sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 1876 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-520< SERVICE INFOMATION >

[MR TYPE 1]

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air/ fuel mixture ratio for driveability and emission control.

The three way catal NISSAN LATIO 2009 Service Repair Manual EC-520< SERVICE INFOMATION >

[MR TYPE 1]

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air/ fuel mixture ratio for driveability and emission control.

The three way catal](/img/5/57359/w960_57359-1875.png)

EC-520< SERVICE INFOMATION >

[MR TYPE 1]

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air/ fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better r educe CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to t he sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-698 . This maintains the mixture ratio within the range of stoichiometric

(ideal air/fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, the air/fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the EC M detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

• Deceleration and acceleration

• High-load, high-speed operation

• Malfunction of air fuel ratio (A/F) sensor 1 or its circuit

• Insufficient activation of air fuel ratio (A /F) sensor 1 at low engine coolant temperature

• High engine coolant temperature

• During warm-up

• After shifting from N to D (A/T and CVT models)

• When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixt ure ratio signal transmitted from air fuel ratio (A/F)

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the bas ic mixture ratio is not necessarily controlled as orig-

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic

changes during operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from air fuel ratio (A/F) sensor 1 i ndicates whether the mixture ratio is RICH or LEAN com-

pared to the theoretical value. The signal then triggers a r eduction in fuel volume if the mixture ratio is rich, and

an increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carri ed out long-term to compensate for continual deviation

of the short term fuel trim from t he central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycl e according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four fuel injectors will then receive the signals two times for each engine cycle. SEF337W

Page 1877 of 4331

EC

NP

O

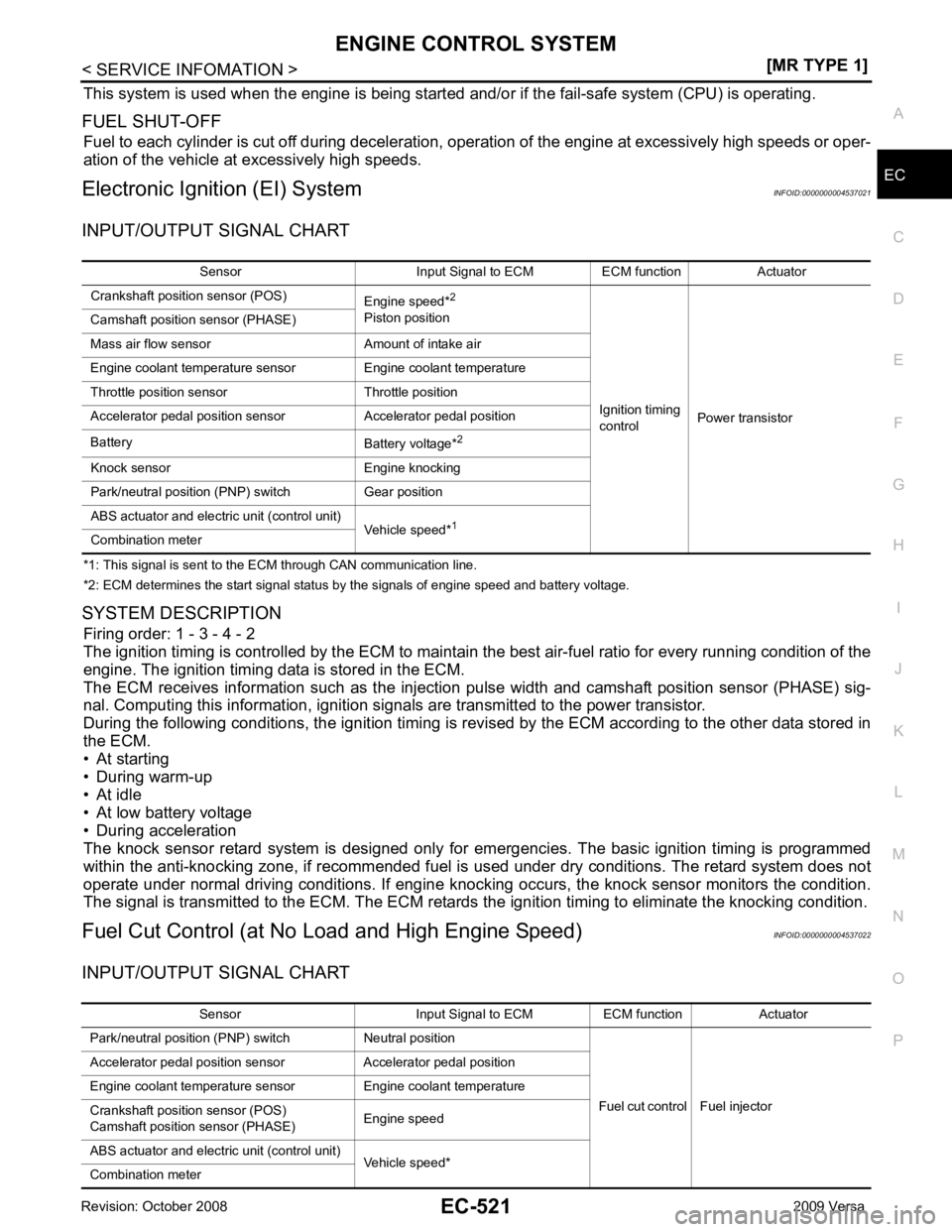

This system is used when the engine is being started

and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speeds.

Electronic Ignition (EI) System INFOID:0000000004537021

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION Firing order: 1 - 3 - 4 - 2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injecti on pulse width and camshaft position sensor (PHASE) sig-

nal. Computing this information, ignition si gnals are transmitted to the power transistor.

During the following conditions, the ignition timing is revi sed by the ECM according to the other data stored in

the ECM.

• At starting

• During warm-up

• At idle

• At low battery voltage

• During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Fuel Cut Control (at No Load and High Engine Speed) INFOID:0000000004537022

INPUT/OUTPUT SIGNAL CHART Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*2

Piston position

Ignition timing

control Power transistor

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Battery Battery voltage*2

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

ABS actuator and electric unit (control unit) Vehicle speed*1

Combination meter Sensor Input Signal to ECM ECM function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injector

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed

ABS actuator and electric unit (control unit) Vehicle speed*

Combination meter

Page 1879 of 4331

EC

NP

O

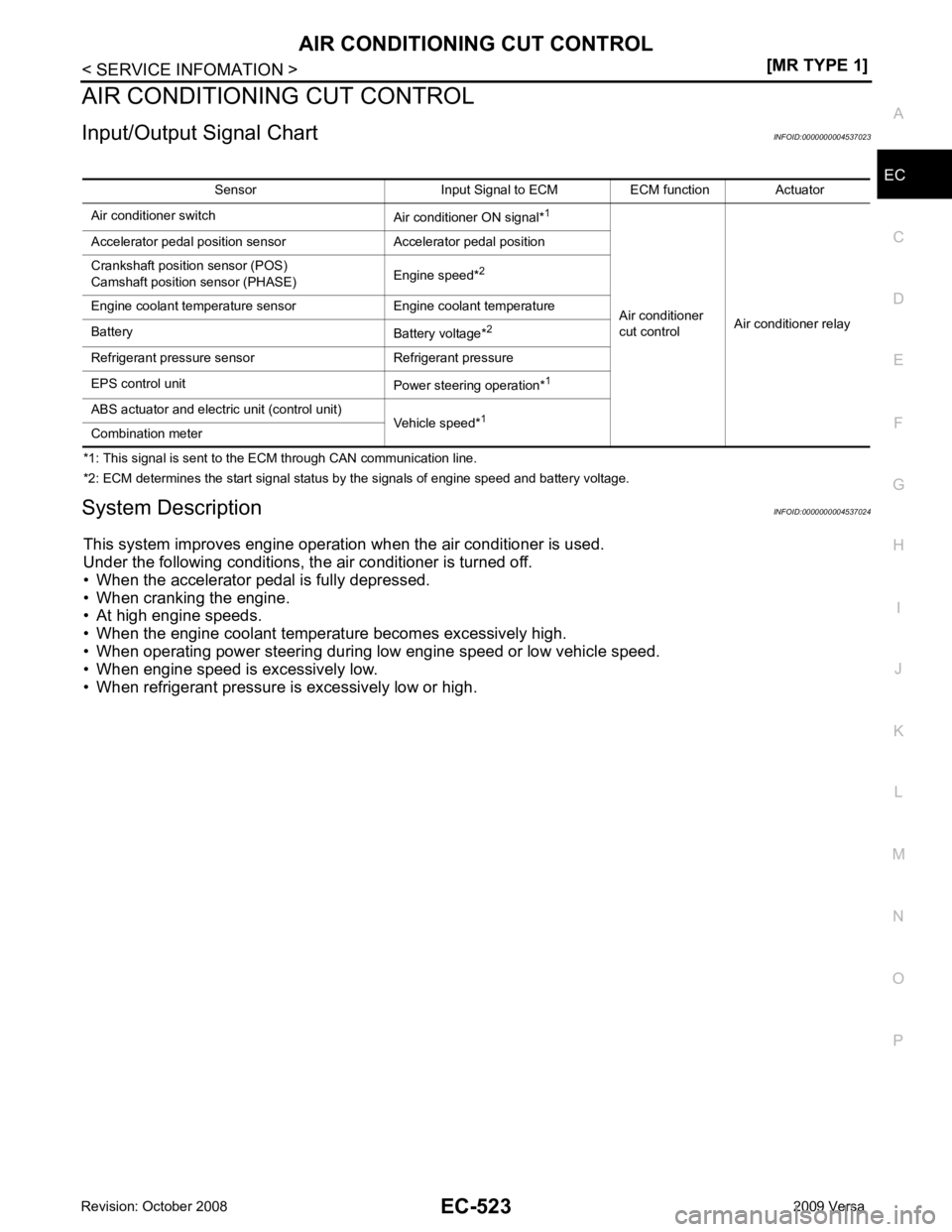

AIR CONDITIONING

CUT CONTROL

Input/Output Signal Chart INFOID:0000000004537023

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

System Description INFOID:0000000004537024

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperature becomes excessively high.

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high. Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch Air conditioner ON signal*1

Air conditioner

cut control Air conditioner relay

Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery Battery voltage*2

Refrigerant pressure sensor Refrigerant pressure

EPS control unit Power steering operation*1

ABS actuator and electric unit (control unit) Vehicle speed*1

Combination meter

Page 1885 of 4331

![NISSAN LATIO 2009 Service Repair Manual EVAPORATIVE EMISSION SYSTEM

EC-529

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Inspection

INFOID:0000000004537029

EVAP CANISTER (A): To previous figure

1. EVAP control NISSAN LATIO 2009 Service Repair Manual EVAPORATIVE EMISSION SYSTEM

EC-529

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Inspection

INFOID:0000000004537029

EVAP CANISTER (A): To previous figure

1. EVAP control](/img/5/57359/w960_57359-1884.png)

EVAPORATIVE EMISSION SYSTEM

EC-529

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Component Inspection

INFOID:0000000004537029

EVAP CANISTER (A): To previous figure

1. EVAP control system pressure sensor 2. EVAP canister 3. EVAP canister vent control valve

NOTE: Do not use soapy water or any type of so lvent while installing vacuum hose or purge hoses. BBIA0692E

Page 1886 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-530< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

Check EVAP canister as follows:

1. Block port B.

2. Blow air into port Aand check that it flows freely out of port C.

3. Release NISSAN LATIO 2009 Service Repair Manual EC-530< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

Check EVAP canister as follows:

1. Block port B.

2. Blow air into port Aand check that it flows freely out of port C.

3. Release](/img/5/57359/w960_57359-1885.png)

EC-530< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

Check EVAP canister as follows:

1. Block port B.

2. Blow air into port Aand check that it flows freely out of port C.

3. Release blocked port B.

4. Apply vacuum pressure to port Band check that vacuum pres-

sure exists at the ports A and C.

5. Block port A and B.

6. Apply pressure to port Cand check that there is no leakage.

FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FILLER CAP)

1. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

3. If out of specification, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may come on.

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to EC-815, " Component Inspection " .

FUEL TANK TEMPERATURE SENSOR

Refer to EC-759, " Component Inspection " .

EVAP CANISTER VENT CONTROL VALVE

Refer to EC-821, " Component Inspection " .

EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-838, " Component Inspection " .

EVAP SERVICE PORT PBIB1212E

SEF445Y

Pressure: 15.3 - 20.0 kPa

(0.156 - 0.204 kg/cm 2

, 2.22 - 2.90 psi)

Vacuum: −6.0 to −3.4 kPa

( − 0.061 to −0.035 kg/cm 2

, −0.87 to −0.48 psi) SEF943S

Page 1888 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-532< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START� NISSAN LATIO 2009 Service Repair Manual EC-532< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START�](/img/5/57359/w960_57359-1887.png)

EC-532< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START”. A bar graph (Pressure indicating display) will appear on the screen.

6. Apply positive pressure to the EVAP system until t he pressure indicator reaches the middle of the bar

graph.

7. Remove EVAP service port adapter and hose with pressure pump.

8. Locate the leak using a leak detector. Refer to EC-527," Description " .

WITHOUT CONSULT-III

1. Attach the EVAP service port adapter securely to the EVAP ser- vice port.

2. Also attach the pressure pump with pressure gauge to the EVAP service port adapter.

3. Apply battery voltage to the terminal of EVAP canister vent con- trol valve (3) to make a closed EVAP system.

• EVAP control system pressure sensor (1)

• EVAP canister (2)

4. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to

2.76 kPa (0.014 to 0.028 kg/cm 2

, 0.2 to 0.4 psi).

5. Remove EVAP service port adapter and hose with pressure pump.

6. Locate the leak using a leak detector. Refer to EC-527, " Description " . SEF200U

SEF462UC

BBIA0693E

Page 1890 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-534< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace NISSAN LATIO 2009 Service Repair Manual EC-534< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace](/img/5/57359/w960_57359-1889.png)

EC-534< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 4. 4.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose. 5.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-535, " Component Inspection " .

OK or NG OK >>

INSPECTION END

NG >> Replace refueling EVAP vapor cut valve with fuel tank.

SYMPTOM: CANNOT REFUEL/FUEL ODOR FROM THE FUEL FILLER OPENING IS STRONG

WHILE REFUELING. 1.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

OK or NG OK >> GO TO 2.

NG >> GO TO 3. 2.

CHECK IF EVAP CANISTER SATURATED WITH WATER

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one. PBIB1213E

PBIB1213E

Page 1897 of 4331

EC

NP

O

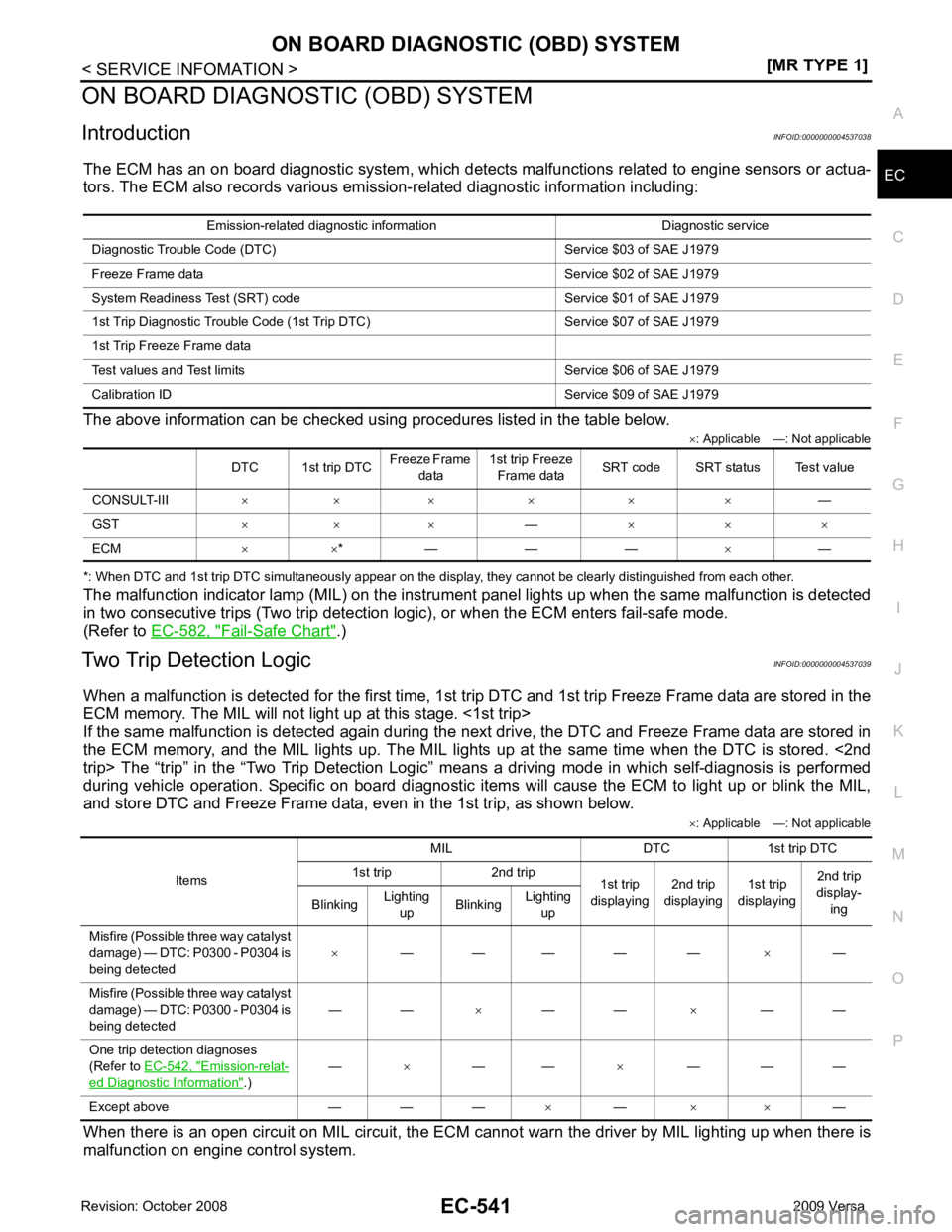

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Introduction INFOID:0000000004537038

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emis sion-related diagnostic information including:

The above information can be checked using procedures listed in the table below. ×: Applicable —: Not applicable

*: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator lamp (MIL) on the instrument panel lights up when the same malfunction is detected

in two consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode.

(Refer to EC-582, " Fail-Safe Chart " .)

Two Trip Detection Logic INFOID:0000000004537039

When a malfunction is detected for the first time, 1st tr ip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MIL will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MIL lights up. The MIL lights up at the same time when the DTC is stored. <2nd

trip> The “trip” in the “Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic item s will cause the ECM to light up or blink the MIL,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

×: Applicable —: Not applicable

When there is an open circuit on MIL circuit, the ECM c annot warn the driver by MIL lighting up when there is

malfunction on engine control system. Emission-related diagnostic information Diagnostic service

Diagnostic Tr ouble Code (DTC) Service $03 of SAE J1979

Freeze Frame data Service $02 of SAE J1979

System Readiness Test (SRT) code Service $01 of SAE J1979

1st Trip Diagnostic Trou ble Code (1st Trip DTC) Service $07 of SAE J1979

1st Trip Freeze Frame data

Test values and Test limi ts Service $06 of SAE J1979

Calibration ID Servic e $09 of SAE J1979

DTC 1st trip DTC Freeze Frame

data 1st trip Freeze

Frame data SRT code SRT status Test value

CONSULT-III × × × × × × —

GST × × × —× × ×

ECM × ×* — — — ×— Items

MIL DTC 1st trip DTC

1st trip 2nd trip 1st trip

displaying 2nd trip

displaying 1st trip

displaying 2nd trip

display-

ing

Blinking Lighting

up Blinking

Lighting

up

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected ×

— — — — — ×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected — —

×— — ×— —

One trip detection diagnoses

(Refer to EC-542, " Emission-relat-

ed Diagnostic Information " .)

—

×— — ×— — —

Except above — — — ×— × × —

Page 1898 of 4331

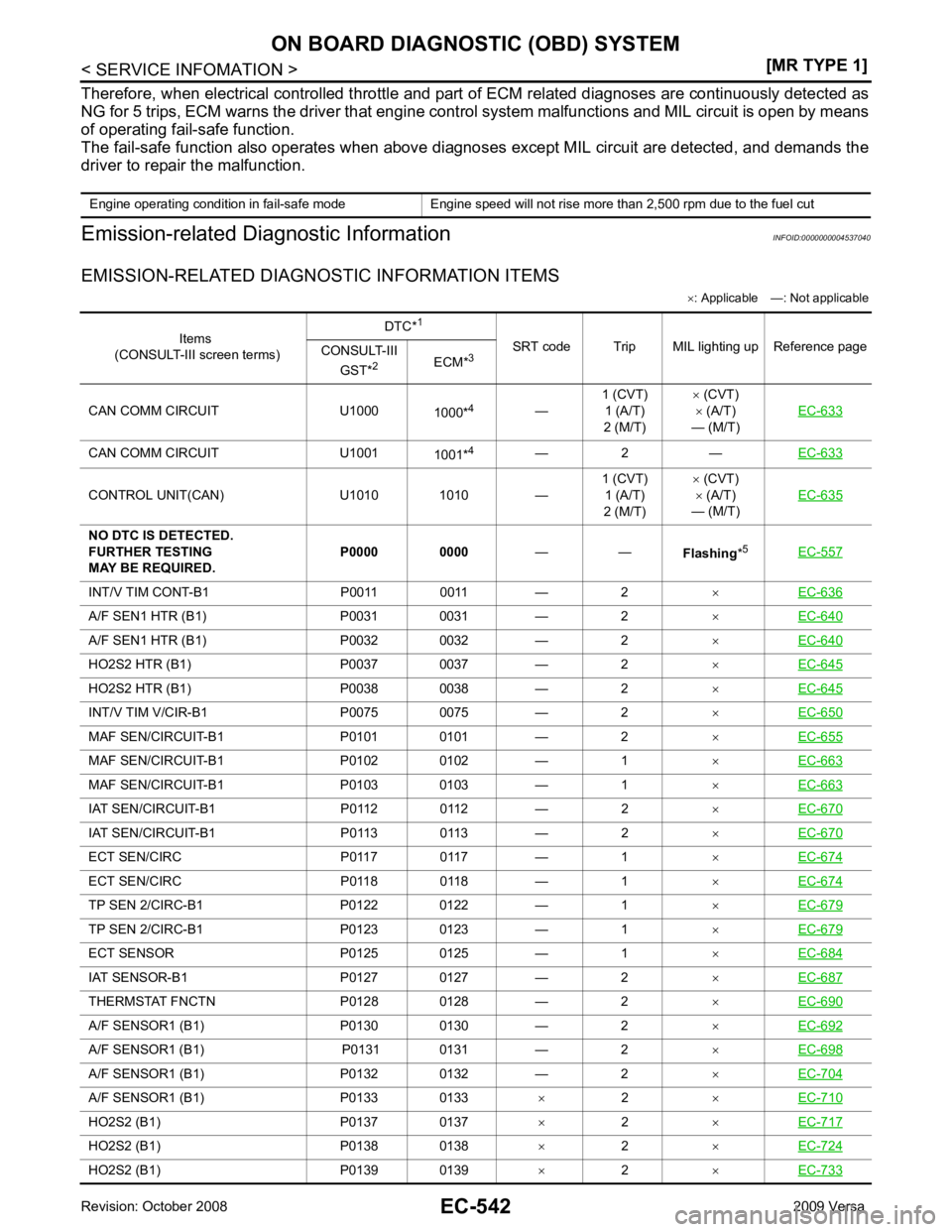

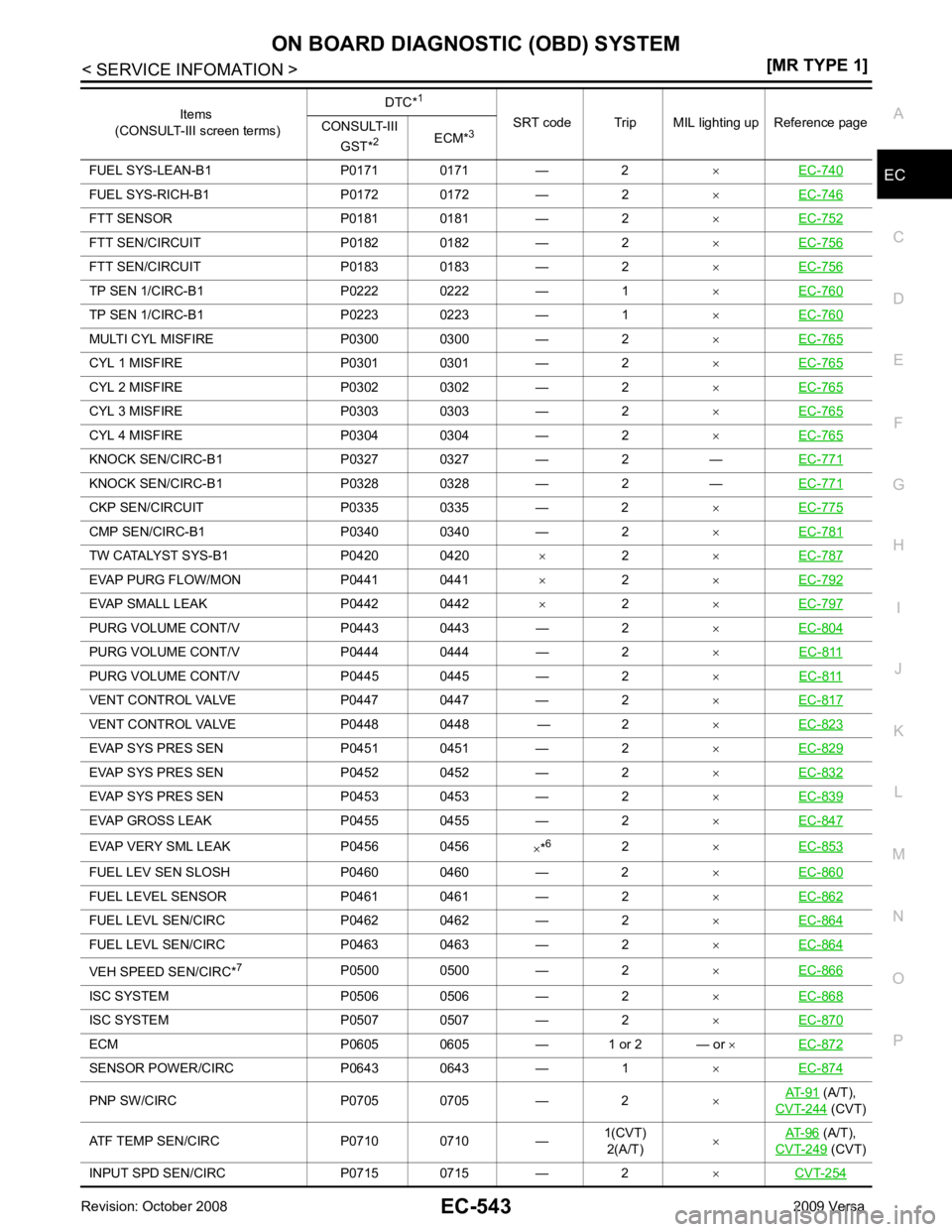

Items

(CONSULT-III screen terms) DTC*

1

SRT code Trip MIL lighting up Reference page

CONSULT-III

GST* 2

ECM*3

CAN COMM CIRCUIT U1000 1000*4

—1 (CVT)

1 (A/T)

2 (M/T) ×

(CVT)

× (A/T)

— (M/T) EC-633CAN COMM CIRCUIT U1001

1001*4

— 2 — EC-633CONTROL UNIT(CAN) U1010 1010 —

1 (CVT)

1 (A/T)

2 (M/T) ×

(CVT)

× (A/T)

— (M/T) EC-635INT/V TIM CONT-B1 P0011 0011 — 2

×EC-636 A/F SEN1 HTR (B1) P0031 0031 — 2

×EC-640 A/F SEN1 HTR (B1) P0032 0032 — 2

×EC-640 HO2S2 HTR (B1) P0037 0037 — 2

×EC-645 HO2S2 HTR (B1) P0038 0038 — 2

×EC-645 INT/V TIM V/CIR-B1 P0075 0075 — 2

×EC-650 MAF SEN/CIRCUIT-B1 P0101 0101 — 2

×EC-655 MAF SEN/CIRCUIT-B1 P0102 0102 — 1

×EC-663 MAF SEN/CIRCUIT-B1 P0103 0103 — 1

×EC-663 IAT SEN/CIRCUIT-B1 P0112 0112 — 2

×EC-670 IAT SEN/CIRCUIT-B1 P0113 0113 — 2

×EC-670 ECT SEN/CIRC P0117 0117 — 1

×EC-674 ECT SEN/CIRC P0118 0118 — 1

×EC-674 TP SEN 2/CIRC-B1 P0122 0122 — 1

×EC-679 TP SEN 2/CIRC-B1 P0123 0123 — 1

×EC-679 ECT SENSOR P0125 0125 — 1

×EC-684 IAT SENSOR-B1 P0127 0127 — 2

×EC-687 THERMSTAT FNCTN P0128 0128 — 2

×EC-690 A/F SENSOR1 (B1) P0130 0130 — 2

×EC-692 A/F SENSOR1 (B1) P0131 0131 — 2

×EC-698 A/F SENSOR1 (B1) P0132 0132 — 2

×EC-704 A/F SENSOR1 (B1) P0133 0133

×2 ×EC-710 HO2S2 (B1) P0137 0137

×2 ×EC-717 HO2S2 (B1) P0138 0138

×2 ×EC-724 HO2S2 (B1) P0139 0139

×2 ×EC-733

Page 1899 of 4331

EC

NP

O

FUEL SYS-LEAN-B1 P0171 0171 — 2

×EC-740 FUEL SYS-RICH-B1 P0172 0172 — 2

×EC-746 FTT SENSOR P0181 0181 — 2

×EC-752 FTT SEN/CIRCUIT P0182 0182 — 2

×EC-756 FTT SEN/CIRCUIT P0183 0183 — 2

×EC-756 TP SEN 1/CIRC-B1 P0222 0222 — 1

×EC-760 TP SEN 1/CIRC-B1 P0223 0223 — 1

×EC-760 MULTI CYL MISFIRE P0300 0300 — 2

×EC-765 CYL 1 MISFIRE P0301 0301 — 2

×EC-765 CYL 2 MISFIRE P0302 0302 — 2

×EC-765 CYL 3 MISFIRE P0303 0303 — 2

×EC-765 CYL 4 MISFIRE P0304 0304 — 2

×EC-765 KNOCK SEN/CIRC-B1 P0327 0327 — 2 —

EC-771KNOCK SEN/CIRC-B1 P0328 0328 — 2 —

EC-771CKP SEN/CIRCUIT P0335 0335 — 2

×EC-775 CMP SEN/CIRC-B1 P0340 0340 — 2

×EC-781 TW CATALYST SYS-B1 P0420 0420

× 2 ×EC-787 EVAP PURG FLOW/MON P0441 0441

×2 ×EC-792 EVAP SMALL LEAK P0442 0442

×2 ×EC-797 PURG VOLUME CONT/V P0443 0443 — 2

×EC-804 PURG VOLUME CONT/V P0444 0444 — 2

×EC-811 PURG VOLUME CONT/V P0445 0445 — 2

×EC-811 VENT CONTROL VALVE P0447 0447 — 2

×EC-817 VENT CONTROL VALVE P0448 0448 — 2

×EC-823 EVAP SYS PRES SEN P0451 0451 — 2

×EC-829 EVAP SYS PRES SEN P0452 0452 — 2

×EC-832 EVAP SYS PRES SEN P0453 0453 — 2

×EC-839 EVAP GROSS LEAK P0455 0455 — 2

×EC-847 EVAP VERY SML LEAK P0456 0456

×*6

2 ×EC-853 FUEL LEV SEN SLOSH P0460 0460 — 2

×EC-860 FUEL LEVEL SEN

SOR P0461 0461 — 2 ×EC-862 FUEL LEVL SEN/C

IRC P0462 0462 — 2 ×EC-864 FUEL LEVL SEN/C

IRC P0463 0463 — 2 ×EC-864 VEH SPEED SEN/CIRC*

7

P0500 0500 — 2 ×EC-866 ISC SYSTEM P0506 0506 — 2

×EC-868 ISC SYSTEM P0507 0507 — 2

×EC-870 ECM P0605 0605 — 1 or 2 — or

×EC-872 SENSOR POWER/CIRC P0643 0643 — 1

×EC-874 PNP SW/CIRC P0705 0705 — 2

×AT-91 (A/T),

CVT-244 (CVT)

ATF TEMP SEN/CIRC P0710 0710 — 1(CVT)

2(A/T) ×

AT-96 (A/T),

CVT-249 (CVT)

INPUT SPD SEN/CIRC P0715 0715 — 2 ×CVT-254 Items

(CONSULT-III screen terms) DTC*

1

SRT code Trip MIL lighting up Reference page

CONSULT-III

GST* 2

ECM*3