NISSAN LATIO 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 3031 of 3745

LT-36

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

How to Perform Trouble Diagnosis

INFOID:0000000005394903

1. Confirm the symptom or customer complaint.

2. Understand operation, description and function description. Refer to LT-28, "

System Description" .

3. Perform the Preliminary Check. Refer to LT-36, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of the malfunction.

5. Does the daytime light syst em operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckINFOID:0000000005394904

CHECK BCM CONFIGURATION

1.CHECK BCM CONFIGURATION

Confirm BCM configuration for "DTRL" is set to "WITH". Refer to BCS-19, "

Configuration" .

OK or NG

OK >> Continue preliminary check. Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspec-

tion" .

NG >> Change BCM configuration for "DTRL" to "WITH". Refer to BCS-19, "

Configuration" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-27, "IPDM E/R Power/Ground Circuit Inspection" .

CONSULT-III Function (BCM)INFOID:0000000005613050

Refer to LT-13, "CONSULT-III Function (BCM)" .

CONSULT-III Function (IPDM E/R)INFOID:0000000005613051

Refer to LT-14, "CONSULT-III Function (IPDM E/R)" .

Daytime Light Control Does Not Operate Properly (High Beam Headlamps Operate

Properly)

INFOID:0000000005394907

1.CHECK DAYTIME LIGHT RELAY 1 FUSE

Inspect daytime light relay fuse 10A fuse (No. 26, located in the fuse and fusible link box).

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

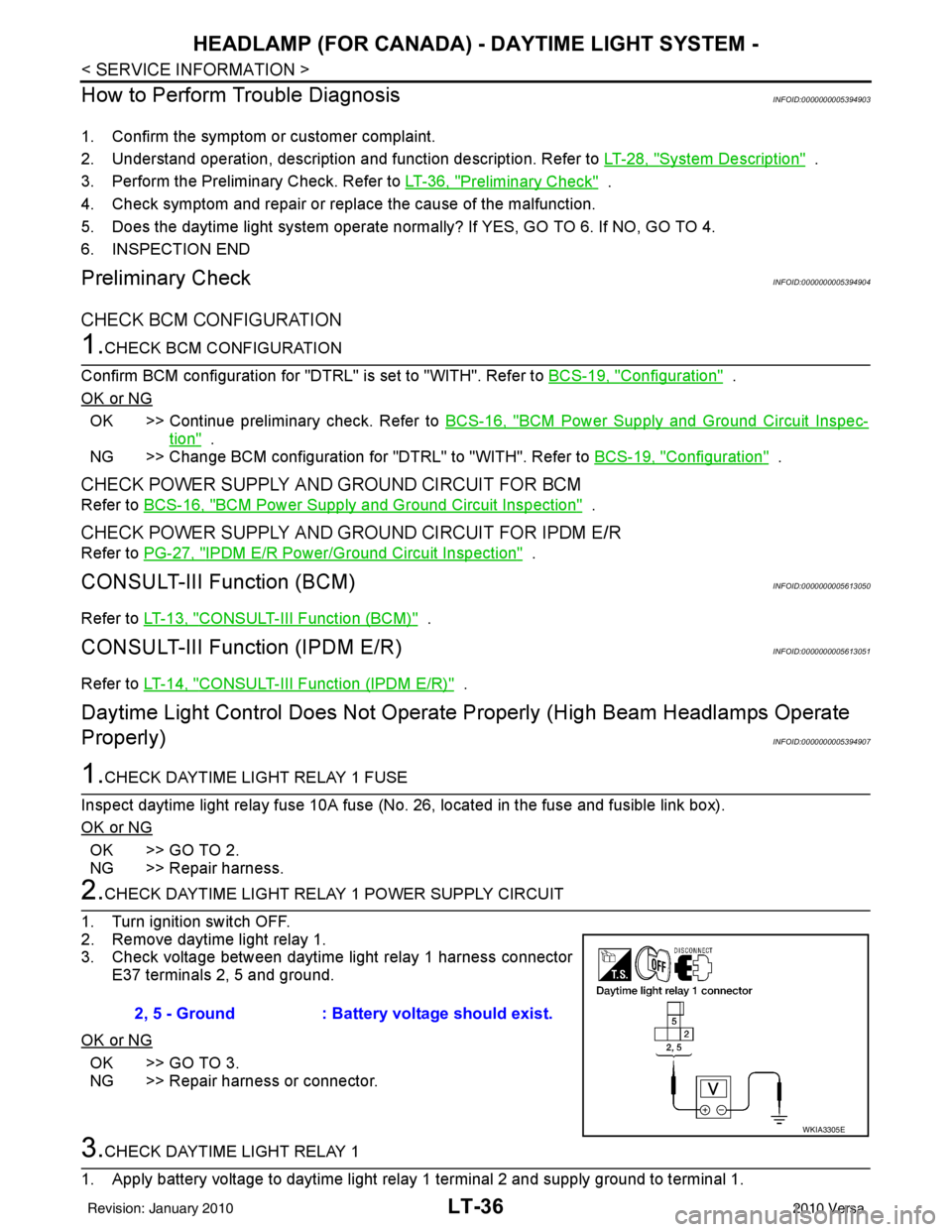

2.CHECK DAYTIME LIGHT RELAY 1 POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Remove daytime light relay 1.

3. Check voltage between daytime light relay 1 harness connector E37 terminals 2, 5 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK DAYTIME LIGHT RELAY 1

1. Apply battery voltage to daytime light relay 1 terminal 2 and supply ground to terminal 1. 2, 5 - Ground

: Battery voltage should exist.

WKIA3305E

Revision: January 20102010 Versa

Page 3032 of 3745

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-37

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

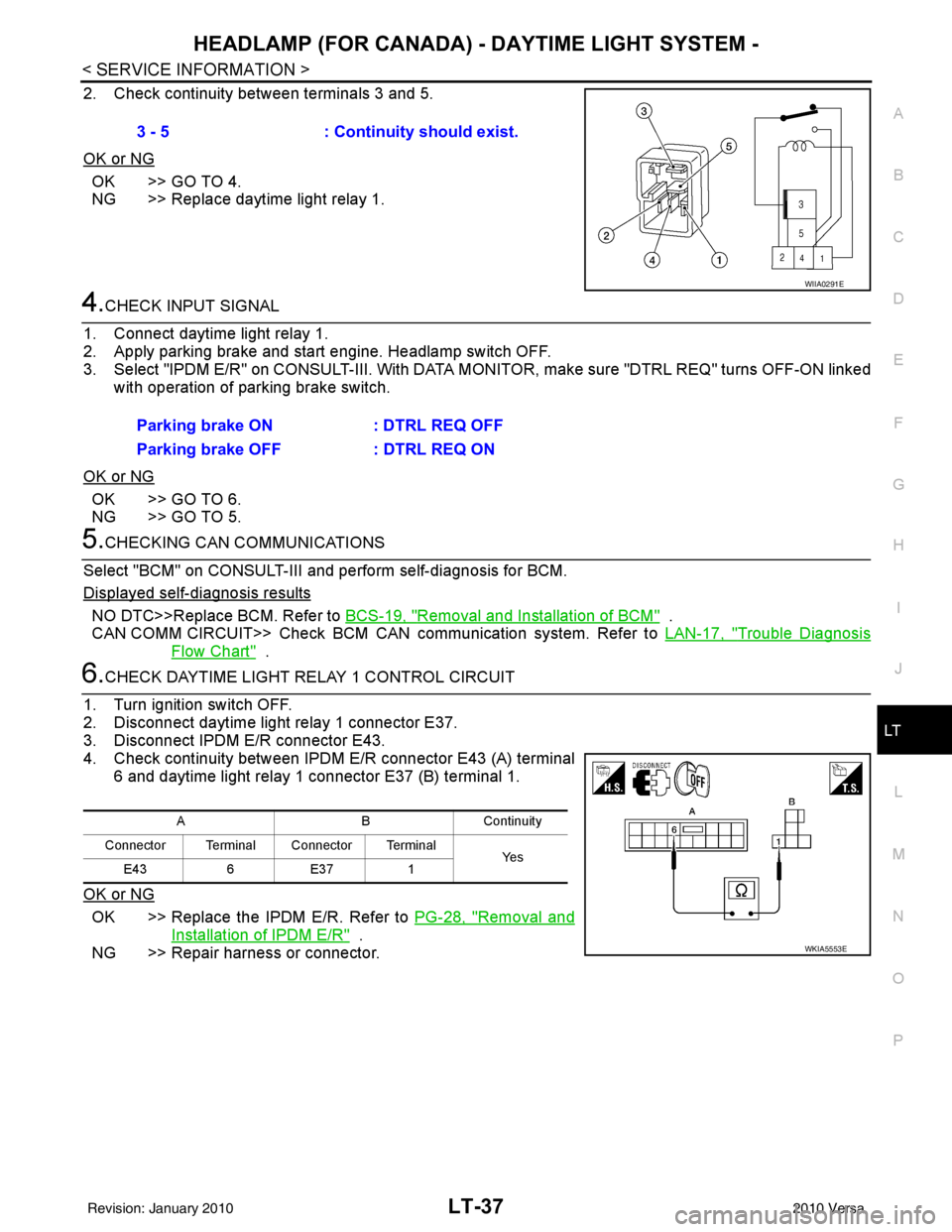

2. Check continuity between terminals 3 and 5.

OK or NG

OK >> GO TO 4.

NG >> Replace daytime light relay 1.

4.CHECK INPUT SIGNAL

1. Connect daytime light relay 1.

2. Apply parking brake and start engine. Headlamp switch OFF.

3. Select "IPDM E/R" on CONSULT-II I. With DATA MONITOR, make sure "DTRL REQ" turns OFF-ON linked

with operation of parking brake switch.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECKING CAN COMMUNICATIONS

Select "BCM" on CONSULT-III and perform self-diagnosis for BCM.

Displayed self-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-19, "Removal and Installation of BCM" .

CAN COMM CIRCUIT>> Check BCM CAN communication system. Refer to LAN-17, "

Trouble Diagnosis

Flow Chart" .

6.CHECK DAYTIME LIGHT RELAY 1 CONTROL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect daytime light relay 1 connector E37.

3. Disconnect IPDM E/R connector E43.

4. Check continuity between IPDM E/R connector E43 (A) terminal 6 and daytime light relay 1 connector E37 (B) terminal 1.

OK or NG

OK >> Replace the IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector. 3 - 5

: Continuity should exist.

WIIA0291E

Parking brake ON : DTRL REQ OFF

Parking brake OFF : DTRL REQ ON

ABC ontin u it y

Connector Terminal Connector Terminal Ye s

E43 6E37 1

WKIA5553E

Revision: January 20102010 Versa

Page 3033 of 3745

LT-38

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

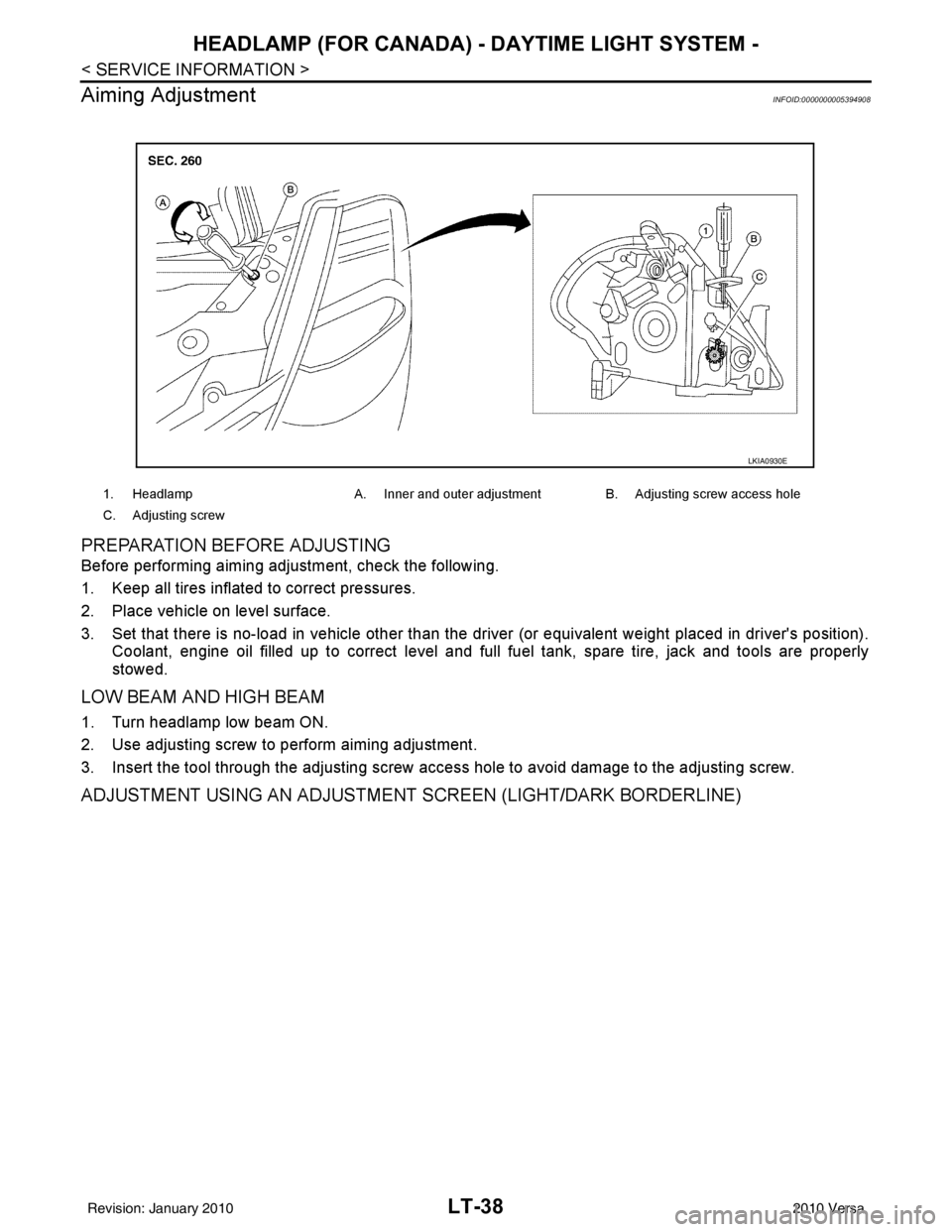

Aiming Adjustment

INFOID:0000000005394908

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level surface.

3. Set that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank, spare tire, jack and tools are properly

stowed.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screw to perform aiming adjustment.

3. Insert the tool through the adjusting screw access hole to avoid damage to the adjusting screw.

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

1. Headlamp A. Inner and outer adjustment B. Adjusting screw access hole

C. Adjusting screw

LKIA0930E

Revision: January 20102010 Versa

Page 3034 of 3745

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-39

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

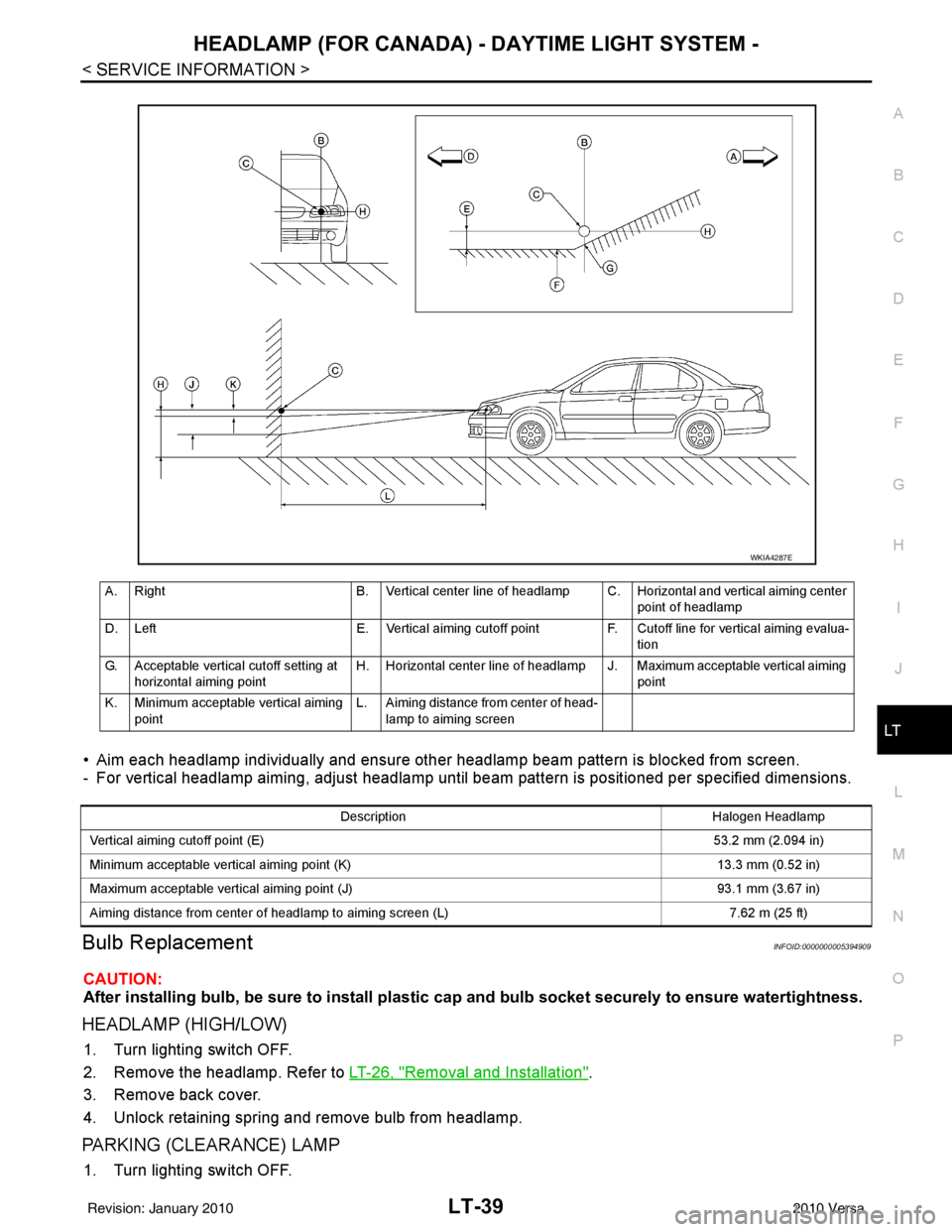

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- For vertical headlamp aiming, adjust headlamp until beam pattern is positioned per specified dimensions.

Bulb ReplacementINFOID:0000000005394909

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to ensure watertightness.

HEADLAMP (HIGH/LOW)

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-26, "

Removal and Installation".

3. Remove back cover.

4. Unlock retaining spring and remove bulb from headlamp.

PARKING (CLEARANCE) LAMP

1. Turn lighting switch OFF.

A. Right B. Vertical center line of headlamp C. Horizontal and vertical aiming center

point of headlamp

D. Left E. Vertical aiming cutoff pointF. Cutoff line for vertical aiming evalua-

tion

G. Acceptable vertical cutoff setting at horizontal aiming point H. Horizontal center line of headlamp J. Maximum acceptable vertical aiming

point

K. Minimum acceptable vertical aiming point L. Aiming distance from center of head-

lamp to aiming screen

WKIA4287E

Description Halogen Headlamp

Vertical aiming cutoff point (E) 53.2 mm (2.094 in)

Minimum acceptable vertical aiming point (K) 13.3 mm (0.52 in)

Maximum acceptable vertical aiming point (J) 93.1 mm (3.67 in)

Aiming distance from center of headlamp to aiming screen (L) 7.62 m (25 ft)

Revision: January 20102010 Versa

Page 3035 of 3745

LT-40

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

2. Remove the headlamp. Refer to LT-26, "Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-26, "

Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

Removal and InstallationINFOID:0000000005394910

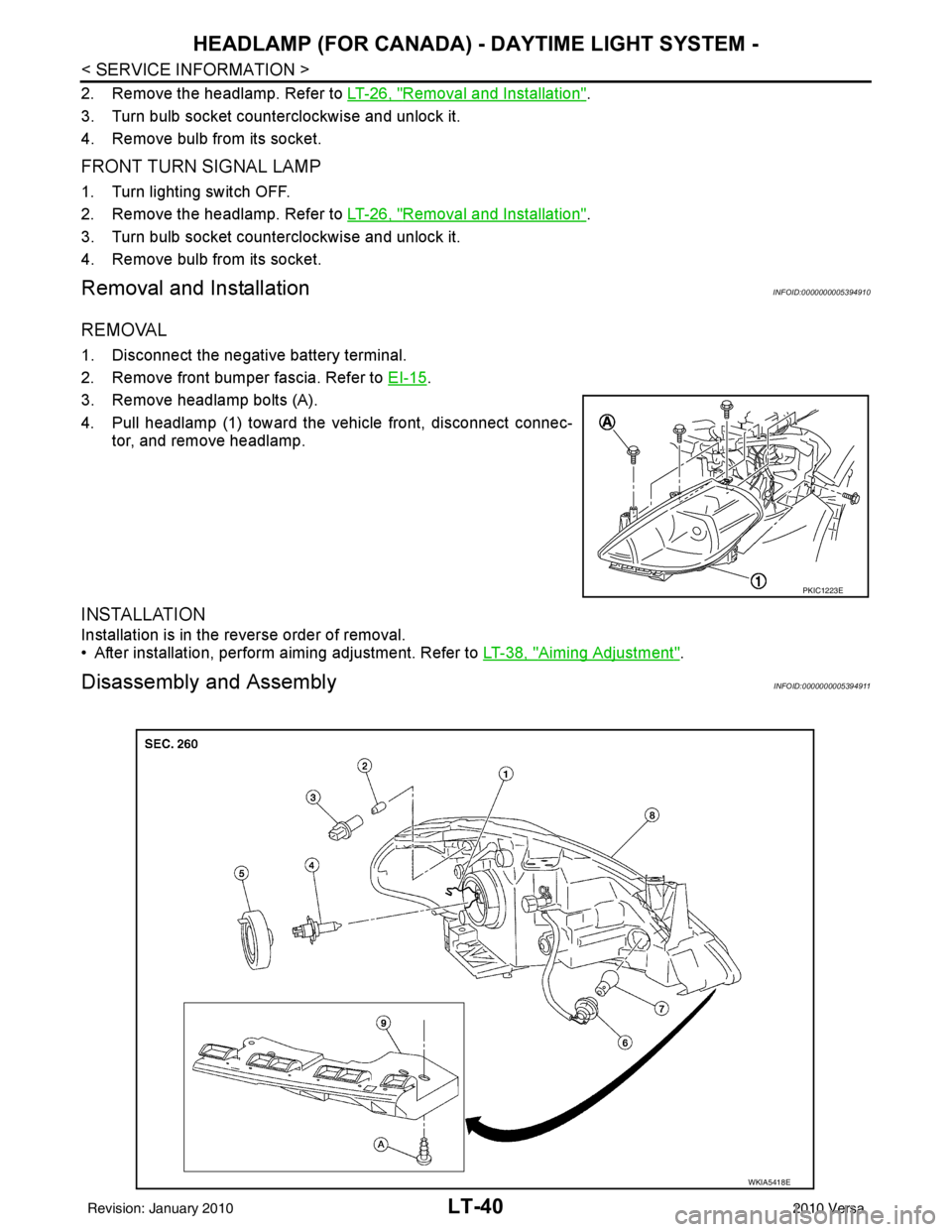

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove front bumper fascia. Refer to EI-15

.

3. Remove headlamp bolts (A).

4. Pull headlamp (1) toward the vehicle front, disconnect connec- tor, and remove headlamp.

INSTALLATION

Installation is in the reverse order of removal.

• After installation, perform aiming adjustment. Refer to LT-38, "

Aiming Adjustment".

Disassembly and AssemblyINFOID:0000000005394911

PKIC1223E

WKIA5418E

Revision: January 20102010 Versa

Page 3036 of 3745

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-41

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

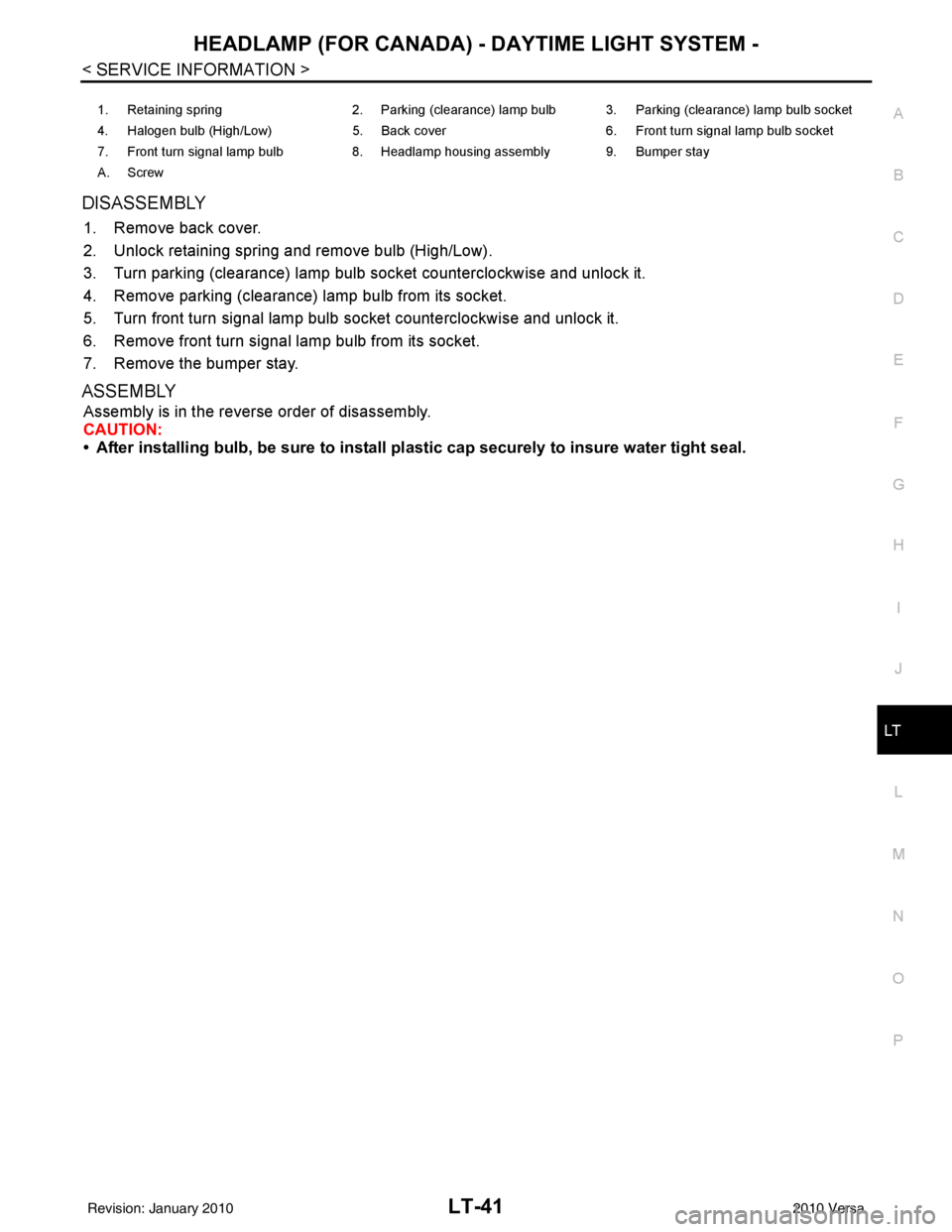

DISASSEMBLY

1. Remove back cover.

2. Unlock retaining spring and remove bulb (High/Low).

3. Turn parking (clearance) lamp bulb socket counterclockwise and unlock it.

4. Remove parking (clearance) lamp bulb from its socket.

5. Turn front turn signal lamp bulb socket counterclockwise and unlock it.

6. Remove front turn signal lamp bulb from its socket.

7. Remove the bumper stay.

ASSEMBLY

Assembly is in the reverse order of disassembly.

CAUTION:

• After installing bulb, be sure to install plastic cap securely to insure water tight seal.

1. Retaining spring 2. Parking (clearance) lamp bulb 3. Parking (clearance) lamp bulb socket

4. Halogen bulb (High/Low) 5. Back cover6. Front turn signal lamp bulb socket

7. Front turn signal lamp bulb 8. Headlamp housing assembly 9. Bumper stay

A. Screw

Revision: January 20102010 Versa

Page 3037 of 3745

LT-42

< SERVICE INFORMATION >

FRONT FOG LAMP

FRONT FOG LAMP

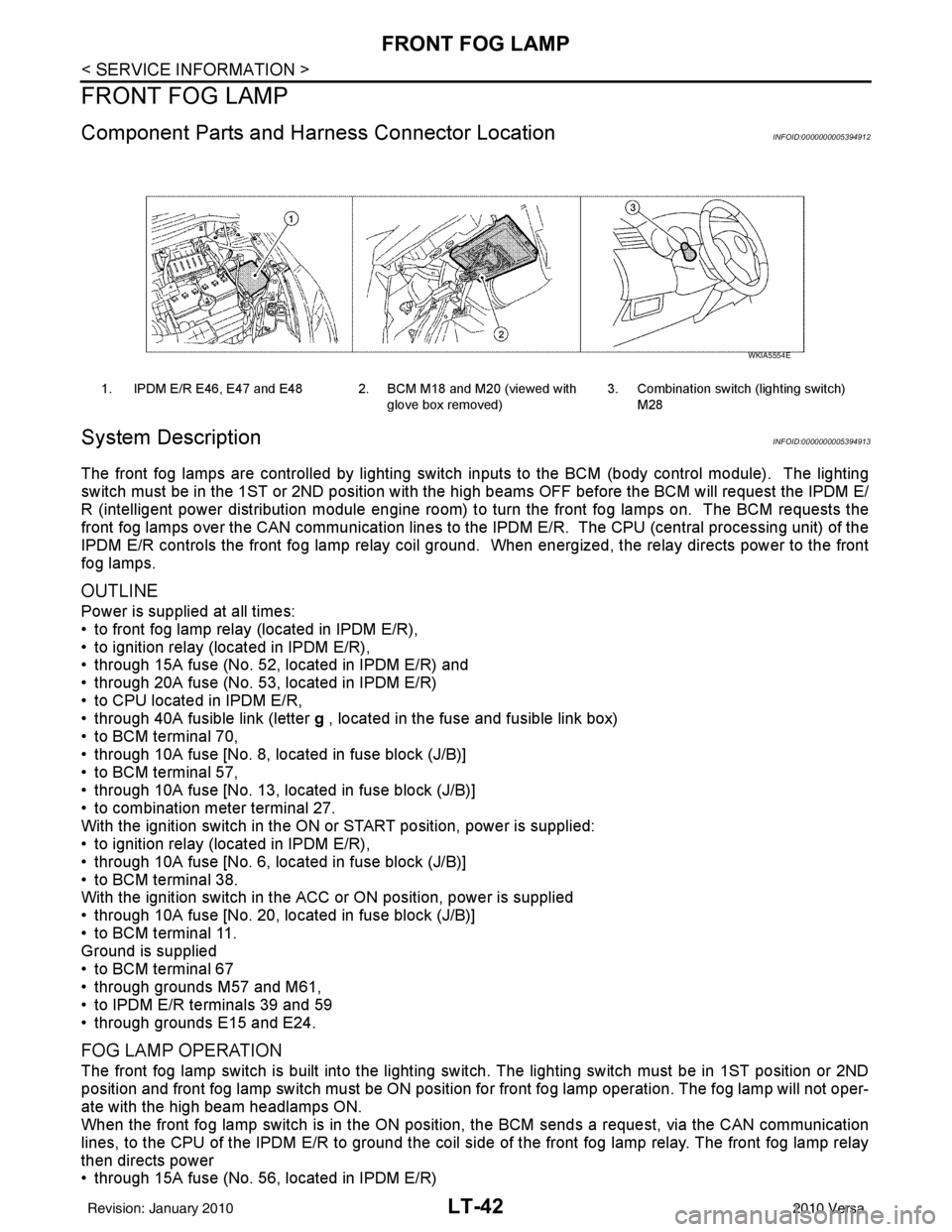

Component Parts and Harness Connector LocationINFOID:0000000005394912

System DescriptionINFOID:0000000005394913

The front fog lamps are controlled by lighting switch inputs to the BCM (body control module). The lighting

switch must be in the 1ST or 2ND position with t he high beams OFF before the BCM will request the IPDM E/

R (intelligent power distribution module engine room) to turn the front fog lamps on. The BCM requests the

front fog lamps over the CAN communication lines to the IPDM E/R. The CPU (central processing unit) of the

IPDM E/R controls the front fog lamp relay coil ground. When energized, the relay directs power to the front

fog lamps.

OUTLINE

Power is supplied at all times:

• to front fog lamp relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied:

• to ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

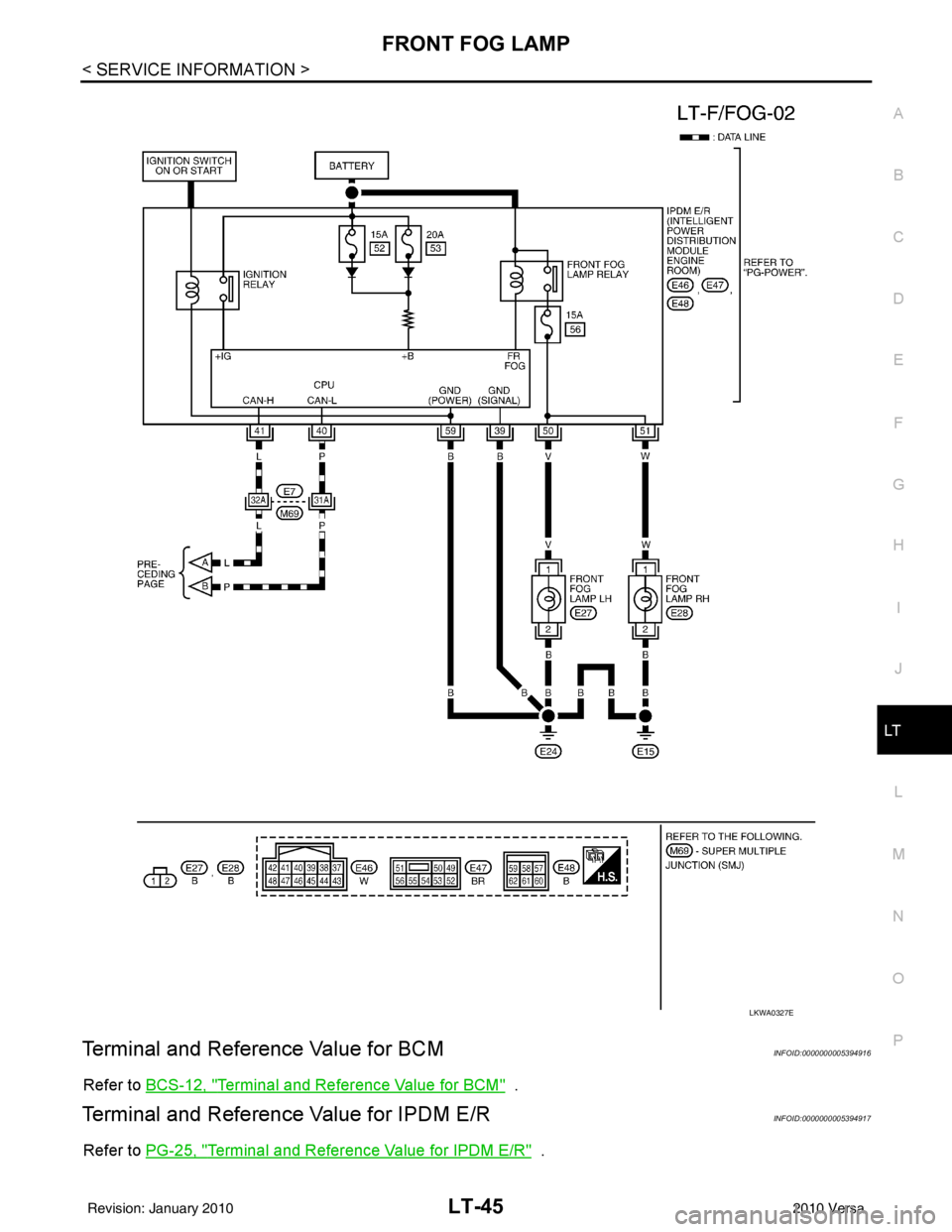

FOG LAMP OPERATION

The front fog lamp switch is built into the lighting s witch. The lighting switch must be in 1ST position or 2ND

position and front fog lamp switch must be ON position fo r front fog lamp operation. The fog lamp will not oper-

ate with the high beam headlamps ON.

When the front fog lamp switch is in the ON positi on, the BCM sends a request, via the CAN communication

lines, to the CPU of the IPDM E/R to ground the coil side of the front fog lamp relay. The front fog lamp relay

then directs power

• through 15A fuse (No. 56, located in IPDM E/R)

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (viewed with

glove box removed)3. Combination switch (lighting switch)

M28

WKIA5554E

Revision: January 20102010 Versa

Page 3038 of 3745

FRONT FOG LAMPLT-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

• through IPDM E/R terminal 50

• to front fog lamp LH terminal 1, and

• through IPDM E/R terminal 51

• to front fog lamp RH terminal 1.

Ground is supplied

• to front fog lamp terminal 2,

• through grounds E15 and E24.

With power and grounds supplied, front fog lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-75, "System Description" .

CAN Communication System DescriptionINFOID:0000000005394914

Refer to LAN-7, "System Description" .

Revision: January 20102010 Versa

Page 3039 of 3745

LT-44

< SERVICE INFORMATION >

FRONT FOG LAMP

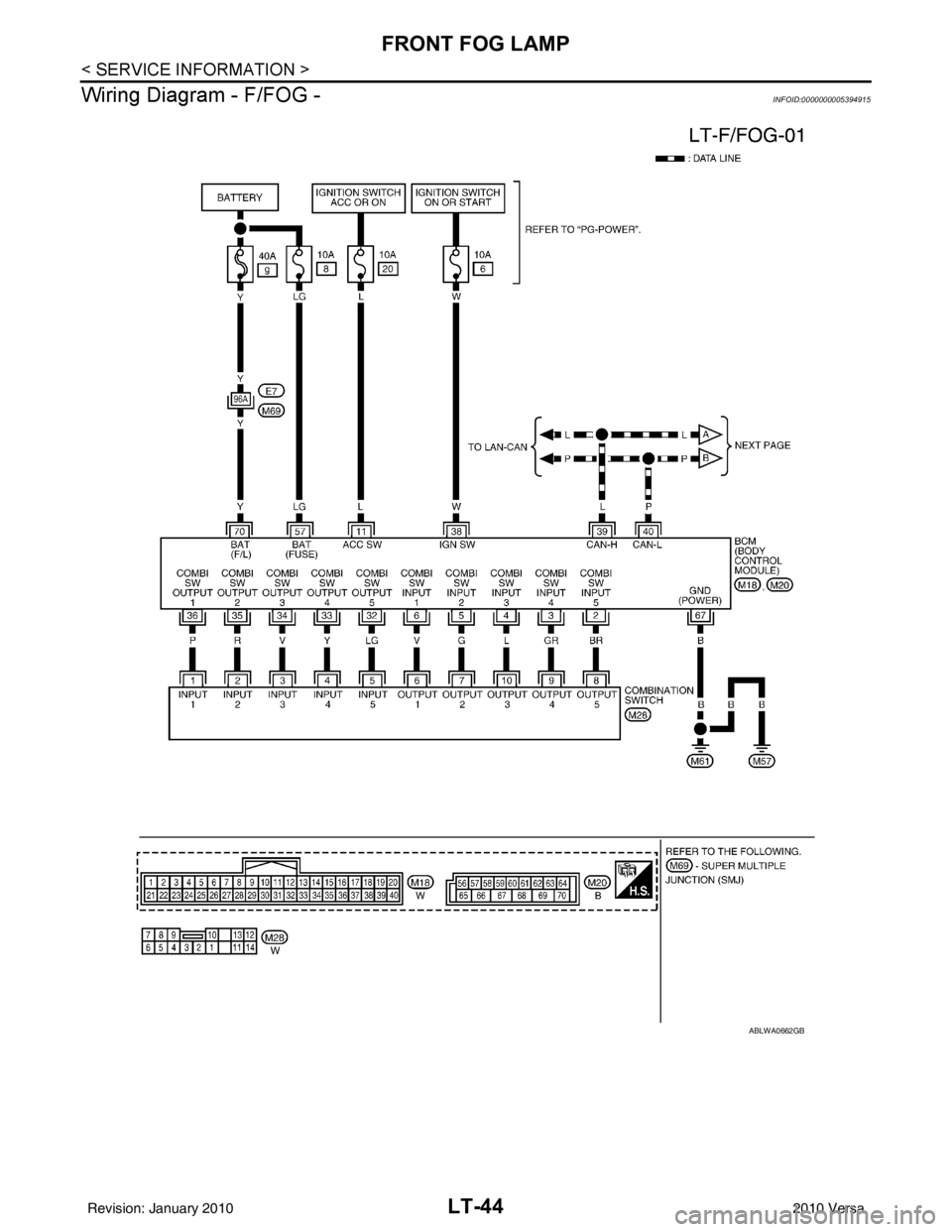

Wiring Diagram - F/FOG -

INFOID:0000000005394915

ABLWA0662GB

Revision: January 20102010 Versa

Page 3040 of 3745

FRONT FOG LAMPLT-45

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Terminal and Reference Value for BCMINFOID:0000000005394916

Refer to BCS-12, "Terminal and Reference Value for BCM" .

Terminal and Reference Value for IPDM E/RINFOID:0000000005394917

Refer to PG-25, "Terminal and Reference Value for IPDM E/R" .

LKWA0327E

Revision: January 20102010 Versa