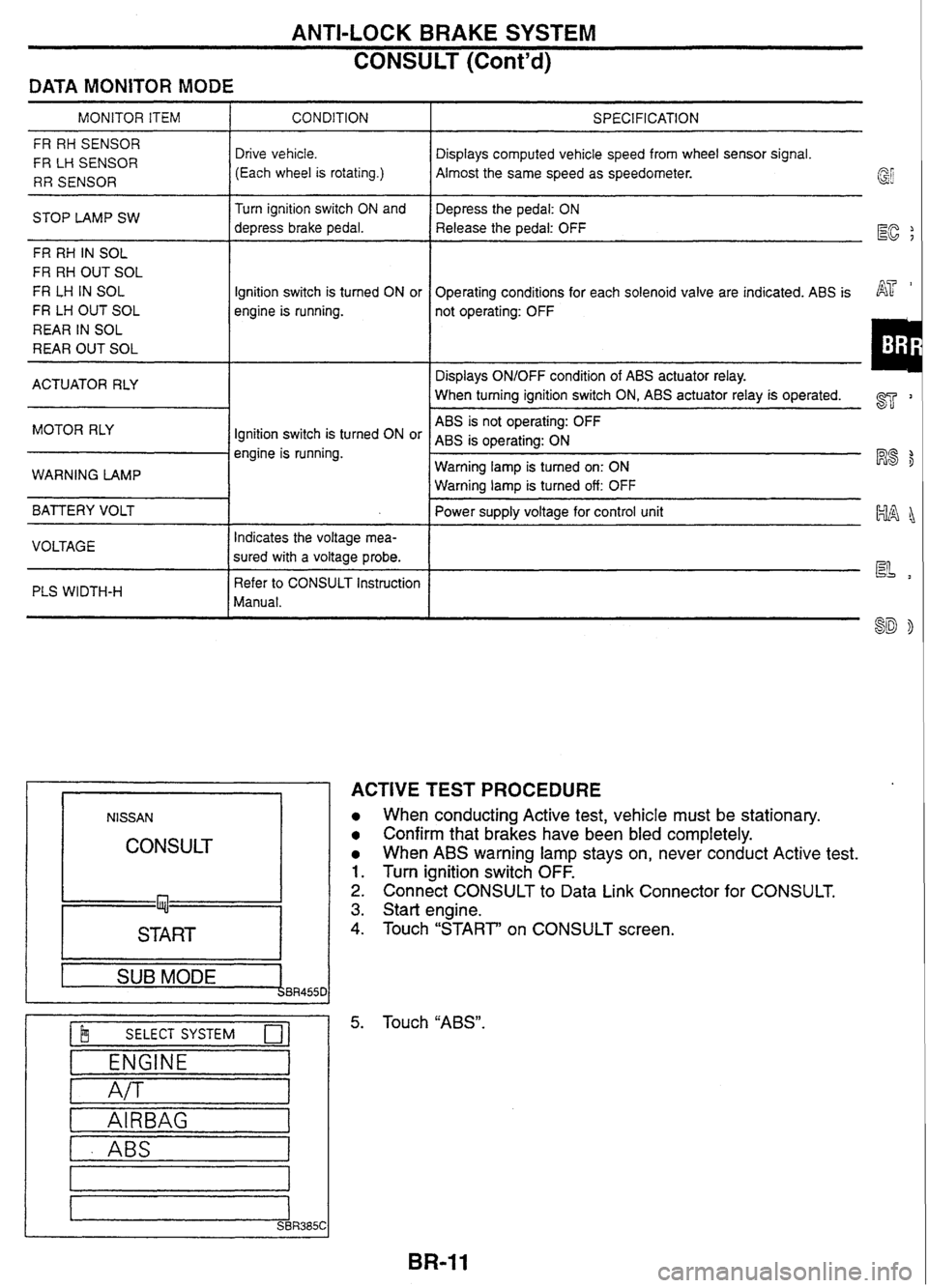

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd)

DATA MONITOR MODE

MONITOR ITEM I CONDITION

FR RH SENSOR

FR

LH SENSOR

RR SENSOR Drive vehicle.

(Each wheel is rotating.)

STOP LAMP SW Turn

ignition switch ON and

depress brake pedal.

FR RH

IN SOL

FR RH OUT SOL

FR

LH IN SOL

FR LH OUT SOL

REAR IN SOL

REAR OUT SOL Ignition

switch is turned ON or

engine is running.

ACTUATOR RLY

MOTOR RLY

Ignition switch is turned ON or

engine is running.

WARNING LAMP

BATTERY VOLT

I

VOLTAGE Indicates

the voltage mea-

sured with a voltage probe.

PLS WIDTH-H

I

Refer to CONSULT Instruction

Manual.

NlSSAN

CONSULT

START I --

1 SUB MODE BR455C

$ SELECT SYSTEM 0-

ENGINE

A/T

I - ABS I

SPECIFICATION

Displays computed vehicle speed from wheel sensor signal.

Almost the same speed as speedometer.

Depress the pedal: ON

Release the pedal: OFF

EC ;

Operating conditions for each solenoid valve are indicated. ABS is AT '

not operating: OFF

Displays ON/OFF condition of ABS actuator relay.

When turning ignition switch ON,

ABS actuator relay

is operated. 2

ABS is not operating: OFF

ABS

is operating: ON

Warning lamp is turned on: ON

R8 $

Warning lamp is turned off: OFF

Power supply voltage for control unit

~~~~

ACTIVE TEST PROCEDURE

When conducting Active test, vehicle must be stationary.

Confirm that brakes have been bled completely.

When ABS warning lamp stays on, never conduct Active test.

Turn ignition switch OFF.

Connect CONSULT to Data Link Connector for CONSULT.

Start engine.

Touch "START' on CONSULT screen.

Touch

"ABS".