service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1691 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

GW-5

C

D

E

F

G

H

J

K

L

MA

B

GW

SQUEAK AND RATTLE TROUBLE DIAGNOSESPFP:00000

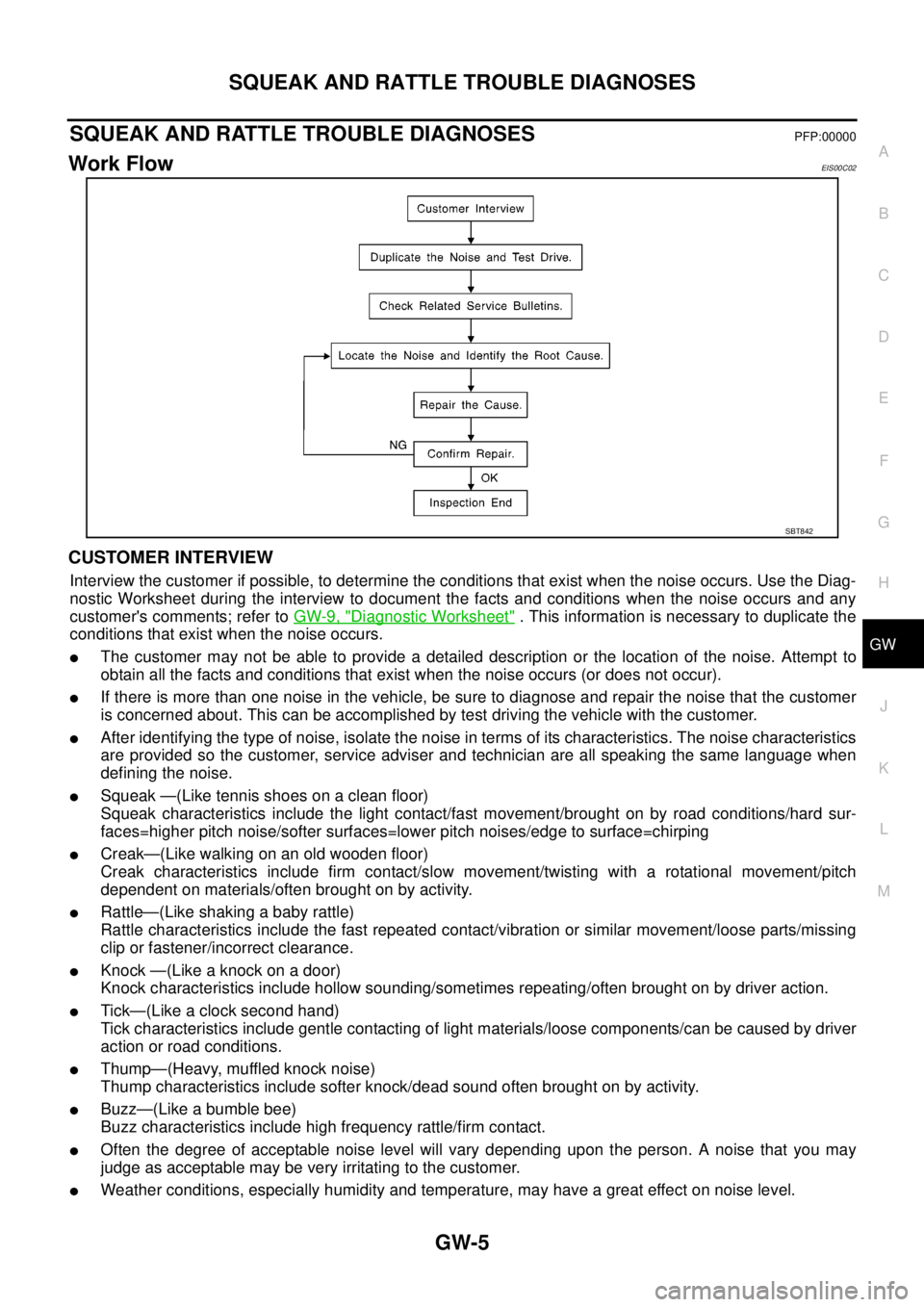

Work FlowEIS00C02

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer toGW-9, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

lThe customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

lIf there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

lAfter identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

lSqueak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

lCreak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

lRattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

lKnock—(Likeaknockonadoor)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

lTick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

lThump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

lBuzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

lOften the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

lWeather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842

Page 1692 of 3171

GW-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrowdownthenoisetoamorespecificareaandidentifythecauseofthenoiseby:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toGW-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape are available through your authorized Nissan Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

Each item can be ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100´135 mm (3.94´5.31 in)/76884-71L01: 60´85 mm (2.36´3.35 in)/76884-71L02: 15´

25 mm (0.59´0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50´50 mm (1.97´1.97 in)/73982-50Y00: 10 mm (0.39 in) think, 50

´50 mm (1.97´1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30´50 mm (1.18´1.97 in)

Page 1711 of 3171

POWER WINDOW SYSTEM

GW-25

C

D

E

F

G

H

J

K

L

MA

B

GW

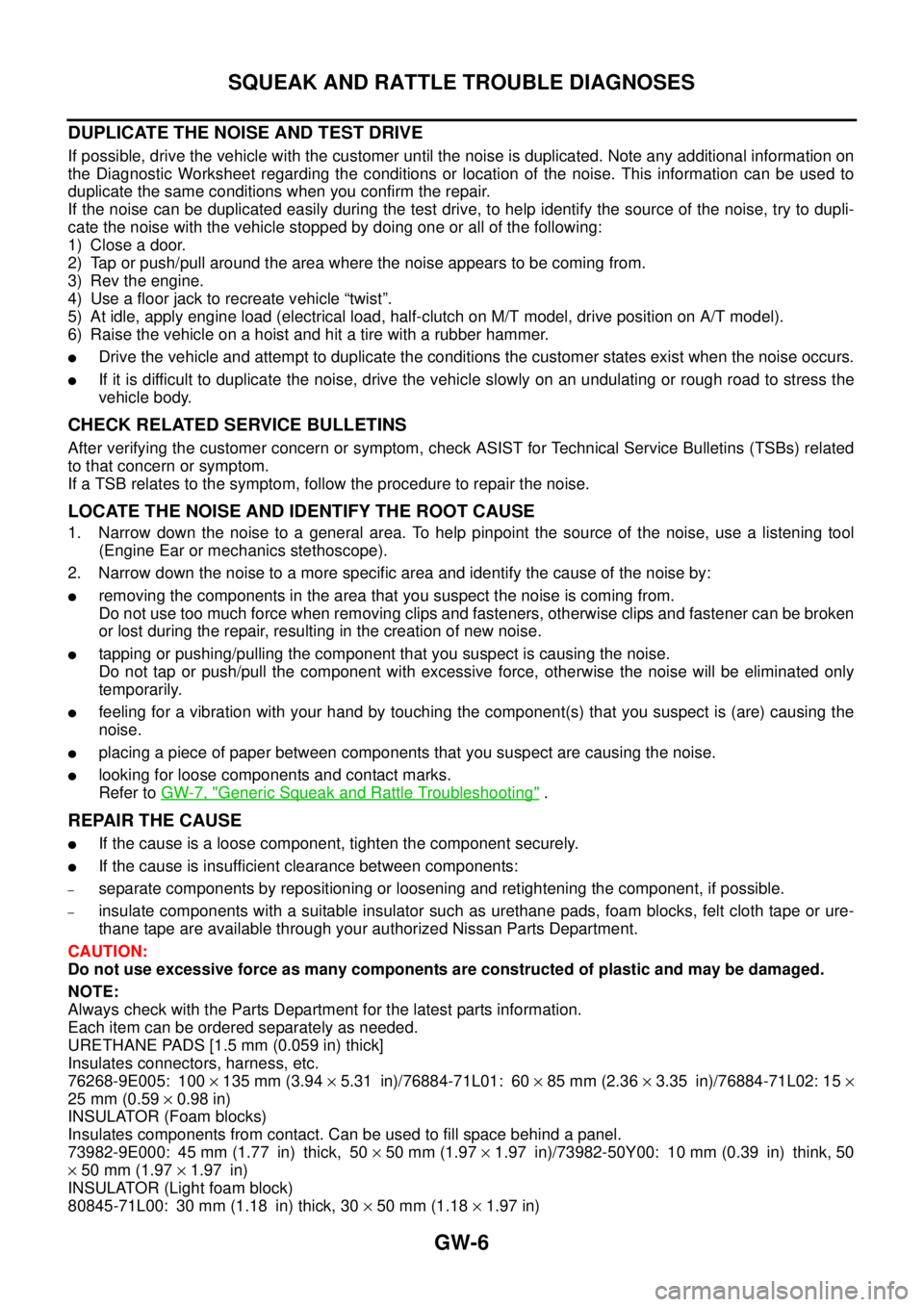

Terminal and Reference Value for BCMEIS00B7P

Work FlowEIS00B7Q

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer toGW-15, "

System Description".

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction.

Refer toGW-25, "

Trouble Diagnosis Symptom Chart".

4. Does power window system operate normally? Yes, GO TO 5, If No, GO TO 3.

5. Inspection end.

Trouble Diagnosis Symptom ChartEIS00C0A

Terminal Wire color Item ConditionVoltage (V)

(Approx.)

3 Y Ignition switch (ON or START)Ignition switch

(ON or START position)Battery voltage

41 Y Battery power supply (Fuse) — Battery voltage

53 W Power window pow er supply (IGN)When ignition switch ON Battery voltage

When ignition switch OFF 0

55 B Ground — 0

57 W Battery power supply (Fusible link) — Battery voltage

58 P Power window power supply (BAT) — Battery voltage

Symptom Diagnosis / service procedure Refer to page

None of the power window can be operated using any

switch1. BCM power supply and ground circuit check.GW-26

2. Power window main switch power supply and

ground circuit check.GW-27

Driver side power window cannot be operated 1. Driver side power window motor check.GW-28

Passenger side power window cannot be operated1. Passenger side power window motor circuit checkGW-292. Power window switch check 1GW-33

3. passenger side power window circuit checkGW-31

Rear LH side power window cannot be operated1. Rear LH power window motor circuit checkGW-302. Power window switch check 1GW-33

3. Rear LH power window circuit checkGW-32

Rear RH side power window cannot be operated1. Rear RH power window motor circuit checkGW-312. Power window switch check 1GW-33

3. Rear RH power window circuit checkGW-33

Power window does not operate using power window

switch. (Power window can be operated using power win-

dow main switch)1. Power window switch check 2GW-34

Anti-pinch system does not operate normal

Replace front power window motor and control unit

(driver side)—

Power window timer does not operated

Page 1742 of 3171

GW-56

REAR WINDOW DEFOGGER

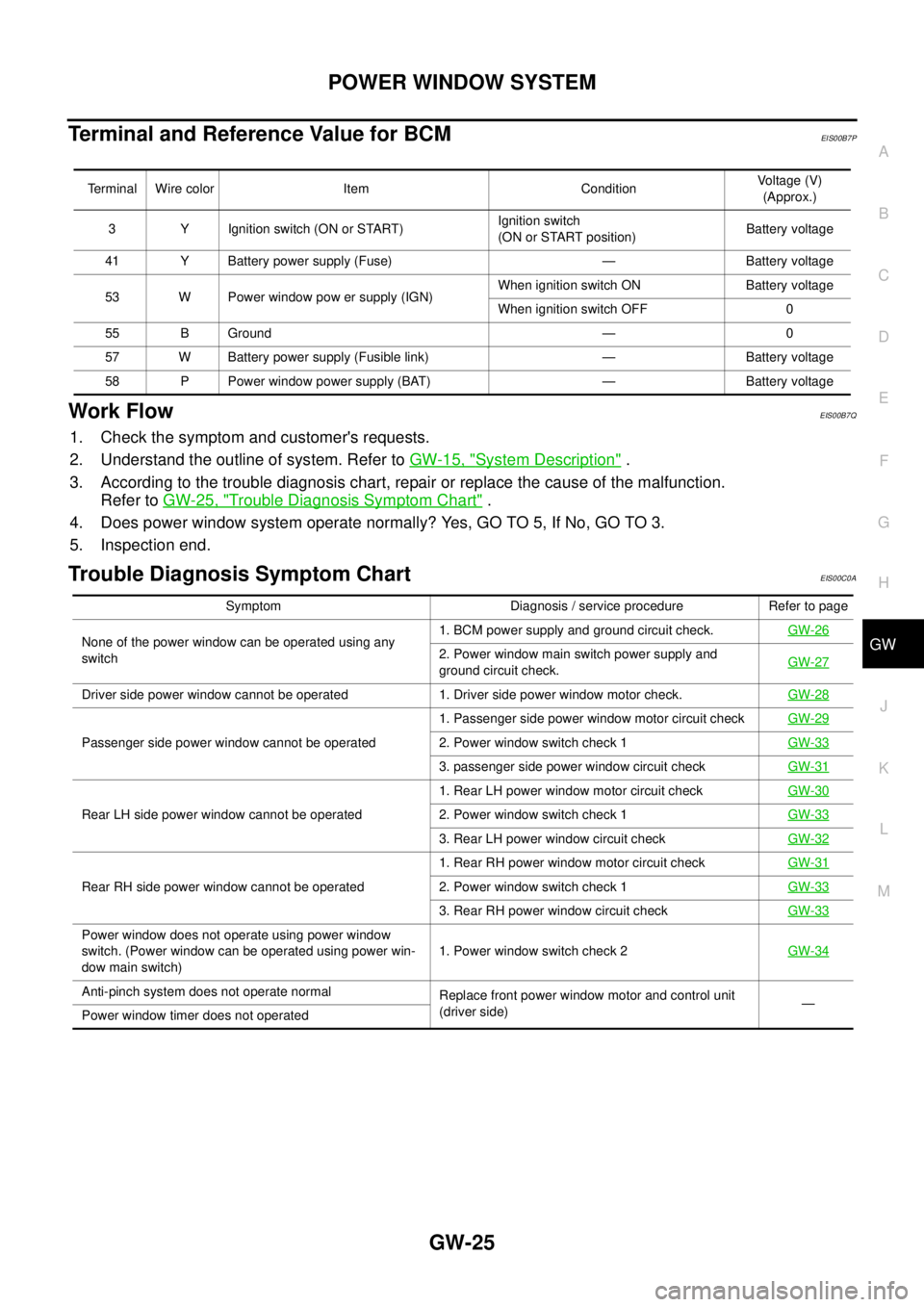

Trouble Diagnoses Symptom Chart

EIS00B8N

lMake sure other systems using the signal of the following systems operate normally.

BCM Power Supply and Ground Circuit CheckEIS00B8O

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, when perform the each trouble

diagnosis. Refer toBCS-16, "

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)".

1.CHECK FUSE

lCheck 10A fuse [No. 1, located in the fuse block (J/B)]

lCheck 50A fusible link (letterGlocated in the fuse and fusible link box)

NOTE:

Refer toGW-47, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Turn ignition switch ON.

4. Check voltage between BCM connector M42, M44 terminal 3,

57 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Symptom Diagnoses / Service procedure Refer to page

Rear window defogger and door mirror defoggers do not

operate.1. BCM power supply and ground circuit checkGW-56

2. IPDM E/R auto active test checkPG-19

3. Rear window defogger power supply circuit checkGW-59

4. Rear window defogger switch circuit checkGW-57

5. Rear window defogger circuit checkGW-59

6. Replace IPDM E/RPG-26

Rear window defogger switch does not light, and rear win-

dow defogger is not displayed on the display, but rear win-

dow defogger operates.1. Rear window defogger signal checkGW-60

3 - Ground : Battery voltage

57 - Ground : Battery voltage

MIIB0730E

Page 1754 of 3171

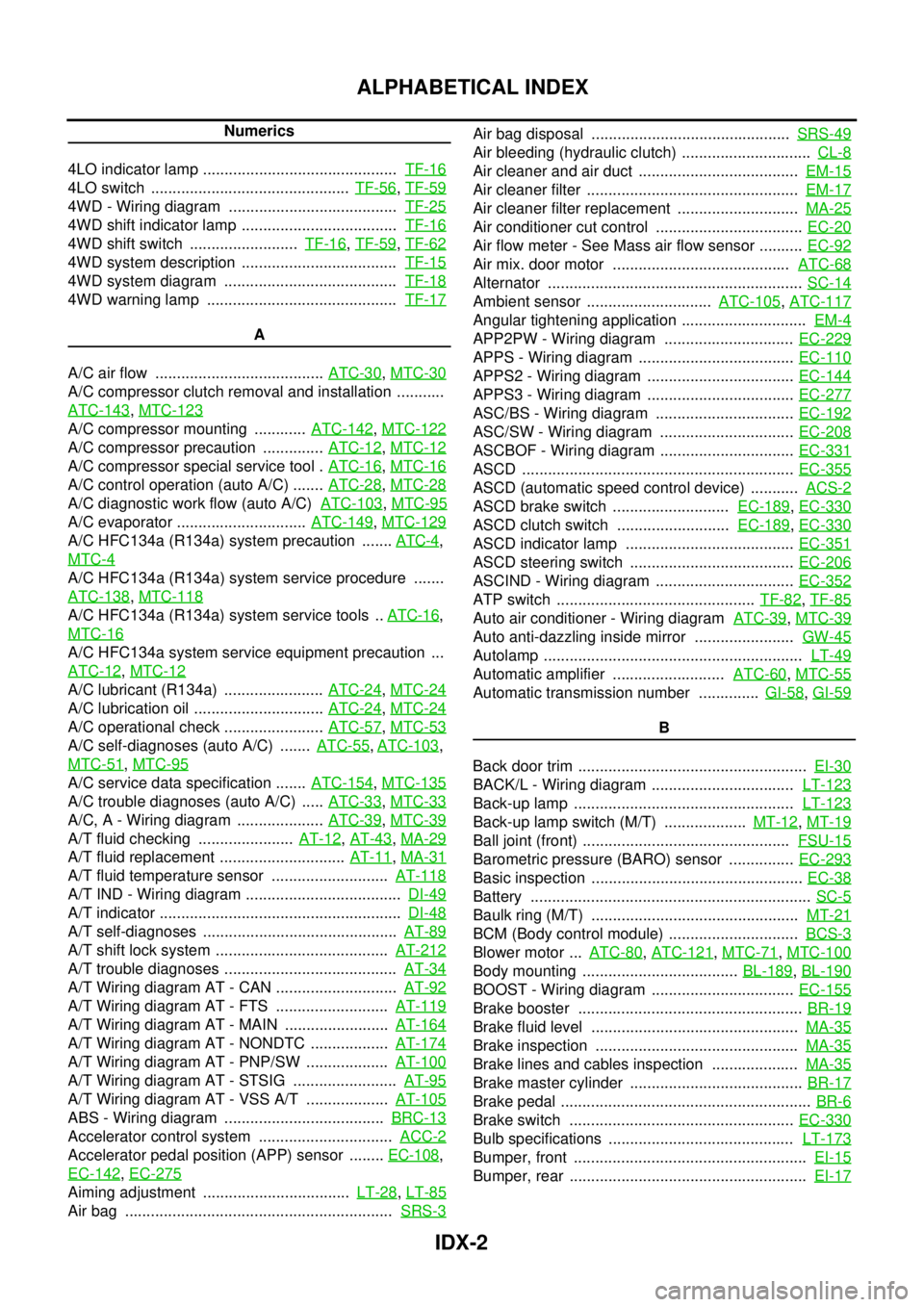

IDX-2

ALPHABETICAL INDEX

Numerics

4LO indicator lamp .............................................TF-16

4LO switch ..............................................TF-56,TF-59

4WD - Wiring diagram .......................................TF-25

4WD shift indicator lamp ....................................TF-16

4WD shift switch .........................TF-16,TF-59,TF-62

4WD system description ....................................TF-15

4WD system diagram ........................................TF-18

4WD warning lamp ............................................TF-17

A

A/C air flow .......................................ATC-30

,MTC-30

A/C compressor clutch removal and installation ...........

ATC-143

,MTC-123

A/C compressor mounting ............ATC-142,MTC-122

A/C compressor precaution ..............ATC-12,MTC-12

A/C compressor special service tool .ATC-16,MTC-16

A/C control operation (auto A/C) .......ATC-28,MTC-28

A/C diagnostic work flow (auto A/C)ATC-103,MTC-95

A/C evaporator ..............................ATC-149,MTC-129

A/C HFC134a (R134a) system precaution .......ATC-4,

MTC-4

A/C HFC134a (R134a) system service procedure .......

ATC-138

,MTC-118

A/C HFC134a (R134a) system service tools ..ATC-16,

MTC-16

A/C HFC134a system service equipment precaution ...

ATC-12

,MTC-12

A/C lubricant (R134a) .......................ATC-24,MTC-24

A/C lubrication oil ..............................ATC-24,MTC-24

A/C operational check .......................ATC-57,MTC-53

A/C self-diagnoses (auto A/C) .......ATC-55,ATC-103,

MTC-51

,MTC-95

A/C service data specification .......ATC-154,MTC-135

A/C trouble diagnoses (auto A/C) .....ATC-33,MTC-33

A/C, A - Wiring diagram ....................ATC-39,MTC-39

A/T fluid checking ......................AT-12,AT-43,MA-29

A/T fluid replacement .............................AT-11,MA-31

A/T fluid temperature sensor ...........................AT-118

A/T IND - Wiring diagram ....................................DI-49

A/T indicator ........................................................DI-48

A/T self-diagnoses .............................................AT-89

A/T shift lock system ........................................AT-212

A/T trouble diagnoses ........................................AT-34

A/T Wiring diagram AT - CAN ............................AT-92

A/T Wiring diagram AT - FTS ..........................AT-119

A/T Wiring diagram AT - MAIN ........................AT-164

A/T Wiring diagram AT - NONDTC ..................AT-174

A/T Wiring diagram AT - PNP/SW ...................AT-100

A/T Wiring diagram AT - STSIG ........................AT-95

A/T Wiring diagram AT - VSS A/T ...................AT-105

ABS - Wiring diagram .....................................BRC-13

Accelerator control system ...............................ACC-2

Accelerator pedal position (APP) sensor ........EC-108,

EC-142

,EC-275

Aiming adjustment ..................................LT-28,LT-85

Air bag ..............................................................SRS-3

Air bag disposal ..............................................SRS-49

Air bleeding (hydraulic clutch) ..............................CL-8

Air cleaner and air duct .....................................EM-15

Air cleaner filter .................................................EM-17

Air cleaner filter replacement ............................MA-25

Air conditioner cut control ..................................EC-20

Air flow meter - See Mass air flow sensor ..........EC-92

Air mix. door motor .........................................ATC-68

Alternator ...........................................................SC-14

Ambient sensor .............................ATC-105,ATC-117

Angular tightening application .............................EM-4

APP2PW - Wiring diagram ..............................EC-229

APPS - Wiring diagram ....................................EC-110

APPS2 - Wiring diagram ..................................EC-144

APPS3 - Wiring diagram ..................................EC-277

ASC/BS - Wiring diagram ................................EC-192

ASC/SW - Wiring diagram ...............................EC-208

ASCBOF - Wiring diagram ...............................EC-331

ASCD ...............................................................EC-355

ASCD (automatic speed control device) ...........ACS-2

ASCD brake switch ...........................EC-189,EC-330

ASCD clutch switch ..........................EC-189,EC-330

ASCD indicator lamp .......................................EC-351

ASCD steering switch ......................................EC-206

ASCIND - Wiring diagram ................................EC-352

ATP switch ..............................................TF-82,TF-85

Auto air conditioner - Wiring diagramATC-39,MTC-39

Auto anti-dazzling inside mirror .......................GW-45

Autolamp ............................................................LT-49

Automatic amplifier ..........................ATC-60,MTC-55

Automatic transmission number ..............GI-58,GI-59

B

Back door trim .....................................................EI-30

BACK/L - Wiring diagram .................................LT-123

Back-up lamp ...................................................LT-123

Back-up lamp switch (M/T) ...................MT-12,MT-19

Ball joint (front) ................................................FSU-15

Barometric pressure (BARO) sensor ...............EC-293

Basic inspection .................................................EC-38

Battery .................................................................SC-5

Baulk ring (M/T) ................................................MT-21

BCM (Body control module) ..............................BCS-3

Blower motor ...ATC-80,ATC-121,MTC-71,MTC-100

Body mounting ....................................BL-189,BL-190

BOOST - Wiring diagram .................................EC-155

Brake booster ....................................................BR-19

Brake fluid level ................................................MA-35

Brake inspection ...............................................MA-35

Brake lines and cables inspection ....................MA-35

Brake master cylinder ........................................BR-17

Brake pedal ..........................................................BR-6

Brake switch ....................................................EC-330

Bulb specifications ...........................................LT-173

Bumper, front ......................................................EI-15

Bumper, rear .......................................................EI-17

Page 1755 of 3171

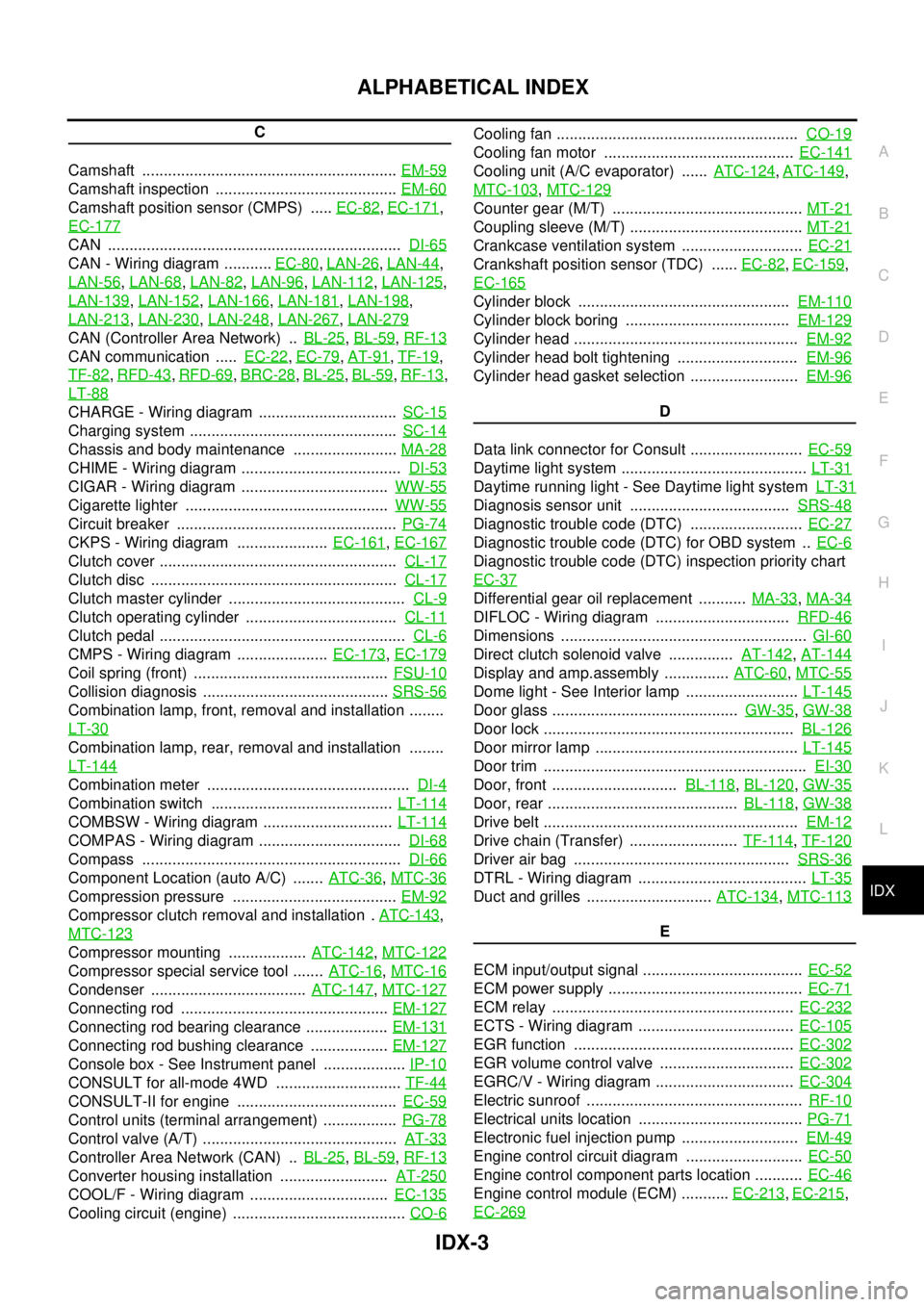

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

C

Camshaft ...........................................................EM-59

Camshaft inspection ..........................................EM-60

Camshaft position sensor (CMPS) .....EC-82,EC-171,

EC-177

CAN ....................................................................DI-65

CAN - Wiring diagram ...........EC-80,LAN-26,LAN-44,

LAN-56

,LAN-68,LAN-82,LAN-96,LAN-112,LAN-125,

LAN-139

,LAN-152,LAN-166,LAN-181,LAN-198,

LAN-213

,LAN-230,LAN-248,LAN-267,LAN-279

CAN (Controller Area Network) ..BL-25,BL-59,RF-13

CAN communication .....EC-22,EC-79,AT-91,TF-19,

TF-82

,RFD-43,RFD-69,BRC-28,BL-25,BL-59,RF-13,

LT-88

CHARGE - Wiring diagram ................................SC-15

Charging system ................................................SC-14

Chassis and body maintenance ........................MA-28

CHIME - Wiring diagram .....................................DI-53

CIGAR - Wiring diagram ..................................WW-55

Cigarette lighter ...............................................WW-55

Circuit breaker ...................................................PG-74

CKPS - Wiring diagram .....................EC-161,EC-167

Clutch cover .......................................................CL-17

Clutch disc .........................................................CL-17

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-6

CMPS - Wiring diagram .....................EC-173,EC-179

Coil spring (front) .............................................FSU-10

Collision diagnosis ...........................................SRS-56

Combination lamp, front, removal and installation ........

LT-30

Combination lamp, rear, removal and installation ........

LT-144

Combination meter ...............................................DI-4

Combination switch ..........................................LT-114

COMBSW - Wiring diagram ..............................LT-114

COMPAS - Wiring diagram .................................DI-68

Compass ............................................................DI-66

Component Location (auto A/C) .......ATC-36,MTC-36

Compression pressure ......................................EM-92

Compressor clutch removal and installation .ATC-143,

MTC-123

Compressor mounting ..................ATC-142,MTC-122

Compressor special service tool .......ATC-16,MTC-16

Condenser ....................................ATC-147,MTC-127

Connecting rod ................................................EM-127

Connecting rod bearing clearance ...................EM-131

Connecting rod bushing clearance ..................EM-127

Console box - See Instrument panel ...................IP-10

CONSULT for all-mode 4WD .............................TF-44

CONSULT-II for engine .....................................EC-59

Control units (terminal arrangement) .................PG-78

Control valve (A/T) .............................................AT-33

Controller Area Network (CAN) ..BL-25,BL-59,RF-13

Converter housing installation .........................AT-250

COOL/F - Wiring diagram ................................EC-135

Cooling circuit (engine) ........................................CO-6

Cooling fan ........................................................CO-19

Cooling fan motor ............................................EC-141

Cooling unit (A/C evaporator) ......ATC-124,ATC-149,

MTC-103

,MTC-129

Counter gear (M/T) ............................................MT-21

Coupling sleeve (M/T) ........................................MT-21

Crankcase ventilation system ............................EC-21

Crankshaft position sensor (TDC) ......EC-82,EC-159,

EC-165

Cylinder block .................................................EM-110

Cylinder block boring ......................................EM-129

Cylinder head ....................................................EM-92

Cylinder head bolt tightening ............................EM-96

Cylinder head gasket selection .........................EM-96

D

Data link connector for Consult ..........................EC-59

Daytime light system ...........................................LT-31

Daytime running light - See Daytime light systemLT-31

Diagnosis sensor unit .....................................SRS-48

Diagnostic trouble code (DTC) ..........................EC-27

Diagnostic trouble code (DTC) for OBD system ..EC-6

Diagnostic trouble code (DTC) inspection priority chart

EC-37

Differential gear oil replacement ...........MA-33,MA-34

DIFLOC - Wiring diagram ...............................RFD-46

Dimensions .........................................................GI-60

Direct clutch solenoid valve ...............AT-142,AT-144

Display and amp.assembly ...............ATC-60,MTC-55

Dome light - See Interior lamp ..........................LT-145

Door glass ...........................................GW-35,GW-38

Door lock ..........................................................BL-126

Door mirror lamp ...............................................LT-145

Door trim .............................................................EI-30

Door, front .............................BL-118,BL-120,GW-35

Door, rear ............................................BL-118,GW-38

Drive belt ...........................................................EM-12

Drive chain (Transfer) .........................TF-114,TF-120

Driver air bag ..................................................SRS-36

DTRL - Wiring diagram .......................................LT-35

Duct and grilles .............................ATC-134,MTC-113

E

ECM input/output signal .....................................EC-52

ECM power supply .............................................EC-71

ECM relay ........................................................EC-232

ECTS - Wiring diagram ....................................EC-105

EGR function ...................................................EC-302

EGR volume control valve ...............................EC-302

EGRC/V - Wiring diagram ................................EC-304

Electric sunroof ..................................................RF-10

Electrical units location ......................................PG-71

Electronic fuel injection pump ...........................EM-49

Engine control circuit diagram ...........................EC-50

Engine control component parts location ...........EC-46

Engine control module (ECM) ...........EC-213,EC-215,

EC-269

Page 1756 of 3171

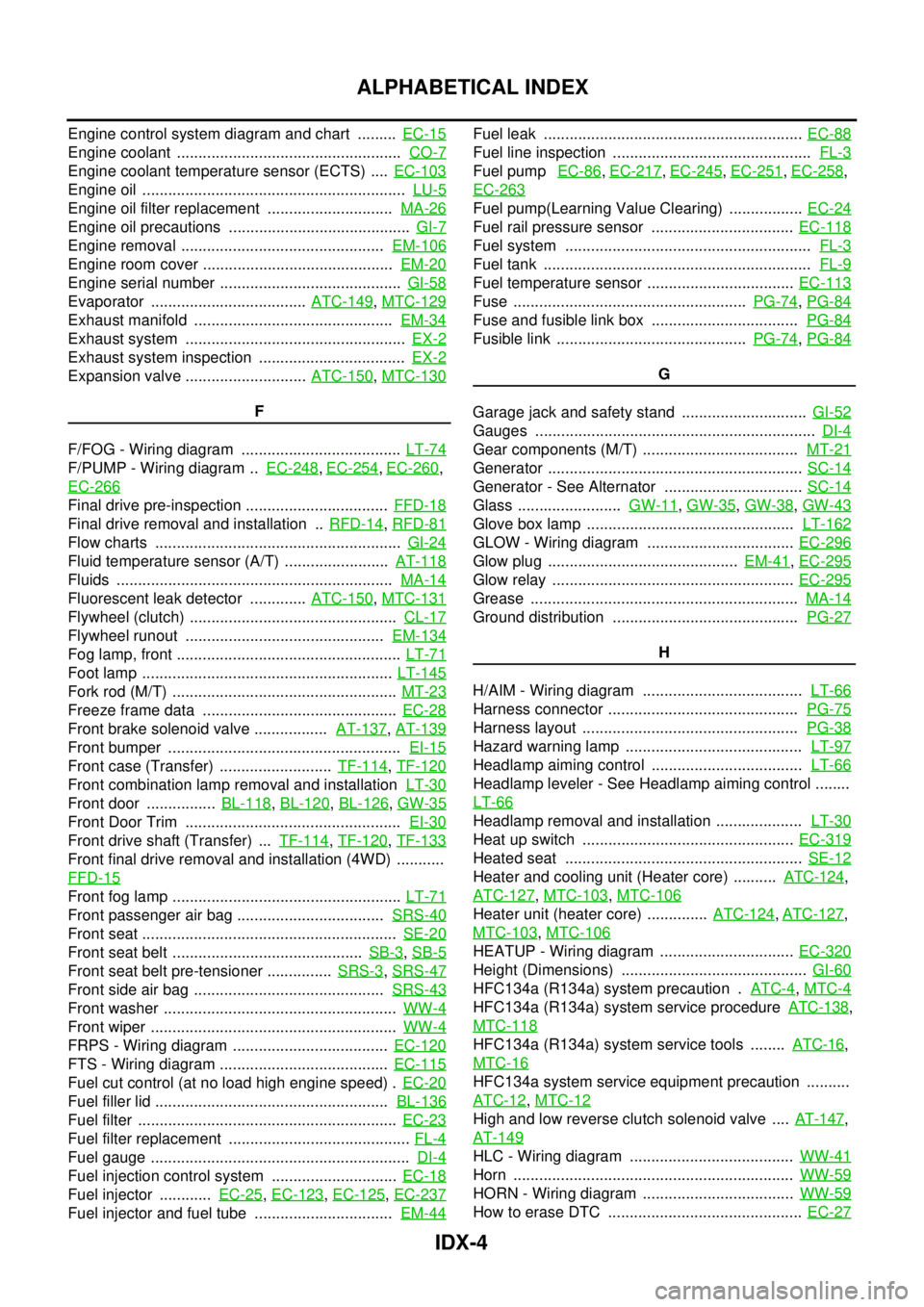

IDX-4

ALPHABETICAL INDEX

Engine control system diagram and chart .........EC-15

Engine coolant ....................................................CO-7

Engine coolant temperature sensor (ECTS) ....EC-103

Engine oil .............................................................LU-5

Engine oil filter replacement .............................MA-26

Engine oil precautions ..........................................GI-7

Engine removal ...............................................EM-106

Engine room cover ............................................EM-20

Engine serial number ..........................................GI-58

Evaporator ....................................ATC-149,MTC-129

Exhaust manifold ..............................................EM-34

Exhaust system ...................................................EX-2

Exhaust system inspection ..................................EX-2

Expansion valve ............................ATC-150,MTC-130

F

F/FOG - Wiring diagram .....................................LT-74

F/PUMP - Wiring diagram ..EC-248,EC-254,EC-260,

EC-266

Final drive pre-inspection .................................FFD-18

Final drive removal and installation ..RFD-14,RFD-81

Flow charts .........................................................GI-24

Fluid temperature sensor (A/T) ........................AT-118

Fluids ................................................................MA-14

Fluorescent leak detector .............ATC-150,MTC-131

Flywheel (clutch) ................................................CL-17

Flywheel runout ..............................................EM-134

Fog lamp, front ....................................................LT-71

Foot lamp ..........................................................LT-145

Fork rod (M/T) ....................................................MT-23

Freeze frame data .............................................EC-28

Front brake solenoid valve .................AT-137,AT-139

Front bumper ......................................................EI-15

Front case (Transfer) ..........................TF-114,TF-120

Front combination lamp removal and installationLT-30

Front door ................BL-118,BL-120,BL-126,GW-35

Front Door Trim ..................................................EI-30

Front drive shaft (Transfer) ...TF-114,TF-120,TF-133

Front final drive removal and installation (4WD) ...........

FFD-15

Front fog lamp .....................................................LT-71

Front passenger air bag ..................................SRS-40

Front seat ...........................................................SE-20

Front seat belt ............................................SB-3,SB-5

Front seat belt pre-tensioner ...............SRS-3,SRS-47

Front side air bag ............................................SRS-43

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FRPS - Wiring diagram ....................................EC-120

FTS - Wiring diagram .......................................EC-115

Fuel cut control (at no load high engine speed) .EC-20

Fuel filler lid ......................................................BL-136

Fuel filter ............................................................EC-23

Fuel filter replacement ..........................................FL-4

Fuel gauge ............................................................DI-4

Fuel injection control system .............................EC-18

Fuel injector ............EC-25,EC-123,EC-125,EC-237

Fuel injector and fuel tube ................................EM-44

Fuel leak ............................................................EC-88

Fuel line inspection ..............................................FL-3

Fuel pumpEC-86,EC-217,EC-245,EC-251,EC-258,

EC-263

Fuel pump(Learning Value Clearing) .................EC-24

Fuel rail pressure sensor .................................EC-118

Fuel system .........................................................FL-3

Fuel tank ..............................................................FL-9

Fuel temperature sensor ..................................EC-113

Fuse ......................................................PG-74,PG-84

Fuse and fusible link box ..................................PG-84

Fusible link ............................................PG-74,PG-84

G

Garage jack and safety stand .............................GI-52

Gauges .................................................................DI-4

Gear components (M/T) ....................................MT-21

Generator ...........................................................SC-14

Generator - See Alternator ................................SC-14

Glass ........................GW-11,GW-35,GW-38,GW-43

Glove box lamp ................................................LT-162

GLOW - Wiring diagram ..................................EC-296

Glow plug ............................................EM-41,EC-295

Glow relay ........................................................EC-295

Grease ..............................................................MA-14

Ground distribution ...........................................PG-27

H

H/AIM - Wiring diagram .....................................LT-66

Harness connector ............................................PG-75

Harness layout ..................................................PG-38

Hazard warning lamp .........................................LT-97

Headlamp aiming control ...................................LT-66

Headlamp leveler - See Headlamp aiming control ........

LT-66

Headlamp removal and installation ....................LT-30

Heat up switch .................................................EC-319

Heated seat .......................................................SE-12

Heater and cooling unit (Heater core) ..........ATC-124,

ATC-127

,MTC-103,MTC-106

Heater unit (heater core) ..............ATC-124,ATC-127,

MTC-103

,MTC-106

HEATUP - Wiring diagram ...............................EC-320

Height (Dimensions) ...........................................GI-60

HFC134a (R134a) system precaution .ATC-4,MTC-4

HFC134a (R134a) system service procedureATC-138,

MTC-118

HFC134a (R134a) system service tools ........ATC-16,

MTC-16

HFC134a system service equipment precaution ..........

ATC-12

,MTC-12

High and low reverse clutch solenoid valve ....AT-147,

AT-149

HLC - Wiring diagram ......................................WW-41

Horn .................................................................WW-59

HORN - Wiring diagram ...................................WW-59

How to erase DTC .............................................EC-27

Page 1758 of 3171

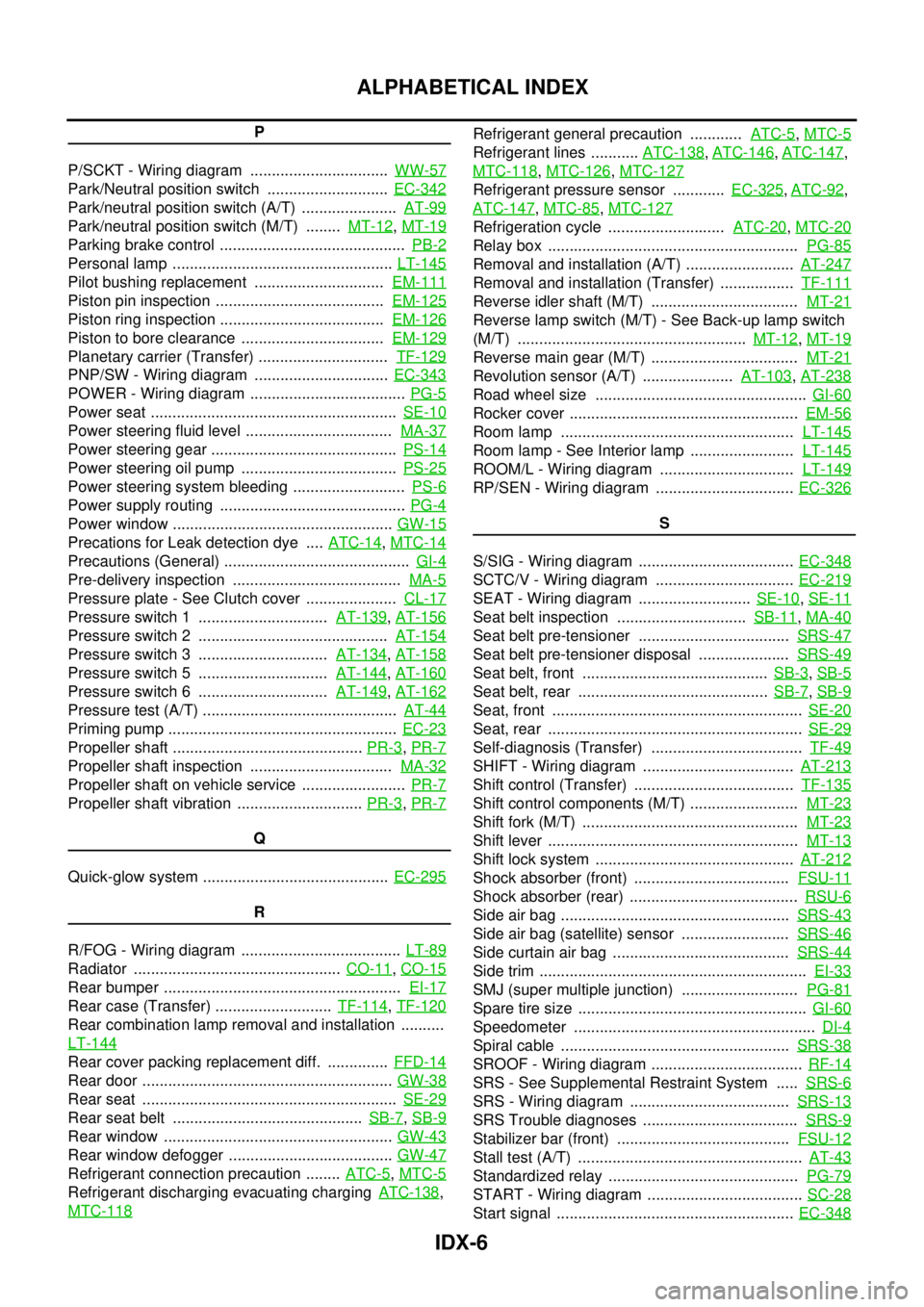

IDX-6

ALPHABETICAL INDEX

P

P/SCKT - Wiring diagram ................................WW-57

Park/Neutral position switch ............................EC-342

Park/neutral position switch (A/T) ......................AT-99

Park/neutral position switch (M/T) ........MT-12,MT-19

Parking brake control ...........................................PB-2

Personal lamp ...................................................LT-145

Pilot bushing replacement ..............................EM-111

Piston pin inspection .......................................EM-125

Piston ring inspection ......................................EM-126

Piston to bore clearance .................................EM-129

Planetary carrier (Transfer) ..............................TF-129

PNP/SW - Wiring diagram ...............................EC-343

POWER - Wiring diagram ....................................PG-5

Power seat .........................................................SE-10

Power steering fluid level ..................................MA-37

Power steering gear ...........................................PS-14

Power steering oil pump ....................................PS-25

Power steering system bleeding ..........................PS-6

Power supply routing ...........................................PG-4

Power window ...................................................GW-15

Precations for Leak detection dye ....ATC-14,MTC-14

Precautions (General) ...........................................GI-4

Pre-delivery inspection .......................................MA-5

Pressure plate - See Clutch cover .....................CL-17

Pressure switch 1 ..............................AT-139,AT-156

Pressure switch 2 ............................................AT-154

Pressure switch 3 ..............................AT-134,AT-158

Pressure switch 5 ..............................AT-144,AT-160

Pressure switch 6 ..............................AT-149,AT-162

Pressure test (A/T) .............................................AT-44

Priming pump .....................................................EC-23

Propeller shaft ............................................PR-3,PR-7

Propeller shaft inspection .................................MA-32

Propeller shaft on vehicle service ........................PR-7

Propeller shaft vibration .............................PR-3,PR-7

Q

Quick-glow system ...........................................EC-295

R

R/FOG - Wiring diagram .....................................LT-89

Radiator ................................................CO-11,CO-15

Rear bumper .......................................................EI-17

Rear case (Transfer) ...........................TF-114,TF-120

Rear combination lamp removal and installation ..........

LT-144

Rear cover packing replacement diff. ..............FFD-14

Rear door ..........................................................GW-38

Rear seat ...........................................................SE-29

Rear seat belt ............................................SB-7,SB-9

Rear window .....................................................GW-43

Rear window defogger ......................................GW-47

Refrigerant connection precaution ........ATC-5,MTC-5

Refrigerant discharging evacuating chargingATC-138,

MTC-118

Refrigerant general precaution ............ATC-5,MTC-5

Refrigerant lines ...........ATC-138,ATC-146,ATC-147,

MTC-118

,MTC-126,MTC-127

Refrigerant pressure sensor ............EC-325,ATC-92,

ATC-147

,MTC-85,MTC-127

Refrigeration cycle ...........................ATC-20,MTC-20

Relay box ..........................................................PG-85

Removal and installation (A/T) .........................AT-247

Removal and installation (Transfer) .................TF-111

Reverse idler shaft (M/T) ..................................MT-21

Reverse lamp switch (M/T) - See Back-up lamp switch

(M/T) .....................................................MT-12

,MT-19

Reverse main gear (M/T) ..................................MT-21

Revolution sensor (A/T) .....................AT-103,AT-238

Road wheel size .................................................GI-60

Rocker cover .....................................................EM-56

Room lamp ......................................................LT-145

Room lamp - See Interior lamp ........................LT-145

ROOM/L - Wiring diagram ...............................LT-149

RP/SEN - Wiring diagram ................................EC-326

S

S/SIG - Wiring diagram ....................................EC-348

SCTC/V - Wiring diagram ................................EC-219

SEAT - Wiring diagram ..........................SE-10,SE-11

Seat belt inspection ..............................SB-11,MA-40

Seat belt pre-tensioner ...................................SRS-47

Seat belt pre-tensioner disposal .....................SRS-49

Seat belt, front ...........................................SB-3,SB-5

Seat belt, rear ............................................SB-7,SB-9

Seat, front ..........................................................SE-20

Seat, rear ...........................................................SE-29

Self-diagnosis (Transfer) ...................................TF-49

SHIFT - Wiring diagram ...................................AT-213

Shift control (Transfer) .....................................TF-135

Shift control components (M/T) .........................MT-23

Shift fork (M/T) ..................................................MT-23

Shift lever ..........................................................MT-13

Shift lock system ..............................................AT-212

Shock absorber (front) ....................................FSU-11

Shock absorber (rear) .......................................RSU-6

Side air bag .....................................................SRS-43

Side air bag (satellite) sensor .........................SRS-46

Side curtain air bag .........................................SRS-44

Side trim ..............................................................EI-33

SMJ (super multiple junction) ...........................PG-81

Spare tire size .....................................................GI-60

Speedometer ........................................................DI-4

Spiral cable .....................................................SRS-38

SROOF - Wiring diagram ...................................RF-14

SRS - See Supplemental Restraint System .....SRS-6

SRS - Wiring diagram .....................................SRS-13

SRS Trouble diagnoses ....................................SRS-9

Stabilizer bar (front) ........................................FSU-12

Stall test (A/T) ....................................................AT-43

Standardized relay ............................................PG-79

START - Wiring diagram ....................................SC-28

Start signal .......................................................EC-348

Page 1760 of 3171

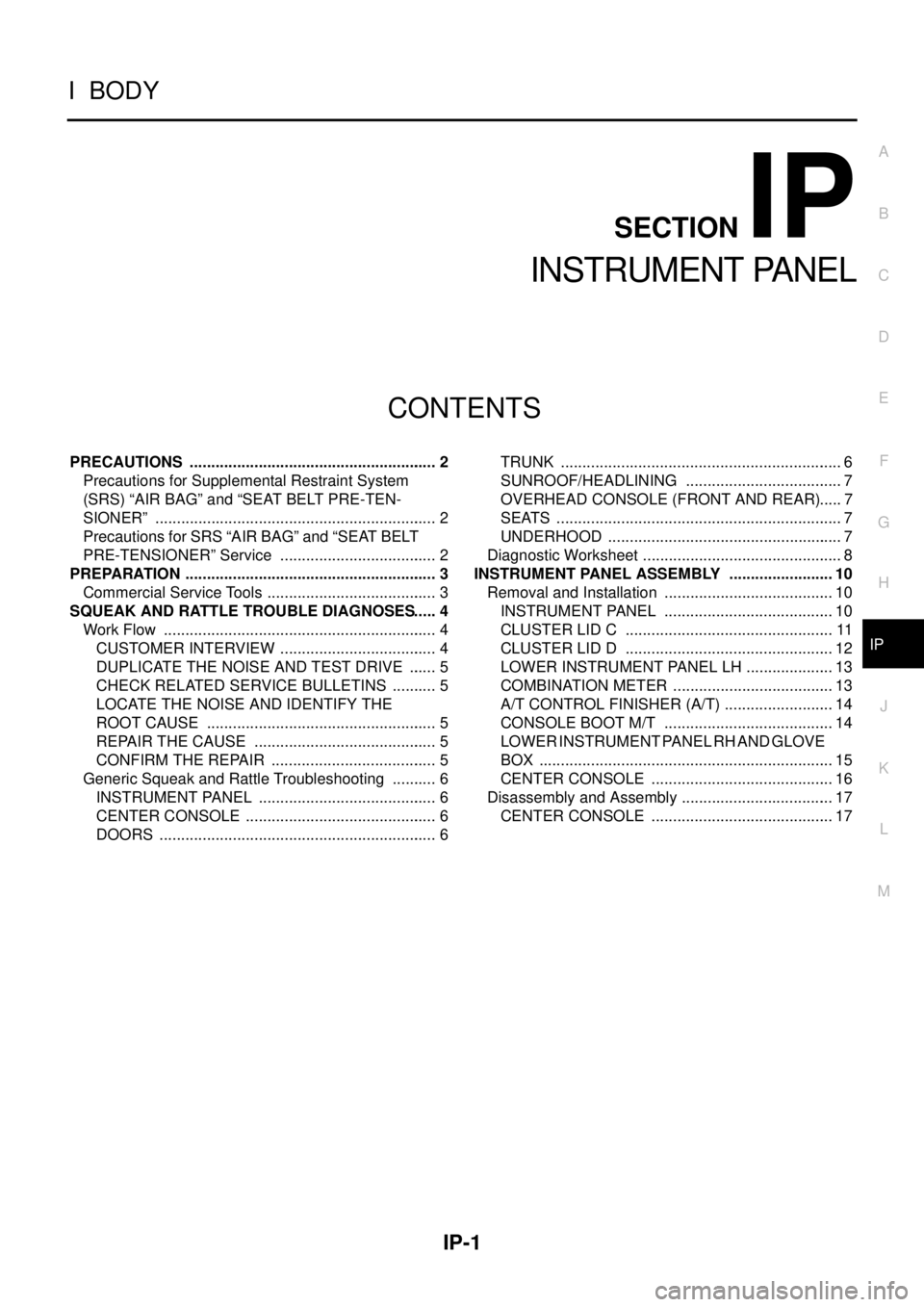

IP-1

INSTRUMENT PANEL

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONIP

A

B

IP

INSTRUMENT PANEL

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 2

PREPARATION ........................................................... 3

Commercial Service Tools ........................................ 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 5

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6TRUNK .................................................................. 6

SUNROOF/HEADLINING ..................................... 7

OVERHEAD CONSOLE (FRONT AND REAR)..... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet ............................................... 8

INSTRUMENT PANEL ASSEMBLY ......................... 10

Removal and Installation ........................................ 10

INSTRUMENT PANEL ........................................ 10

CLUSTER LID C ................................................. 11

CLUSTER LID D ................................................. 12

LOWER INSTRUMENT PANEL LH ..................... 13

COMBINATION METER ...................................... 13

A/T CONTROL FINISHER (A/T) .......................... 14

CONSOLE BOOT M/T ........................................ 14

LOWER INSTRUMENT PANEL RH AND GLOVE

BOX ..................................................................... 15

CENTER CONSOLE ........................................... 16

Disassembly and Assembly .................................... 17

CENTER CONSOLE ........................................... 17

Page 1761 of 3171

IP-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ8

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ4

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.