sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 4032 of 4331

PG

N

O P

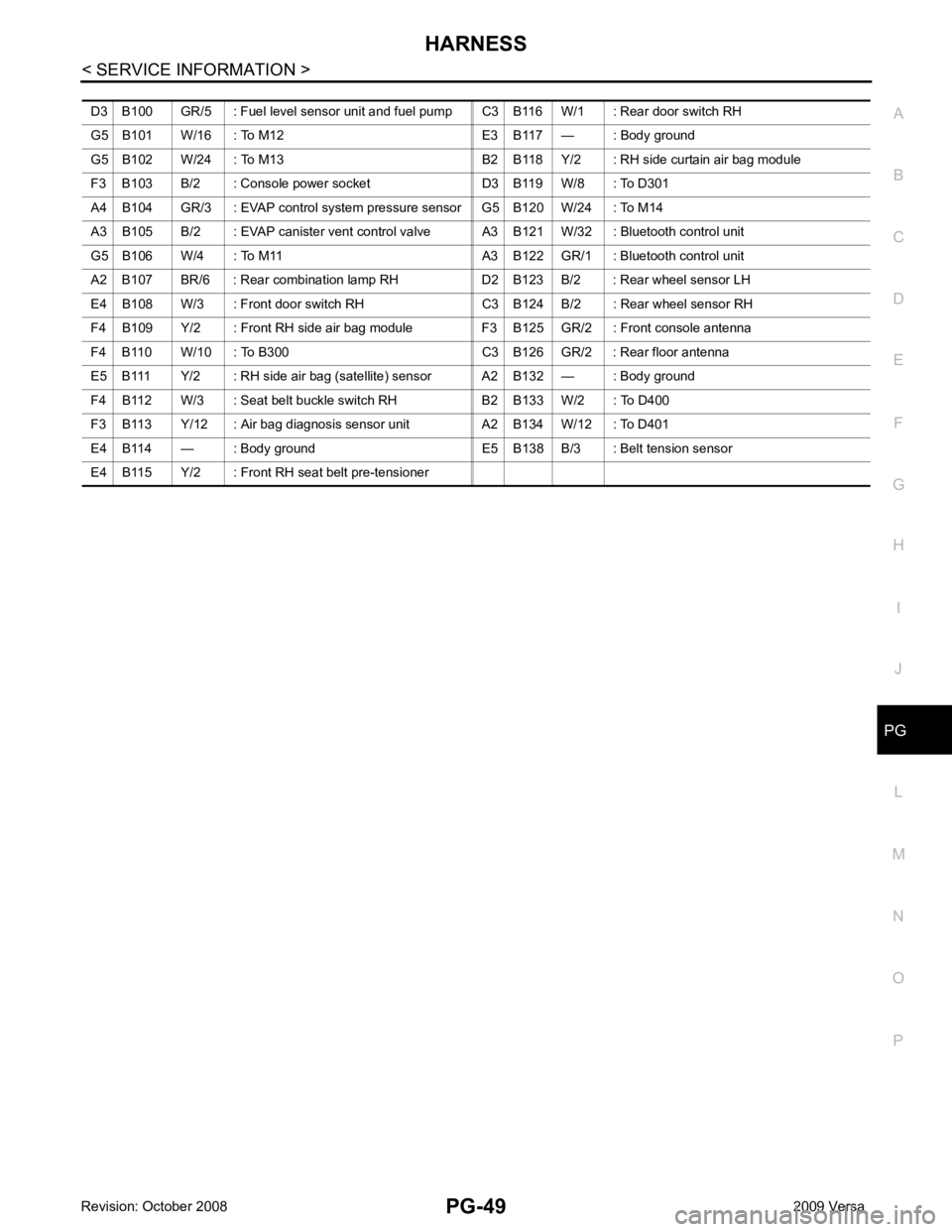

D3 B100 GR/5 : Fuel level sensor unit and fuel pump C3 B116 W/1 : Rear door switch RH

G5 B101 W/16 : To M12 E3 B117 — : Body ground

G5 B102 W/24 : To M13 B2 B118 Y/2 : RH side curtain air bag module

F3 B103 B/2 : Console power socket D3 B119 W/8 : To D301

A4 B104 GR/3 : EVAP control system pressure sensor G5 B120 W/24 : To M14

A3 B105 B/2 : EVAP canister vent control valve A3 B121 W/32 : Bluetooth control unit

G5 B106 W/4 : To M11 A3 B122 GR/1 : Bluetooth control unit

A2 B107 BR/6 : Rear combination lamp RH D2 B123 B/2 : Rear wheel sensor LH

E4 B108 W/3 : Front door switch RH C3 B124 B/2 : Rear wheel sensor RH

F4 B109 Y/2 : Front RH side air bag module F3 B125 GR/2 : Front console antenna

F4 B110 W/10 : To B300 C3 B126 GR/2 : Rear floor antenna

E5 B111 Y/2 : RH side air bag (satellite) sensor A2 B132 — : Body ground

F4 B112 W/3 : Seat belt buckle switch RH B2 B133 W/2 : To D400

F3 B113 Y/12 : Air bag diagnosis sensor unit A2 B134 W/12 : To D401

E4 B114 — : Body ground E5 B138 B/3 : Belt tension sensor

E4 B115 Y/2 : Front RH seat belt pre-tensioner

Page 4034 of 4331

PG

N

O P

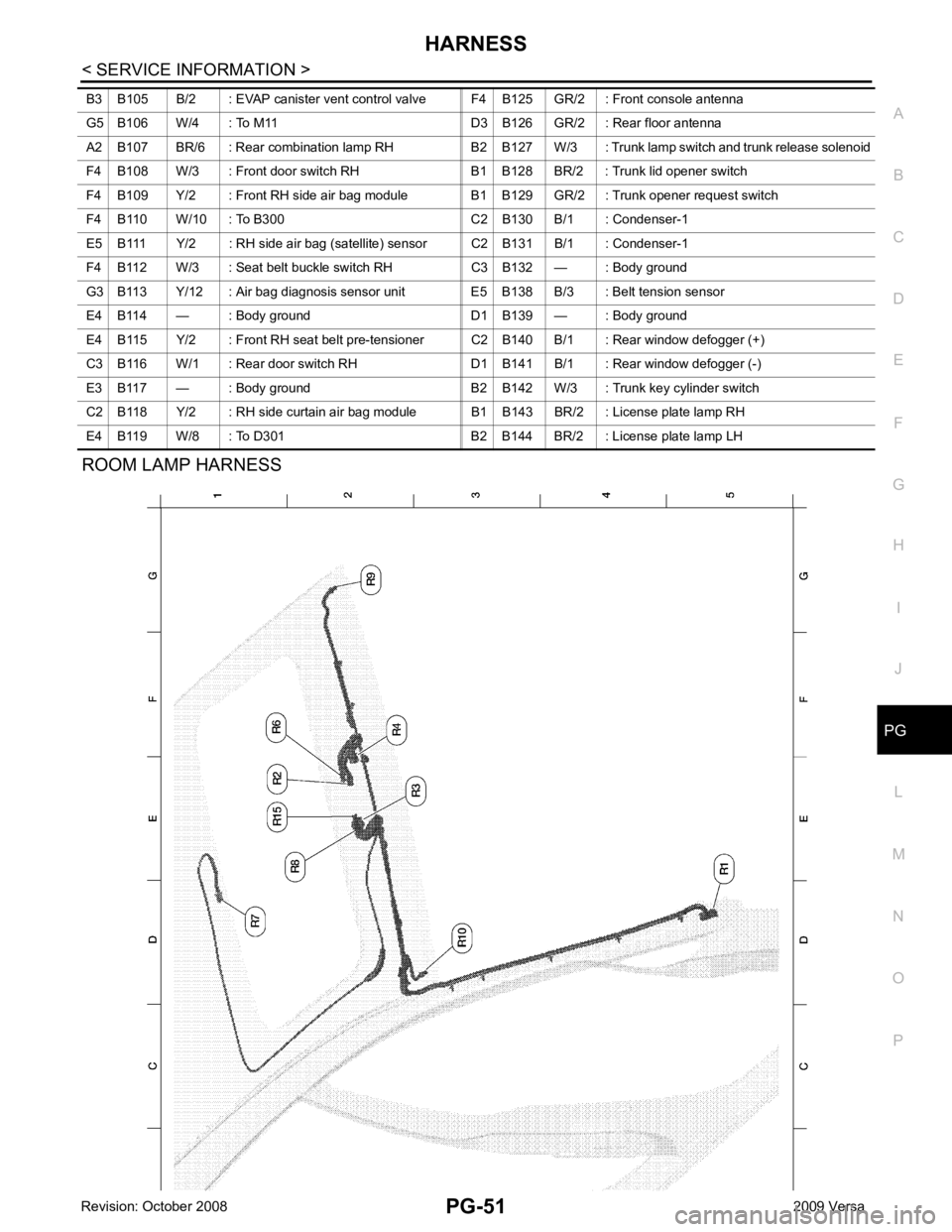

ROOM LAMP HARNESS

B3 B105 B/2 : EVAP canister vent control valve F4 B125 GR/2 : Front console antenna

G5 B106 W/4 : To M11 D3 B126 GR/2 : Rear floor antenna

A2 B107 BR/6 : Rear combination lamp RH B2 B127 W/3 : Trunk lamp switch and trunk release solenoid

F4 B108 W/3 : Front door switch RH B1 B128 BR/2 : Trunk lid opener switch

F4 B109 Y/2 : Front RH side air bag module B1 B129 GR/2 : Trunk opener request switch

F4 B110 W/10 : To B300 C2 B130 B/1 : Condenser-1

E5 B111 Y/2 : RH side air bag (satellite) sensor C2 B131 B/1 : Condenser-1

F4 B112 W/3 : Seat belt buckle switch RH C3 B132 — : Body ground

G3 B113 Y/12 : Air bag diagnosis sensor unit E5 B138 B/3 : Belt tension sensor

E4 B114 — : Body ground D1 B139 — : Body ground

E4 B115 Y/2 : Front RH seat belt pre-tensioner C2 B140 B/1 : Rear window defogger (+)

C3 B116 W/1 : Rear door switch RH D1 B141 B/1 : Rear window defogger (-)

E3 B117 — : Body ground B2 B142 W/3 : Trunk key cylinder switch

C2 B118 Y/2 : RH side curtain air bag module B1 B143 BR/2 : License plate lamp RH

E4 B119 W/8 : To D301 B2 B144 BR/2 : License plate lamp LH

Page 4040 of 4331

PG

N

O P

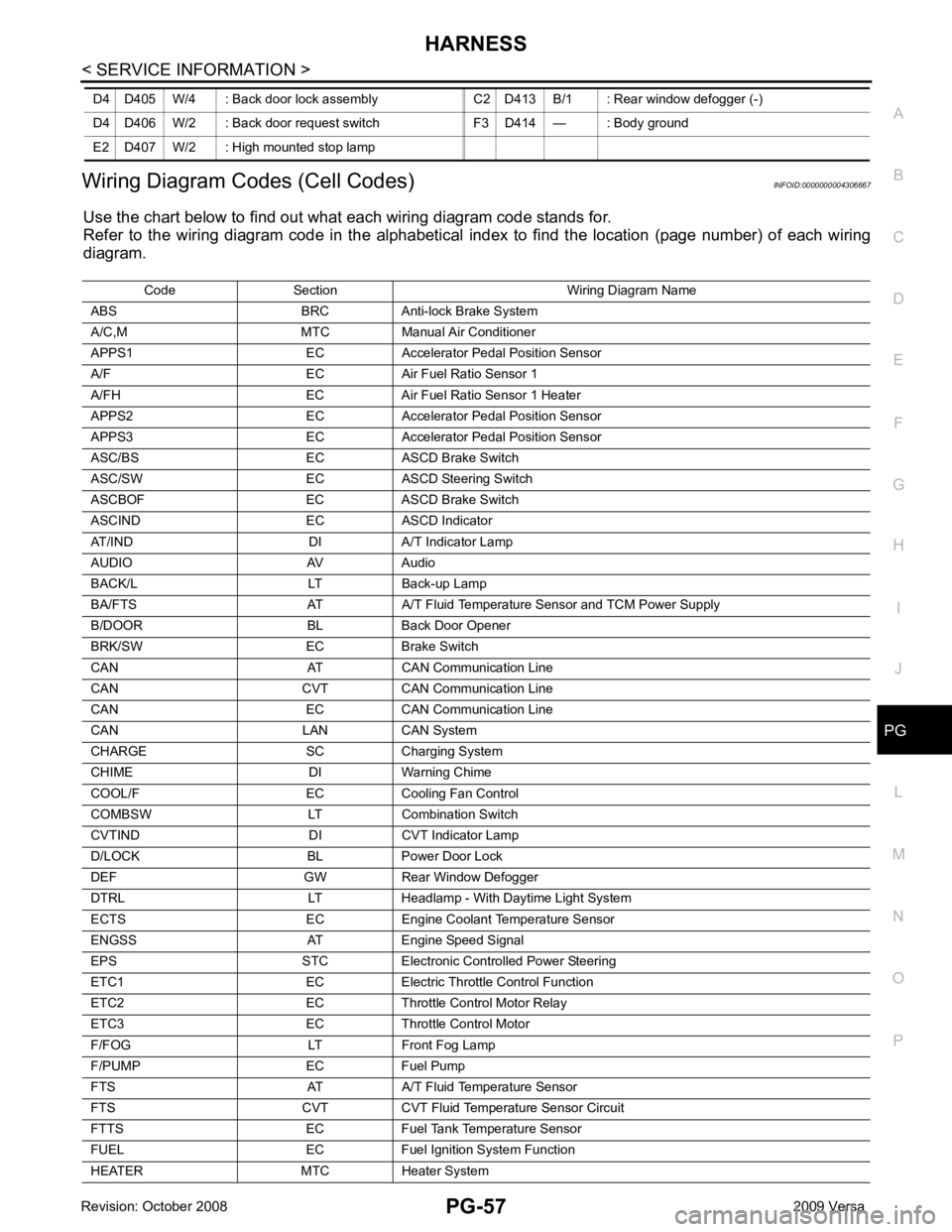

Wiring Diagram Codes (Cell Codes)

INFOID:0000000004306667

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram. D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pe dal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pe dal Position Sensor

APPS3 EC Accelerator Pe dal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Comm unication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

HEATER MTC Heater System

Page 4042 of 4331

PG

N

O P

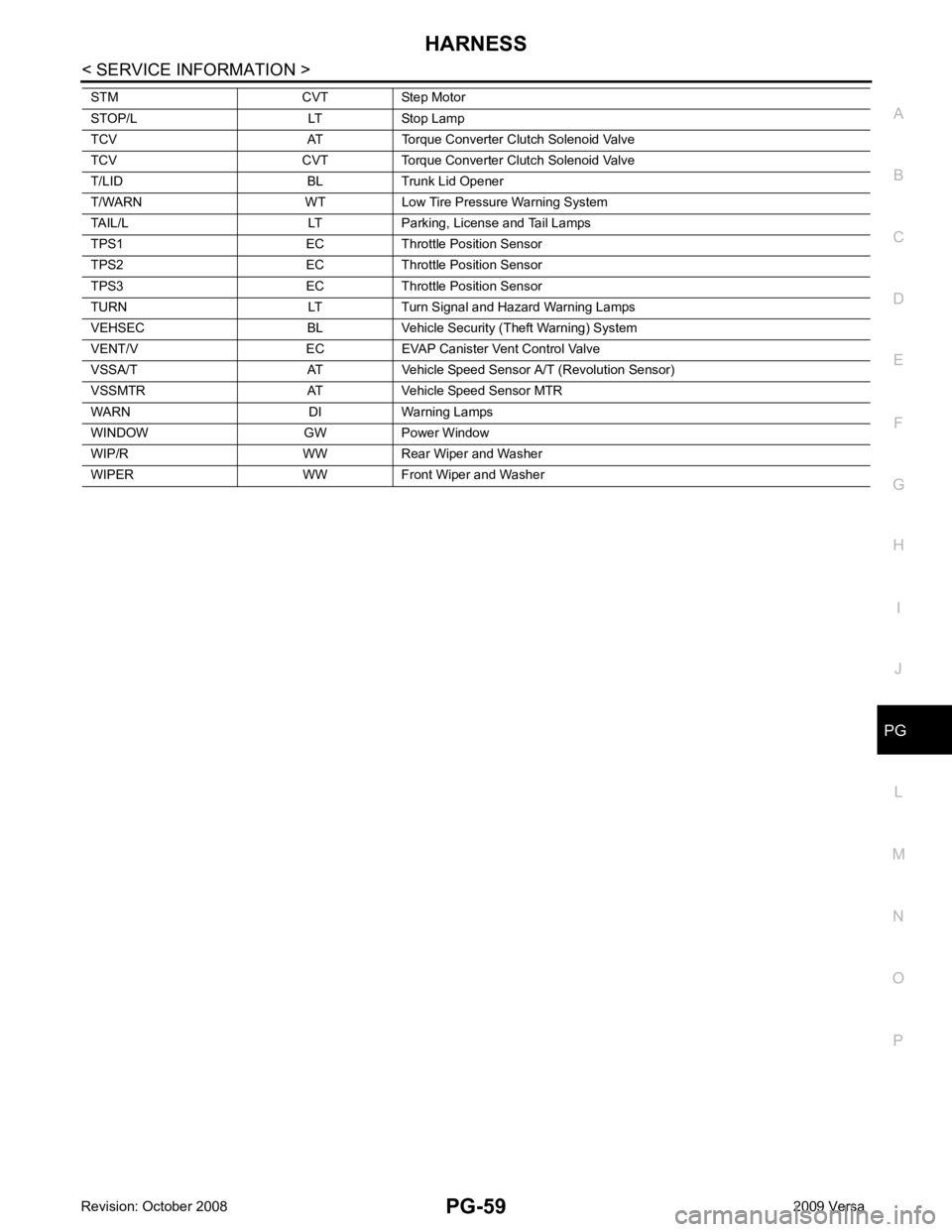

STM CVT Step Motor

STOP/L LT Stop Lamp

TCV AT Torque Converter Clutch Solenoid Valve

TCV CVT Torque Converter Clutch Solenoid Valve

T/LID BL Trunk Lid Opener

T/WARN WT Low Tire Pr essure Warning System

TAIL/L LT Parking, License and Tail Lamps

TPS1 EC Throttle Position Sensor

TPS2 EC Throttle Position Sensor

TPS3 EC Throttle Position Sensor

TURN LT Turn Signal and Hazard Warning Lamps

VEHSEC BL Vehicle Security (Theft Warning) System

VENT/V EC EVAP Canister Vent Control Valve

VSSA/T AT Vehicle Speed Sensor A/T (Revolution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN DI Warning Lamps

WINDOW GW Power Window

WIP/R WW Rear Wiper and Washer

WIPER WW Front Wiper and Washer

Page 4065 of 4331

PS

N

O P

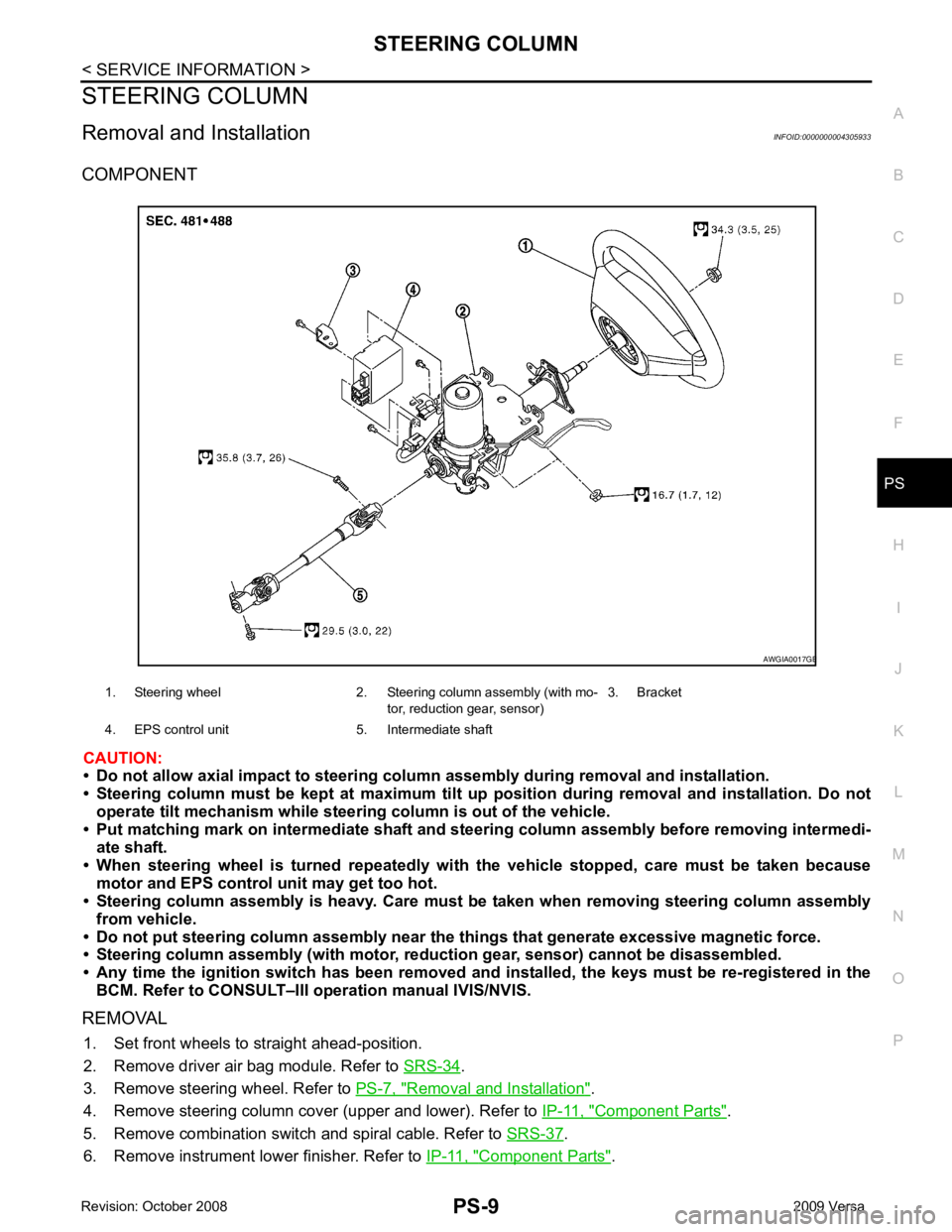

STEERING COLUMN

Removal and Installation INFOID:0000000004305933

COMPONENT

CAUTION:

• Do not allow axial impact to steering colu mn assembly during removal and installation.

• Steering column must be kept at maximum tilt up position during removal and installation. Do not

operate tilt mechanism while steeri ng column is out of the vehicle.

• Put matching mark on intermediate shaft and st eering column assembly before removing intermedi-

ate shaft.

• When steering wheel is turned re peatedly with the vehicle stopped, care must be taken because

motor and EPS control unit may get too hot.

• Steering column assembly is heavy . Care must be taken when removing steering column assembly

from vehicle.

• Do not put steering column assem bly near the things that generate excessive magnetic force.

• Steering column assembly (with motor, reduc tion gear, sensor) cannot be disassembled.

• Any time the ignition switch h as been removed and installed, the keys must be re-registered in the

BCM. Refer to CONSULT–III ope ration manual IVIS/NVIS.

REMOVAL 1. Set front wheels to straight ahead-position.

2. Remove driver air bag module. Refer to SRS-34 .

3. Remove steering wheel. Refer to PS-7, " Removal and Installation " .

4. Remove steering column cover (upper and lower). Refer to IP-11, " Component Parts " .

5. Remove combination switch and spiral cable. Refer to SRS-37 .

6. Remove instrument lower finisher. Refer to IP-11, " Component Parts " .

1. Steering wheel 2. Steering column assembly (with mo-

tor, reduction gear, sensor)3. Bracket

4. EPS control unit 5. Intermediate shaft B

Page 4079 of 4331

WHEEL HUB

RAX-5

< SERVICE INFORMATION >

C

E F

G H

I

J

K L

M A

B RAX

N

O P

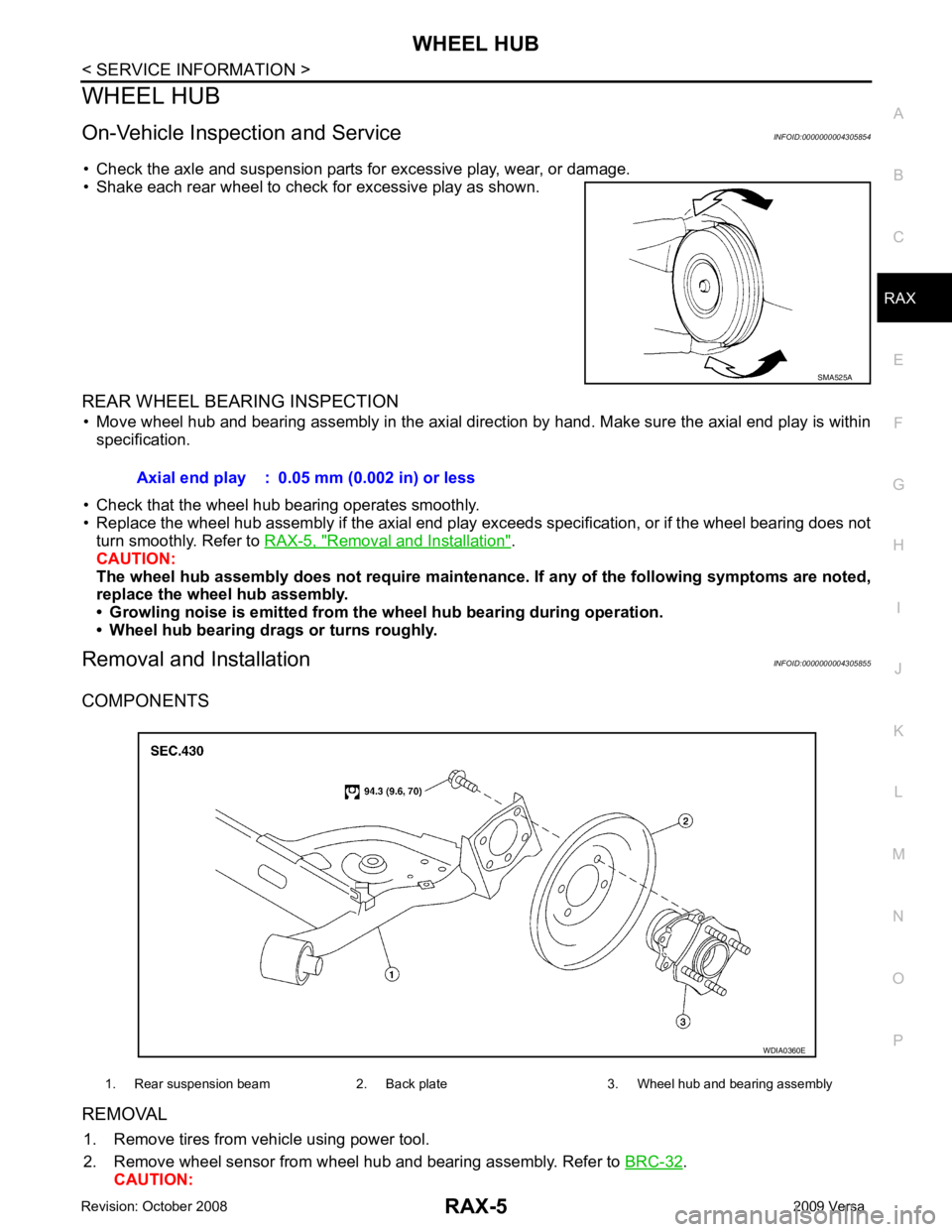

WHEEL HUB

On-Vehicle Inspection and Service INFOID:0000000004305854

• Check the axle and suspension parts for excessive play, wear, or damage.

• Shake each rear wheel to check for excessive play as shown.

REAR WHEEL BEARING INSPECTION • Move wheel hub and bearing assembly in the axial direction by hand. Make sure the axial end play is within specification.

• Check that the wheel hub bearing operates smoothly.

• Replace the wheel hub assembly if the axial end play e xceeds specification, or if the wheel bearing does not

turn smoothly. Refer to RAX-5, " Removal and Installation " .

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from th e wheel hub bearing during operation.

• Wheel hub bearing dr ags or turns roughly.

Removal and Installation INFOID:0000000004305855

COMPONENTS

REMOVAL 1. Remove tires from vehicle using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to BRC-32 .

CAUTION: SMA525A

Axial end play : 0.05 mm (0.002 in) or less

1. Rear suspension beam 2. Back plate 3. Wheel hub and bearing assembly WDIA0360E

Page 4117 of 4331

.

3. Wheel bearing axial end play. Refer to RAX-5, " On-Vehicle Inspection and Service " .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-13, " Wheel

Alignment (Unladen*) " .

1. When displaying the alignment settings, many alignm ent machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Page 4120 of 4331

RSU

N

O P

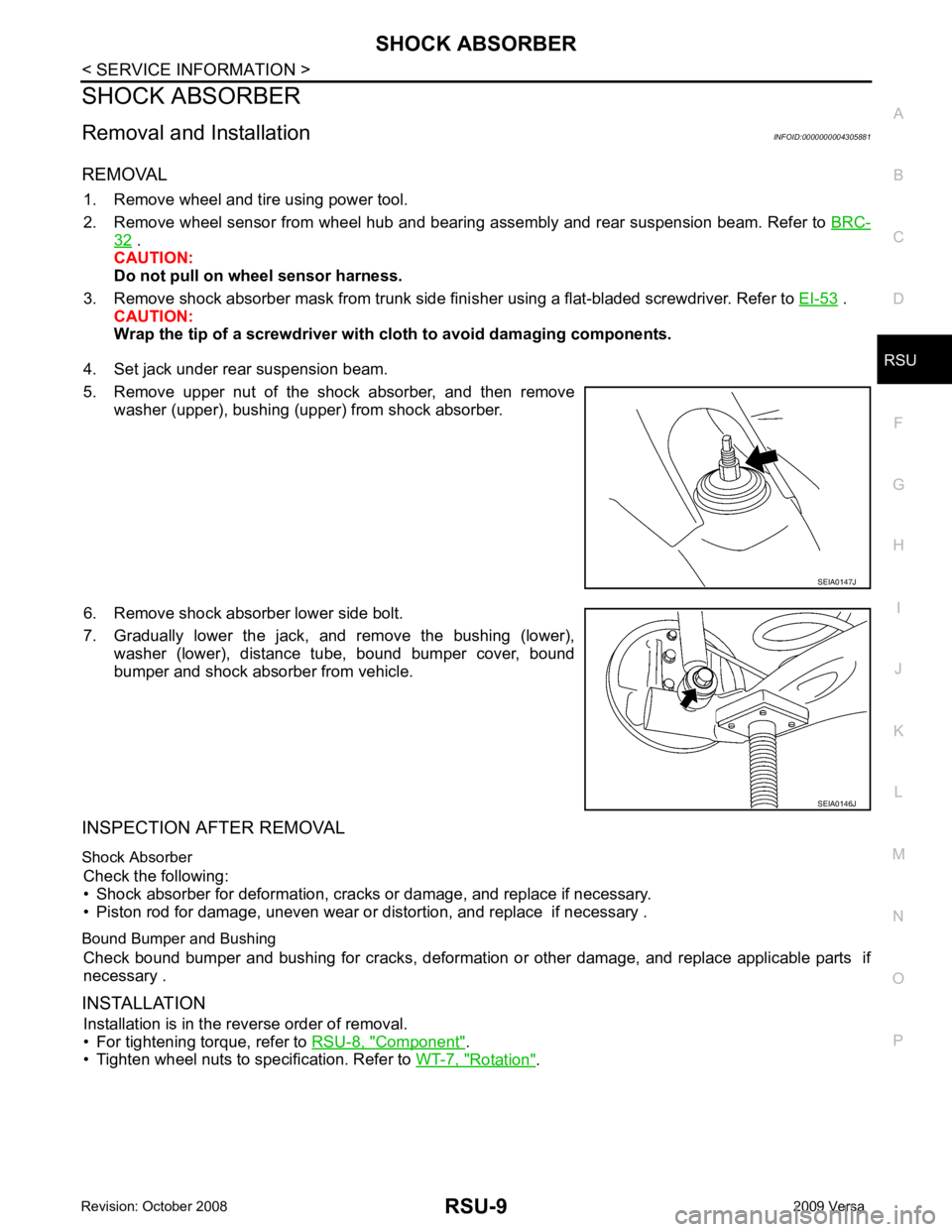

SHOCK ABSORBER

Removal and Installation INFOID:0000000004305881

REMOVAL 1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly and rear suspension beam. Refer to BRC-32 .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove shock absorber mask from trunk side fini sher using a flat-bladed screwdriver. Refer to EI-53 .

CAUTION:

Wrap the tip of a screwdriver with cl oth to avoid damaging components.

4. Set jack under rear suspension beam.

5. Remove upper nut of the shock absorber, and then remove washer (upper), bushing (upper) from shock absorber.

6. Remove shock absorber lower side bolt.

7. Gradually lower the jack, and remove the bushing (lower), washer (lower), distance tube, bound bumper cover, bound

bumper and shock absorber from vehicle.

INSPECTION AFTER REMOVAL

Shock Absorber Check the following:

• Shock absorber for deformation, cracks or damage, and replace if necessary.

• Piston rod for damage, uneven wear or di stortion, and replace if necessary .

Bound Bumper and Bushing Check bound bumper and bushing for cracks, deformation or other damage, and replace applicable parts if

necessary .

INSTALLATION Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, " Component " .

• Tighten wheel nuts to specification. Refer to WT-7, " Rotation " .

Page 4122 of 4331

COIL SPRING

RSU-11

< SERVICE INFORMATION >

C

D

F

G H

I

J

K L

M A

B RSU

N

O P

COIL SPRING

Removal and Installation INFOID:0000000004305882

REMOVAL 1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to BRC-32, " Removal and Installa-

tion " .

CAUTION:

Do not pull on wheel sensor harness.

3. Separate brake tube from wheel cylinder. Refer to BR-12, " Rear Brake Tube and Hose " .

4. Set jack under rear suspension beam.

5. Remove shock absorber lower side bolt. Refer to RSU-9," Removal and Installation " .

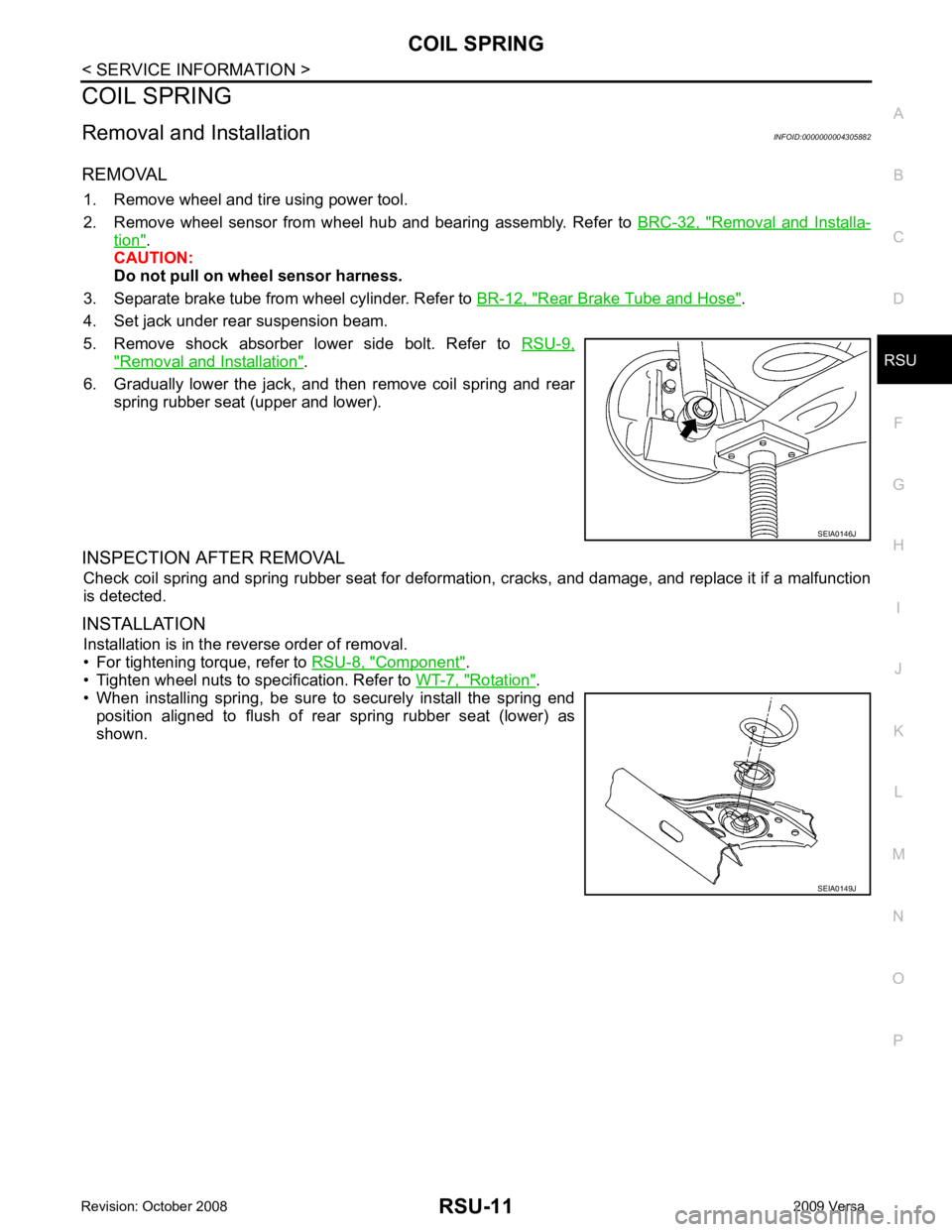

6. Gradually lower the jack, and then remove coil spring and rear spring rubber seat (upper and lower).

INSPECTION AFTER REMOVAL Check coil spring and spring rubber seat for deformation, cracks, and damage, and replace it if a malfunction

is detected.

INSTALLATION Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, " Component " .

• Tighten wheel nuts to specification. Refer to WT-7, " Rotation " .

• When installing spring, be sure to securely install the spring end

position aligned to flush of rear spring rubber seat (lower) as

shown. SEIA0146J

SEIA0149J

Page 4123 of 4331

On-

Vehicle Service " .

3. Remove wheel sensor and wheel sensor harness from wheel hub and bearing assembly and rear suspen-

sion beam. Refer to BRC-32, " Removal and Installation " .

4. Remove lock plate and separate brake tube from brake hose. Refer to BR-12, " Rear Brake Tube and Hose " .

5. Remove wheel hub and bearing assembly and back plate. Refer to RAX-5, " On-Vehicle Inspection and Service " .

6. Set jack under rear suspension beam.

7. Remove coil spring (left/right). Refer to RSU-11, " Removal and

Installation " .

8. Remove bolts between body and rear suspension beam bracket. Refer to RSU-8, " Component " .

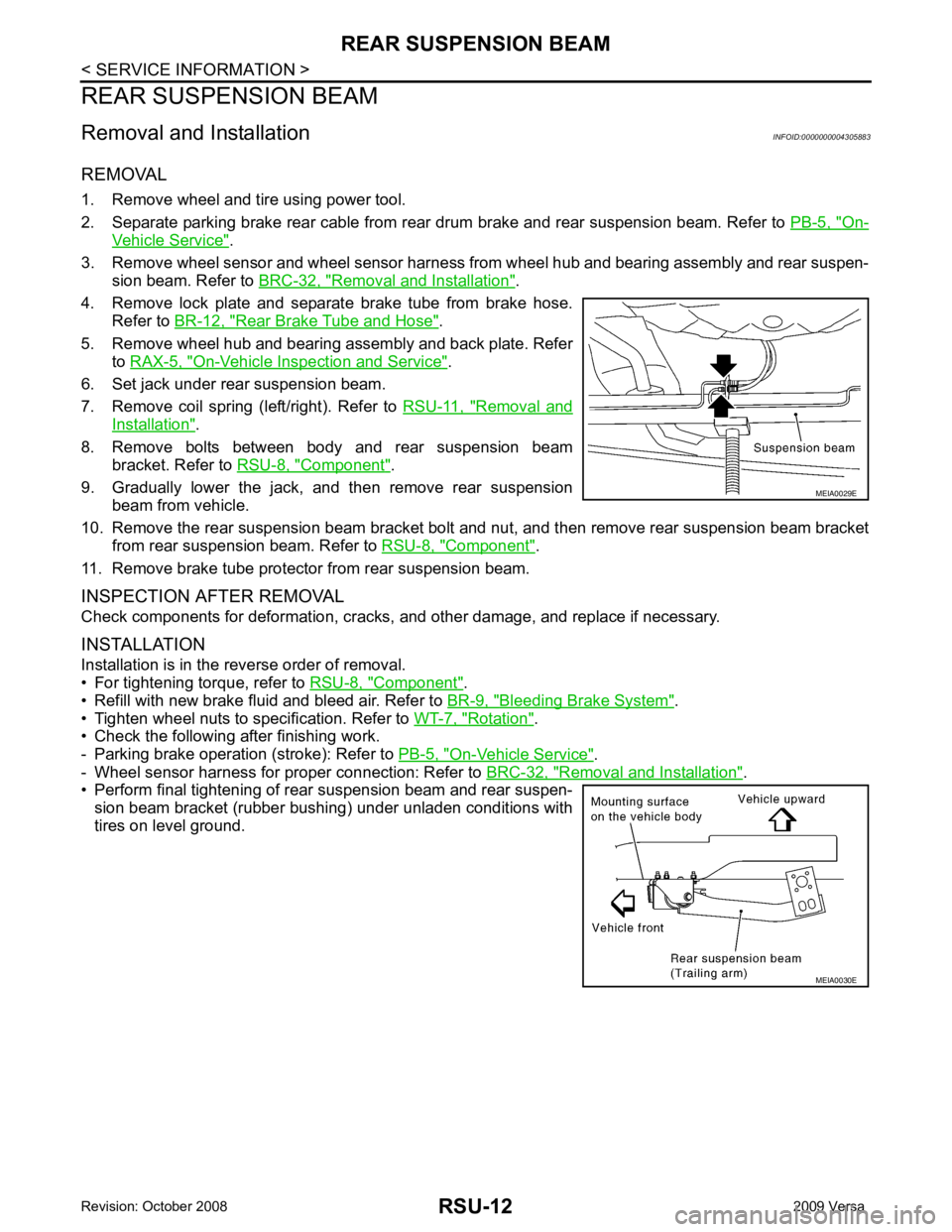

9. Gradually lower the jack, and then remove rear suspension beam from vehicle.

10. Remove the rear suspension beam bracket bolt and nut, and then remove rear suspension beam bracket

from rear suspension beam. Refer to RSU-8, " Component " .

11. Remove brake tube protector from rear suspension beam.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage, and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, " Component " .

• Refill with new brake fluid and bleed air. Refer to BR-9, " Bleeding Brake System " .

• Tighten wheel nuts to specification. Refer to WT-7, " Rotation " .

• Check the following after finishing work.

- Parking brake operation (stroke): Refer to PB-5, " On-Vehicle Service " .

- Wheel sensor harness for proper connection: Refer to BRC-32, " Removal and Installation " .

• Perform final tightening of rear suspension beam and rear suspen-

sion beam bracket (rubber bushing) under unladen conditions with

tires on level ground. MEIA0030E