ignition NISSAN GT-R 1998 Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 157 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis by Self-diagnosis Function

There are 5 steps in the self-diagnosis: to check for any sensor failure, and to check that a given control sig-

nal is transmitted to each output device.

Diagnosis

content

- - -

Diagnostic

item

i Step I I Step 2 - - - - - - - --

Each sensor check

Indicator lamp check

Display segments Ambient sensor

0 Indicator lamp In-vehicle sensor

lntake air tempera-

ture sensor

Sunload sensor Step

3

Each

actuator check

and reset check display for each

sen-

lntake door actuator

Air mix door actua-

tor Mode door actuator

lntake door actuator

Air mix door actua-

tor

Mode door actuator

Blower fan motor

Compressor

Air purifier (only

when connected)

Ambient sensor

In-vehicle sensor

lntake air tempera-

ture sensor

SELF-DIAGNOSIS OPERATION PROCEDURE R8

Switching to self-diagnosis mode

Turn the temperature adjustment dial all the way to the left.

Start the engine with the ignition switch from OFF position. Within 10 seconds, press and hold the OFF

switch for more than approx. 5 seconds, to start the self-diagnosis step 1.

Self-diagnosis completion EL

a Turn the ignition switch OFF.

Turn the AUTO switch ON.

Switching between self-diagnosis steps

Use the temperature adjustment dial to switch between self-diagnosis steps 1 to 5.

Temperature adjustment dial (turn clockwise): Step

1-5

Temperature adjustment dial (turn counterclockwise): Step

5- 1

a Refer to "SELF-DIAGNOSIS DISPLAY ITEM" for the diagnosis contents of each step.

Page 161 of 230

FULLY AUTOMATIC AIR CONDITIONER

Magnet Clutch System Check

MAGNET CLUTCH

Disconnect the compressor connector. Apply approx. 12V to the compressor to check the magnet clutch

operation.

/;sn

AIR CONDITIONER RELAY QJg

Remove the air conditioner relay. Apply approx. 12V between the air conditioner relay terminals No. 1 and

2. Check the relay operation sound. Ec Check the continuity between terminals No. 3 and 5.

REFRIGERANT CHARGE AMOUNT AT

Connect the manifold gauge to the vehicle side service valve.

Check that the lower pressure side (gauge pressure) is more than approx. 0.1 8 MPa (1.8 kg/cm2.G). BR

ECM

Start the engine, and short-circuit the ECM terminal No. 14 to the ground. Check the magnet clutch operation.

INTAKE AIR TEMPERATURE SENSOR

Start the engine, and short-circuit the intake air temperature sensor terminal No. 1 to the ground. Check the Rs

maanet clutch o~eration.

Blower Fan Motor System Check

BLOWER FAN MOTOR

Disconnect the blower fan motor connector. Short-circuit the blower fan motor terminals No. 2 and 5 to El!, (

the ground. Apply approx. 12V to the terminal No. 6, and check the motor operation.

Connect the blower fan motor connector. Turn the ignition switch to the ON position, and change the fan sD

switch from 1st to 4th. Check the blower fan motor terminal No. 5 with an oscilloscope. When the termi-

nal No.

5 is normal according to the following table and the fan airflow does not change, this indicates a

faulty blower fan motor.

When the terminal No.

5 results differ from the following table and the fan airflow does not change, this

indicates either a faulty harness between the blower fan motor and automatic amplifier, or a faulty auto-

matic amplifier.

Page 164 of 230

FULLY AUTOMATIC AIR CONDITIONER

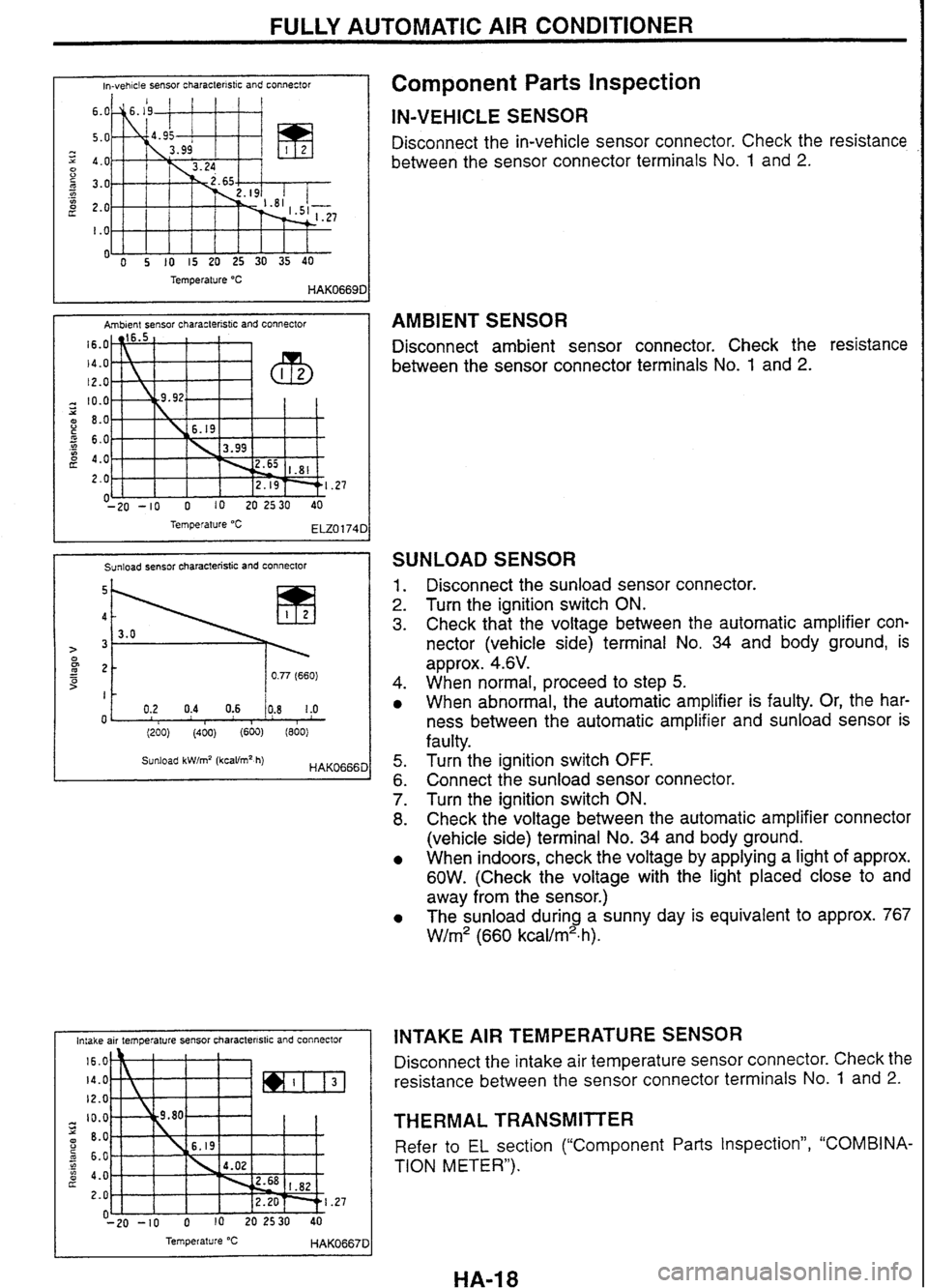

ln-vehcle sensor characterlstlc and connector I

Temperature "C HAK0669D

Ambient sensor characteristic and connector

Temperature

"C ELZ0174C

I Sunload sensor characteristic and connector

I Sunload kW/m2 (kcaVm2 h) HAK0666C

cake alr temperature sensor characlerlstrc and connector

Temperature

'C ~~~0667~1

Component Parts Inspection

IN-VEHICLE SENSOR

Disconnect the in-vehicle sensor connector. Check the resistance

between the sensor connector terminals No.

1 and 2.

AMBIENT SENSOR

Disconnect ambient sensor connector. Check the resistance

between the sensor connector terminals No.

1 and 2.

SUNLOAD SENSOR

Disconnect the sunload sensor connector.

Turn the ignition switch

ON.

Check that the voltage between the automatic amplifier con-

nector (vehicle side) terminal No.

34 and body ground, is

approx.

4.6V.

When normal, proceed to step

5.

When abnormal, the automatic amplifier is faulty. Or, the har-

ness between the automatic amplifier and

sunload sensor is

faulty. Turn the ignition switch

OFF.

Connect the sunload sensor connector.

Turn the ignition switch

ON.

Check the voltage between the automatic amplifier connector

(vehicle side) terminal

No. 34 and body ground.

When indoors, check the voltage by applying a light of approx.

60W. (Check the voltage with the light placed close to and

away from the sensor.)

The

sunload during a sunny day is equivalent to approx.

767

W/m2 (660 kcal/m2- h).

INTAKE AIR TEMPERATURE SENSOR

Disconnect the intake air temperature sensor connector. Check the

resistance between the sensor connector terminals No.

1 and 2.

THERMAL TRANSMITER

Refer to EL section ("Component Parts Inspection", "COMBINA-

TION

METER").

HA-I 8

Page 165 of 230

ELECTRICAL SYSTEM

SECTION EL

CONTENTS

CENTRAL DOOR LOCK SYSTEM ................................. 2

Component Parts Location .......................................... 2

Circuit Diagram ............................................................ 2

Combination Meter (meter control unit) Input/

Output Signal Specifications

........................................ 2

Inspection before Trouble Diagnoses ......................... -3

Trouble Diagnoses ....................................................... 3

REMOTE CONTROL ENTRY SYSTEM .......................... 4

Component Parts Location .......................................... 4

Circuit Diagram ............................................................ 4

Remote Control Entry Control Unit Input/Output

Signal Specifications

.................................................... 5

System Check ............................................................. -5

Inspection before Trouble Diagnoses .......................... 6

Trouble Diagnoses ....................................................... 6

Component Parts inspection ....................................... 6

ID Code Entry Procedure ............................................ 7

POWER WINDOW SYSTEM ........................................... 8

System Description ..................................................... -8

Precautions ................................................................. -8

Component Parts Location .......................................... 8

Circuit Diagram ............................................................ 9

Power Window Main Switch Input/Output Signal

Specifications

............................................................... 9

Inspection before Trouble Diagnoses ........................ 11

Trouble Diagnoses .................................................... 11

SUNROOF SYSTEM ...................................................... 12

Component Parts Location ........................................ 12

Circuit Diagram .......................................................... 12

Sunroof Switch and Sunroof Motor Assembly

lnputiOutput Signal Specifications

............................. 12

AUTO LIGHT SYSTEM ................................................. 1 3

Component Parts Location ........................................ 13

Auto Light Control Unit Input/Output Signal

Specifications

............................................................. 13

Circuit Diagram ........................................................ 14

Trouble Diagnoses .................................................. I 4

..................................... XENON HEADLAMP SYSTEM 15

Trouble Diagnoses ..................................................... 15

IGNITION KEY-OPERATED ILLUMINATION

SYSTEM

................................................................... 7

Component Parts Location ........................................ 17

.......................................................... Circuit Diagram 17

Meter Control Unit InputlOutput Signal

....................................................... Specifications 1 7

METER ........................................................................\

18

Corn bination Meter .................................................... 18

Triple Meter ................................................................ 20

................................................ COMBINATION METER 21

.................................................... System Description 21

........................................ Component Parts Location 21

Diagnosis Function .................................................... 21

................................... Meter-related Circuit Diagram 22

..................................................... Trouble Diagnoses 23

Combination Meter InpuVOutput Signal

Specifications

............................................................ -25

..................................... Component Parts Inspection 26

TRIPLE METER ............................................................. 29

Special Service Tool ................................................... 29

........................................ Component Parts Location 29

Circuit Diagram .......................................................... 29

Triple Meter InputfOutput Signal Specifications ........ 30

Component Parts Inspection ..................................... 30

IGNITION KEY WARNING BUZZER AND LIGHT

WARNING BUZZER

...................................................... 31

Component Parts Location ........................................ 31

Circuit Diagram .......................................................... 31

Meter Control Unit InpuVOutput Signal

Specifications

............................................................. 31

FRONT WIPER .............................................................. 32

Component Parts Location ........................................ 32

Circuit Diagram .......................................................... 32

Front Wiper Input/Output Signal Specifications ........ 32

Page 170 of 230

REMOTE CONTROL ENTRY SYSTEM

Remote Control Entry Control Unit

Terminal No.

InputIOutput Signal specifications

Signal name Operation or cond~t~on Specificatton

Close the driver door. (OFF) Approx.

12V Driver door

switch input signal . @ Open the driver door. (ON) Approx. OV

Close

all the doors. (OFF) Approx. 12V All door

switch input signal Ec Open one of the doors. (ON) Approx. OV

Driver door

lock actuator lock

output signal Lock with the remote control. Changes from

approx. 0 to 12V and back to approx. OV. t

Ground - Approx. OV BR Locked (OFF) Approx. 5V Driver door lock switch signal

Unlocked (ON) Approx. OV

Key-in detection switch input Insert (ON) Approx. 12V 87

signal

Ignition key Remove (OFF)

Approx. OV

ACC power supply Ignition switch to ACC Approx. 12V Rs

Passenger door and rear RH & Press the lock switch on the remote control. Changes

from approx. 5 to OV LH door lock output signal

and back to approx. 5V.

Passenger door and rear RH & Changes from approx. 5 to OV HA

LH door unlock output signal Press the unlock switch

on the remote control.

and back to approx. 5V.

Driver door lock actuator

Unlock with the remote control. Changes from approx. 0 to

unlock output signal 12V and back to approx. OV.

System Check

Easy way to confirm the func+ion of the remote control: Works

properly.

Program the remote control (A) to another vehicle

of the

same type and check if the remote control works properly. Does not work. is OK.

Turn

a radio ON. Touch the radio aerial with the remote

control (A). Press a switch on the remote control with . is heard.

the

remote

control on the aerial. Listen for noise.

(Radio frequency: around

78.6, 78.7, 78.8 MHz)

B f ' Works properly.

I

Program another remote control (6) to the vehicle

concerned and check if the remote control works properly. No noise

is heard. t The vehicle is OK.

Does not work.

Check item

Operation check

Remote control

(A) is OK. Remote control (A)

is

NG.

r The vehicle is NG. 0CC3078D

I

I System check A

Remote control

(A) is OK.

Remote control (A) is

NG.

System check B

The vehicle is OK.

Remote control (A) is NG. Program the remote control

(A) to the vehicle concerned again and check

for proper operation.

The vehicle is NG.

The vehicle is OK. Perform trouble diagnosis

to determine what causes the problem.

Check the remote control

(A) battery voltage.

The vehicle is NG. Check the

remote control (A) battery voltage and then perform trouble

diag- nosis to determine what causes the problem.

Page 172 of 230

REMOTE CONTROL ENTRY SYSTEM

ID Code Entry Procedure

Enter the identity (ID) code manually when:

remote controller or control unit is replaced.

an additional remote controller is activated.

To enter the ID code, follow the procedures below.

PROCEDURE

I Close all doors and lock driveis side door. I

Insert and remove the key from the ignition more than six times within 10 seconds.

(Power door lock will then unlock.)

Within

3 seconds after door lock is unlocked, turn ignition key switch to "ACCn posi-

tion and lock the driver's side door.

At this time, the original ID codes are erased.

Push any button on the new remote controller once. (Power door lock will then

unlock.)

At this time, the new ID code is entered. e

Lock driver's side door.

Do you

want to enter any additional remote controller ID codes?

A maximum four ID codes may be entered. Any attempt to enter more will be

ignored.

I Open driver's side door or turn the ignition key switch to 'OFF position. I

No

END.

After entering the identity (ID) code, check the operation of remote control

entry system.

Yes

NOTE

If you need to activate more than two additional new remote controllers, repeat the procedure

"Additional ID code entry" for each new remote controller.

If the same ID code that exists in the memory is input, the entry will be ignored.

Entry of maximum four ID codes is allowed and any attempt to enter more will be ignored.

Page 173 of 230

POWER WINDOW SYSTEM

System Description

When the ignition switch is turned OFF, timer function allows

the driver door power window to operate for up to approxi-

mately

15 minutes. Opening (door switch ON) and closing

(door switch OFF) the driver door or entering the ignition switch

OFF to ON signal will reset the timer.

If the driver door window is obstructed when it is going up, the

window moves down approximately

150 mm.

OPERATING CONDITIONS

The driver door window is between fully-open position and

almost fully-closed position (with the limit switch

ON).

a Automatic operation when the ignition switch is turned ON

a Automatic or manual operation when the ignition switch is

turned to any position other than ON (with the timer active)

Precautions

When the driver door window is between fully-open position

and almost fully-closed position with the limit switch

ON,

removing or installing the battery or the power window main

switch will deactivate the auto

UP mode and the timer function.

If the step above has been taken, operate the power window

switch to close the driver door glass fully. This activates the

auto

UP mode and the timer function.

Component Parts Location

) Dash panel, driver side Driver door

power window motor (limit switch and encoder built-in)

(amplifier built-in) OCC3269D

Page 174 of 230

POWER WINDOW SYSTEM

Circuit Diagram

PiW SW power supply

I

.20(14) Lmt sw sgnai ")' Encoder power supply '8112 ' Encoder pulse signal I It>.

v Driver door PNV mot01

W (4-door Sedan)

Driver door

PMI motor

W

DOWN signal ~~~. Dz

UP signal 6 door P/W

( )' 2-door

Coupe DOWN signal

13 UP signal PMI maln SW connector 16 @-door Sedan) 9(11)

17 DOWN signal 2 -r UP signal Drrver I-------------J

I-

$ 4-door Sedan only

- 891011 141516 - Passenger door and

PiW

main

SW connector

(2-door Coupe) rear RH & LH

door

PiW SW connector OCC3265D 1

Power Window Main Switch Input/Output

Signal Specifications

Signal name

Limit switch and encoder

ground

( ): 2-door Coupe

Measurir

Ignition switch

ON or another position

(Timer is in operation.)

-

condition

Terminal No.

Specification

Operation or condition

Approx.

OV

Encoder pulse signal Approx.

2V

ON

or another position

(Timer is in operation.) Power window motor

is in

operation.

Driver door window is

between fully-open position and almost fully-closed

posit~on. (ON)

Driver door window is

between almost fully-closed position and fully-closed position. (OFF)

DOWN operation

Other than DOWN operation Approx.

OV

ON

or another position

(Timer is in operation.)

Lim~t

switch signal

Approx.

5V

Driver door power window

motor DOWN signal ON

or another position

(Timer is in operation.) Approx. 12V

Approx. OV

Approx. 12V Battery

Page 175 of 230

POWER WINDOW SYSTEM

Power Window Main Switch Input/Output

Signal Specifications (Cont'd) -

Terminal No.

Ground Signal

name

Driver door switch signal

Driver door power window

motor UP signal

Rear RH door power window

DOWN signal Specification

Approx.

OV

Approx. 12V

Measuring condition

ON or another position

(Timer is in operation.)

Encoder power supply Ignition switch

-

ON

or another position

(Tmer is in operation.)

Passenger door power win-

dow DOWN signal Operation

or condition

Driver door is opened. (ON)

-

Driver door is closed. (OFF)

Ignition power supply

Rear RH door power window

UP signal

ON

Rear LH door power window

DOWN signal

Rear LH door power window

UP signal

Passenger door power

win-

3ow UP signal

Power supply to the

passen-

jer door and rear RH

8 LH

joor

power window switch

UP operation

The rear

RH window DOWN

switch in the main switch is

operated. Approx.

OV

Approx. 12V

Other than UP operation

-

Approx. 12V

-- -- Appro~. OV

Approx. 5V

Operation other than

above

-

The passenger door DOWN

switch in the main switch is

operated.

Operation other than above Approx.

OV

Approx. 12V

Approx. 12V

Approx. OV

The

rear RH window UP switch in the main switch is operated.

Operation other than above

The rear LH window UP

switch in the main switch

is operated.

--

Appro~. 12V

Approx. OV

The rear LH window DOWN

switch in the main switch is operated.

Operation other than above

Approx.

12V

Approx. 12V

Approx. OV

Operation other than above

The passenger door UP

switch in the main switch is

operated.

-

I

Approx. 12V

-- - Approx. OV

Approx. 12V

Operation other than above - - Approx. OV

Page 177 of 230

I Sunroof motor assembly 1 Component Parts Location

I Sunroof switch < OCEM57DI

Circuit Diagram

CIB PMl relay

Sunroof motor assembly (Fully-closed position)

I I Limit SW 2 I -1 I i

3

5

1 1 -- LL

1 --

CLOSE relay - I ~irnitsw~ I

Sunroof SW

Slide SW

CLOSE 5--1

Sunroof Switch and Sunroof Motor Assembly

InputlOutput Signal Specifications

-

Measuring condition

I I

- Operation

Terminal No.

1

2

Ignition switch

3

4

5

ON

ON

'lased

ON

ON

ON Approx.

12V

OV

~~ll~ closed position to fully open position

Approx. 2V

OV

Approx. OV OV

OV

'Pen

Position

to fully closed

position

Approx.

OV (Motor is running.)

Approx. 2V

Approx. OV OV

OV

Fully closed position

to tilt UP position

Approx.

12V

Approx. OV (Motor is running.)

Approx.

OV

Tilt UP position to

fully closed position

Approx.

OV (Motor is running.)

12'

Approx. 12V

Approx.

OV (Motor is running.)

ov

OV

Approx. OV

ov

OV

Approx. OV