sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3050 of 4331

![NISSAN LATIO 2009 Service Repair Manual CYLINDER BLOCK

EM-103

< DISASSEMBLY AND ASSEMBLY >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

18. Install knock sensor (1).

• Install connectors so that they are positioned towards the rearof the engi NISSAN LATIO 2009 Service Repair Manual CYLINDER BLOCK

EM-103

< DISASSEMBLY AND ASSEMBLY >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

18. Install knock sensor (1).

• Install connectors so that they are positioned towards the rearof the engi](/img/5/57359/w960_57359-3049.png)

CYLINDER BLOCK

EM-103

< DISASSEMBLY AND ASSEMBLY >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

18. Install knock sensor (1).

• Install connectors so that they are positioned towards the rearof the engine.

CAUTION:

• Never tighten bolt while holding the connector.

• If any impact by dropping is applied to knock sensor,

replace it with a new one.

NOTE:

• Make sure that there is no foreign material on the cylinder block mating surface and the back surface of knock sensor.

• Make sure that knock sensor does not interfere with other parts.

19. Install crankshaft position sensor (POS) and cover. • Tighten bolts with it seated completely.

20. For the oil level gauge guide (1), fix the position (B) shown to the water inlet clip (A) after inserting to the cylinder block side.

21. Assembly is in the reverse order of disassembly after this step.

Inspection INFOID:0000000004784318

CRANKSHAFT END PLAY • Measure the clearance between thrust bearings and crankshaft arm when crankshaft is moved fully forward or backward with a dial

indicator (A).

• If the measured value exceeds the limit, replace thrust bearings, and measure again. If it still exceeds the limit, replace crankshaft

also.

CONNECTING ROD SIDE CLEARANCE • Measure the side clearance between connecting rod and crank- shaft arm with a feeler gauge (A).

• If the measured value exceeds the limit, replace connecting rod, and measure again. If it still exc eeds the standard, replace crank-

shaft also.

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter : Engine front

PBIC3754E

PBIC3755E

Standard and Limit : Refer to

EM-121, " Cylinder Block " .

PBIC3762E

Standard : Refer to

EM-121, " Cylinder Block " .

PBIC3763E

Page 3078 of 4331

![NISSAN LATIO 2009 Service Repair Manual PREPARATION

EM-131

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

ST16610001

(J-23907)

Pilot bushing puller Removing crankshaft pilot bushing

KV11103000

( — )

Pulley puller Rem NISSAN LATIO 2009 Service Repair Manual PREPARATION

EM-131

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

ST16610001

(J-23907)

Pilot bushing puller Removing crankshaft pilot bushing

KV11103000

( — )

Pulley puller Rem](/img/5/57359/w960_57359-3077.png)

PREPARATION

EM-131

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

ST16610001

(J-23907)

Pilot bushing puller Removing crankshaft pilot bushing

KV11103000

( — )

Pulley puller Removing crankshaft pulley

KV991J0050

(J-44626)

Air fuel sensor Socket Loosening or tightening air fuel ratio sen-

sor

a: 22 mm (0.87 in)

KV10114400

(J-38365)

Heated oxygen sensor wrench Loosening or tightening rear heated oxy-

gen sensor

a: 22 mm (0.87 in)

KV11105210

(J-44716)

Stopper plate Securing drive plate and flywheel

KV10115600

(J-38958)

Valve oil seal drift Installing valve oil seal

Use side A.

a: 20 (0.79) dia .

b: 13 (0.51) dia.

c: 10.3 (0.406) dia .

d: 8 (0.31) dia.

e: 10.7 (0.421)

f: 5 (0.20)

KV10115801

( — )

Oil filter wrench Removing and installing oil filter

a: 64.3 mm (2.531 in)

Tool number

(Kent-Moore No.)

Tool name DescriptionNT045

NT676

LBIA0444E

NT636

ZZA0009D

S-NT603

S-NT375

Page 3080 of 4331

![NISSAN LATIO 2009 Service Repair Manual PREPARATION

EM-133

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

Valve guide reamer (1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

(J-43897-18)

(J-43 NISSAN LATIO 2009 Service Repair Manual PREPARATION

EM-133

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

Valve guide reamer (1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

(J-43897-18)

(J-43](/img/5/57359/w960_57359-3079.png)

PREPARATION

EM-133

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

Valve guide reamer (1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads

before installing a new oxygen sensor (Use

with anti-seize lubricant shown below.)

a: J-43897-18 (18 mm dia.) for zirconia ox-

ygen sensor

b: J-43897-12 (12 mm dia.) for titania oxy-

gen sensor

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

E20 Torx® Socket

(J-45816) Removing and installing drive plate and fly-

wheel bolts

(Kent-Moore No.)

Tool name Description PBIC4013E

AEM488

AEM489

LBIA0285E

Page 3086 of 4331

EM

NP

O

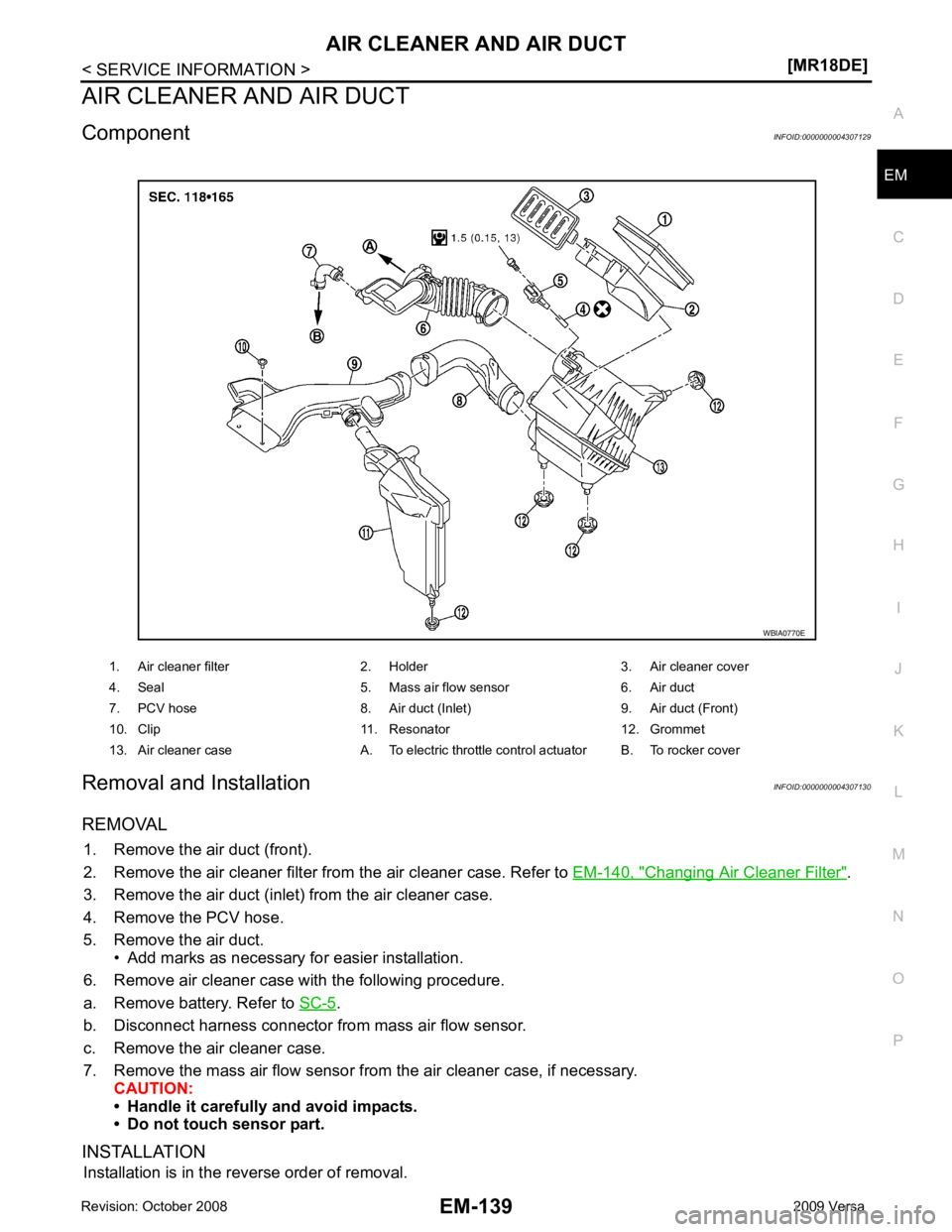

AIR CLEANER AND AIR DUCT

Component INFOID:0000000004307129

Removal and Installation INFOID:0000000004307130

REMOVAL 1. Remove the air duct (front).

2. Remove the air cleaner filter from the air cleaner case. Refer to EM-140, " Changing Air Cleaner Filter " .

3. Remove the air duct (inlet) from the air cleaner case.

4. Remove the PCV hose.

5. Remove the air duct. • Add marks as necessary for easier installation.

6. Remove air cleaner case with the following procedure.

a. Remove battery. Refer to SC-5 .

b. Disconnect harness connector from mass air flow sensor.

c. Remove the air cleaner case.

7. Remove the mass air flow sensor from the air cleaner case, if necessary. CAUTION:

• Handle it carefully and avoid impacts.

• Do not touch sensor part.

INSTALLATION Installation is in the reverse order of removal. 1. Air cleaner filter 2. Holder 3. Air cleaner cover

4. Seal 5. Mass air flow sensor 6. Air duct

7. PCV hose 8. Air duct (Inlet) 9. Air duct (Front)

10. Clip 11. Resonator 12. Grommet

13. Air cleaner case A. To electric throttle control actuator B. To rocker cover

Page 3091 of 4331

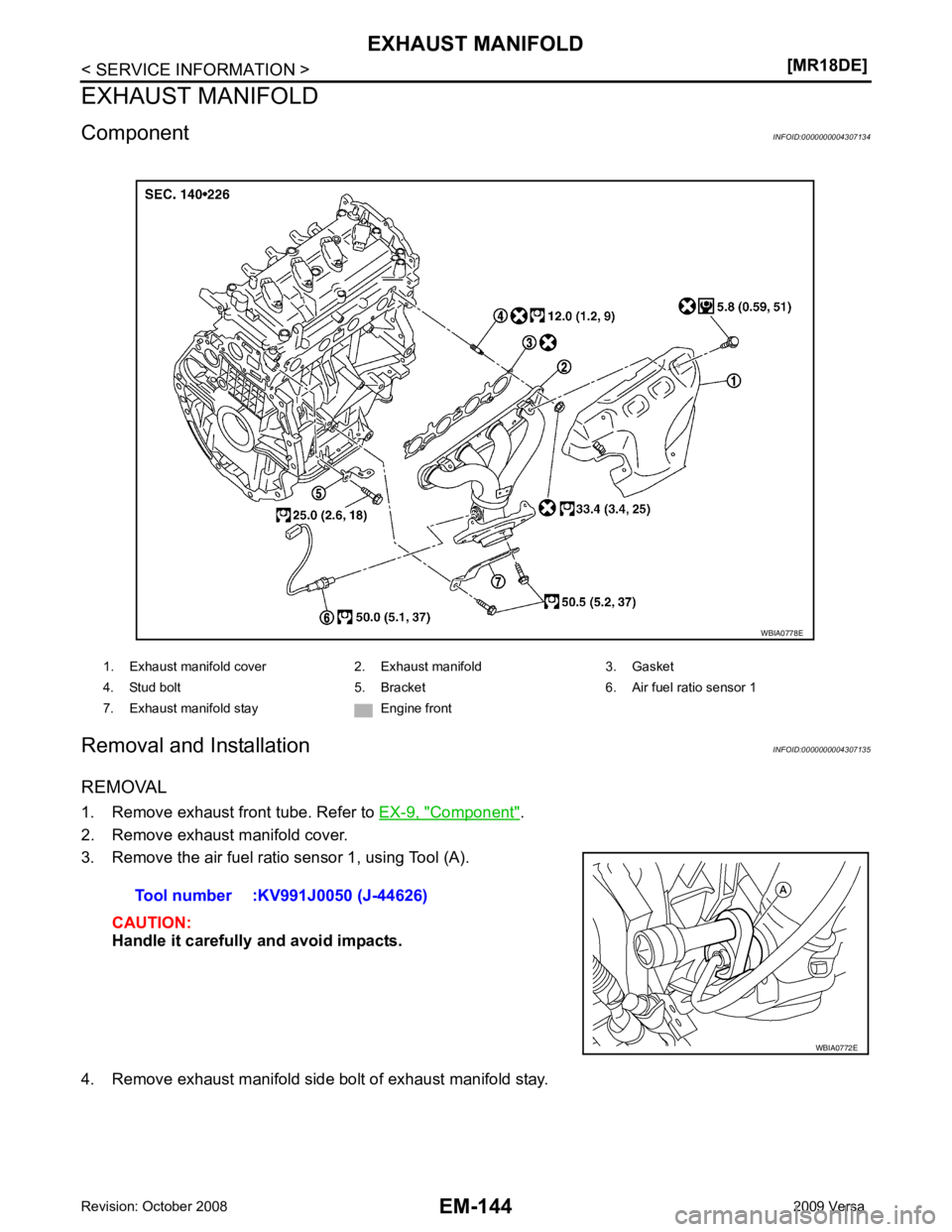

Component " .

2. Remove exhaust manifold cover.

3. Remove the air fuel ratio sensor 1, using Tool (A).

CAUTION:

Handle it carefully and avoid impacts.

4. Remove exhaust manifold side bolt of exhaust manifold stay. 1. Exhaust manifold cover 2. Exhaust manifold 3. Gasket

4. Stud bolt 5. Bracket 6. Air fuel ratio sensor 1

7. Exhaust manifold stay Engine front

Page 3117 of 4331

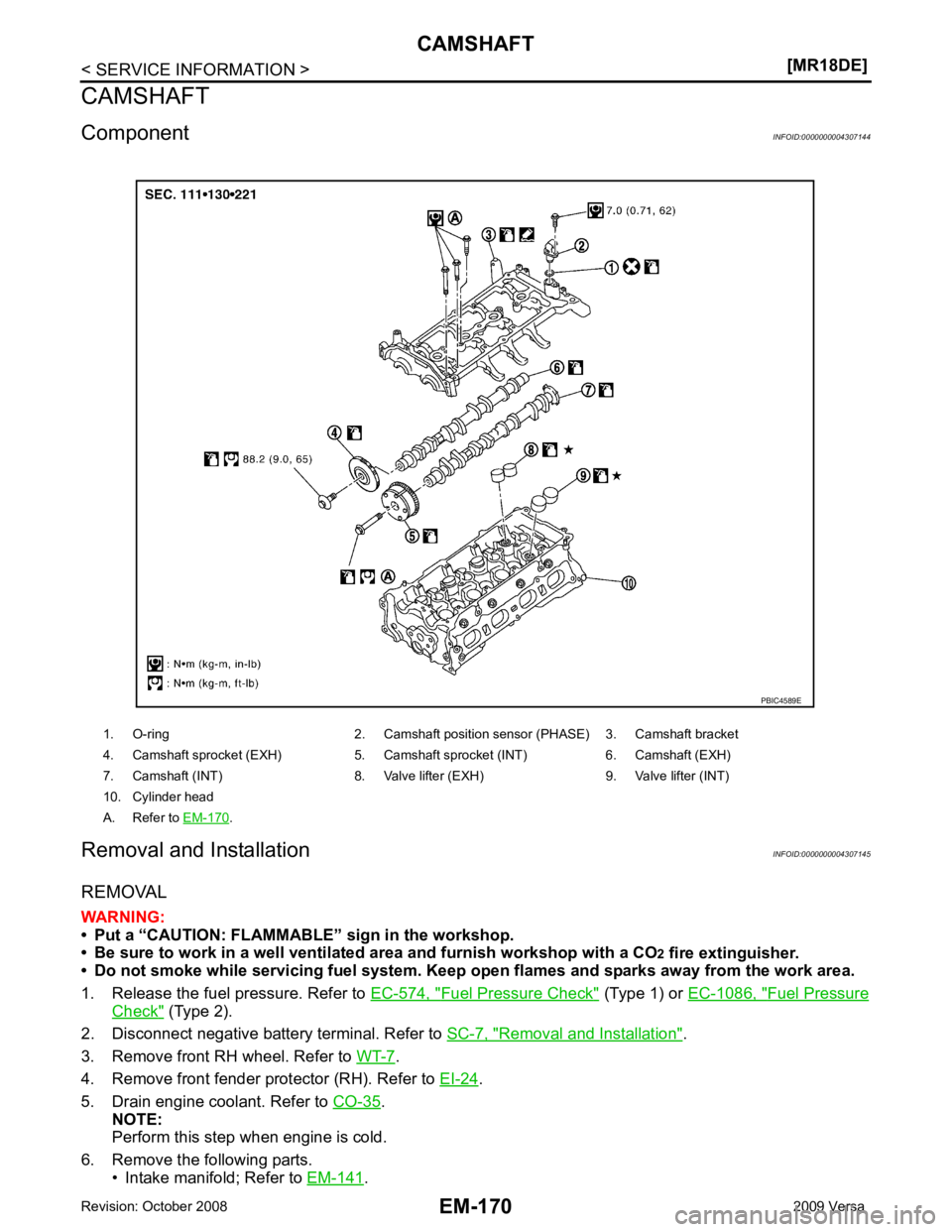

Fuel Pressure Check " (Type 1) or

EC-1086, " Fuel Pressure

Check " (Type 2).

2. Disconnect negative battery terminal. Refer to SC-7, " Removal and Installation " .

3. Remove front RH wheel. Refer to WT-7 .

4. Remove front fender protector (RH). Refer to EI-24 .

5. Drain engine coolant. Refer to CO-35 .

NOTE:

Perform this step when engine is cold.

6. Remove the following parts. • Intake manifold; Refer to EM-141 .

1. O-ring 2. Camshaft po

sition sensor (PHASE) 3. Camshaft bracket

4. Camshaft sprocket (EXH) 5. Camshaft sprocket (INT) 6. Camshaft (EXH)

7. Camshaft (INT) 8. Valve lifter (EXH) 9. Valve lifter (INT)

10. Cylinder head

A. Refer to EM-170 .

Page 3118 of 4331

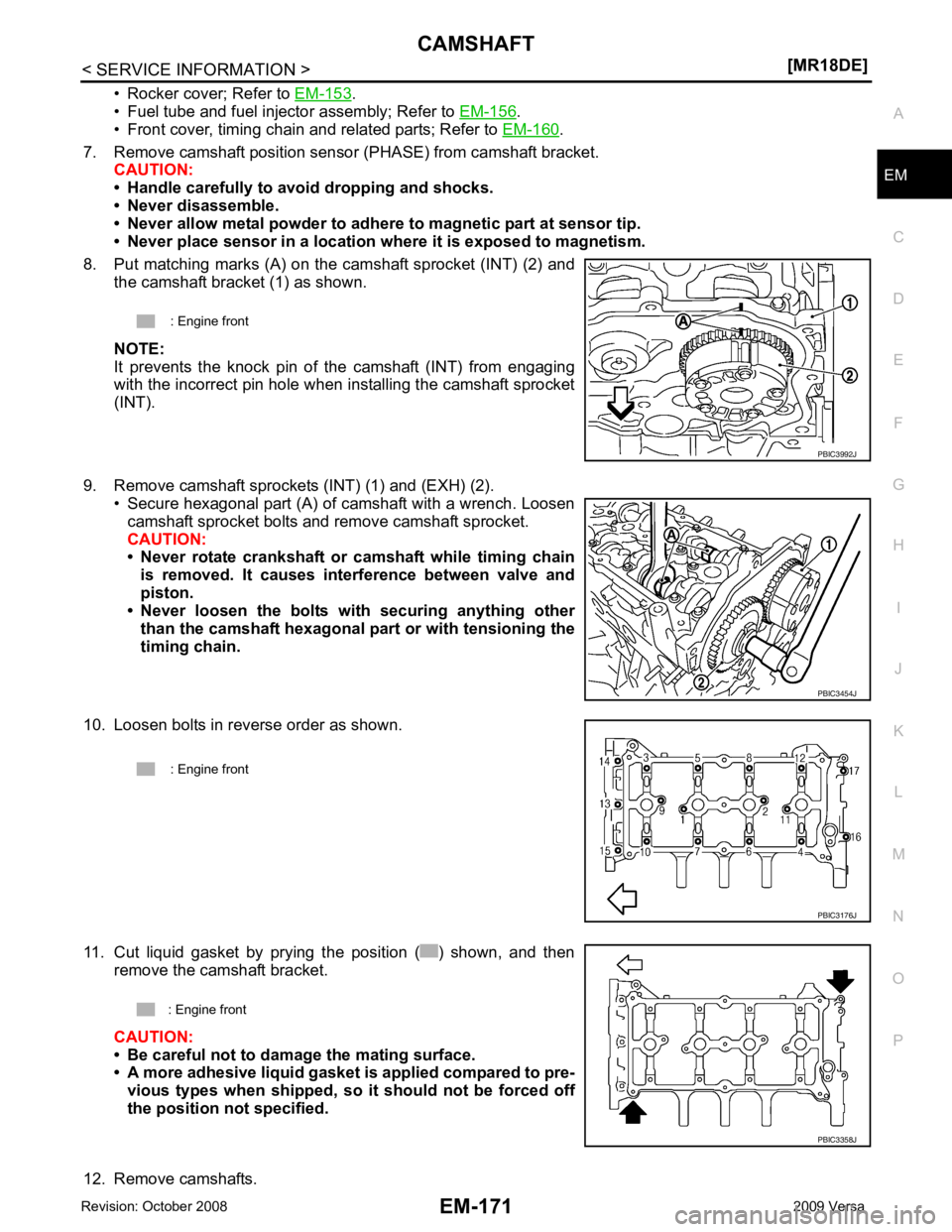

EM

NP

O

• Rocker cover; Refer to

EM-153 .

• Fuel tube and fuel injector assembly; Refer to EM-156 .

• Front cover, timing chain and related parts; Refer to EM-160 .

7. Remove camshaft position sensor (PHASE) from camshaft bracket. CAUTION:

• Handle carefully to avoid dropping and shocks.

• Never disassemble.

• Never allow metal powder to adhere to magnetic part at sensor tip.

• Never place sensor in a location wher e it is exposed to magnetism.

8. Put matching marks (A) on the camshaft sprocket (INT) (2) and the camshaft bracket (1) as shown.

NOTE:

It prevents the knock pin of the camshaft (INT) from engaging

with the incorrect pin hole when installing the camshaft sprocket

(INT).

9. Remove camshaft sprockets (INT) (1) and (EXH) (2). • Secure hexagonal part (A) of camshaft with a wrench. Loosen

camshaft sprocket bolts and remove camshaft sprocket.

CAUTION:

• Never rotate crankshaft or camshaft while timing chain

is removed. It causes interference between valve and

piston.

• Never loosen the bolts with securing anything other

than the camshaft hexagonal part or with tensioning the

timing chain.

10. Loosen bolts in reverse order as shown.

11. Cut liquid gasket by prying the position ( ) shown, and then remove the camshaft bracket.

CAUTION:

• Be careful not to damage the mating surface.

• A more adhesive liquid gasket is applied compared to pre-

vious types when shipped, so it should not be forced off

the position not specified.

12. Remove camshafts. : Engine front

PBIC3454J

Page 3146 of 4331

EM

NP

O

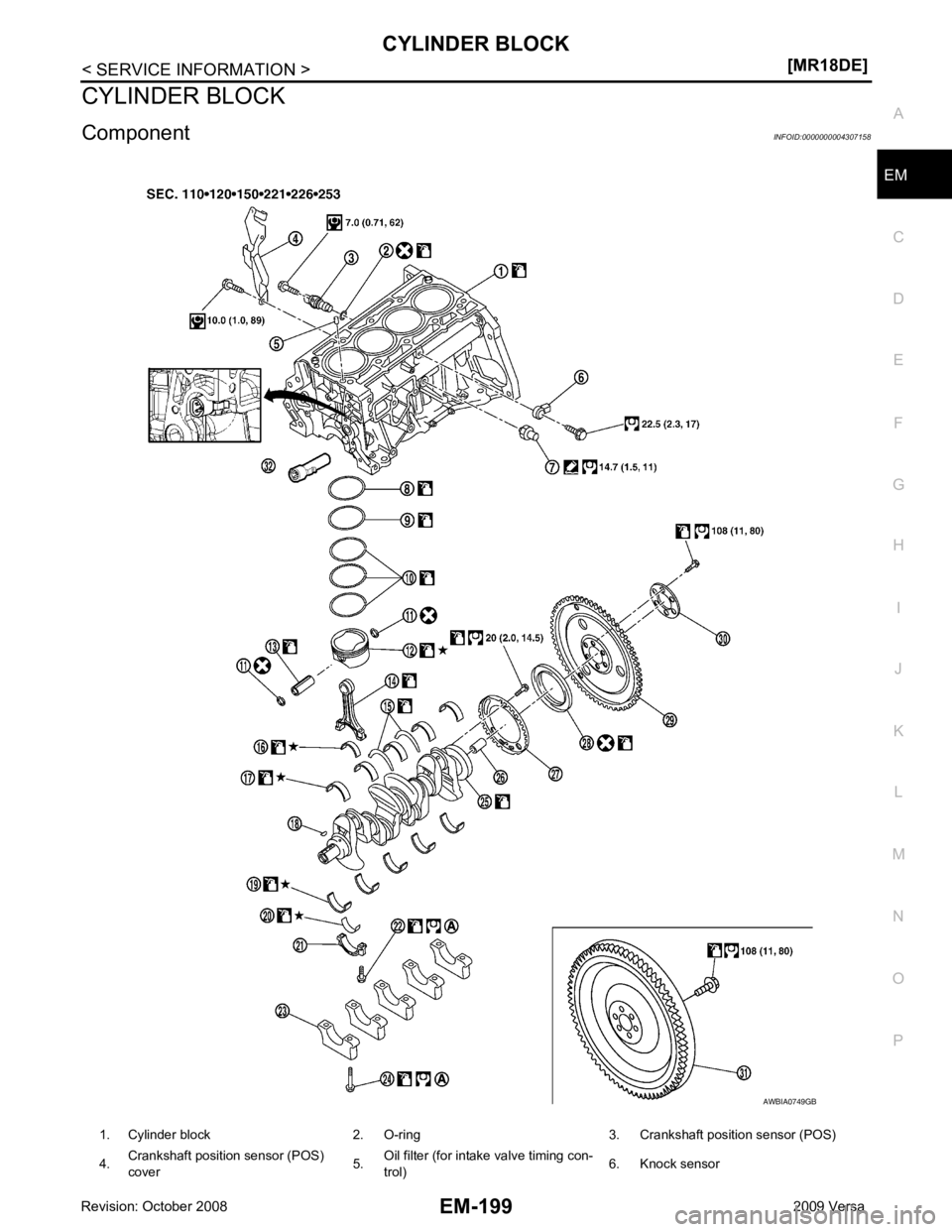

CYLINDER BLOCK

Component INFOID:0000000004307158

1. Cylinder block 2. O-ring 3. Crankshaft position sensor (POS)

4. Crankshaft position sensor (POS)

cover 5.Oil filter (for intake valve timing con-

trol) 6. Knock sensor

Page 3147 of 4331

.

2. Install engine to engine stand as follows;

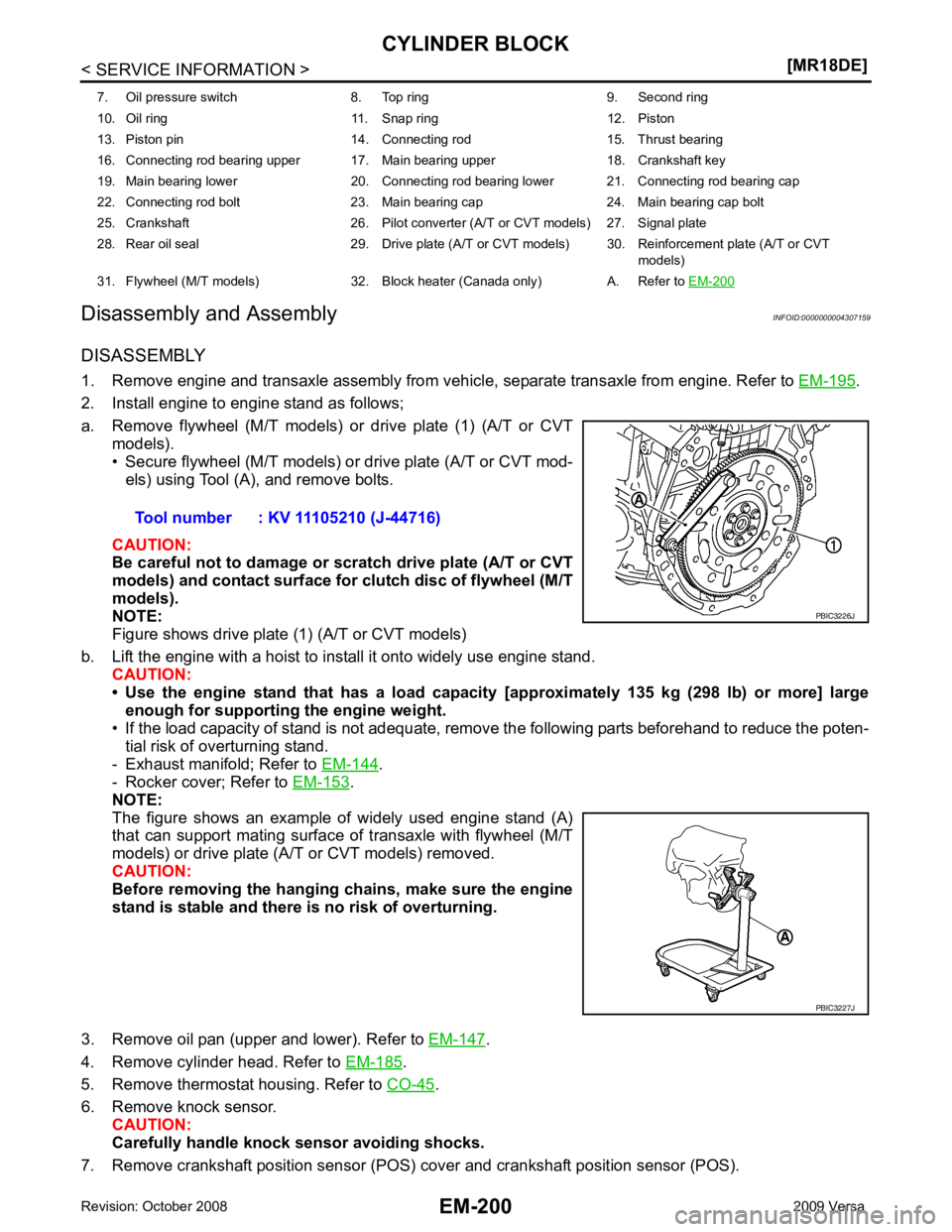

a. Remove flywheel (M/T models) or drive plate (1) (A/T or CVT models).

• Secure flywheel (M/T models) or drive plate (A/T or CVT mod-

els) using Tool (A), and remove bolts.

CAUTION:

Be careful not to damage or scratch drive plate (A/T or CVT

models) and contact surface for clutch disc of flywheel (M/T

models).

NOTE:

Figure shows drive plate (1) (A/T or CVT models)

b. Lift the engine with a hoist to install it onto widely use engine stand. CAUTION:

• Use the engine stand that has a load capacity [approximately 135 kg (298 lb) or more] large

enough for supporting the engine weight.

• If the load capacity of stand is not adequate, remo ve the following parts beforehand to reduce the poten-

tial risk of overturning stand.

- Exhaust manifold; Refer to EM-144 .

- Rocker cover; Refer to EM-153 .

NOTE:

The figure shows an example of widely used engine stand (A)

that can support mating surface of transaxle with flywheel (M/T

models) or drive plate (A/T or CVT models) removed.

CAUTION:

Before removing the hanging chains, make sure the engine

stand is stable and there is no risk of overturning.

3. Remove oil pan (upper and lower). Refer to EM-147 .

4. Remove cylinder head. Refer to EM-185 .

5. Remove thermostat housing. Refer to CO-45 .

6. Remove knock sensor. CAUTION:

Carefully handle knock sensor avoiding shocks.

7. Remove crankshaft position sensor (POS) cover and crankshaft position sensor (POS).

7. Oil pressure switch 8. Top ring 9. Second ring

10. Oil ring 11. Snap ring 12. Piston

13. Piston pin 14. Connecting rod 15. Thrust bearing

16. Connecting rod bearing upper 17. Main bearing upper 18. Crankshaft key

19. Main bearing lower 20. Connecting rod bearing lower 21. Connecting rod bearing cap

22. Connecting rod bolt 23. Main bearing cap 24. Main bearing cap bolt

25. Crankshaft 26. Pilot converter (A/T or CVT models) 27. Signal plate

28. Rear oil seal 29. Drive plate (A/T or CVT models) 30. Reinforcement plate (A/T or CVT models)

31. Flywheel (M/T models) 32. Block heater (Canada only) A. Refer to EM-200 PBIC3227J

Page 3148 of 4331

EM

NP

O

CAUTION:

• Avoid impacts such as a dropping.

• Never disassemble.

• Keep it away from metal particles.

• Never place sensor in a location wher e it is exposed to magnetism.

8. Remove oil filter (for intake valve timing control).

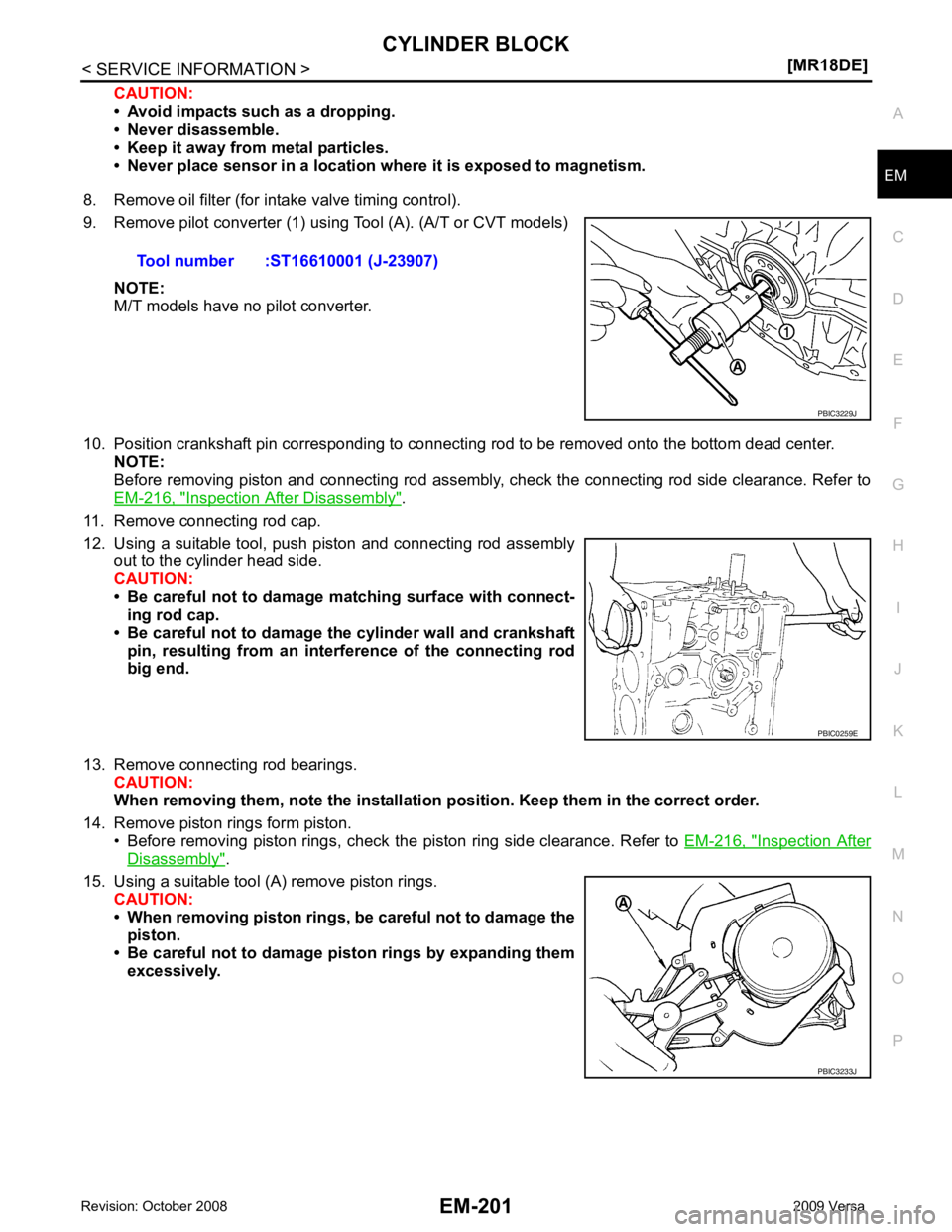

9. Remove pilot converter (1) using Tool (A). (A/T or CVT models)

NOTE:

M/T models have no pilot converter.

10. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center. NOTE:

Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer to

EM-216, " Inspection After Disassembly " .

11. Remove connecting rod cap.

12. Using a suitable tool, push piston and connecting rod assembly out to the cylinder head side.

CAUTION:

• Be careful not to damage matching surface with connect- ing rod cap.

• Be careful not to damage the cylinder wall and crankshaft pin, resulting from an inte rference of the connecting rod

big end.

13. Remove connecting rod bearings. CAUTION:

When removing them, note the installation position. Keep them in the correct order.

14. Remove piston rings form piston. • Before removing piston rings, check the piston ring side clearance. Refer to EM-216, " Inspection After

Disassembly " .

15. Using a suitable tool (A) remove piston rings. CAUTION:

• When removing piston rings, be careful not to damage the

piston.

• Be careful not to damage piston rings by expanding them excessively.Tool number :ST16610001 (J-23907)

PBIC0259E

PBIC3233J