service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2405 of 3171

MTC-18

PREPARATION

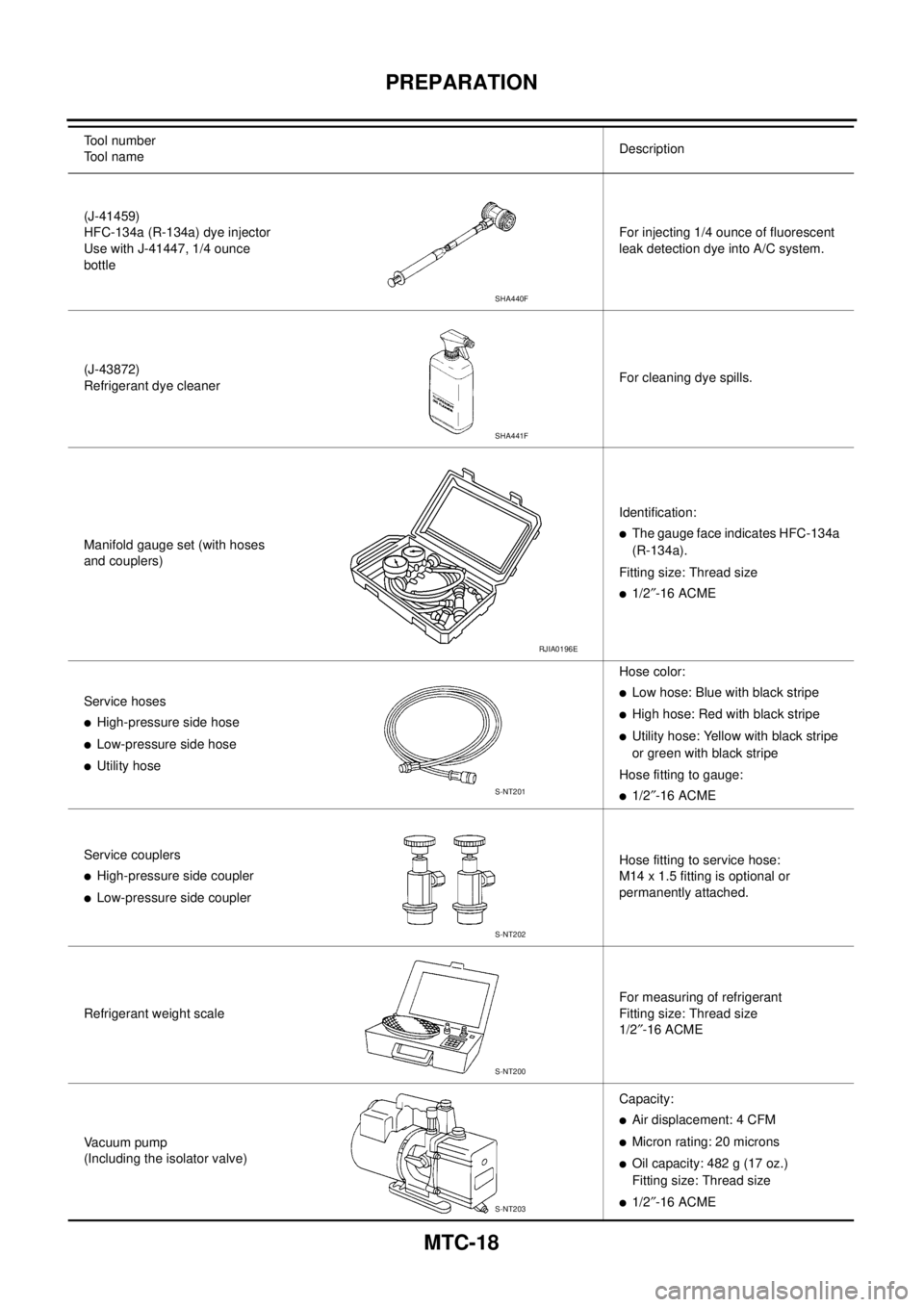

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottleFor injecting 1/4 ounce of fluorescent

leak detection dye into A/C system.

(J-43872)

Refrigerant dye cleanerFor cleaning dye spills.

Manifold gauge set (with hoses

and couplers)Identification:

lThe gauge face indicates HFC-134a

(R-134a).

Fitting size: Thread size

l1/2²-16 ACME

Service hoses

lHigh-pressure side hose

lLow-pressure side hose

lUtility hoseHose color:

lLow hose: Blue with black stripe

lHigh hose: Red with black stripe

lUtility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

l1/2²-16 ACME

Service couplers

lHigh-pressure side coupler

lLow-pressure side couplerHose fitting to service hose:

M14 x 1.5 fitting is optional or

permanently attached.

Refrigerant weight scaleFor measuring of refrigerant

Fitting size: Thread size

1/2²-16 ACME

Vacuum pump

(Including the isolator valve)Capacity:

lAir displacement: 4 CFM

lMicron rating: 20 microns

lOil capacity: 482 g (17 oz.)

Fitting size: Thread size

l1/2²-16 ACME Tool number

Tool nameDescription

SHA440F

SHA441F

RJIA0196E

S-NT201

S-NT202

S-NT200

S-NT203

Page 2406 of 3171

PREPARATION

MTC-19

C

D

E

F

G

H

I

K

L

MA

B

MTC

Commercial Service ToolsEJS00638

Tool number

Tool nameDescription

(J-44614)

Clutch disk holding toolClutch disk holding tool

WHA230

Page 2505 of 3171

MTC-118

REFRIGERANT LINES

REFRIGERANT LINES

PFP:92600

HFC-134a (R-134a) Service ProcedureEJS005HA

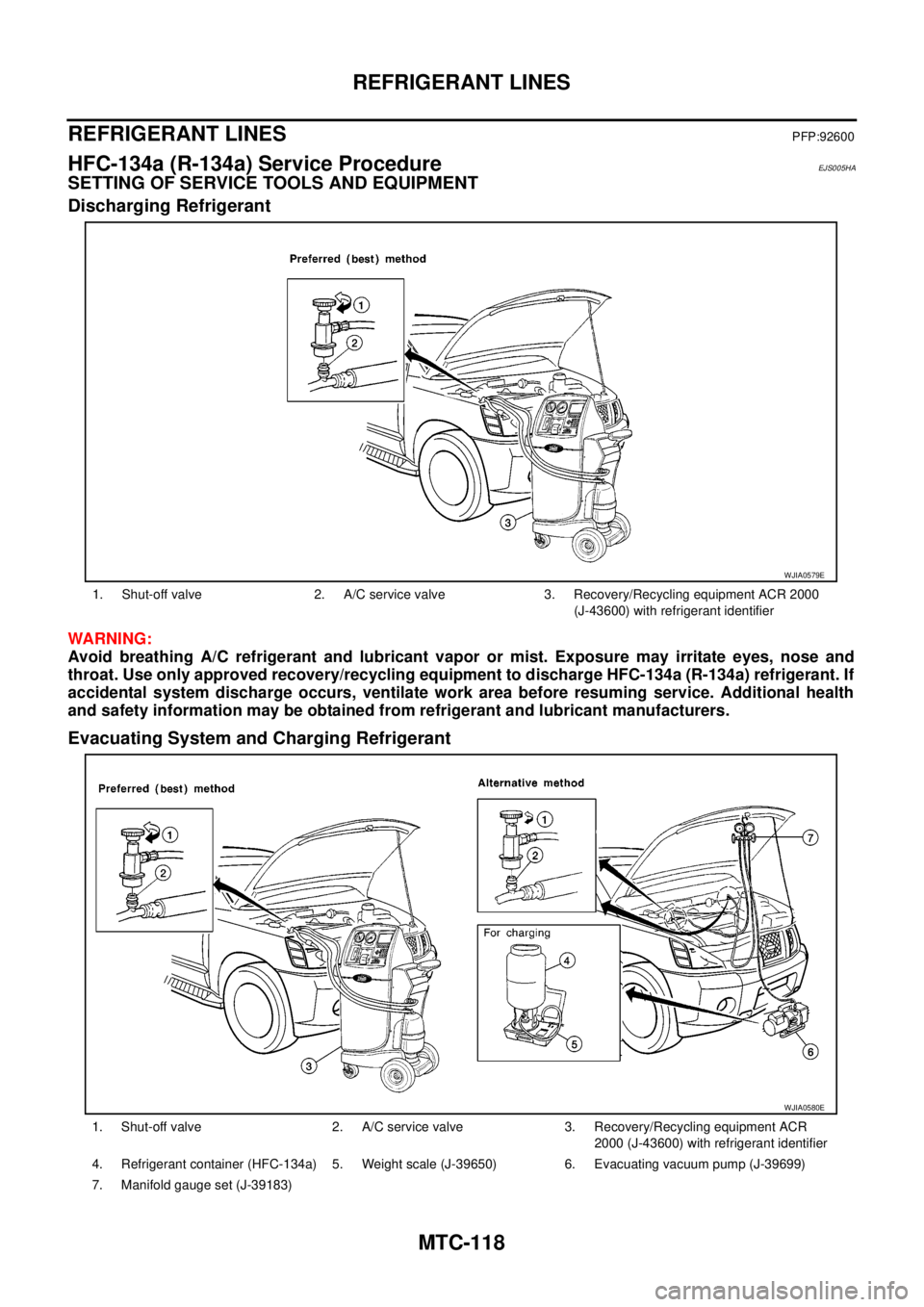

SETTING OF SERVICE TOOLS AND EQUIPMENT

Discharging Refrigerant

WARNING:

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If

accidental system discharge occurs, ventilate work area before resuming service. Additional health

and safety information may be obtained from refrigerant and lubricant manufacturers.

Evacuating System and Charging Refrigerant

1. Shut-off valve 2. A/C service valve 3. Recovery/Recycling equipment ACR 2000

(J-43600) with refrigerant identifier

WJIA0579E

1. Shut-off valve 2. A/C service valve 3. Recovery/Recycling equipment ACR

2000 (J-43600) with refrigerant identifier

4. Refrigerant container (HFC-134a) 5. Weight scale (J-39650) 6. Evacuating vacuum pump (J-39699)

7. Manifold gauge set (J-39183)

WJIA0580E

Page 2507 of 3171

MTC-120

REFRIGERANT LINES

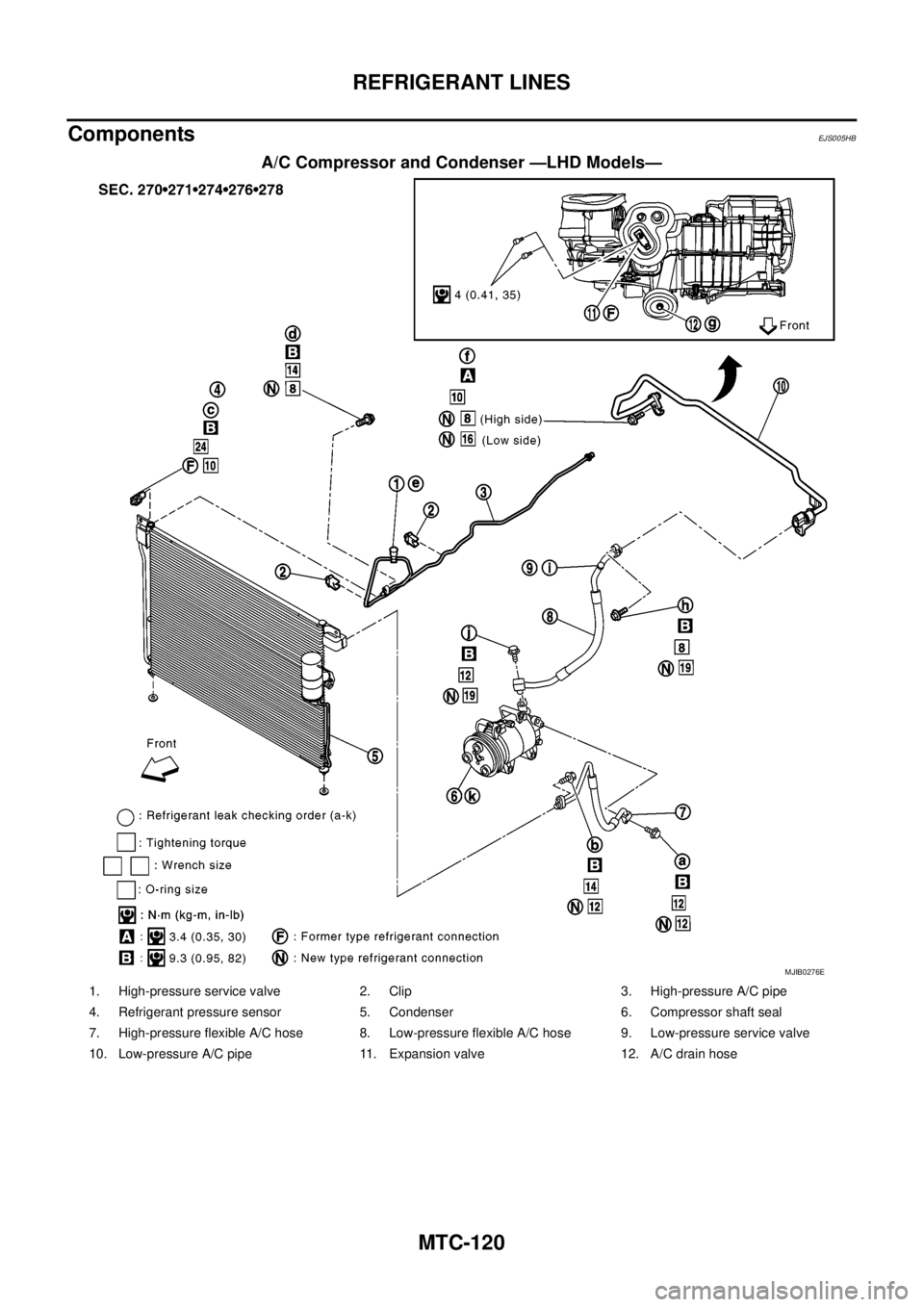

Components

EJS005HB

A/C Compressor and Condenser —LHD Models—

MJIB0276E

1. High-pressure service valve 2. Clip 3. High-pressure A/C pipe

4. Refrigerant pressure sensor 5. Condenser 6. Compressor shaft seal

7. High-pressure flexible A/C hose 8. Low-pressure flexible A/C hose 9. Low-pressure service valve

10. Low-pressure A/C pipe 11. Expansion valve 12. A/C drain hose

Page 2508 of 3171

REFRIGERANT LINES

MTC-121

C

D

E

F

G

H

I

K

L

MA

B

MTC

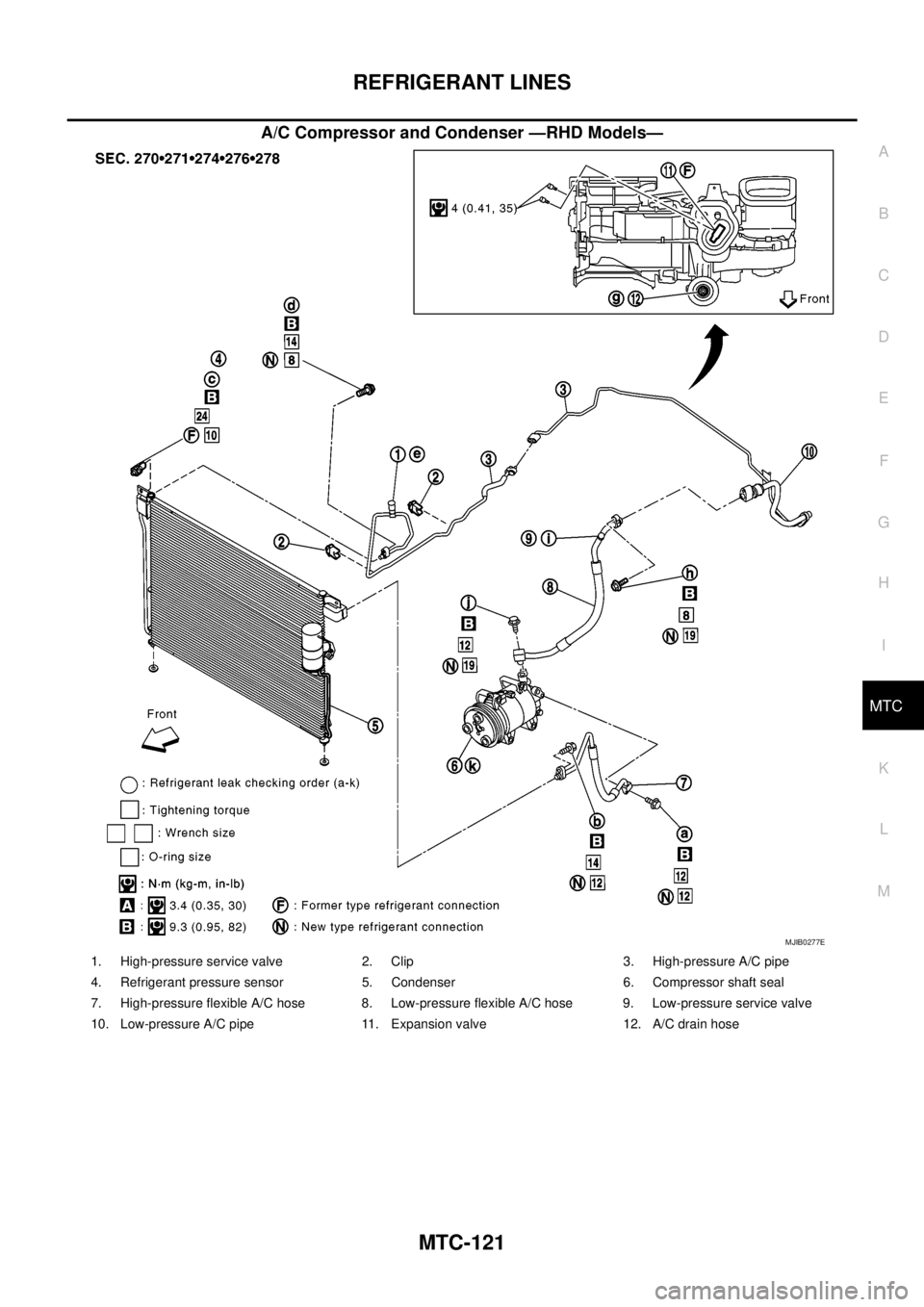

A/C Compressor and Condenser —RHD Models—

MJIB0277E

1. High-pressure service valve 2. Clip 3. High-pressure A/C pipe

4. Refrigerant pressure sensor 5. Condenser 6. Compressor shaft seal

7. High-pressure flexible A/C hose 8. Low-pressure flexible A/C hose 9. Low-pressure service valve

10. Low-pressure A/C pipe 11. Expansion valve 12. A/C drain hose

Page 2509 of 3171

MTC-122

REFRIGERANT LINES

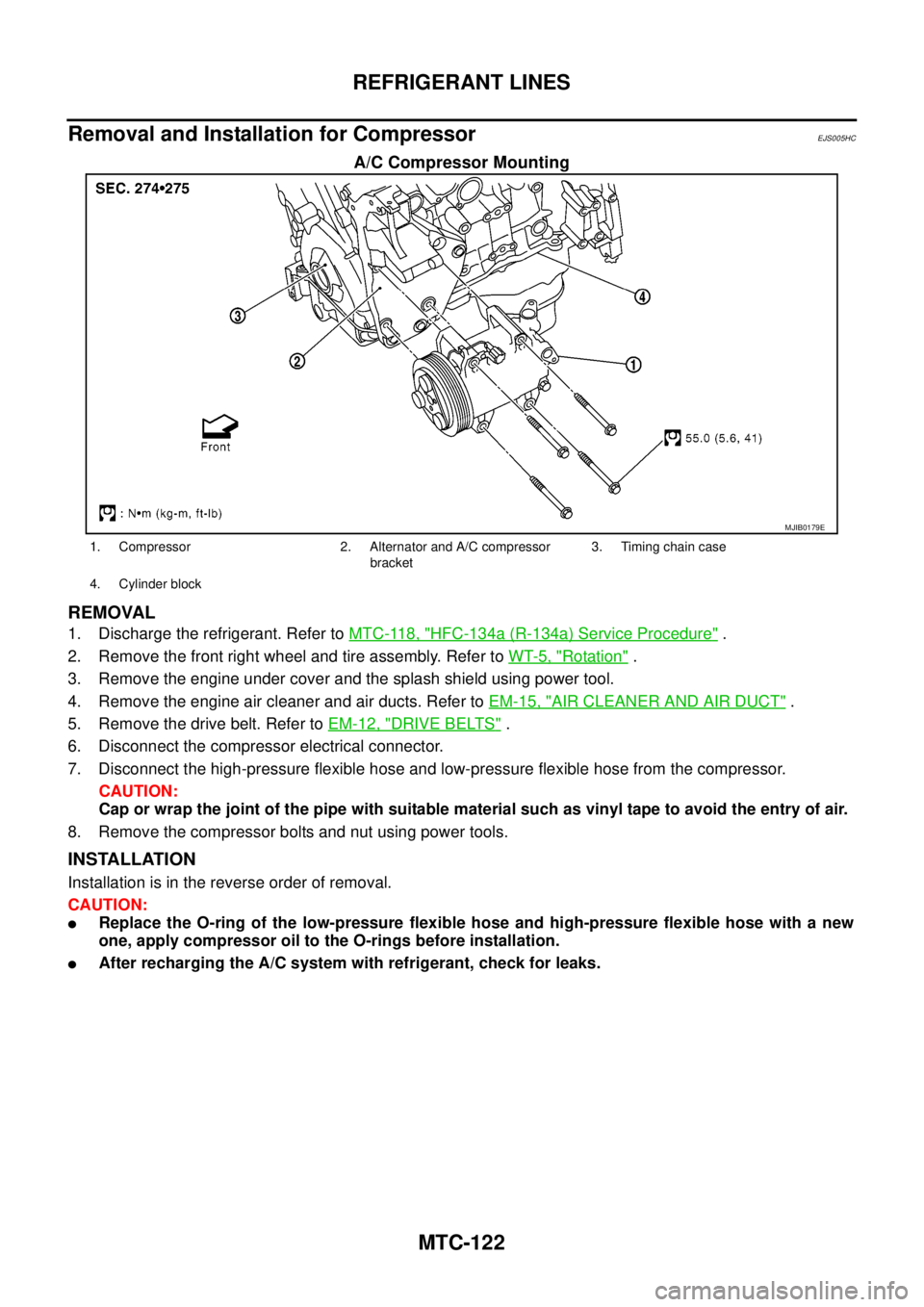

Removal and Installation for Compressor

EJS005HC

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine under cover and the splash shield using power tool.

4. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

5. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

6. Disconnect the compressor electrical connector.

7. Disconnect the high-pressure flexible hose and low-pressure flexible hose from the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

8. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure flexible hose and high-pressure flexible hose with a new

one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks.

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block

Page 2513 of 3171

MTC-126

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Low-pressure Flexible HoseEJS005HE

REMOVAL

1. Remove the engine room cover using power tools.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

3. Remove the cowl top extension. Refer toEI-20, "

COWL TOP".

4. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible hose. Refer toMTC-120, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure Flexible HoseEJS005HF

REMOVAL

1. Remove the engine under cover.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT"

3. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

4. Remove the high-pressure flexible hose. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure PipeEJS005HG

REMOVAL

1. Remove the cowl top extension. Refer toEI-20, "COWL TOP".

2. Disconnect the battery negative cable.

3. Reposition the IPDM E/R aside.

4. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

7. Remove the low pressure pipe. Refer toMTC-127, "

Removal and Installation for Low-pressure Pipe".

8. Remove the high-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

Page 2514 of 3171

REFRIGERANT LINES

MTC-127

C

D

E

F

G

H

I

K

L

MA

B

MTC

CAUTION:

lReplace the O-ring of the high-pressure pipe with a new one, then apply compressor oil to it when

installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for Low-pressure PipeEJS005HH

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the cowl top and the cowl top extension. Refer toEI-20, "

COWL TOP".

3. Remove the low-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high/low-pressure pipe with a new one, then apply compressor oil to it

when installing it.

lAfter charging refrigerant, check for leaks.

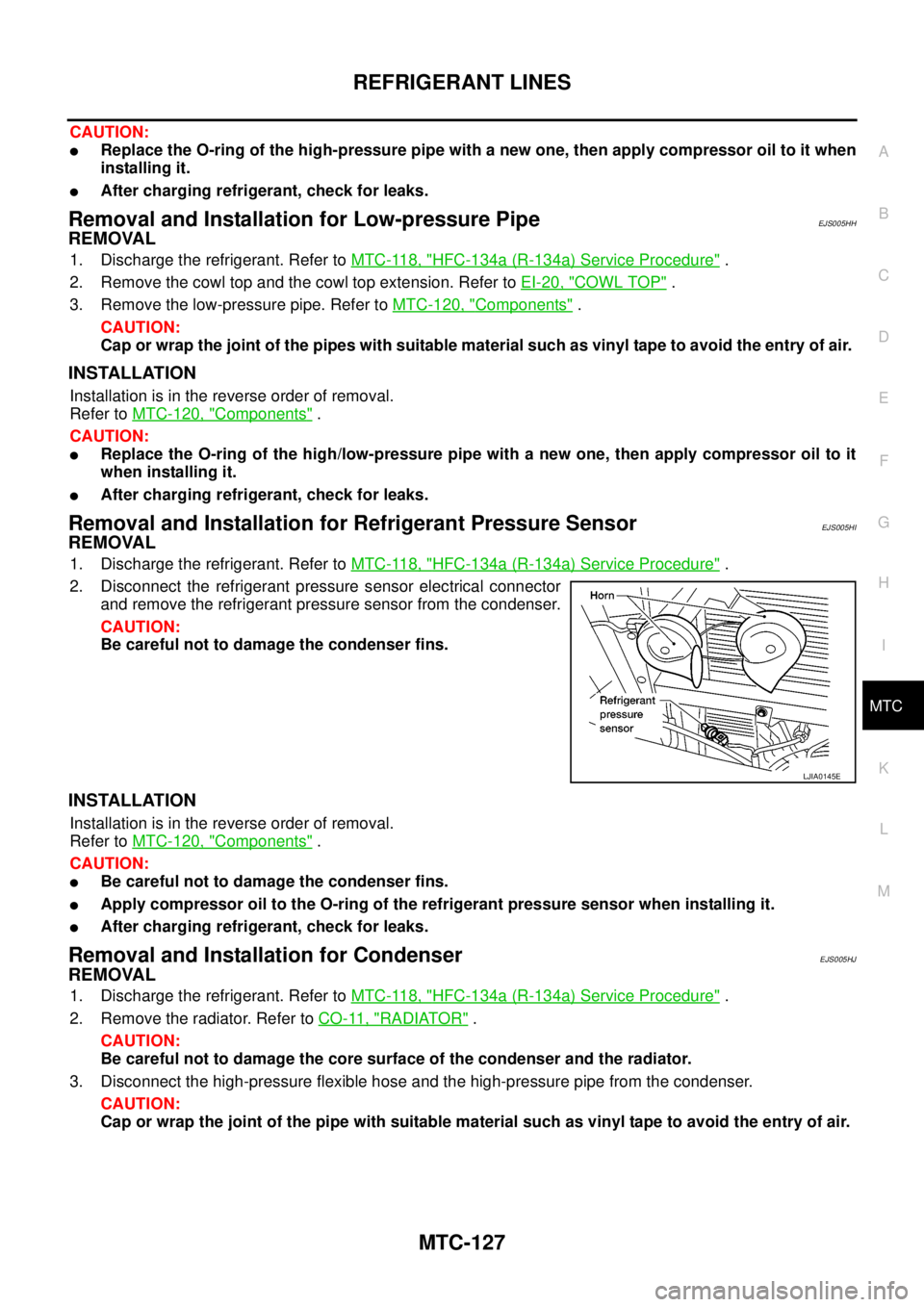

Removal and Installation for Refrigerant Pressure SensorEJS005HI

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the refrigerant pressure sensor electrical connector

and remove the refrigerant pressure sensor from the condenser.

CAUTION:

Be careful not to damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lBe careful not to damage the condenser fins.

lApply compressor oil to the O-ring of the refrigerant pressure sensor when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for CondenserEJS005HJ

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the radiator. Refer toCO-11, "

RADIATOR".

CAUTION:

Be careful not to damage the core surface of the condenser and the radiator.

3. Disconnect the high-pressure flexible hose and the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

LJIA0145E

Page 2517 of 3171

MTC-130

REFRIGERANT LINES

REMOVAL

1. Remove the heater core. Refer toMTC-106, "HEATER CORE".

2. Remove the defroster mode door arm.

3. Separate the heater core and cooling unit case.

4. Remove the evaporator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-rings on the low-pressure flexible hose and the high-pressure pipe with new ones.

Apply compressor oil to the O-rings before installing them.

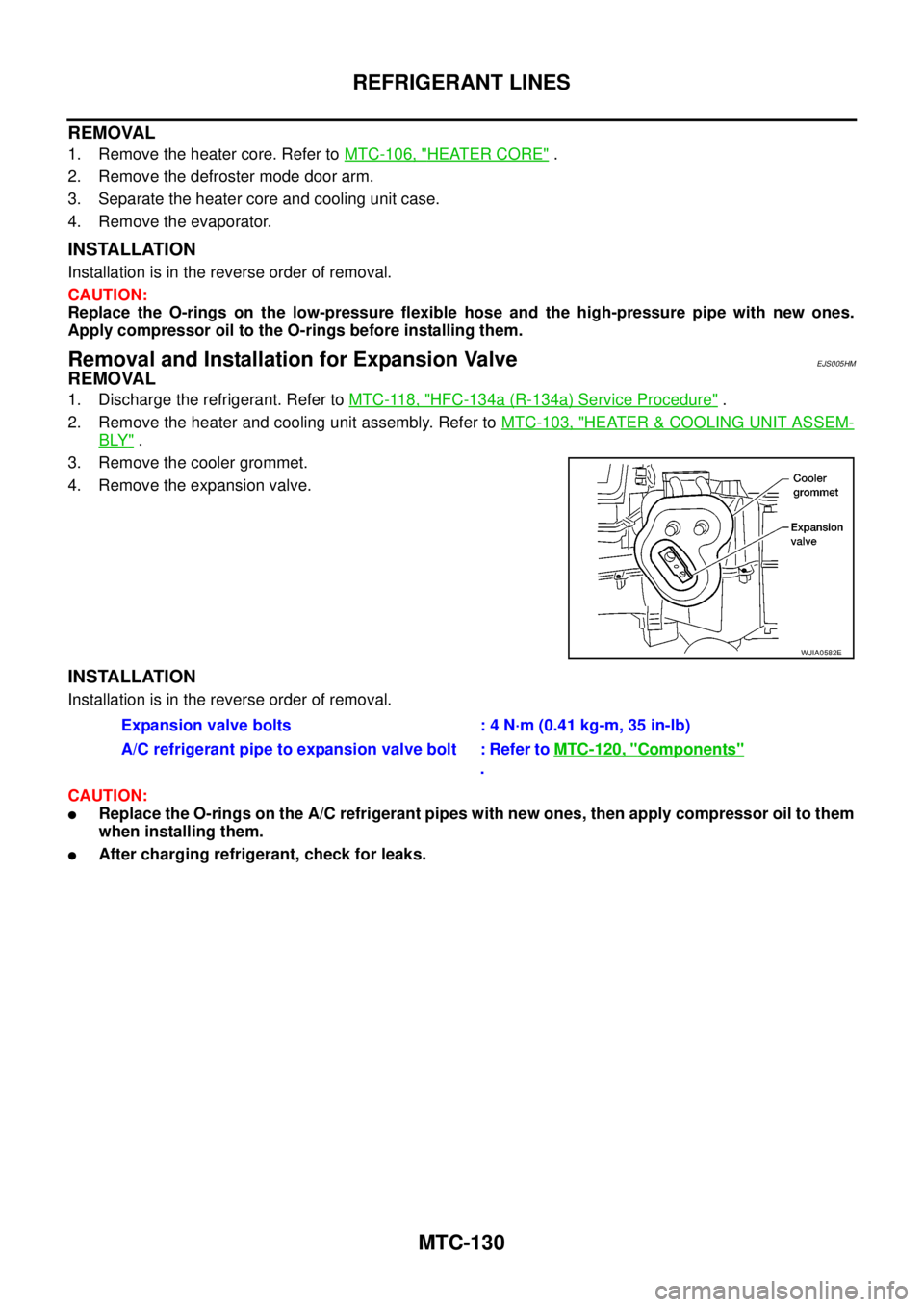

Removal and Installation for Expansion ValveEJS005HM

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the heater and cooling unit assembly. Refer toMTC-103, "

HEATER&COOLING UNIT ASSEM-

BLY".

3. Remove the cooler grommet.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-rings on the A/C refrigerant pipes with new ones, then apply compressor oil to them

when installing them.

lAfter charging refrigerant, check for leaks.

WJIA0582E

Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer toMTC-120, "

Components"

.

Page 2518 of 3171

REFRIGERANT LINES

MTC-131

C

D

E

F

G

H

I

K

L

MA

B

MTC

Checking for Refrigerant LeaksEJS0062F

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS0062G

1. Check A/C system for leaks using the UV lamp and safety goggles [SST: J-42220] in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner [SST: J-43872] to prevent future mis-

diagnosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionEJS0062H

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool [SST: J-41459].

3. Connect the injector tool to the A/C Low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.