NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2381 of 3171

MT-64

TRANSMISSION ASSEMBLY

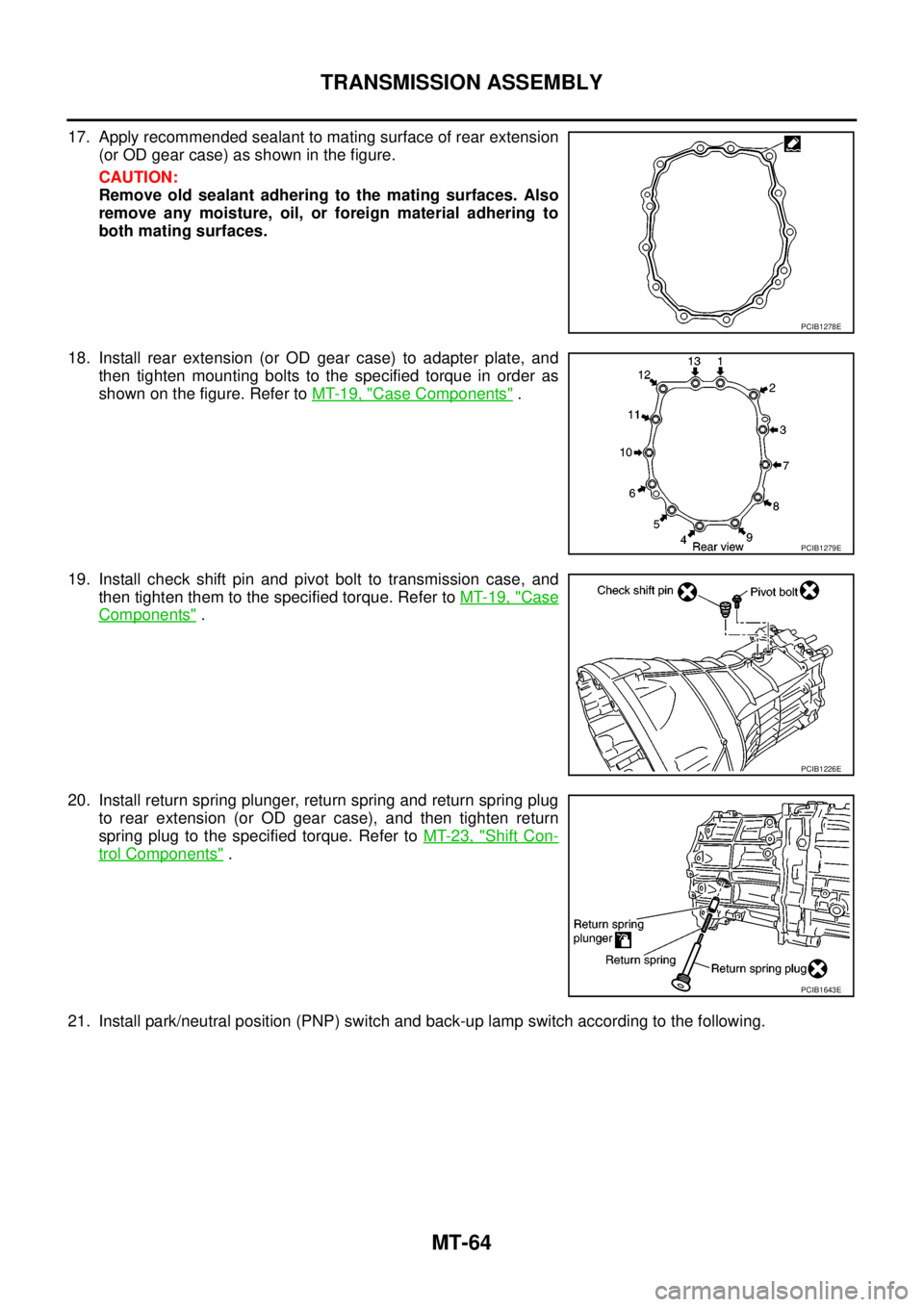

17. Apply recommended sealant to mating surface of rear extension

(or OD gear case) as shown in the figure.

CAUTION:

Remove old sealant adhering to the mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

both mating surfaces.

18. Install rear extension (or OD gear case) to adapter plate, and

then tighten mounting bolts to the specified torque in order as

shown on the figure. Refer toMT-19, "

Case Components".

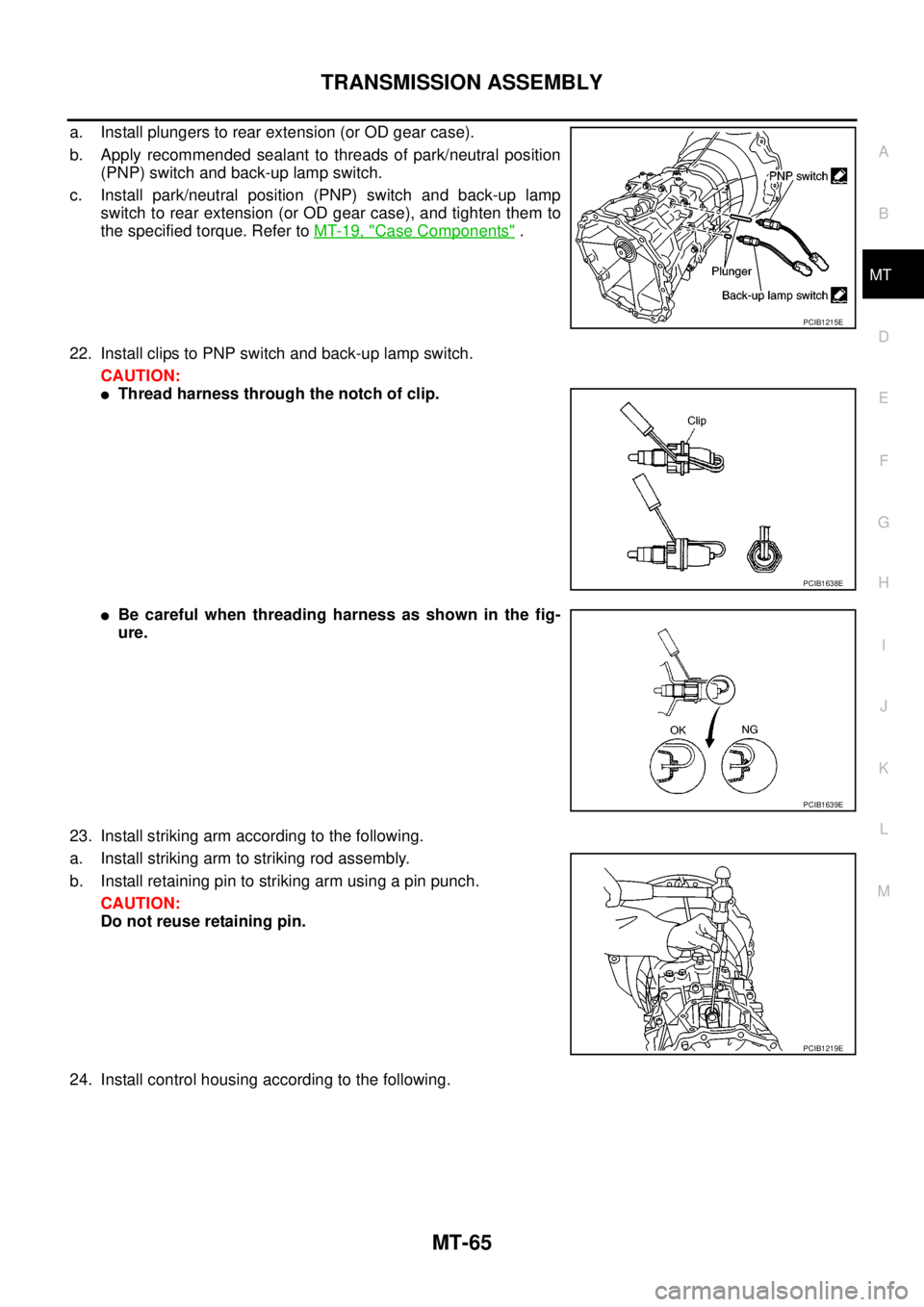

19. Install check shift pin and pivot bolt to transmission case, and

then tighten them to the specified torque. Refer toMT-19, "

Case

Components".

20. Install return spring plunger, return spring and return spring plug

to rear extension (or OD gear case), and then tighten return

spring plug to the specified torque. Refer toMT-23, "

Shift Con-

trol Components".

21. Install park/neutral position (PNP) switch and back-up lamp switch according to the following.

PCIB1278E

PCIB1279E

PCIB1226E

PCIB1643E

Page 2382 of 3171

TRANSMISSION ASSEMBLY

MT-65

D

E

F

G

H

I

J

K

L

MA

B

MT

a. Install plungers to rear extension (or OD gear case).

b. Apply recommended sealant to threads of park/neutral position

(PNP) switch and back-up lamp switch.

c. Install park/neutral position (PNP) switch and back-up lamp

switch to rear extension (or OD gear case), and tighten them to

the specified torque. Refer toMT-19, "

Case Components".

22. Install clips to PNP switch and back-up lamp switch.

CAUTION:

lThread harness through the notch of clip.

lBe careful when threading harness as shown in the fig-

ure.

23. Install striking arm according to the following.

a. Install striking arm to striking rod assembly.

b. Install retaining pin to striking arm using a pin punch.

CAUTION:

Do not reuse retaining pin.

24. Install control housing according to the following.

PCIB1215E

PCIB1638E

PCIB1639E

PCIB1219E

Page 2383 of 3171

MT-66

TRANSMISSION ASSEMBLY

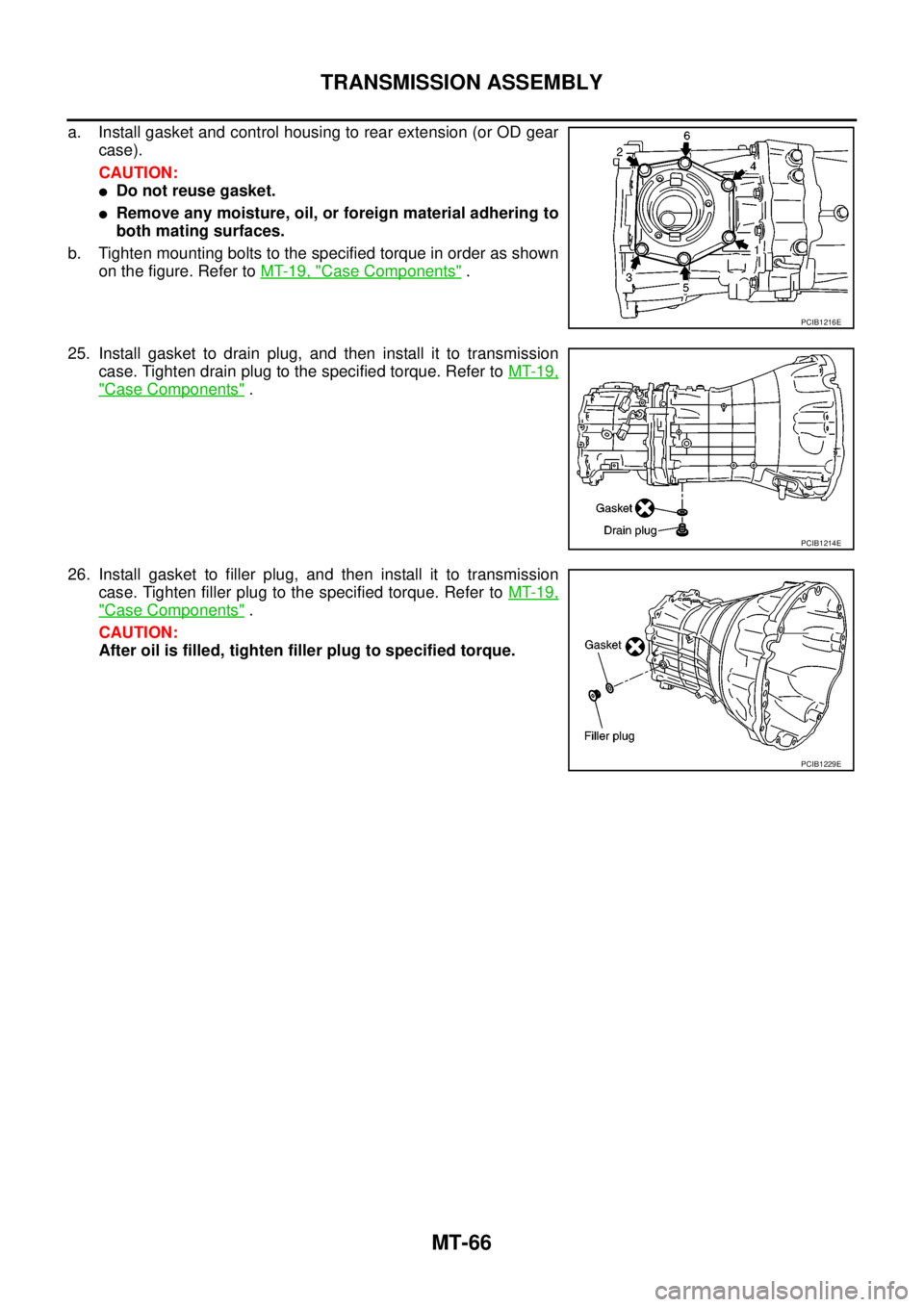

a. Install gasket and control housing to rear extension (or OD gear

case).

CAUTION:

lDo not reuse gasket.

lRemove any moisture, oil, or foreign material adhering to

both mating surfaces.

b. Tighten mounting bolts to the specified torque in order as shown

on the figure. Refer toMT-19, "

Case Components".

25. Install gasket to drain plug, and then install it to transmission

case. Tighten drain plug to the specified torque. Refer toMT-19,

"Case Components".

26. Install gasket to filler plug, and then install it to transmission

case. Tighten filler plug to the specified torque. Refer toMT-19,

"Case Components".

CAUTION:

After oil is filled, tighten filler plug to specified torque.

PCIB1216E

PCIB1214E

PCIB1229E

Page 2384 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-67

D

E

F

G

H

I

J

K

L

MA

B

MT

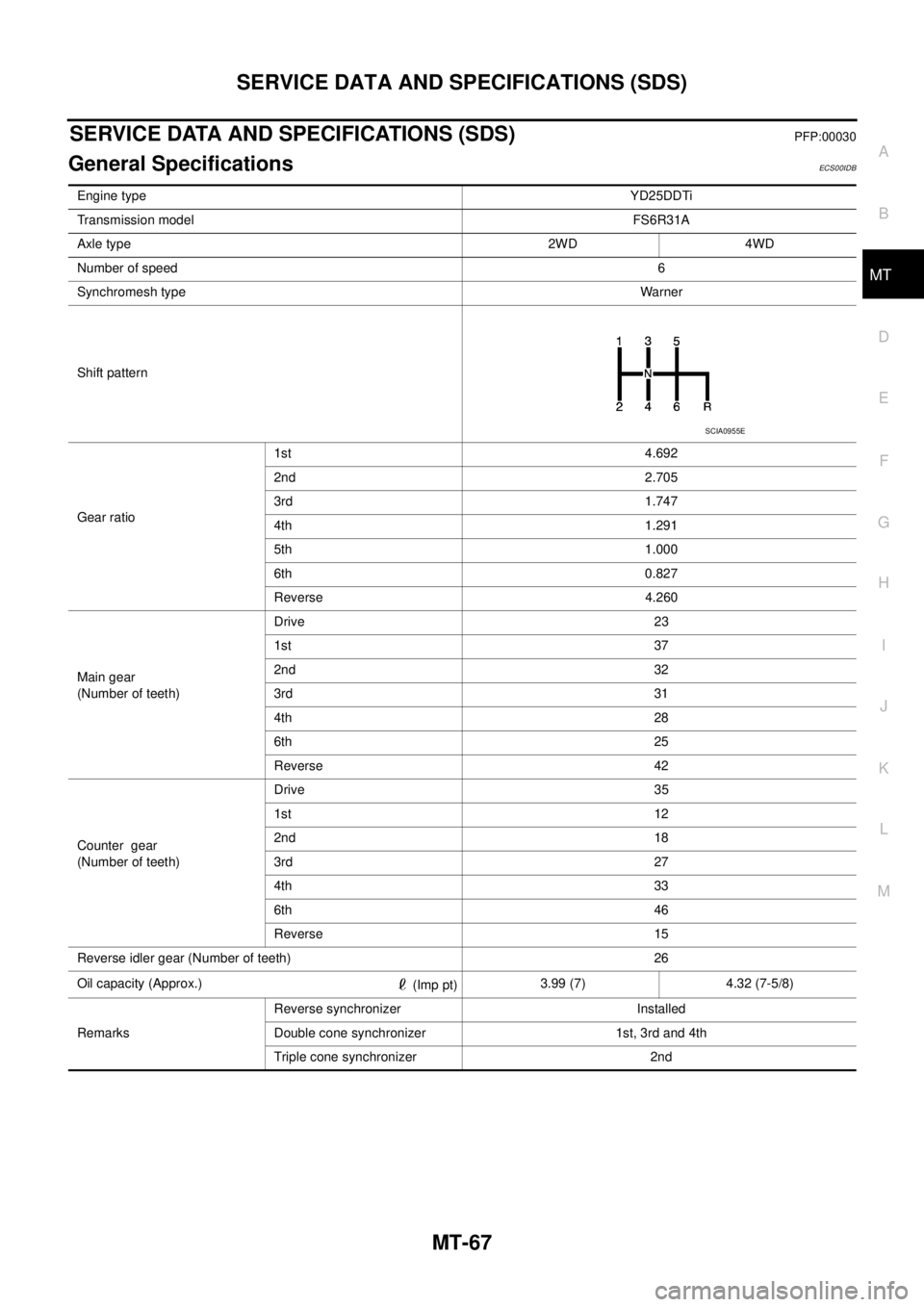

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00IDB

Engine typeYD25DDTi

Transmission modelFS6R31A

Axle type 2WD 4WD

Number of speed6

Synchromesh typeWarner

Shift pattern

Gear ratio1st 4.692

2nd 2.705

3rd 1.747

4th 1.291

5th 1.000

6th 0.827

Reverse 4.260

Main gear

(Number of teeth)Drive 23

1st 37

2nd 32

3rd 31

4th 28

6th 25

Reverse 42

Counter gear

(Number of teeth)Drive 35

1st 12

2nd 18

3rd 27

4th 33

6th 46

Reverse 15

Reverse idler gear (Number of teeth) 26

Oil capacity (Approx.)

(Imp pt)3.99 (7) 4.32 (7-5/8)

RemarksReverse synchronizer Installed

Double cone synchronizer 1st, 3rd and 4th

Triple cone synchronizer 2nd

SCIA0955E

Page 2385 of 3171

MT-68

SERVICE DATA AND SPECIFICATIONS (SDS)

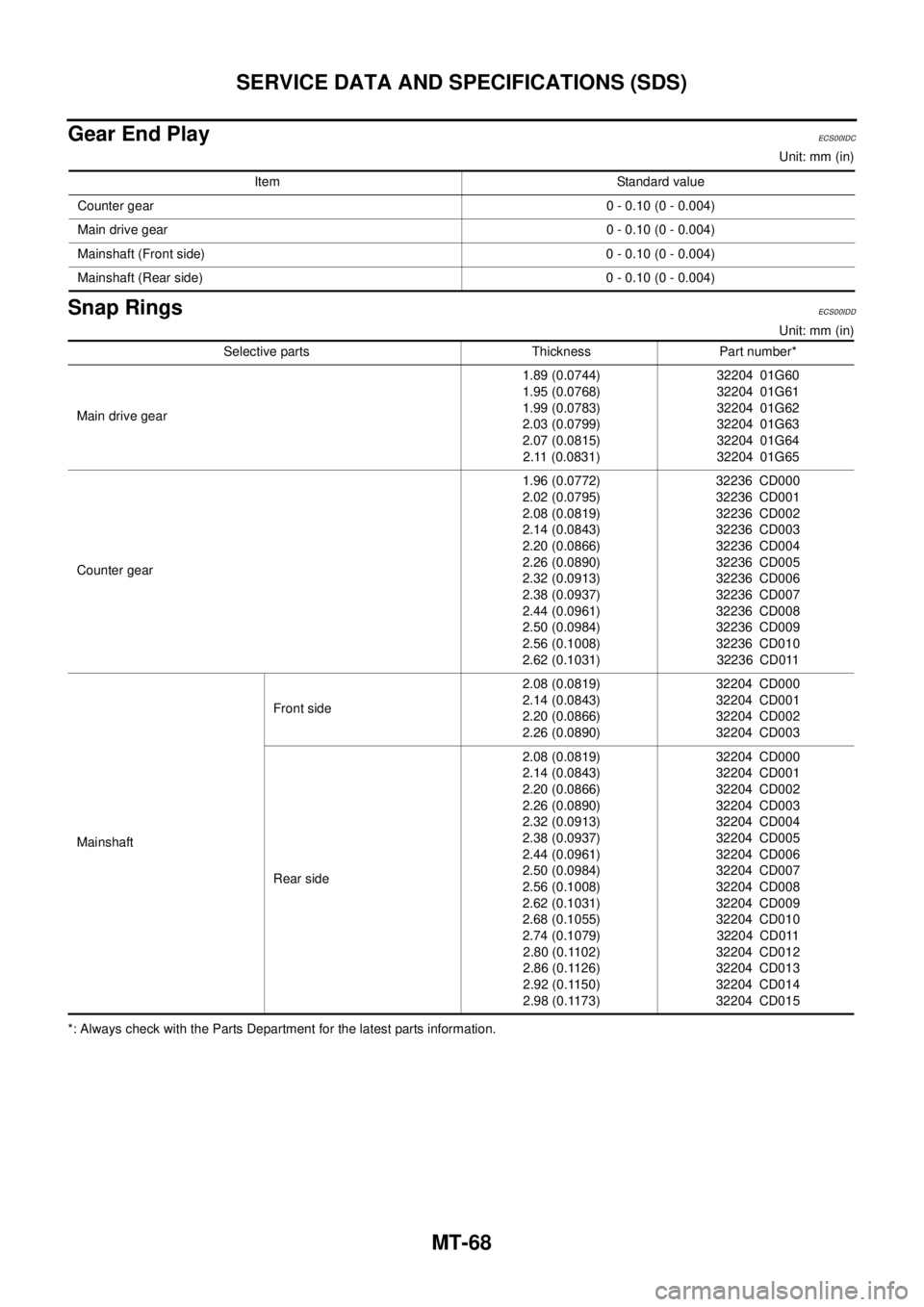

Gear End Play

ECS00IDC

Unit: mm (in)

Snap RingsECS00IDD

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.Item Standard value

Counter gear0 - 0.10 (0 - 0.004)

Main drive gear0 - 0.10 (0 - 0.004)

Mainshaft (Front side) 0 - 0.10 (0 - 0.004)

Mainshaft (Rear side) 0 - 0.10 (0 - 0.004)

Selective parts Thickness Part number*

Main drive gear1.89 (0.0744)

1.95 (0.0768)

1.99 (0.0783)

2.03 (0.0799)

2.07 (0.0815)

2.11 (0.0831)32204 01G60

32204 01G61

32204 01G62

32204 01G63

32204 01G64

32204 01G65

Counter gear1.96 (0.0772)

2.02 (0.0795)

2.08 (0.0819)

2.14 (0.0843)

2.20 (0.0866)

2.26 (0.0890)

2.32 (0.0913)

2.38 (0.0937)

2.44 (0.0961)

2.50 (0.0984)

2.56 (0.1008)

2.62 (0.1031)32236 CD000

32236 CD001

32236 CD002

32236 CD003

32236 CD004

32236 CD005

32236 CD006

32236 CD007

32236 CD008

32236 CD009

32236 CD010

32236 CD011

MainshaftFront side2.08 (0.0819)

2.14 (0.0843)

2.20 (0.0866)

2.26 (0.0890)32204 CD000

32204 CD001

32204 CD002

32204 CD003

Rear side2.08 (0.0819)

2.14 (0.0843)

2.20 (0.0866)

2.26 (0.0890)

2.32 (0.0913)

2.38 (0.0937)

2.44 (0.0961)

2.50 (0.0984)

2.56 (0.1008)

2.62 (0.1031)

2.68 (0.1055)

2.74 (0.1079)

2.80 (0.1102)

2.86 (0.1126)

2.92 (0.1150)

2.98 (0.1173)32204 CD000

32204 CD001

32204 CD002

32204 CD003

32204 CD004

32204 CD005

32204 CD006

32204 CD007

32204 CD008

32204 CD009

32204 CD010

32204 CD011

32204 CD012

32204 CD013

32204 CD014

32204 CD015

Page 2386 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-69

D

E

F

G

H

I

J

K

L

MA

B

MT

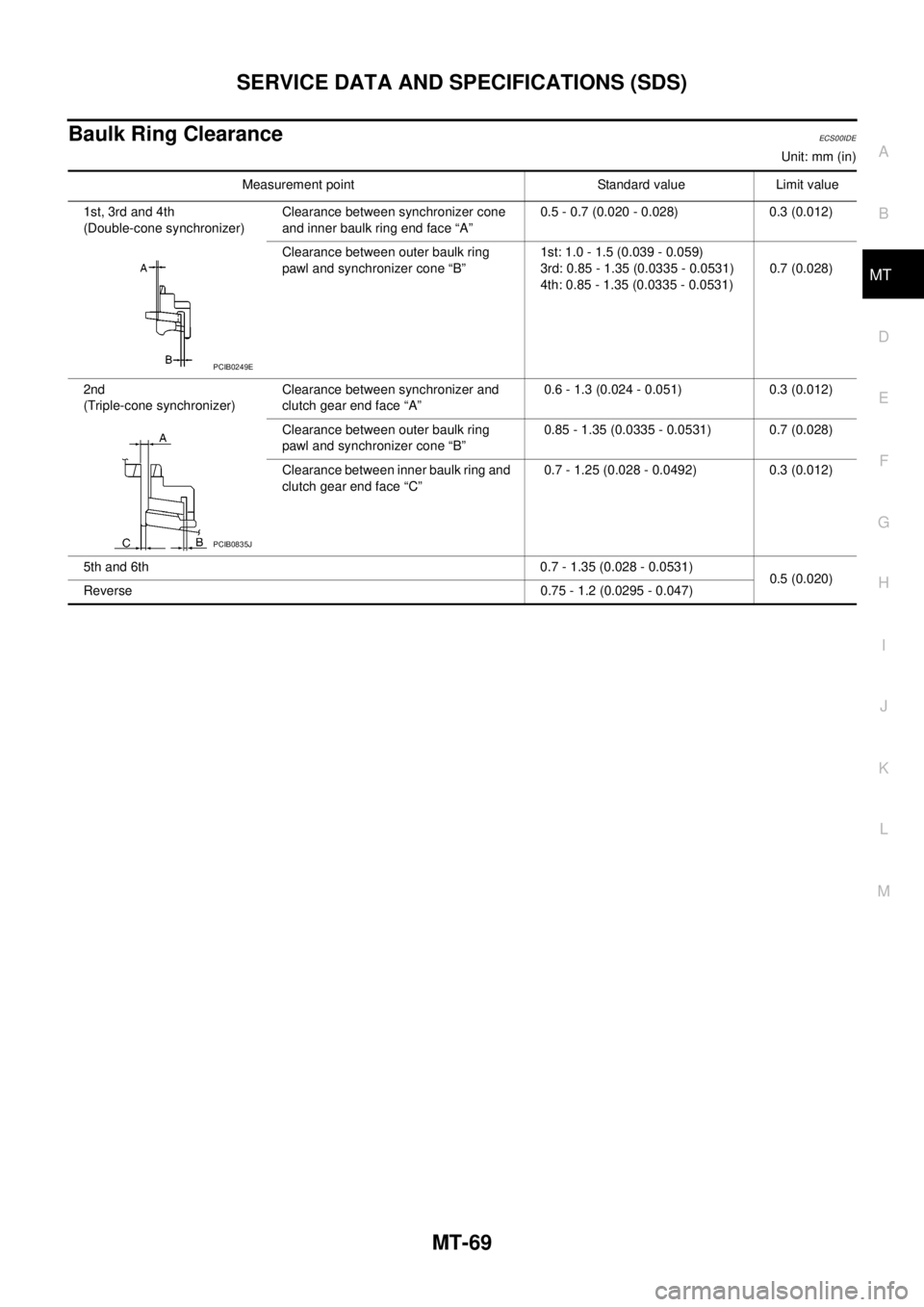

Baulk Ring ClearanceECS00IDE

Unit: mm (in)

Measurement point Standard value Limit value

1st, 3rd and 4th

(Double-cone synchronizer)Clearance between synchronizer cone

and inner baulk ring end face “A”0.5 - 0.7 (0.020 - 0.028) 0.3 (0.012)

Clearance between outer baulk ring

pawl and synchronizer cone “B”1st: 1.0 - 1.5 (0.039 - 0.059)

3rd: 0.85 - 1.35 (0.0335 - 0.0531)

4th: 0.85 - 1.35 (0.0335 - 0.0531)0.7 (0.028)

2nd

(Triple-cone synchronizer)Clearance between synchronizer and

clutch gear end face “A”0.6 - 1.3 (0.024 - 0.051) 0.3 (0.012)

Clearance between outer baulk ring

pawl and synchronizer cone “B”0.85 - 1.35 (0.0335 - 0.0531) 0.7 (0.028)

Clearance between inner baulk ring and

clutch gear end face “C”0.7 - 1.25 (0.028 - 0.0492) 0.3 (0.012)

5th and 6th 0.7 - 1.35 (0.028 - 0.0531)

0.5 (0.020)

Reverse 0.75 - 1.2 (0.0295 - 0.047)

PCIB0249E

PCIB0835J

Page 2387 of 3171

MT-70

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2388 of 3171

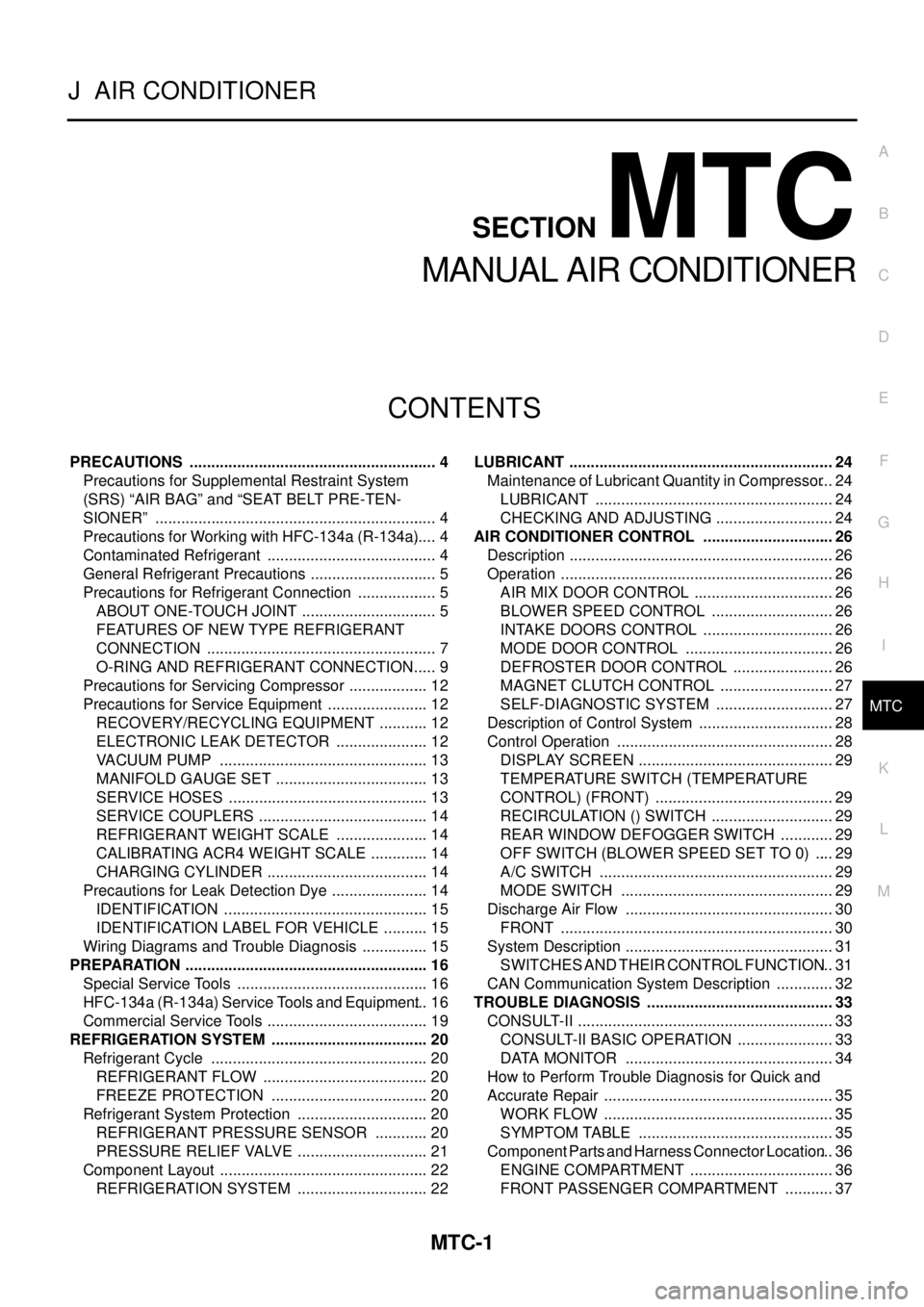

MTC-1

MANUAL AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTIONMTC

A

B

MTC

MANUAL AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

Contaminated Refrigerant ........................................ 4

General Refrigerant Precautions .............................. 5

Precautions for Refrigerant Connection ................... 5

ABOUT ONE-TOUCH JOINT ................................ 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 7

O-RING AND REFRIGERANT CONNECTION..... 9

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 12

RECOVERY/RECYCLING EQUIPMENT ............ 12

ELECTRONIC LEAK DETECTOR ...................... 12

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 13

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CALIBRATING ACR4 WEIGHT SCALE .............. 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 14

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

Wiring Diagrams and Trouble Diagnosis ................ 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment... 16

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 21

Component Layout ................................................. 22

REFRIGERATION SYSTEM ............................... 22LUBRICANT .............................................................. 24

Maintenance of Lubricant Quantity in Compressor... 24

LUBRICANT ........................................................ 24

CHECKING AND ADJUSTING ............................ 24

AIR CONDITIONER CONTROL ............................... 26

Description .............................................................. 26

Operation ................................................................ 26

AIR MIX DOOR CONTROL ................................. 26

BLOWER SPEED CONTROL ............................. 26

INTAKE DOORS CONTROL ............................... 26

MODE DOOR CONTROL ................................... 26

DEFROSTER DOOR CONTROL ........................ 26

MAGNET CLUTCH CONTROL ........................... 27

SELF-DIAGNOSTIC SYSTEM ............................ 27

Description of Control System ................................ 28

Control Operation ................................................... 28

DISPLAY SCREEN .............................................. 29

TEMPERATURE SWITCH (TEMPERATURE

CONTROL) (FRONT) .......................................... 29

RECIRCULATION () SWITCH ............................. 29

REAR WINDOW DEFOGGER SWITCH ............. 29

OFF SWITCH (BLOWER SPEED SET TO 0) ..... 29

A/C SWITCH ....................................................... 29

MODE SWITCH .................................................. 29

Discharge Air Flow ................................................. 30

FRONT ................................................................ 30

System Description ................................................. 31

SWITCHES AND THEIR CONTROL FUNCTION... 31

CAN Communication System Description .............. 32

TROUBLE DIAGNOSIS ............................................ 33

CONSULT-II ............................................................ 33

CONSULT-II BASIC OPERATION ....................... 33

DATA MONITOR ................................................. 34

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 35

WORK FLOW ...................................................... 35

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location... 36

ENGINE COMPARTMENT .................................. 36

FRONT PASSENGER COMPARTMENT ............ 37

Page 2389 of 3171

MTC-2

Schematic —LHD MODELS— ............................... 38

Wiring Diagram —A/C— —LHD MODELS— ......... 39

Schematic —RHD MODELS— ............................... 44

Wiring Diagram —A/C— —RHD MODELS— ......... 45

Front Air Control Terminals and Reference Value... 49

PIN CONNECTOR TERMINAL LAYOUT ............ 49

TERMINALS AND REFERENCE VALUE FOR

FRONT AIR CONTROL ....................................... 49

A/C System Self-diagnosis Function ...................... 51

DESCRIPTION .................................................... 51

Operational Check .................................................. 53

CHECKING BLOWER ......................................... 53

CHECKING DISCHARGE AIR ............................ 53

CHECKING RECIRCULATION ............................ 53

CHECKING TEMPERATURE DECREASE ......... 54

CHECKING TEMPERATURE INCREASE .......... 54

CHECK A/C SWITCH .......................................... 54

Power Supply and Ground Circuit for Front Air Con-

trol ........................................................................... 55

INSPECTION FLOW ........................................... 55

COMPONENT DESCRIPTION ............................ 56

DIAGNOSTIC PROCEDURE FOR A/C SYSTEM... 56

Mode Door Motor Circuit ........................................ 58

INSPECTION FLOW ........................................... 58

SYSTEM DESCRIPTION .................................... 59

COMPONENT DESCRIPTION ............................ 59

DIAGNOSTIC PROCEDURE FOR MODE

DOOR MOTOR ................................................... 59

Air Mix Door Motor Circuit ...................................... 63

INSPECTION FLOW ........................................... 63

SYSTEM DESCRIPTION .................................... 64

COMPONENT DESCRIPTION ............................ 64

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (FRONT) .................................... 64

Intake Door Motor Circuit ........................................ 68

INSPECTION FLOW ........................................... 68

SYSTEM DESCRIPTION .................................... 69

COMPONENT DESCRIPTION ............................ 69

DIAGNOSTIC PROCEDURE FOR INTAKE

DOOR MOTOR ................................................... 69

Blower Motor Circuit ............................................... 71

INSPECTION FLOW ........................................... 71

SYSTEM DESCRIPTION .................................... 72

COMPONENT DESCRIPTION ............................ 72

DIAGNOSTIC PROCEDURE FOR BLOWER

MOTOR ............................................................... 73

COMPONENT INSPECTION .............................. 77

Magnet Clutch Circuit ............................................. 79

INSPECTION FLOW ........................................... 79

SYSTEM DESCRIPTION .................................... 80

DIAGNOSTIC PROCEDURE FOR MAGNET

CLUTCH .............................................................. 80

COMPONENT INSPECTION .............................. 85

Insufficient Cooling ................................................. 86

INSPECTION FLOW ........................................... 86

PERFORMANCE TEST DIAGNOSES ................ 87

PERFORMANCE CHART ................................... 89

TROUBLE DIAGNOSES FOR UNUSUAL PRES-

SURE ................................................................... 90Insufficient Heating ................................................. 93

INSPECTION FLOW ............................................ 93

Noise ....................................................................... 94

INSPECTION FLOW ............................................ 94

Self-diagnosis ......................................................... 95

INSPECTION FLOW ............................................ 95

Intake Sensor Circuit ............................................... 95

COMPONENT DESCRIPTION ............................ 95

DIAGNOSTIC PROCEDURE FOR INTAKE SEN-

SOR ..................................................................... 96

COMPONENT INSPECTION ............................... 97

CONTROL UNIT ........................................................ 98

Removal and Installation ......................................... 98

REMOVAL ............................................................ 98

INSTALLATION .................................................... 98

INTAKE SENSOR ...................................................... 99

Removal and Installation ......................................... 99

REMOVAL ............................................................ 99

INSTALLATION .................................................... 99

BLOWER MOTOR ...................................................100

Components ..........................................................100

Removal and Installation .......................................100

REMOVAL ..........................................................100

INSTALLATION ..................................................100

AIR CONDITIONER FILTER ...................................101

Removal and Installation .......................................101

FUNCTION ........................................................101

REPLACEMENT TIMING ..................................101

REPLACEMENT PROCEDURE ........................101

HEATER & COOLING UNIT ASSEMBLY ...............103

Components ..........................................................103

Removal and Installation .......................................105

REMOVAL ..........................................................105

INSTALLATION ..................................................105

HEATER CORE .......................................................106

Components ..........................................................106

Removal and Installation .......................................107

REMOVAL ..........................................................107

INSTALLATION ..................................................107

DEFROSTER DOOR MOTOR .................................108

Components ..........................................................108

Removal and Installation .......................................108

REMOVAL ..........................................................108

INSTALLATION ..................................................108

INTAKE DOOR MOTOR ..........................................109

Components ..........................................................109

Removal and Installation .......................................109

REMOVAL ..........................................................109

INSTALLATION ..................................................109

MODE DOOR MOTOR ............................................110

Components ..........................................................110

Removal and Installation .......................................110

REMOVAL ..........................................................110

INSTALLATION ..................................................110

AIR MIX DOOR MOTOR ......................................... 111

Components .......................................................... 111

Removal and Installation ....................................... 111

REMOVAL .......................................................... 111

INSTALLATION .................................................. 111

Page 2390 of 3171

MTC-3

C

D

E

F

G

H

I

K

L

MA

B

MTC BLOWER MOTOR RESISTOR ................................112

Components .......................................................... 112

Removal and Installation ....................................... 112

REMOVAL .......................................................... 112

INSTALLATION .................................................. 112

DUCTS AND GRILLES ...........................................113

Components .......................................................... 113

Removal and Installation ....................................... 116

CENTER CONSOLE HEAT DUCT AND REAR

FINISHER ASSEMBLY GRILLE ........................ 116

DEFROSTER NOZZLE ...................................... 116

RH AND LH SIDE DEMISTER DUCT ................ 116

RH AND LH VENTILATOR DUCT ...................... 116

CENTER VENTILATOR DUCT .......................... 116

FLOOR DUCT .................................................... 116

GRILLES ............................................................ 116

REFRIGERANT LINES ............................................118

HFC-134a (R-134a) Service Procedure ................ 118

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................. 118

Components ......................................................... 120

Removal and Installation for Compressor ............ 122

REMOVAL ......................................................... 122

INSTALLATION ................................................. 122

Removal and Installation for Compressor Clutch . 123

REMOVAL ......................................................... 123

INSPECTION .................................................... 124

INSTALLATION ................................................. 124

BREAK-IN OPERATION ................................... 126

Removal and Installation for Low-pressure Flexible

Hose ..................................................................... 126

REMOVAL ......................................................... 126

INSTALLATION ................................................. 126

Removal and Installation for High-pressure Flexible

Hose ..................................................................... 126

REMOVAL ......................................................... 126INSTALLATION .................................................126

Removal and Installation for High-pressure Pipe . 126

REMOVAL .........................................................126

INSTALLATION .................................................126

Removal and Installation for Low-pressure Pipe ..127

REMOVAL .........................................................127

INSTALLATION .................................................127

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................127

REMOVAL .........................................................127

INSTALLATION .................................................127

Removal and Installation for Condenser ..............127

REMOVAL .........................................................127

INSTALLATION .................................................128

Removal and Installation for Evaporator ..............129

REMOVAL .........................................................130

INSTALLATION .................................................130

Removal and Installation for Expansion Valve ......130

REMOVAL .........................................................130

INSTALLATION .................................................130

Checking for Refrigerant Leaks ............................131

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................131

Dye Injection .........................................................131

Electronic Refrigerant Leak Detector ....................132

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................132

CHECKING PROCEDURE ...............................133

SERVICE DATA AND SPECIFICATIONS (SDS) ....135

Service Data and Specifications (SDS) ................135

COMPRESSOR ................................................135

LUBRICANT ......................................................135

REFRIGERANT .................................................135

ENGINE IDLING SPEED ..................................135

BELT TENSION .................................................135