NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3141 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-194< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

VALVE SPRING SQUARENESS

• Set try square along the side of valve spring and rotate the spring. Measure the maximum clearance between the to NISSAN LATIO 2009 Service Repair Manual EM-194< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

VALVE SPRING SQUARENESS

• Set try square along the side of valve spring and rotate the spring. Measure the maximum clearance between the to](/img/5/57359/w960_57359-3140.png)

EM-194< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

VALVE SPRING SQUARENESS

• Set try square along the side of valve spring and rotate the spring. Measure the maximum clearance between the top of valve spring

and try square.

CAUTION:

Never remove valve spring seat from valve spring.

• If it exceeds the limit, replace valve spring (with valve spring seat).

VALVE SPRING DIMENSIONS AND VALVE SPRING PRESSURE LOAD

• Check valve spring pressure with valve spring seat installed at the specified spring height.

CAUTION:

Never remove valve spring seat from valve spring.

Standard:

• If the installation load or load with valve open is out of the standard, replace valve spring (with valve spring seat). Limit: 1.9 mm (0.075 in) PBIC0080E

SEM113

Items Intake Exhaust

Free height 44.90 - 45.10 mm (1.7677 - 1.7755 in) 45.74 - 45.94 mm (1.8007 - 1.8086 in)

Installation height 35.30 mm (1.390 in) 35.30 mm (1.390 in)

Installation load 153 - 173 N (15.6 - 17.6 kg, 34 - 39 lb) 139 - 157 N (14.2 - 16 kg, 31 - 35 lb)

Height during valve open 26.36 mm (1.0377 in) 27.80 mm (1.0944 in)

Load with valve open 335 - 377 N (34.2 - 38.5 kg, 75 - 85 lb) 266 - 297 N (27.1 - 30.3 kg, 60 - 67 lb)

Identification color White Orange

Page 3142 of 4331

EM

NP

O

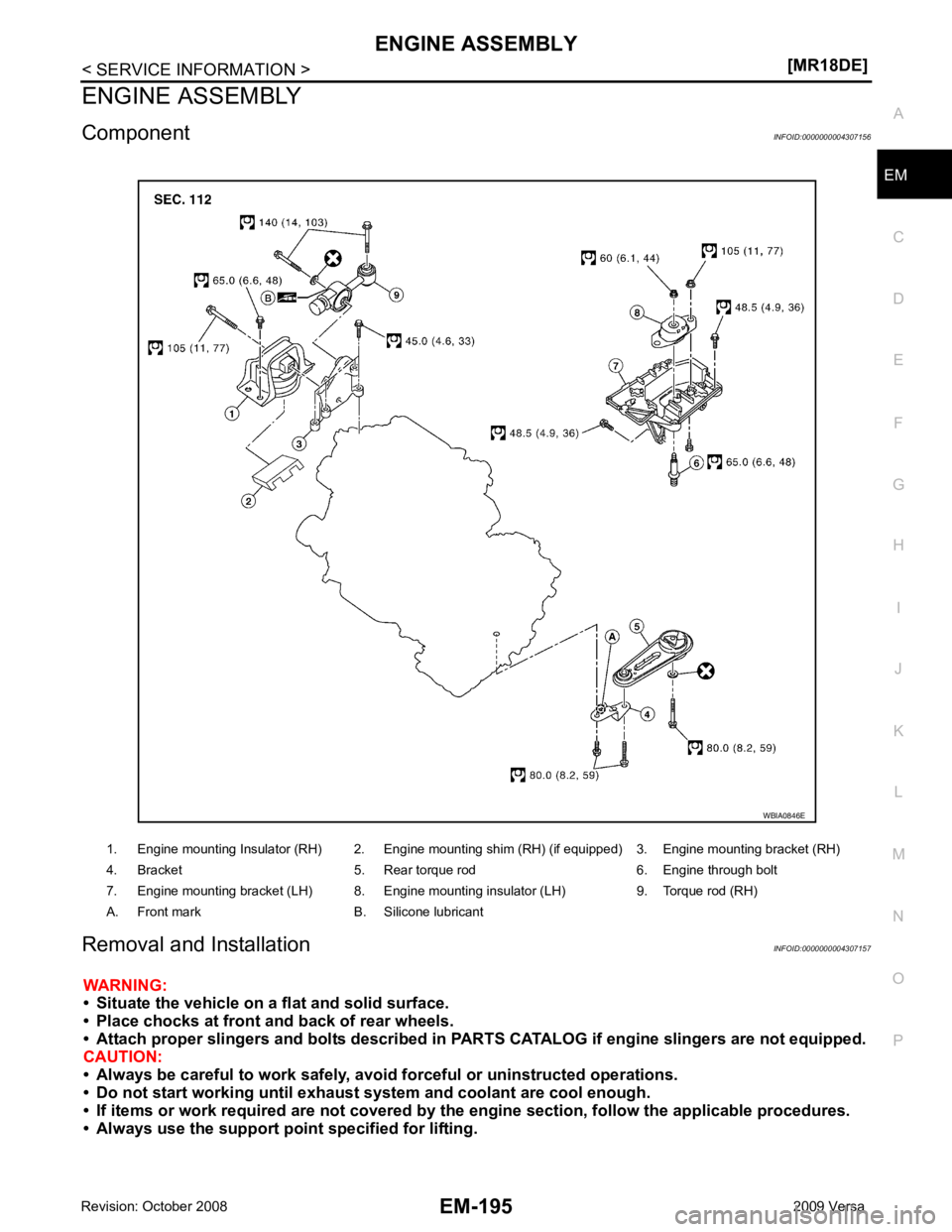

ENGINE ASSEMBLY

Component INFOID:0000000004307156

Removal and Installation INFOID:0000000004307157

WARNING:

• Situate the vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• Attach proper slingers and bolts described in P ARTS CATALOG if engine slingers are not equipped.

CAUTION:

• Always be careful to work safely, avoid forceful or uninstructed operations.

• Do not start working until exhaust system and coolant are cool enough.

• If items or work required are not covered by th e engine section, follow the applicable procedures.

• Always use the support poin t specified for lifting.

1. Engine mounting Insulator (RH) 2. Engine mounting shim (RH) (if equipped) 3. Engine mounting bracket (RH)

4. Bracket 5. Rear torque rod 6. Engine through bolt

7. Engine mounting bracket (LH) 8. Engine mounting insulator (LH) 9. Torque rod (RH)

A. Front mark B. Silicone lubricant

Page 3143 of 4331

Garage Jack and

Safety Stand and 2-Pole Lift " .

REMOVAL

Remove the engine and the transaxle assembly from t he vehicle downward. Separate the engine and the tran-

saxle.

1. Remove engine undercover.

2. Drain engine coolant from radiator. Refer to CO-35, " Changing Engine Coolant " .

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belt.

3. Remove front fender protector (RH and LH). Refer to EI-24 .

4. Remove exhaust front tube. Refer to EX-9 .

5. Remove drive shafts (LH and RH) from steering knuckle. Refer to FAX-9 .

6. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to AT-232 (A/T models),

CVT-182 or

CVT-354 (CVT models) or

MT-58 (M/T models).

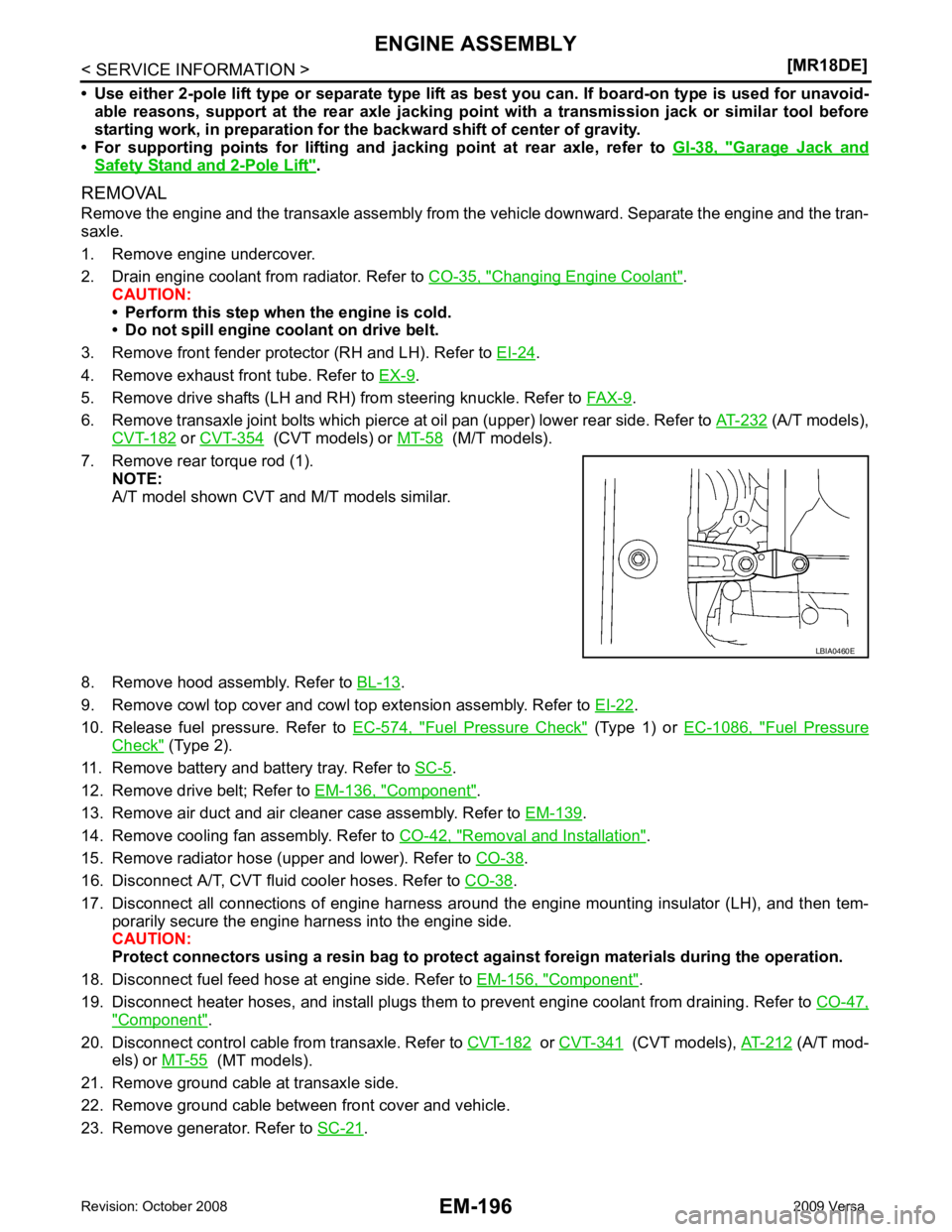

7. Remove rear torque rod (1). NOTE:

A/T model shown CVT and M/T models similar.

8. Remove hood assembly. Refer to BL-13 .

9. Remove cowl top cover and cowl top extension assembly. Refer to EI-22 .

10. Release fuel pressure. Refer to EC-574, " Fuel Pressure Check " (Type 1) or

EC-1086, " Fuel Pressure

Check " (Type 2).

11. Remove battery and battery tray. Refer to SC-5 .

12. Remove drive belt; Refer to EM-136, " Component " .

13. Remove air duct and air cleaner case assembly. Refer to EM-139 .

14. Remove cooling fan assembly. Refer to CO-42, " Removal and Installation " .

15. Remove radiator hose (upper and lower). Refer to CO-38 .

16. Disconnect A/T, CVT fluid cooler hoses. Refer to CO-38 .

17. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then tem- porarily secure the engine harness into the engine side.

CAUTION:

Protect connectors using a resin bag to protect against foreign materials during the operation.

18. Disconnect fuel feed hose at engine side. Refer to EM-156, " Component " .

19. Disconnect heater hoses, and install plugs them to prevent engine coolant from draining. Refer to CO-47," Component " .

20. Disconnect control cable from transaxle. Refer to CVT-182 or

CVT-341 (CVT models),

AT-212 (A/T mod-

els) or MT-55 (MT models).

21. Remove ground cable at transaxle side.

22. Remove ground cable between front cover and vehicle.

23. Remove generator. Refer to SC-21 .

Page 3144 of 4331

EM

NP

O

24. Remove A/C compressor with piping connected from t

he engine. Temporarily secure it on the vehicle side

with a rope to avoid putting load on it. Refer to MTC-80, " Removal and Installation of Compressor -

MR18DE " .

25. Remove the intake manifold to prevent the hanging chain from interfering. Refer to EM-141, " Compo-

nent " .

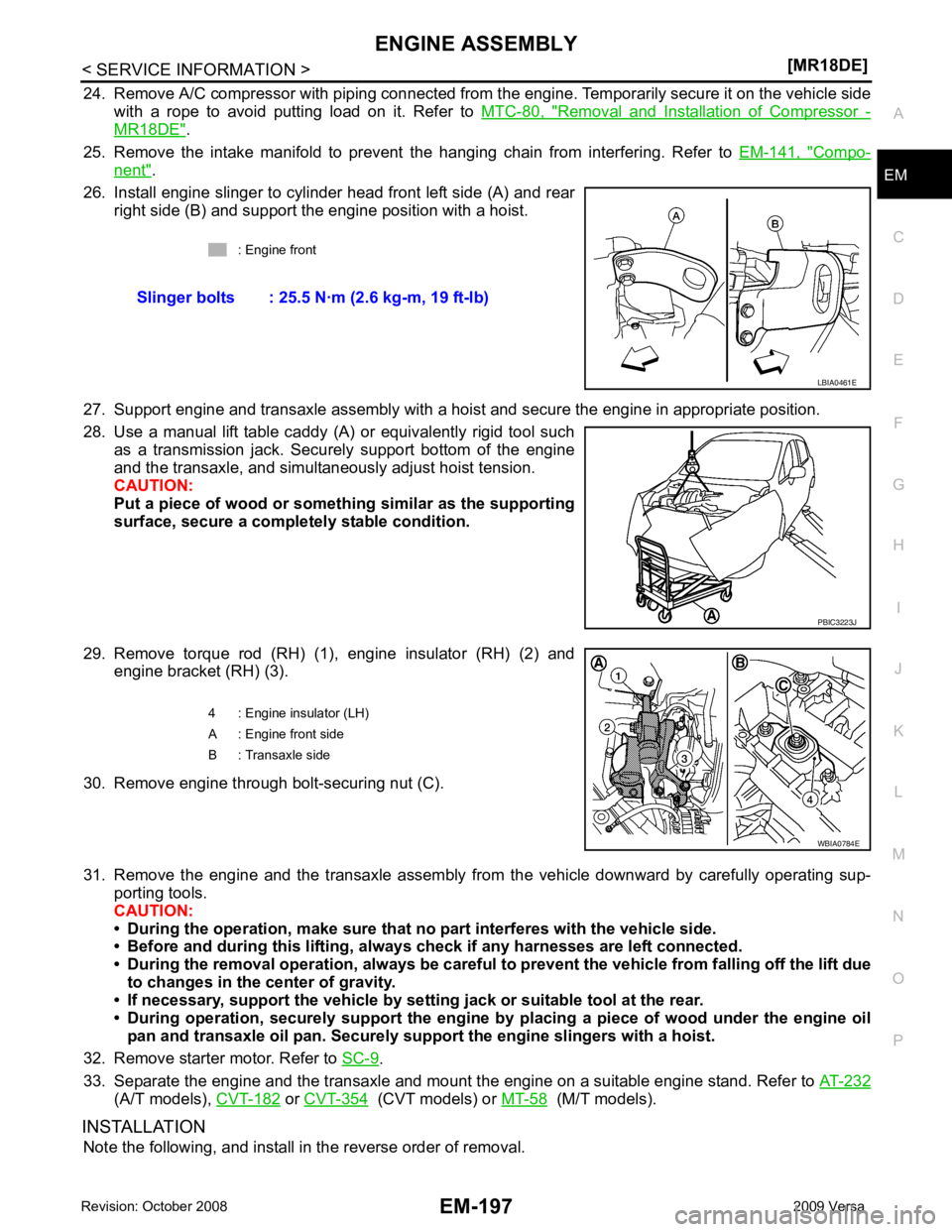

26. Install engine slinger to cylinder head front left side (A) and rear right side (B) and support the engine position with a hoist.

27. Support engine and transaxle assembly with a hoist and secure the engine in appropriate position.

28. Use a manual lift table caddy (A) or equivalently rigid tool such as a transmission jack. Securely support bottom of the engine

and the transaxle, and simultaneously adjust hoist tension.

CAUTION:

Put a piece of wood or someth ing similar as the supporting

surface, secure a completely stable condition.

29. Remove torque rod (RH) (1), engine insulator (RH) (2) and engine bracket (RH) (3).

30. Remove engine through bolt-securing nut (C).

31. Remove the engine and the transaxle assembly from the vehicle downward by carefully operating sup- porting tools.

CAUTION:

• During the operation, make sure that no part interferes with the vehicle side.

• Before and during this lifting, alw ays check if any harnesses are left connected.

• During the removal operation, alw ays be careful to prevent the vehicle from falling off the lift due

to changes in the center of gravity.

• If necessary, support the vehicle by setting jack or suitable tool at the rear.

• During operation, securely suppor t the engine by placing a piece of wood under the engine oil

pan and transaxle oil pan. Securely sup port the engine slingers with a hoist.

32. Remove starter motor. Refer to SC-9 .

33. Separate the engine and the transaxle and mount the engine on a suitable engine stand. Refer to AT-232(A/T models),

CVT-182 or

CVT-354 (CVT models) or

MT-58 (M/T models).

INSTALLATION Note the following, and install in the reverse order of removal. : Engine front

Slinger bolts : 25.5 N·m (2.6 kg-m, 19 ft-lb) PBIC3223J

Page 3145 of 4331

Com-

ponent " .

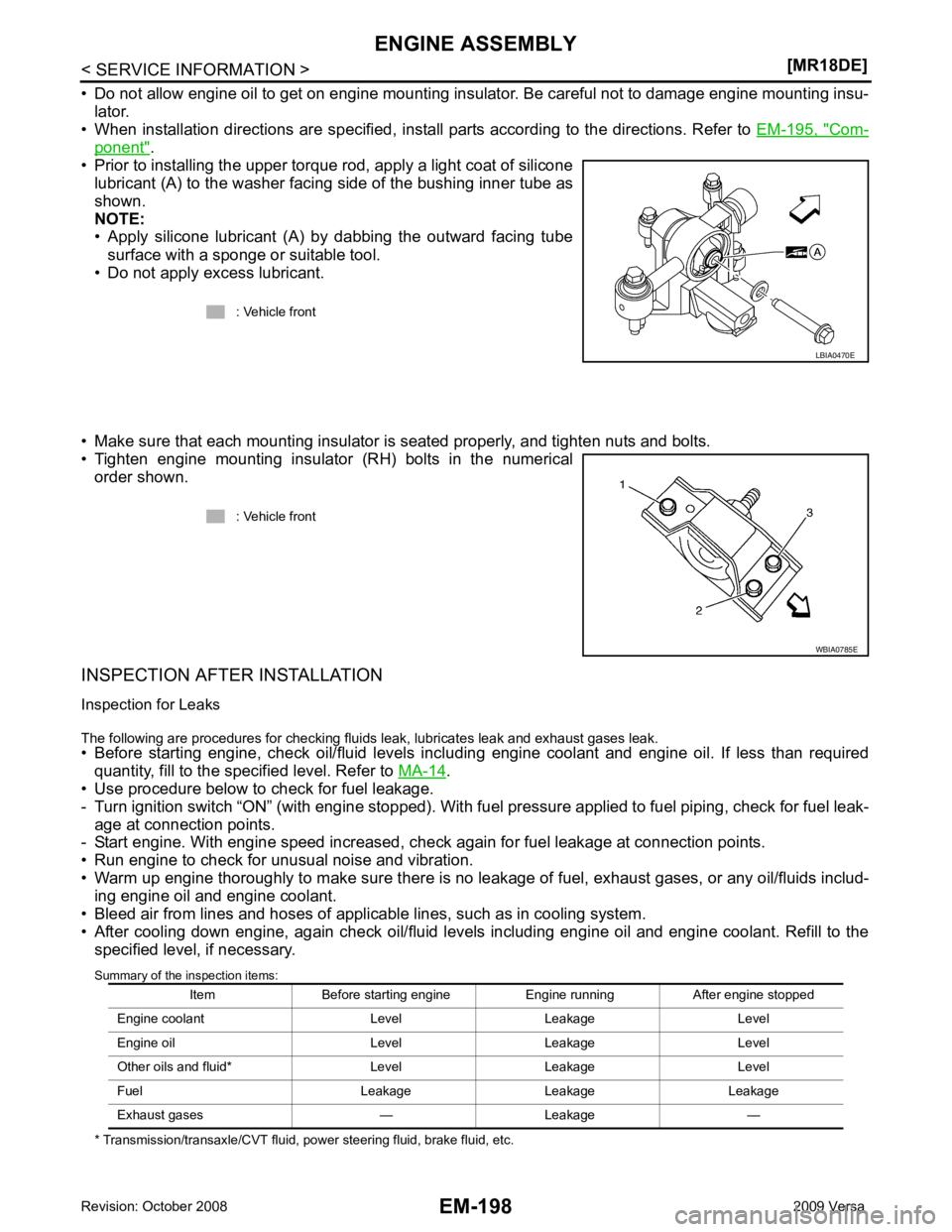

• Prior to installing the upper torque rod, apply a light coat of silicone lubricant (A) to the washer facing side of the bushing inner tube as

shown.

NOTE:

• Apply silicone lubricant (A) by dabbing the outward facing tube

surface with a sponge or suitable tool.

• Do not apply excess lubricant.

• Make sure that each mounting insulator is seated properly, and tighten nuts and bolts.

• Tighten engine mounting insulator (RH) bolts in the numerical order shown.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14 .

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. : Vehicle front

Page 3146 of 4331

EM

NP

O

CYLINDER BLOCK

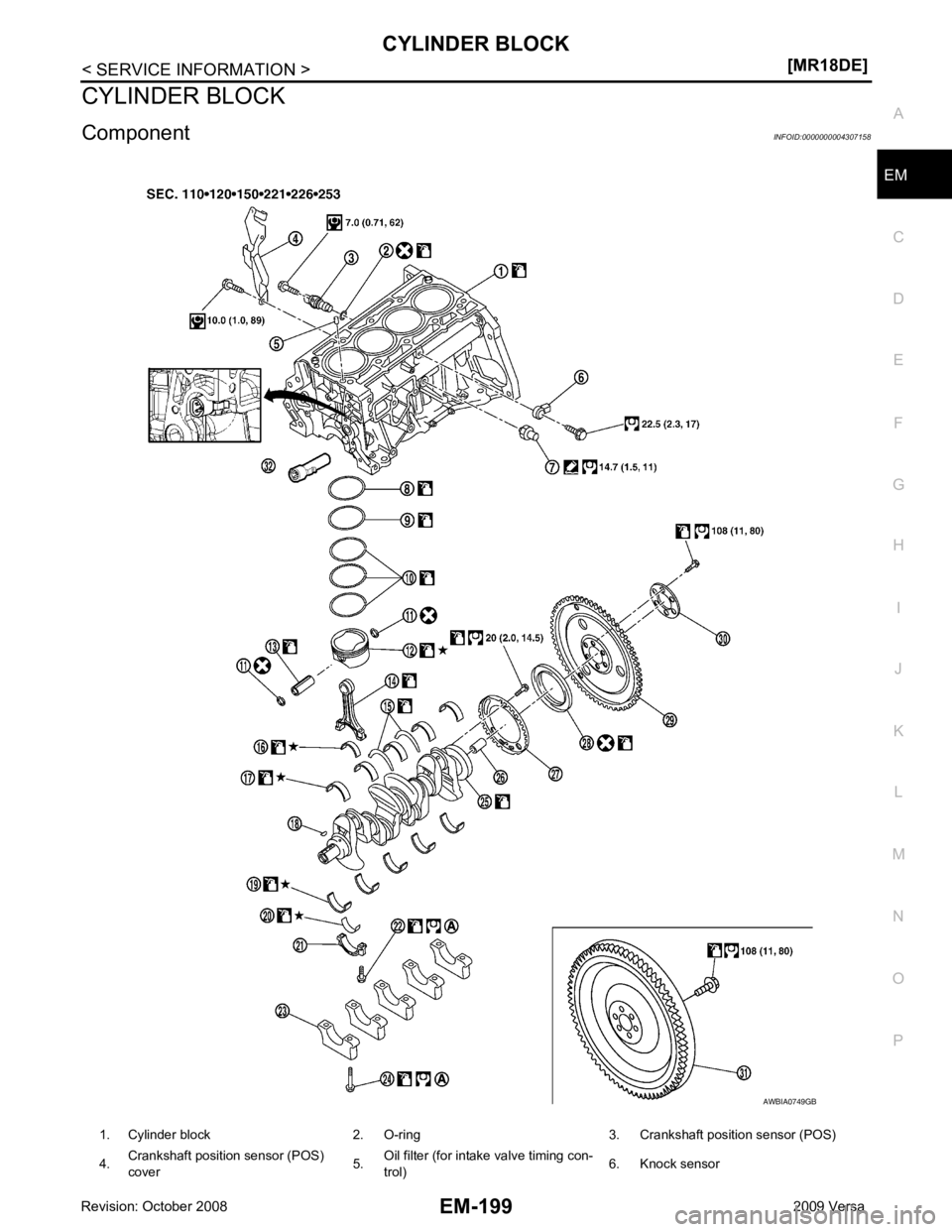

Component INFOID:0000000004307158

1. Cylinder block 2. O-ring 3. Crankshaft position sensor (POS)

4. Crankshaft position sensor (POS)

cover 5.Oil filter (for intake valve timing con-

trol) 6. Knock sensor

Page 3147 of 4331

.

2. Install engine to engine stand as follows;

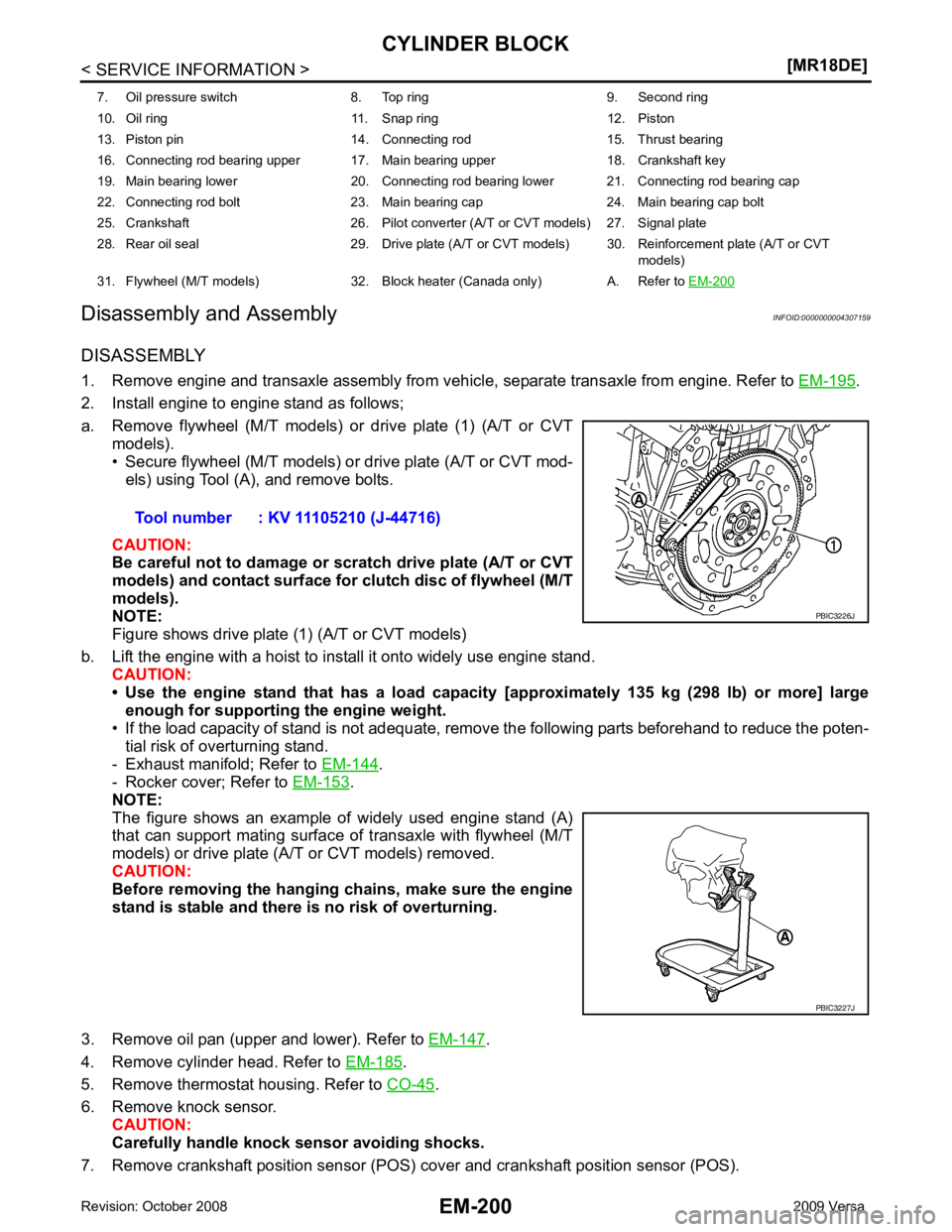

a. Remove flywheel (M/T models) or drive plate (1) (A/T or CVT models).

• Secure flywheel (M/T models) or drive plate (A/T or CVT mod-

els) using Tool (A), and remove bolts.

CAUTION:

Be careful not to damage or scratch drive plate (A/T or CVT

models) and contact surface for clutch disc of flywheel (M/T

models).

NOTE:

Figure shows drive plate (1) (A/T or CVT models)

b. Lift the engine with a hoist to install it onto widely use engine stand. CAUTION:

• Use the engine stand that has a load capacity [approximately 135 kg (298 lb) or more] large

enough for supporting the engine weight.

• If the load capacity of stand is not adequate, remo ve the following parts beforehand to reduce the poten-

tial risk of overturning stand.

- Exhaust manifold; Refer to EM-144 .

- Rocker cover; Refer to EM-153 .

NOTE:

The figure shows an example of widely used engine stand (A)

that can support mating surface of transaxle with flywheel (M/T

models) or drive plate (A/T or CVT models) removed.

CAUTION:

Before removing the hanging chains, make sure the engine

stand is stable and there is no risk of overturning.

3. Remove oil pan (upper and lower). Refer to EM-147 .

4. Remove cylinder head. Refer to EM-185 .

5. Remove thermostat housing. Refer to CO-45 .

6. Remove knock sensor. CAUTION:

Carefully handle knock sensor avoiding shocks.

7. Remove crankshaft position sensor (POS) cover and crankshaft position sensor (POS).

7. Oil pressure switch 8. Top ring 9. Second ring

10. Oil ring 11. Snap ring 12. Piston

13. Piston pin 14. Connecting rod 15. Thrust bearing

16. Connecting rod bearing upper 17. Main bearing upper 18. Crankshaft key

19. Main bearing lower 20. Connecting rod bearing lower 21. Connecting rod bearing cap

22. Connecting rod bolt 23. Main bearing cap 24. Main bearing cap bolt

25. Crankshaft 26. Pilot converter (A/T or CVT models) 27. Signal plate

28. Rear oil seal 29. Drive plate (A/T or CVT models) 30. Reinforcement plate (A/T or CVT models)

31. Flywheel (M/T models) 32. Block heater (Canada only) A. Refer to EM-200 PBIC3227J

Page 3148 of 4331

EM

NP

O

CAUTION:

• Avoid impacts such as a dropping.

• Never disassemble.

• Keep it away from metal particles.

• Never place sensor in a location wher e it is exposed to magnetism.

8. Remove oil filter (for intake valve timing control).

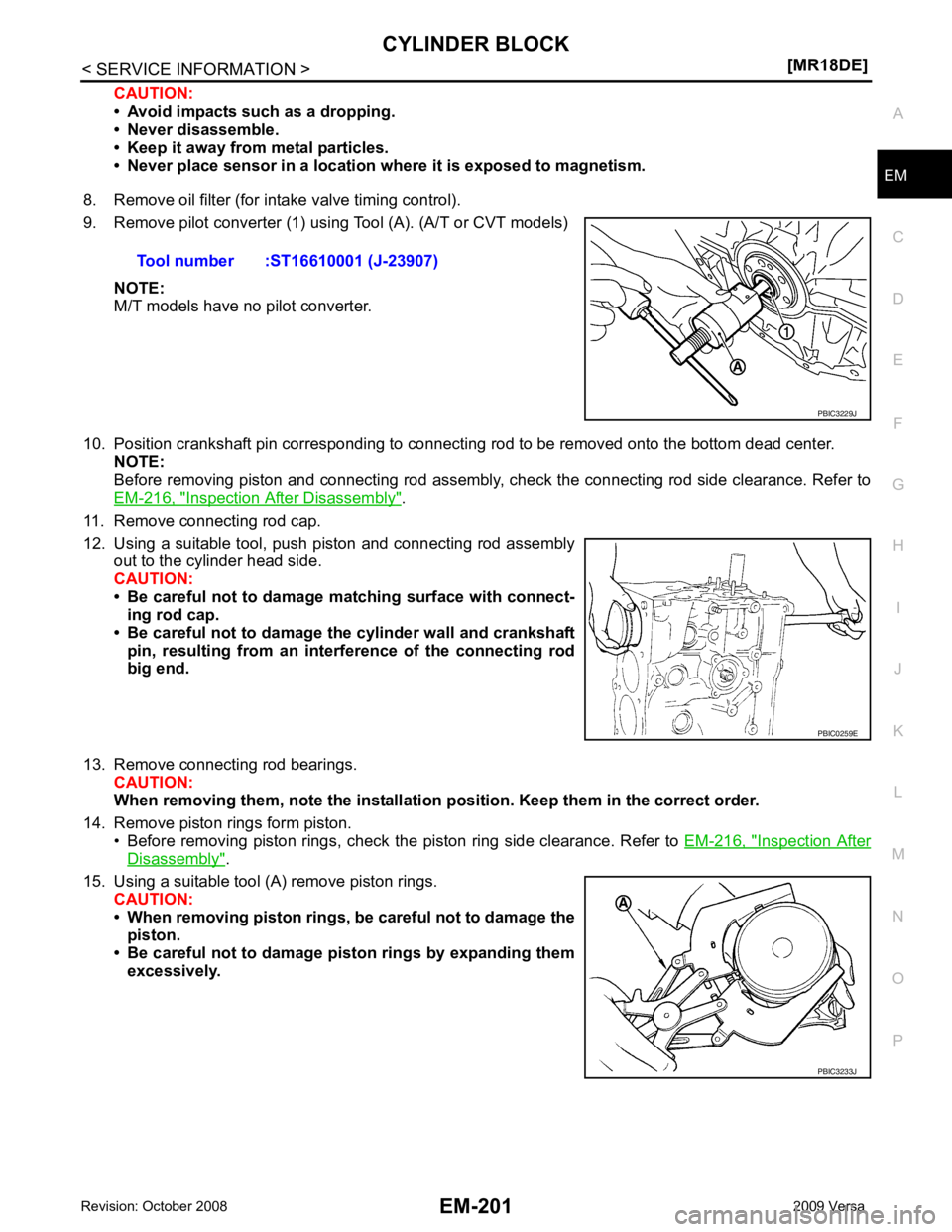

9. Remove pilot converter (1) using Tool (A). (A/T or CVT models)

NOTE:

M/T models have no pilot converter.

10. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center. NOTE:

Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer to

EM-216, " Inspection After Disassembly " .

11. Remove connecting rod cap.

12. Using a suitable tool, push piston and connecting rod assembly out to the cylinder head side.

CAUTION:

• Be careful not to damage matching surface with connect- ing rod cap.

• Be careful not to damage the cylinder wall and crankshaft pin, resulting from an inte rference of the connecting rod

big end.

13. Remove connecting rod bearings. CAUTION:

When removing them, note the installation position. Keep them in the correct order.

14. Remove piston rings form piston. • Before removing piston rings, check the piston ring side clearance. Refer to EM-216, " Inspection After

Disassembly " .

15. Using a suitable tool (A) remove piston rings. CAUTION:

• When removing piston rings, be careful not to damage the

piston.

• Be careful not to damage piston rings by expanding them excessively.Tool number :ST16610001 (J-23907)

PBIC0259E

PBIC3233J

Page 3149 of 4331

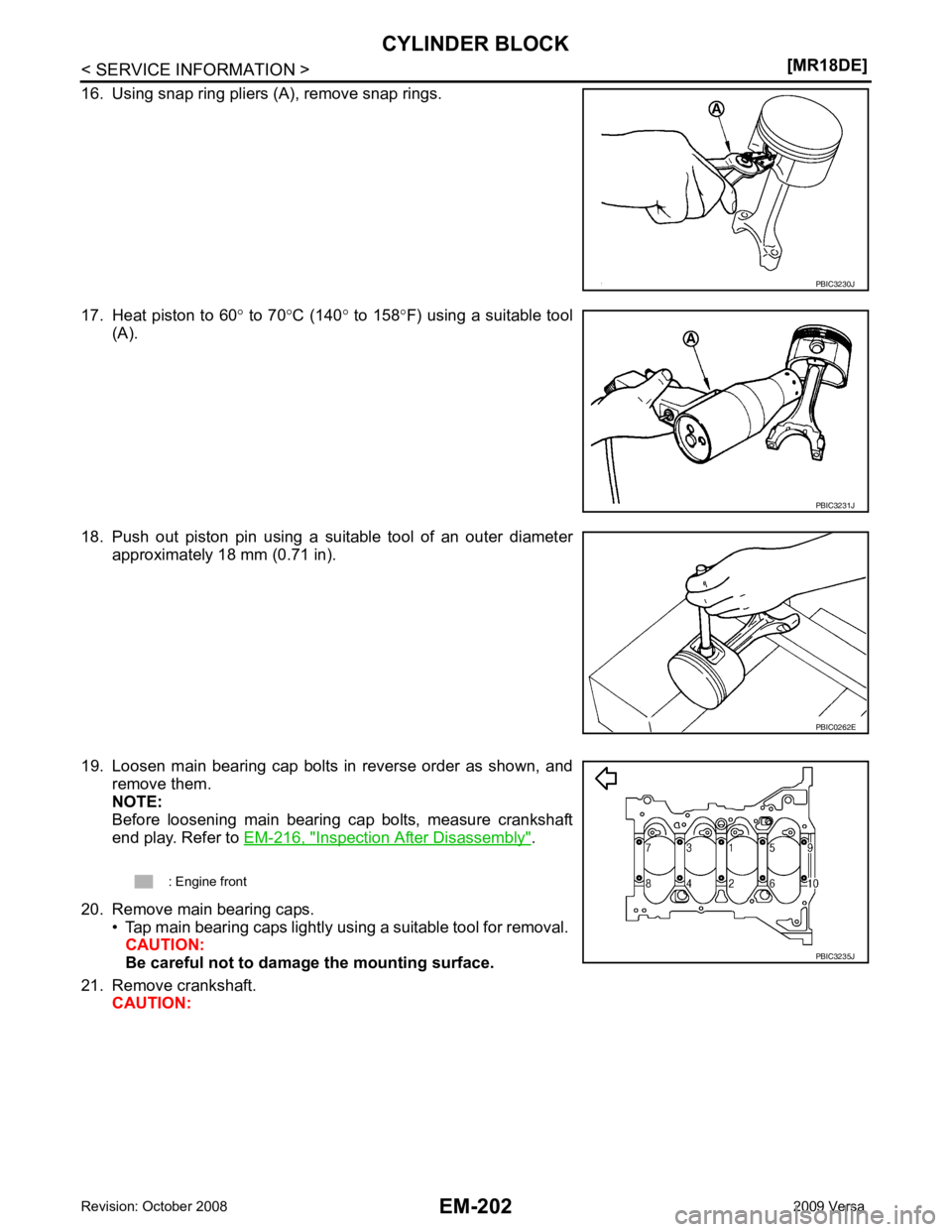

Inspection After Disassembly " .

20. Remove main bearing caps. • Tap main bearing caps lightly using a suitable tool for removal. CAUTION:

Be careful not to damage the mounting surface.

21. Remove crankshaft. CAUTION: PBIC3231J

PBIC0262E

Page 3150 of 4331

EM

NP

O

• Be careful not to damage or deform signal plate (1)

mounted on rear end of crankshaft (A).

• When setting crankshaft on a flat floor surface, use a

block of wood to avoid inte rference between signal plate

and the floor surface.

• Never remove signal plate unl ess it is necessary to do so.

22. Pull rear oil seal out from rear end of crankshaft.

23. Remove main bearings and thrust bearings from cylinder block and main bearing caps.

CAUTION:

Identify installation positions, and store them without mix-

ing them up.

ASSEMBLY 1. Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to remove any foreign material.

WARNING:

Use goggles to protect your eyes.

2. Install water drain plug (1) to cylinder block.

• Apply liquid gasket to the drain plug thread.

Use Genuine Silicone RTV Seal ant or equivalent. Refer to

GI-42, " Recommended Chemical Product and Sealant " .

3. Remove dust, dirt, and engine oil on the bearing mating sur- faces of cylinder block and main bearing cap.

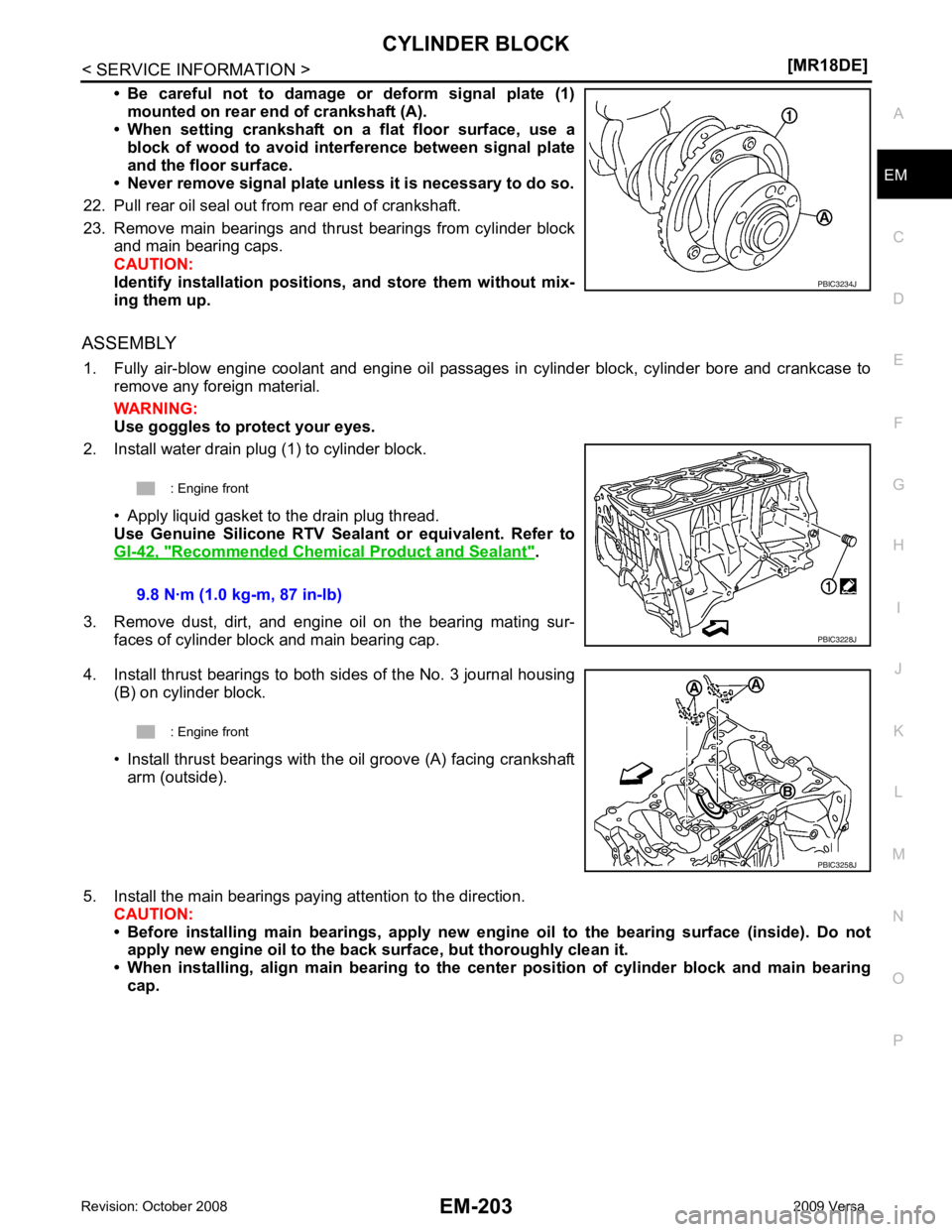

4. Install thrust bearings to both sides of the No. 3 journal housing (B) on cylinder block.

• Install thrust bearings with the oil groove (A) facing crankshaft arm (outside).

5. Install the main bearings paying attention to the direction. CAUTION:

• Before installing main bearings , apply new engine oil to the bearing surface (inside). Do not

apply new engine oil to the back surface, but thoroughly clean it.

• When installing, align main b earing to the center position of cylinder block and main bearing

cap.