ignition NISSAN GT-R 1998 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 47 of 230

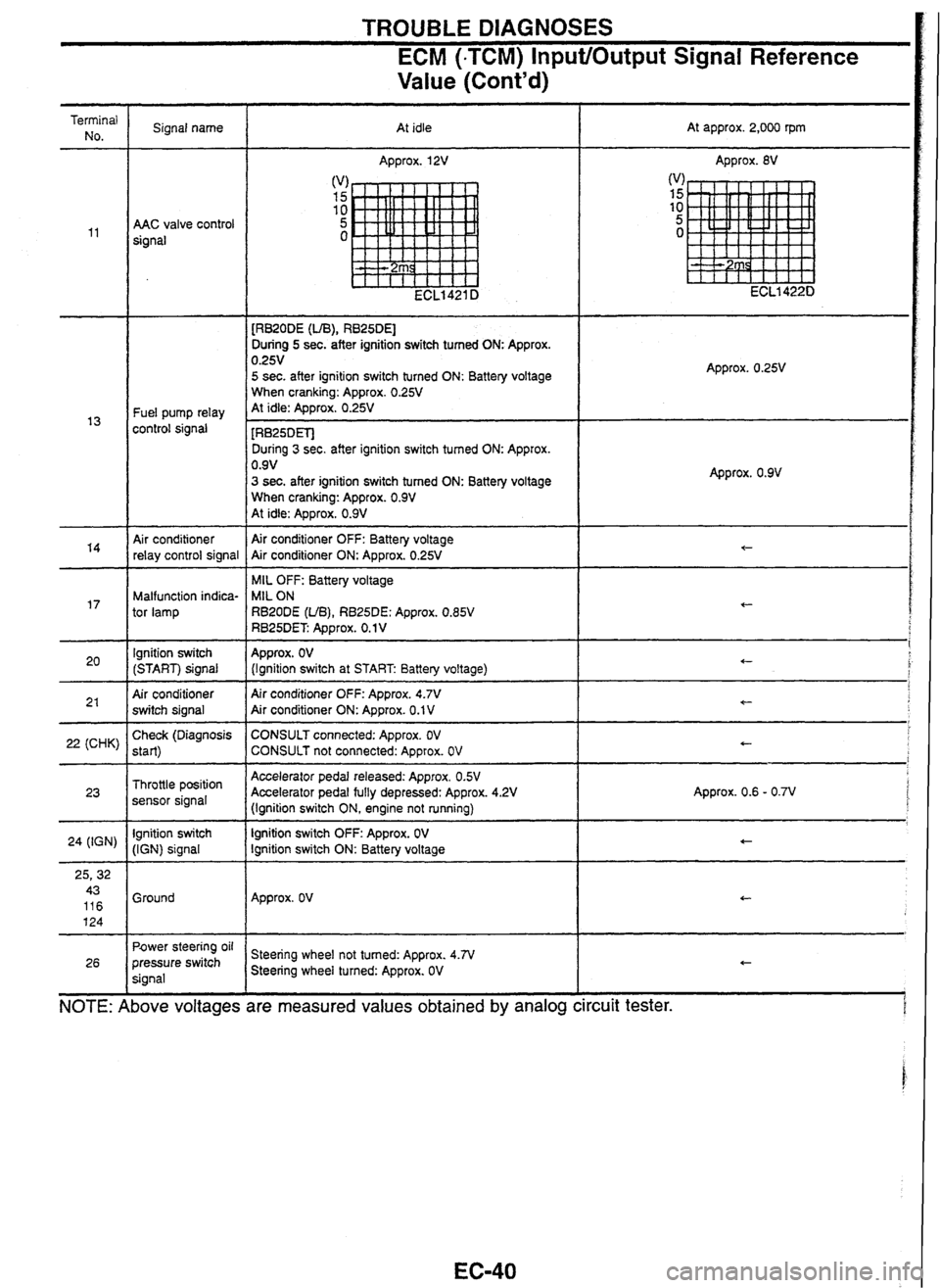

TROUBLE DIAGNOSES

ECM (-TCM) InputlOutput Signal Reference

Value (Cont'd)

d

voltages are

Terminal No. Signal name

At idle At

approx. 2,000 rpm

Approx.

12V Approx. 8V

AAC valve control

signal

[RB20DE

(UB), RB25DEl

During 5 sec. after ignition switch tumed ON: Approx. 0.25V 5 sec. after ignition switch turned ON: Battery voltage

When cranking: Approx. 0.25V At idle: Approx. 0.25V Fuel pump relay

control signal - - [RB25DETJ

During 3 sec. after ignition switch tumed ON: Approx.

0.9V

3 sec. after ignition switch tumed ON: Battery voltage

When cranking: Approx. 0.9V At idle: Approx. 0.9V

Approx. 0.9V

Air conditioner

relay control signal Air conditioner

OFF: Battery voltage

Air conditioner ON: Approx. 0.25V

MIL OFF: Battery voltage

MIL ON

RBZODE

(UB), RB25DE: Approx. 0.85V RB25DET Approx. 0.1 V

Malfunction indica-

tor lamp

lgnition switch

(START) signal

Air conditioner

switch signal Approx.

OV (Ignition

switch at START Battery voltage)

Air conditioner OFF: Approx.

4.7V Air conditioner ON: Approx. 0.1 V -

22 (CHK) Check

(Diagnosis

start)

Throttle position

sensor signal

lgnition switch

(IGN) signal CONSULT

connected: Approx. OV CONSULT not connected: Approx. OV

Accelerator pedal released: Approx. OSV Accelerator pedal fully depressed: Approx. 4.2V

(Ignition switch ON, engine not running)

lgnition switch

OFF: Approx. OV lgnition switch ON: Battery voltage Approx.

0.6 - 0.7V

24

(IGN)

Ground Approx.

OV

Power

steering oil

pressure switch

signal Steering

wheel not tumed: Approx. 4.N Steering wheel turned: Approx. OV

26

NOTE: I bove measured values obtained by analog ircuit

tester.

Page 48 of 230

TROUBLE DIAGNOSES

ECM (*TCM) InpuWOutput Signal Reference

Value (Cont'd)

Terminal

No.

41

NOTE: I

Signal name At

idle

rlehicle speed sen-

;or signal

dead lamp switch Light switch OFF: Approx. OV

;ignal

Light switch ON: Battery voltage

gnition power

sup- Ignition switch OFF: Approx. OV

)iY Ignition switch ON: Battery voltage

dle position switch

lB25DET.m

Mottle

opening Accelerator pedal released: Approx.

0.5V

ignal

Accelerator pedal fully depressed: Approx.

4.2V RB25DE.4WD.W

(Ignition switch ON, engine not running) ; RB25D€.AlT,

3R25Dm

Jeutral signal Selector lever in Neutral or in

N or P position: Approx. OV ParWNeutral posi- Selector lever in other positions: Approx. 4.8V

on switch)

:ull switch signal Accelerator pedal released: Approx. OV

?B20DE

(UB), Accelerator pedal fully depressed: Battery voltage

lB25DET-A/Tl (Ignition switch ON, engine not running)

- - - - -- - love voltages are measured values obtained by analog

At approx. 2,000 rpm

IRB20DE

(UB)] When driving at approx. 40 km/h: Approx. 2.4V @I

i ECL 1 7920

[RB25DE, RB25DETI

When driving at approx. 40

kmk: Approx. 2.4V %R

Approx. OV

(When accelerator pedal is depressed)

Approx.

0.N

rcuit tester.

Page 50 of 230

TROUBLE DIAGNOS

ECM (.TCM) lnpu

:s

3utput Signal Reference

Value (Cont'd)

.. No.

Fluctuates between approx. 0.1 to

0.4V and approx.

0.7 to

0.9V At

idle

- I I - I I -

I

I

- are measured

At approx. 2,000 rpm

:v: i .5 I .O 0.5 0

ECL 1 8645 11jllllllll ECL 1 8630

Throttle motor sensor

signal

[RB25DET'J Approx. 3.4V

I (Voltage becomes lower when TCS operates.)

Motor throttle switch

signal

[RB25DET]

Approx.

4.7V

Mass air flow sensor

signal

t

(When TCS is operating: Approx. OV)

Ignition switch ON: Approx.

0.2V

At idle: Approx.

1

.I - 1.2V Approx.

1.6 - 1.7V

Mass air flow sensor

ground Approx.

OV

I

Coolant temperature approx. 20°C: Approx. 3.5V

Coolant temperature approx.

80°C: Approx. 1.2V

Approx. 0.36V min.

(Voltage increases as the air conditioner refrigerant

pressure increases.)

Approx. 0.4

- 2V (') ': Voltage varies with measuring range (internal resis-

tame) of a circuit tester.

Battery voltage

C

+

+

+

56

-

62 1 Knock sensor signal 1

Engine coolant tem-

perature sensor signal

57

- -- -

63 1 Knock sensor signal 2

Refrigerant pressure

sensor

67 Control unit power

sup-

72

I PIY Receive (Data input to

control unit) 1

Transmit (Data output

from control unit) CONSULT

connected: Approx. 0.25V

CONSULT

not connected: Battery voltage

CONSULT connected: Approx.

9V max. CONSULT not connected: Approx. OV

C

Fan stopped: Battery voltage

Fan operating: Approx. 0.2 - 0.3V 78

NOTE: Above

Auxiliary electric fan

relay control signal

[RB25DE, RB25Dm

voltages values obtained

analog circuit

tester.

Page 52 of 230

TROUBLE DIAGNOSES

ECM (.TCM) InputlOutput Signal Reference

Value (Cont'd)

I Signal name

No. At

idle 7 At approx. 2,000 rpm

Control unit power sup-

ply (Counter-electromo-

live current feedback

circuit)

Fuel pump terminal

voltage control output

1 signal

IRB25DETI

Variable valve timing ,- control signal Battery voltage

Ignition switch at START: Approx.

OV During approx. 30 sec. after engine started with cool-

ant temperature 50°C or above: Approx. OV At idle: Approx. 1 OV

Battery voltage (Solenoid valve OFF)

Approx.

0.3V

Approx. OV

I t [With driving wheels lifted and gear in D position:

Approx. 0.45V (Solenoid valve ON)] AT

Approx. 0.3V (At approx. 2,800 rpm and above: Battery voltage) 1 I I

NOTE: Above voltages are measured values obtained by analogue circuit tester. BR

Page 62 of 230

TROUBLE DIAGNOSES

Control Unit Input/Output Signal Specifications

Refer to EC section ("ECM.TCM or ECM Input/Output Signal

Reference Value").

USING CONSULT -

Monitor item Indication value Operating status

Throttle position sensor Approx.

0.4 - 4.OV

Throttle fully - closed to fully-open --

AK fluid temperature sensor I Appro~. 1.5 - 0.5V I A/T fluid: Appro~. 20 - 80°C -- - - --- -

ON Overdrive control switch: OFF

Lever switch

OFF Overdrive control switch: ON

Line pressure

duty 29 - 94% Low

pressure - High pressure

Lock-up duty

4 - 94% Lock-up released - Lock-up engaged

USING CIRCUIT TESTER

Terminal

No.' 1 Condition Specifications

.- Refer to EC section

("ECM-TCM or

5 (39) Engine speed signal - ECM Input/Output Signal Reference

Value*).

Voltage increases gradually in

Throttle position sensor

signal After

engine warm-up, depress accelerator pedal

slowly. response

to throttle position.

Fully-closed throttle

: Approx. 0.5V

Fully-open throttle : Approx. 4.2V

24 (I0) Power source

31 (19) Turn

ignition switch ON. Battery

voltage

Turn ignition switch OFF. Approx.

OV

--

25 (25) 1 Ground 32 (48) Turn ignition switch ON. Approx. OV

Shift control

signal SB1 - - 28 (I4) (Except RB20DE)

Vehicle speed sensor

2 When vehicle is moved at 2 to 3 km/h for more than Voltage varies approx. between OV 29 (40) (vehicle speed

signal in 1 m. and 4.5V intermittently.

speedometer)

*: Each number in parenthesis ( ) shows the terminal No. for TCM (RB25DE).

Page 63 of 230

TROUBLE DIAGNOSES

Control Unit

InputlOutput Signal Specifications

Terminal

No.' Operation

or measurement condition Specifications

Idle switch

(in throttle position switch) After

engine warm-up, release accelerator pedal.

After engine warm-up, depress accelerator

pedal.

PNP switch "1"

(c > is used for M-AT.) Battery voltage

@ Approx.

OV

PNP switch

"2"

<"33 position

(c > is used for M-AT.) Selector lever:

"1"

&?"2 position

Selector lever;

Exce~t

"1"

<"2"> ~osition Battery voltage

gz

A~~rox.

OV

PNP switch

"Dm position Selector

lever:

2" <3*> position

Selector lever: Except

"Y 4'3'5 position

Selector lever;

"Dn

position Battery voltage

Approx. OV

Battery voltage

Neutral signal

(PNP switch

"N-P"

position)

- -- Selector lever: Except "Dm position Approx.

OV

PNP switch

"Rn

position RR Selector lever: "Nn, "P" position

Selector lever: Except

"N", "Pn position

Selector lever:

"Rn

~osition

I Selector lever: Except "Rn position 1 Approx. OV

U" " Approx. OV

Approx. 4.7V

. Batterv voltaae ST

I

After engine warm-up, depress accelerator pedal

partially. (Throttle opening: More than 50%) Battery voltage i% Full

switch

(in throttle position switch)

I After engine warm-up, release accelerator pedal. I Approx. OV

Sensor ground

Throttle position sensor

power -- -- - - - I

-- --- Turn iqnition switch ON. Ao~rox. OV @z!.

Shift control signal SB2

(Except RB20DE) Turn ignition switch

ON. Turn ignition switch

OFF.

Approx.

4.5 - 5.5V

Approx. OV

EL

Vehicle speed sensor 1

(Output shaft speed sensor) When vehicle

cruises at 30 kwh (Inspected in AC posi-

tion) More

than approx. 1 V

80

(Voltage increases in

resDonse to vehicle

meed.)

Turbine sensor (Except

RB20DE)

When vehicle parks (Inspected in AC position)

When turbine rotates at approx. 1,000

rpm I Approx. 0.1 V

Approx.

OV

rn fluid temperature sensor 5 I A/l fluid temperature: Approx. 20°C Approx. 1.5V

c

3 V) Battery voltage

Approx. OV .- Y .- c a, -

Afr mode switch (POWER)

(Except M-AT)

A/T fluid temperature: Approx. 80°C ,

AIT mode switch: POWER

A/T mode switch: Except POWER - - - - - - -- Shift control signal DB1

(Except RB20DE)

Shift control signal

DB3

(Except RB20DE) Approx. 0.5V

Overdrive control switch

(Except M-AT) Battery voltage

z g 0

Shift

control signal DB2

(Except RB20DE)

A/T mode switch (SNOW)

(Except TCS) Overdrive

control switch: ON (Contact: OFF)

- .= c .- & .&!

- 5

Stop lamp switch Overdrive

control switch:

OFF (Contact: ON)

CONSULT

(RX) signal Approx.

OV

Battery voltage Appro~. OV

Battery voltage

Approx. OV

.z w .- cJ=- T) .g

2

CONSULT (TX) signal

A/l mode switch: SNOW

A/l mode switch: Except SNOW

Depress brake pedal.

' Release brake pedal.

*: Each number in parenthesis ( ) shows the terminal No. for TCM (RB25DE).

AT-1 1

Page 64 of 230

TROUBLE DIAGNOSES

Control Unit InputlOutput Signal Specifications

(Cont'd)

Terminal

No.' Operation

or measurement condition

Specifications

Total control signal

(multiple communication)

(Except

RB20DE) Refer to

EC section

("ECM.TCM or ECM Input1

Output Signal Reference Value").

I I

I Turn ignition swi?ch ON. I Battery voltage

Power supply (Backup)

Line pressure solenoid - - Turn ignition switch OFF. Battery voltage

r After engine

warm-up, depress accelerator pedal

Line pressure solenoid

(dropping resistor circuit) 5

Approx. OV

w

0.

s

Overrun clutch solenoid After engine

wan-up, release accelerator pedal.

After engine warm-up, release accelerator pedal.

After engine warm-up, depress accelerator pedal

fullv. .- >. .- 5

POWER indicator lamp (4AT)

Dual rnatic

AK waming lamp

(M-AT)

Approx. 1.5 - 3.OV

Approx. 4 - 14V

Approx. OV

When POWER indicator lamp is tumed on (W

mode switch: POWER), or dual matic warn-

ing lamp

is turned on

When

overrun clutch solenoid operates

When overrun clutch solenoid does not operate

Approx.

OV

Battery voltage Approx.

OV

When POWER indicator lamp is tumed off (NT

mode switch:Except POWER), or dual matic A/T Battery voltage

I warning lamp is turned off 1

I When vehicle is locked UD I Approx. 8 - 15V Lock-up solenoid I . .

When vehicle is not locked up I Approx. OV

When shift solenoid A operates

(Driving in 'Dln or

"D,")

When

shift solenoid A does not operate

(Driving in

"D," or "D,")

parenthesis

(

Battery voltage

Approx.

OV

Shift solenoid B

) shows the terminal No. for TCM (RB25DE ).

I

*: Each

When shift solenoid B operates

(Driving in 'Dln or

'D,")

When shift solenoid

B does not operate

(Driving in

"D,"

or

"Dd)

number Battery voltage

Approx. OV

Page 71 of 230

TROUBLE DIAGNOSES

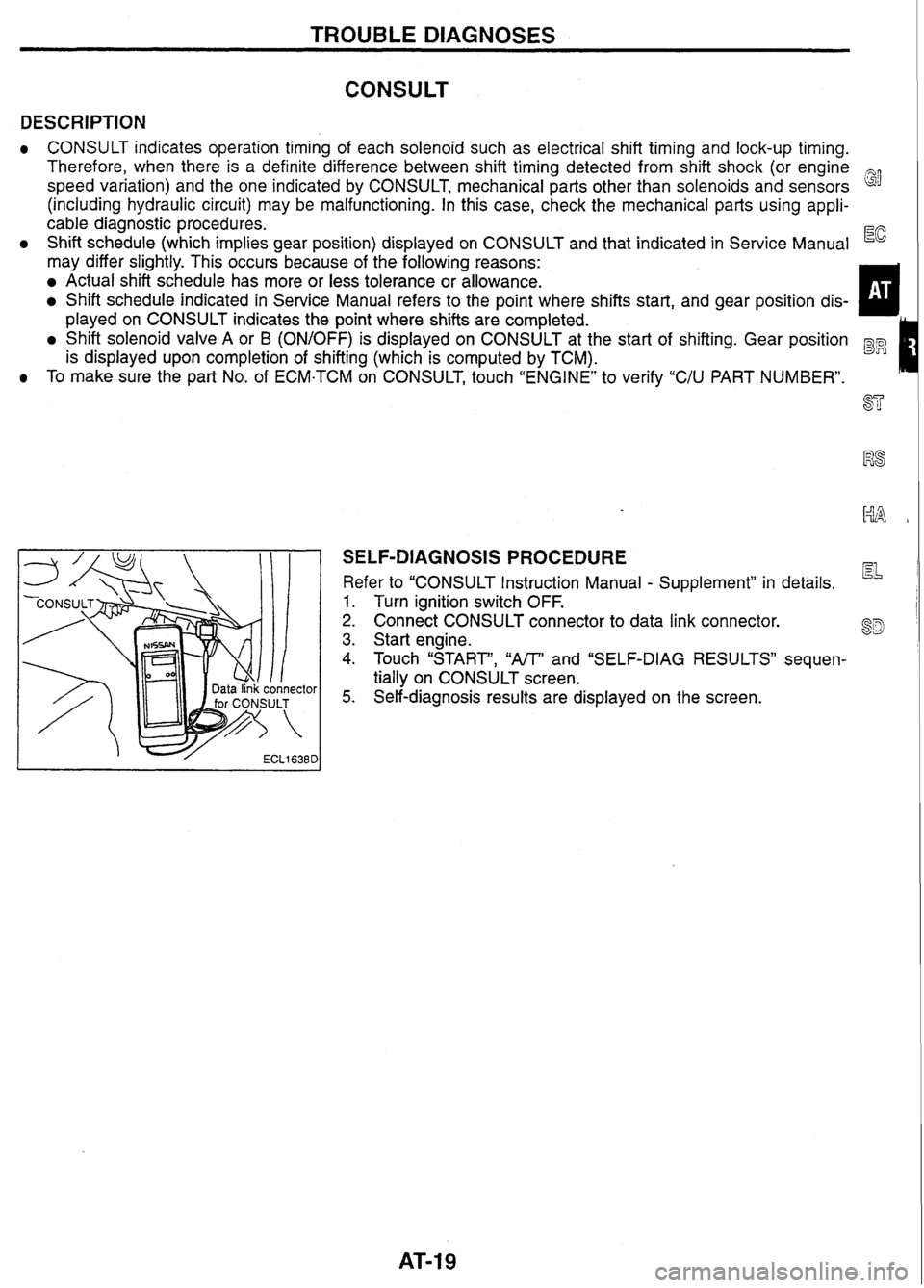

DESCRIPTION

CONSULT indicates operation timing of each solenoid such as electrical shift timing and lock-up timing.

Therefore, when there is a definite difference between shift timing detected from shift shock (or engine

speed variation) and the one indicated by CONSULT, mechanical parts other than solenoids and sensors

(including hydraulic circuit) may be malfunctioning. In this case, check the mechanical parts using appli-

cable diagnostic procedures.

Shift schedule (which implies gear position) displayed on CONSULT and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

Actual shift schedule has more or less tolerance or allowance.

Shift schedule indicated in Service Manual refers to the point where shifts start, and gear position dis-

played on CONSULT indicates the point where shifts are completed.

Shift solenoid valve A or B (ON/OFF) is displayed on CONSULT at the start of shifting. Gear position

is displayed upon completion of shifting (which is computed by TCM).

To make sure the part No. of ECM-TCM on CONSULT, touch "ENGINE" to verify "C/U PART NUMBER".

SELF-DIAGNOSIS PROCEDURE

Refer to "CONSULT Instruction Manual - Supplement" in details.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector.

3. Start engine.

4. Touch "START', "NT and "SELF-DIAG RESULTS" sequen-

tially on CONSULT screen.

5. Self-diagnosis results are displayed on the screen.

Page 72 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item 1 Diagnostic item is detected when ... Inspection item - -- -

I TCM does not receive vehicle speed sensor 1 signal due to

open circuit, etc.

TCM receives improper signal during driving. After ignition switch is turned ON, vehicle speed sensor 2 receives improper signal until vehicle starts to run.

VHCL

SPEED

SEN.A/T Vehicle

speed sensor 1 circuit

TCM does not receive vehicle speed sensor 2 signal due to

open circuit, etc.

TCM receives improper signal during driving.

VHCL

SPEED

SEN.MTR Vehicle

speed sensor 2 circuit

TCM detects

folfowing conditions during driving (Except N and

P positions). 0 Excessively high throttle position sensor signal voltage Excessive1 low throttle position sensor signal voltage with idle

switch OF; or full switch ON

THROTTLE

POSl

SEN

Throttle position sensor circuit

SHIFT SOLENOIDN A

SHIFT SOLENOIDN B Shift

solenoid A circuit

Shift solenoid

B circuit

Overrun clutch solenoid circuit

TIC

CLUTCH SOW

I

OVERRUN CLUTCH SN

Lock-up solenoid circuit Specified voltage is not applied to solenoid due to open and/or

short circuit.

LINE

PRESSURE SN

I Line pressure solenoid circuit

0 Excessively low supply voltage to TCM during driving

Excessively high si nal voltage of AIT fluid temperature sensor

(excessively low d fluid temperature) during driving This message is displayed only when malfunction occurs with ignition switch ON, and does not have memory func-

tion.

fluid temperature sensor circuit,

TCM power supply circuit, or

throttle position sensor power sup-

ply circuit

BATT/FLUID

TEMP SEN

ENGINE SPEED SIG

I Excessively low engine speed during driving Engine speed

signal circuit

Turbine sensor circuit

TURBINE

SENSOR

(Except

RB20DE)

SHIFT SOLENOIDN C

(Except

RB20DE)

TCM does not receive input shaft speed sensor signal due to

open circuit,

etc.

0 TCM receives improper signal during driving.

0 TCM does not receive shift solenoid A pressure detection switch

signal due to open

andfor short circuit. Shift solenoid A pressure

detection

switch circuit

MANUAL MODE SW

(Except

RB20DE)

TCM does not receive proper manual mode switch signal due to

open and/or short circuit. Manual

mode switch circuit

ENGINE BRAKE

C/U'1

(Except

RB20DE)

Shift control unit does not operate properly due to open and/or

short circuit of each

input/output signal wire.

Malfunction occurs in shift control unit. Each

signal wire circuit connected

to shift control unit

'INITIAL START*

Power supply to TCM is shut down, and self-diagnostic memory

function is canceled due to battery removal, etc.

CONTROL UNIT (RAM)

I Malfunction is detected in TCM memory (RAM) function.

CONTROL

UNIT

(ROM)

I Malfunction is detected in TCM memory (ROM) function.

'1 : Indicates shift control unit.

DATA MONITOR PROCEDURE

Refer to "CONSULT Instruction Manual - Supplement" and "CON-

SULT Service Manual

- Supplement" in details.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector.

3. Turn ignition switch ON.

4. Touch "START', ''AT and "DATA MONITOR" sequentially on

CONSULT screen.

Page 75 of 230

TROUBLE DIAGNOSES

Self-diagnosis

DESCRIPTION

If malfunction should occur in electrical systems, turning ignition switch ON lights M mode switch POWER

indicator lamp

(M-AT Dual matic AfT warning lamp) for 2 seconds, and then flashes the indicator lamp for 8 Gc

seconds. If malfunction does not occur, A/T mode switch POWER indicator lamp (M-AT Dual matic A/T warn-

ing lamp) is turned on for

2 seconds upon turning ignition switch ON. To locate and display the malfunction-

ing part, output the trouble information memory and flash

A/T mode switch POWER indicator lamp (M-AT Dual

matic

A/T warning lamp) by inputting self-diagnostic startup signal.

SELF-DIAGNOSIS PROCEDURE

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Move A/T mode switch to AUTO, and turn overdrive control switch to O/D ON.

4. Turn ignition switch ON with selector lever in "Pn position, and ensure POWER indicator lamp is turned on

for

2 seconds.

5. Turn ignition switch OFF.

6. Move selector lever to "D" position.

7. Turn overdrive control switch O/D OFF.

8. Turn ignition switch ON.

9. Move selector lever to "2" position.

10. Turn overdrive control switch OID ON.

11. Move selector lever to "I" position.

12. Turn overdrive control switch O/D OFF.

13. Depress accelerator pedal fully, and release it.

14. Read flashing status of POWER indicator lamp to complete self-diagnosis procedures.

M-AT

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Turn ignition switch ON with selector lever in "P" position, and ensure dual matic PJT warning lamp is turned

on for

2 seconds.

4. Turn ignition switch OFF.

5. Depress brake pedal, release accelerator pedal, and then move selector lever to "D" position.

6. Turn ignition switch ON.

7. Release brake pedal, and move selector lever to "3" position.

8. While depressing brake pedal with left foot, depress accelerator pedal fully with right foot, and move

selector lever to

"2" position.

9. Read dual matic A/T warning lamp indication to complete self-diagnosis procedures.