service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2275 of 3171

LU-18

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2276 of 3171

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTIONMA

A

B

MA

MAINTENANCE

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

DESCRIPTION ............................................................ 5

Pre-Delivery Inspection Items .................................. 5

GENERAL MAINTENANCE ....................................... 7

General Maintenance ............................................... 7

PERIODIC MAINTENANCE ....................................... 8

Periodic Maintenance ............................................... 8

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD25DDTI DIESEL ENGINE) ................ 8

CHASSIS AND BODY MAINTENANCE

(YD25DDTI DIESEL ENGINE) .............................. 9

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 10

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD25DDTI DIESEL ENGINE) ............... 11

CHASSIS AND BODY MAINTENANCE

(YD25DDTI DIESEL ENGINE) ............................. 11

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 13

RECOMMENDED FLUIDS AND LUBRICANTS ...... 14

Fluids and Lubricants ............................................. 14

SAE Viscosity Number ........................................... 15

DIESEL ENGINE ................................................. 15

GEAR OIL ........................................................... 15

Engine Coolant Mixture Ratio ................................ 16

ENGINE MAINTENANCE ......................................... 17

Checking Drive Belts .............................................. 17

Deflection Adjustment ............................................ 18

POWER STEERING OIL PUMP BELT ............... 18

A/C COMPRESSOR, ALTERNATOR AND

WATER PUMP BELT .......................................... 19

Changing Engine Coolant ...................................... 19

DRAINING ENGINE COOLANT ......................... 19

REFILLING ENGINE COOLANT ........................ 20FLUSHING COOLING SYSTEM ......................... 21

Checking Cooling System ...................................... 21

CHECKING COOLING SYSTEM HOSES ........... 21

CHECKING RADIATOR ...................................... 21

CHECKING RESERVOIR TANK CAP ................. 21

CHECKING RADIATOR SYSTEM FOR LEAKS... 22

Checking Fuel Lines ............................................... 23

Changing Fuel Filter ............................................... 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 24

Draining Water from Fuel Filter .............................. 25

Changing Engine Air Cleaner Filter ........................ 25

DRY PAPER TYPE .............................................. 25

Changing Engine Oil ............................................... 25

Changing Oil Filter .................................................. 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 27

CHASSIS AND BODY MAINTENANCE ................... 28

Checking the Exhaust System ................................ 28

Checking Clutch Fluid Level and Leaks ................. 28

Checking Clutch System ........................................ 28

Checking M/T Oil .................................................... 28

Changing M/T Oil .................................................... 29

Checking A/T Fluid ................................................. 29

Changing A/T Fluid ................................................. 31

Checking Transfer Fluid ......................................... 31

FLUID LEAKAGE AND FLUID LEVEL ................ 31

Changing Transfer Fluid ......................................... 32

DRAINING ........................................................... 32

FILLING ............................................................... 32

Checking Propeller Shaft ........................................ 32

Checking Front Final Drive Oil (Front Differential

Gear Oil) ................................................................. 32

OIL LEAKAGE AND OIL LEVEL ......................... 32

Changing Front Final Drive Oil (Front Differential

Gear Oil) ................................................................. 33

DRAINING ........................................................... 33

FILLING ............................................................... 33

Page 2277 of 3171

MA-2

Checking Rear Final Drive Oil (Rear Differential

Gear Oil) ................................................................. 33

OIL LEAKAGE AND OIL LEVEL ......................... 33

Changing Rear Final Drive Oil (Rear Differential

Gear Oil) ................................................................. 34

DRAINING ........................................................... 34

FILLING ............................................................... 34

Balancing Wheels ................................................... 34

Tire Rotation ........................................................... 34

Checking Brake Fluid Level and Leaks .................. 35

Checking Brake Lines and Cables ......................... 35

Changing Brake Fluid ............................................. 35

Checking Disc Brake .............................................. 35

ROTOR ................................................................ 35

CALIPER ............................................................. 36

PAD ..................................................................... 36

Checking Drum Brake ............................................ 36

DRUM .................................................................. 36

WHEEL CYLINDER ............................................. 36

LINING ................................................................. 37

Checking Steering Gear and Linkage ..................... 37

STEERING GEAR ............................................... 37

STEERING LINKAGE .......................................... 37

Checking Power Steering Fluid and Lines .............. 37CHECKING FLUID LEVEL .................................. 37

CHECKING LINES ............................................... 37

Checking Axle and Suspension Parts ..................... 38

FRONT AND REAR AXLE AND SUSPENSION

PARTS ................................................................. 38

FRONT DRIVE SHAFT ........................................ 38

Lubricating Locks, Hinges and Hood Latches ......... 39

Checking Seat Belts, Buckles, Retractors, Anchors

and Adjusters .......................................................... 40

Checking Body Corrosion ....................................... 40

HEMMED PANELS .............................................. 40

PANEL JOINT ...................................................... 40

PANEL EDGE ...................................................... 40

PARTS CONTACT ............................................... 40

PROTECTORS .................................................... 40

ANTI-CORROSION MATERIALS ........................ 40

DRAIN HOLES ..................................................... 40

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 41

Standard and Limit .................................................. 41

BELT DEFLECTION ............................................ 41

RESERVOIR TANK ............................................. 41

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 41

ENGINE OIL CAPACITY (APPROXIMATE) ........ 41

Page 2278 of 3171

PRECAUTIONS

MA-3

C

D

E

F

G

H

I

J

K

MA

B

MA

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

ELS001HP

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Page 2279 of 3171

MA-4

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsELS001HQ

Commercial Service ToolsELS001HR

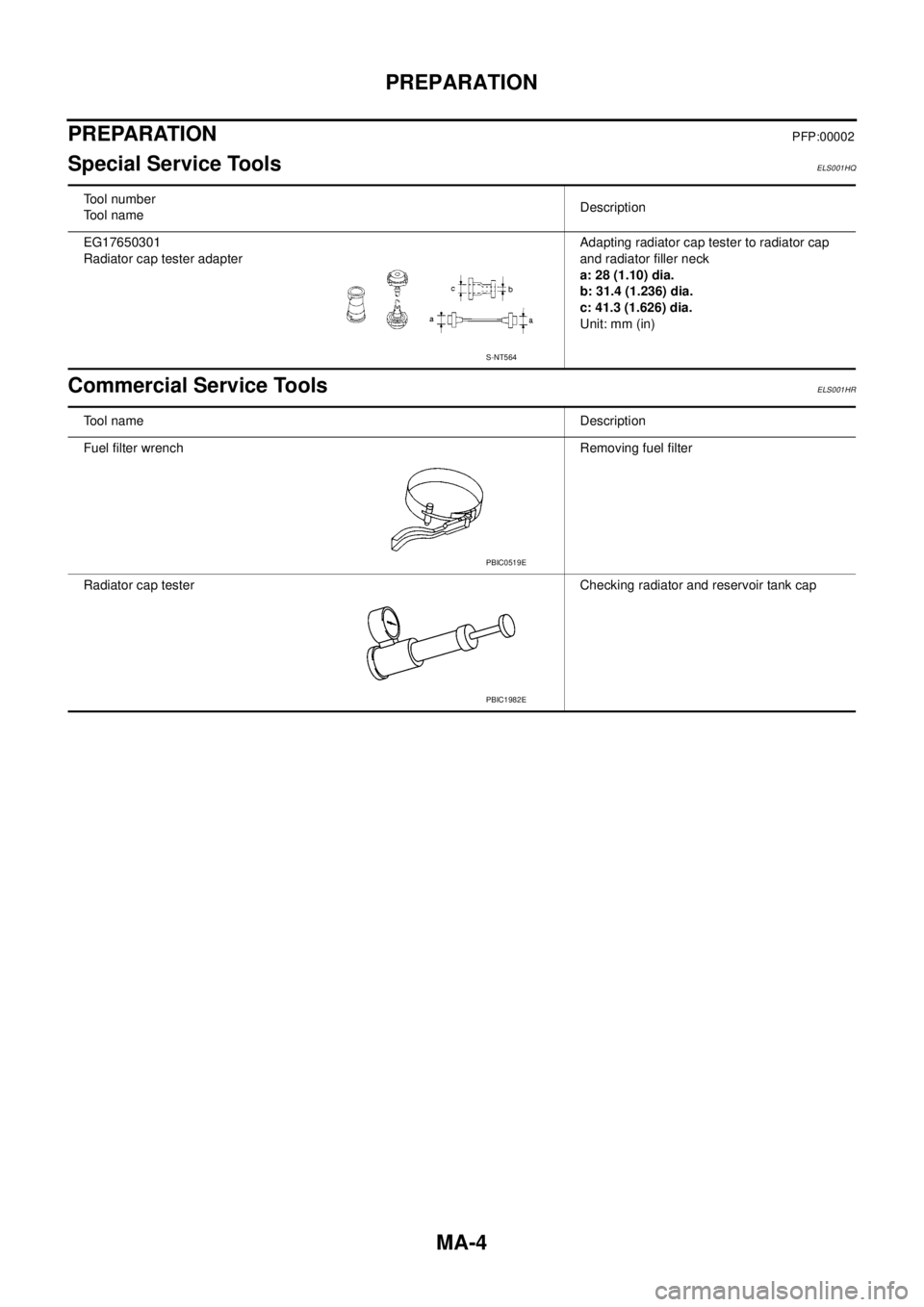

Tool number

Tool nameDescription

EG17650301

Radiator cap tester adapterAdapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT564

Tool nameDescription

Fuel filter wrench Removing fuel filter

Radiator cap tester Checking radiator and reservoir tank cap

PBIC0519E

PBIC1982E

Page 2282 of 3171

GENERAL MAINTENANCE

MA-7

C

D

E

F

G

H

I

J

K

MA

B

MA

GENERAL MAINTENANCEPFP:00000

General MaintenanceELS001HT

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station, includ-

ing the spare, and adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate prop-

erly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch keeps the hood from opening when the primary latch is

released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.MA-39

,BL-12

Tire rotationTires should be rotated every 10,000 km (6,000 miles) for 2WD models and

every 5,000 km (3,000 miles) for 4WD models.MA-34

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.MA-40

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.MA-19

(YD25DDTi)

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.MA-25

(YD25DDTi)

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.MA-28

,MA-35

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

Page 2297 of 3171

MA-22

ENGINE MAINTENANCE

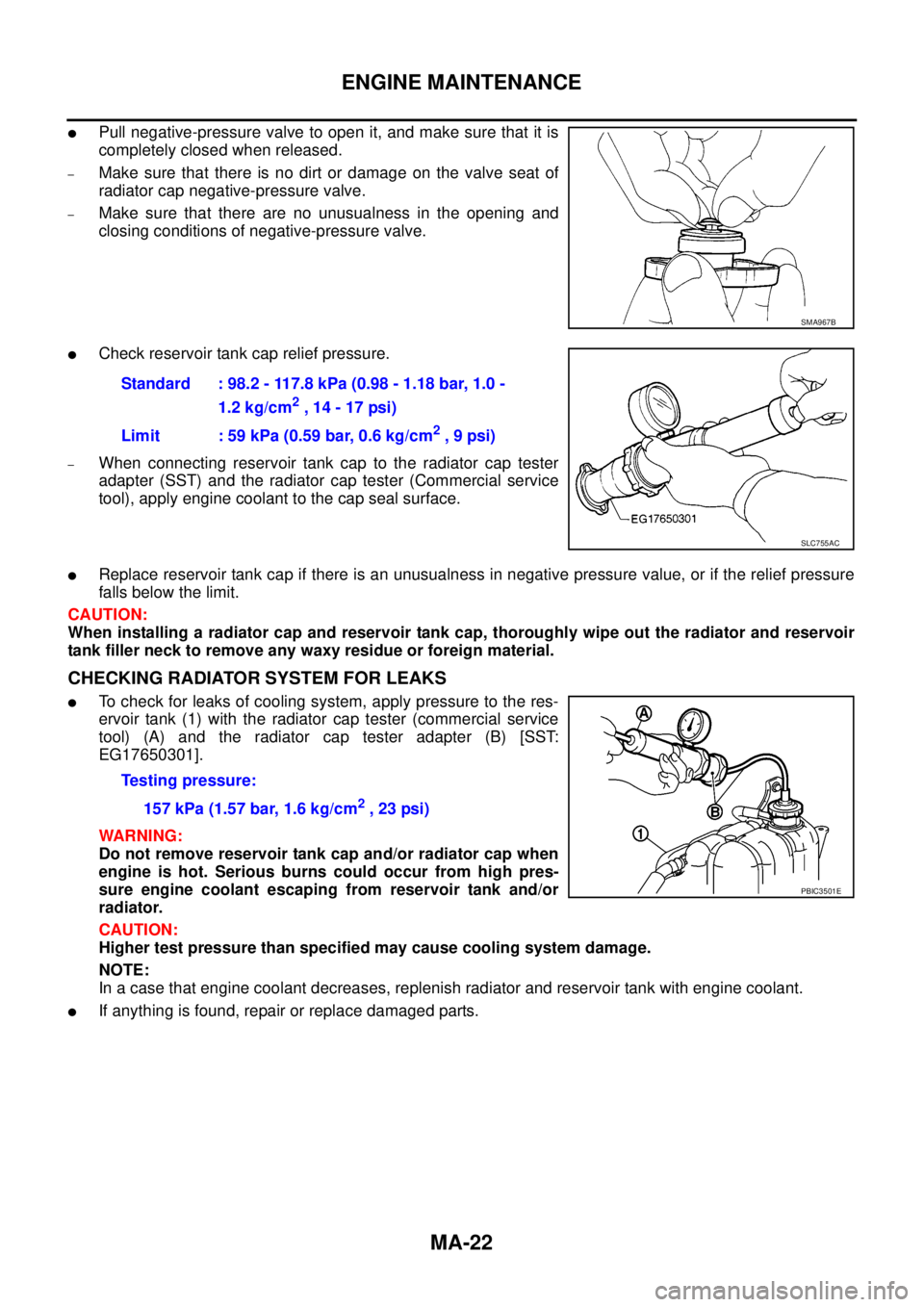

lPull negative-pressure valve to open it, and make sure that it is

completely closed when released.

–Makesurethatthereisnodirtordamageonthevalveseatof

radiator cap negative-pressure valve.

–Make sure that there are no unusualness in the opening and

closing conditions of negative-pressure valve.

lCheck reservoir tank cap relief pressure.

–When connecting reservoir tank cap to the radiator cap tester

adapter (SST) and the radiator cap tester (Commercial service

tool), apply engine coolant to the cap seal surface.

lReplace reservoir tank cap if there is an unusualness in negative pressure value, or if the relief pressure

falls below the limit.

CAUTION:

When installing a radiator cap and reservoir tank cap, thoroughly wipe out the radiator and reservoir

tank filler neck to remove any waxy residue or foreign material.

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

SMA967B

Standard : 98.2 - 117.8 kPa (0.98 - 1.18 bar, 1.0 -

1.2 kg/cm

2,14-17psi)

Limit : 59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 2299 of 3171

MA-24

ENGINE MAINTENANCE

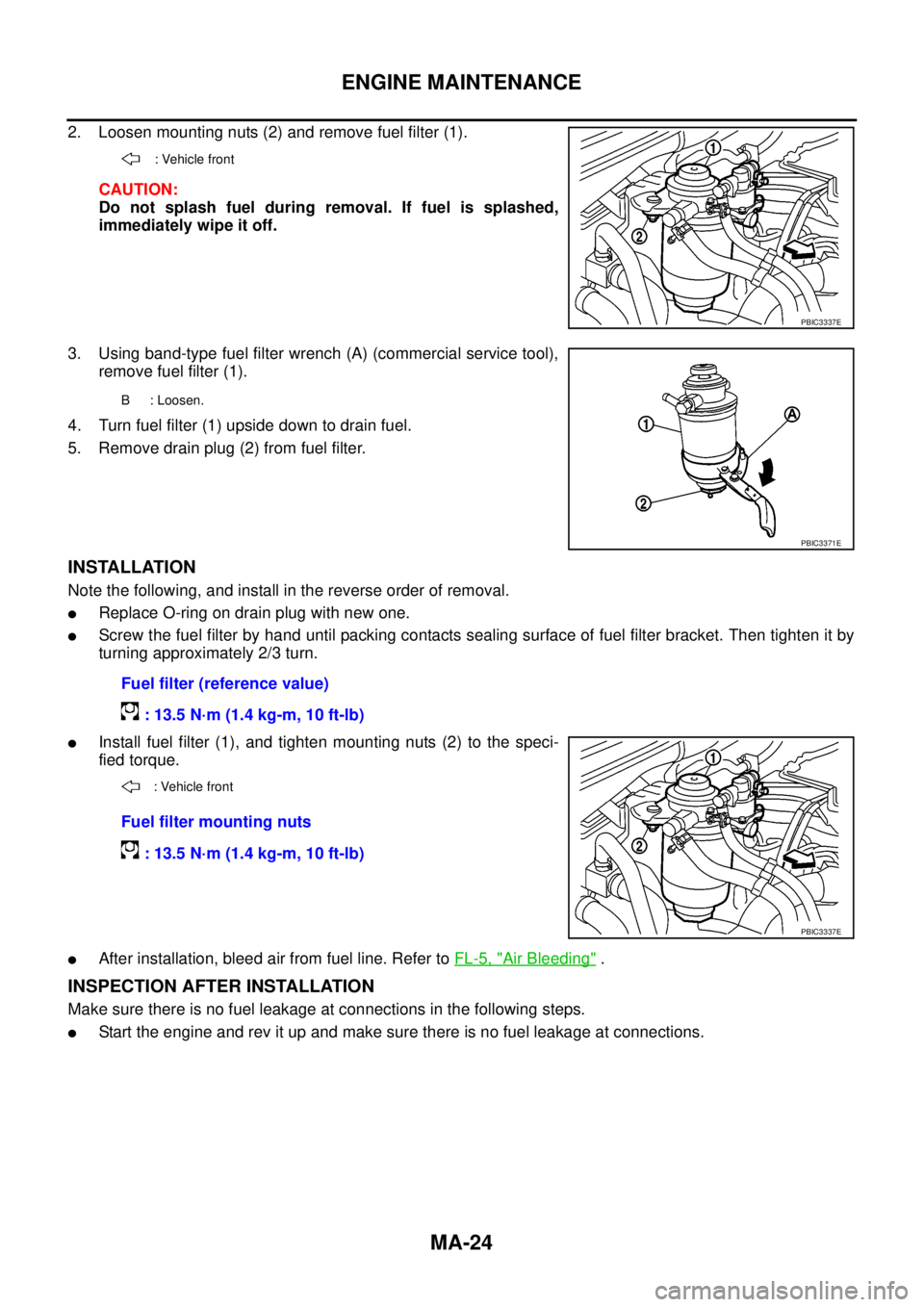

2. Loosen mounting nuts (2) and remove fuel filter (1).

CAUTION:

Do not splash fuel during removal. If fuel is splashed,

immediately wipe it off.

3. Using band-type fuel filter wrench (A) (commercial service tool),

remove fuel filter (1).

4. Turn fuel filter (1) upside down to drain fuel.

5. Remove drain plug (2) from fuel filter.

INSTALLATION

Note the following, and install in the reverse order of removal.

lReplace O-ring on drain plug with new one.

lScrew the fuel filter by hand until packing contacts sealing surface of fuel filter bracket. Then tighten it by

turning approximately 2/3 turn.

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

lAfter installation, bleed air from fuel line. Refer toFL-5, "Air Bleeding".

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

lStart the engine and rev it up and make sure there is no fuel leakage at connections.

: Vehicle front

PBIC3337E

B : Loosen.

PBIC3371E

Fuel filter (reference value)

: 13.5 N·m (1.4 kg-m, 10 ft-lb)

: Vehicle front

Fuel filter mounting nuts

: 13.5 N·m (1.4 kg-m, 10 ft-lb)

PBIC3337E

Page 2309 of 3171

MA-34

CHASSIS AND BODY MAINTENANCE

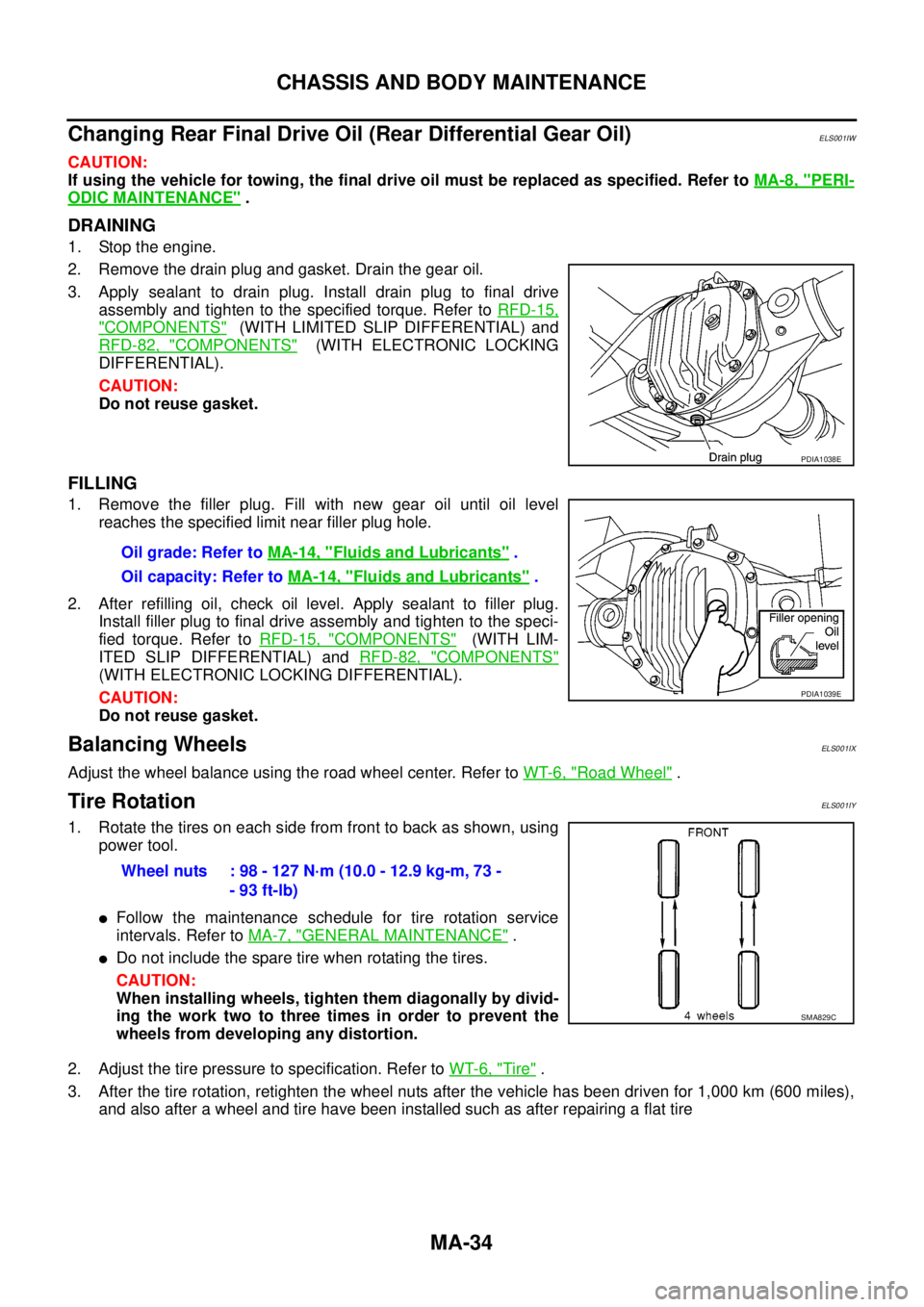

Changing Rear Final Drive Oil (Rear Differential Gear Oil)

ELS001IW

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS"(WITH LIMITED SLIP DIFFERENTIAL) and

RFD-82, "

COMPONENTS"(WITH ELECTRONIC LOCKING

DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug. Fill with new gear oil until oil level

reaches the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS"(WITH LIM-

ITED SLIP DIFFERENTIAL) andRFD-82, "

COMPONENTS"

(WITH ELECTRONIC LOCKING DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

Balancing WheelsELS001IX

Adjust the wheel balance using the road wheel center. Refer toWT-6, "Road Wheel".

Tire RotationELS001IY

1. Rotate the tires on each side from front to back as shown, using

power tool.

lFollow the maintenance schedule for tire rotation service

intervals. Refer toMA-7, "

GENERAL MAINTENANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

2. Adjust the tire pressure to specification. Refer toWT-6, "

Tire".

3. After the tire rotation, retighten the wheel nuts after the vehicle has been driven for 1,000 km (600 miles),

and also after a wheel and tire have been installed such as after repairing a flat tire

PDIA1038E

Oil grade: Refer toMA-14, "Fluids and Lubricants".

Oil capacity: Refer toMA-14, "

Fluids and Lubricants".

PDIA1039E

Wheel nuts : 98 - 127 N·m (10.0 - 12.9 kg-m, 73 -

- 93 ft-lb)

SMA829C

Page 2316 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

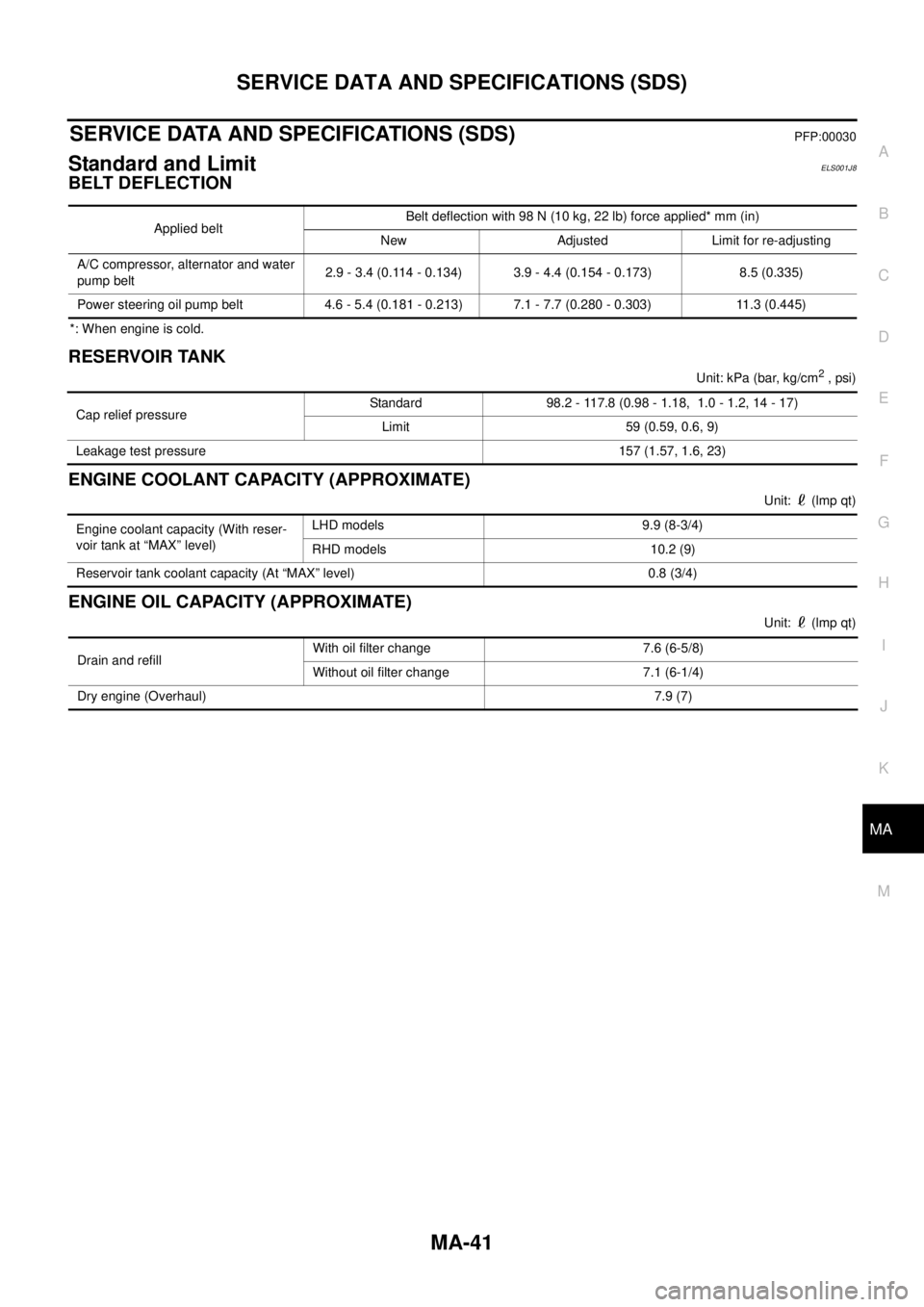

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitELS001J8

BELT DEFLECTION

*: When engine is cold.

RESERVOIR TANK

Unit:kPa(bar,kg/cm2, psi)

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (lmp qt)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (lmp qt) Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

A/C compressor, alternator and water

pump belt2.9 - 3.4 (0.114 - 0.134) 3.9 - 4.4 (0.154 - 0.173) 8.5 (0.335)

Power steering oil pump belt 4.6 - 5.4 (0.181 - 0.213) 7.1 - 7.7 (0.280 - 0.303) 11.3 (0.445)

Cap relief pressureStandard 98.2 - 117.8 (0.98 - 1.18, 1.0 - 1.2, 14 - 17)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Engine coolant capacity (With reser-

voir tank at “MAX” level)LHD models 9.9 (8-3/4)

RHD models 10.2 (9)

Reservoir tank coolant capacity (At “MAX” level) 0.8 (3/4)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)