relay NISSAN GT-R 1998 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 151 of 230

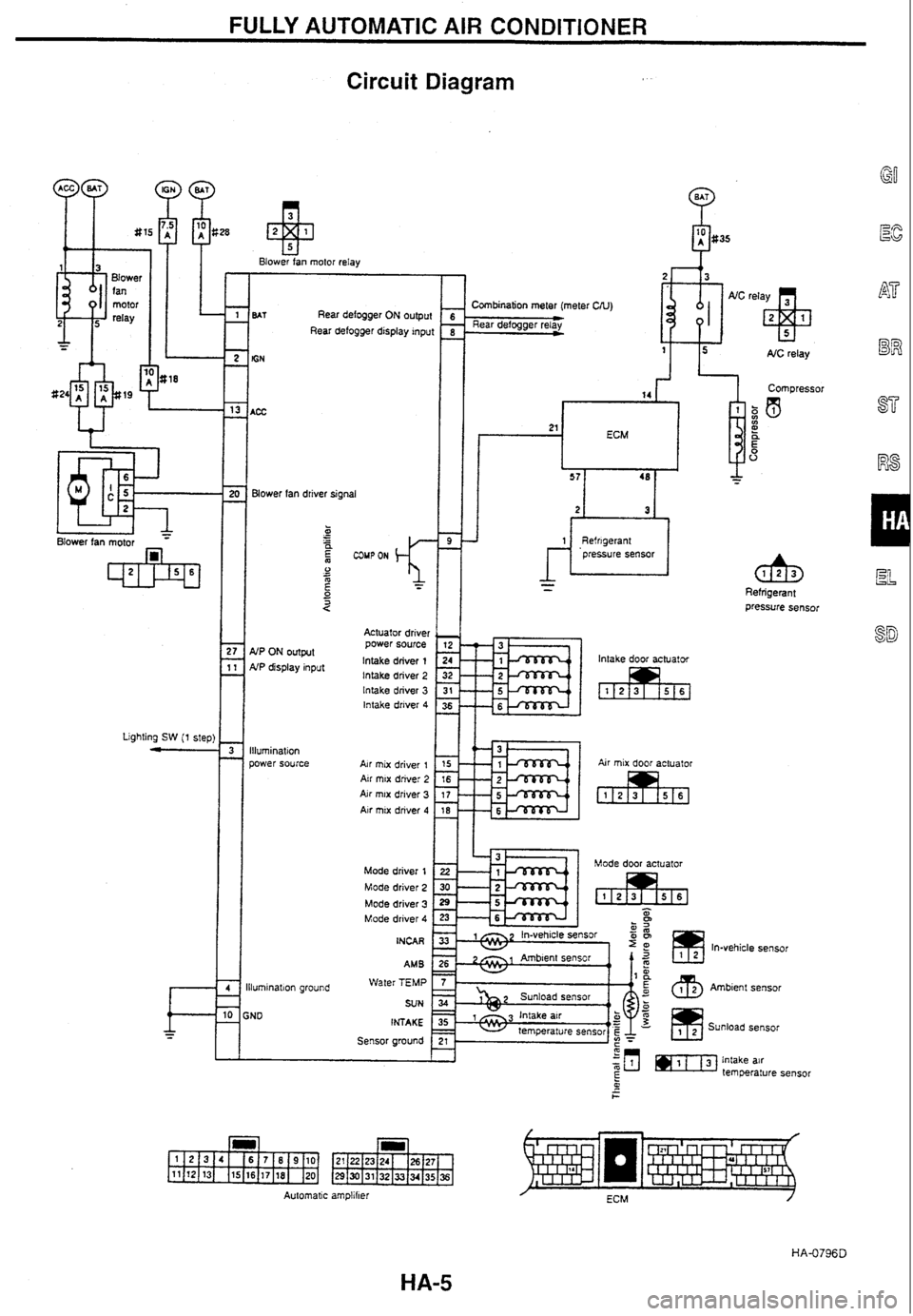

FULLY AUTOMATIC AIR CONDITIONER

Circuit

Diagram

Blower tan motor relay

Rear defogger

A Combination meter (meter UU) output * I Rear defogger relay - Rear defogger display inpui

I Compressor

Blower

fan driver signal Refrigerant Pressure sensor

Actuator driver power source

lntake driver

1 lntake driver 2 lntake driver 3 lntake driver 4

lntake door actuator NP ON output NP display input

Lighting

SW (1 step)

Y-lkEka Air mix door actuator

Illumination

power

source

Air mix driver 1 Air mrx drive: 2 Air mix driver 3 Air mix driver 4

Mode driver 1 1 Mode driver 2 Mode driver 3 Mode driver 4

INCAR In-vehicle sensor

Ambienl sensor

Sunload sensor

AM B

Water TEMP

SUN

INTAKE

Sensor around

lluminatron

groun:!

iND

Automatic

amp!iher

Page 161 of 230

FULLY AUTOMATIC AIR CONDITIONER

Magnet Clutch System Check

MAGNET CLUTCH

Disconnect the compressor connector. Apply approx. 12V to the compressor to check the magnet clutch

operation.

/;sn

AIR CONDITIONER RELAY QJg

Remove the air conditioner relay. Apply approx. 12V between the air conditioner relay terminals No. 1 and

2. Check the relay operation sound. Ec Check the continuity between terminals No. 3 and 5.

REFRIGERANT CHARGE AMOUNT AT

Connect the manifold gauge to the vehicle side service valve.

Check that the lower pressure side (gauge pressure) is more than approx. 0.1 8 MPa (1.8 kg/cm2.G). BR

ECM

Start the engine, and short-circuit the ECM terminal No. 14 to the ground. Check the magnet clutch operation.

INTAKE AIR TEMPERATURE SENSOR

Start the engine, and short-circuit the intake air temperature sensor terminal No. 1 to the ground. Check the Rs

maanet clutch o~eration.

Blower Fan Motor System Check

BLOWER FAN MOTOR

Disconnect the blower fan motor connector. Short-circuit the blower fan motor terminals No. 2 and 5 to El!, (

the ground. Apply approx. 12V to the terminal No. 6, and check the motor operation.

Connect the blower fan motor connector. Turn the ignition switch to the ON position, and change the fan sD

switch from 1st to 4th. Check the blower fan motor terminal No. 5 with an oscilloscope. When the termi-

nal No.

5 is normal according to the following table and the fan airflow does not change, this indicates a

faulty blower fan motor.

When the terminal No.

5 results differ from the following table and the fan airflow does not change, this

indicates either a faulty harness between the blower fan motor and automatic amplifier, or a faulty auto-

matic amplifier.

Page 162 of 230

FULLY AUTOMATIC AIR CONDITIONER

Blower Fan Motor System Check (Cont'd)

Terminal No. 5 (oscilloscope)

1 st speed

TI : Approx. 3.2 ms

Duty ratio: Approx. 20% 2nd

speed

3rd speed

T2: Approx. 2.2

ms

Duty ratio: Approx. 45%

T3: Approx. 1.44 ms

Duty ratio: bprox. 64%

4th speed

Duty ratio: Approx. 100%

Approx. 4 ms-Tx Duty ratio = Approx. 4 ms x 100%

BLOWER FAN RELAY

Remove the blower fan relay. Apply approx. 12V to the blower fan relay terminals No. 1 and 2. Check the

relay operation sound.

Check the continuity between terminals No.

3 and 5.

Actuator System Check

DOOR ACTUATOR MOTOR

Disconnect every door actuator connector. Check the continuity between each door actuator terminals No. 3

and 1, 3 and 2, 3 and 5, and 3 and 6.

DOOR ACTUATOR HARNESS

Check the continuity between the automatic amplifier and every actuator.

Check that there is no short-circuit between actuator driver signals. (If there is a short-circuit, the actua-

tors

will vibrate during operation.)

Page 167 of 230

CENTRAL DOOR LOCK SYSTEM

Component

Parts Location

Door lock relay

LOCK -

Door lock relay

connector

1 LOCK 1

TK20 I I 5\41 1 (Brown) 1 11el j I 1

Combination meter

(Meter C/U) connector

I

Circuit Diagram

Driver door lock

Remote control entry

SW signal C/U connector

Lock signal

18. Unlock sign311 5 T 1

PMI main SW

(Central door lock SW)

----- I . RH door1

actuator 1 I I I Rear LH door I lock actuator I I I,,,,,,,------J

Driver door lock

actuator SW

P/'W main SW connector PNV main SW connector

(2-door Coupe) 1 (4-door Sedan) OCC3324 C

Combination Meter (meter control unit) Input/

Output Signal Specifications

-

I

. . 4 1 Driver door lock switch signal I

Specification

Approx. OV

Locked (OFF)

5

18

55

56

60

Operation or condition

Unlocked (ON1

Terminal No.

Approx.

5V

Signal name

Central door lock switch unlock signal

Central door lock switch lock signal

Ground Passenger and rear

RH 8 LH door lock

actuator lock signal

Passenger and rear RH & LH door lock actuator unlock siqnal Unlocked

(ON)

Operation other than above (OFF)

Locked (ON)

Operation other than above (OFF)

-

Central door lock switch is locked.

Central door lock switch is unlocked. Approx.

OV

Approx. 5V

Approx.

OV

Approx. 5V

Approx.

OV

Changes from approx. 12 to OV and back

to approx. 12V.

Changes from approx.

12 to OV and back

to approx. 12V.

Page 168 of 230

CENTRAL DOOR LOCK SYSTEM

Symptom

Passenger door lock and rear

RH & LH door locks do not lock or unlock with the

central door lock switch.

Passenger door lock, rear

RH door lock,

or rear LH dooc lock do not lock or unlock

with the central door lock switch.

Passenger door lock and rear

RH & LH door locks do not lock or unlock with the

driver door lock knob. (They operate

properly with the central door lock switch.)

Inspection before Trouble Diagnoses

Check that components connectors are properly connected.

Trouble Diagnoses

SYMPTOM CHART

Malfunctioning item

Door lock relay circuit Possible

cause E8G Faulty power window main switch (central door lock switch)

Power window main switch circuit

Faulty door lock relay

Faulty door lock relay to combination meter (meter control unit)

BR harness

0 Faulty power window main switch (central door lock switch) to

combination meter (meter control unit) harness

Faulty power window main switch (central door lock switch) ground

circuit

I Faulty door lock relay to door lock actuator harness

Door lock actuator circuit

Combination meter

(meter control unit)

0 Faulty door lock actuator Faulty door lock actuator to door lock relay harness

0 Faulty combination meter (meter control unit) ST

Driver door lock switch circuit

0 Faulty driver door lock switch . Faulty driver door lock switch to combination meter (meter control

unit) harness

Combination meter (meter control unit)

Faulty driver door lock switch ground circuit

Faulty combination meter (meter control unit) m

Page 177 of 230

I Sunroof motor assembly 1 Component Parts Location

I Sunroof switch < OCEM57DI

Circuit Diagram

CIB PMl relay

Sunroof motor assembly (Fully-closed position)

I I Limit SW 2 I -1 I i

3

5

1 1 -- LL

1 --

CLOSE relay - I ~irnitsw~ I

Sunroof SW

Slide SW

CLOSE 5--1

Sunroof Switch and Sunroof Motor Assembly

InputlOutput Signal Specifications

-

Measuring condition

I I

- Operation

Terminal No.

1

2

Ignition switch

3

4

5

ON

ON

'lased

ON

ON

ON Approx.

12V

OV

~~ll~ closed position to fully open position

Approx. 2V

OV

Approx. OV OV

OV

'Pen

Position

to fully closed

position

Approx.

OV (Motor is running.)

Approx. 2V

Approx. OV OV

OV

Fully closed position

to tilt UP position

Approx.

12V

Approx. OV (Motor is running.)

Approx.

OV

Tilt UP position to

fully closed position

Approx.

OV (Motor is running.)

12'

Approx. 12V

Approx.

OV (Motor is running.)

ov

OV

Approx. OV

ov

OV

Approx. OV

Page 178 of 230

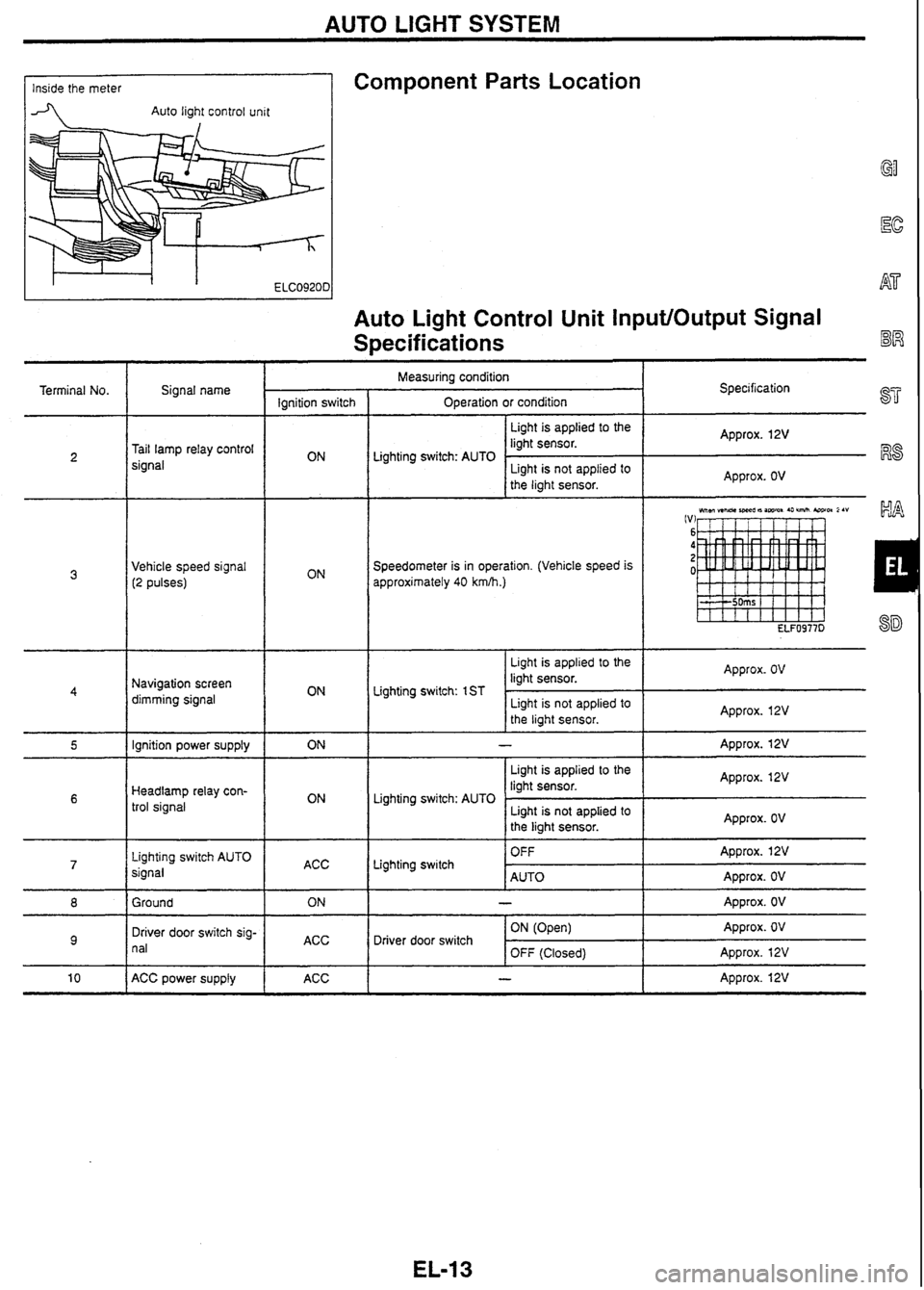

AUTO LIGHT SYSTEM

Component

Parts Location Inside the meter

-4 Auto light control unit

Auto Light Control Unit InputlOutput Signal

Specifications

Terminal No. Measuring

condition

Operation or condition

I

Signal name Specification

Ignition switch

I Light is applied to the I Approx. 12V

liaht sensor.

Tail lamp relay control

signal

Speedometer is in operation. (Vehicle speed is

approximately 40

kmlh.)

Lighting switch: AUTO

Vehicle speed signal (2 pulses)

Light is applied to the

liaht

sensor.

I

4

Light is not applied to

the light sensor.

Approx. OV

Approx.

OV

Navigation screen

dimming signal Liahtina

switch: 1 ST

- I I

I

Light is not applied to

the light sensor.

ignition power supply Approx. 12V

I - I

I Light

is applied to the I Approx. 12V

liaht sensor. Approx. 12V

Headlamp

relay con-

trol signal Lighting

switch: AUTO

Lighting switch AUTO

signal Lighting switch

ACC -

Light is not applied to

the light sensor.

Ground Approx.

OV

OFF

AUTO Approx. 12V

Approx. OV

Driver door switch sig-

n

al

ACC Approx.

OV

Approx.

OV

Approx. 12V

-

ACC power supply Driver

door switch

ACC ON

(Open)

OFF (Closed)

- I Approx. 12V

Page 179 of 230

AUTO LIGHT SYSTEM

Circuit Diagram

Xenon

headlamp

relay

To clearance

lamp and

tail lamp

I---- I : High-voltage parts ----- EL-2163D

Trouble Diagnoses

SYMPTOM CHART

Symptom I Possible cause

I a Faulty auto light control unit power supply or ground harnesi

I Faulty auto light control unit

When outside

is dark, neither small lamps nor headlamps

tum

ON

by

auto light operation. [Lighting switch

(1ST

and 2ND)

is normal.]

When outside is dark, small lamps turn ON but headlamps do not turn

Faulty lighting switch to auto light control unit harness

ON by auto light operation. [Lighting switch (1 ST and 2ND) is normal.] Faulty auto light control unit

0 Faulty lighting switch Faulty lighting switch to auto light control unit harness a Faulty lighting switch ground harness

When outside is dark, headlamps turn ON but small lamps do not turn

ON by auto light operation. [Lighting switch

(1ST

and 2ND) is normal.]

Faulty lighting switch to auto light control unit hamess Faulty auto light control unit

a Neither headlamps nor small lamps turn OFF when the driver door is

opened with the ignition switch at ACC. a Headlamps and small lamps turn OFF when the ignition switch is

turned to ACC with the driver door closed.

0 While the vehicle is driven at night, headlamps go off momentarily

~~- - - pp a Faulty door switch a Faulty door switch to auto light control unit harness a Faulty door switch ground harness 0 Faulty auto light control unit

when it passes under street lamps.

0 While the vehicle is driven in the early morning or evening, headlamps

turn ON momentarily when it passes under an overpass or through a Faulty speedometer to auto light control unit harness a Faulty auto light control unit

building shadows.

During the day, neither small lamps nor headlamps turn OFF. During the day, headlamps tum OFF but small lamps do not turn OFF. a Faulty auto light control unit

Page 180 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses

DESCRIPTION

Problems with xenon headlamps are as follows:

They do not light up.

They blink.

GD

They are not bright enough.

In most cases the problems above are caused by faulty xenon bulbs.

There might be the possibility that the problems are caused by faulty HID control unit or lamp sockets.

ec

Follow the diagnostic procedure to determine what causes the problem.

PRECAUTIONS AT

Connect or disconnect connectors with the lighting switch OFF.

Do not touch harnesses, HID control unit, internal lamp, or metal part of the lamp while the lamps are

ON B2

(Lighting switch is ON).

Before verifying that the lamps are ON, install the parts to the vehicle temporarily and connect the battery

cable with

the connector on the vehicle. ST

If the electrical system is suspected to be the cause of the symptom, check for blown fuse or fusible link,

broken connectors, disconnected terminals, or faulty engagement.

Do not use wet hands when performing the trouble diagnoses.

F@

CIRCUIT DIAGRAM

, MA Xenon

headlamp

relay

To clearance

JJ$Rkj

lamp and

tail lamp

Headlamp

1 -- - -1 : High-voltage parts

Driver door SM

CAUTION:

0 Do not use a tester to diagnose the HID control unit circuit.

0 Do not disassemble the HID control unit and harnesses (bulb socket harness and control unit har-

ness).

0 Immediately after the headlamps turn ON, brightness and emission color vary. This is a normal

condition.

When a bulb has reached the end of its life, the brightness becomes extremely low, the bulb con-

tinues to blink, or the light looks reddish.

Page 181 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses (Cont'd)

DIAGNOSTIC PROCEDURE

I

FUSE, FUSIBLE LINK, AND XENON Fuse, fusible link, or xenon

HEADLAMP RELAY CHECK headlamp relay is faulty.

CONNECTOR CHECK ON THE VEHICLE Harness on the vehicle is

FOR BATTERY VOLTAGE faulty.

With lighting switch ON, check HID control

unit connector on the vehicle for battery

I voltage. I

OK

XENON HEADLAMP BULB REPLACE- Xenon bulb is faulty.

MENT

Replace the xenon headiamp bulb with a

known

good bulb and check for proper

operation.

HID CONTROL UNIT REPLACEMENT HID control unit is faulty.

Install a known good

HID control unit to

I

the xenon headlarnp and check for proper

operation.

NG

XENON HEADLAMP HOUSING ASSEM- OK, BLY REPLACEMENT

Install a known good xenon headlamp

housing assembly to the xenon

headlamp

and check for proper operation.

---

Starter in xenon headlamp

housing (boost circuit) is

faulty. (Xenon

headlamp housing

assembly

is faulty.)