NISSAN LATIO 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 311 of 3745

AT-294

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

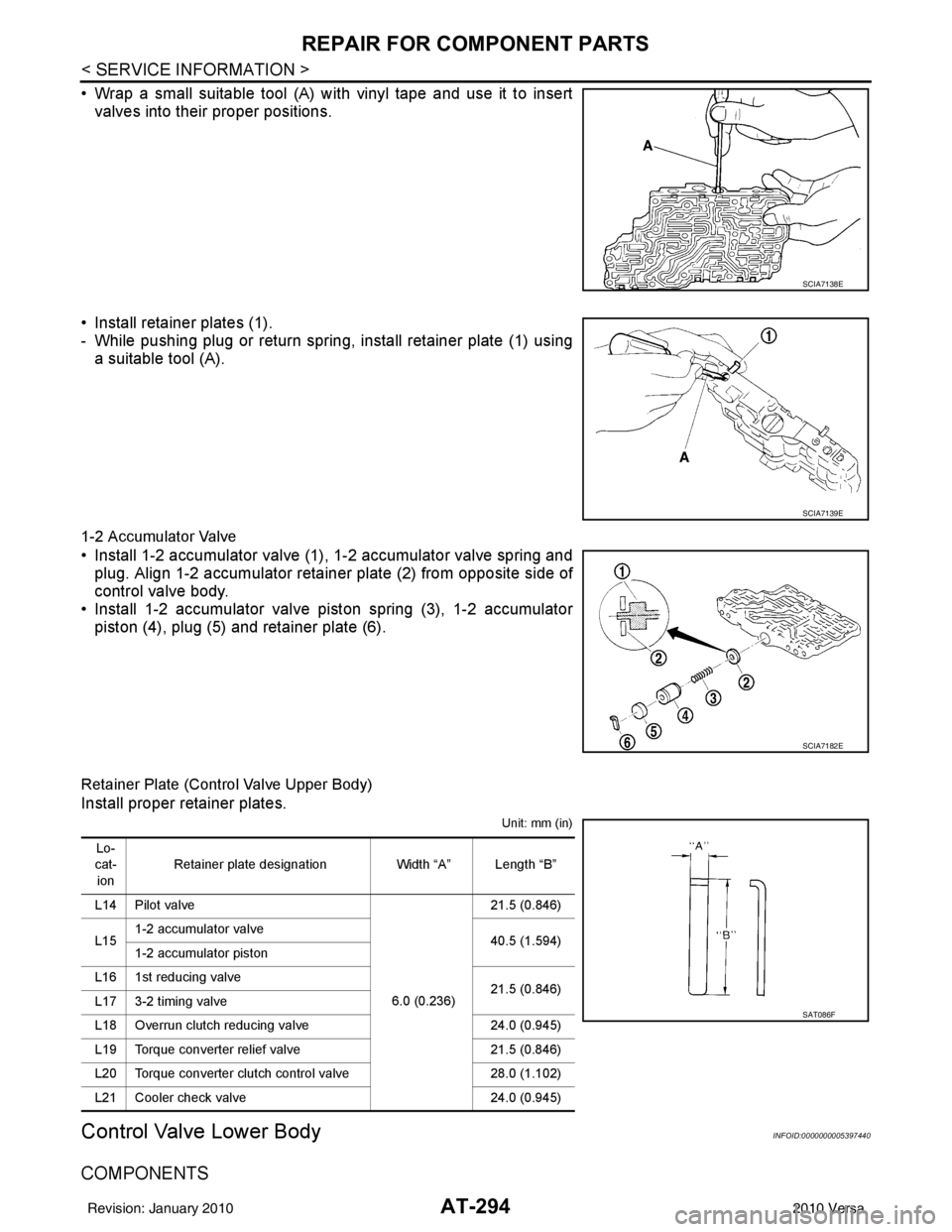

• Wrap a small suitable tool (A) with vinyl tape and use it to insertvalves into their proper positions.

• Install retainer plates (1).

- While pushing plug or return spring, install retainer plate (1) using a suitable tool (A).

1-2 Accumulator Valve

• Install 1-2 accumulator valve (1), 1-2 accumulator valve spring and

plug. Align 1-2 accumulator retainer plate (2) from opposite side of

control valve body.

• Install 1-2 accumulator valve piston spring (3), 1-2 accumulator

piston (4), plug (5) and retainer plate (6).

Retainer Plate (Control Valve Upper Body)

Install proper retainer plates.

Unit: mm (in)

Control Valve Lower BodyINFOID:0000000005397440

COMPONENTS

SCIA7138E

SCIA7139E

SCIA7182E

Lo-

cat-

ion Retainer plate designation

Width “A” Length “B”

L14 Pilot valve

6.0 (0.236)21.5 (0.846)

L15 1-2 accumulator valve

40.5 (1.594)

1-2 accumulator piston

L16 1st reducing valve 21.5 (0.846)

L17 3-2 timing valve

L18 Overrun clutch reducing valve 24.0 (0.945)

L19 Torque converter relief valve 21.5 (0.846)

L20 Torque converter clutch control valve 28.0 (1.102)

L21 Cooler check valve 24.0 (0.945)

SAT086F

Revision: January 20102010 Versa

Page 312 of 3745

REPAIR FOR COMPONENT PARTSAT-295

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

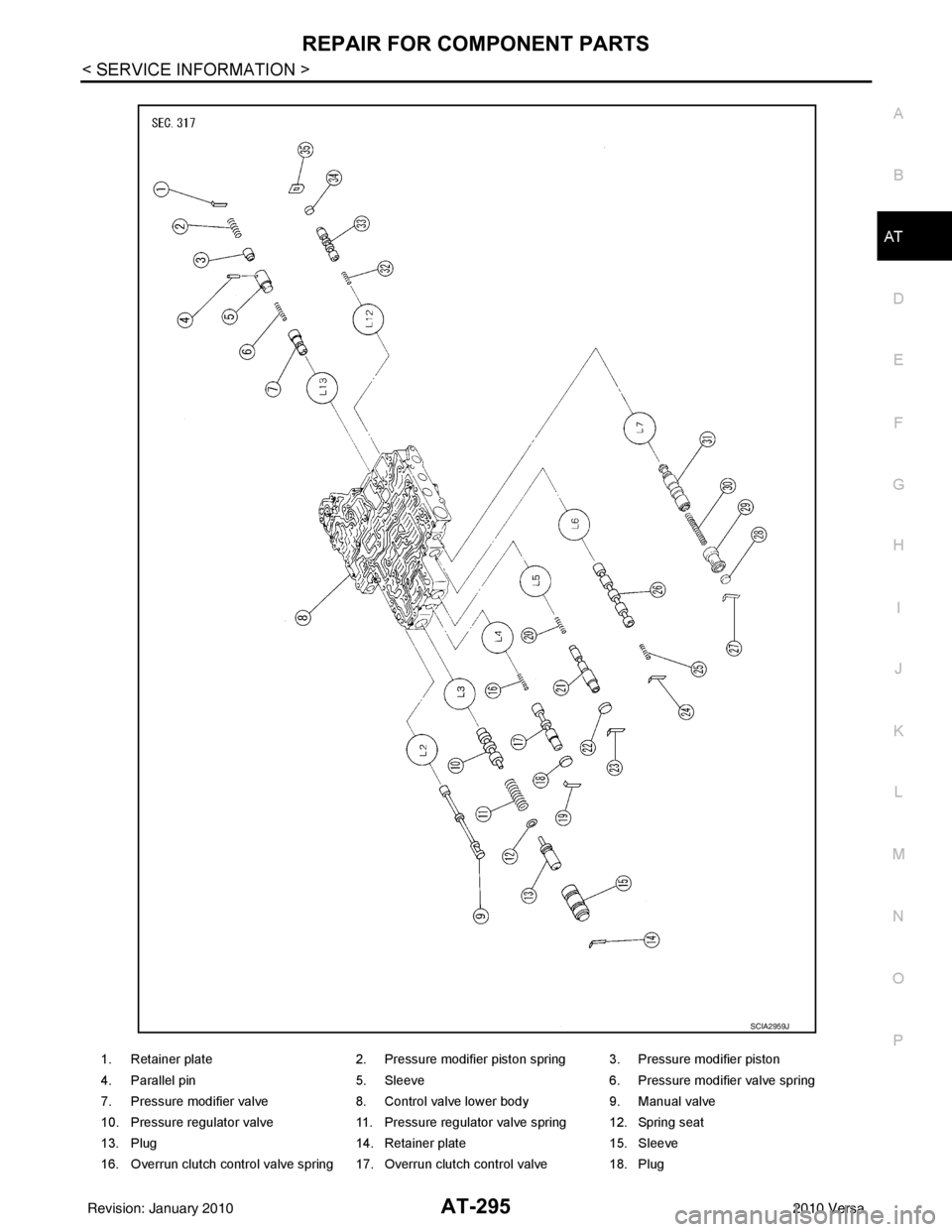

1. Retainer plate 2. Pressure modifier piston spring 3. Pressure modifier piston

4. Parallel pin 5. Sleeve6. Pressure modifier valve spring

7. Pressure modifier valve 8. Control valve lower body9. Manual valve

10. Pressure regulator valve 11. Pressure regulator valve spring 12. Spring seat

13. Plug 14. Retainer plate15. Sleeve

16. Overrun clutch control valve spring 17. Overrun clutch control valve 18. Plug

SCIA2959J

Revision: January 20102010 Versa

Page 313 of 3745

AT-296

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

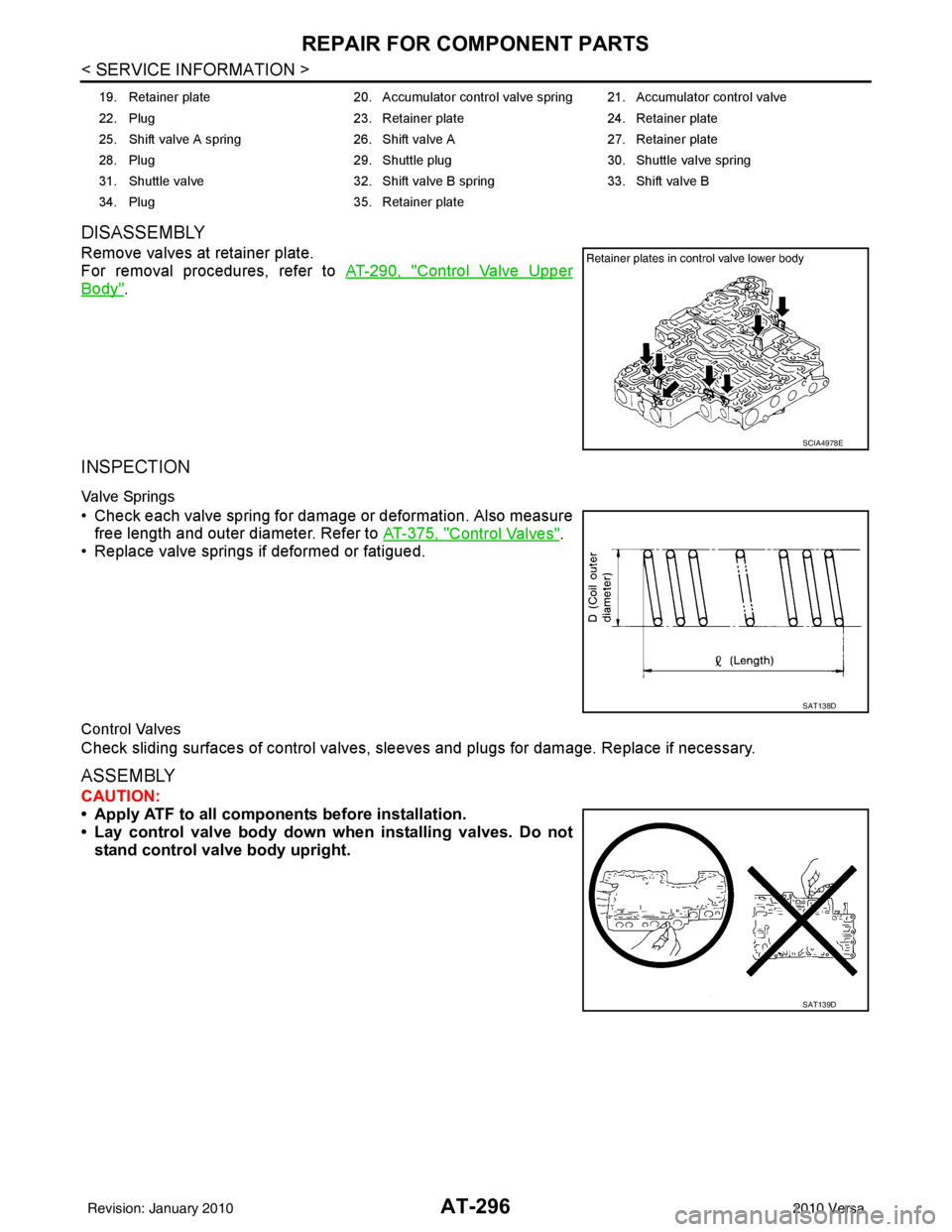

DISASSEMBLY

Remove valves at retainer plate.

For removal procedures, refer to AT-290, "

Control Valve Upper

Body".

INSPECTION

Valve Springs

• Check each valve spring for damage or deformation. Also measure

free length and outer diameter. Refer to AT-375, "

Control Valves".

• Replace valve springs if deformed or fatigued.

Control Valves

Check sliding surfaces of control valves, sl eeves and plugs for damage. Replace if necessary.

ASSEMBLY

CAUTION:

• Apply ATF to all components before installation.

• Lay control valve body down wh en installing valves. Do not

stand control valve body upright.

19. Retainer plate 20. Accumulator control valve spring 21. Accumulator control valve

22. Plug 23. Retainer plate24. Retainer plate

25. Shift valve A spring 26. Shift valve A27. Retainer plate

28. Plug 29. Shuttle plug 30. Shuttle valve spring

31. Shuttle valve 32. Shift valve B spring33. Shift valve B

34. Plug 35. Retainer plate

SCIA4978E

SAT138D

SAT139D

Revision: January 20102010 Versa

Page 314 of 3745

REPAIR FOR COMPONENT PARTSAT-297

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

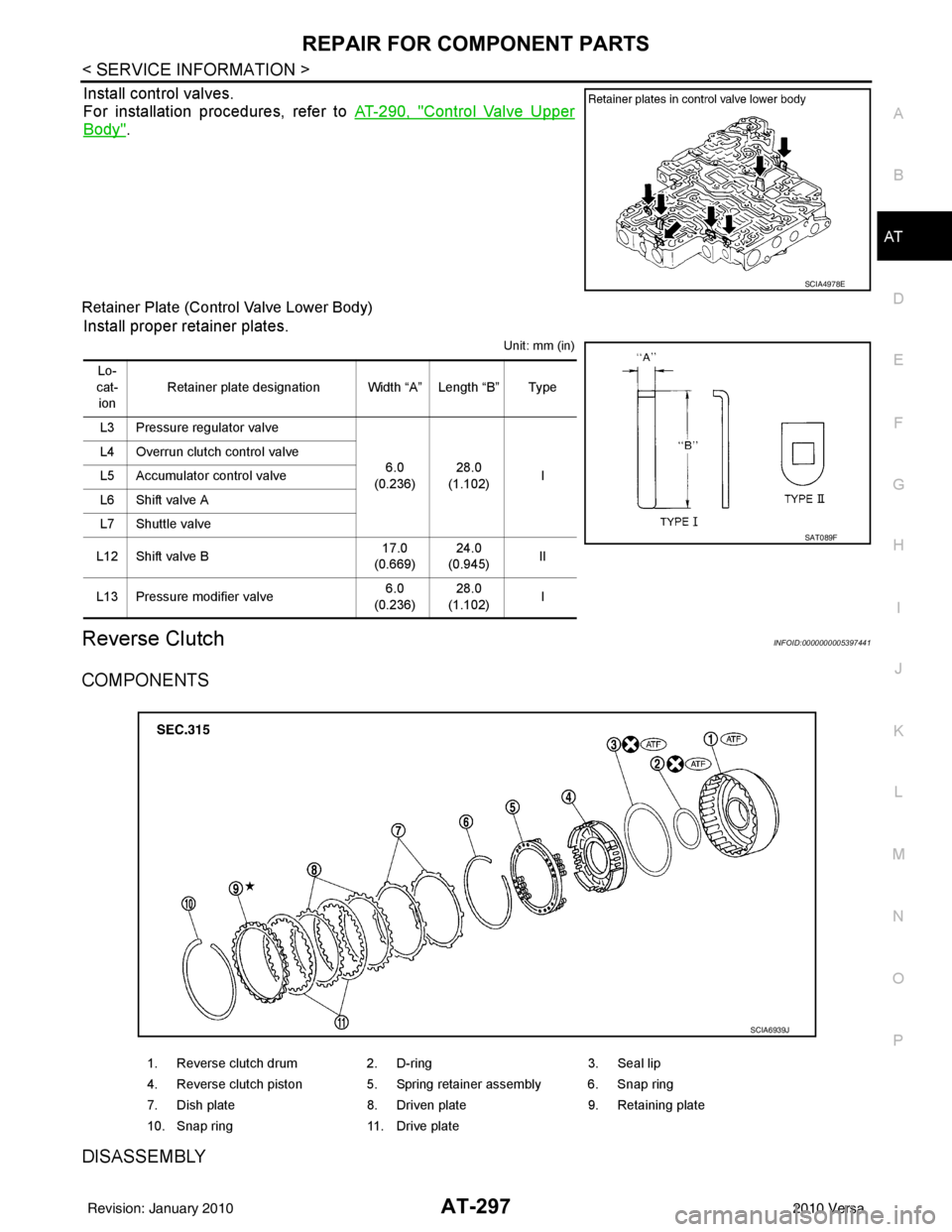

Install control valves.

For installation procedures, refer to AT-290, "

Control Valve Upper

Body".

Retainer Plate (Control Valve Lower Body)

Install proper retainer plates.

Unit: mm (in)

Reverse ClutchINFOID:0000000005397441

COMPONENTS

DISASSEMBLY

SCIA4978E

Lo-

cat- ion Retainer plate designation Width “A” Length “B” Type

L3 Pressure regulator valve 6.0

(0.236) 28.0

(1.102) I

L4 Overrun clutch control valve

L5 Accumulator control valve

L6 Shift valve A

L7 Shuttle valve

L12 Shift valve B 17.0

(0.669) 24.0

(0.945) II

L13 Pressure modifier valve 6.0

(0.236) 28.0

(1.102) I

SAT089F

1. Reverse clutch drum

2. D-ring 3. Seal lip

4. Reverse clutch piston 5. Spring retainer assembly 6. Snap ring

7. Dish plate 8. Driven plate 9. Retaining plate

10. Snap ring 11. Drive plate

SCIA6939J

Revision: January 20102010 Versa

Page 315 of 3745

AT-298

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

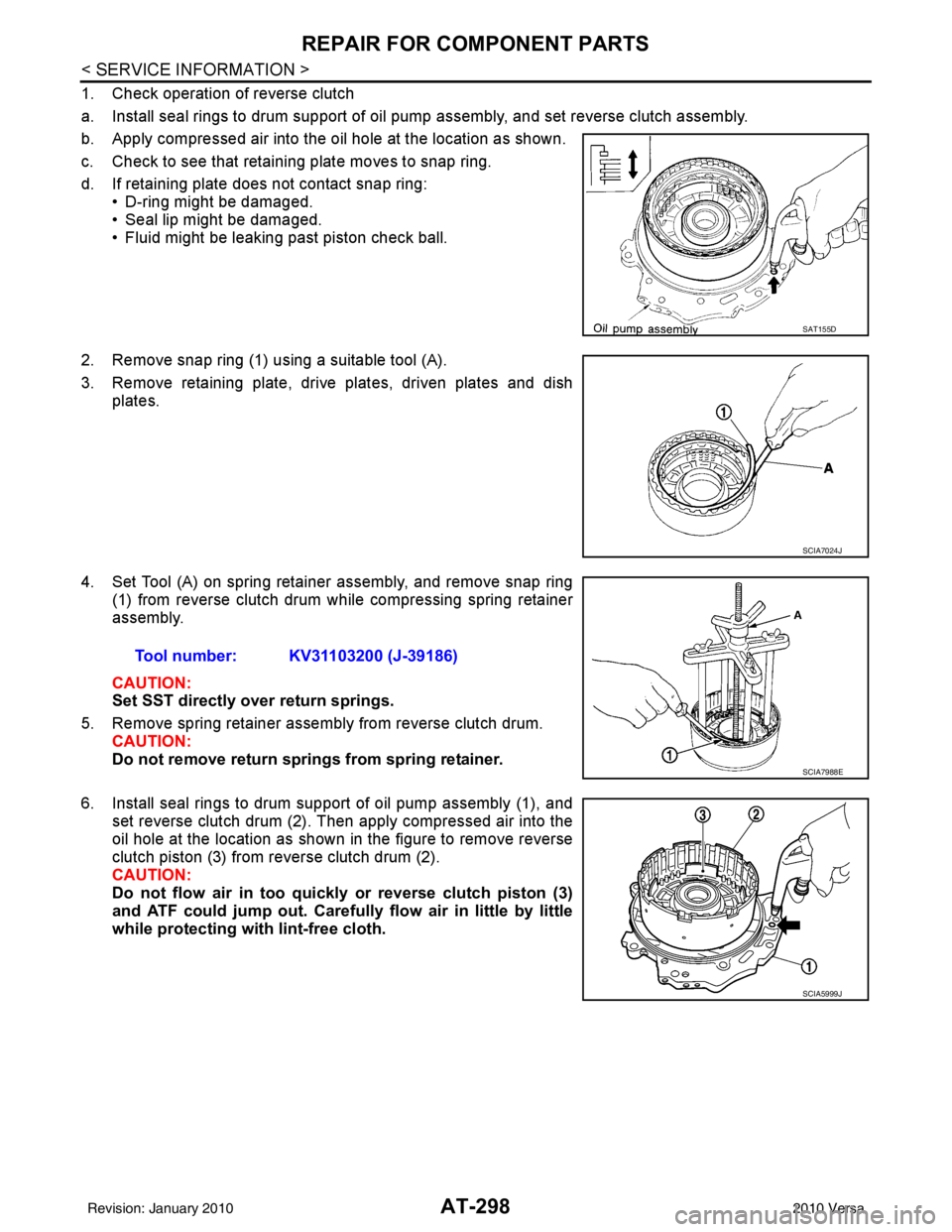

1. Check operation of reverse clutch

a. Install seal rings to drum support of oil pump assembly, and set reverse clutch assembly.

b. Apply compressed air into the oil hole at the location as shown.

c. Check to see that retaining plate moves to snap ring.

d. If retaining plate does not contact snap ring:• D-ring might be damaged.

• Seal lip might be damaged.

• Fluid might be leaking past piston check ball.

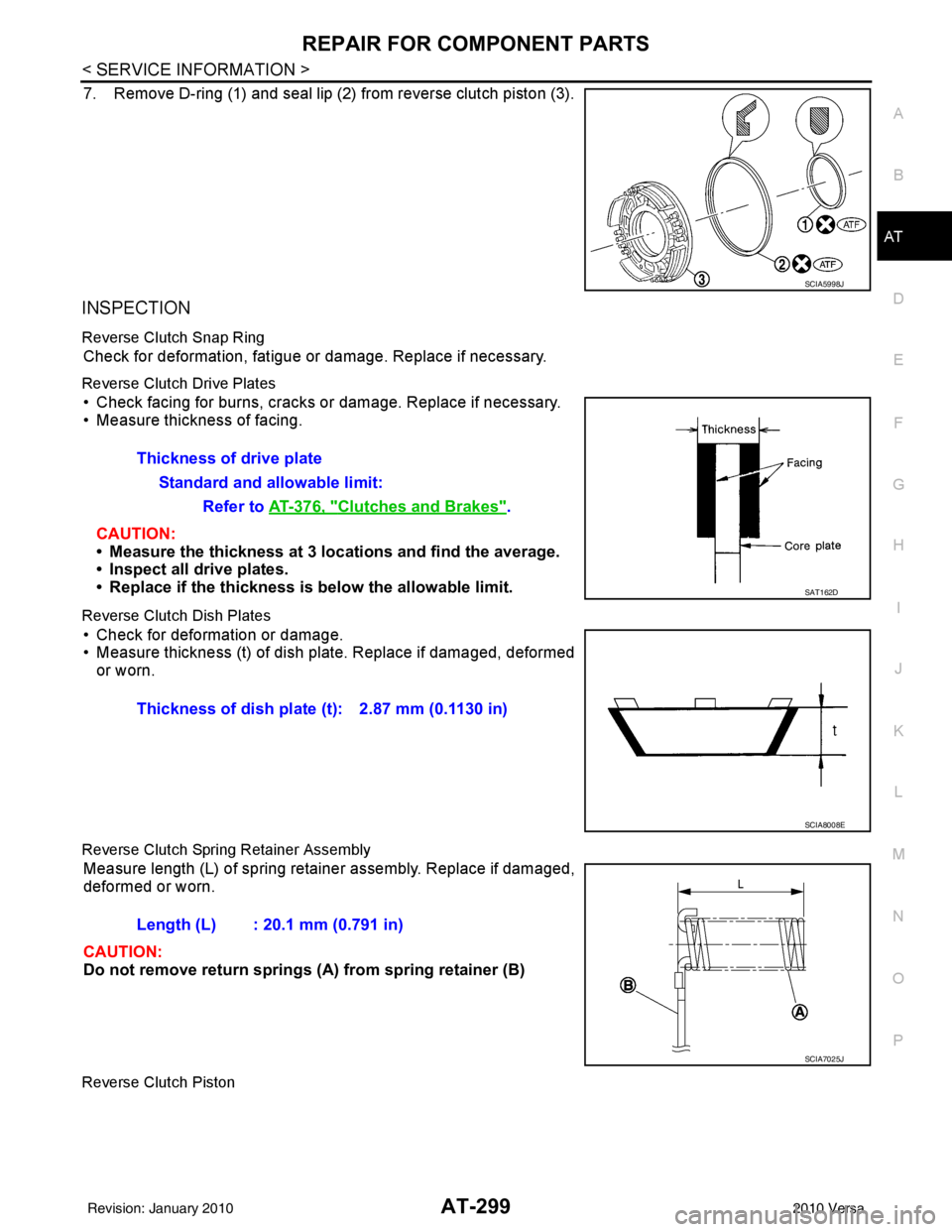

2. Remove snap ring (1) using a suitable tool (A).

3. Remove retaining plate, drive plates, driven plates and dish plates.

4. Set Tool (A) on spring retainer assembly, and remove snap ring (1) from reverse clutch drum while compressing spring retainer

assembly.

CAUTION:

Set SST directly over return springs.

5. Remove spring retainer assembly from reverse clutch drum. CAUTION:

Do not remove return springs from spring retainer.

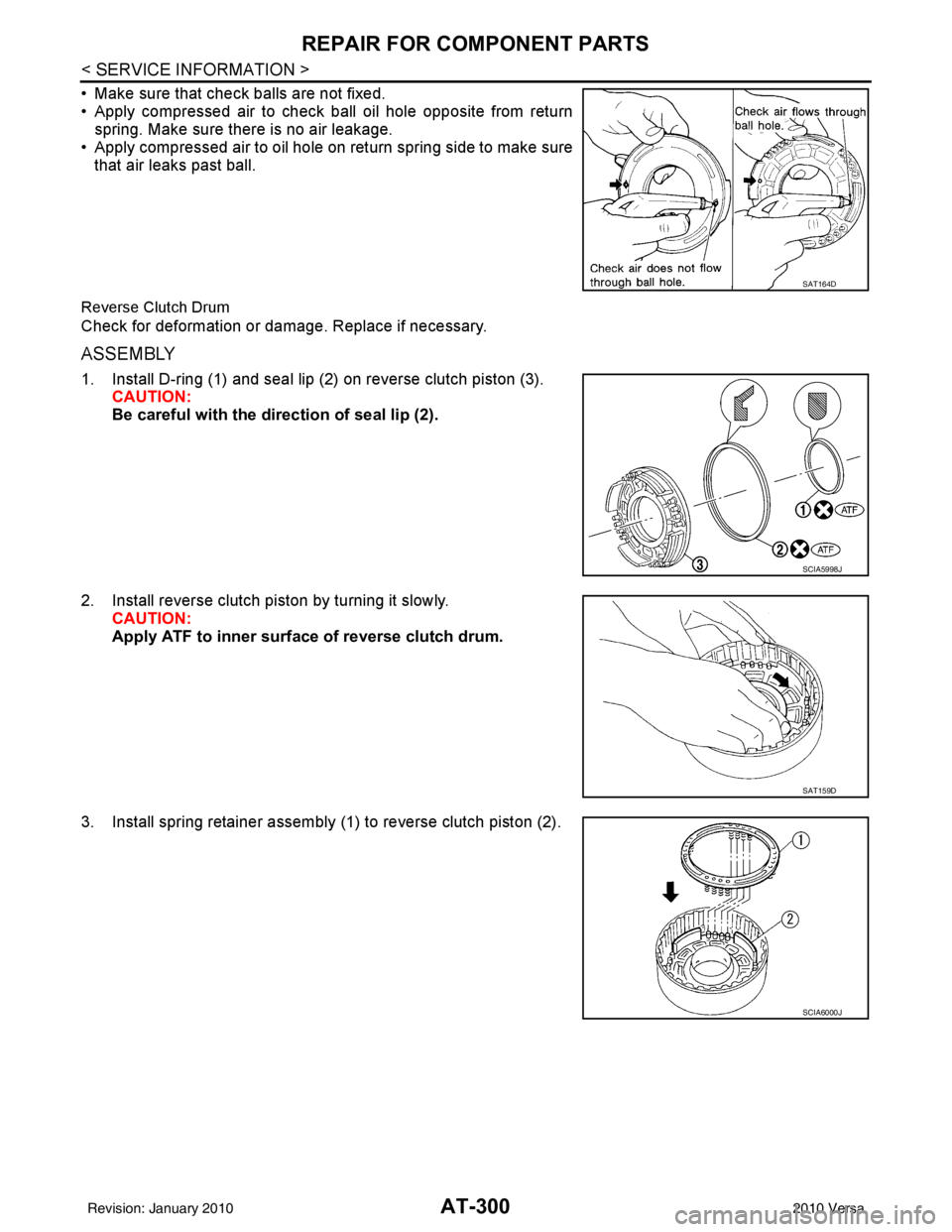

6. Install seal rings to drum support of oil pump assembly (1), and set reverse clutch drum (2). Then apply compressed air into the

oil hole at the location as shown in the figure to remove reverse

clutch piston (3) from reverse clutch drum (2).

CAUTION:

Do not flow air in too quickl y or reverse clutch piston (3)

and ATF could jump out. Carefully flow air in little by little

while protecting wi th lint-free cloth.

SAT155D

SCIA7024J

Tool number: KV31103200 (J-39186)

SCIA7988E

SCIA5999J

Revision: January 20102010 Versa

Page 316 of 3745

REPAIR FOR COMPONENT PARTSAT-299

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

7. Remove D-ring (1) and seal lip (2) from reverse clutch piston (3).

INSPECTION

Reverse Clutch Snap Ring

Check for deformation, fatigue or damage. Replace if necessary.

Reverse Clutch Drive Plates

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 lo cations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Reverse Clutch Dish Plates

• Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed

or worn.

Reverse Clutch Spring Retainer Assembly

Measure length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainer (B)

Reverse Clutch Piston

SCIA5998J

Thickness of drive plate

Standard and allowable limit: Refer to AT-376, "

Clutches and Brakes".

SAT162D

Thickness of dish plate (t): 2.87 mm (0.1130 in)

SCIA8008E

Length (L) : 20.1 mm (0.791 in)

SCIA7025J

Revision: January 20102010 Versa

Page 317 of 3745

AT-300

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

• Make sure that check balls are not fixed.

• Apply compressed air to check ball oil hole opposite from returnspring. Make sure there is no air leakage.

• Apply compressed air to oil hole on return spring side to make sure that air leaks past ball.

Reverse Clutch Drum

Check for deformation or damage. Replace if necessary.

ASSEMBLY

1. Install D-ring (1) and seal lip (2) on reverse clutch piston (3). CAUTION:

Be careful with the direction of seal lip (2).

2. Install reverse clutch piston by turning it slowly. CAUTION:

Apply ATF to inner surface of reverse clutch drum.

3. Install spring retainer assembly (1) to reverse clutch piston (2).

SAT164D

SCIA5998J

SAT159D

SCIA6000J

Revision: January 20102010 Versa

Page 318 of 3745

REPAIR FOR COMPONENT PARTSAT-301

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

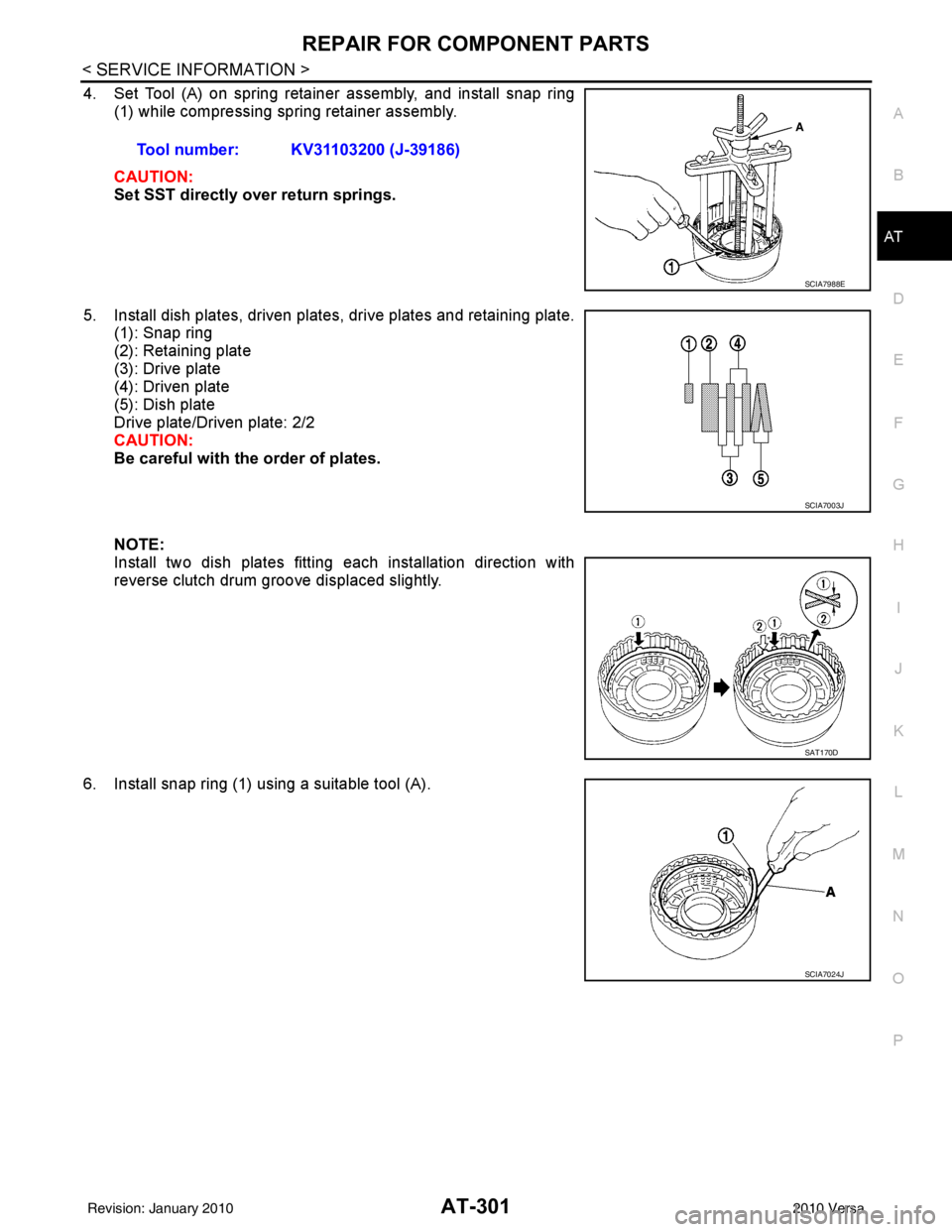

4. Set Tool (A) on spring retainer assembly, and install snap ring (1) while compressing spring retainer assembly.

CAUTION:

Set SST directly over return springs.

5. Install dish plates, driven plates, drive plates and retaining plate. (1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 2/2

CAUTION:

Be careful with the order of plates.

NOTE:

Install two dish plates fitting each installation direction with

reverse clutch drum groove displaced slightly.

6. Install snap ring (1) using a suitable tool (A). Tool number: KV31103200 (J-39186)

SCIA7988E

SCIA7003J

SAT170D

SCIA7024J

Revision: January 20102010 Versa

Page 319 of 3745

AT-302

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

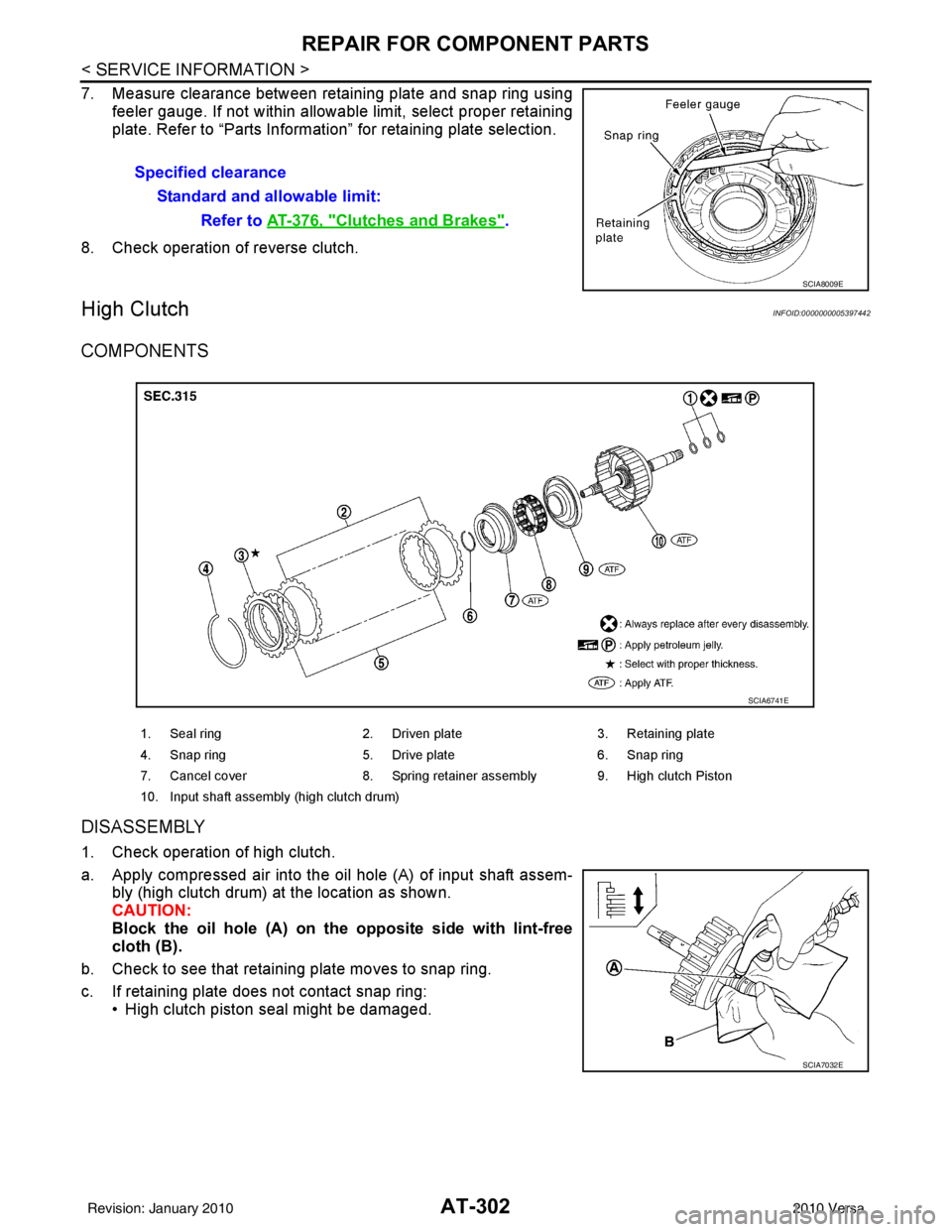

7. Measure clearance between retaining plate and snap ring usingfeeler gauge. If not within allowable limit, select proper retaining

plate. Refer to “Parts Information” for retaining plate selection.

8. Check operation of reverse clutch.

High ClutchINFOID:0000000005397442

COMPONENTS

DISASSEMBLY

1. Check operation of high clutch.

a. Apply compressed air into the oil hole (A) of input shaft assem- bly (high clutch drum) at the location as shown.

CAUTION:

Block the oil hole (A) on the opposite side with lint-free

cloth (B).

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring: • High clutch piston seal might be damaged.Specified clearance

Standard and allowable limit: Refer to AT-376, "

Clutches and Brakes".

SCIA8009E

1. Seal ring 2. Driven plate 3. Retaining plate

4. Snap ring 5. Drive plate 6. Snap ring

7. Cancel cover 8. Spring retainer assembly 9. High clutch Piston

10. Input shaft assembly (high clutch drum)

SCIA6741E

SCIA7032E

Revision: January 20102010 Versa

Page 320 of 3745

REPAIR FOR COMPONENT PARTSAT-303

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

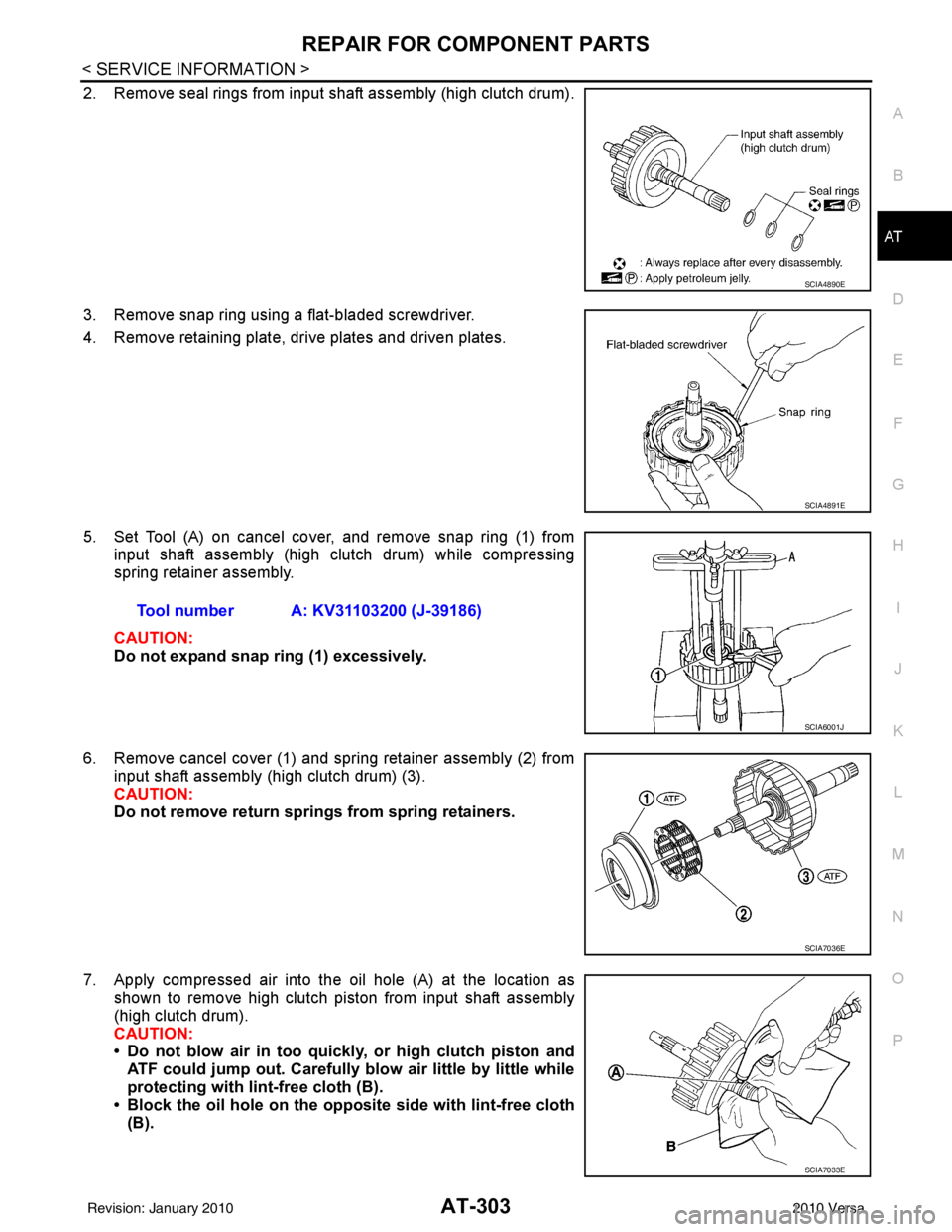

2. Remove seal rings from input shaft assembly (high clutch drum).

3. Remove snap ring using a flat-bladed screwdriver.

4. Remove retaining plate, drive plates and driven plates.

5. Set Tool (A) on cancel cover, and remove snap ring (1) from input shaft assembly (high clutch drum) while compressing

spring retainer assembly.

CAUTION:

Do not expand snap ring (1) excessively.

6. Remove cancel cover (1) and spring retainer assembly (2) from input shaft assembly (high clutch drum) (3).

CAUTION:

Do not remove return springs from spring retainers.

7. Apply compressed air into the oil hole (A) at the location as shown to remove high clutch piston from input shaft assembly

(high clutch drum).

CAUTION:

• Do not blow air in too quickly, or high clutch piston and

ATF could jump out. Carefully blow air little by little while

protecting with lint-free cloth (B).

• Block the oil hole on the oppo site side with lint-free cloth

(B).

SCIA4890E

SCIA4891E

Tool number A: KV31103200 (J-39186)

SCIA6001J

SCIA7036E

SCIA7033E

Revision: January 20102010 Versa