horn NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2547 of 3171

PG-18

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

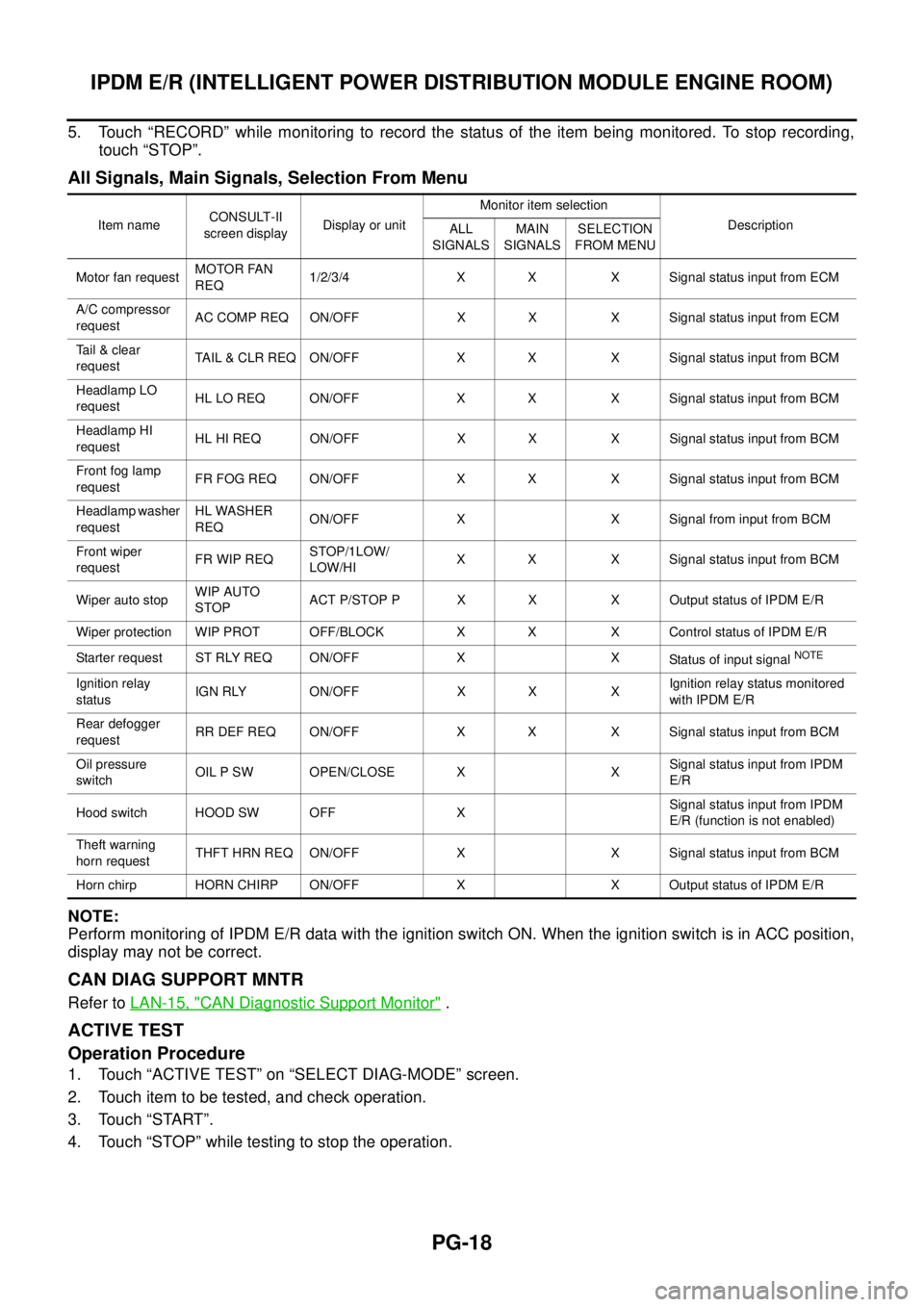

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position,

display may not be correct.

CAN DIAG SUPPORT MNTR

Refer toLAN-15, "CAN Diagnostic Support Monitor".

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG-MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Motor fan requestMOTOR FAN

REQ1/2/3/4 X X X Signal status input from ECM

A/C compressor

requestAC COMP REQ ON/OFF X X X Signal status input from ECM

Tail & clear

requestTAIL & CLR REQ ON/OFF X X X Signal status input from BCM

Headlamp LO

requestHL LO REQ ON/OFF X X X Signal status input from BCM

Headlamp HI

requestHL HI REQ ON/OFF X X X Signal status input from BCM

Front fog lamp

requestFR FOG REQ ON/OFF X X X Signal status input from BCM

Headlamp washer

requestHL WASHER

REQON/OFF X X Signal from input from BCM

Front wiper

requestFR WIP REQSTOP/1LOW/

LOW/HIX X X Signal status input from BCM

Wiper auto stopWIP AUTO

STOPACT P/STOP P X X X Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF X X

Status of input signal

NOTE

Ignition relay

statusIGN RLY ON/OFF X X XIgnition relay status monitored

with IPDM E/R

Rear defogger

requestRR DEF REQ ON/OFF X X X Signal status input from BCM

Oil pressure

switchOIL P SW OPEN/CLOSE X XSignal status input from IPDM

E/R

Hood switch HOOD SW OFF XSignal status input from IPDM

E/R (function is not enabled)

Theft warning

horn requestTHFT HRN REQ ON/OFF X X Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF X X Output status of IPDM E/R

Page 2548 of 3171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

C

D

E

F

G

H

I

J

L

MA

B

PG

Auto Active TestEKS00PAC

DESCRIPTION

lIn auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to

the following systems:

–Rear window defogger

–Front wiper

–Tail lamps, front fog lamps, parking lamps and license plate lamps

–Headlamps (HI, LO)

–A/C compressor (magnetic clutch)

–Cooling fan

–Oil pressure warning lamp

OPERATION PROCEDURE

1. Close hood and front door passenger side, and then lift wiper arms away from windshield (to prevent

glass damage by wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON and, within 20 seconds, press driver's door switch 10 times (close other doors).

Then turn ignition switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, oil pressure warning lamp starts blinking.

6. After a series of operations is repeated three times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway, turn ignition switch OFF.

CAUTION:

Be sure to performBL-39, "

Check Door Switch"when the auto active test cannot be performed.

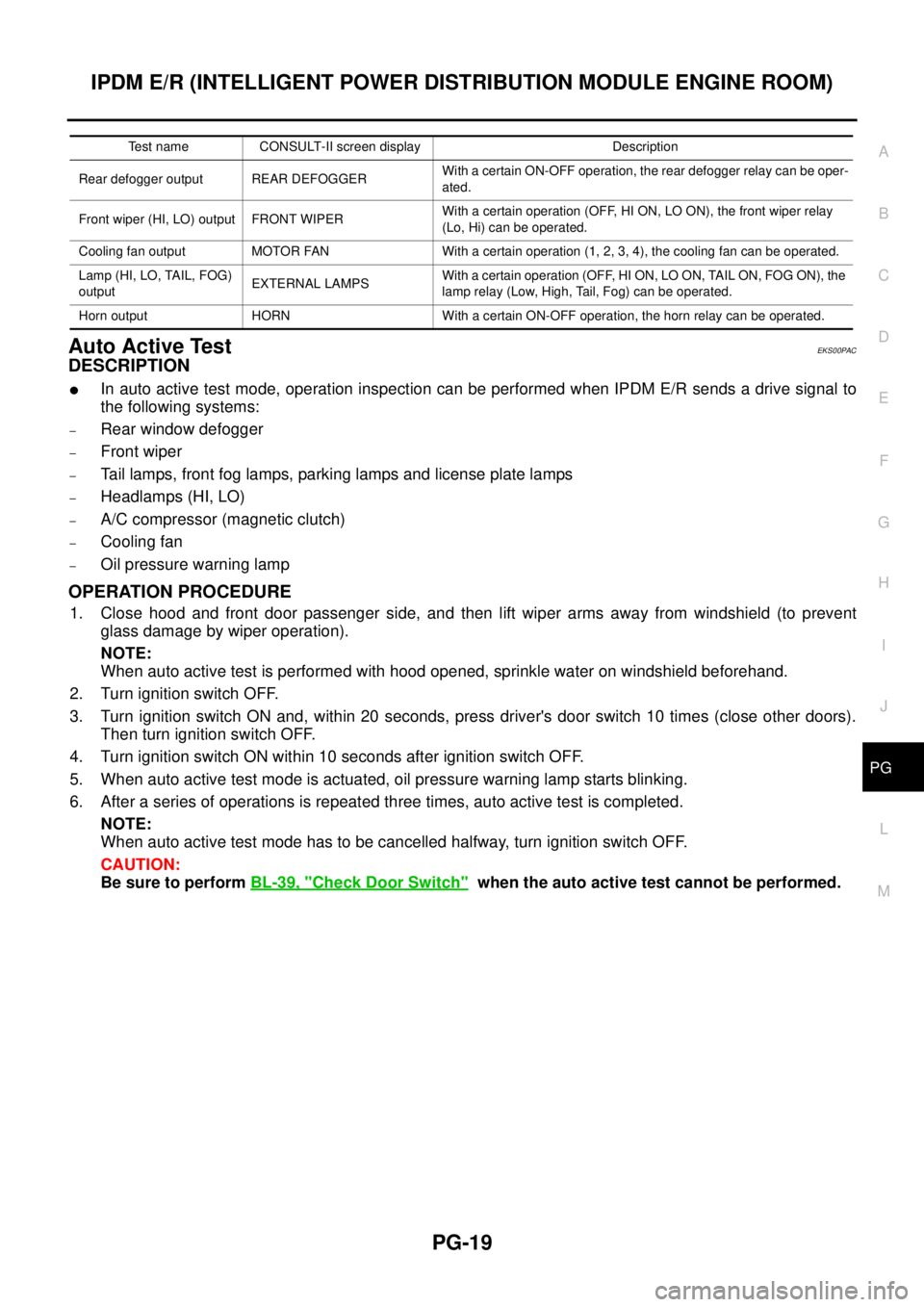

Test name CONSULT-II screen display Description

Rear defogger output REAR DEFOGGERWith a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPERWith a certain operation (OFF, HI ON, LO ON), the front wiper relay

(Lo, Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan can be operated.

Lamp (HI, LO, TAIL, FOG)

outputEXTERNAL LAMPSWith a certain operation (OFF, HI ON, LO ON, TAIL ON, FOG ON), the

lamp relay (Low, High, Tail, Fog) can be operated.

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

Page 2598 of 3171

HARNESS

PG-69

C

D

E

F

G

H

I

J

L

MA

B

PG

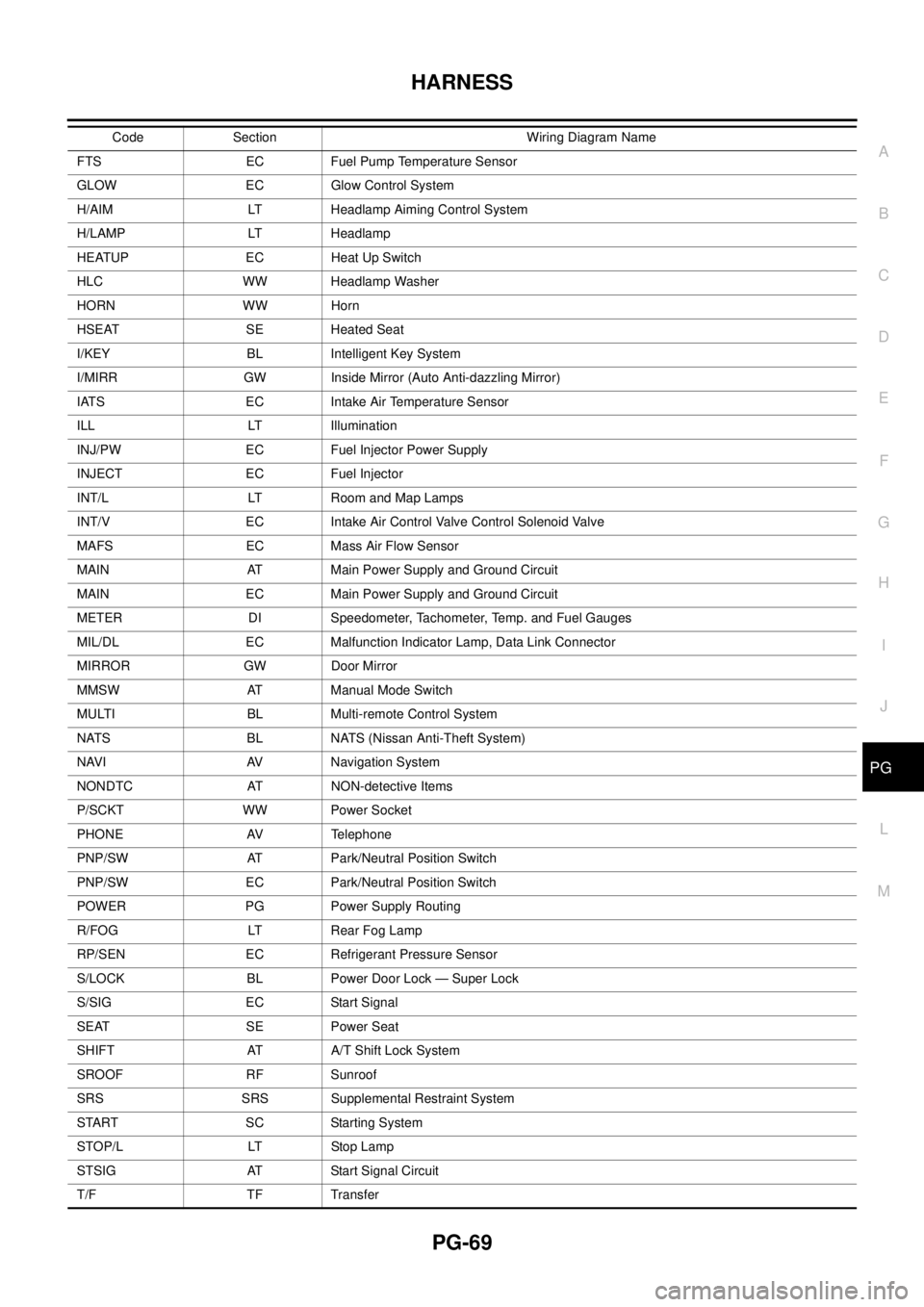

FTS EC Fuel Pump Temperature Sensor

GLOW EC Glow Control System

H/AIM LT Headlamp Aiming Control System

H/LAMP LT Headlamp

HEATUP EC Heat Up Switch

HLC WW Headlamp Washer

HORN WW Horn

HSEAT SE Heated Seat

I/KEY BL Intelligent Key System

I/MIRR GW Inside Mirror (Auto Anti-dazzling Mirror)

IATS EC Intake Air Temperature Sensor

ILL LT Illumination

INJ/PW EC Fuel Injector Power Supply

INJECT EC Fuel Injector

INT/L LT Room and Map Lamps

INT/V EC Intake Air Control Valve Control Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp, Data Link Connector

MIRROR GW Door Mirror

MMSW AT Manual Mode Switch

MULTI BL Multi-remote Control System

NATS BL NATS (Nissan Anti-Theft System)

NAVI AV Navigation System

NONDTC AT NON-detective Items

P/SCKT WW Power Socket

PHONE AV Telephone

PNP/SW AT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POWER PG Power Supply Routing

R/FOG LT Rear Fog Lamp

RP/SEN EC Refrigerant Pressure Sensor

S/LOCK BL Power Door Lock — Super Lock

S/SIG EC Start Signal

SEAT SE Power Seat

SHIFT AT A/T Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

START SC Starting System

STOP/L LT Stop Lamp

STSIG AT Start Signal Circuit

T/F TF TransferCode Section Wiring Diagram Name

Page 2945 of 3171

SRS-36

DRIVER AIR BAG MODULE

DRIVER AIR BAG MODULE

PFP:K8510

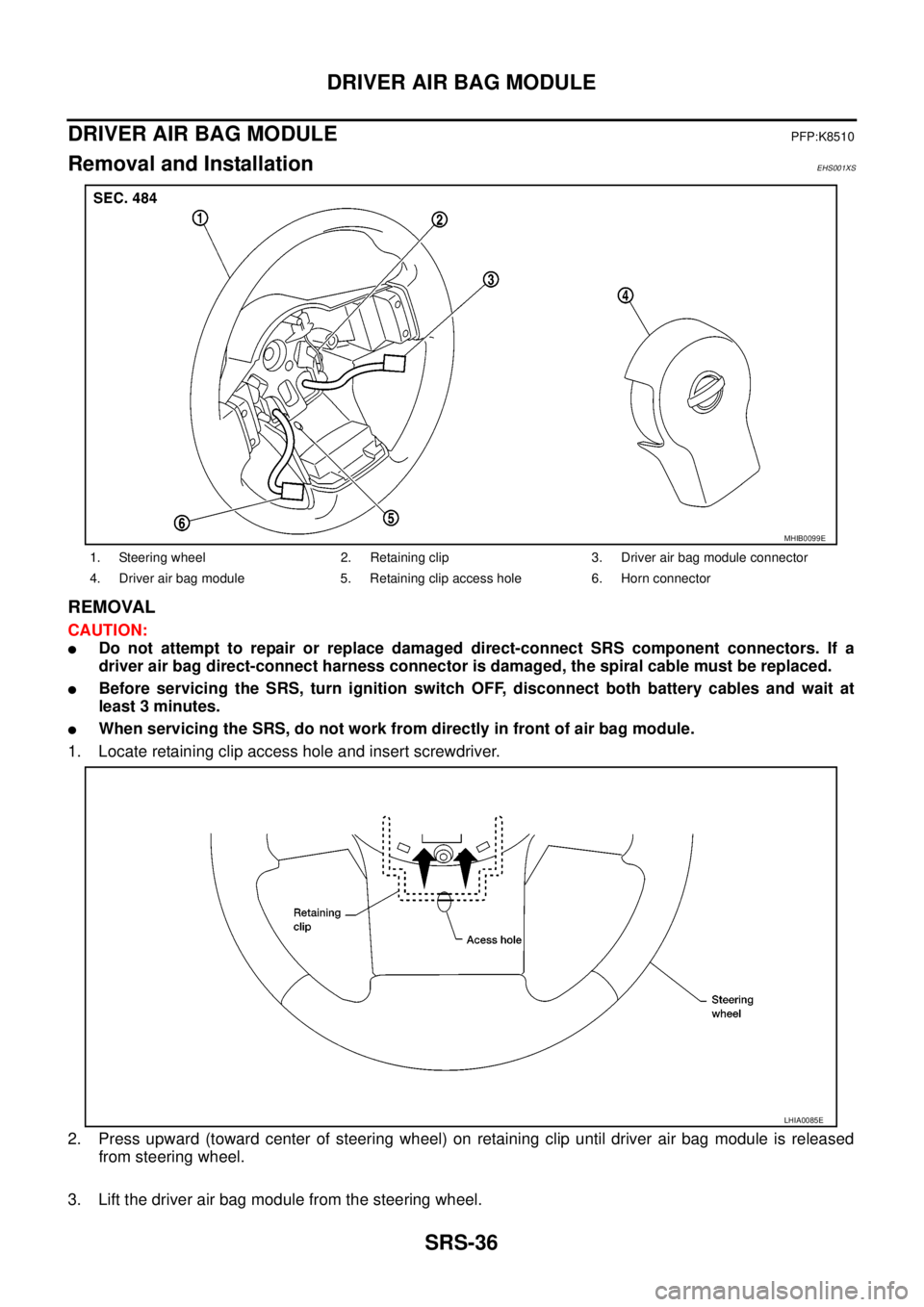

Removal and InstallationEHS001XS

REMOVAL

CAUTION:

lDo not attempt to repair or replace damaged direct-connect SRS component connectors. If a

driver air bag direct-connect harness connector is damaged, the spiral cable must be replaced.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at

least 3 minutes.

lWhen servicing the SRS, do not work from directly in front of air bag module.

1. Locate retaining clip access hole and insert screwdriver.

2. Press upward (toward center of steering wheel) on retaining clip until driver air bag module is released

from steering wheel.

3. Lift the driver air bag module from the steering wheel.

1. Steering wheel 2. Retaining clip 3. Driver air bag module connector

4. Driver air bag module 5. Retaining clip access hole 6. Horn connector

MHIB0099E

LHIA0085E

Page 2946 of 3171

DRIVER AIR BAG MODULE

SRS-37

C

D

E

F

G

I

J

K

L

MA

B

SRS

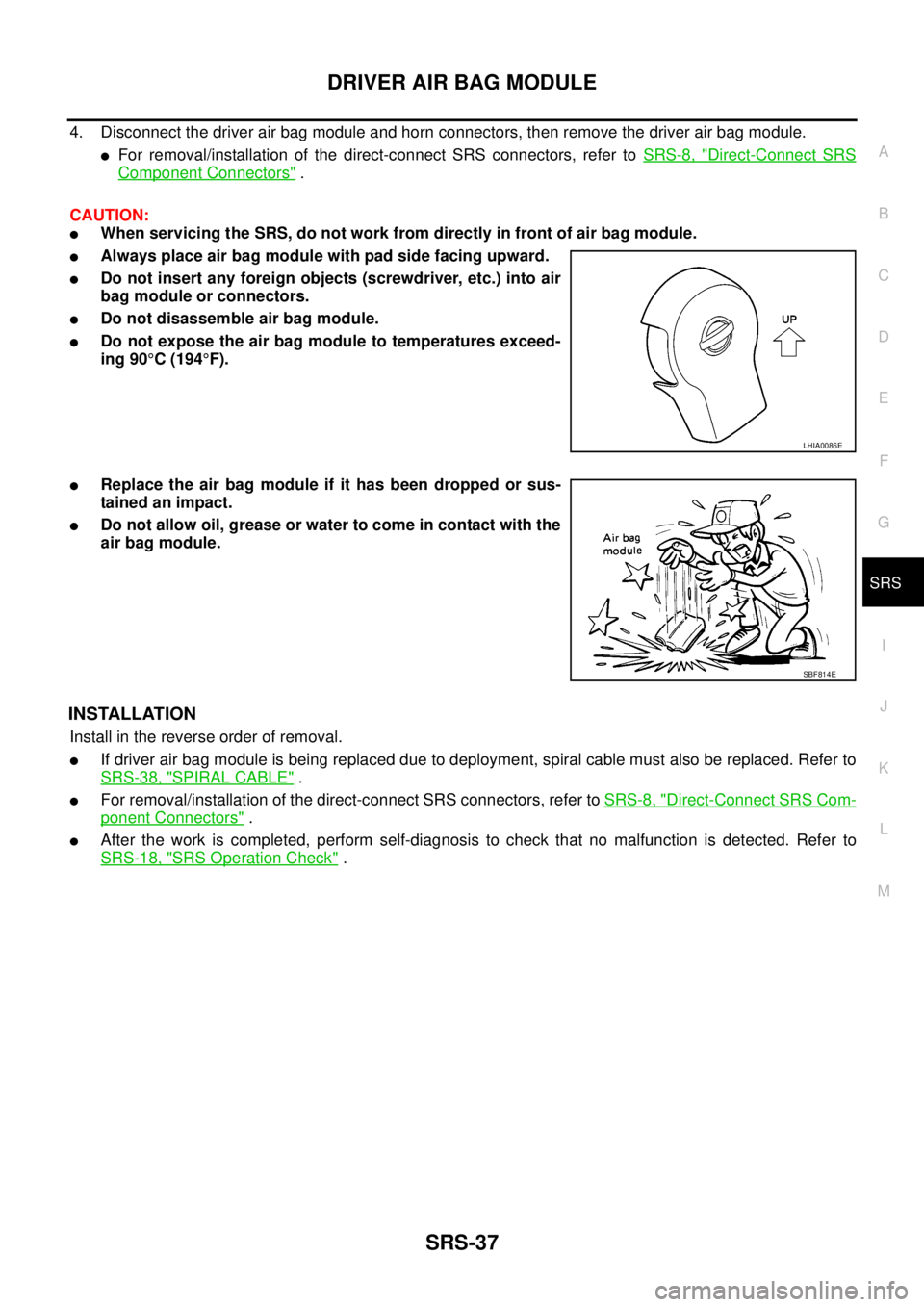

4. Disconnect the driver air bag module and horn connectors, then remove the driver air bag module.

lFor removal/installation of the direct-connect SRS connectors, refer toSRS-8, "Direct-Connect SRS

Component Connectors".

CAUTION:

lWhen servicing the SRS, do not work from directly in front of air bag module.

lAlways place air bag module with pad side facing upward.

lDo not insert any foreign objects (screwdriver, etc.) into air

bag module or connectors.

lDo not disassemble air bag module.

lDo not expose the air bag module to temperatures exceed-

ing 90°C(194°F).

lReplace the air bag module if it has been dropped or sus-

tainedanimpact.

lDo not allow oil, grease or water to come in contact with the

air bag module.

INSTALLATION

Install in the reverse order of removal.

lIf driver air bag module is being replaced due to deployment, spiral cable must also be replaced. Refer to

SRS-38, "

SPIRAL CABLE".

lFor removal/installation of the direct-connect SRS connectors, refer toSRS-8, "Direct-Connect SRS Com-

ponent Connectors".

lAfter the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRS-18, "

SRS Operation Check".

LHIA0086E

SBF814E

Page 3112 of 3171

WW-1

WIPER, WASHER & HORN

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONWW

A

B

WW

WIPER, WASHER & HORN

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

FRONT WIPER AND WASHER SYSTEM .................. 4

Components Parts and Harness Connector Loca-

tion ........................................................................... 4

System Description .................................................. 4

LOW SPEED WIPER OPERATION ...................... 5

HI SPEED WIPER OPERATION ........................... 5

INTERMITTENT OPERATION .............................. 6

AUTO STOP OPERATION .................................... 6

FRONT WASHER OPERATION ........................... 6

MIST OPERATION ................................................ 7

FAIL-SAFE FUNCTION ......................................... 7

COMBINATION SWITCH READING FUNCTION..... 8

CAN Communication System Description .............. 10

Schematic ............................................................... 11

Wiring Diagram — WIPER — ................................ 12

Terminals and Reference Values for BCM ............. 15

Terminals and Reference Values for IPDM E/R ..... 16

How To Proceed With Trouble Diagnosis ............... 16

Preliminary Inspection ............................................ 16

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ............................................. 16

CONSULT-II Function (BCM) ................................. 18

CONSULT-II OPERATION .................................. 18

WORK SUPPORT ............................................... 19

DATA MONITOR ................................................. 19

ACTIVE TEST ..................................................... 20

CONSULT-II Function (IPDM E/R) ......................... 21

CONSULT-II OPERATION .................................. 21

DATA MONITOR ................................................. 22

ACTIVE TEST ..................................................... 22

Front Wiper Does Not Operate in Rain (Front Wiper

Switch Turned to INT Position) ............................... 23

Front Wiper Does Not Operate .............................. 25

Front Wiper Does Not Return to Stop Position (After

Front Wiper for 10 Seconds, They Stop for 20 sec-onds, and After Repeating the Operations Five

Times, They Become Inoperative) .......................... 28

Only Front Wiper LO Does Not Operate ................. 29

Only Front Wiper HI Does Not Operate .................. 31

Only Front Wiper INT Does Not Operate ................ 32

Front Wiper Intermittent Operation Switch Position

Cannot Be Adjusted ................................................ 33

Front Wiper Interval Time Is Not Controlled by Vehi-

cle Speed ................................................................ 33

Wipers Do Not Wipe When Front Washer Operates... 33

Removal and Installation of Front Wiper Arms,

Adjustment of Wiper Arms Stop Location ............... 34

REMOVAL ........................................................... 34

INSTALLATION ................................................... 34

Removal and Installation of Wiper Motor and Link-

age .......................................................................... 35

REMOVAL ........................................................... 35

INSTALLATION ................................................... 35

Washer Nozzle Adjustment .................................... 36

Washer Tube Layout .............................................. 36

Removal and Installation of Wiper and Washer

Switch ..................................................................... 36

REMOVAL ........................................................... 36

INSTALLATION ................................................... 36

Removal and Installation of Front Washer Tank ..... 37

REMOVAL ........................................................... 37

INSTALLATION ................................................... 37

Removal and Installation of Front Washer Motor ... 38

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

Removal and Installation of Washer Fluid Level Sen-

sor ........................................................................... 38

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

HEADLAMP WASHER ............................................. 39

Components Parts and Harness Connector Loca-

tion .......................................................................... 39

System Description ................................................. 39

OUTLINE ............................................................. 40

HEADLAMP WASHER OPERATION .................. 40

Page 3113 of 3171

WW-2

Wiring Diagram — HLC — ..................................... 41

Terminals and Reference Values for BCM .............. 43

Terminals and Reference Values for IPDM E/R ...... 43

How to Proceed with Trouble Diagnosis ................. 44

Preliminary Check .................................................. 44

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 44

CONSULT-II Functions (BCM) ................................ 45

CONSULT-II BASIC OPERATION ....................... 45

DATA MONITOR .................................................. 46

ACTIVE TEST ..................................................... 47

CONSULT-II Functions (IPDM E/R) ........................ 48

CONSULT-II BASIC OPERATION ....................... 48

DATA MONITOR .................................................. 49

ACTIVE TEST ..................................................... 49

Headlamp Washer Does Not Operate .................... 50

Removal and Installation of Washer Nozzle ........... 53

REMOVAL ........................................................... 53

INSTALLATION .................................................... 53

Removal and Installation of Washer Tank .............. 53

Removal and Installation of Headlamp Washer

Motor ...................................................................... 53REMOVAL ............................................................ 53

INSTALLATION .................................................... 53

Washer Tube Layout ............................................... 54

CIGARETTE LIGHTER ............................................. 55

Wiring Diagram — CIGAR — .................................. 55

Removal and Installation of Cigarette Lighter ......... 56

REMOVAL ............................................................ 56

INSTALLATION .................................................... 56

POWER SOCKET ..................................................... 57

Wiring Diagram — P/SCKT — ................................ 57

Removal and Installation of Front Power Socket .... 58

REMOVAL ............................................................ 58

INSTALLATION .................................................... 58

Removal and Installation of Console Power Socket...58

REMOVAL ............................................................ 58

INSTALLATION .................................................... 58

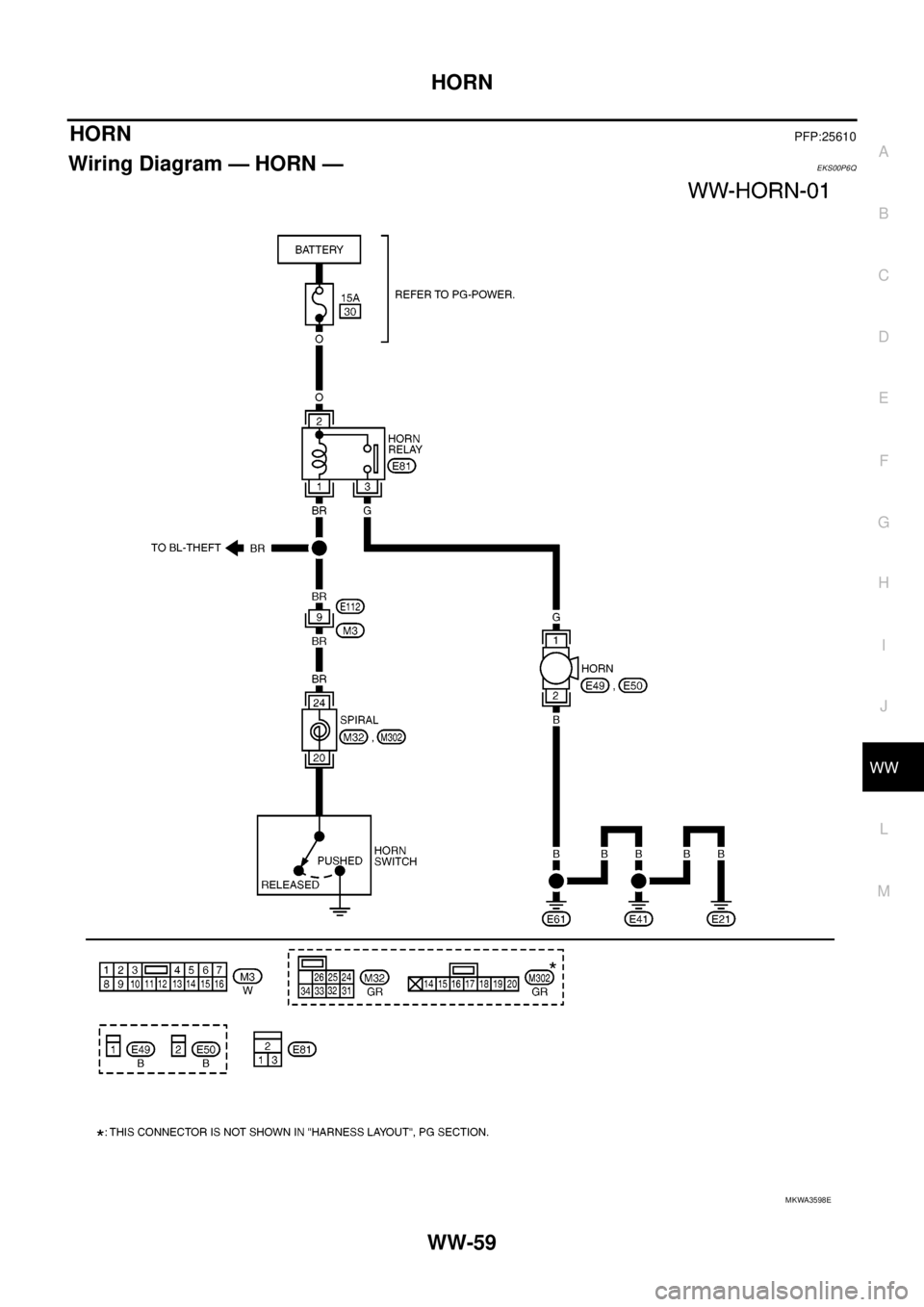

HORN ........................................................................ 59

Wiring Diagram — HORN — .................................. 59

Removal and Installation of Horn ............................ 60

REMOVAL ............................................................ 60

INSTALLATION .................................................... 60

Page 3170 of 3171

HORN

WW-59

C

D

E

F

G

H

I

J

L

MA

B

WW

HORNPFP:25610

Wiring Diagram — HORN —EKS00P6Q

MKWA3598E

Page 3171 of 3171

WW-60

HORN

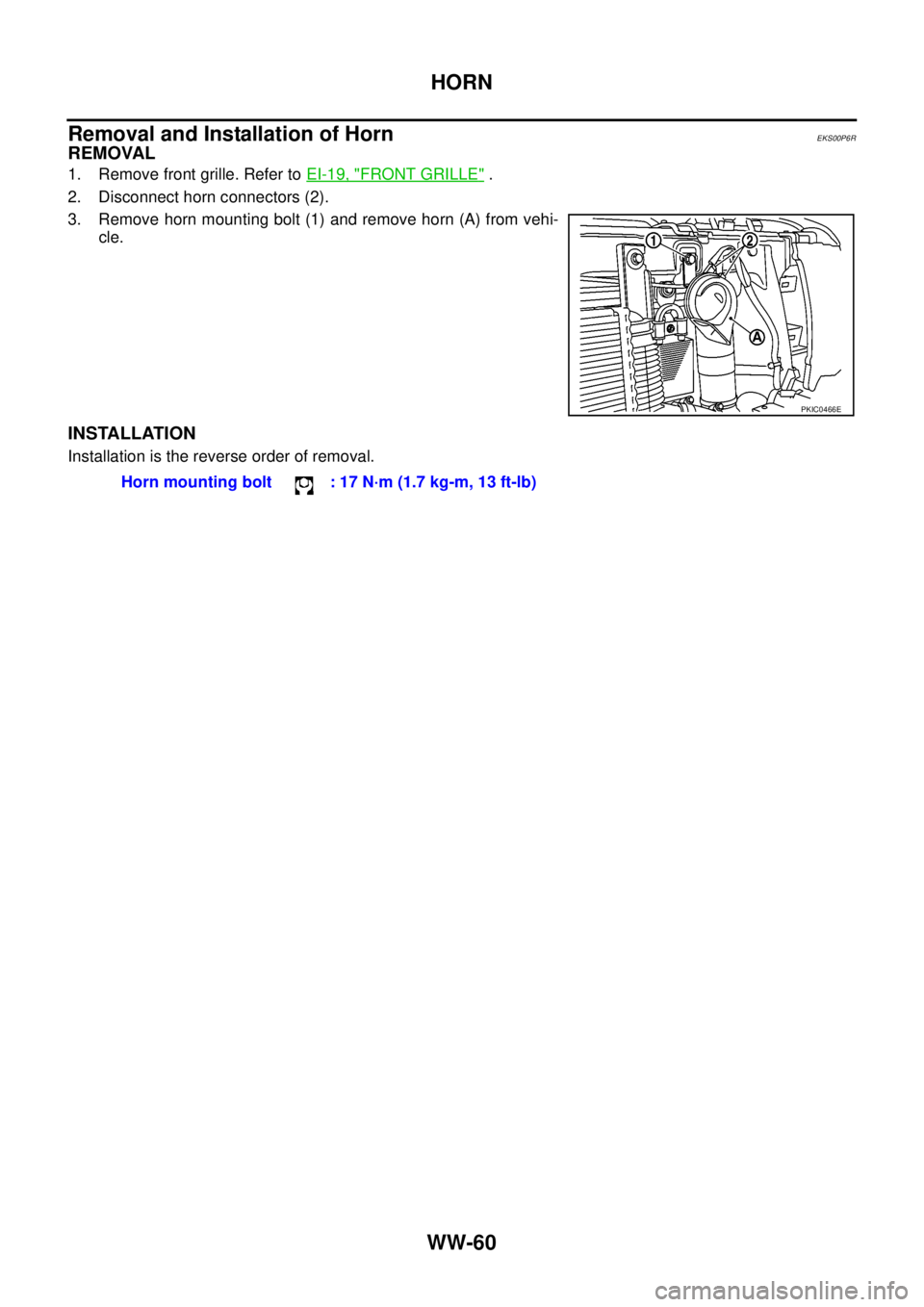

Removal and Installation of Horn

EKS00P6R

REMOVAL

1. Remove front grille. Refer toEI-19, "FRONT GRILLE".

2. Disconnect horn connectors (2).

3. Remove horn mounting bolt (1) and remove horn (A) from vehi-

cle.

INSTALLATION

Installation is the reverse order of removal.

PKIC0466E

Horn mounting bolt : 17 N·m (1.7 kg-m, 13 ft-lb)