horn NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 745 of 3171

THEFT WARNING SYSTEM

BL-161

C

D

E

F

G

H

J

K

L

MA

B

BL

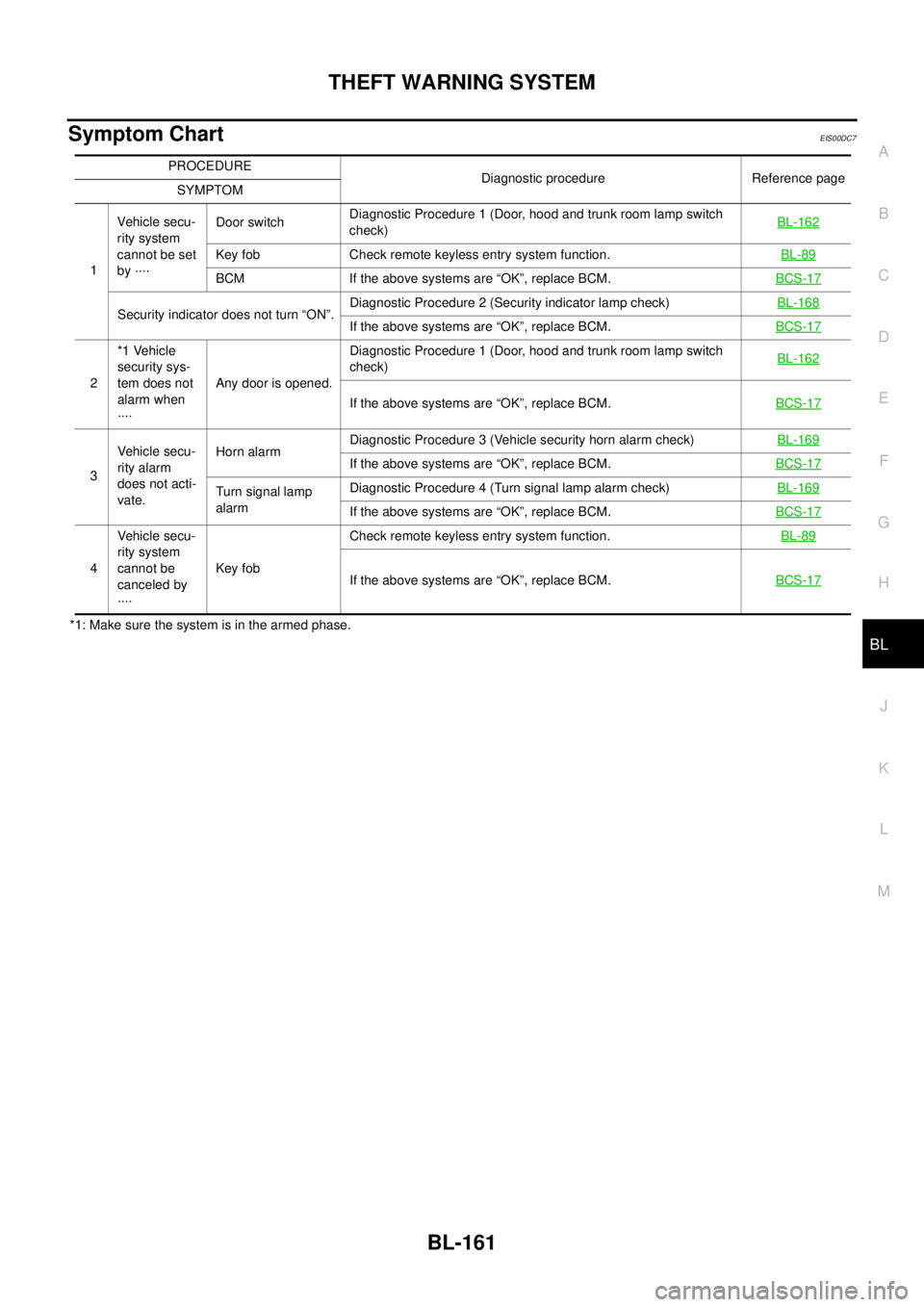

Symptom ChartEIS00DC7

*1: Make sure the system is in the armed phase.PROCEDURE

Diagnostic procedure Reference page

SYMPTOM

1Vehicle secu-

rity system

cannot be set

by ····Door switchDiagnostic Procedure 1 (Door, hood and trunk room lamp switch

check)BL-162

Key fob Check remote keyless entry system function.BL-89

BCM If the above systems are “OK”, replace BCM.BCS-17

Security indicator does not turn “ON”.Diagnostic Procedure 2 (Security indicator lamp check)BL-168If the above systems are “OK”, replace BCM.BCS-17

2*1 Vehicle

security sys-

tem does not

alarm when

····Any door is opened.Diagnostic Procedure 1 (Door, hood and trunk room lamp switch

check)BL-162

If the above systems are “OK”, replace BCM.BCS-17

3Vehicle secu-

rity alarm

does not acti-

vate.Horn alarmDiagnostic Procedure 3 (Vehicle security horn alarm check)BL-169If the above systems are “OK”, replace BCM.BCS-17

Turn signal lamp

alarmDiagnostic Procedure 4 (Turn signal lamp alarm check)BL-169

If the above systems are “OK”, replace BCM.BCS-17

4Vehicle secu-

rity system

cannot be

canceled by

····Key fobCheck remote keyless entry system function.BL-89If the above systems are “OK”, replace BCM.BCS-17

Page 753 of 3171

THEFT WARNING SYSTEM

BL-169

C

D

E

F

G

H

J

K

L

MA

B

BL

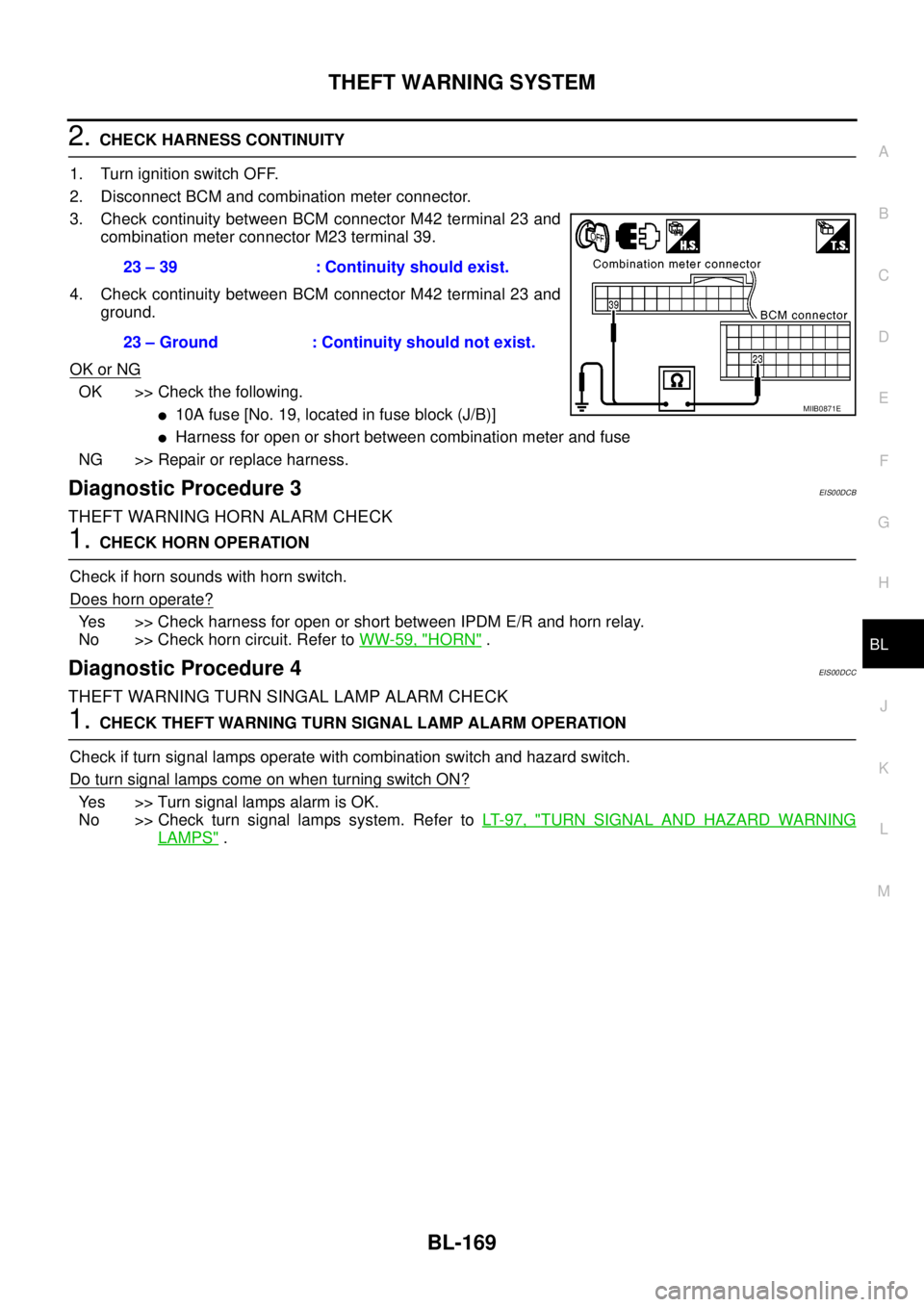

2.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and combination meter connector.

3. Check continuity between BCM connector M42 terminal 23 and

combination meter connector M23 terminal 39.

4. Check continuity between BCM connector M42 terminal 23 and

ground.

OK or NG

OK >> Check the following.

l10Afuse[No.19,locatedinfuseblock(J/B)]

lHarness for open or short between combination meter and fuse

NG >> Repair or replace harness.

Diagnostic Procedure 3EIS00DCB

THEFT WARNING HORN ALARM CHECK

1.CHECK HORN OPERATION

Check if horn sounds with horn switch.

Does horn operate?

Yes >> Check harness for open or short between IPDM E/R and horn relay.

No >> Check horn circuit. Refer toWW-59, "

HORN".

Diagnostic Procedure 4EIS00DCC

THEFT WARNING TURN SINGAL LAMP ALARM CHECK

1.CHECK THEFT WARNING TURN SIGNAL LAMP ALARM OPERATION

Check if turn signal lamps operate with combination switch and hazard switch.

DoturnsignallampscomeonwhenturningswitchON?

Yes >> Turn signal lamps alarm is OK.

No >> Check turn signal lamps system. Refer toLT- 9 7 , "

TURN SIGNAL AND HAZARD WARNING

LAMPS". 23 – 39 : Continuity should exist.

23 – Ground : Continuity should not exist.

MIIB0871E

Page 897 of 3171

RADIATOR

CO-13

C

D

E

F

G

H

I

J

K

L

MA

CO

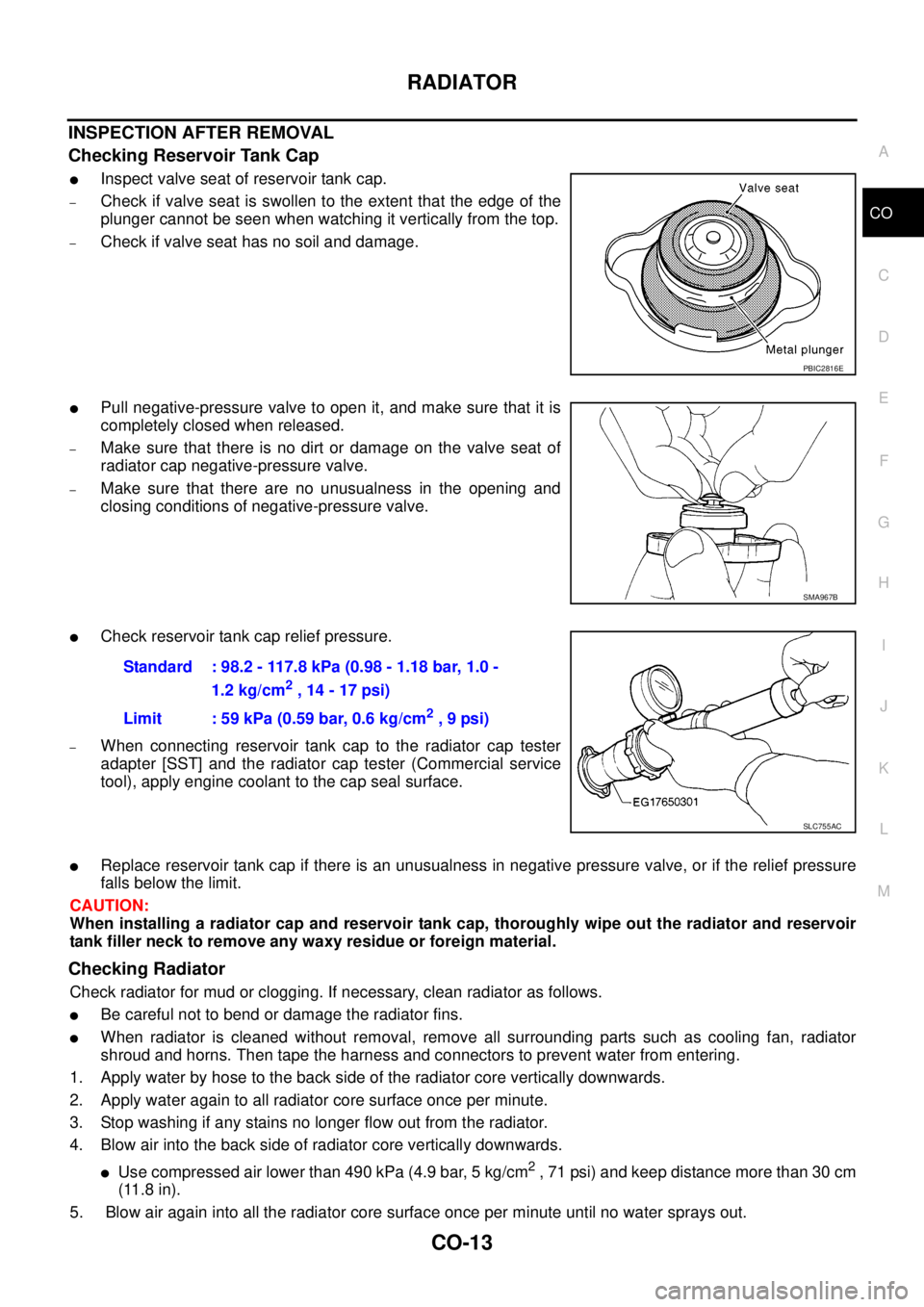

INSPECTION AFTER REMOVAL

Checking Reservoir Tank Cap

lInspect valve seat of reservoir tank cap.

–Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

–Check if valve seat has no soil and damage.

lPull negative-pressure valve to open it, and make sure that it is

completely closed when released.

–Make sure that there is no dirt or damage on the valve seat of

radiator cap negative-pressure valve.

–Make sure that there are no unusualness in the opening and

closing conditions of negative-pressure valve.

lCheck reservoir tank cap relief pressure.

–When connecting reservoir tank cap to the radiator cap tester

adapter [SST] and the radiator cap tester (Commercial service

tool), apply engine coolant to the cap seal surface.

lReplace reservoir tank cap if there is an unusualness in negative pressure valve, or if the relief pressure

falls below the limit.

CAUTION:

When installing a radiator cap and reservoir tank cap, thoroughly wipe out the radiator and reservoir

tank filler neck to remove any waxy residue or foreign material.

Checking Radiator

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kPa (4.9 bar, 5 kg/cm2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

PBIC2816E

SMA967B

Standard : 98.2 - 117.8 kPa (0.98 - 1.18 bar, 1.0 -

1.2 kg/cm

2,14-17psi)

Limit : 59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

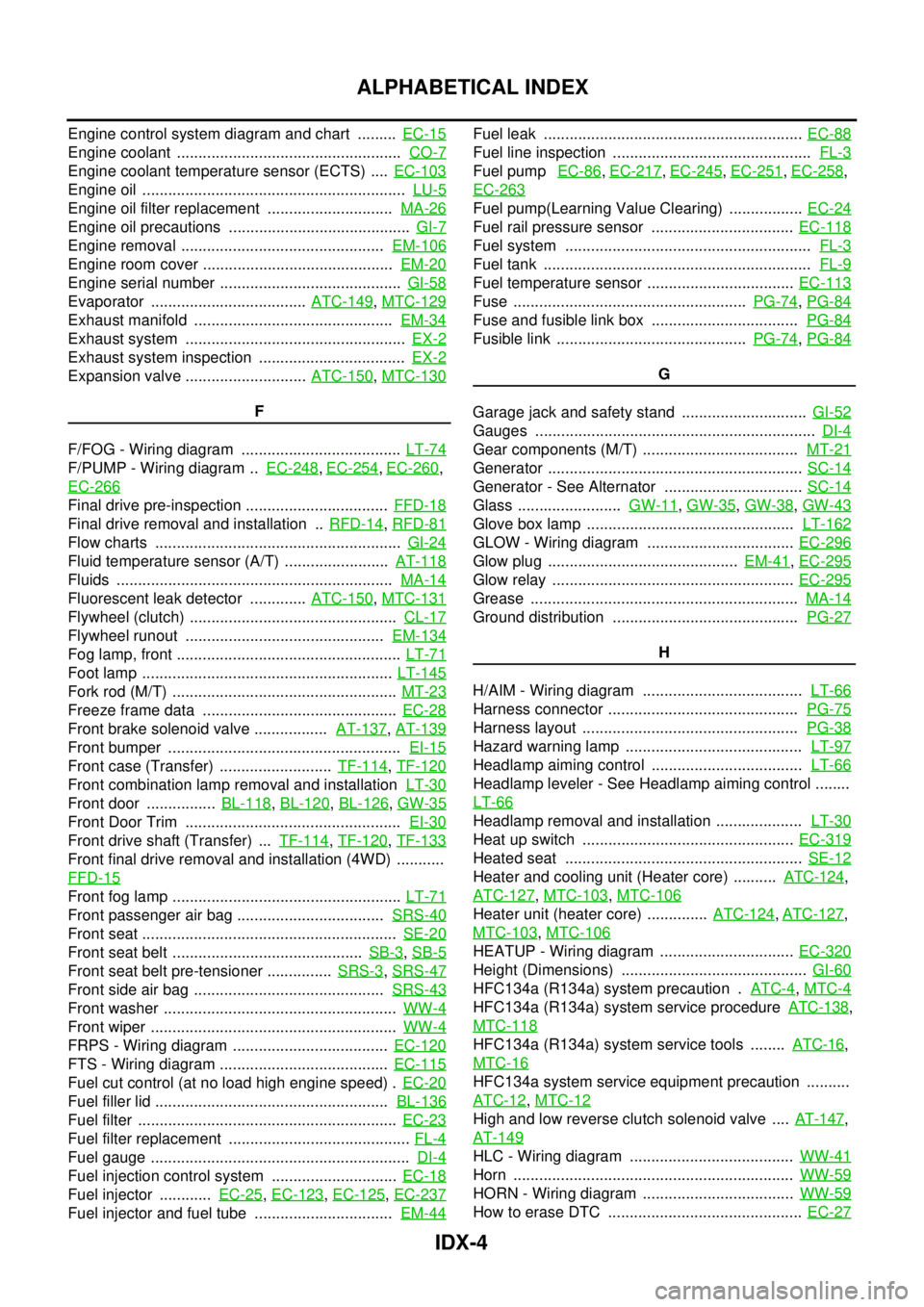

Page 1756 of 3171

IDX-4

ALPHABETICAL INDEX

Engine control system diagram and chart .........EC-15

Engine coolant ....................................................CO-7

Engine coolant temperature sensor (ECTS) ....EC-103

Engine oil .............................................................LU-5

Engine oil filter replacement .............................MA-26

Engine oil precautions ..........................................GI-7

Engine removal ...............................................EM-106

Engine room cover ............................................EM-20

Engine serial number ..........................................GI-58

Evaporator ....................................ATC-149,MTC-129

Exhaust manifold ..............................................EM-34

Exhaust system ...................................................EX-2

Exhaust system inspection ..................................EX-2

Expansion valve ............................ATC-150,MTC-130

F

F/FOG - Wiring diagram .....................................LT-74

F/PUMP - Wiring diagram ..EC-248,EC-254,EC-260,

EC-266

Final drive pre-inspection .................................FFD-18

Final drive removal and installation ..RFD-14,RFD-81

Flow charts .........................................................GI-24

Fluid temperature sensor (A/T) ........................AT-118

Fluids ................................................................MA-14

Fluorescent leak detector .............ATC-150,MTC-131

Flywheel (clutch) ................................................CL-17

Flywheel runout ..............................................EM-134

Fog lamp, front ....................................................LT-71

Foot lamp ..........................................................LT-145

Fork rod (M/T) ....................................................MT-23

Freeze frame data .............................................EC-28

Front brake solenoid valve .................AT-137,AT-139

Front bumper ......................................................EI-15

Front case (Transfer) ..........................TF-114,TF-120

Front combination lamp removal and installationLT-30

Front door ................BL-118,BL-120,BL-126,GW-35

Front Door Trim ..................................................EI-30

Front drive shaft (Transfer) ...TF-114,TF-120,TF-133

Front final drive removal and installation (4WD) ...........

FFD-15

Front fog lamp .....................................................LT-71

Front passenger air bag ..................................SRS-40

Front seat ...........................................................SE-20

Front seat belt ............................................SB-3,SB-5

Front seat belt pre-tensioner ...............SRS-3,SRS-47

Front side air bag ............................................SRS-43

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FRPS - Wiring diagram ....................................EC-120

FTS - Wiring diagram .......................................EC-115

Fuel cut control (at no load high engine speed) .EC-20

Fuel filler lid ......................................................BL-136

Fuel filter ............................................................EC-23

Fuel filter replacement ..........................................FL-4

Fuel gauge ............................................................DI-4

Fuel injection control system .............................EC-18

Fuel injector ............EC-25,EC-123,EC-125,EC-237

Fuel injector and fuel tube ................................EM-44

Fuel leak ............................................................EC-88

Fuel line inspection ..............................................FL-3

Fuel pumpEC-86,EC-217,EC-245,EC-251,EC-258,

EC-263

Fuel pump(Learning Value Clearing) .................EC-24

Fuel rail pressure sensor .................................EC-118

Fuel system .........................................................FL-3

Fuel tank ..............................................................FL-9

Fuel temperature sensor ..................................EC-113

Fuse ......................................................PG-74,PG-84

Fuse and fusible link box ..................................PG-84

Fusible link ............................................PG-74,PG-84

G

Garage jack and safety stand .............................GI-52

Gauges .................................................................DI-4

Gear components (M/T) ....................................MT-21

Generator ...........................................................SC-14

Generator - See Alternator ................................SC-14

Glass ........................GW-11,GW-35,GW-38,GW-43

Glove box lamp ................................................LT-162

GLOW - Wiring diagram ..................................EC-296

Glow plug ............................................EM-41,EC-295

Glow relay ........................................................EC-295

Grease ..............................................................MA-14

Ground distribution ...........................................PG-27

H

H/AIM - Wiring diagram .....................................LT-66

Harness connector ............................................PG-75

Harness layout ..................................................PG-38

Hazard warning lamp .........................................LT-97

Headlamp aiming control ...................................LT-66

Headlamp leveler - See Headlamp aiming control ........

LT-66

Headlamp removal and installation ....................LT-30

Heat up switch .................................................EC-319

Heated seat .......................................................SE-12

Heater and cooling unit (Heater core) ..........ATC-124,

ATC-127

,MTC-103,MTC-106

Heater unit (heater core) ..............ATC-124,ATC-127,

MTC-103

,MTC-106

HEATUP - Wiring diagram ...............................EC-320

Height (Dimensions) ...........................................GI-60

HFC134a (R134a) system precaution .ATC-4,MTC-4

HFC134a (R134a) system service procedureATC-138,

MTC-118

HFC134a (R134a) system service tools ........ATC-16,

MTC-16

HFC134a system service equipment precaution ..........

ATC-12

,MTC-12

High and low reverse clutch solenoid valve ....AT-147,

AT-149

HLC - Wiring diagram ......................................WW-41

Horn .................................................................WW-59

HORN - Wiring diagram ...................................WW-59

How to erase DTC .............................................EC-27

Page 1810 of 3171

![NISSAN NAVARA 2005 Repair User Guide CAN COMMUNICATION

LAN-33

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Input/output signal chart

T: Transmit R: Receive

Signals ECMNAVI con-

trol unitFront air

controlBCMCombina-

tion meterABS actua-

tor and

elect NISSAN NAVARA 2005 Repair User Guide CAN COMMUNICATION

LAN-33

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Input/output signal chart

T: Transmit R: Receive

Signals ECMNAVI con-

trol unitFront air

controlBCMCombina-

tion meterABS actua-

tor and

elect](/img/5/57362/w960_57362-1809.png)

CAN COMMUNICATION

LAN-33

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Input/output signal chart

T: Transmit R: Receive

Signals ECMNAVI con-

trol unitFront air

controlBCMCombina-

tion meterABS actua-

tor and

electric unit

(control

unit)IPDM E/R

A/C compressor request signal TR

ASCD CRUISE lamp signal T R

ASCD SET lamp signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow relay signal T R

Malfunction indicator signal T R

A/C switch/indicator signal T

R

*

PTC heater signal R T

A/C switch signal R

R

*T

Buzzer output signal T R

Day time running light request signal R T R R

Door switch signal T R R

Front fog light request signal R T R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signal T R

Low beam request signal T R

Position light request signal T R R

Rear fog light request signal R T R

Rear window defogger switch signal

R

*TR

Sleep wake up signal T R R

Theft warning horn request signal T R

Trailer lamp signal T R

Turn indicator signal T R

Distance to empty signal R T

Fuel level low warning signal R T

ABS warning lamp signalRT

Vehicle speed signalR

*RT

RR

R

*RT

Front wiper stop position signal R T

Hood switch signal R T

Oil pressure switch signalRT

Rear window defogger control signal R T

Page 1812 of 3171

![NISSAN NAVARA 2005 Repair User Guide CAN COMMUNICATION

LAN-35

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

En NISSAN NAVARA 2005 Repair User Guide CAN COMMUNICATION

LAN-35

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

En](/img/5/57362/w960_57362-1811.png)

CAN COMMUNICATION

LAN-35

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow relay signal T R

Malfunction indicator signal T R

Wide open throttle position signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal T R

OD OFF indicator lamp signal T R

Output shaft revolution signal R T

Turbine revolution signal R T

A/C switch/indicator signal T R

PTC heater signal R T

A/C switch signal R R T

Buzzer output signal T R

Day time running light request signal R T R R

Door switch signalTR R

Front fog light request signal R T R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signalTR

Low beam request signal T R

Position light request signal T R R

Rear fog light request signal R T R

Rear window defogger switch signal R T R

Sleep wake up signal T R R

Theft warning horn request signal T R

Trailer lamp signalTR

Turn indicator signal T R

1st position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Overdrive control switch signal R T

Stop lamp switch signal R T

ABS operation signal R T

ABS warning lamp signalRT Signals ECM TCMNAVI

control

unitFront air

controlBCMCombi-

nation

meterABS

actuator

and elec-

tric unit

(control

unit)IPDM

E/R

Page 1816 of 3171

![NISSAN NAVARA 2005 Repair User Guide CAN COMMUNICATION

LAN-39

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Input/output signal chart

T: Transmit R: Receive

Signals ECMNAVI

control

unitDiffer-

ential

lock

control

unitFront air

con-

trol

*1BCMCombi-

n NISSAN NAVARA 2005 Repair User Guide CAN COMMUNICATION

LAN-39

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Input/output signal chart

T: Transmit R: Receive

Signals ECMNAVI

control

unitDiffer-

ential

lock

control

unitFront air

con-

trol

*1BCMCombi-

n](/img/5/57362/w960_57362-1815.png)

CAN COMMUNICATION

LAN-39

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Input/output signal chart

T: Transmit R: Receive

Signals ECMNAVI

control

unitDiffer-

ential

lock

control

unitFront air

con-

trol

*1BCMCombi-

nation

meterTrans-

fer con-

trol unitABS

actua-

tor and

electric

unit

(control

unit)IPDM

E/R

A/C compressor request signal TR

ASCD CRUISE lamp signal T R

ASCD SET lamp signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow relay signal T R

Malfunction indicator signal T R

A/C switch/indicator signal T

R

*2

Differential lock indicator signal T R

Differential lock switch signal T R

PTC heater signal

*3RT

A/C switch signal R

R

*2T

Buzzer output signal T R

Day time running light request signal R T R R

Door switch signal T R R

Front fog light request signal R T R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signal T R

Low beam request signal T R

Position light request signal T R R

Rear fog light request signal R T R

Rear window defogger switch signal R T R

Sleep wake up signal T R R

Theft warning horn request signal T R

Trailer lamp signal T R

Turn indicator signal T R

Distance to empty signal R T

Fuel level low warning signal R T

4WD shift switch signal R T

ABS warning lamp signal R T

Stop lamp switch signalRT

Page 1819 of 3171

![NISSAN NAVARA 2005 Repair User Guide LAN-42

[CAN]

CAN COMMUNICATION

Engine coolant temperature signal T R R

Engine speed signal T R R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow rela NISSAN NAVARA 2005 Repair User Guide LAN-42

[CAN]

CAN COMMUNICATION

Engine coolant temperature signal T R R

Engine speed signal T R R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow rela](/img/5/57362/w960_57362-1818.png)

LAN-42

[CAN]

CAN COMMUNICATION

Engine coolant temperature signal T R R

Engine speed signal T R R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow relay signal T R

Malfunction indicator signal T R

Wide open throttle position signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal T R R

OD OFF indicator lamp signal T R

Output shaft revolution signal R T R

Turbine revolution signal R T

A/C switch/indicator signal T R

Differential lock indicator signal T R

Differential lock switch signal T R

PTC heater signal

*RT

A/C switch signal R R T

Buzzer output signal T R

Day time running light request signal R T R R

Door switch signal T R R

Front fog light request signal R T R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signalTR

Low beam request signal T R

Position light request signal T R R

Rear fog light request signal R T R

Rear window defogger switch signal R T R

Sleepwakeupsignal T R R

Theft warning horn request signal T R

Trailer lamp signal T R

Turn indicator signal T R

1st position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Overdrive control switch signal R T

Stop lamp switch signal R TSignals ECM TCMNAVI

con-

trol

unitDiffer-

ential

lock

con-

trol

unitFront

air

controlBCMCom-

bina-

tion

meterTrans-

fer

con-

trol

unitABS

actua-

tor and

elec-

tric unit

(con-

trol

unit)IPDM

E/R

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)

Page 2296 of 3171

ENGINE MAINTENANCE

MA-21

C

D

E

F

G

H

I

J

K

MA

B

MA

11. Repeat step 10 three times.

12. If sound is heard, bleed air from cooling system by repeating steps 3 through 6 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer toMA-19, "

DRAINING ENGINE COOLANT".

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS001JR

WARNING:

Never remove the radiator cap and reservoir tank cap when the engine is hot. Serious burns could

occur from high pressure engine coolant escaping from the radiator and the reservoir tank. Wrap a

thick cloth around the cap. Slowly turn it a quarter turn to allow built-up pressure to escape. Carefully

remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (4.9 bar, 5 kg/cm2, 71psi) and keep distance more than 30

cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

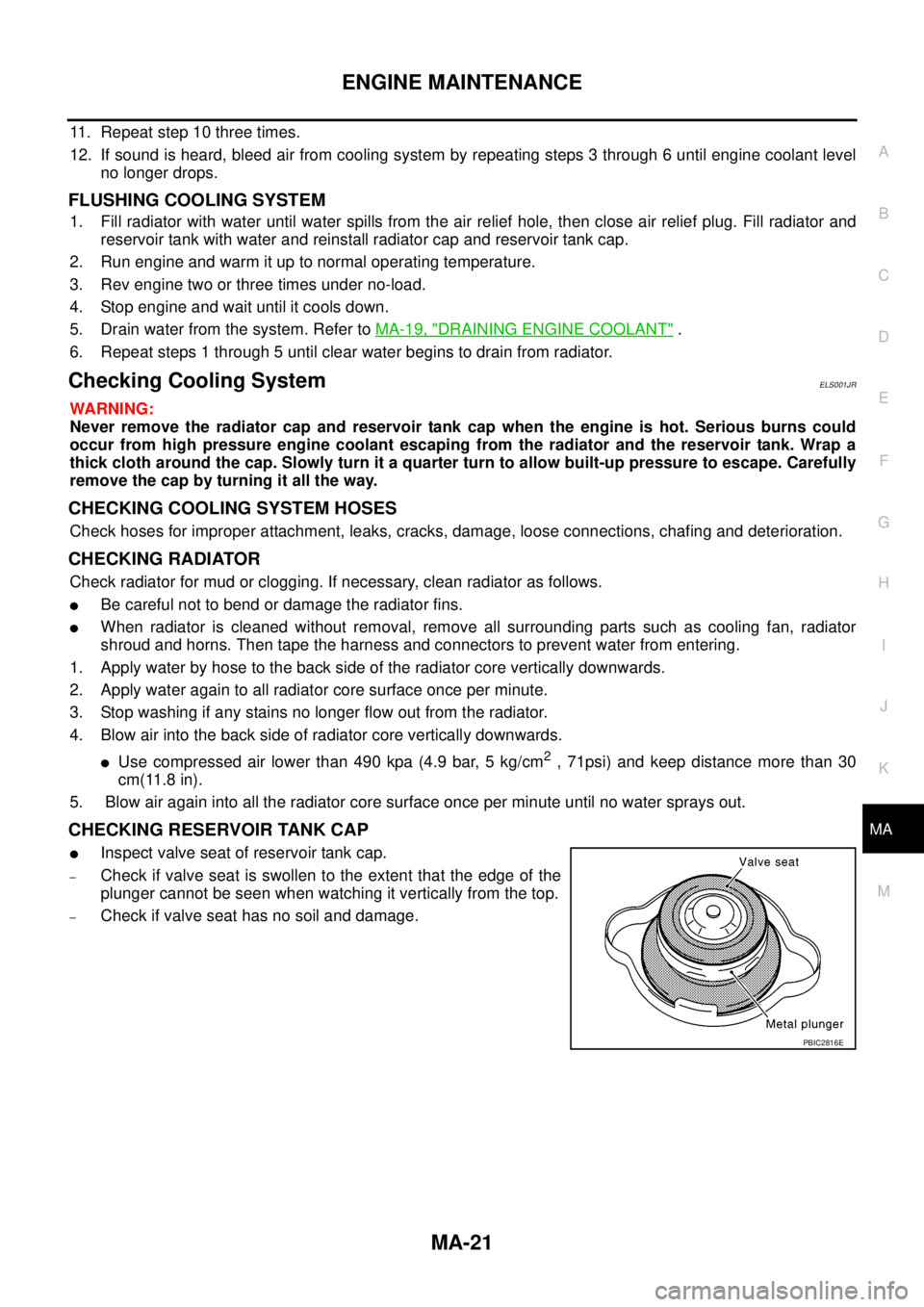

CHECKING RESERVOIR TANK CAP

lInspect valve seat of reservoir tank cap.

–Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

–Check if valve seat has no soil and damage.

PBIC2816E