NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1611 of 3171

COIL SPRING AND SHOCK ABSORBER

FSU-11

C

D

F

G

H

I

J

K

L

MA

B

FSU

INSPECTION AFTER DISASSEMBLY

Shock Absorber Assembly

lCheck for smooth operation through a full stroke, both compression and extension.

lCheck for oil leakage on welded or gland packing portions.

lCheck piston rod for cracks, deformation or other damage and replace if necessary.

Mounting Insulator and Rubber Parts

Check cemented rubber-to-metal portion for separation or cracks. Check rubber parts for deterioration and

replace if necessary.

Coil Spring

lCheck for cracks, deformation or other damage and replace if necessary.

ASSEMBLY

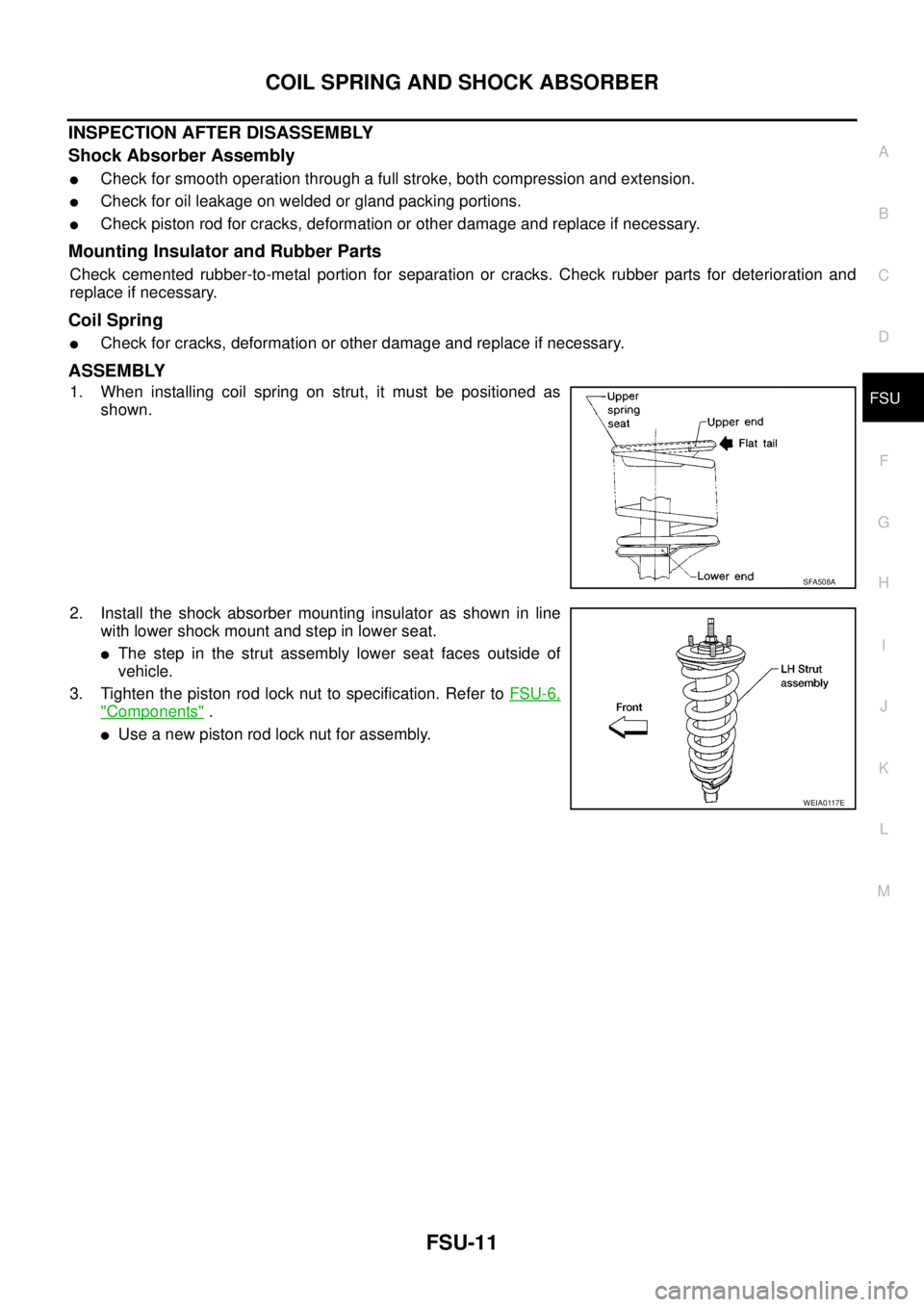

1. When installing coil spring on strut, it must be positioned as

shown.

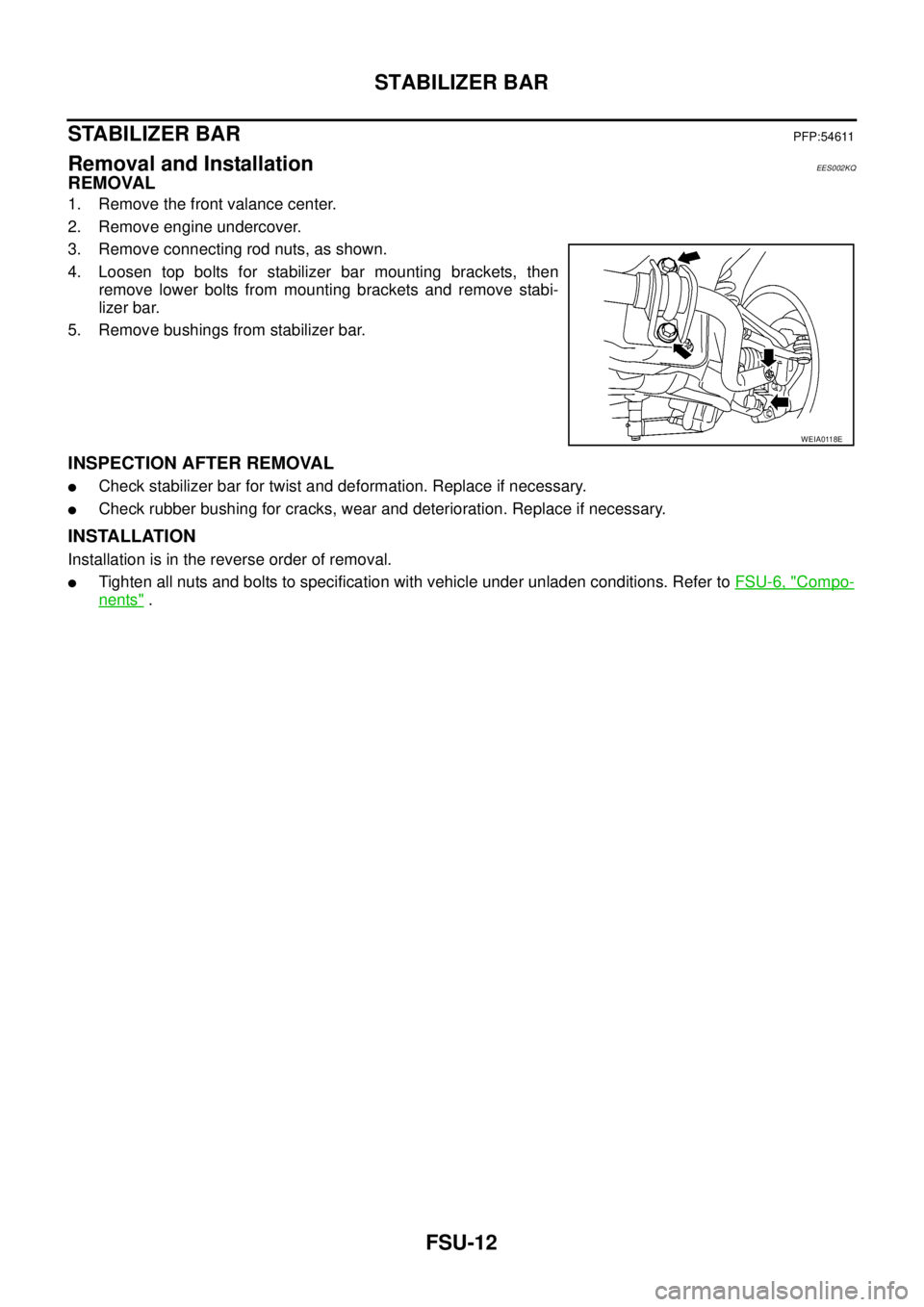

2. Install the shock absorber mounting insulator as shown in line

with lower shock mount and step in lower seat.

lThe step in the strut assembly lower seat faces outside of

vehicle.

3. Tighten the piston rod lock nut to specification. Refer toFSU-6,

"Components".

lUse a new piston rod lock nut for assembly.

SFA508A

WEIA0117E

Page 1612 of 3171

FSU-12

STABILIZER BAR

STABILIZER BAR

PFP:54611

Removal and InstallationEES002KQ

REMOVAL

1. Remove the front valance center.

2. Remove engine undercover.

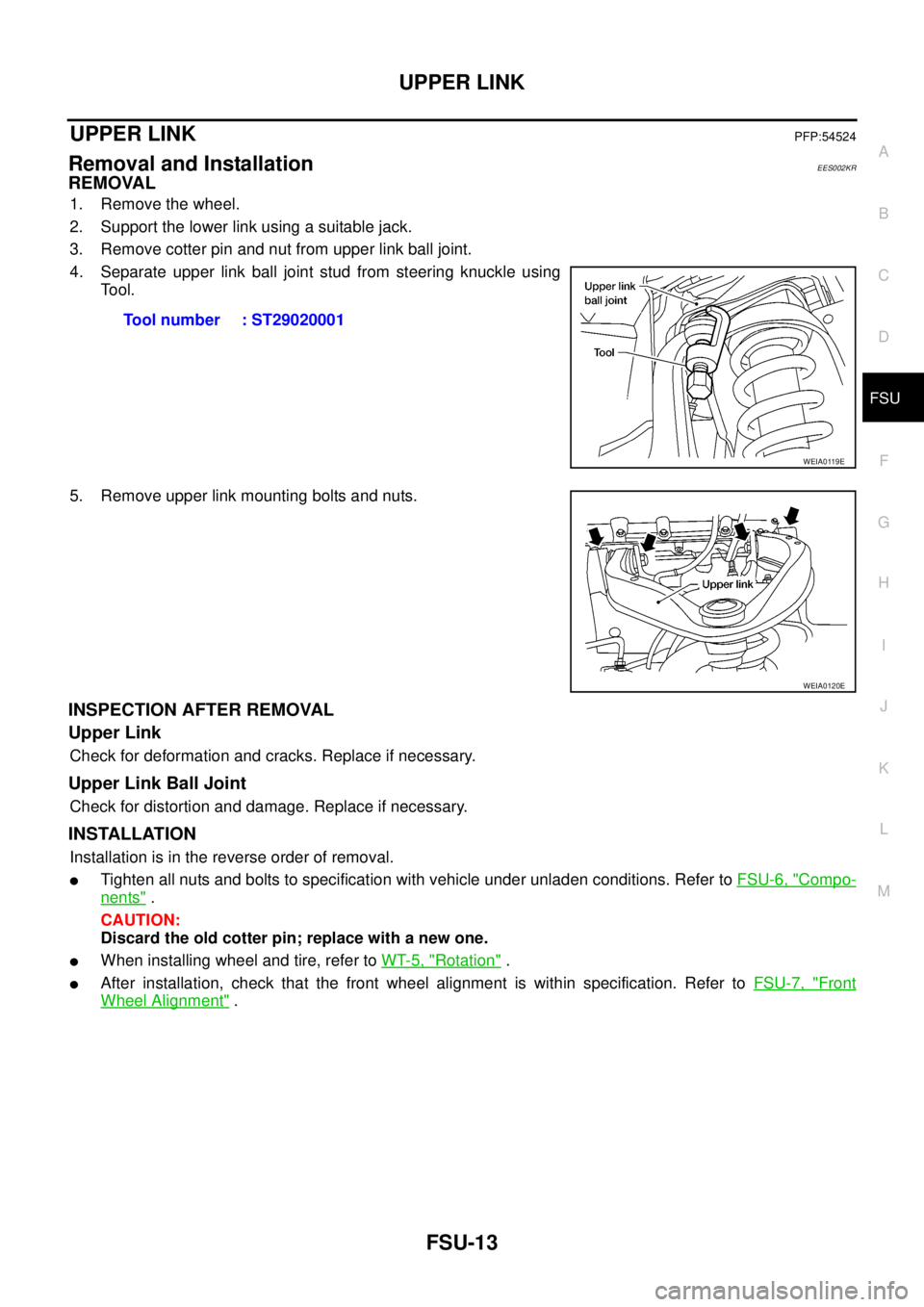

3. Remove connecting rod nuts, as shown.

4. Loosen top bolts for stabilizer bar mounting brackets, then

remove lower bolts from mounting brackets and remove stabi-

lizer bar.

5. Remove bushings from stabilizer bar.

INSPECTION AFTER REMOVAL

lCheck stabilizer bar for twist and deformation. Replace if necessary.

lCheck rubber bushing for cracks, wear and deterioration. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lTighten all nuts and bolts to specification with vehicle under unladen conditions. Refer toFSU-6, "Compo-

nents".

WEIA0118E

Page 1613 of 3171

UPPER LINK

FSU-13

C

D

F

G

H

I

J

K

L

MA

B

FSU

UPPER LINKPFP:54524

Removal and InstallationEES002KR

REMOVAL

1. Remove the wheel.

2. Support the lower link using a suitable jack.

3. Remove cotter pin and nut from upper link ball joint.

4. Separate upper link ball joint stud from steering knuckle using

Tool.

5. Remove upper link mounting bolts and nuts.

INSPECTION AFTER REMOVAL

Upper Link

Check for deformation and cracks. Replace if necessary.

Upper Link Ball Joint

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lTighten all nuts and bolts to specification with vehicle under unladen conditions. Refer toFSU-6, "Compo-

nents".

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lAfter installation, check that the front wheel alignment is within specification. Refer toFSU-7, "Front

Wheel Alignment". Tool number : ST29020001

WEIA0119E

WEIA0120E

Page 1614 of 3171

FSU-14

LOWER LINK

LOWER LINK

PFP:55020

Removal and InstallationEES002KS

REMOVAL

1. Remove the wheel.

2. Remove stabilizer bar connecting rod. Refer toFSU-12, "

Removal and Installation".

3. Remove lower shock absorber bolt.

4. Remove steering knuckle. Refer toFSU-16, "

Removal and Installation".

5. Remove lower link adjusting bolts and nuts, then the lower link.

6. Remove the jounce bumper from the lower link.

INSPECTION AFTER REMOVAL

Lower Link

Check for deformation and cracks. Replace if necessary.

Lower Link Bushing

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

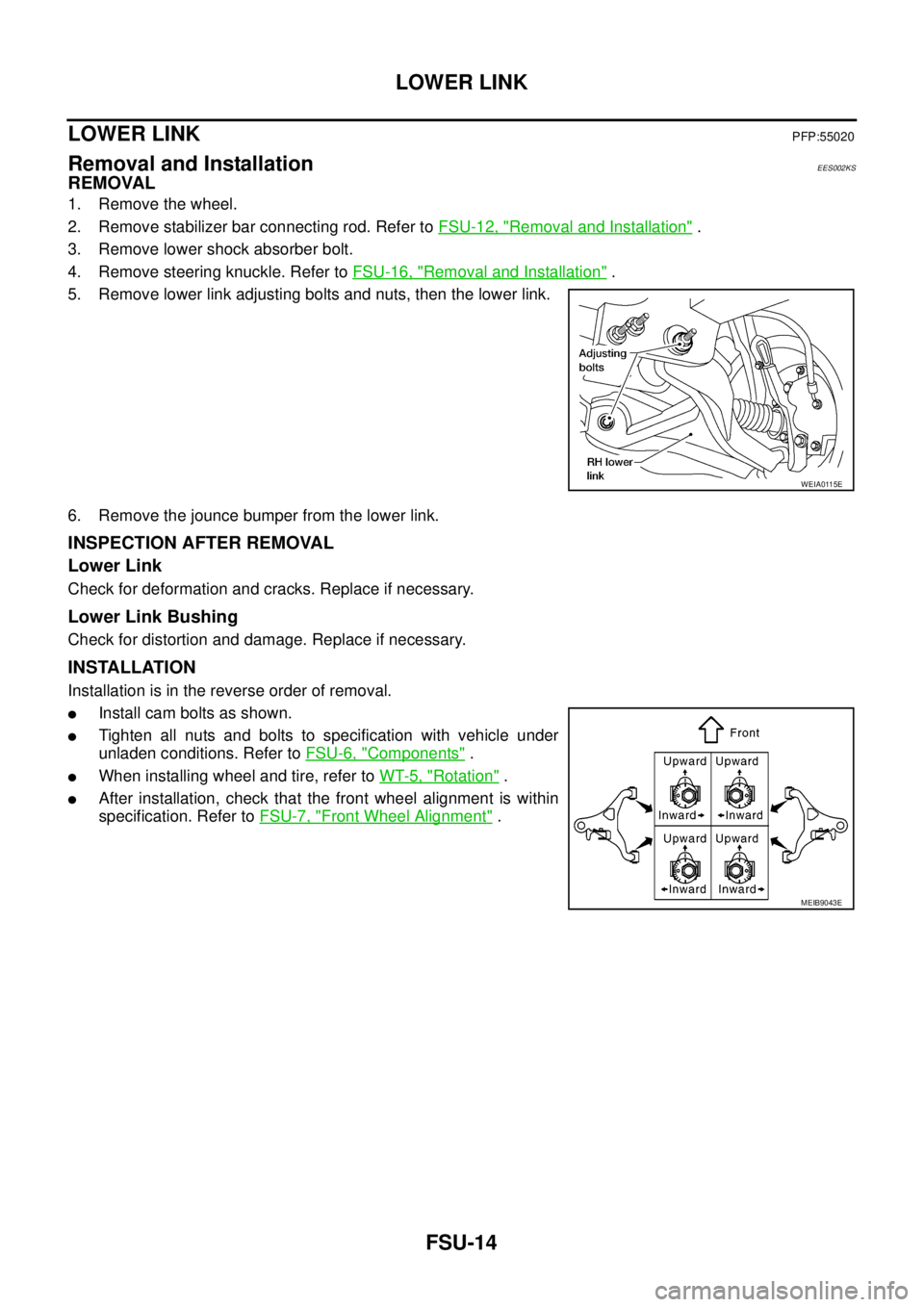

lInstall cam bolts as shown.

lTighten all nuts and bolts to specification with vehicle under

unladen conditions. Refer toFSU-6, "

Components".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lAfter installation, check that the front wheel alignment is within

specification. Refer toFSU-7, "

Front Wheel Alignment".

WEIA0115E

MEIB9043E

Page 1615 of 3171

UPPER BALL JOINT AND LOWER BALL JOINT

FSU-15

C

D

F

G

H

I

J

K

L

MA

B

FSU

UPPER BALL JOINT AND LOWER BALL JOINTPFP:40110

Removal and InstallationEES002KT

The ball joints are part of the upper and lower links. Refer toFSU-13, "Removal and Installation"(upper link),

FSU-14, "

Removal and Installation"(lower link).

InspectionEES002KU

lCheck the ball joint for excessive play. Replace the upper or lower link assembly if any of the following

exists:

lBall joint stud is worn.

lBalljointishardtoswing.

lBall joint play in axial directions or end play is excessive.

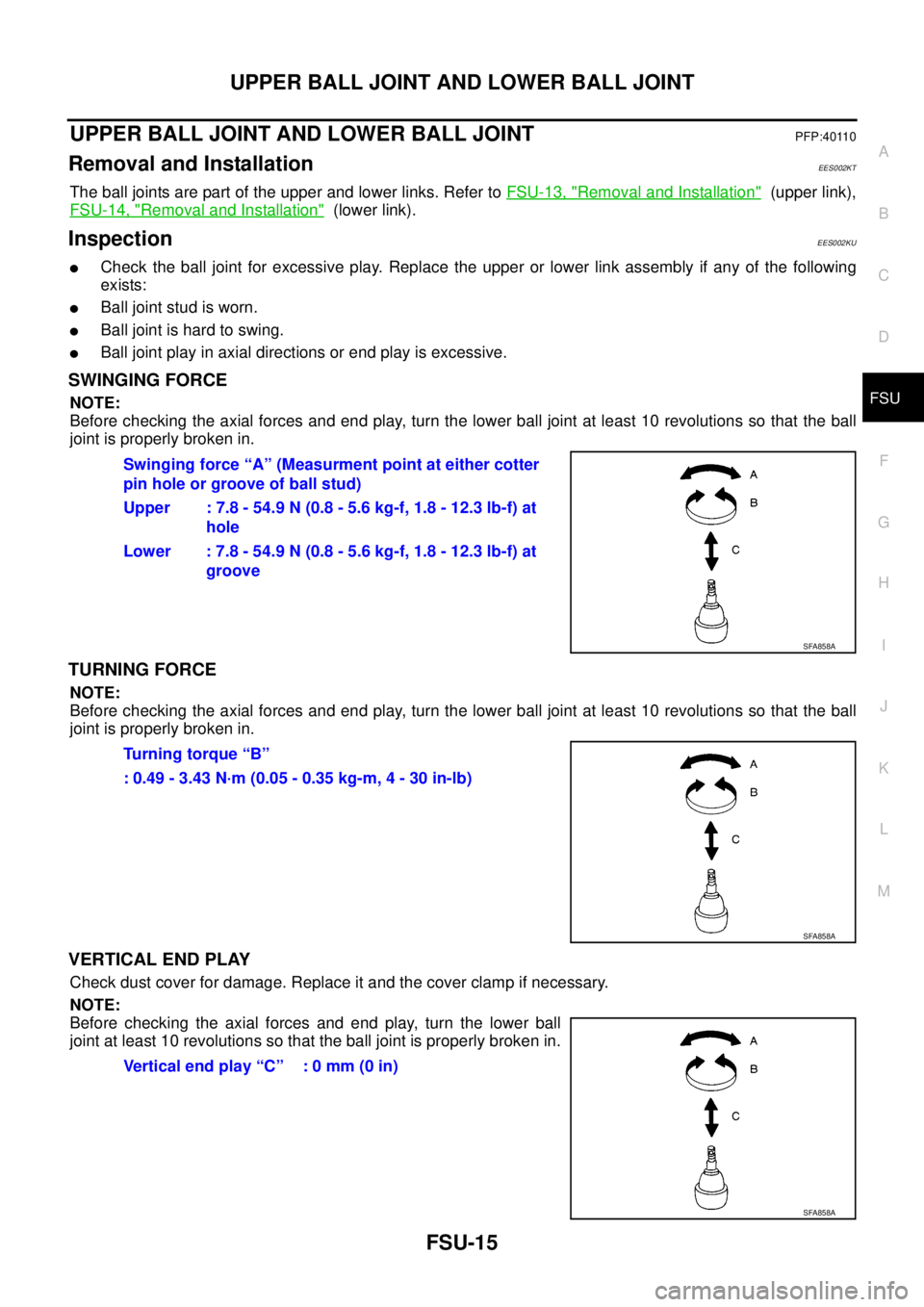

SWINGING FORCE

NOTE:

Before checking the axial forces and end play, turn the lower ball joint at least 10 revolutions so that the ball

joint is properly broken in.

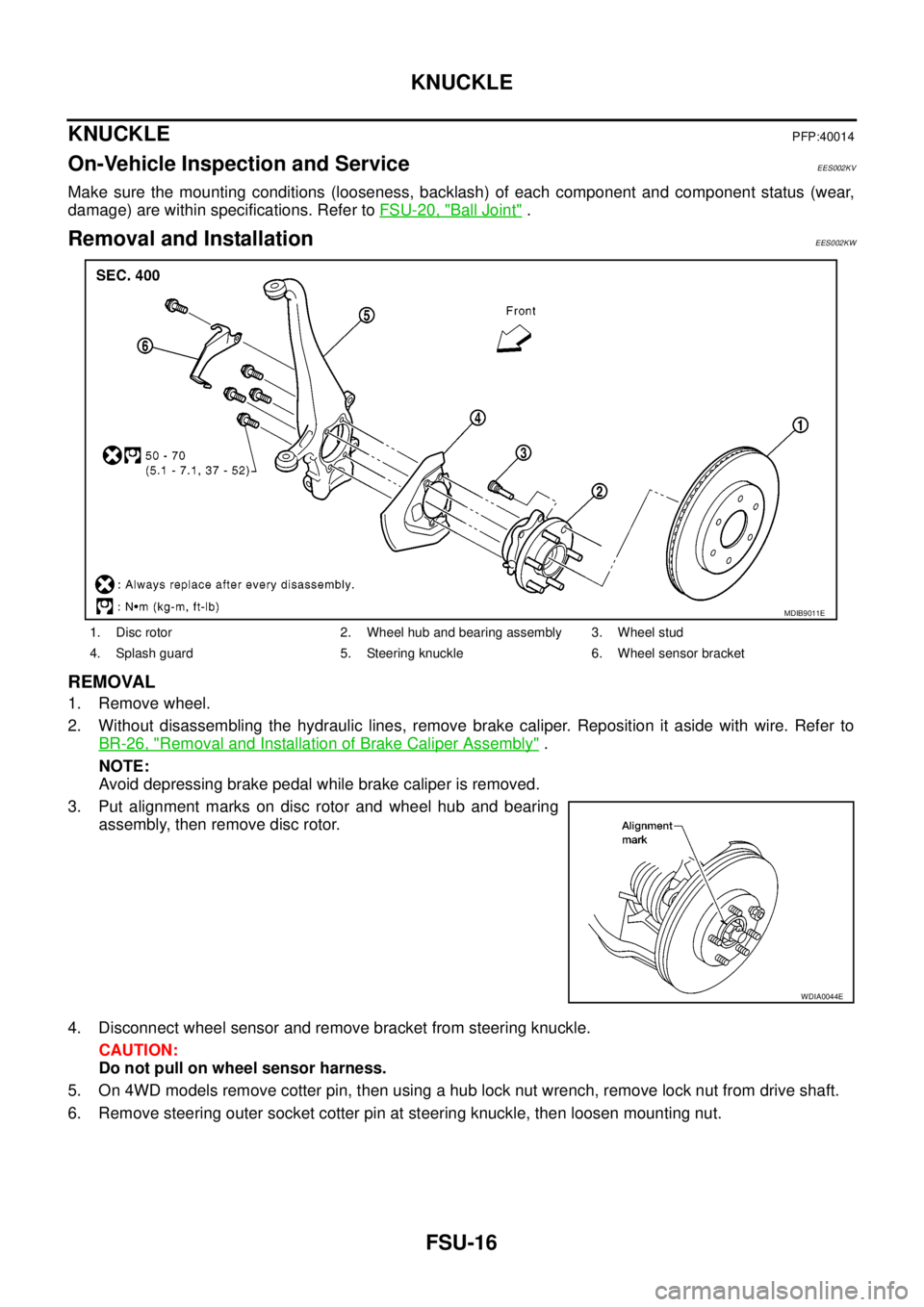

TURNING FORCE

NOTE:

Before checking the axial forces and end play, turn the lower ball joint at least 10 revolutions so that the ball

joint is properly broken in.

VERTICAL END PLAY

Check dust cover for damage. Replace it and the cover clamp if necessary.

NOTE:

Before checking the axial forces and end play, turn the lower ball

joint at least 10 revolutions so that the ball joint is properly broken in.Swinging force “A” (Measurment point at either cotter

pin hole or groove of ball stud)

Upper : 7.8 - 54.9 N (0.8 - 5.6 kg-f, 1.8 - 12.3 lb-f) at

hole

Lower : 7.8 - 54.9 N (0.8 - 5.6 kg-f, 1.8 - 12.3 lb-f) at

groove

SFA858A

Turning torque “B”

: 0.49 - 3.43 N·m (0.05 - 0.35 kg-m, 4 - 30 in-lb)

SFA858A

Vertical end play “C” : 0 mm (0 in)

SFA858A

Page 1616 of 3171

FSU-16

KNUCKLE

KNUCKLE

PFP:40014

On-Vehicle Inspection and ServiceEES002KV

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are within specifications. Refer toFSU-20, "

Ball Joint".

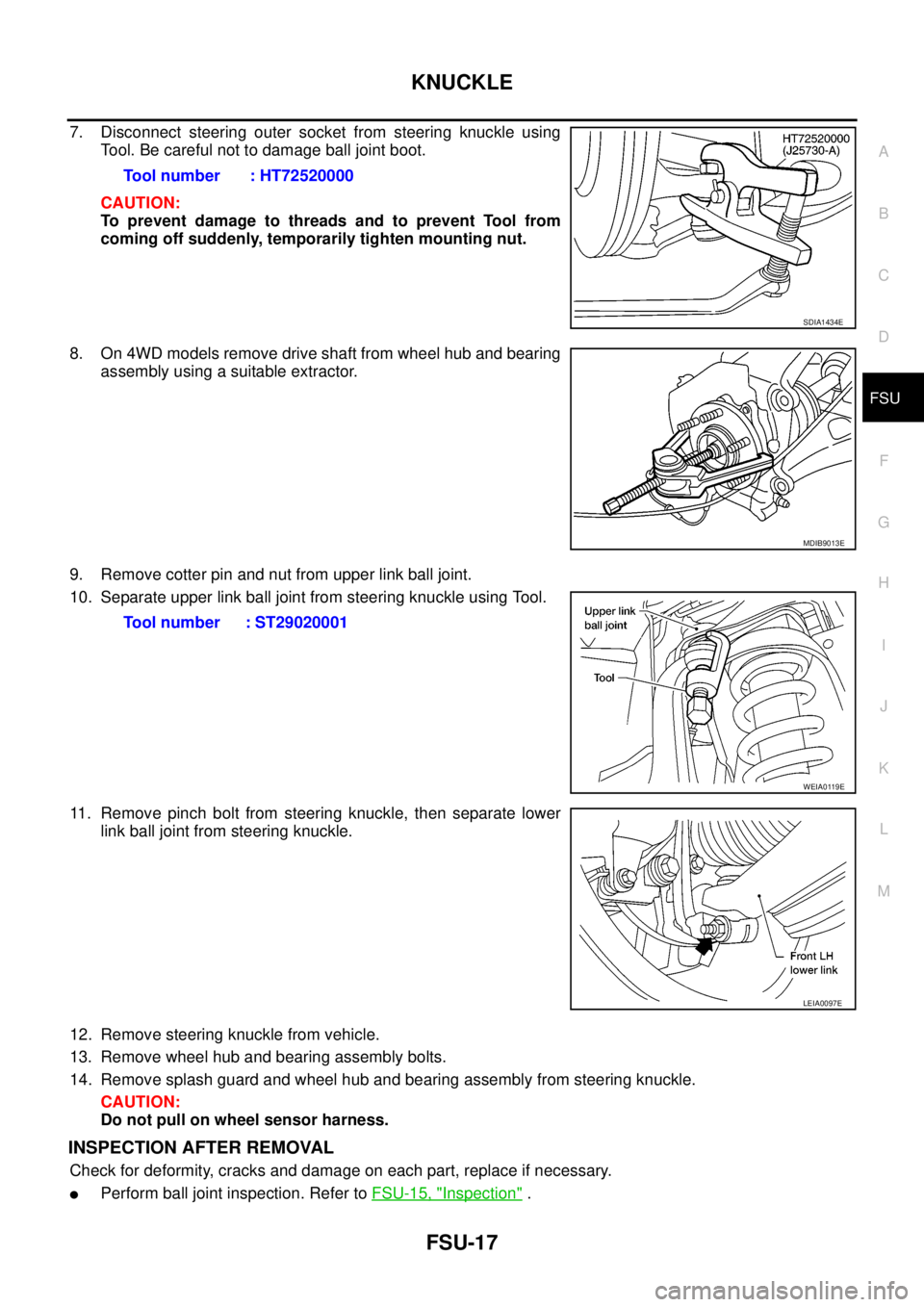

Removal and InstallationEES002KW

REMOVAL

1. Remove wheel.

2. Without disassembling the hydraulic lines, remove brake caliper. Reposition it aside with wire. Refer to

BR-26, "

Removal and Installation of Brake Caliper Assembly".

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

3. Put alignment marks on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

4. Disconnect wheel sensor and remove bracket from steering knuckle.

CAUTION:

Do not pull on wheel sensor harness.

5. On 4WD models remove cotter pin, then using a hub lock nut wrench, remove lock nut from drive shaft.

6. Remove steering outer socket cotter pin at steering knuckle, then loosen mounting nut.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle 6. Wheel sensor bracket

MDIB9011E

WDIA0044E

Page 1617 of 3171

KNUCKLE

FSU-17

C

D

F

G

H

I

J

K

L

MA

B

FSU

7. Disconnect steering outer socket from steering knuckle using

Tool. Be careful not to damage ball joint boot.

CAUTION:

To prevent damage to threads and to prevent Tool from

coming off suddenly, temporarily tighten mounting nut.

8. On 4WD models remove drive shaft from wheel hub and bearing

assembly using a suitable extractor.

9. Remove cotter pin and nut from upper link ball joint.

10. Separate upper link ball joint from steering knuckle using Tool.

11. Remove pinch bolt from steering knuckle, then separate lower

link ball joint from steering knuckle.

12. Remove steering knuckle from vehicle.

13. Remove wheel hub and bearing assembly bolts.

14. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

CAUTION:

Do not pull on wheel sensor harness.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

lPerform ball joint inspection. Refer toFSU-15, "Inspection". Tool number : HT72520000

SDIA1434E

MDIB9013E

Tool number : ST29020001

WEIA0119E

LEIA0097E

Page 1618 of 3171

FSU-18

KNUCKLE

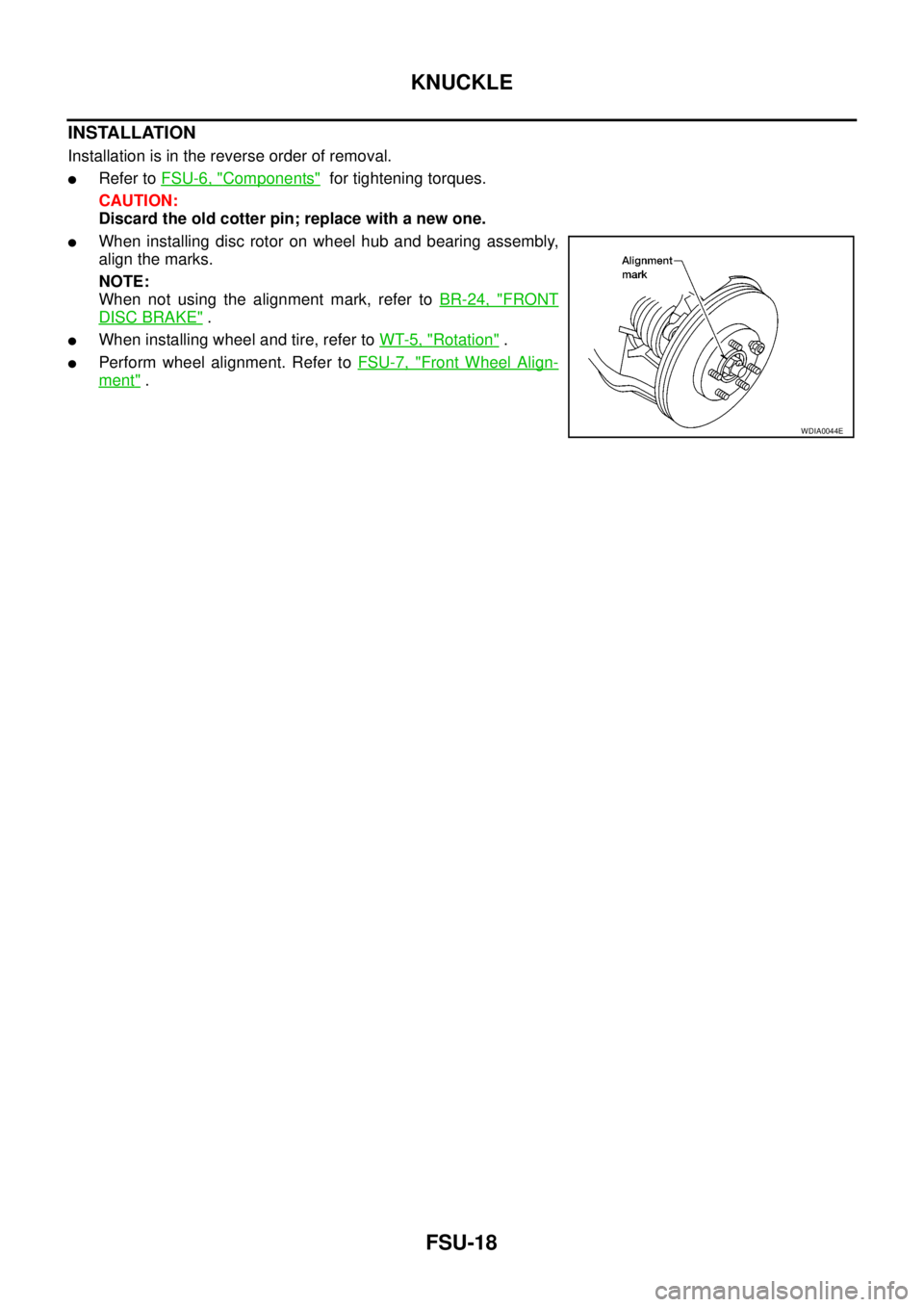

INSTALLATION

Installation is in the reverse order of removal.

lRefer toFSU-6, "Components"for tightening torques.

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing disc rotor on wheel hub and bearing assembly,

align the marks.

NOTE:

When not using the alignment mark, refer toBR-24, "

FRONT

DISC BRAKE".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lPerform wheel alignment. Refer toFSU-7, "Front Wheel Align-

ment".

WDIA0044E

Page 1619 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-19

C

D

F

G

H

I

J

K

L

MA

B

FSU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Front)EES002KX

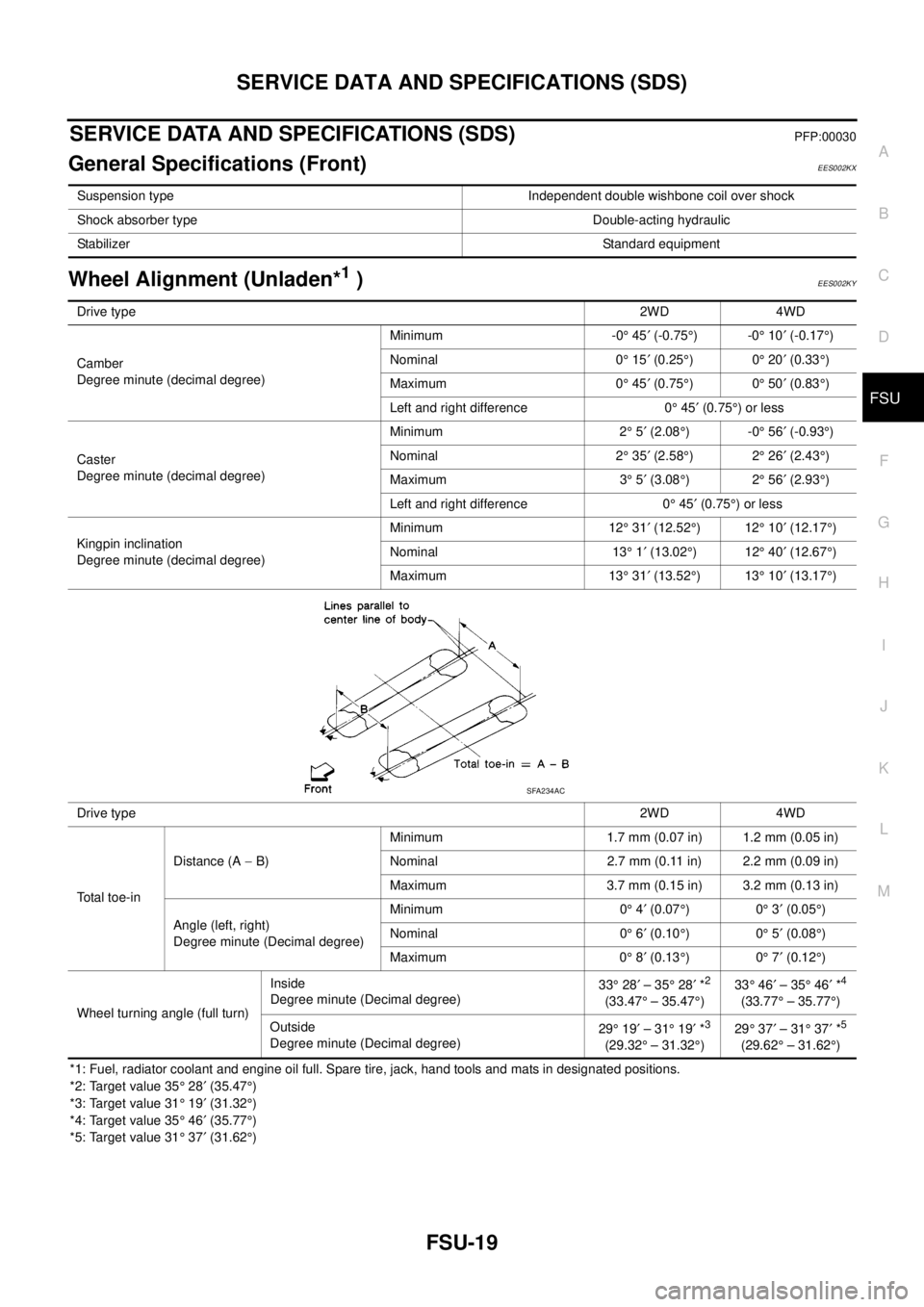

Wheel Alignment (Unladen*1)EES002KY

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Target value 35°28¢(35.47°)

*3: Target value 31°19¢(31.32°)

*4: Target value 35°46¢(35.77°)

*5: Target value 31°37¢(31.62°) Suspension type Independent double wishbone coil over shock

Shock absorber type Double-acting hydraulic

StabilizerStandard equipment

Drive type2WD 4WD

Camber

Degree minute (decimal degree)Minimum -0°45¢(-0.75°)-0°10¢(-0.17°)

Nominal 0°15¢(0.25°)0°20¢(0.33°)

Maximum 0°45¢(0.75°)0°50¢(0.83°)

Left and right difference 0°45¢(0.75°)orless

Caster

Degree minute (decimal degree)Minimum 2°5¢(2.08°)-0°56¢(-0.93°)

Nominal 2°35¢(2.58°)2°26¢(2.43°)

Maximum 3°5¢(3.08°)2°56¢(2.93°)

Left and right difference 0°45¢(0.75°)orless

Kingpin inclination

Degree minute (decimal degree)Minimum 12°31¢(12.52°)12°10¢(12.17°)

Nominal 13°1¢(13.02°)12°40¢(12.67°)

Maximum 13°31¢(13.52°)13°10¢(13.17°)

Drive type2WD 4WD

Total toe-inDistance (A-B)Minimum 1.7 mm (0.07 in) 1.2 mm (0.05 in)

Nominal 2.7 mm (0.11 in) 2.2 mm (0.09 in)

Maximum 3.7 mm (0.15 in) 3.2 mm (0.13 in)

Angle (left, right)

Degree minute (Decimal degree)Minimum 0°4¢(0.07°)0°3¢(0.05°)

Nominal 0°6¢(0.10°)0°5¢(0.08°)

Maximum 0°8¢(0.13°)0°7¢(0.12°)

Wheel turning angle (full turn)Inside

Degree minute (Decimal degree)33°28¢–35°28¢*

2

(33.47°– 35.47°)33°46¢–35°46¢*

4

(33.77°– 35.77°)

Outside

Degree minute (Decimal degree)29°19¢–31°19¢*

3

(29.32°– 31.32°)29°37¢–31°37¢*

5

(29.62°– 31.62°)

SFA234AC

Page 1620 of 3171

FSU-20

SERVICE DATA AND SPECIFICATIONS (SDS)

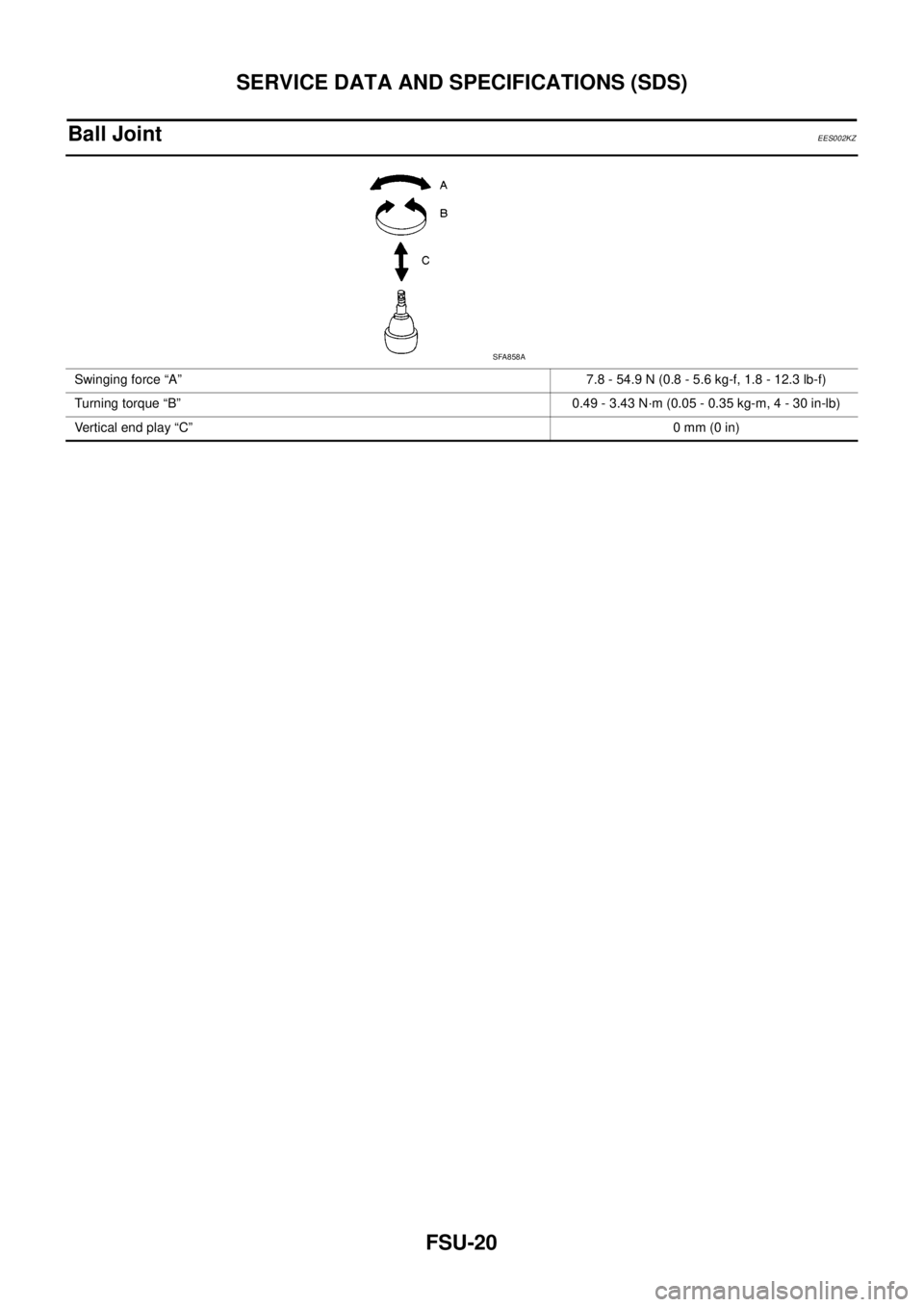

Ball Joint

EES002KZ

Swinging force “A” 7.8 - 54.9 N (0.8 - 5.6 kg-f, 1.8 - 12.3 lb-f)

Turning torque “B” 0.49 - 3.43 N·m (0.05 - 0.35 kg-m, 4 - 30 in-lb)

Vertical end play “C”0mm(0in)

SFA858A