service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2317 of 3171

MA-42

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2318 of 3171

MT-1

MANUAL TRANSMISSION

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTIONMT

A

B

MT

MANUAL TRANSMISSION

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Sectional View ............................................... 7

DOUBLE-CONE SYNCHRONIZER ...................... 8

TRIPLE-CONE SYNCHRONIZER ........................ 8

M/T OIL ....................................................................... 9

Changing M/T Oil ..................................................... 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking M/T Oil ...................................................... 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

REAR OIL SEAL ...................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

POSITION SWITCH .................................................. 12

Checking ................................................................ 12

BACK-UP LAMP SWITCH .................................. 12

PARK/NEUTRAL POSITION (PNP) SWITCH ..... 12SHIFT CONTROL ..................................................... 13

Removal and Installation ........................................ 13

COMPONENTS ................................................... 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

INSPECTION AFTER INSTALLATION ................ 14

AIR BREATHER HOSE ............................................ 15

Removal and Installation ........................................ 15

TRANSMISSION ASSEMBLY .................................. 16

Removal and Installation from Vehicle ................... 16

COMPONENTS ................................................... 16

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18

Disassembly and Assembly .................................... 19

COMPONENTS ................................................... 19

DISASSEMBLY ................................................... 25

INSPECTION AFTER DISASSEMBLY ................ 40

ASSEMBLY ......................................................... 44

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 67

General Specifications ............................................ 67

Gear End Play ........................................................ 68

Snap Rings ............................................................. 68

Baulk Ring Clearance ............................................. 69

Page 2319 of 3171

MT-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

ServiceNoticeorPrecautionsECS00ICY

lDo not reuse transmission oil, once it has been drained.

lCheck oil level or replace oil with vehicle on level surface.

lDuring removal or installation, keep inside of transmission clear of dust or dirt.

lCheck for the correct installation status prior to removal or disassembly. If matching mark are required, be

certain they do not interfere with the function of the parts they are applied.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

lBe careful not to damage sliding surfaces and mating surfaces.

Page 2320 of 3171

PREPARATION

MT-3

D

E

F

G

H

I

J

K

L

MA

B

MT

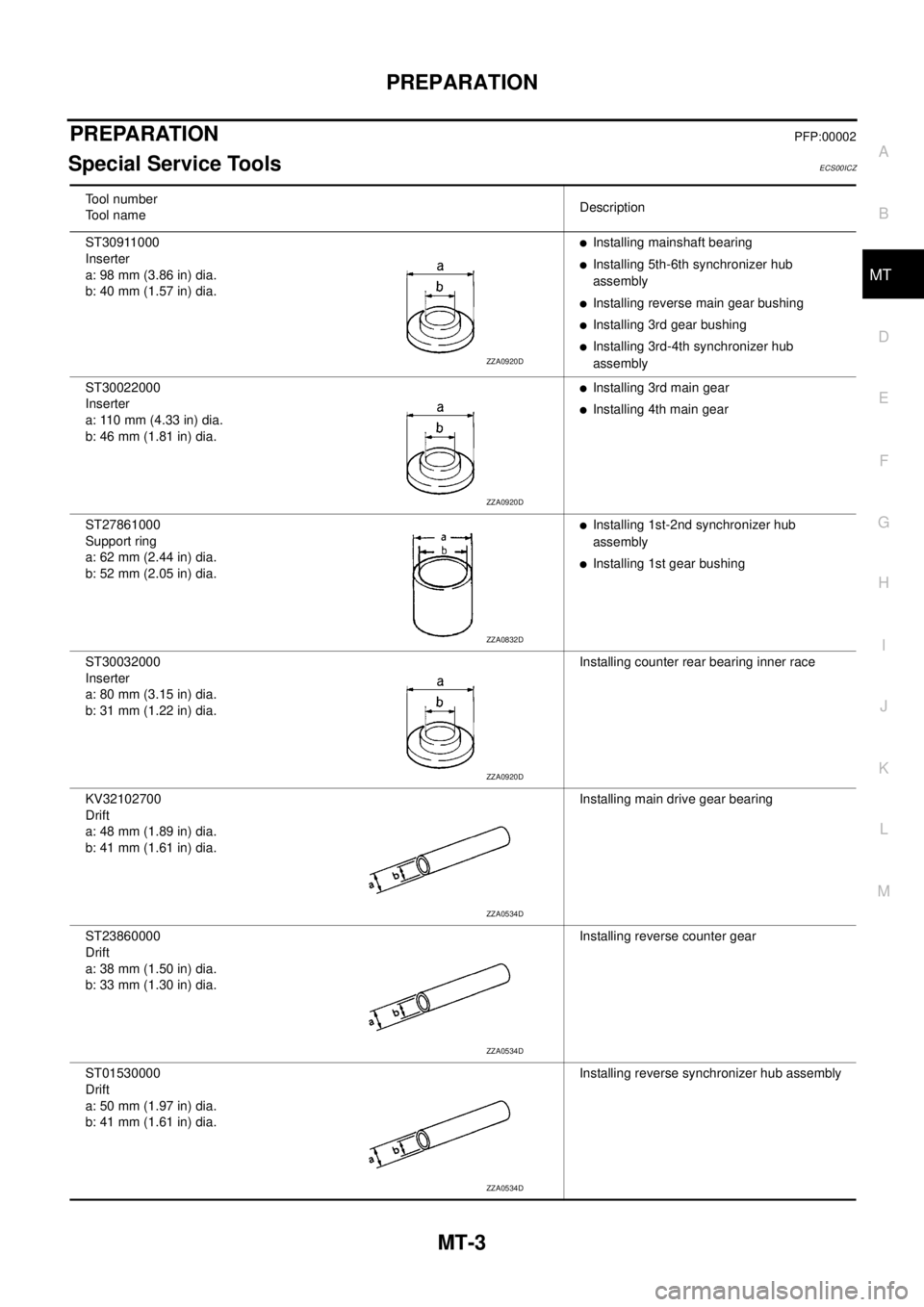

PREPARATIONPFP:00002

Special Service ToolsECS00ICZ

Tool number

Tool nameDescription

ST30911000

Inserter

a: 98 mm (3.86 in) dia.

b: 40 mm (1.57 in) dia.

lInstalling mainshaft bearing

lInstalling 5th-6th synchronizer hub

assembly

lInstalling reverse main gear bushing

lInstalling 3rd gear bushing

lInstalling 3rd-4th synchronizer hub

assembly

ST30022000

Inserter

a: 110 mm (4.33 in) dia.

b: 46 mm (1.81 in) dia.

lInstalling 3rd main gear

lInstalling 4th main gear

ST27861000

Support ring

a: 62 mm (2.44 in) dia.

b: 52 mm (2.05 in) dia.

lInstalling 1st-2nd synchronizer hub

assembly

lInstalling 1st gear bushing

ST30032000

Inserter

a: 80 mm (3.15 in) dia.

b: 31 mm (1.22 in) dia.Installing counter rear bearing inner race

KV32102700

Drift

a: 48 mm (1.89 in) dia.

b: 41 mm (1.61 in) dia.Installing main drive gear bearing

ST23860000

Drift

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.Installing reverse counter gear

ST01530000

Drift

a: 50 mm (1.97 in) dia.

b: 41 mm (1.61 in) dia.Installing reverse synchronizer hub assembly

ZZA0920D

ZZA0920D

ZZA0832D

ZZA0920D

ZZA0534D

ZZA0534D

ZZA0534D

Page 2322 of 3171

PREPARATION

MT-5

D

E

F

G

H

I

J

K

L

MA

B

MT

Commercial Service ToolsECS00ID0

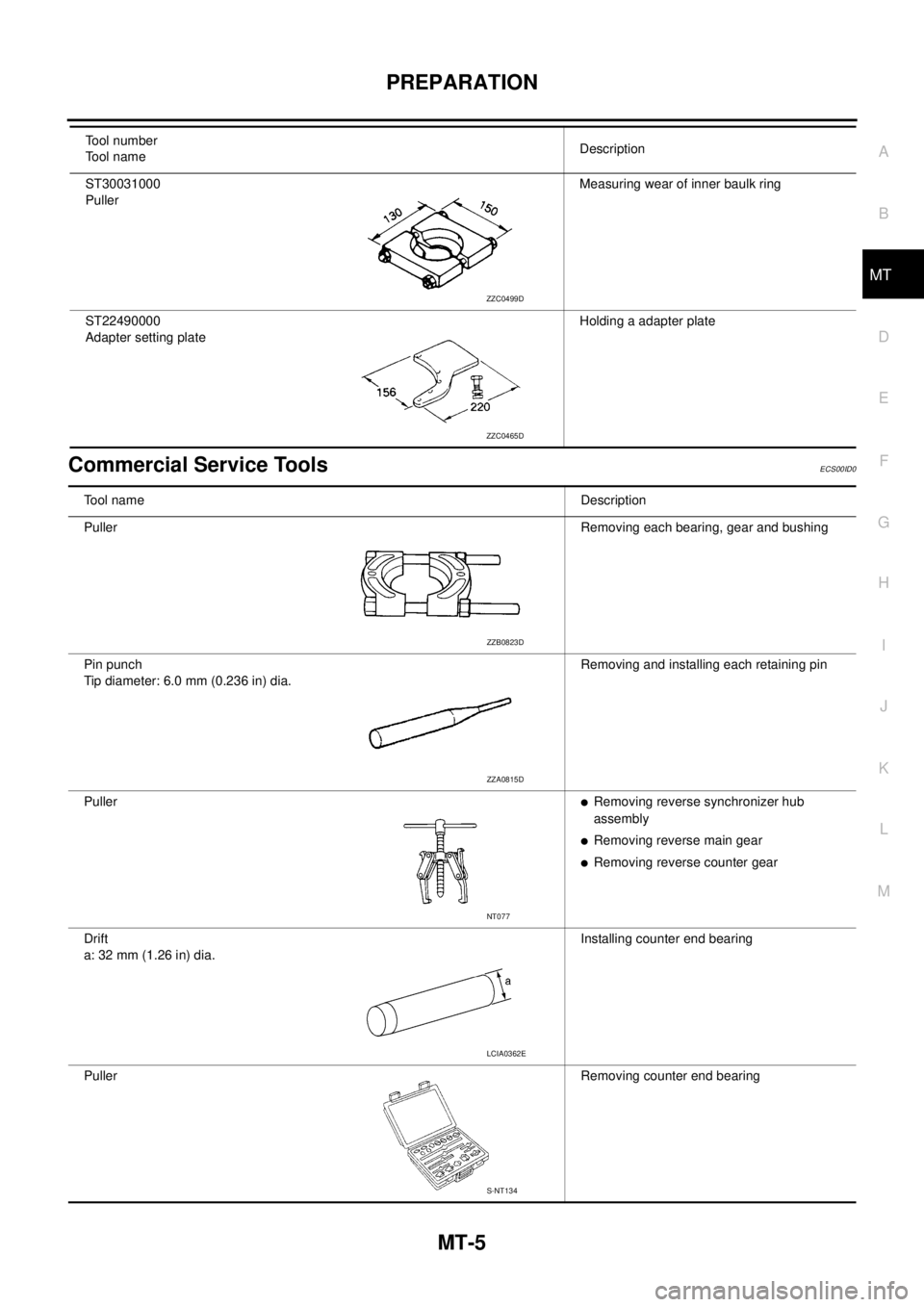

ST30031000

PullerMeasuring wear of inner baulk ring

ST22490000

Adapter setting plateHolding a adapter plate Tool number

Tool nameDescription

ZZC0499D

ZZC0465D

Tool nameDescription

PullerRemoving each bearing, gear and bushing

Pin punch

Tipdiameter:6.0mm(0.236in)dia.Removing and installing each retaining pin

Puller

lRemoving reverse synchronizer hub

assembly

lRemoving reverse main gear

lRemoving reverse counter gear

Drift

a: 32 mm (1.26 in) dia.Installing counter end bearing

PullerRemoving counter end bearing

ZZB0823D

ZZA0815D

NT077

LCIA0362E

S-NT134

Page 2384 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-67

D

E

F

G

H

I

J

K

L

MA

B

MT

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

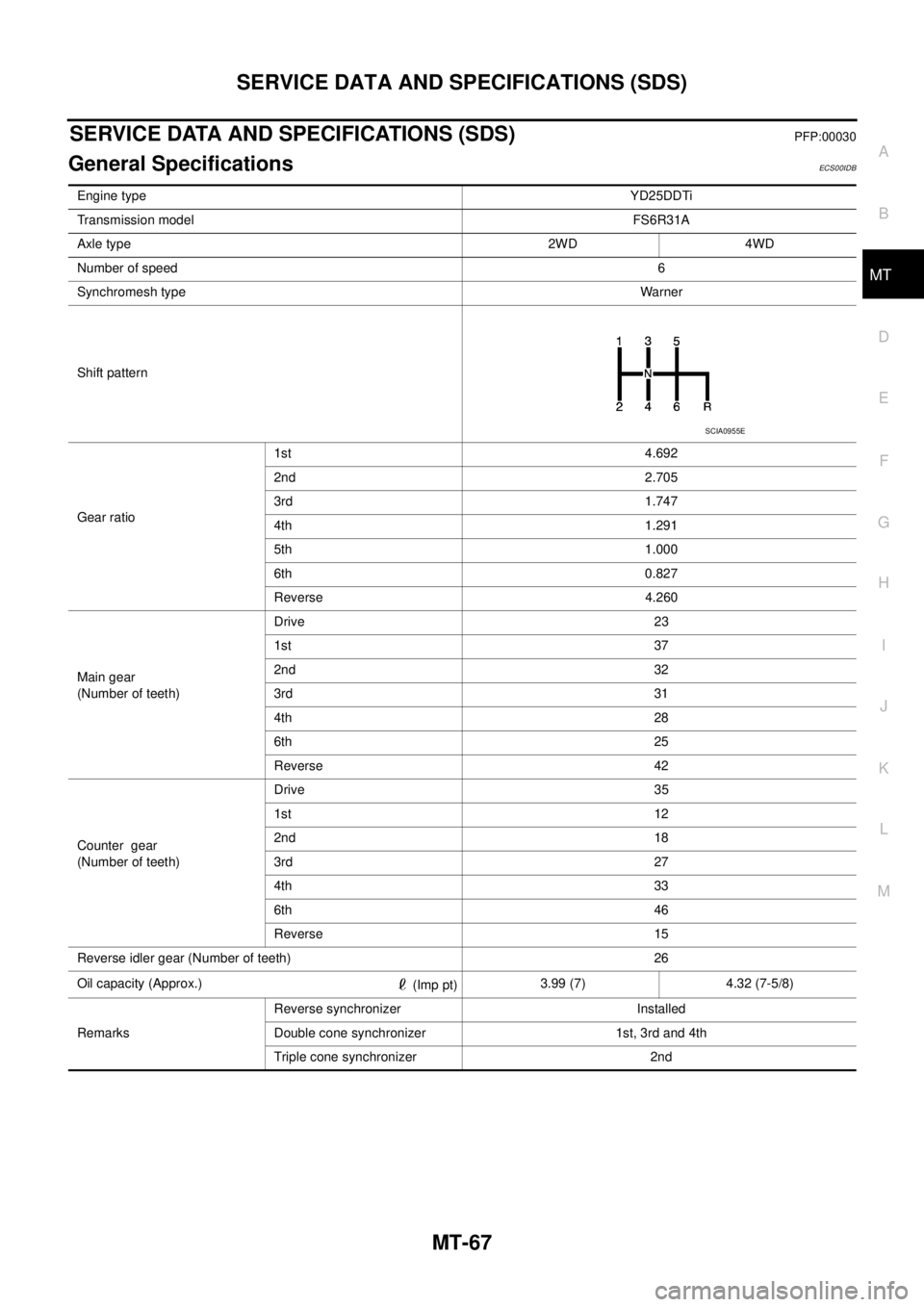

General SpecificationsECS00IDB

Engine typeYD25DDTi

Transmission modelFS6R31A

Axle type 2WD 4WD

Number of speed6

Synchromesh typeWarner

Shift pattern

Gear ratio1st 4.692

2nd 2.705

3rd 1.747

4th 1.291

5th 1.000

6th 0.827

Reverse 4.260

Main gear

(Number of teeth)Drive 23

1st 37

2nd 32

3rd 31

4th 28

6th 25

Reverse 42

Counter gear

(Number of teeth)Drive 35

1st 12

2nd 18

3rd 27

4th 33

6th 46

Reverse 15

Reverse idler gear (Number of teeth) 26

Oil capacity (Approx.)

(Imp pt)3.99 (7) 4.32 (7-5/8)

RemarksReverse synchronizer Installed

Double cone synchronizer 1st, 3rd and 4th

Triple cone synchronizer 2nd

SCIA0955E

Page 2385 of 3171

MT-68

SERVICE DATA AND SPECIFICATIONS (SDS)

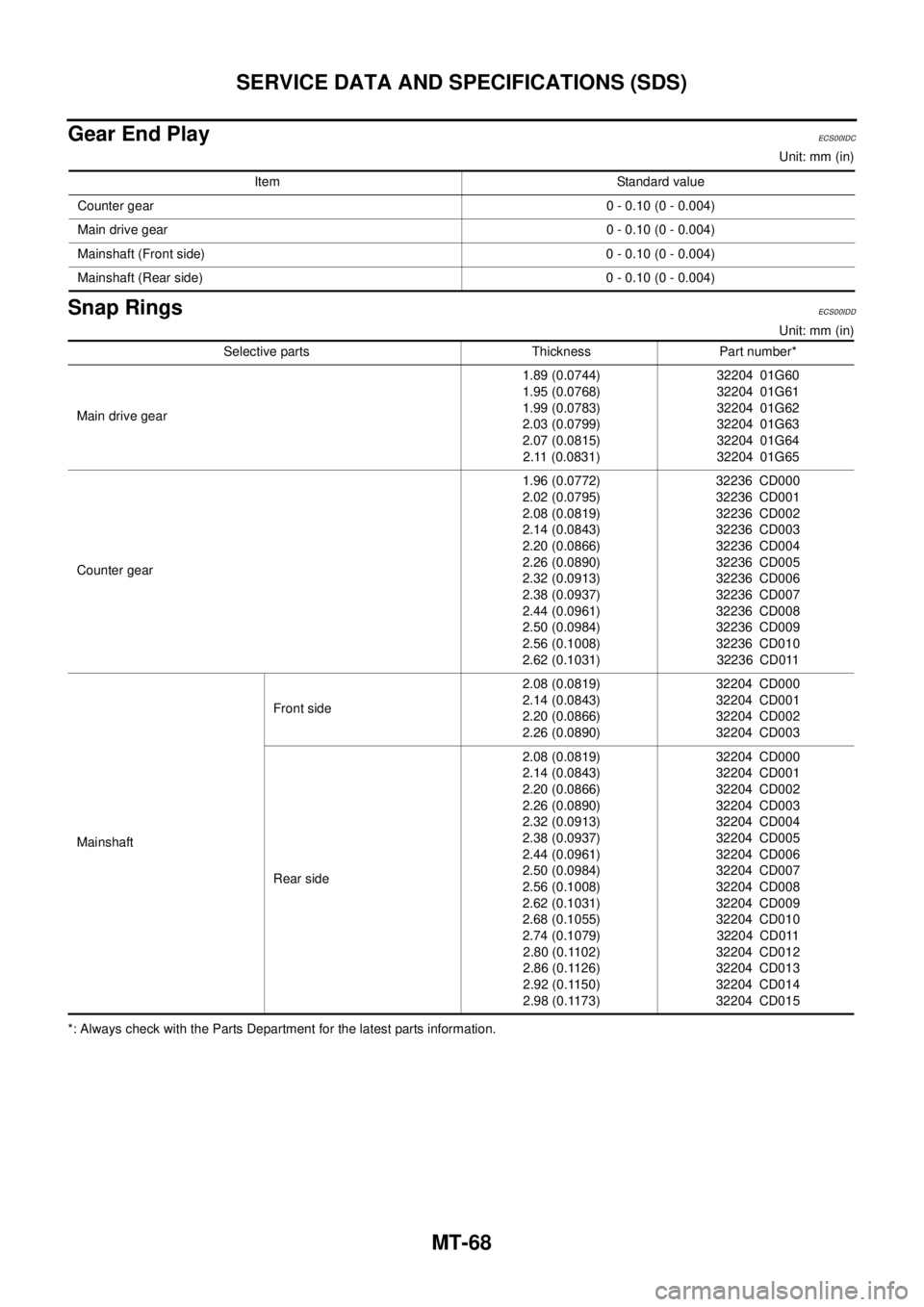

Gear End Play

ECS00IDC

Unit: mm (in)

Snap RingsECS00IDD

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.Item Standard value

Counter gear0 - 0.10 (0 - 0.004)

Main drive gear0 - 0.10 (0 - 0.004)

Mainshaft (Front side) 0 - 0.10 (0 - 0.004)

Mainshaft (Rear side) 0 - 0.10 (0 - 0.004)

Selective parts Thickness Part number*

Main drive gear1.89 (0.0744)

1.95 (0.0768)

1.99 (0.0783)

2.03 (0.0799)

2.07 (0.0815)

2.11 (0.0831)32204 01G60

32204 01G61

32204 01G62

32204 01G63

32204 01G64

32204 01G65

Counter gear1.96 (0.0772)

2.02 (0.0795)

2.08 (0.0819)

2.14 (0.0843)

2.20 (0.0866)

2.26 (0.0890)

2.32 (0.0913)

2.38 (0.0937)

2.44 (0.0961)

2.50 (0.0984)

2.56 (0.1008)

2.62 (0.1031)32236 CD000

32236 CD001

32236 CD002

32236 CD003

32236 CD004

32236 CD005

32236 CD006

32236 CD007

32236 CD008

32236 CD009

32236 CD010

32236 CD011

MainshaftFront side2.08 (0.0819)

2.14 (0.0843)

2.20 (0.0866)

2.26 (0.0890)32204 CD000

32204 CD001

32204 CD002

32204 CD003

Rear side2.08 (0.0819)

2.14 (0.0843)

2.20 (0.0866)

2.26 (0.0890)

2.32 (0.0913)

2.38 (0.0937)

2.44 (0.0961)

2.50 (0.0984)

2.56 (0.1008)

2.62 (0.1031)

2.68 (0.1055)

2.74 (0.1079)

2.80 (0.1102)

2.86 (0.1126)

2.92 (0.1150)

2.98 (0.1173)32204 CD000

32204 CD001

32204 CD002

32204 CD003

32204 CD004

32204 CD005

32204 CD006

32204 CD007

32204 CD008

32204 CD009

32204 CD010

32204 CD011

32204 CD012

32204 CD013

32204 CD014

32204 CD015

Page 2386 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-69

D

E

F

G

H

I

J

K

L

MA

B

MT

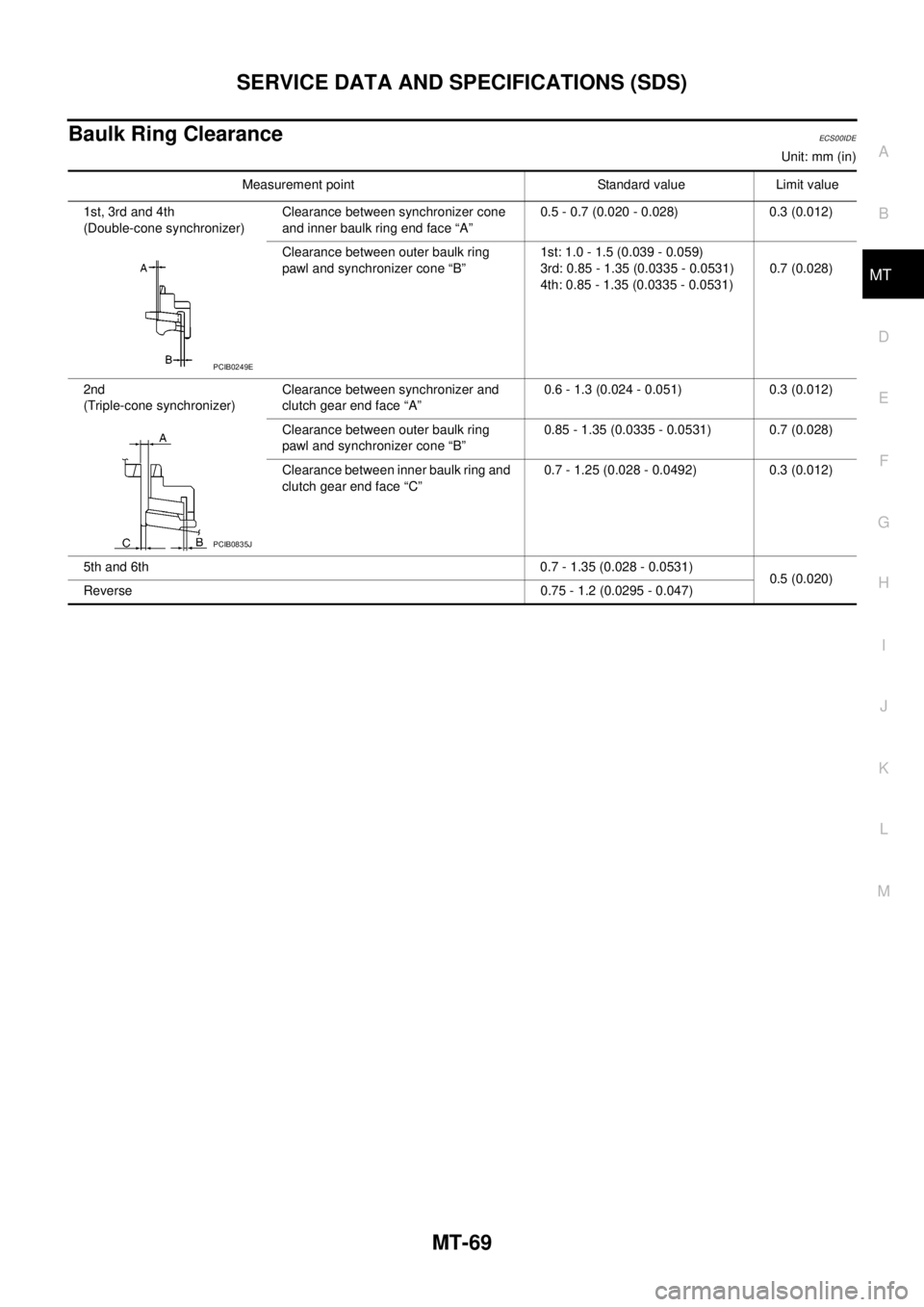

Baulk Ring ClearanceECS00IDE

Unit: mm (in)

Measurement point Standard value Limit value

1st, 3rd and 4th

(Double-cone synchronizer)Clearance between synchronizer cone

and inner baulk ring end face “A”0.5 - 0.7 (0.020 - 0.028) 0.3 (0.012)

Clearance between outer baulk ring

pawl and synchronizer cone “B”1st: 1.0 - 1.5 (0.039 - 0.059)

3rd: 0.85 - 1.35 (0.0335 - 0.0531)

4th: 0.85 - 1.35 (0.0335 - 0.0531)0.7 (0.028)

2nd

(Triple-cone synchronizer)Clearance between synchronizer and

clutch gear end face “A”0.6 - 1.3 (0.024 - 0.051) 0.3 (0.012)

Clearance between outer baulk ring

pawl and synchronizer cone “B”0.85 - 1.35 (0.0335 - 0.0531) 0.7 (0.028)

Clearance between inner baulk ring and

clutch gear end face “C”0.7 - 1.25 (0.028 - 0.0492) 0.3 (0.012)

5th and 6th 0.7 - 1.35 (0.028 - 0.0531)

0.5 (0.020)

Reverse 0.75 - 1.2 (0.0295 - 0.047)

PCIB0249E

PCIB0835J

Page 2387 of 3171

MT-70

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2388 of 3171

MTC-1

MANUAL AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTIONMTC

A

B

MTC

MANUAL AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

Contaminated Refrigerant ........................................ 4

General Refrigerant Precautions .............................. 5

Precautions for Refrigerant Connection ................... 5

ABOUT ONE-TOUCH JOINT ................................ 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 7

O-RING AND REFRIGERANT CONNECTION..... 9

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 12

RECOVERY/RECYCLING EQUIPMENT ............ 12

ELECTRONIC LEAK DETECTOR ...................... 12

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 13

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CALIBRATING ACR4 WEIGHT SCALE .............. 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 14

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

Wiring Diagrams and Trouble Diagnosis ................ 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment... 16

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 21

Component Layout ................................................. 22

REFRIGERATION SYSTEM ............................... 22LUBRICANT .............................................................. 24

Maintenance of Lubricant Quantity in Compressor... 24

LUBRICANT ........................................................ 24

CHECKING AND ADJUSTING ............................ 24

AIR CONDITIONER CONTROL ............................... 26

Description .............................................................. 26

Operation ................................................................ 26

AIR MIX DOOR CONTROL ................................. 26

BLOWER SPEED CONTROL ............................. 26

INTAKE DOORS CONTROL ............................... 26

MODE DOOR CONTROL ................................... 26

DEFROSTER DOOR CONTROL ........................ 26

MAGNET CLUTCH CONTROL ........................... 27

SELF-DIAGNOSTIC SYSTEM ............................ 27

Description of Control System ................................ 28

Control Operation ................................................... 28

DISPLAY SCREEN .............................................. 29

TEMPERATURE SWITCH (TEMPERATURE

CONTROL) (FRONT) .......................................... 29

RECIRCULATION () SWITCH ............................. 29

REAR WINDOW DEFOGGER SWITCH ............. 29

OFF SWITCH (BLOWER SPEED SET TO 0) ..... 29

A/C SWITCH ....................................................... 29

MODE SWITCH .................................................. 29

Discharge Air Flow ................................................. 30

FRONT ................................................................ 30

System Description ................................................. 31

SWITCHES AND THEIR CONTROL FUNCTION... 31

CAN Communication System Description .............. 32

TROUBLE DIAGNOSIS ............................................ 33

CONSULT-II ............................................................ 33

CONSULT-II BASIC OPERATION ....................... 33

DATA MONITOR ................................................. 34

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 35

WORK FLOW ...................................................... 35

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location... 36

ENGINE COMPARTMENT .................................. 36

FRONT PASSENGER COMPARTMENT ............ 37