NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3201 of 4331

Removal and Installation " .

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

Removal and Installation INFOID:0000000004305844

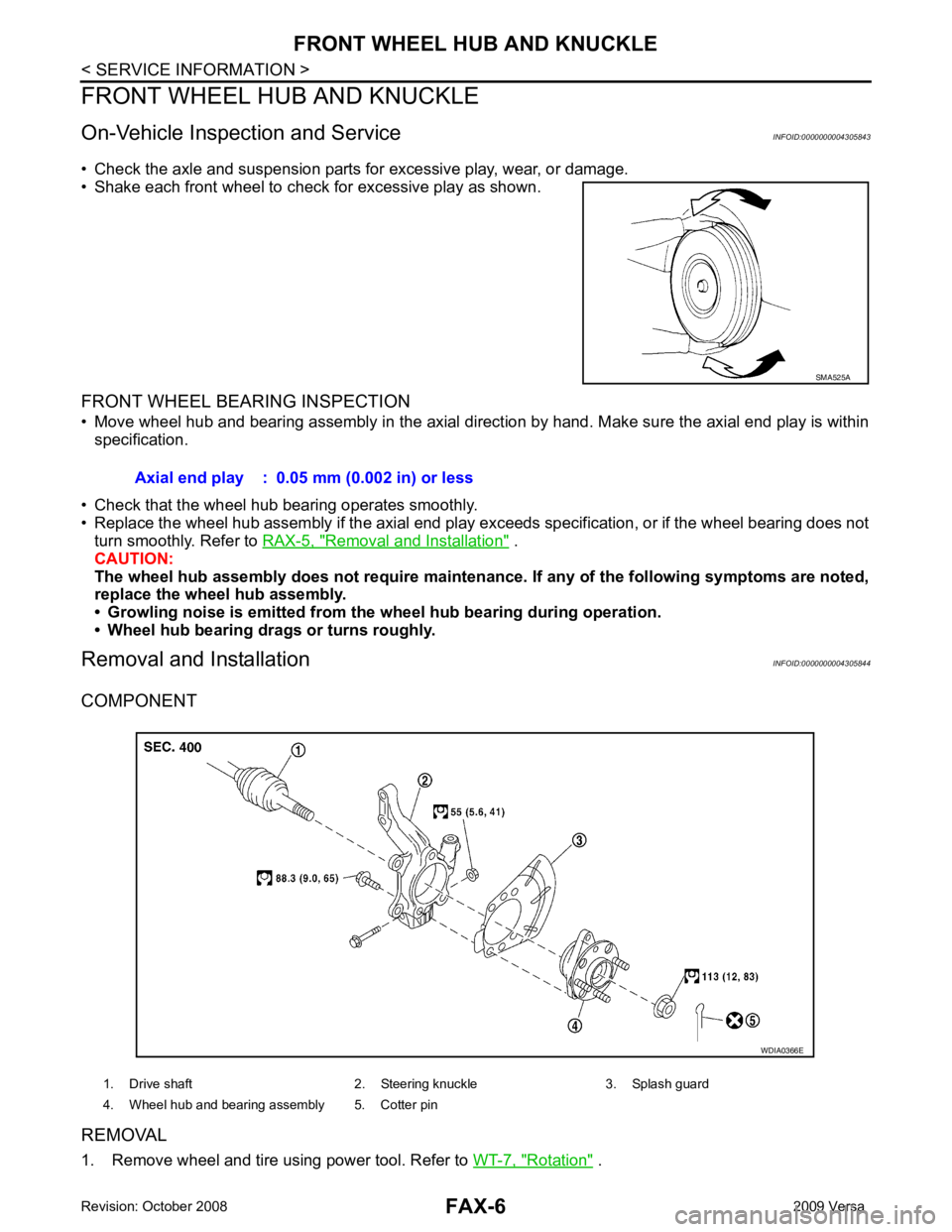

COMPONENT

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, " Rotation " .

Page 3202 of 4331

FAX

N

O P

2. Without disassembling the hydraulic lines, remove the torque member bolts using power tool. Then repo-

sition the torque member and brake caliper assembly aside with wire. Refer to BR-25 .

CAUTION:

Do not depress brake pedal while brake caliper is removed.

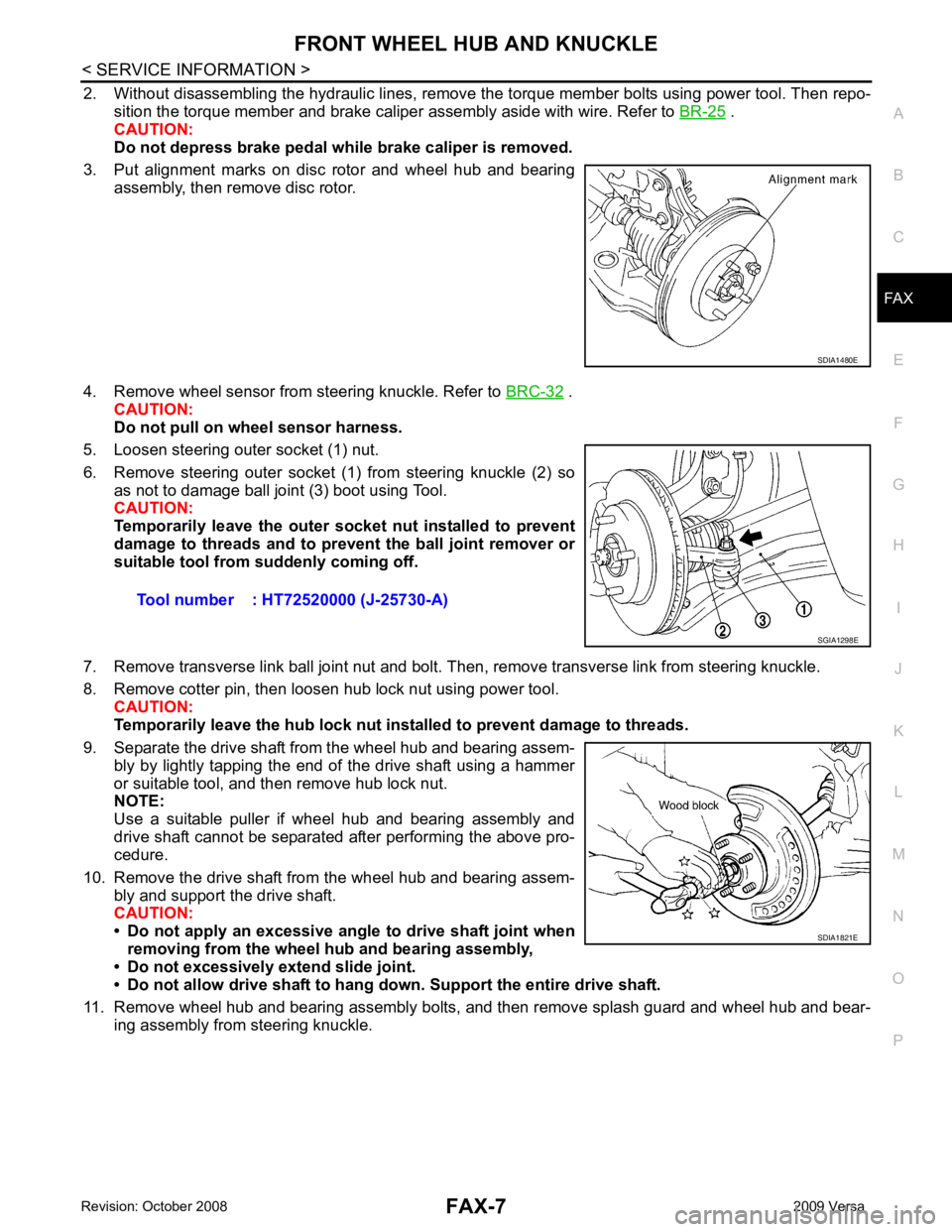

3. Put alignment marks on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

4. Remove wheel sensor from steering knuckle. Refer to BRC-32 .

CAUTION:

Do not pull on wheel sensor harness.

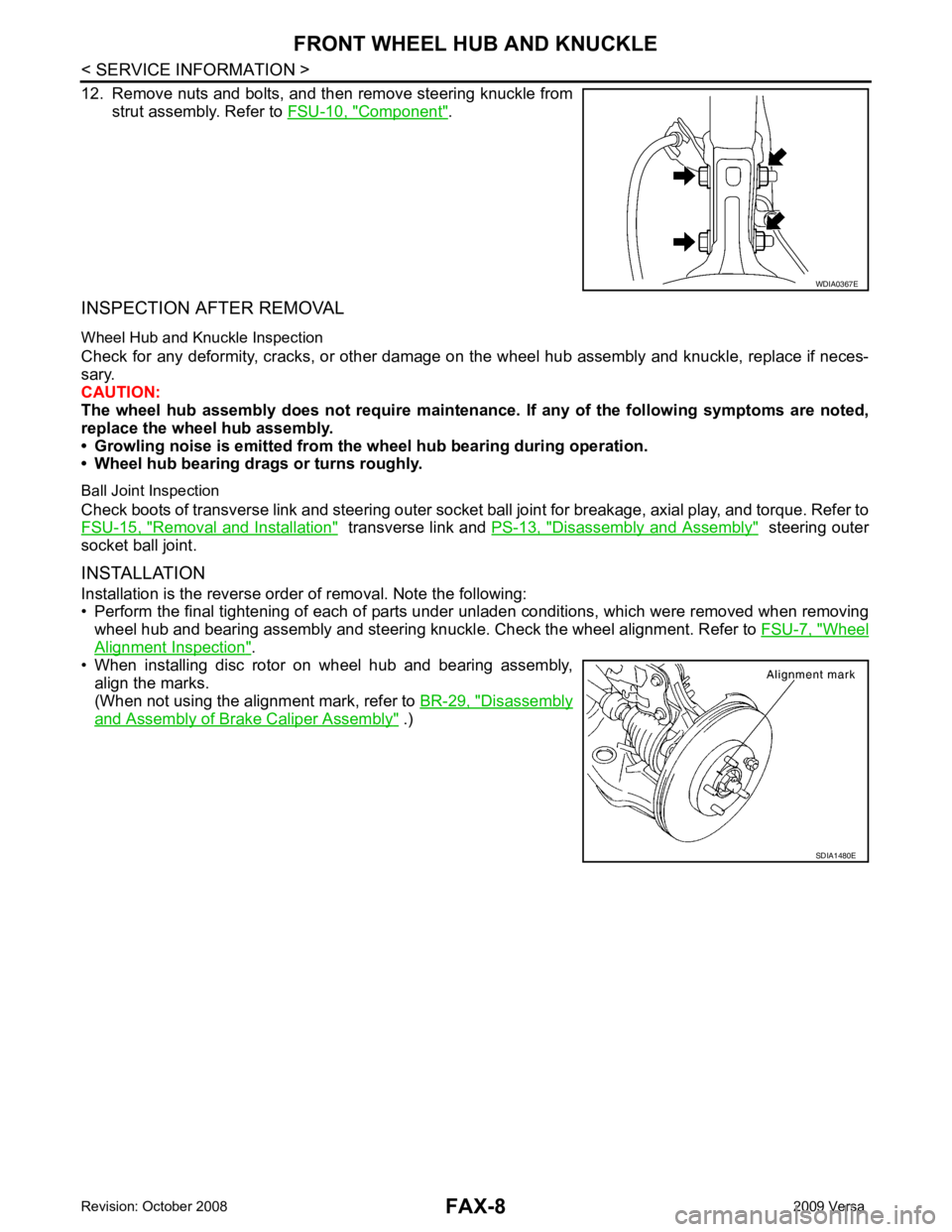

5. Loosen steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so as not to damage ball joint (3) boot using Tool.

CAUTION:

Temporarily leave the outer so cket nut installed to prevent

damage to threads and to pr event the ball joint remover or

suitable tool from suddenly coming off.

7. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

8. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

9. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

10. Remove the drive shaft from the wheel hub and bearing assem- bly and support the drive shaft.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

11. Remove wheel hub and bearing assembly bolts, and then remove splash guard and wheel hub and bear- ing assembly from steering knuckle.

Page 3203 of 4331

FAX-8< SERVICE INFORMATION >

FRONT WHEEL HUB AND KNUCKLE

12. Remove nuts and bolts, and then remove steering knuckle from strut assembly. Refer to FSU-10, " Component " .

INSPECTION AFTER REMOVAL

Wheel Hub and Knuckle Inspection

Check for any deformity, cracks, or other damage on t he wheel hub assembly and knuckle, replace if neces-

sary.

CAUTION:

The wheel hub assembly does not require maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-15, " Removal and Installation " transverse link and

PS-13, " Disassembly and Assembly " steering outer

socket ball joint.

INSTALLATION

Installation is the reverse order of removal. Note the following:

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing

wheel hub and bearing assembly and steering knuckl e. Check the wheel alignment. Refer to FSU-7, " Wheel

Alignment Inspection " .

• When installing disc rotor on wheel hub and bearing assembly,

align the marks.

(When not using the alignment mark, refer to BR-29, " Disassembly

and Assembly of Brake Caliper Assembly " .) WDIA0367E

SDIA1480E

Page 3204 of 4331

FAX

N

O P

FRONT DRIVE SHAFT

On-Vehicle Inspection and Service INFOID:0000000004305845

• Check drive shaft mounting point and joint for looseness and other damage.

• Check boot for cracks and other damage.

Replace or repair components as necessary. Refer to FAX-9, " Removal and Installation (Left Side) " ,

FAX-10, " Removal and Installation (Right Side) " ,

FAX-13, " Disassembly and Assembly (Left Side) " or

FAX-18, " Disas-

sembly and Assembly (Right Side) " .

CAUTION:

Replace entire drive shaft assembly when noi se or vibration occur from drive shaft.

Removal and Installation (Left Side) INFOID:0000000004305846

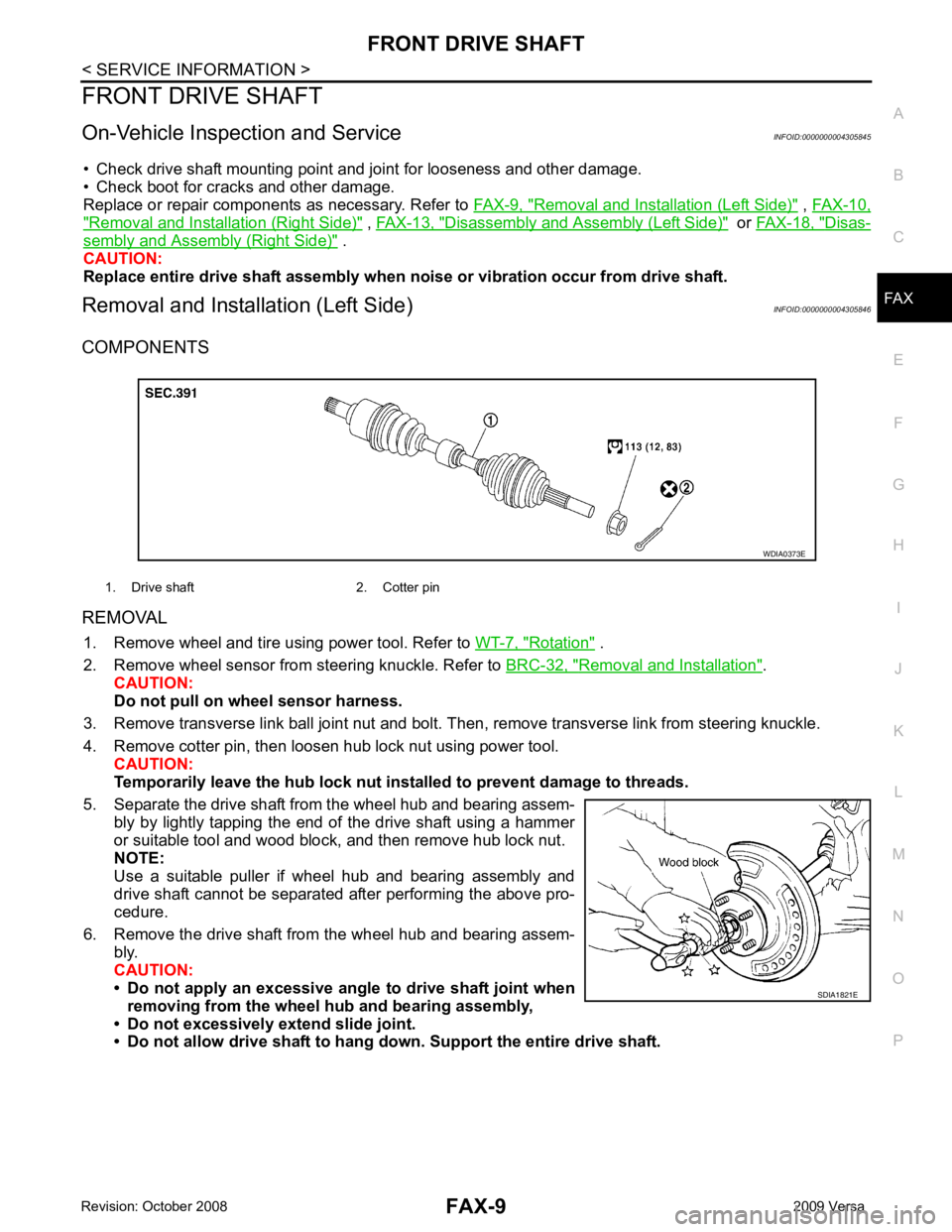

COMPONENTS

REMOVAL 1. Remove wheel and tire using power tool. Refer to WT-7, " Rotation " .

2. Remove wheel sensor from steering knuckle. Refer to BRC-32, " Removal and Installation " .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem- bly.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

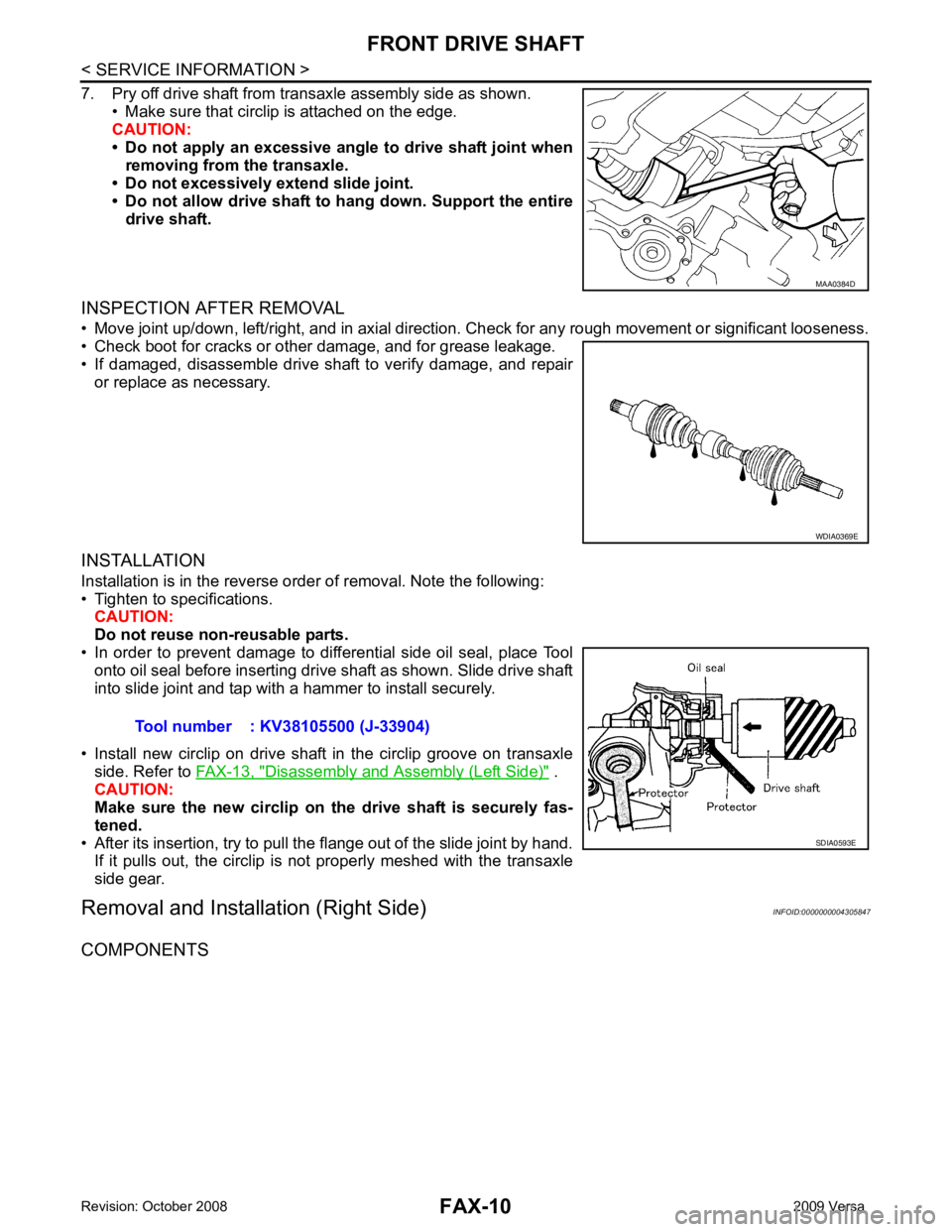

1. Drive shaft 2. Cotter pin

Page 3205 of 4331

Disassembly and Assembly (Left Side) " .

CAUTION:

Make sure the new circlip on the drive shaft is securely fas-

tened.

• After its insertion, try to pull the flange out of the slide joint by hand. If it pulls out, the circlip is not properly meshed with the transaxle

side gear.

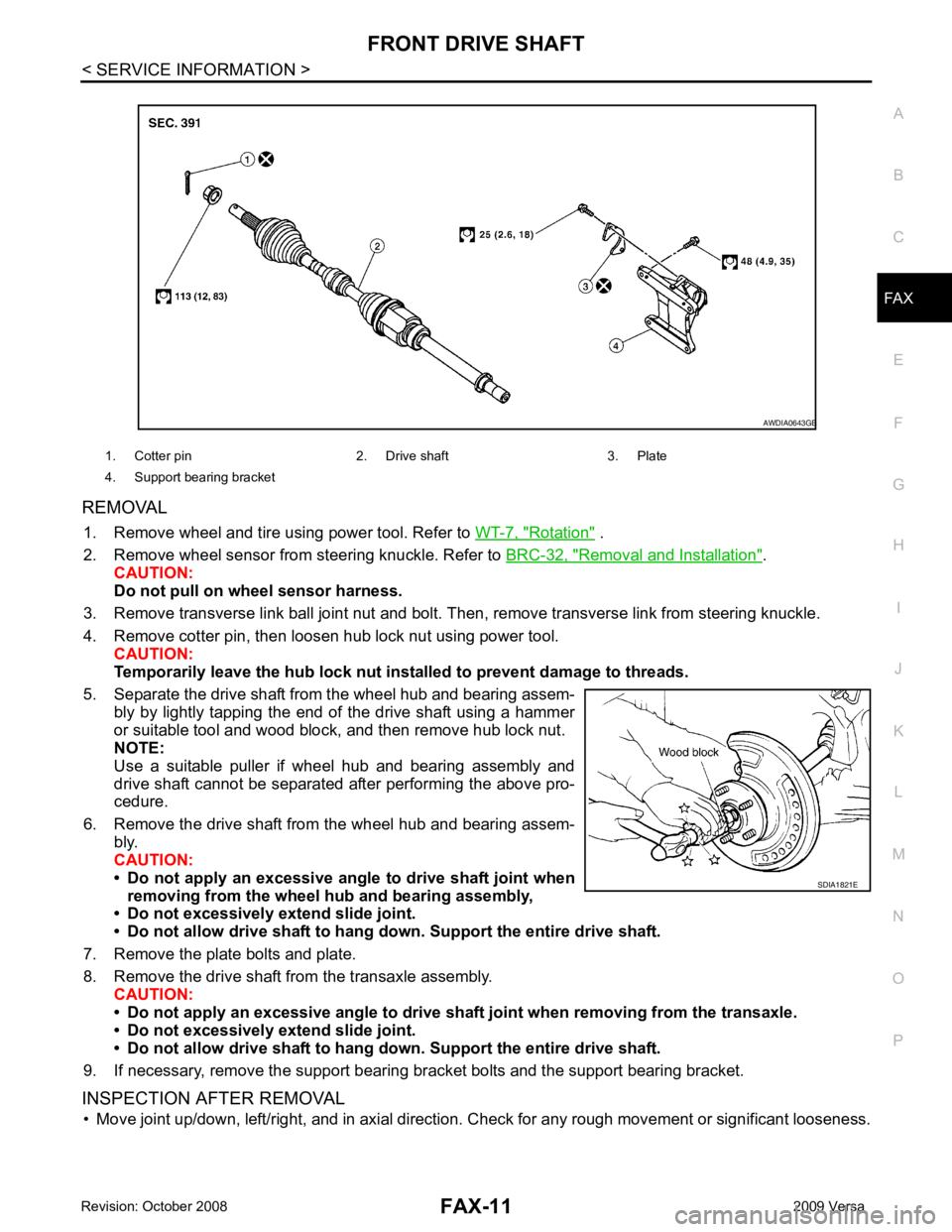

Removal and Installation (Right Side) INFOID:0000000004305847

COMPONENTS WDIA0369E

Page 3206 of 4331

FAX

N

O P

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, " Rotation " .

2. Remove wheel sensor from steering knuckle. Refer to BRC-32, " Removal and Installation " .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem- bly.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

7. Remove the plate bolts and plate.

8. Remove the drive shaft from the transaxle assembly. CAUTION:

• Do not apply an excessive angle to drive shaf t joint when removing from the transaxle.

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

9. If necessary, remove the support bearing bracket bolts and the support bearing bracket.

INSPECTION AFTER REMOVAL • Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

1. Cotter pin 2. Drive shaft 3. Plate

4. Support bearing bracket B

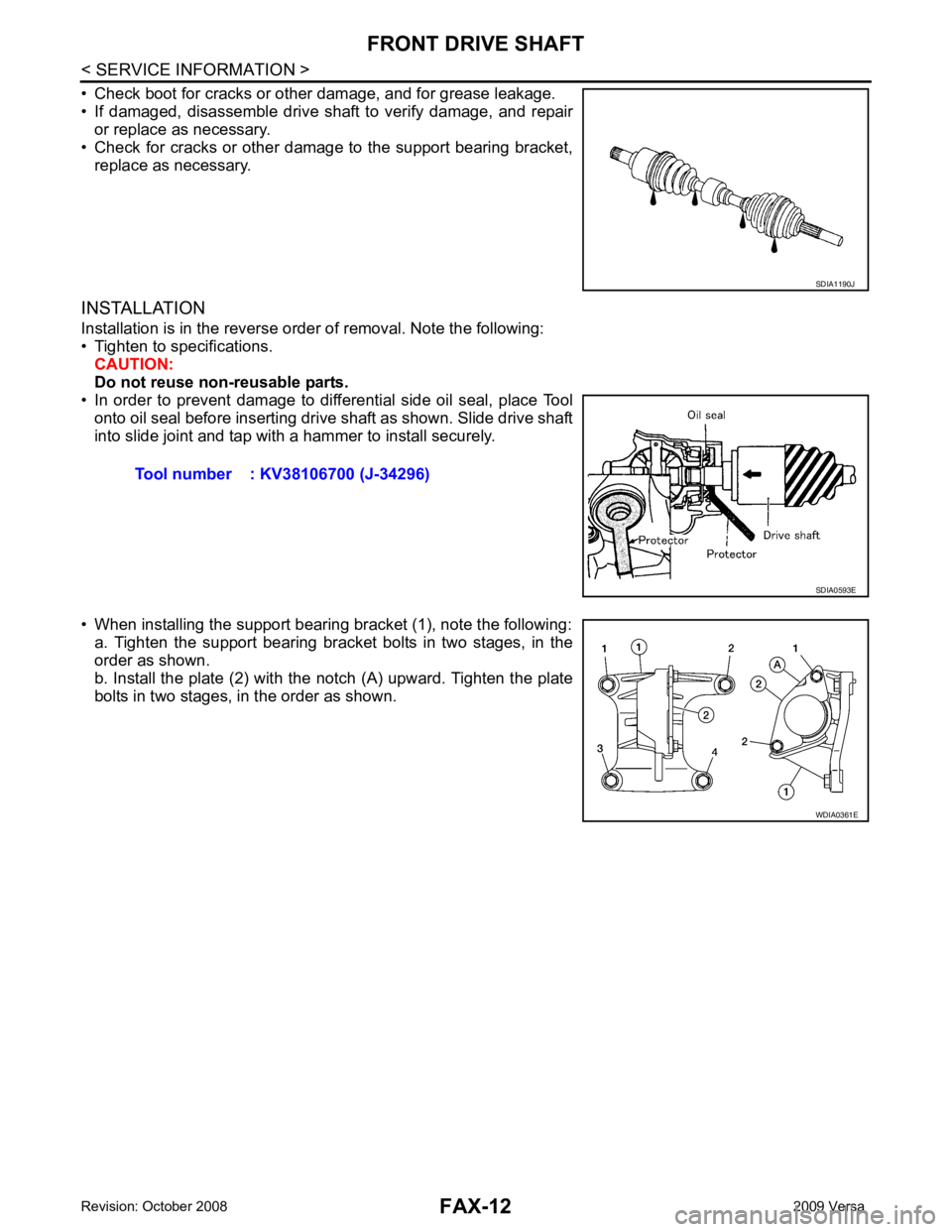

Page 3207 of 4331

Page 3208 of 4331

FAX

N

O P

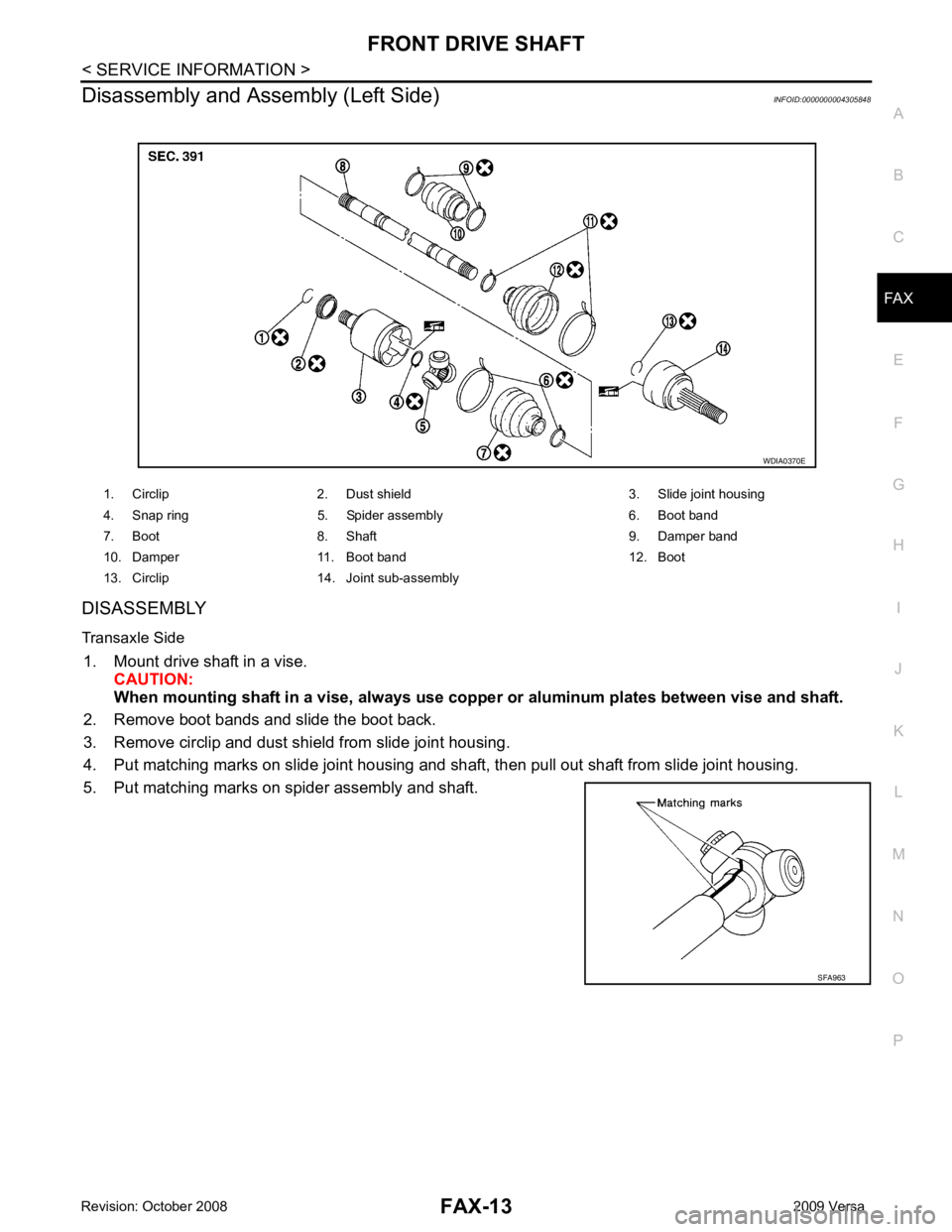

Disassembly and Assembly (Left Side)

INFOID:0000000004305848

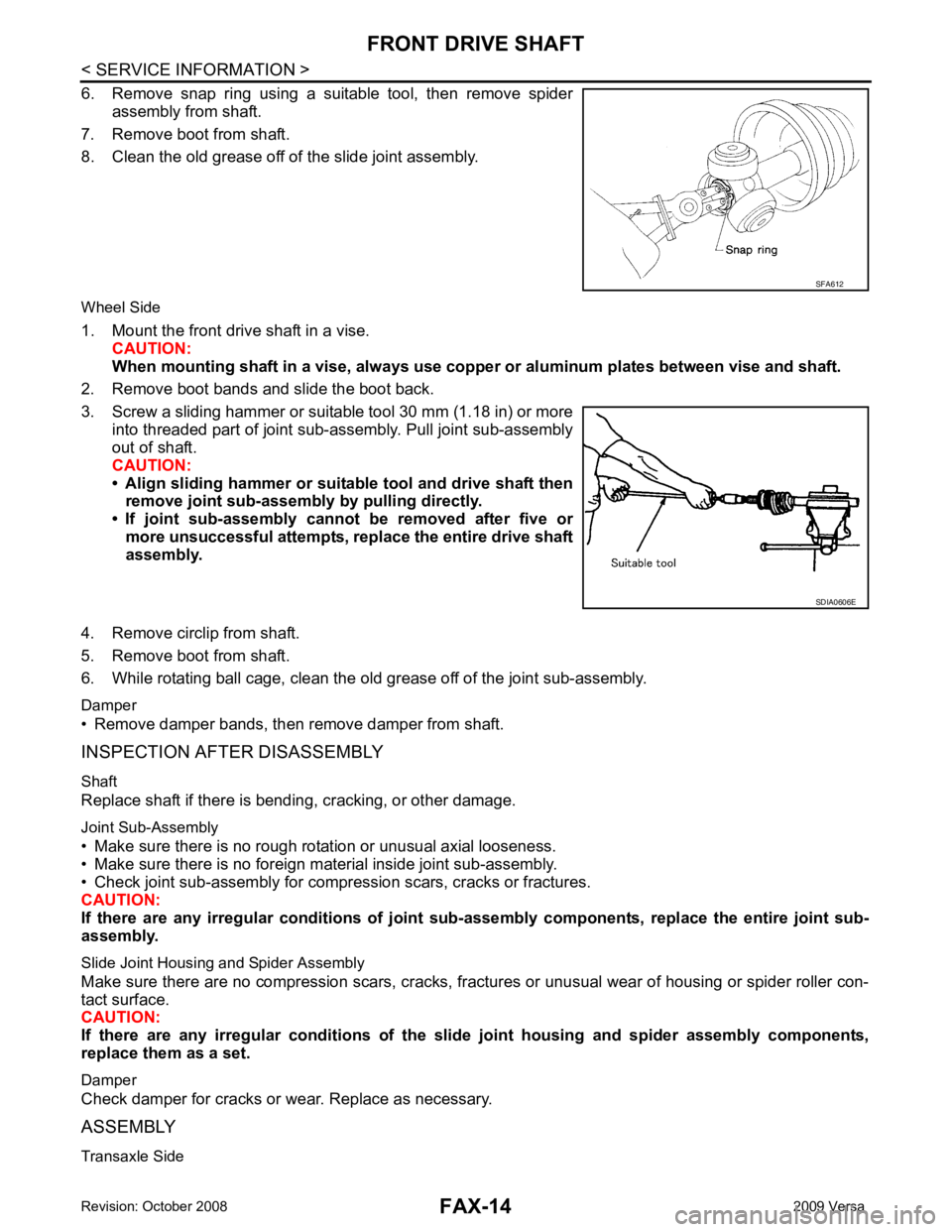

DISASSEMBLY

Transaxle Side 1. Mount drive shaft in a vise. CAUTION:

When mounting shaft in a vise, always use copper or alum inum plates between vise and shaft.

2. Remove boot bands and slide the boot back.

3. Remove circlip and dust shield from slide joint housing.

4. Put matching marks on slide joint housing and shaf t, then pull out shaft from slide joint housing.

5. Put matching marks on spider assembly and shaft. 1. Circlip 2. Dust shield 3. Slide joint housing

4. Snap ring 5. Spider assembly 6. Boot band

7. Boot 8. Shaft 9. Damper band

10. Damper 11. Boot band 12. Boot

13. Circlip 14. Joint sub-assembly SFA963

Page 3209 of 4331

SDIA0606E

Page 3210 of 4331

FAX

N

O P

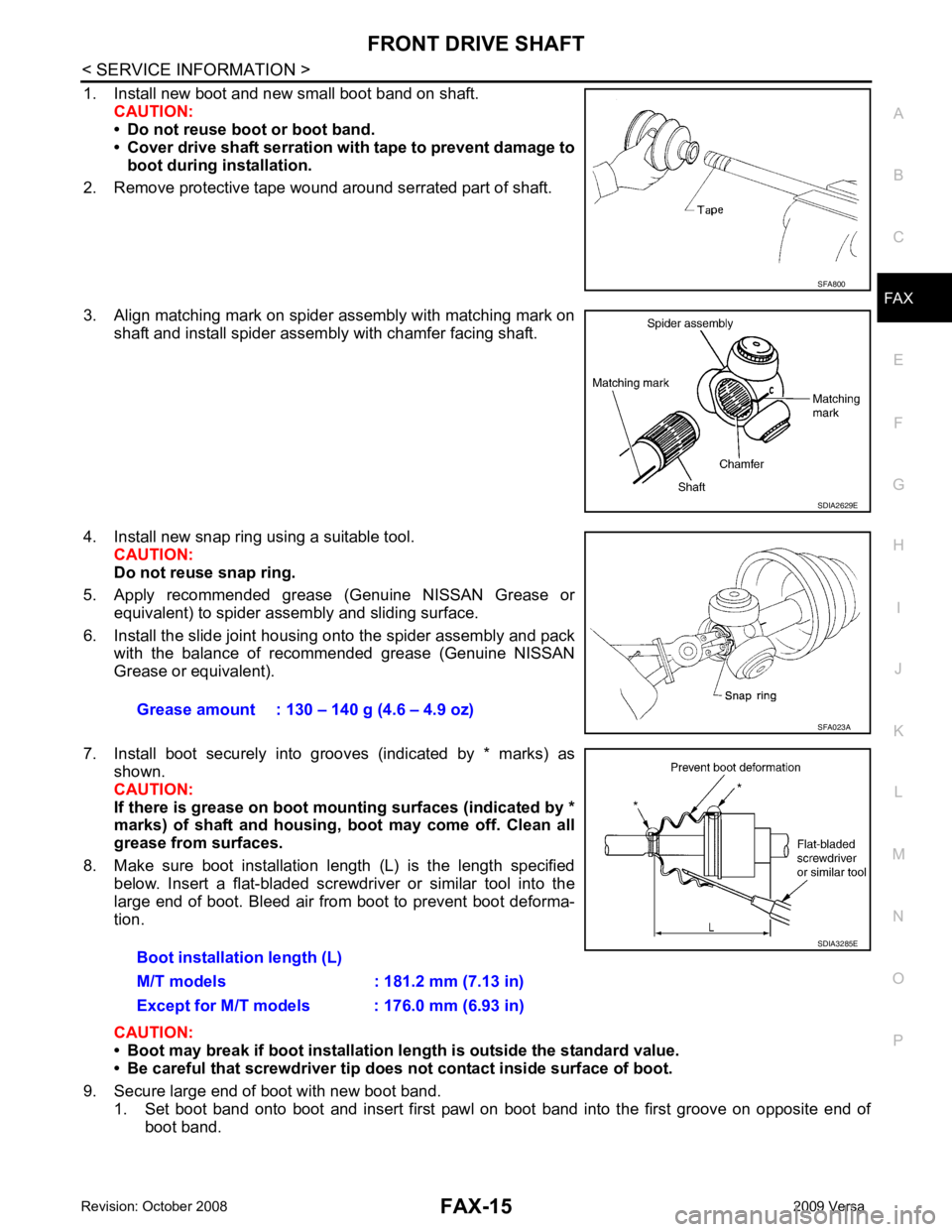

1. Install new boot and new small boot band on shaft.

CAUTION:

• Do not reuse boot or boot band.

• Cover drive shaft serration with tape to prevent damage to

boot during installation.

2. Remove protective tape wound around serrated part of shaft.

3. Align matching mark on spider assembly with matching mark on shaft and install spider assembly with chamfer facing shaft.

4. Install new snap ring using a suitable tool. CAUTION:

Do not reuse snap ring.

5. Apply recommended grease (Genuine NISSAN Grease or equivalent) to spider assembly and sliding surface.

6. Install the slide joint housing onto the spider assembly and pack with the balance of recommended grease (Genuine NISSAN

Grease or equivalent).

7. Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Clean all

grease from surfaces.

8. Make sure boot installation length (L) is the length specified below. Insert a flat-bladed screwdriver or similar tool into the

large end of boot. Bleed air from boot to prevent boot deforma-

tion.

CAUTION:

• Boot may break if boot installation le ngth is outside the standard value.

• Be careful that screwdriver tip does not contact inside surface of boot.

9. Secure large end of boot with new boot band. 1. Set boot band onto boot and insert first pawl on boot band into the first groove on opposite end of boot band.