ECO mode NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1235 of 3171

DTC P1273 FUEL PUMP

EC-255

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KJW

1.CHECK INJECTOR ADJUSTMENT VALUE

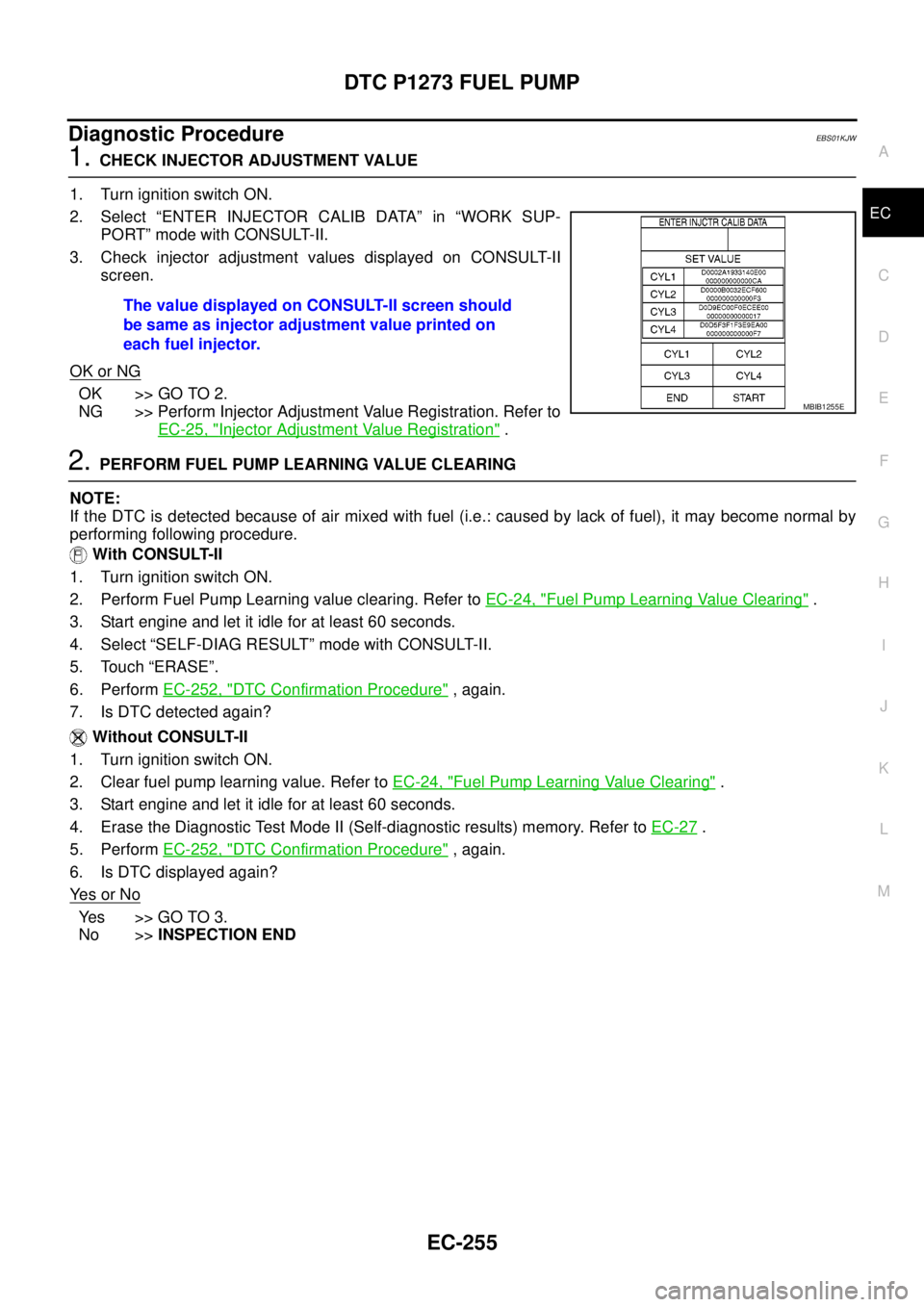

1. Turn ignition switch ON.

2. Select “ENTER INJECTOR CALIB DATA” in “WORK SUP-

PORT” mode with CONSULT-II.

3. Check injector adjustment values displayed on CONSULT-II

screen.

OK or NG

OK >> GO TO 2.

NG >> Perform Injector Adjustment Value Registration. Refer to

EC-25, "

Injector Adjustment Value Registration".

2.PERFORM FUEL PUMP LEARNING VALUE CLEARING

NOTE:

If the DTC is detected because of air mixed with fuel (i.e.: caused by lack of fuel), it may become normal by

performing following procedure.

With CONSULT-II

1. Turn ignition switch ON.

2. Perform Fuel Pump Learning value clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

3. Start engine and let it idle for at least 60 seconds.

4. Select “SELF-DIAG RESULT” mode with CONSULT-II.

5. Touch “ERASE”.

6. PerformEC-252, "

DTC Confirmation Procedure", again.

7. Is DTC detected again?

Without CONSULT-II

1. Turn ignition switch ON.

2. Clear fuel pump learning value. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

3. Start engine and let it idle for at least 60 seconds.

4. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

5. PerformEC-252, "

DTC Confirmation Procedure", again.

6. Is DTC displayed again?

Ye s o r N o

Ye s > > G O T O 3 .

No >>INSPECTION END The value displayed on CONSULT-II screen should

be same as injector adjustment value printed on

each fuel injector.

MBIB1255E

Page 1239 of 3171

DTC P1274 FUEL PUMP

EC-259

C

D

E

F

G

H

I

J

K

L

MA

EC

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicEBS01KK2

NOTE:

If DTC P1274 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KK3

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Tuning ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let idle for at least 5 seconds.

4. If DTC is detected, go toEC-261, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let idle for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-261, "

Diagnostic Procedure".

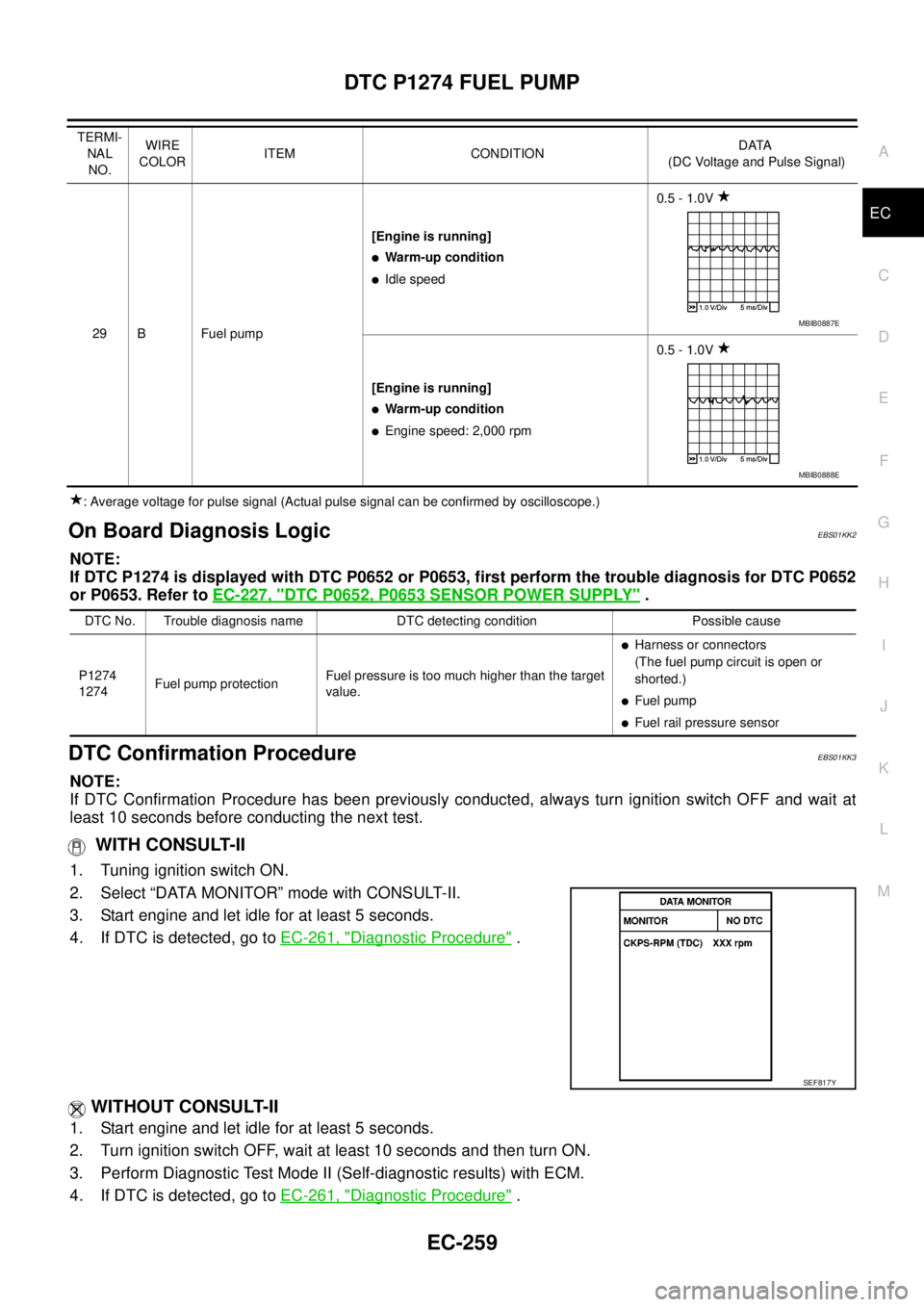

29 B Fuel pump[Engine is running]

lWarm-up condition

lIdle speed0.5 - 1.0V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpm0.5 - 1.0V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

MBIB0887E

MBIB0888E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1274

1274Fuel pump protectionFuel pressure is too much higher than the target

value.

lHarness or connectors

(The fuel pump circuit is open or

shorted.)

lFuel pump

lFuel rail pressure sensor

SEF817Y

Page 1244 of 3171

EC-264

DTC P1275 FUEL PUMP

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicEBS01KKB

NOTE:

If DTC P1275 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KKC

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Keep engine speed more than 2,000 rpm for at least 60 sec-

onds.

4. If DTC is detected, go toEC-267, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Keep engine speed more than 2,000 rpm for at least 60 seconds.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

29 B Fuel pump[Engine is running]

lWarm-up condition

lIdle speed0.5 - 1.0V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpm0.5 - 1.0V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

MBIB0887E

MBIB0888E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1275

1275Fuel pump exchangeFuel pressure is too much higher than the target

value.

lHarness or connectors

(The fuel pump circuit is open or

shorted.)

lFuel pump

lFuel rail pressure sensor

SEF817Y

Page 1249 of 3171

DTC P1616 ECM

EC-269

C

D

E

F

G

H

I

J

K

L

MA

EC

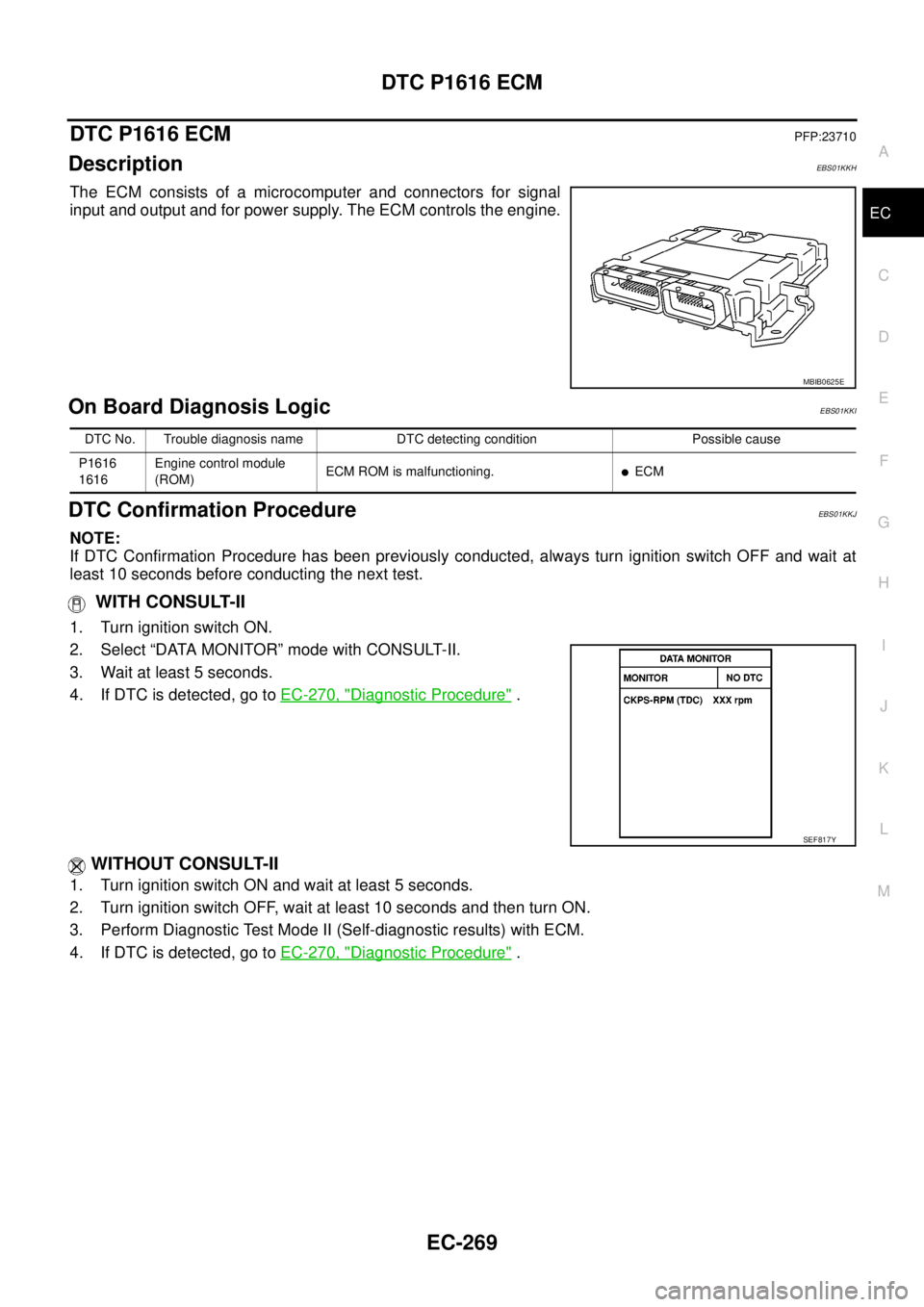

DTC P1616 ECMPFP:23710

DescriptionEBS01KKH

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The ECM controls the engine.

On Board Diagnosis LogicEBS01KKI

DTC Confirmation ProcedureEBS01KKJ

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-270, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-270, "

Diagnostic Procedure".

MBIB0625E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1616

1616Engine control module

(ROM)ECM ROM is malfunctioning.

lECM

SEF817Y

Page 1251 of 3171

DTC P1622 INJECTOR ADJUSTMENT VALUE

EC-271

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1622 INJECTOR ADJUSTMENT VALUEPFP:23710

DescriptionEBS01KKL

Injector adjustment value indicates manufacturing tolerance and the value is printed on the top of fuel injec-

tor.The injector adjustment value which is correctly stored in ECM is needed for precise fuel injection control.

A performance of emission control and a drivability may effect when there is a mismatch between the following

two values.

lThe injector adjustment value stored in ECM

lThe injector adjustment value of the fuel injector which is installed on the vehicle

On Board Diagnosis LogicEBS01KKM

The MI will not light up for this self-diagnosis.

DTC Confirmation ProcedureEBS01KKN

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-272, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-272, "

Diagnostic Procedure".

Example: Injector adjustment value = D021ABCD1A061234000000000000E6

MBIB1251E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1622

1622Injector adjustment value

data uninputInjector adjustment value is not stored in ECM.

lInjector adjustment value

(Injector adjustment value has not

been written onto ECM memory yet,

or the value has been initialized.)

SEF817Y

Page 1253 of 3171

DTC P1623 INJECTOR ADJUSTMENT VALUE

EC-273

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1623 INJECTOR ADJUSTMENT VALUEPFP:23710

DescriptionEBS01KKP

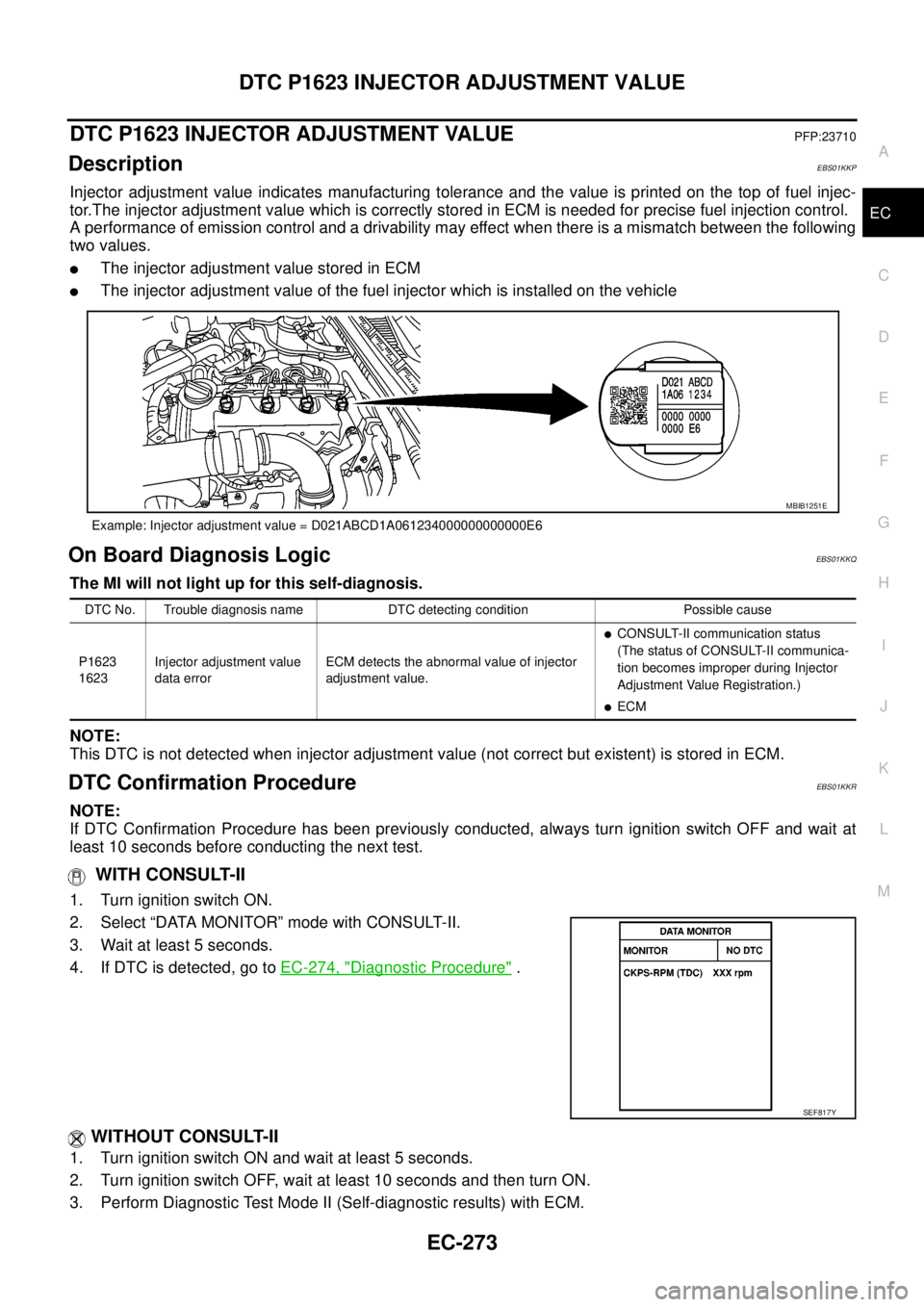

Injector adjustment value indicates manufacturing tolerance and the value is printed on the top of fuel injec-

tor.The injector adjustment value which is correctly stored in ECM is needed for precise fuel injection control.

A performance of emission control and a drivability may effect when there is a mismatch between the following

two values.

lThe injector adjustment value stored in ECM

lThe injector adjustment value of the fuel injector which is installed on the vehicle

On Board Diagnosis LogicEBS01KKQ

The MI will not light up for this self-diagnosis.

NOTE:

This DTC is not detected when injector adjustment value (not correct but existent) is stored in ECM.

DTC Confirmation ProcedureEBS01KKR

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-274, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

Example: Injector adjustment value = D021ABCD1A061234000000000000E6

MBIB1251E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1623

1623Injector adjustment value

data errorECM detects the abnormal value of injector

adjustment value.

lCONSULT-II communication status

(The status of CONSULT-II communica-

tion becomes improper during Injector

Adjustment Value Registration.)

lECM

SEF817Y

Page 1256 of 3171

EC-276

DTC P2135 APP SENSOR

On Board Diagnosis Logic

EBS01KKW

The MI will not light up for this self-diagnosis.

NOTE:

lIf DTC P2135 is displayed with DTC P0642 or P0643, first perform the trouble diagnosis for DTC

P0642 or P0643. Refer toEC-222, "

DTC P0642, P0643 SENSOR POWER SUPPLY".

lIf DTC P2135 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC

P0652 or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KKX

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. Depress accelerator pedal slowly spending 5 seconds, and then

release it slowly spending 5 seconds.

5. If DTC is detected, go toEC-278, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Depress accelerator pedal slowly spending 5 seconds, and then release it slowly spending 5 seconds.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

5. If DTC is detected, go toEC-278, "

Diagnostic Procedure".

91 RAccelerator pedal position sen-

sor 2[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully released0.58 - 0.78V

[Ignition switch ON]

lEngine: Stopped

lAccelerator pedal: Fully depressedMore than 2.3V

92 BAccelerator pedal position sen-

sor 2 ground[Ignition switch ON]Approximately 0.3V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2135

2135Accelerator pedal position

sensor 1, 2 signal correla-

tionThe correlation between APP sensor 1 signal

and APP sensor 2 signal is out of the normal

range.

lHarness or connectors

(The APP sensor circuit is open or

shorted.)

lAccelerator pedal position sensor

SEF817Y

Page 1263 of 3171

DTC P2146, P2149 FUEL INJECTOR POWER SUPPLY

EC-283

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC Confirmation ProcedureEBS01KL6

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION

Before performing the following procedure, confirm the ambient temperature is more than -20°C (-4°F).

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

4. If DTC is detected, go toEC-285, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-285, "

Diagnostic Procedure".

SEF817Y

Page 1268 of 3171

EC-288

DTC P2147, P2148 FUEL INJECTOR CIRCUIT

DTC Confirmation Procedure

EBS01KLD

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

4. If DTC is detected, go toEC-290, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-290, "

Diagnostic Procedure".

SEF817Y

Page 1273 of 3171

DTC P2228, P2229 BARO SENSOR

EC-293

C

D

E

F

G

H

I

J

K

L

MA

EC

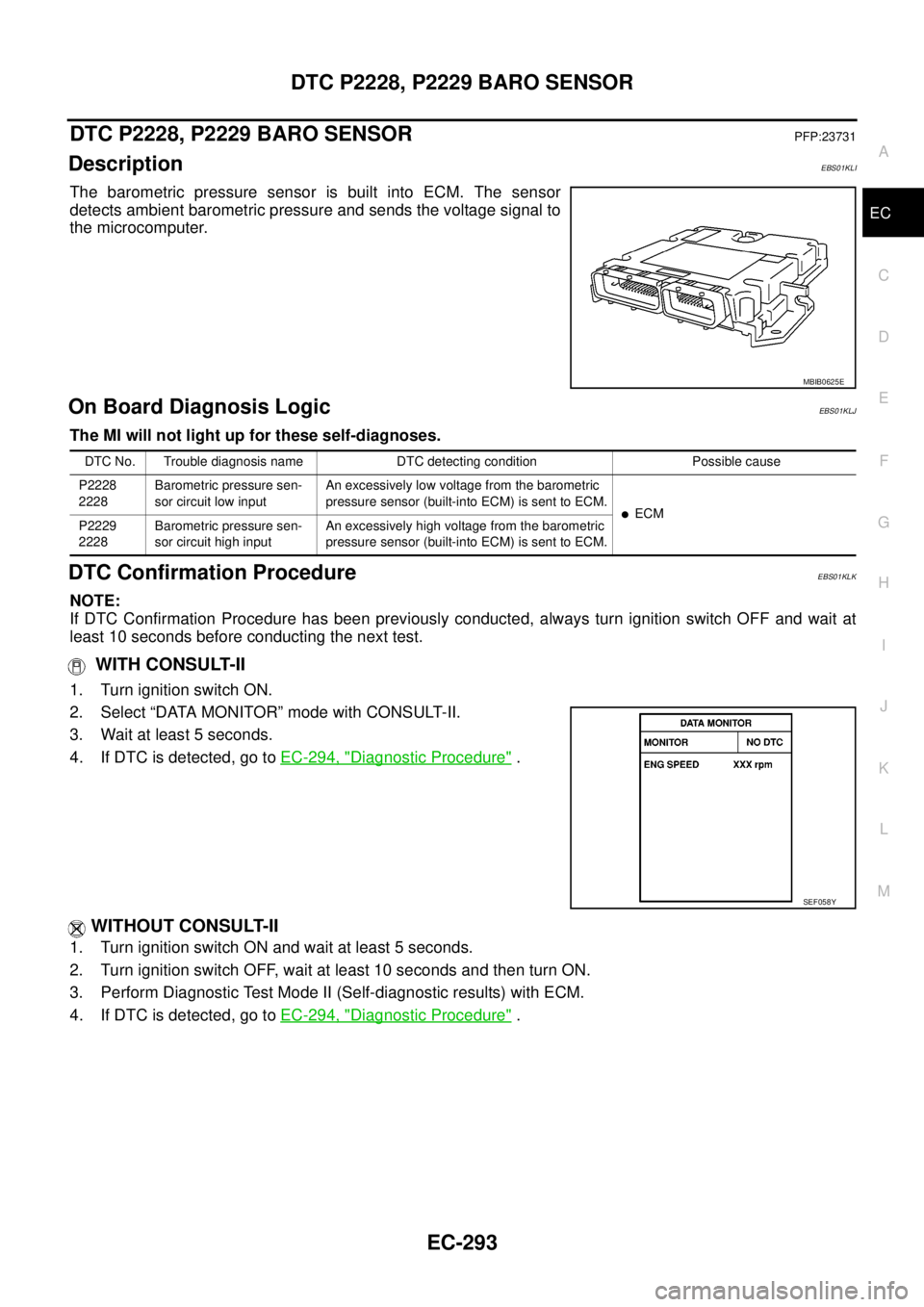

DTC P2228, P2229 BARO SENSORPFP:23731

DescriptionEBS01KLI

The barometric pressure sensor is built into ECM. The sensor

detects ambient barometric pressure and sends the voltage signal to

the microcomputer.

On Board Diagnosis LogicEBS01KLJ

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KLK

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-294, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-294, "

Diagnostic Procedure".

MBIB0625E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P2228

2228Barometric pressure sen-

sor circuit low inputAn excessively low voltage from the barometric

pressure sensor (built-into ECM) is sent to ECM.

lECM

P2229

2228Barometric pressure sen-

sor circuit high inputAn excessively high voltage from the barometric

pressure sensor (built-into ECM) is sent to ECM.

SEF058Y