NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3181 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-234< SERVICE INFORMATION >

[MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

CONNECTING ROD Unit: mm (in)

*: After installing in connecting rod

CRANKSHAFT Unit: mm (in)

Items Standard Li NISSAN LATIO 2009 Service Repair Manual EM-234< SERVICE INFORMATION >

[MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

CONNECTING ROD Unit: mm (in)

*: After installing in connecting rod

CRANKSHAFT Unit: mm (in)

Items Standard Li](/img/5/57359/w960_57359-3180.png)

EM-234< SERVICE INFORMATION >

[MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

CONNECTING ROD Unit: mm (in)

*: After installing in connecting rod

CRANKSHAFT Unit: mm (in)

Items Standard Limit

Piston pin outer diameter 19.989 - 19.995 (0.7870 - 0.7872) —

Piston to piston pin oil clearance 0.002 - 0.006 (0.0001 - 0.0002) —

Connecting rod bushing oil clearance 0.005 - 0.023 (0.0002 - 0.0009) 0.03 (0.0012) Center distance

143.44 - 143.54 (5.647 - 5.650)

Bend [per 100 (3.94)] Limit 0.15 (0.0059)

Torsion [per 100 (3.94)] Limit 0.30 (0.0118)

Connecting rod bushing inner diameter* 20.000 - 20.012 (0.7874 - 0.7879)

Side clearance Standard 0.20 - 0.35 (0.0079 - 0.0138)

Limit 0.40 (0.0157)

Connecting rod big end diameter Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N 47.000 - 47.001 (1.8504 - 1.8504)

47.001 - 47.002 (1.8504 - 1.8505)

47.002 - 47.003 (1.8505 - 1.8505)

47.003 - 47.004 (1.8505 - 1.8505)

47.004 - 47.005 (1.8505 - 1.8506)

47.005 - 47.006 (1.8506 - 1.8506)

47.006 - 47.007 (1.8506 - 1.8507)

47.007 - 47.008 (1.8507 - 1.8507)

47.008 - 47.009 (1.8507- 1.8507)

47.009 - 47.010 (1.8507- 1.8508)

47.010 - 47.011 (1.8508 - 1.8508)

47.011 - 47.012 (1.8508 - 1.8509)

47.012 - 47.013 (1.8509 - 1.8509) Center distance (r)

40.41 - 40.49 (1.5909 - 1.5940)

Out-of-round [Difference between (X) and (Y)] Limit 0.0035 (0.0001)

Taper [Difference between (A) and (B)] Limit 0.0035 (0.0001)

Runout [TIR*] Standard 0.05 (0.0020)

Limit 0.10 (0.0040)

Crankshaft end play Standard 0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.012) SEM645 PBIC3459J

Page 3182 of 4331

EM

NP

O

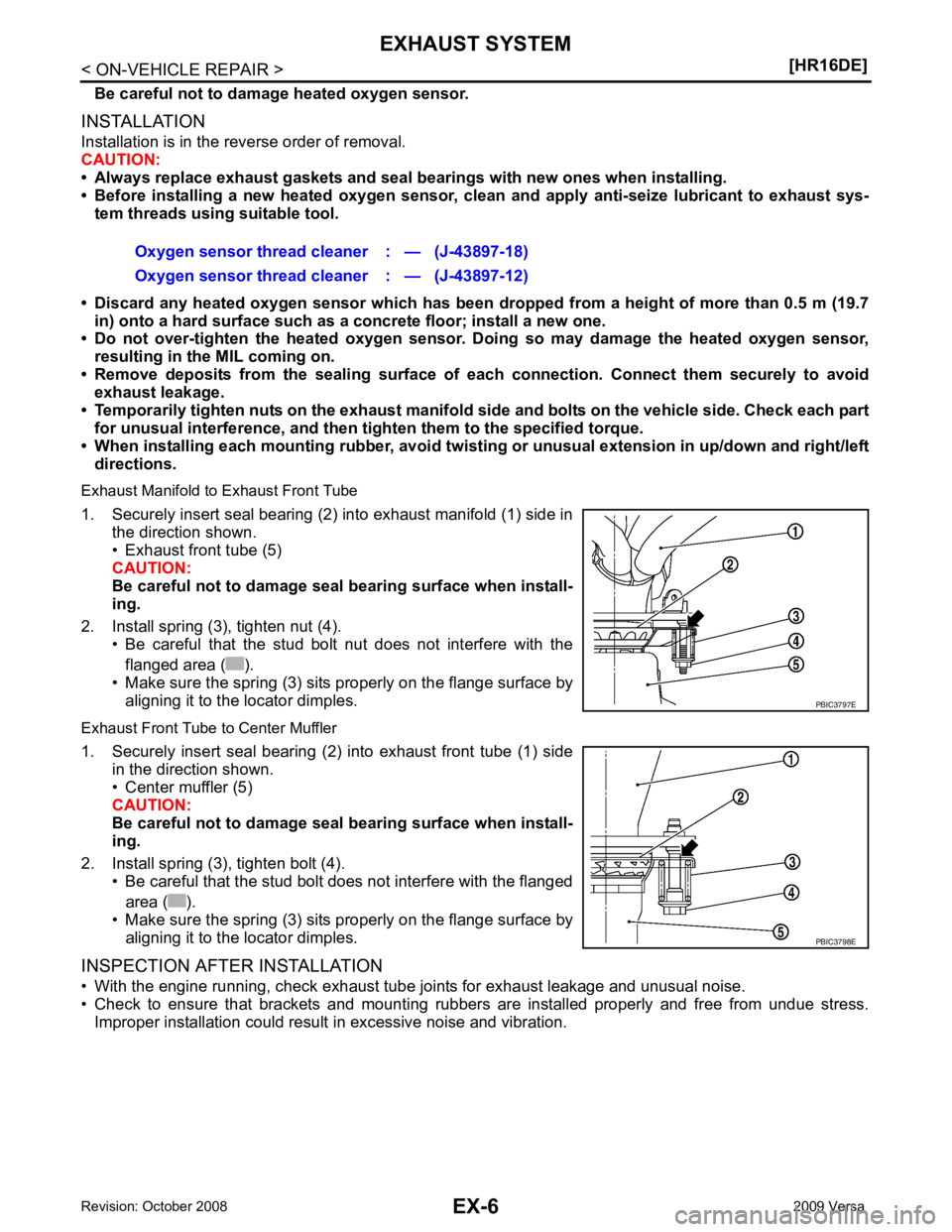

*: Total indicator reading

MAIN BEARING Unit: mm (in)

Pin journal diameter grade. (Dp)

Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U 43.970 - 43.971 (1.7311 - 1.7311)

43.969 - 43.970 (1.7311 - 1.7311)

43.968 - 43.969 (1.7310 - 1.7311)

43.967 - 43.968 (1.7310 - 1.7310)

43.966 - 43.967 (1.7309 - 1.7310)

43.965 - 43.966 (1.7309 - 1.7309)

43.964 - 43.965 (1.7309 - 1.7309)

43.963 - 43.964 (1.7308 - 1.7309)

43.962 - 43.963 (1.7308 - 1.7308)

43.961 - 43.962 (1.7307 - 1.7308)

43.960 - 43.961 (1.7307 - 1.7307)

43.959 - 43.960 (1.7307 - 1.7307)

43.958 - 43.959 (1.7306 - 1.7307)

43.957 - 43.958 (1.7306 - 1.7306)

43.956 - 43.957 (1.7305 - 1.7306)

43.955 - 43.956 (1.7305 - 1.7305)

43.954 - 43.955 (1.7305 - 1.7305)

43.953 - 43.954 (1.7304 - 1.7305)

Main journal diameter grade. (Dm) Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W 51.978 - 51.979 (2.0464 - 2.0464)

51.977 - 51.978 (2.0463 - 2.0464)

51.976 - 51.977 (2.0463 - 2.0463)

51.975 - 51.976 (2.0463 - 2.0463)

51.974 - 51.975 (2.0462 - 2.0463)

51.973 - 51.974 (2.0462 - 2.0462)

51.972 - 51.973 (2.0461 - 2.0462)

51.971 - 51.972 (2.0461 - 2.0461)

51.970 - 51.971 (2.0461 - 2.0461)

51.969 - 51.970 (2.0460 - 2.0461)

51.968 - 51.969 (2.0460 - 2.0460)

51.967 - 51.968 (2.0459 - 2.0460)

51.966 - 51.967 (2.0459 - 2.0459)

51.965 - 51.966 (2.0459 - 2.0459)

51.964 - 51.965 (2.0458 - 2.0459)

51.963 - 51.964 (2.0458 - 2.0458)

51.962 - 51.963 (2.0457 - 2.0458)

51.961 - 51.962 (2.0457 - 2.0457)

51.960 - 51.961 (2.0457 - 2.0457)

51.959 - 51.960 (2.0456 - 2.0457) Grade number Thickness Identification color Remarks

0 1.996 - 1.999 (0.0786 - 0.0787) Black

Grade and color are the same

for upper and lower bearings.

1 1.999 - 2.002 (0.0787 - 0.0788) Brown

2 2.002 - 2.005 (0.0788 - 0.0789) Green

3 2.005 - 2.008 (0.0789 - 0.0791) Yellow

4 2.008 - 2.011 (0.0791 - 0.0792) Blue

5 2.011 - 2.014 (0.0792 - 0.0793) Pink

6 2.014 - 2.017 (0.0793 - 0.0794) Purple

7 2.017 - 2.020 (0.0794 - 0.0795) White

Page 3183 of 4331

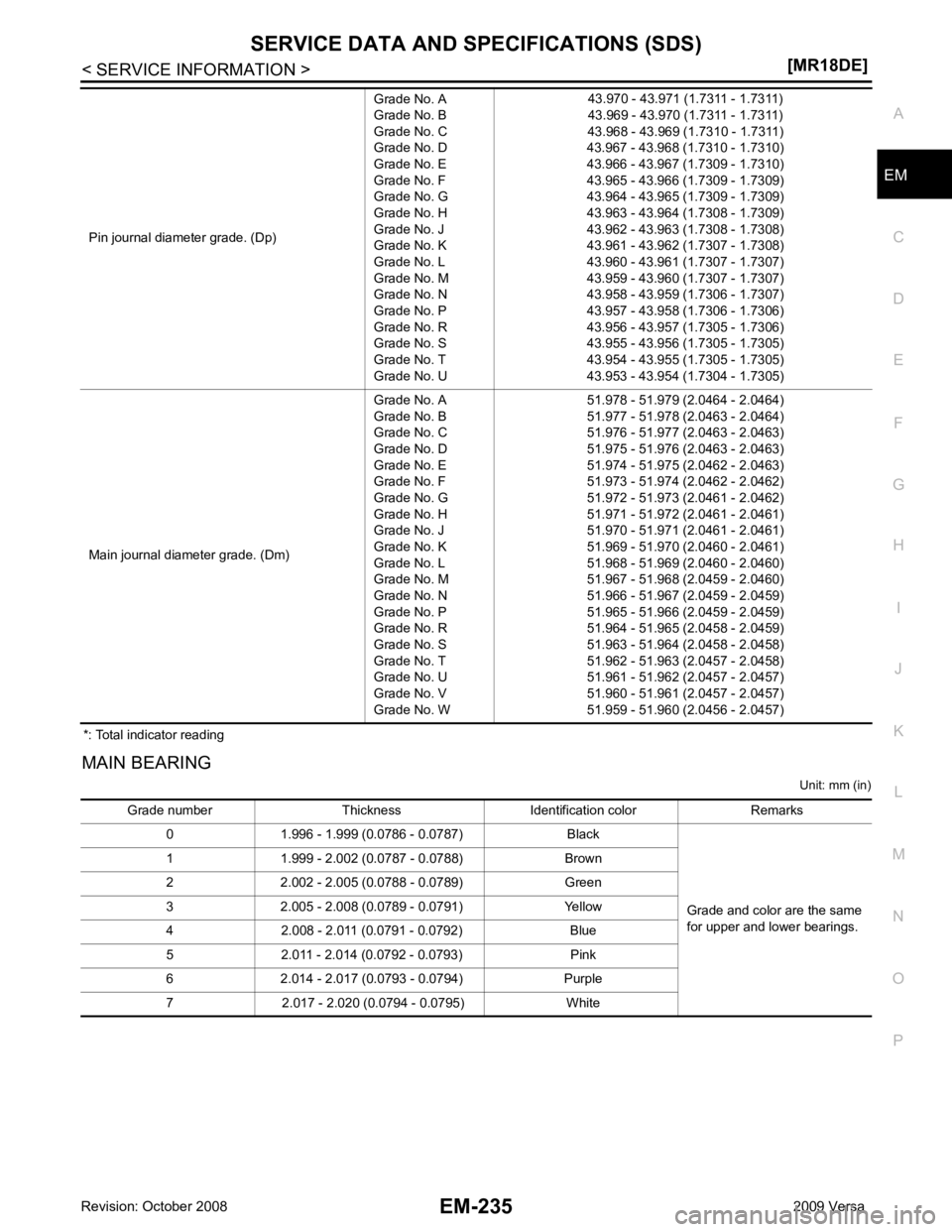

Item Thickness Main journal diameter

US 0.25 (0.0098) 2.126 - 2.134 (0.0837 - 0.0840) Grind so that bearing clearance is the specified value. Main bearing oil clearance

StandardNo. 1, 4 and 5 0.024 - 0.034 (0.0009 - 0.0013)

No. 2 and 3 0.012 - 0.022 (0.0005 - 0.0009)

Limit 0.065 (0.0026) Grade number Thickness mm (in) Identification color Remarks

0 1.494 - 1.497 (0.0588 - 0.0589) Black

Grade and color are the same for upper and lower bearings.

1 1.497 - 1.500 (0.0589 - 0.0591) Brown

2 1.500 - 1.503 (0.0591 - 0.0592) Green

3 1.503 - 1.506 (0.0592 - 0.0593) Yellow

4 1.506 - 1.509 (0.0593 - 0.0594) Blue

01 UPR 1.494 - 1.497 (0.0588 - 0.0589) Black

Grade and color are different

between upper and lower bear- ings.

LWR 1.497 - 1.500 (0.0589 - 0.0591) Brown

12 UPR 1.497 - 1.500 (0.0589 - 0.0591) Brown

LWR 1.500 - 1.503 (0.0591 - 0.0592) Green

23 UPR 1.500 - 1.503 (0.0591 - 0.0592) Green

LWR 1.503 - 1.506 (0.0592 - 0.0593) Yellow

34 UPR 1.503 - 1.506 (0.0592 - 0.0593) Yellow

LWR 1.506 - 1.509 (0.0593 - 0.0594) Blue Item Thickness Crank pin journal diameter

US 0.25 (0.0098) 1.623 - 1.631 (0.0639 - 0.0642) Grind so that bearing clearance is the specified value.

Page 3184 of 4331

EM

NP

O

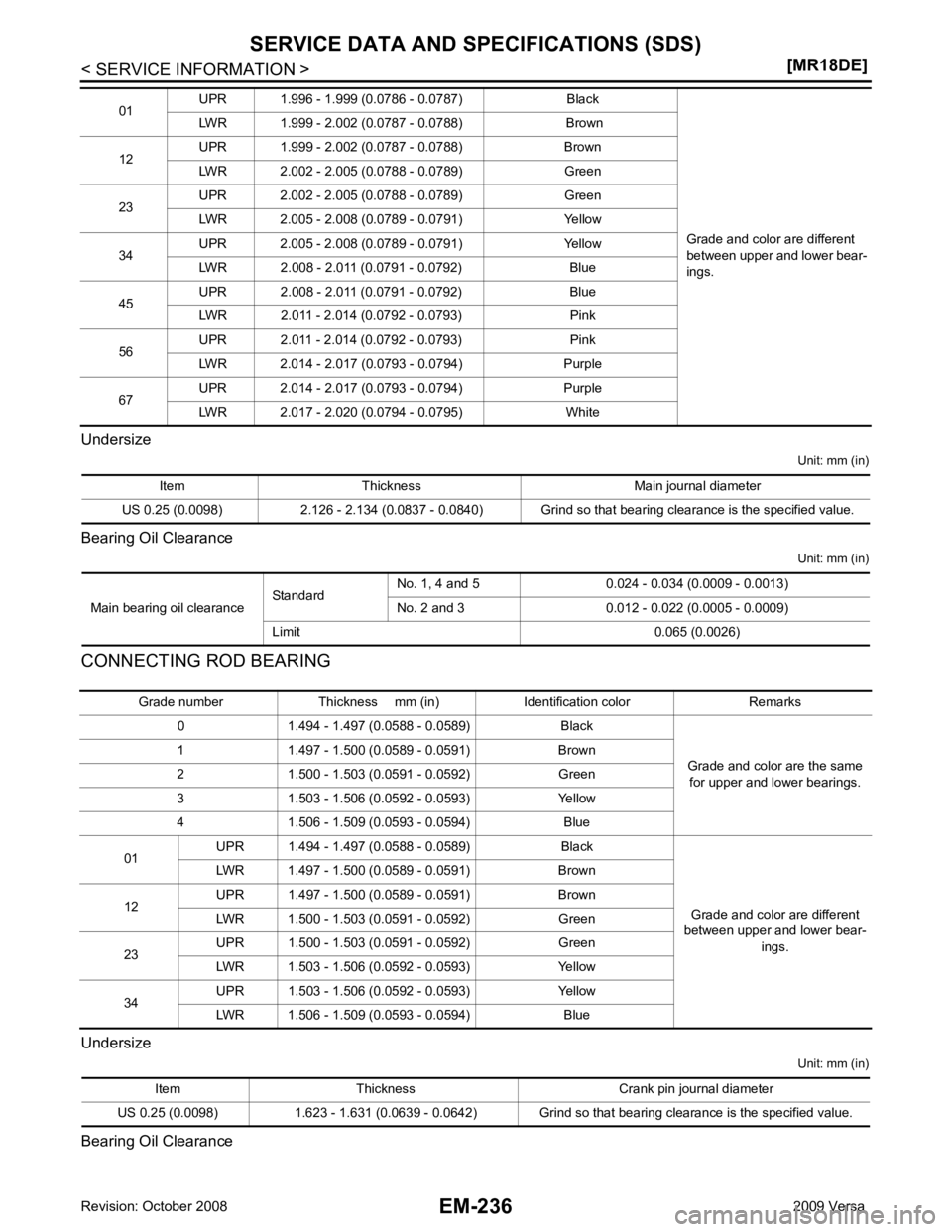

Unit: mm (in)

FLYWHEEL Unit: mm (in)

Connecting rod bearing oil clearance

Standard 0.037 - 0.047 (0.0015 - 0.0019)

Limit 0.07 (0.0028) Items Standard Limit

Flywheel deflection — 0.45 (0.0177) or less

Movement amount in thrust direction 1.8 (0.071) or less —

Movement amount in radial direction — 33.2 (1.307) or less

Page 3185 of 4331

EX

N

O P

CONTENTS

EXHAUST SYSTEM

HR16DE

PRECAUTION ....... ........................................

2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION .... ........................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool .................................... ......3

ON-VEHICLE MAINTENA NCE .....................4

EXHAUST SYSTEM ....................................... .....4

Checking Exhaust System .................................. ......4

ON-VEHICLE REPAIR .... ..............................5 EXHAUST SYSTEM

........................................... 5

Component .......................................................... .....5

Removal and Installation ..................................... .....5

MR18DE

SERVICE INFORMATION .. ..........................7

PRECAUTIONS .................................................. 7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. .....

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... .....

7

PREPARATION .................................................. 8

Special Service Tool ............................................ .....8

Commercial Service Tool .................................... .....8

EXHAUST SYSTEM ........................................... 9

Checking Exhaust System ................................... .....9

Component .......................................................... .....9

Removal and Installation ..................................... .....9

Page 3186 of 4331

Page 3187 of 4331

![NISSAN LATIO 2009 Service Repair Manual PREPARATION

EX-3

< PREPARATION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EX

NP

O

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004784375

Commercial Service Tool INFOID:0000000004784394

Tool numb NISSAN LATIO 2009 Service Repair Manual PREPARATION

EX-3

< PREPARATION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EX

NP

O

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004784375

Commercial Service Tool INFOID:0000000004784394

Tool numb](/img/5/57359/w960_57359-3186.png)

PREPARATION

EX-3

< PREPARATION >

[HR16DE] C

D E

F

G H

I

J

K L

M A EX

NP

O

PREPARATION

PREPARATION

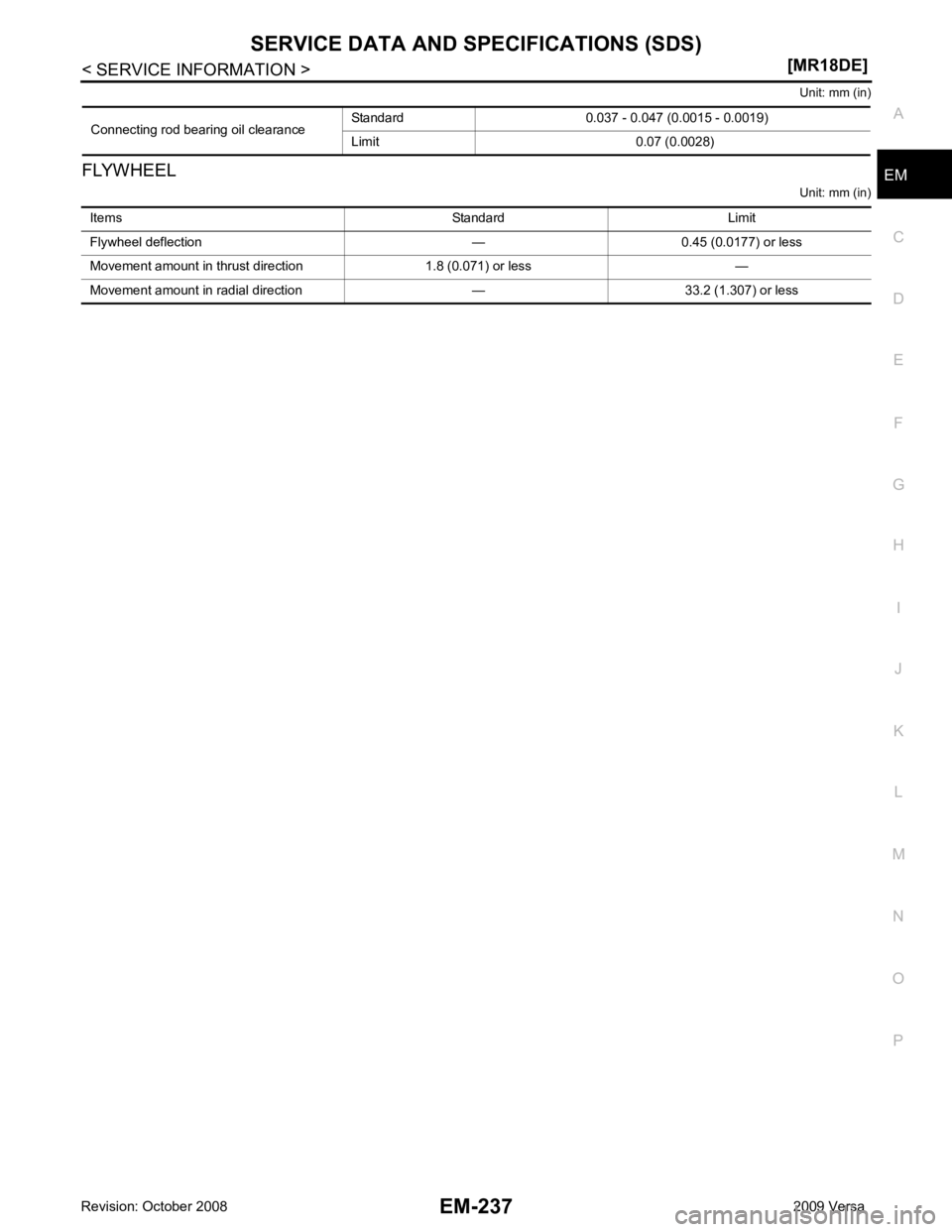

Special Service Tool INFOID:0000000004784375

Commercial Service Tool INFOID:0000000004784394

Tool number

Tool name Description

KV10114400

(J-38365)

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sor

a: 22 mm (0.87 in) NT636

(Kent-Moore No.)

Tool name Description

(J-43897-18)

(J-43897-12)

Heated oxygen sensor thread cleaner Reconditioning the exhaust system threads

before installing new heated oxygen and Air

fuel ratio sensors (Use with anti-seize lubri-

cant shown below.)

a: 18 mm (0.71 in) dia. for zirconia heated

oxygen sensor

b: 12 mm (0.47 in) dia. for titania heated ox-

ygen sensor

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating heated oxygen sensor thread

cleaner when reconditioning exhaust system

threads

Power tool Loosening bolts and nuts AEM488

AEM489

PBIC0190E

Page 3188 of 4331

Page 3189 of 4331

EX

NP

O

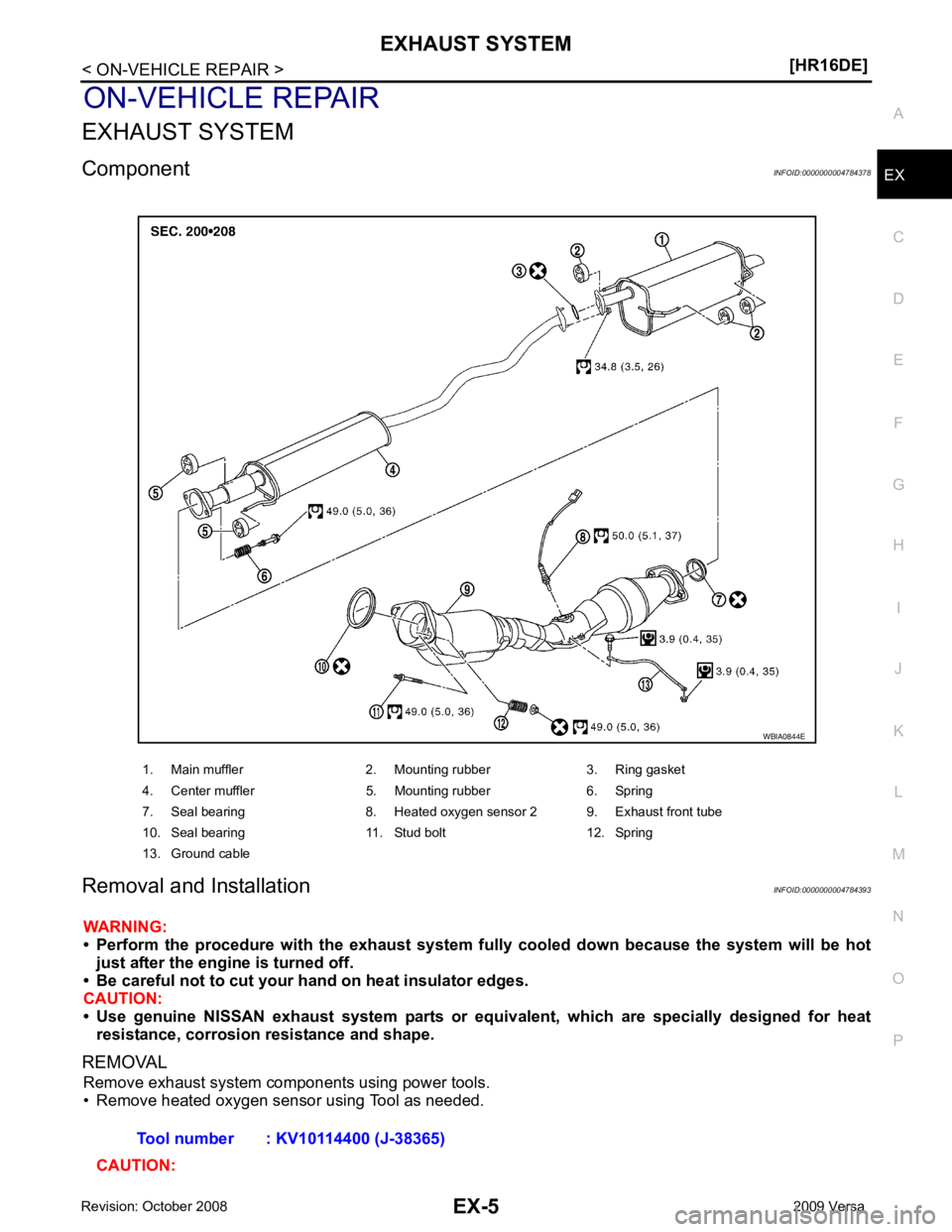

ON-VEHICLE REPAIR

EXHAUST SYSTEM

Component INFOID:0000000004784378

Removal and Installation INFOID:0000000004784393

WARNING:

• Perform the procedure with the exhaust system fu lly cooled down because the system will be hot

just after the engine is turned off.

• Be careful not to cut your hand on heat insulator edges.

CAUTION:

• Use genuine NISSAN exhaust system parts or equi valent, which are specially designed for heat

resistance, corrosion resistance and shape.

REMOVAL Remove exhaust system components using power tools.

• Remove heated oxygen sensor using Tool as needed.

CAUTION: 1. Main muffler 2. Mounting rubber 3. Ring gasket

4. Center muffler 5. Mounting rubber 6. Spring

7. Seal bearing 8. Heated oxygen sensor 2 9. Exhaust front tube

10. Seal bearing 11. Stud bolt 12. Spring

13. Ground cable

Page 3190 of 4331