sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 1771 of 4331

EC

NP

O Component Inspection " .)

• EVAP control system pressure sensor (Refer to EC-314, " Component Inspection " .)

• Refrigerant pressure sensor (Refer to EC-458, " Diagnosis Procedure " .)

Is the inspection result normal? YES >> GO TO 11.

NO >> Replace malfunctioning component. YES >> GO TO 8.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors. YES >> GO TO 9.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 11.

NO >> GO TO 10. Special Repair Requirement " .

>> INSPECTION END Diagnosis Procedure " .

>> INSPECTION END

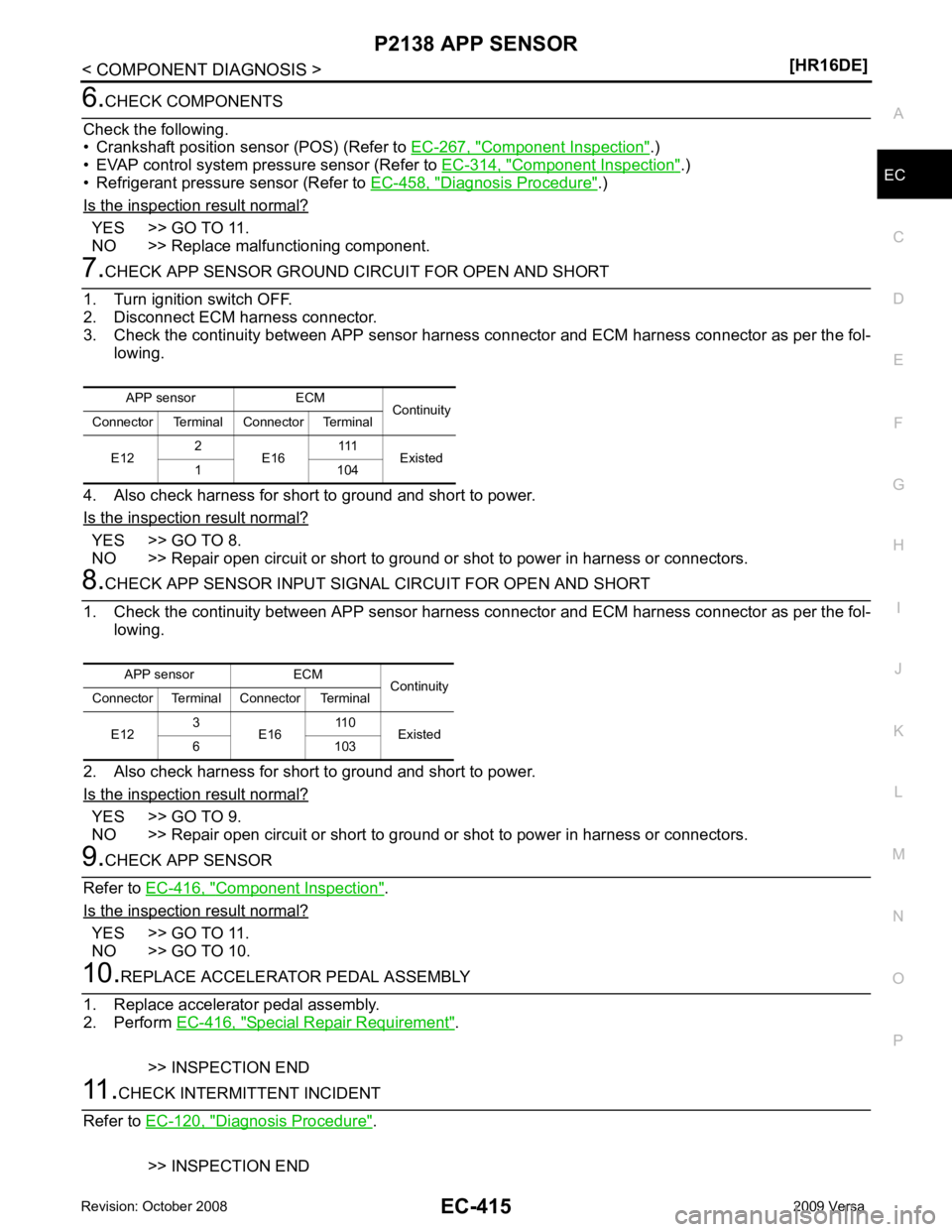

APP sensor ECM

Continuity

Connector Terminal Connector Terminal

E12 2

E16 111

Existed

1 104 APP sensor ECM

Continuity

Connector Terminal Connector Terminal

E12 3

E16 110

Existed

6 103

Page 1772 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-416< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

Component Inspection INFOID:00000000047803361.

CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn NISSAN LATIO 2009 Service Repair Manual EC-416< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

Component Inspection INFOID:00000000047803361.

CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn](/img/5/57359/w960_57359-1771.png)

EC-416< COMPONENT DIAGNOSIS >

[HR16DE]

P2138 APP SENSOR

Component Inspection INFOID:00000000047803361.

CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2. 2.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-416, " Special Repair Requirement " .

>> INSPECTION END

Special Repair Requirement INFOID:00000000047803371.

PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

Refer to EC-31, " ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement " .

>> GO TO 2. 2.

PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Refer to EC-31, " THROTTLE VALVE CLOSED POSITION LE

ARNING : Special Repair Requirement " .

>> GO TO 3. 3.

PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-32, " IDLE AIR VOLUME LEARNING : Special Repair Requirement " .

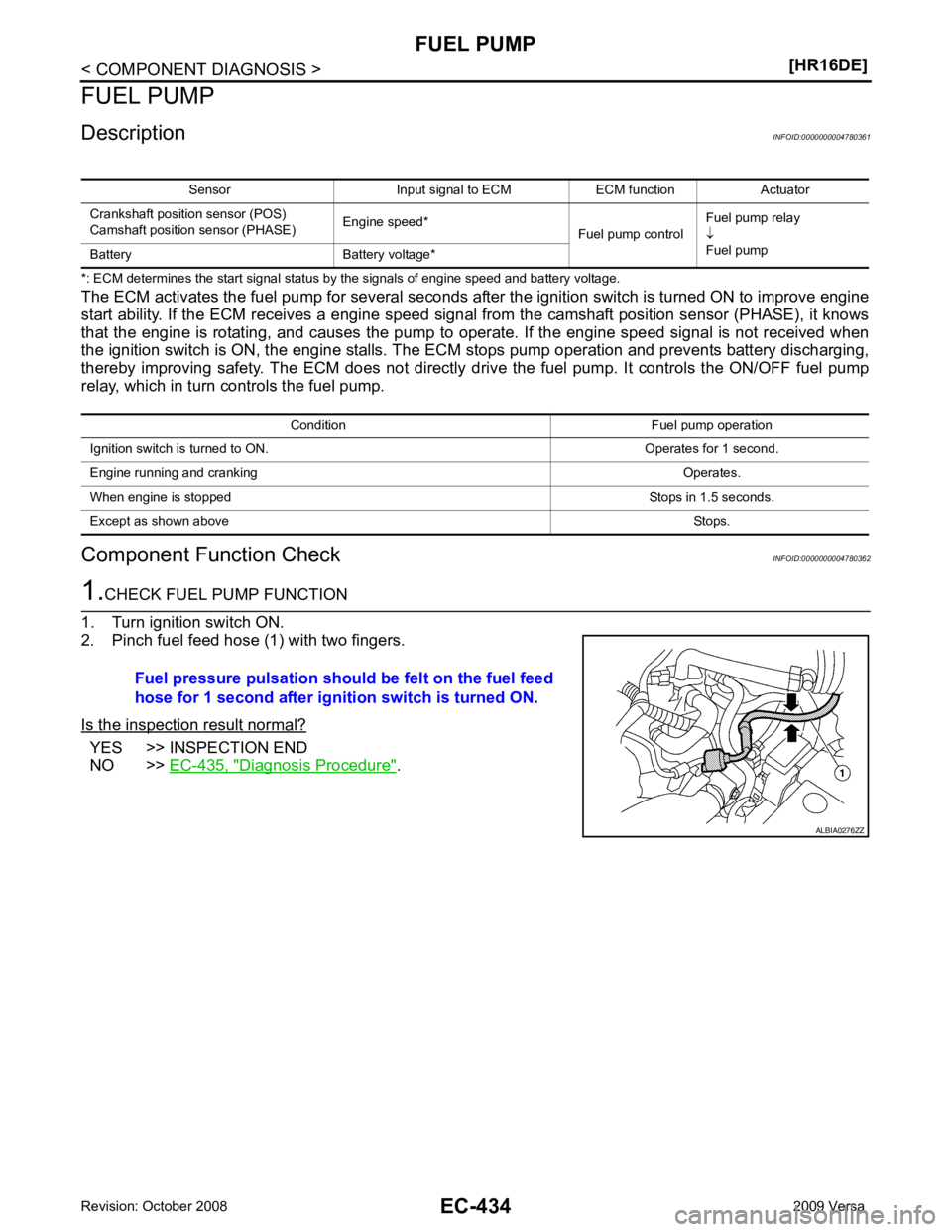

>> END ECM

Ground Condition Voltage

Connector Terminal

E16 110

(APP sensor 1 signal) GroundAccelerator

pedal Fully released 0.6 - 0.9 V

Fully depressed 3.9 - 4.7 V

103

(APP sensor 2 signal) Fully released 0.3 - 0.6 V

Fully depressed 1.95 - 2.4 V PBIA9572J

Page 1773 of 4331

![NISSAN LATIO 2009 Service Repair Manual P2A00 A/F SENSOR 1

EC-417

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2A00 A/F SENSOR 1

Description INFOID:0000000004780338

The air fuel ratio (A/F) sensor 1 is a planar one-cell NISSAN LATIO 2009 Service Repair Manual P2A00 A/F SENSOR 1

EC-417

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2A00 A/F SENSOR 1

Description INFOID:0000000004780338

The air fuel ratio (A/F) sensor 1 is a planar one-cell](/img/5/57359/w960_57359-1772.png)

P2A00 A/F SENSOR 1

EC-417

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P2A00 A/F SENSOR 1

Description INFOID:0000000004780338

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise m easurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780339

DTC DETECTION LOGIC To judge the malfunction, the A/F signal computed by ECM from the A/F sensor 1 signal is monitored not to be

shifted to LEAN side or RICH side.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

>> GO TO 2. 2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Clear the mixture ratio self-learning value. Refer to EC-33, " MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement " .

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for 1 minute under no load.

4. Let engine idle for 1 minute.

5. Keep engine speed between 2,500 and 3,000 rpm for 20 minutes. JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P2A00 Air fuel ratio (A/F) sensor 1

circuit range/performance • The output voltage computed by ECM from the

A/F sensor 1 signal is shifted to the lean side for

a specified period.

• The A/F signal computed by ECM from the A/F sensor 1 signal is shifted to the rich side for a

specified period. • A/F sensor 1

• A/F sensor 1 heater

• Fuel pressure

• Fuel injector

• Intake air leaks

Page 1774 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-418< COMPONENT DIAGNOSIS >

[HR16DE]

P2A00 A/F SENSOR 1

6. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-419, " Diagnosis Procedure " .

NO >> INSPECTION END

Wiring Diagram INFOID:00 NISSAN LATIO 2009 Service Repair Manual EC-418< COMPONENT DIAGNOSIS >

[HR16DE]

P2A00 A/F SENSOR 1

6. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-419, " Diagnosis Procedure " .

NO >> INSPECTION END

Wiring Diagram INFOID:00](/img/5/57359/w960_57359-1773.png)

EC-418< COMPONENT DIAGNOSIS >

[HR16DE]

P2A00 A/F SENSOR 1

6. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to

EC-419, " Diagnosis Procedure " .

NO >> INSPECTION END

Wiring Diagram INFOID:0000000004780722 AABWA0307G B

Page 1775 of 4331

![NISSAN LATIO 2009 Service Repair Manual P2A00 A/F SENSOR 1

EC-419

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000047803401.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check g NISSAN LATIO 2009 Service Repair Manual P2A00 A/F SENSOR 1

EC-419

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000047803401.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check g](/img/5/57359/w960_57359-1774.png)

P2A00 A/F SENSOR 1

EC-419

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000047803401.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connections E15, E24. Refer to EC-125, " Ground Inspection " .

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK HARNESS CONNECTOR

1. Disconnect A/F sensor 1 harness connector.

2. Check harness connector for water.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness connector. 3.

RETIGHTEN A/F SENSOR 1

1. Loosen and retighten the A/F sensor 1. Refer to EM-31, " Exploded View " .

>> GO TO 4. 4.

CHECK FOR INTAKE AIR LEAK

1. Reconnect A/F sensor 1 harness connector.

2. Start engine and run it at idle.

3. Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected? YES >> GO TO 5.

NO >> Repair or replace. 5.

CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

1. Clear the mixture ratio self-learning value. Refer to EC-33, " MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement " .

2. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 or P0172 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0171or P0172. Refer to

EC-229, " DTC Logic " or

EC-235, " DTC Logic " .

NO >> GO TO 6. 6.

CHECK A/F SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F sensor 1 harness connector.

2. Turn ignition switch ON.

3. Check the voltage between A/F sensor 1 harness connector and

ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

DETECT MALFUNCTIONING PART

Check the following. Water should not exit.

A/F sensor 1 Ground Voltage

Connector Terminal

F12 4 Ground Battery voltage PBIB3308E

Page 1790 of 4331

YES >> INSPECTION END

NO >> EC-435, " Diagnosis Procedure " .

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump controlFuel pump relay

↓

Fuel pump

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and cranking Operates.

When engine is stopped Stops in 1.5 seconds.

Except as shown above Stops.

Page 1793 of 4331

EC

NP

O

NO >> Replace15 A fuse.

YES >> GO TO 10.

NO >> GO TO 7. YES >> GO TO 9.

NO >> Repair open circuit or short to power in harness or connectors. Component Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace “fuel level sensor unit and fuel pump”. Diagnosis Procedure " .

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness or connectors.

Component Inspection INFOID:0000000004780364Fuel level sensor unit

and fuel pump Ground Continuity

Connector Terminal

B100 3 Ground Existed

Page 1794 of 4331

![NISSAN LATIO 2009 Service Repair Manual YES >> INSPECTION END

NO >> Replace “fuel level sensor unit and fuel pump”. Terminals Resistance

1 and 3 0.2 - 5.0 Ω [at 25 °C (77 °F)] NISSAN LATIO 2009 Service Repair Manual YES >> INSPECTION END

NO >> Replace “fuel level sensor unit and fuel pump”. Terminals Resistance

1 and 3 0.2 - 5.0 Ω [at 25 °C (77 °F)]](/img/5/57359/w960_57359-1793.png)

YES >> INSPECTION END

NO >> Replace “fuel level sensor unit and fuel pump”. Terminals Resistance

1 and 3 0.2 - 5.0 Ω [at 25 °C (77 °F)]

Page 1807 of 4331

![NISSAN LATIO 2009 Service Repair Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-451

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

B: Cannot refuel/Fuel odor from the fuel

filler opening is strong while refueling.

Whi NISSAN LATIO 2009 Service Repair Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-451

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

B: Cannot refuel/Fuel odor from the fuel

filler opening is strong while refueling.

Whi](/img/5/57359/w960_57359-1806.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-451

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

B: Cannot refuel/Fuel odor from the fuel

filler opening is strong while refueling.

Which symptom is present? A >> GO TO 2.

B >> GO TO 8. 2.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 4. 3.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?YES >> GO TO 4.

NO >> GO TO 7. 4.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 5. 5.

CHECK DRAIN FILTER

Refer to EC-455, " Component Inspection (Drain filter) " .

Is the inspection result normal? OK >> GO TO 6.

NO >> Replace drain filter. 6.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose. 7.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-453, " Component Inspection (Refueling EVAP vapor cut valve) " .

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace refueling EVAP vapor cut valve with fuel tank. 8.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

Is the inspection result normal? PBIB1213E

Page 1813 of 4331

EC

NP

O

REFRIGERANT PRESSURE SENSOR

Description INFOID:0000000004780380

The refrigerant pressure sensor is installed at the c ondenser of the air conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert re frigerant pressure to voltage. The voltage signal is sent

to ECM, and ECM controls cooling fan system.

Component Function Check INFOID:0000000004780381YES >> INSPECTION END

NO >> Go to EC-458, " Diagnosis Procedure " .