service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2520 of 3171

REFRIGERANT LINES

MTC-133

C

D

E

F

G

H

I

K

L

MA

B

MTC

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set (SST) to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50 psi) above 16°C. If

less than specification, recover/evacuate and recharge the system with the specified amount of refriger-

ant.

NOTE:

At temperatures below 16°C, leaks may not be detected since the system may not reach 345 kPa (3.45

bar, 3.52 kg/cm

2,50psi).

4. Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet g) to the

low-pressure side (evaporator drain hose h to shaft seal l). Refer toMTC-120, "

Components". Perform a

leak check for the following areas carefully. Clean the component to be checked and move the leak

detected probe completely around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. MODE control dial: VENT (Ventilation)

c. Intake door position: Recirculation

d. Max. cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

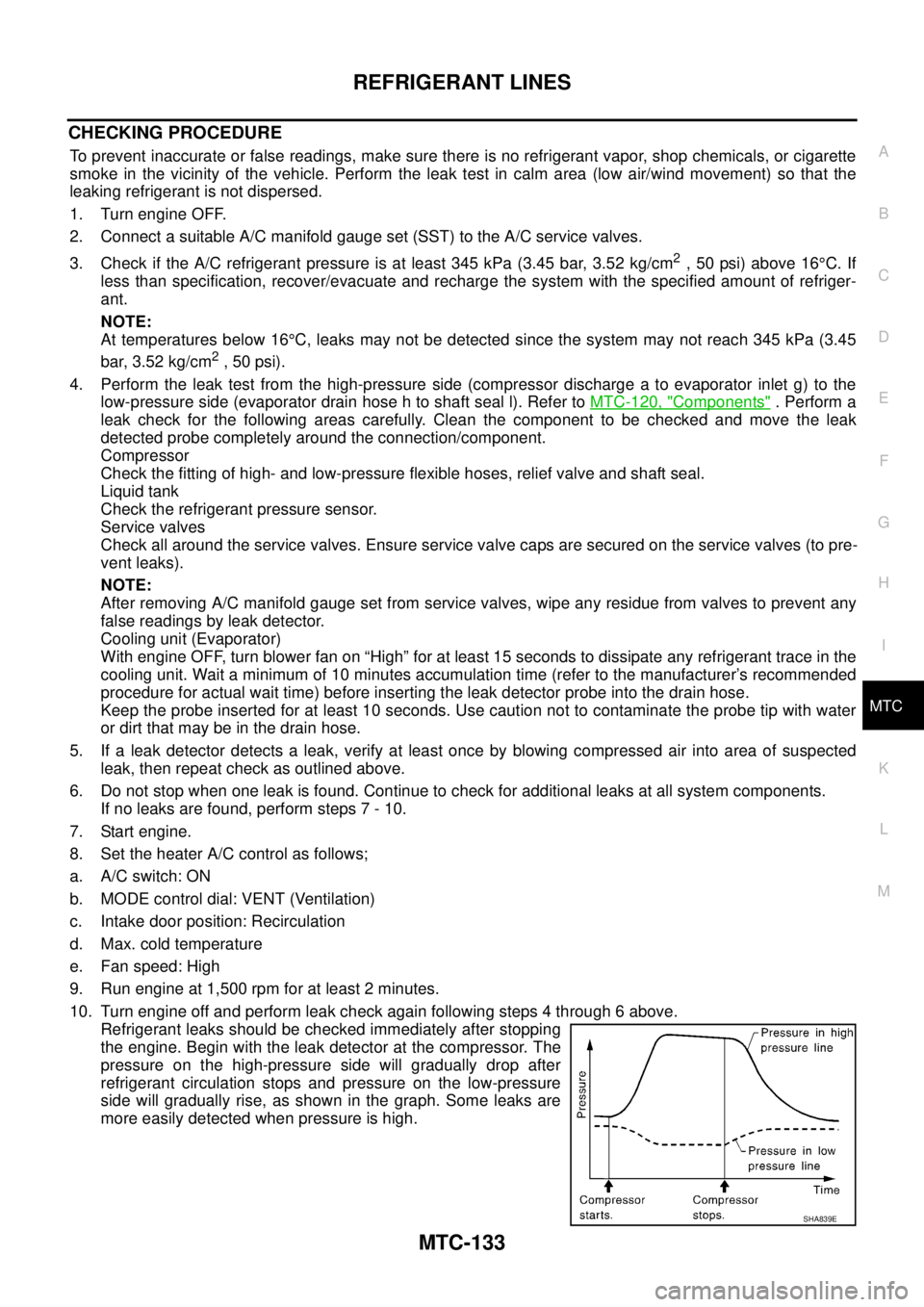

Refrigerant leaks should be checked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

SHA839E

Page 2522 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MTC-135

C

D

E

F

G

H

I

K

L

MA

B

MTC

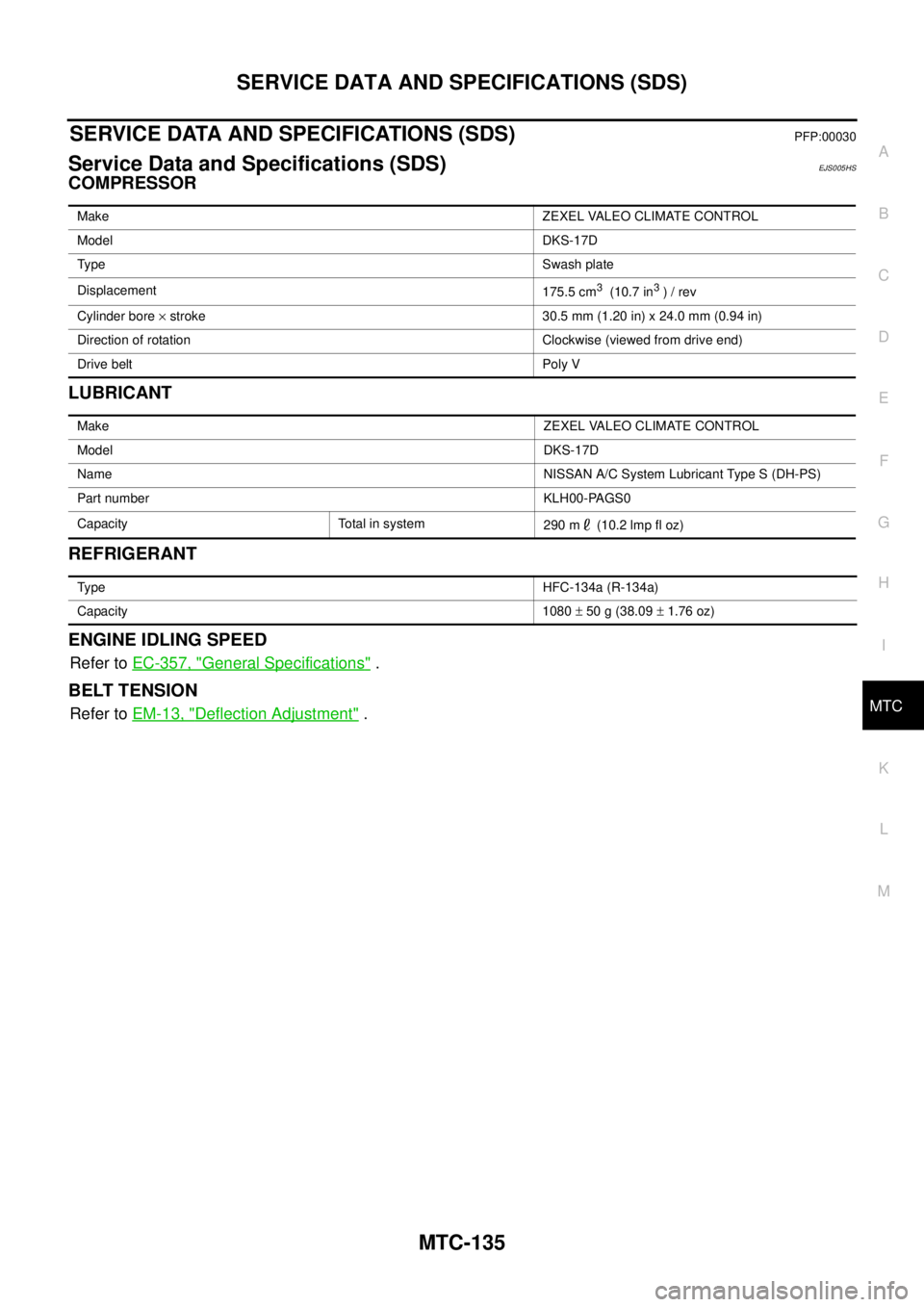

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Service Data and Specifications (SDS)EJS005HS

COMPRESSOR

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toEC-357, "General Specifications".

BELT TENSION

Refer toEM-13, "Deflection Adjustment".

MakeZEXEL VALEO CLIMATE CONTROL

ModelDKS-17D

Ty p eSwash plate

Displacement

175.5 cm

3(10.7 in3)/rev

Cylinder bore´stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

MakeZEXEL VALEO CLIMATE CONTROL

ModelDKS-17D

NameNISSAN A/C System Lubricant Type S (DH-PS)

Part number KLH00-PAGS0

Capacity Total in system

290m (10.2lmpfloz)

Ty p eHFC-134a (R-134a)

Capacity 1080±50g(38.09±1.76 oz)

Page 2523 of 3171

MTC-136

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2524 of 3171

PB-1

PARKING BRAKE SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONPB

A

B

PB

PARKING BRAKE SYSTEM

PARKING BRAKE CONTROL ................................... 2

On-Vehicle Service ................................................... 2

INSPECTION ........................................................ 2

COMPONENTS INSPECTION ............................. 2

ADJUSTMENT ...................................................... 2Components ............................................................. 3

Removal and Installation .......................................... 4

REMOVAL ............................................................. 4

INSTALLATION ..................................................... 5

SERVICE DATA AND SPECIFICATIONS (SDS) ........ 6

Parking Brake Control .............................................. 6

Page 2525 of 3171

PB-2

PARKING BRAKE CONTROL

PARKING BRAKE CONTROL

PFP:36010

On-Vehicle ServiceEFS006AJ

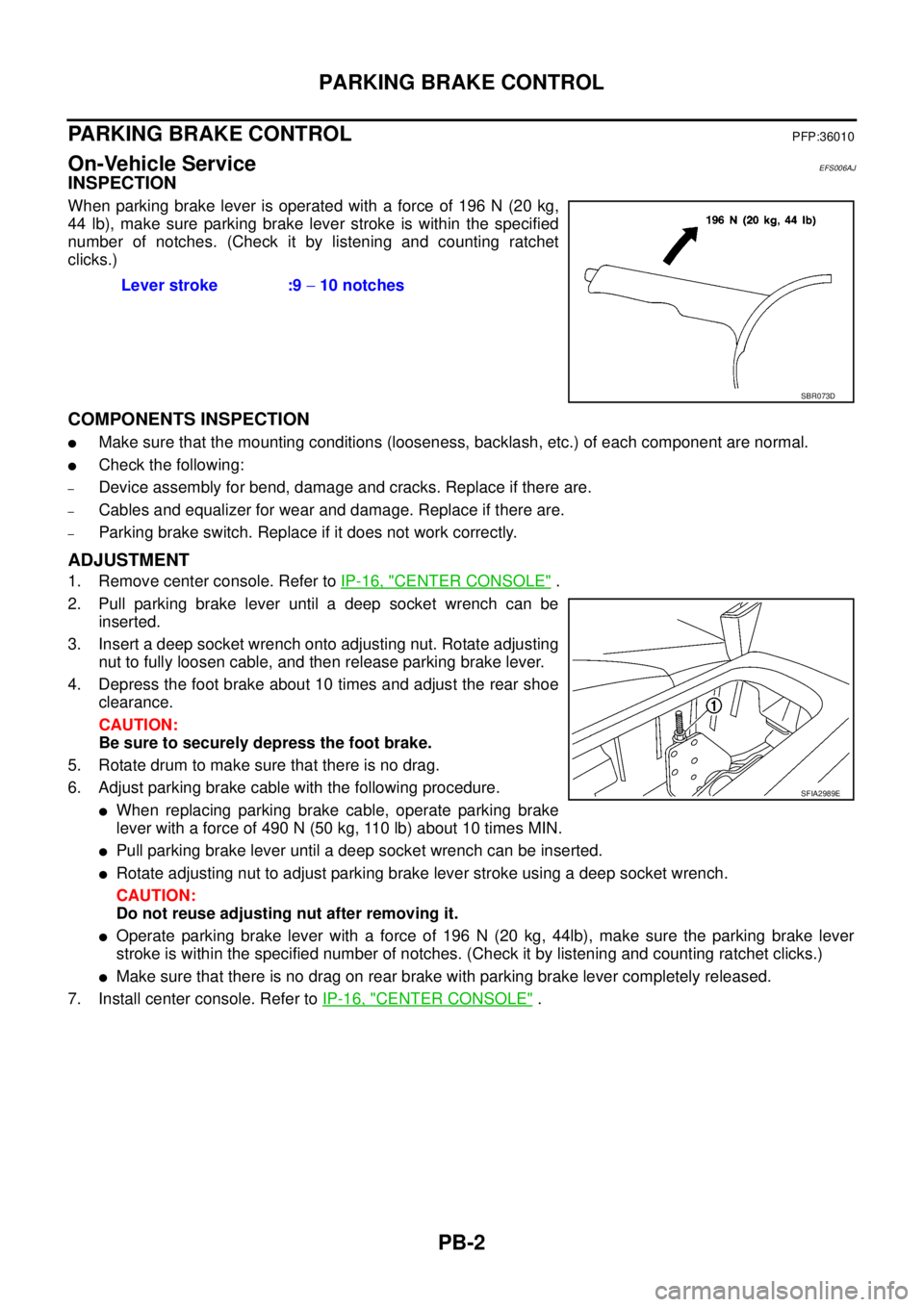

INSPECTION

When parking brake lever is operated with a force of 196 N (20 kg,

44 lb), make sure parking brake lever stroke is within the specified

number of notches. (Check it by listening and counting ratchet

clicks.)

COMPONENTS INSPECTION

lMake sure that the mounting conditions (looseness, backlash, etc.) of each component are normal.

lCheck the following:

–Device assembly for bend, damage and cracks. Replace if there are.

–Cables and equalizer for wear and damage. Replace if there are.

–Parking brake switch. Replace if it does not work correctly.

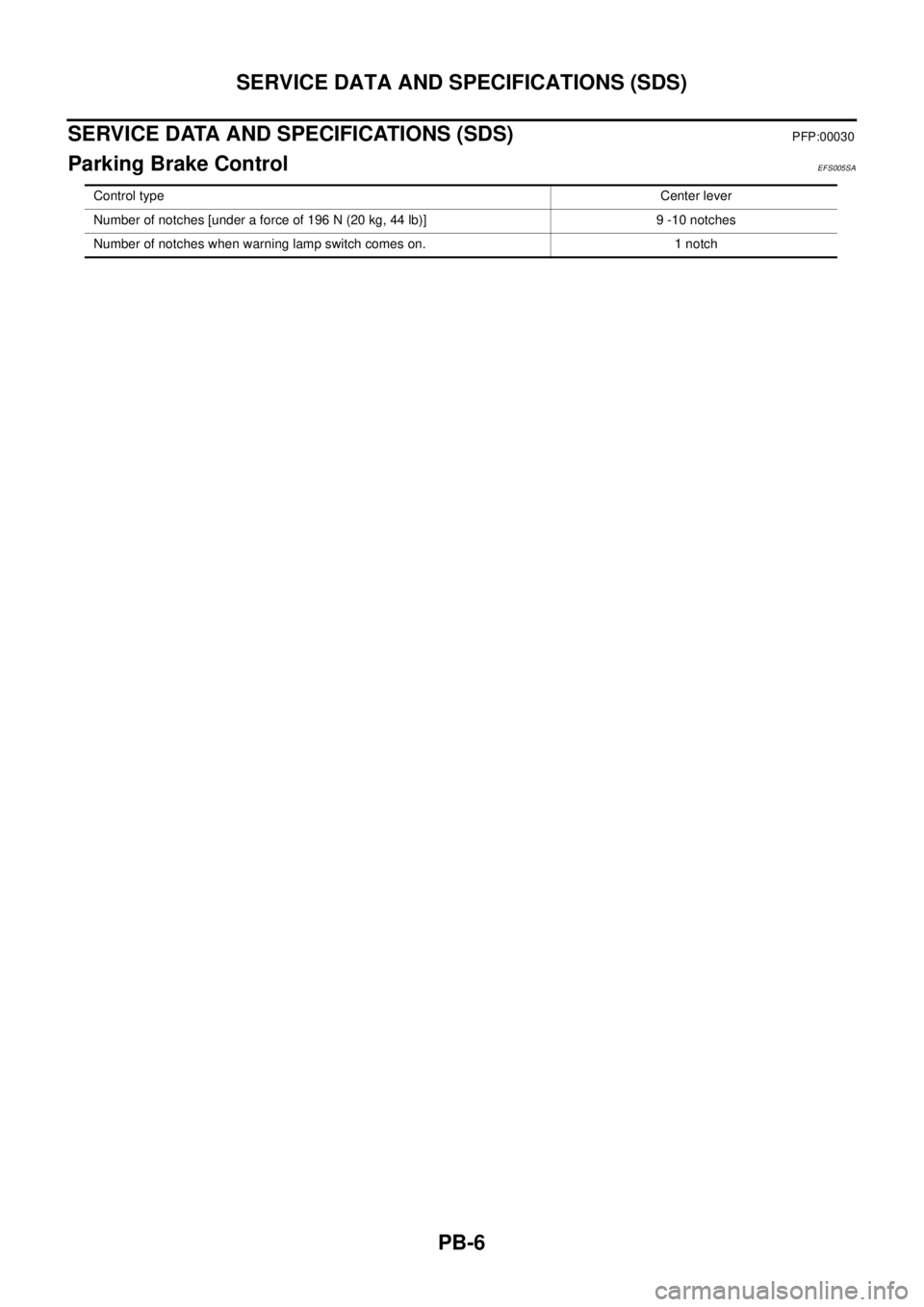

ADJUSTMENT

1. Remove center console. Refer toIP-16, "CENTER CONSOLE".

2. Pull parking brake lever until a deep socket wrench can be

inserted.

3. Insert a deep socket wrench onto adjusting nut. Rotate adjusting

nut to fully loosen cable, and then release parking brake lever.

4. Depress the foot brake about 10 times and adjust the rear shoe

clearance.

CAUTION:

Be sure to securely depress the foot brake.

5. Rotate drum to make sure that there is no drag.

6. Adjust parking brake cable with the following procedure.

lWhen replacing parking brake cable, operate parking brake

leverwithaforceof490N(50kg,110lb)about10timesMIN.

lPull parking brake lever until a deep socket wrench can be inserted.

lRotate adjusting nut to adjust parking brake lever stroke using a deep socket wrench.

CAUTION:

Do not reuse adjusting nut after removing it.

lOperate parking brake lever with a force of 196 N (20 kg, 44lb), make sure the parking brake lever

stroke is within the specified number of notches. (Check it by listening and counting ratchet clicks.)

lMake sure that there is no drag on rear brake with parking brake lever completely released.

7. Install center console. Refer toIP-16, "

CENTER CONSOLE". Lever stroke :9-10 notches

SBR073D

SFIA2989E

Page 2529 of 3171

PB-6

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Parking Brake ControlEFS005SA

Control typeCenter lever

Number of notches [under a force of 196 N (20 kg, 44 lb)] 9 -10 notches

Number of notches when warning lamp switch comes on. 1 notch

Page 2532 of 3171

PRECAUTIONS

PG-3

C

D

E

F

G

H

I

J

L

MA

B

PG

PRECAUTIONSPFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00N4A

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble DiagnosisEKS00LIU

When you read wiring diagrams, refer to the following:

lRefer toGI-15, "HowtoReadWiringDiagrams"in GI section.

lRefer toPG-4, "POWER SUPPLY ROUTING CIRCUIT"for power distribution.

When you perform trouble diagnosis, refer to the following:

lRefer toGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"in GI section.

lRefer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section.

Page 2616 of 3171

PR-1

PROPELLER SHAFT

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONPR

A

B

PR

PROPELLER SHAFT

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 2

NVH Troubleshooting Chart ..................................... 2

FRONT PROPELLER SHAFT .................................... 3

On-Vehicle Service ................................................... 3

APPEARANCE AND NOISE INSPECTION .......... 3

PROPELLER SHAFT VIBRATION ........................ 3

Removal and Installation .......................................... 4

COMPONENTS .................................................... 4

REMOVAL ............................................................. 4

INSPECTION ........................................................ 4

INSTALLATION ..................................................... 5

Disassembly and Assembly ..................................... 5

DISASSEMBLY ..................................................... 5

ASSEMBLY ........................................................... 6

REAR PROPELLER SHAFT ...................................... 7On-Vehicle Service ................................................... 7

APPEARANCE AND NOISE INSPECTION .......... 7

PROPELLER SHAFT VIBRATION ........................ 7

Removal and Installation .......................................... 8

COMPONENTS (2WD) ......................................... 8

COMPONENTS (4WD) ......................................... 8

REMOVAL ............................................................. 9

INSPECTION ........................................................ 9

INSTALLATION ................................................... 10

Disassembly and Assembly .................................... 10

DISASSEMBLY ................................................... 10

ASSEMBLY ......................................................... 11

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 12

General Specifications ............................................ 12

Snap Ring ............................................................... 12

Page 2618 of 3171

FRONT PROPELLER SHAFT

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

FRONT PROPELLER SHAFTPFP:37200

On-Vehicle ServiceEDS002WO

APPEARANCE AND NOISE INSPECTION

lCheck the propeller shaft tube surface for dents or cracks. If damaged, replace the propeller shaft assem-

bly.

lCheck the bearings for noise and damage. Repair or replace the bearings as necessary.

PROPELLER SHAFT VIBRATION

If a vibration is present at high speed, inspect the propeller shaft runout first.

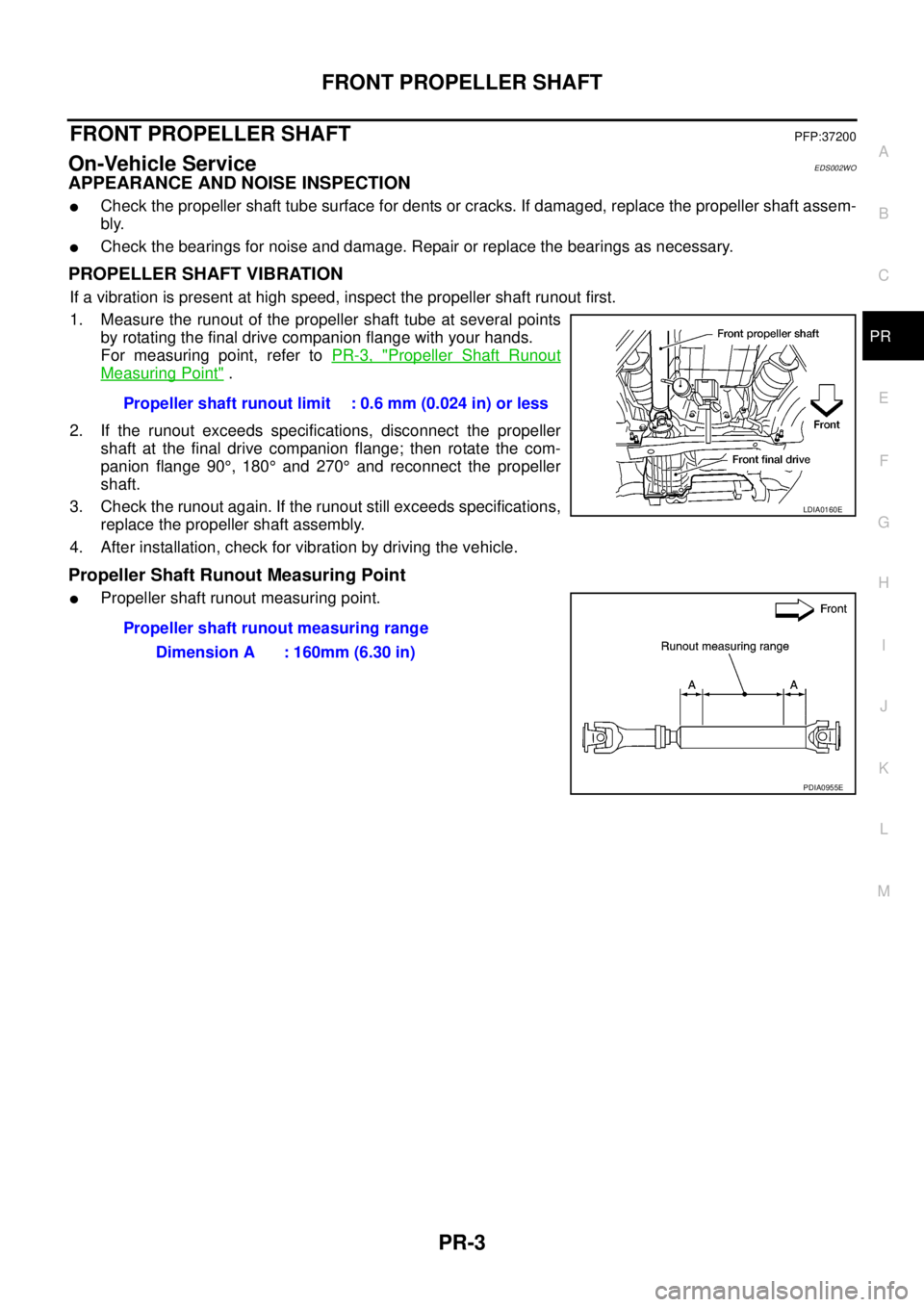

1. Measure the runout of the propeller shaft tube at several points

by rotating the final drive companion flange with your hands.

For measuring point, refer toPR-3, "

Propeller Shaft Runout

Measuring Point".

2. If the runout exceeds specifications, disconnect the propeller

shaft at the final drive companion flange; then rotate the com-

panion flange 90°,180°and 270°and reconnect the propeller

shaft.

3. Check the runout again. If the runout still exceeds specifications,

replace the propeller shaft assembly.

4. After installation, check for vibration by driving the vehicle.

Propeller Shaft Runout Measuring Point

lPropeller shaft runout measuring point.Propeller shaft runout limit : 0.6 mm (0.024 in) or less

LDIA0160E

Propeller shaft runout measuring range

Dimension A : 160mm (6.30 in)

PDIA0955E

Page 2622 of 3171

REAR PROPELLER SHAFT

PR-7

C

E

F

G

H

I

J

K

L

MA

B

PR

REAR PROPELLER SHAFTPFP:37000

On-Vehicle ServiceEDS002WR

APPEARANCE AND NOISE INSPECTION

lCheck the propeller shaft tube surface for dents or cracks. If damaged, replace the propeller shaft assem-

bly.

lCheck the bearings for noise and damage. Repair or replace the bearings as necessary.

PROPELLER SHAFT VIBRATION

If a vibration is present at high speed, inspect the propeller shaft runout first.

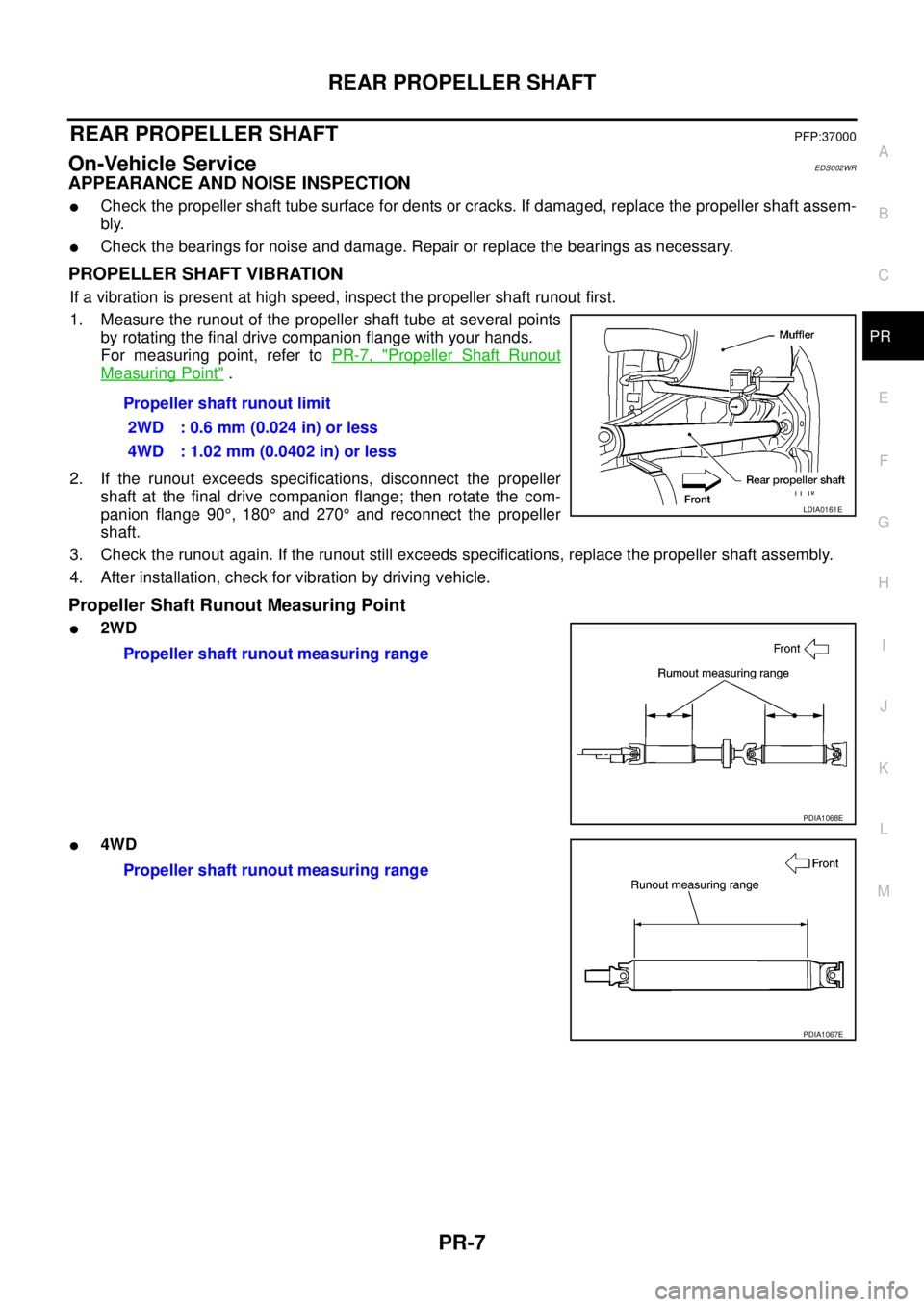

1. Measure the runout of the propeller shaft tube at several points

by rotating the final drive companion flange with your hands.

For measuring point, refer toPR-7, "

Propeller Shaft Runout

Measuring Point".

2. If the runout exceeds specifications, disconnect the propeller

shaft at the final drive companion flange; then rotate the com-

panion flange 90°,180°and 270°and reconnect the propeller

shaft.

3. Check the runout again. If the runout still exceeds specifications, replace the propeller shaft assembly.

4. After installation, check for vibration by driving vehicle.

Propeller Shaft Runout Measuring Point

l2WD

l4WDPropeller shaft runout limit

2WD : 0.6 mm (0.024 in) or less

4WD : 1.02 mm (0.0402 in) or less

LDIA0161E

Propeller shaft runout measuring range

PDIA1068E

Propeller shaft runout measuring range

PDIA1067E