wheel NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 816 of 3171

BR-30

REAR DRUM BRAKE

REAR DRUM BRAKE

PFP:43206

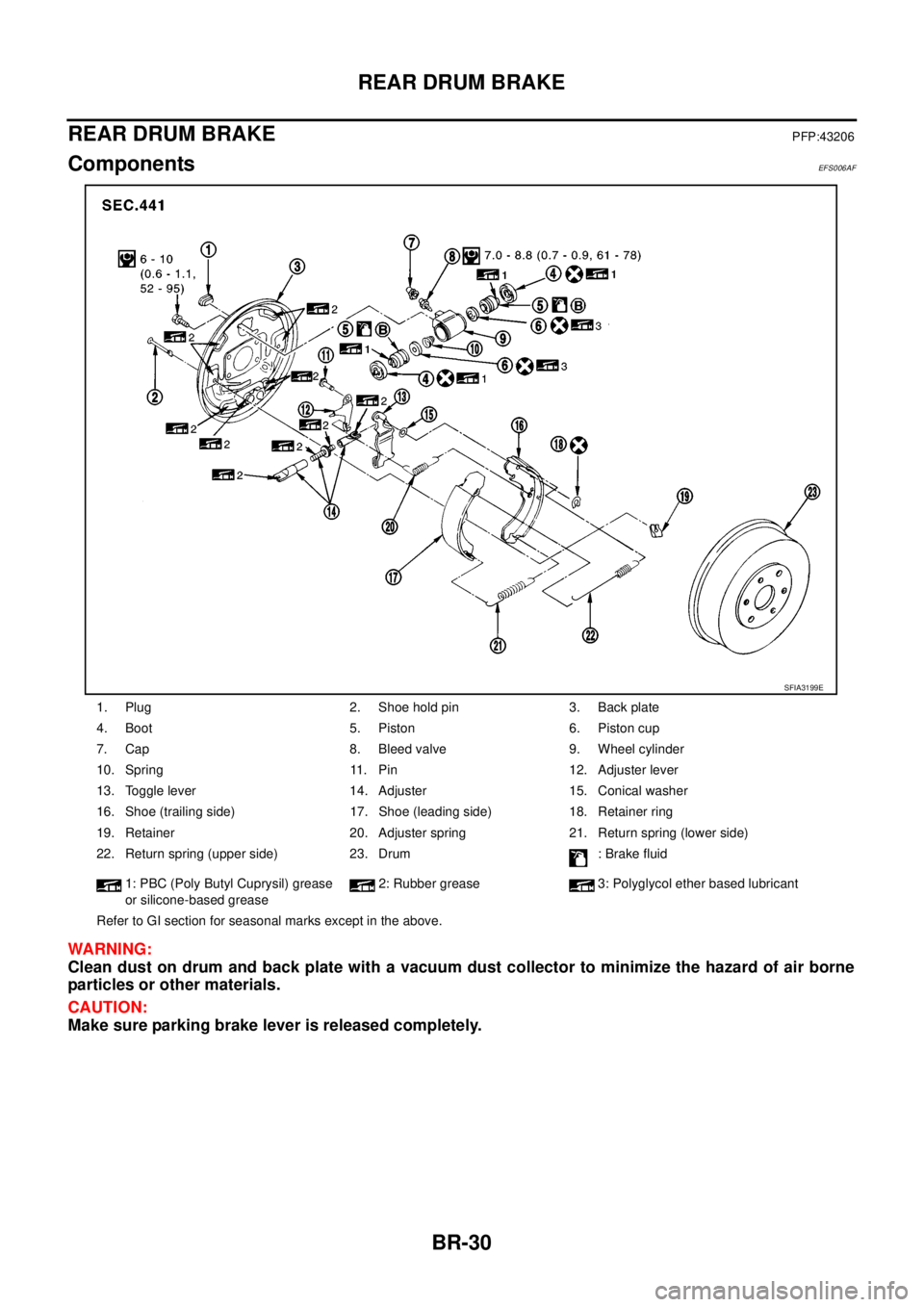

ComponentsEFS006AF

WARNING:

Clean dust on drum and back plate with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

Make sure parking brake lever is released completely.

1. Plug 2. Shoe hold pin 3. Back plate

4. Boot 5. Piston 6. Piston cup

7. Cap 8. Bleed valve 9. Wheel cylinder

10. Spring 11. Pin 12. Adjuster lever

13. Toggle lever 14. Adjuster 15. Conical washer

16. Shoe (trailing side) 17. Shoe (leading side) 18. Retainer ring

19. Retainer 20. Adjuster spring 21. Return spring (lower side)

22. Return spring (upper side) 23. Drum : Brake fluid

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease2: Rubber grease 3: Polyglycol ether based lubricant

Refer to GI section for seasonal marks except in the above.

SFIA3199E

Page 817 of 3171

REAR DRUM BRAKE

BR-31

C

D

E

G

H

I

J

K

L

MA

B

BR

Removal and Installation of Drum Brake AssemblyEFS006AG

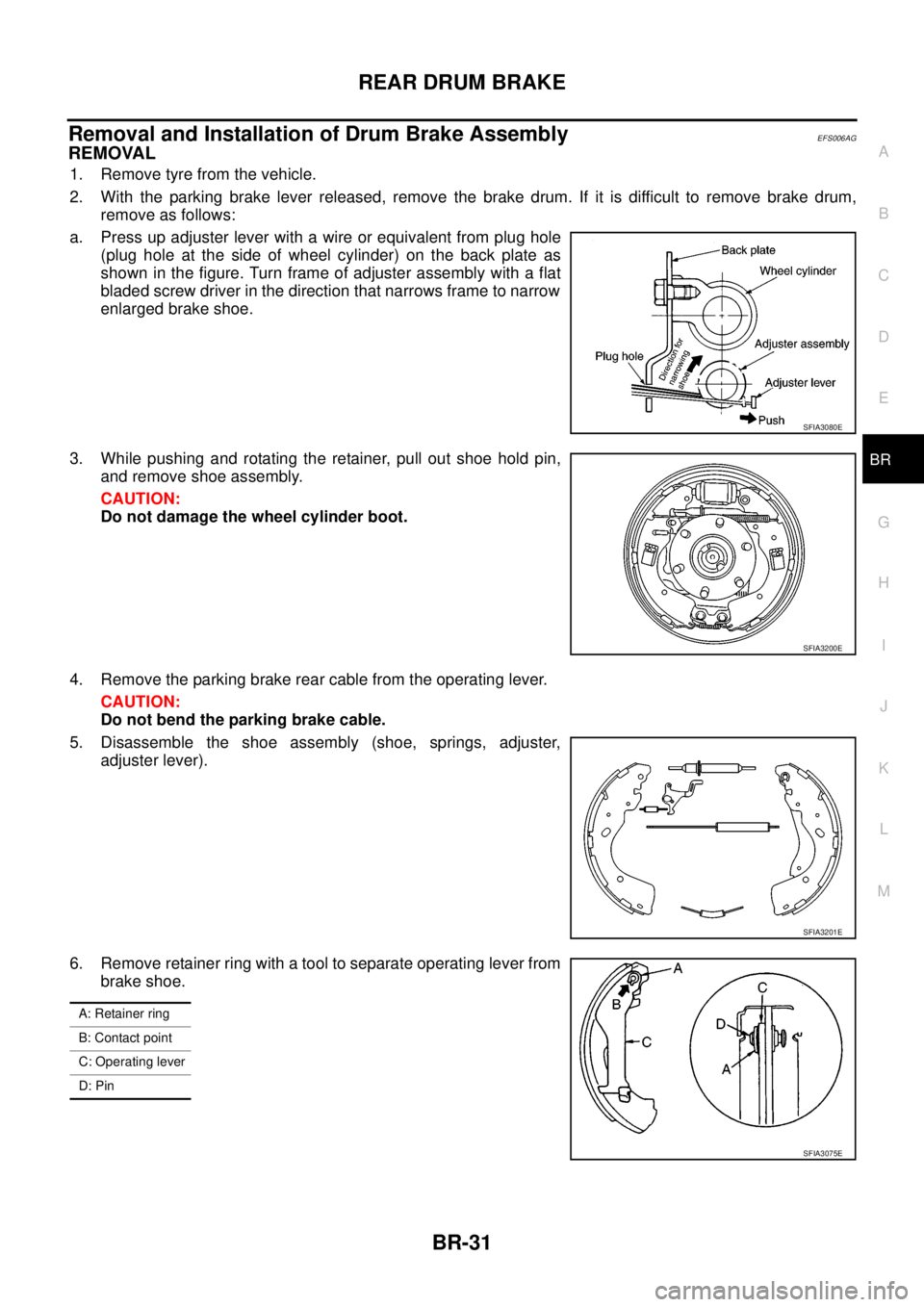

REMOVAL

1. Remove tyre from the vehicle.

2. With the parking brake lever released, remove the brake drum. If it is difficult to remove brake drum,

remove as follows:

a. Press up adjuster lever with a wire or equivalent from plug hole

(plug hole at the side of wheel cylinder) on the back plate as

shown in the figure. Turn frame of adjuster assembly with a flat

bladed screw driver in the direction that narrows frame to narrow

enlarged brake shoe.

3. While pushing and rotating the retainer, pull out shoe hold pin,

and remove shoe assembly.

CAUTION:

Do not damage the wheel cylinder boot.

4. Remove the parking brake rear cable from the operating lever.

CAUTION:

Do not bend the parking brake cable.

5. Disassemble the shoe assembly (shoe, springs, adjuster,

adjuster lever).

6. Remove retainer ring with a tool to separate operating lever from

brake shoe.

SFIA3080E

SFIA3200E

SFIA3201E

A: Retainer ring

B: Contact point

C: Operating lever

D: Pin

SFIA3075E

Page 818 of 3171

BR-32

REAR DRUM BRAKE

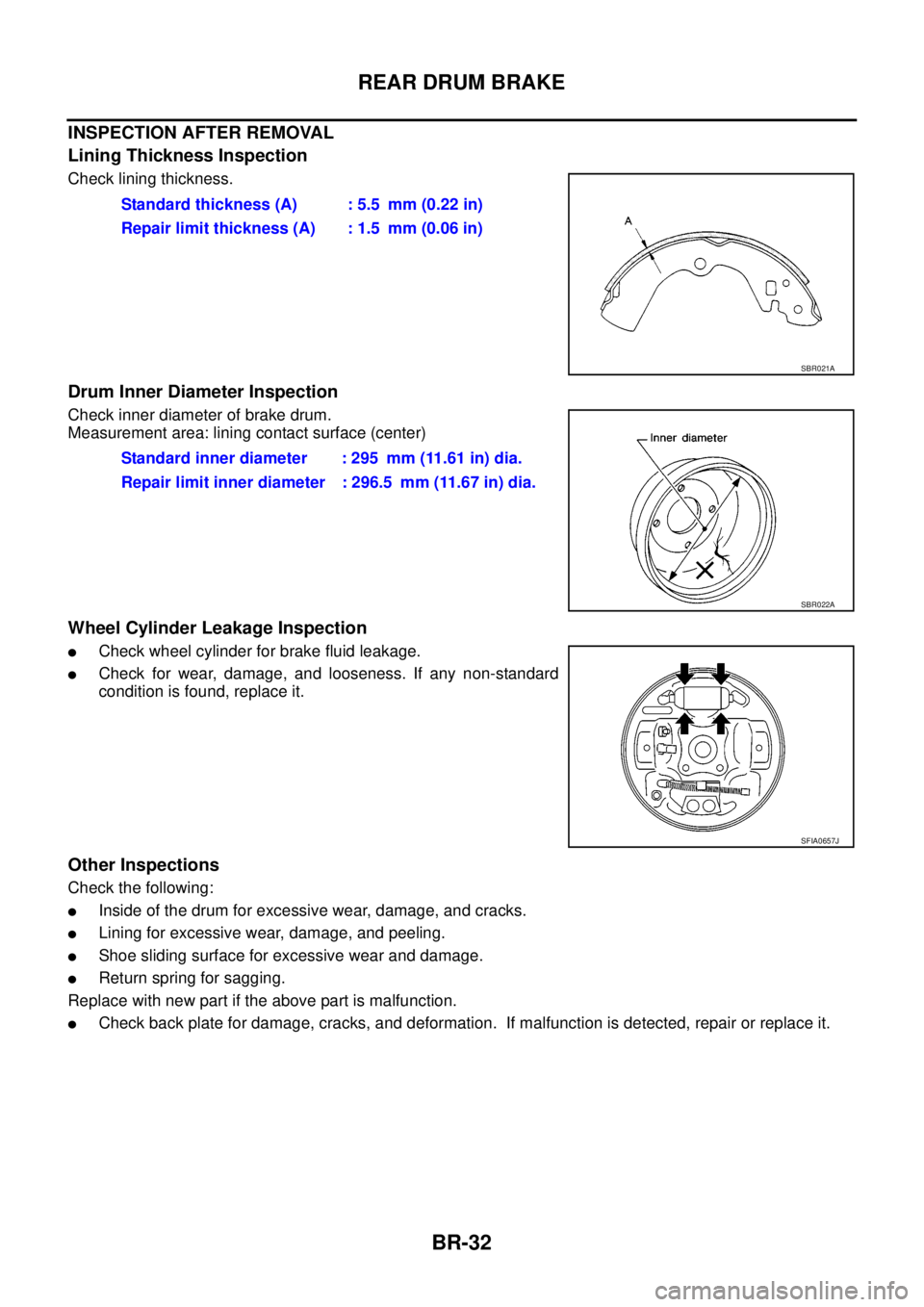

INSPECTION AFTER REMOVAL

Lining Thickness Inspection

Check lining thickness.

Drum Inner Diameter Inspection

Check inner diameter of brake drum.

Measurement area: lining contact surface (center)

Wheel Cylinder Leakage Inspection

lCheck wheel cylinder for brake fluid leakage.

lCheck for wear, damage, and looseness. If any non-standard

condition is found, replace it.

Other Inspections

Check the following:

lInside of the drum for excessive wear, damage, and cracks.

lLining for excessive wear, damage, and peeling.

lShoe sliding surface for excessive wear and damage.

lReturn spring for sagging.

Replace with new part if the above part is malfunction.

lCheck back plate for damage, cracks, and deformation. If malfunction is detected, repair or replace it.Standard thickness (A) : 5.5 mm (0.22 in)

Repair limit thickness (A) : 1.5 mm (0.06 in)

SBR021A

Standard inner diameter : 295 mm (11.61 in) dia.

Repair limit inner diameter : 296.5 mm (11.67 in) dia.

SBR022A

SFIA0657J

Page 819 of 3171

REAR DRUM BRAKE

BR-33

C

D

E

G

H

I

J

K

L

MA

B

BR

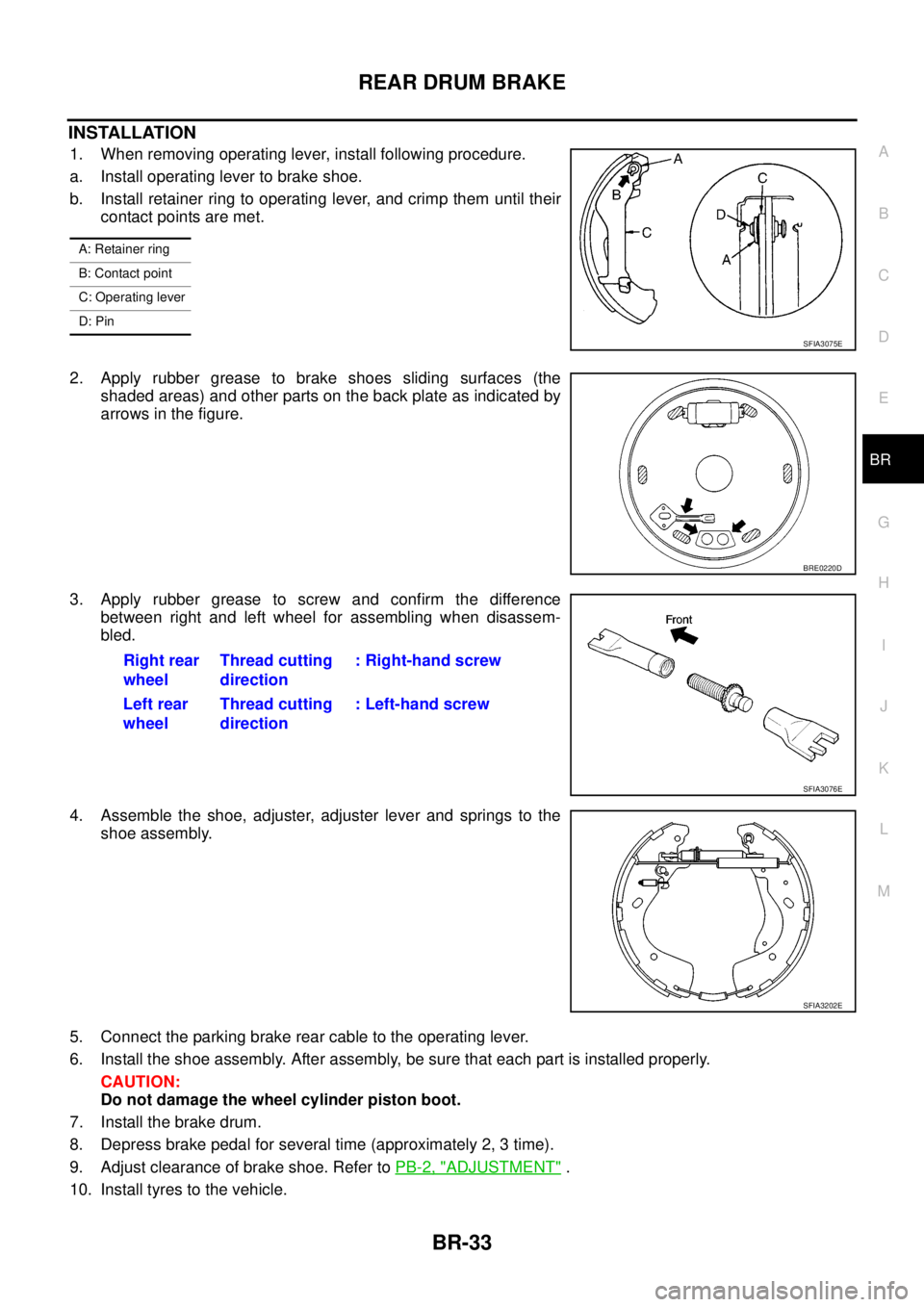

INSTALLATION

1. When removing operating lever, install following procedure.

a. Install operating lever to brake shoe.

b. Install retainer ring to operating lever, and crimp them until their

contact points are met.

2. Apply rubber grease to brake shoes sliding surfaces (the

shaded areas) and other parts on the back plate as indicated by

arrows in the figure.

3. Apply rubber grease to screw and confirm the difference

between right and left wheel for assembling when disassem-

bled.

4. Assemble the shoe, adjuster, adjuster lever and springs to the

shoe assembly.

5. Connect the parking brake rear cable to the operating lever.

6. Install the shoe assembly. After assembly, be sure that each part is installed properly.

CAUTION:

Do not damage the wheel cylinder piston boot.

7. Install the brake drum.

8. Depress brake pedal for several time (approximately 2, 3 time).

9. Adjust clearance of brake shoe. Refer toPB-2, "

ADJUSTMENT".

10. Install tyres to the vehicle.

A: Retainer ring

B: Contact point

C: Operating lever

D: Pin

SFIA3075E

BRE0220D

Right rear

wheelThread cutting

direction: Right-hand screw

Left rear

wheelThread cutting

direction: Left-hand screw

SFIA3076E

SFIA3202E

Page 820 of 3171

BR-34

REAR DRUM BRAKE

Removal and Installation of Wheel Cylinder

EFS006AH

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Remove rear brake shoe assembly.

3. Remove brake tube from the wheel cylinder.

4. Remove bolts on the wheel cylinder, and then remove wheel cylinder from the back plate.

INSTALLATION

lInstallation is the reverse order of removal. Tighten bolts to the specified torque. Refer toBR-30, "Compo-

nents".

lRefill with new brake fluid and bleed air. Refer toBR-11, "Bleeding Brake System".

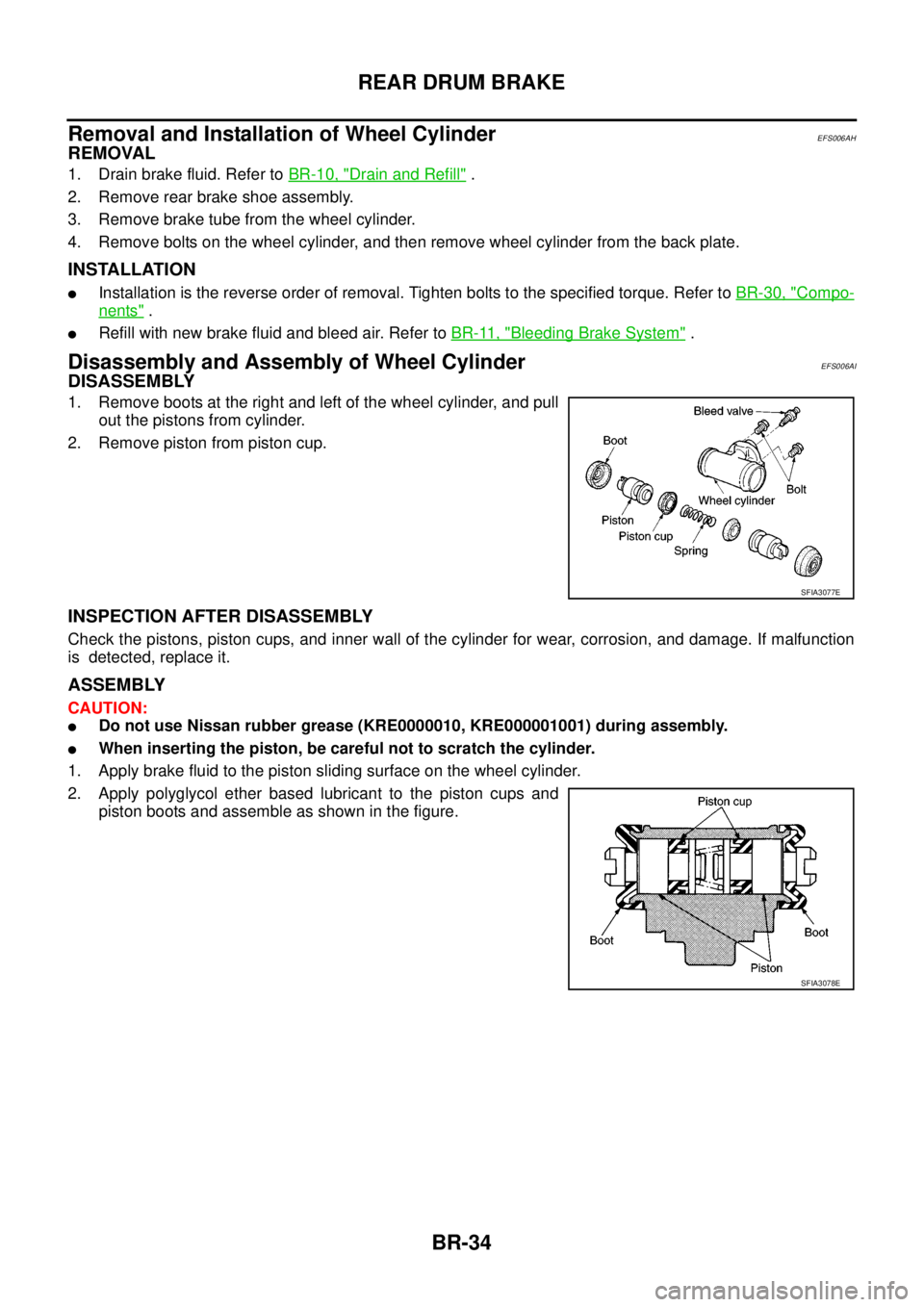

Disassembly and Assembly of Wheel CylinderEFS006AI

DISASSEMBLY

1. Remove boots at the right and left of the wheel cylinder, and pull

out the pistons from cylinder.

2. Remove piston from piston cup.

INSPECTION AFTER DISASSEMBLY

Check the pistons, piston cups, and inner wall of the cylinder for wear, corrosion, and damage. If malfunction

is detected, replace it.

ASSEMBLY

CAUTION:

lDo not use Nissan rubber grease (KRE0000010, KRE000001001) during assembly.

lWhen inserting the piston, be careful not to scratch the cylinder.

1. Apply brake fluid to the piston sliding surface on the wheel cylinder.

2. Apply polyglycol ether based lubricant to the piston cups and

piston boots and assemble as shown in the figure.

SFIA3077E

SFIA3078E

Page 823 of 3171

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONBRC

A

B

BRC

BRAKE CONTROL SYSTEM

ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 3

PREPARATION ........................................................... 4

Special Service Tools (SST) ..................................... 4

SYSTEM DESCRIPTION ............................................ 5

System Diagram ....................................................... 5

Functions .................................................................. 5

Operation That Is Not “System Error” ...................... 5

Fail-Safe Function .................................................... 5

ABS, EBD SYSTEM .............................................. 5

Hydraulic Circuit Diagram ........................................ 6

CAN COMMUNICATION ............................................ 7

System Description .................................................. 7

TROUBLE DIAGNOSIS .............................................. 8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ....................................................... 8

INTRODUCTION ................................................... 8

DIAGNOSIS FLOWCHART .................................. 9

ASKING COMPLAINTS ...................................... 10

EXAMPLE OF DIAGNOSIS SHEET ................... 10

Component Parts Location ...................................... 11

Schematic — ABS — ............................................. 12

Wiring Diagram — ABS — ..................................... 13

CONSULT- II Functions .......................................... 17

CONSULT-II MAIN FUNCTION ........................... 17

CONSULT-II BASIC OPERATION PROCEDURE

... 17

Self-Diagnosis ........................................................ 18

OPERATION PROCEDURE ............................... 18

ERASE MEMORY ............................................... 18

DISPLAY ITEM LIST ........................................... 18

Data Monitor ........................................................... 20

OPERATION PROCEDURE ............................... 20

DISPLAY ITEM LIST ........................................... 20Active Test .............................................................. 21

OPERATION PROCEDURE ................................ 21

SOLENOID VALVE .............................................. 22

ABS MOTOR ....................................................... 22

For Fast and Accurate Diagnosis ........................... 23

PRECAUTIONS FOR DIAGNOSIS ..................... 23

Basic Inspection ..................................................... 23

BASIC INSPECTION 1 BRAKE FLUID LEVEL,

LEAKS, AND BRAKE PADS ................................ 23

BASIC INSPECTION 2 POWER SYSTEM TER-

MINAL LOOSENESS AND BATTERY INSPEC-

TION .................................................................... 23

BASIC INSPECTION 3 ABS WARNING LAMP

AND BRAKE WARNING LAMP INSPECTION .... 24

Inspection 1 Wheel Sensor System ........................ 24

Inspection 2 ABS Actuator and Electric Unit (Control

Unit) ........................................................................ 26

Inspection 3 ABS Actuator Relay or ABS Motor

Relay Circuit ........................................................... 26

Inspection 4 CAN Communication Circuit .............. 28

Inspection 5 ABS Actuator and Electric Unit (Control

Unit) Power Supply and Ground Circuit .................. 28

Inspection 6 Brake Fluid Level Switch Circuit ......... 30

Inspection 7 Parking Brake Switch Circuit .............. 32

Inspection 8 Warning lamp system ......................... 33

Symptom 1: Excessive ABS Function Operation

Frequency ............................................................... 33

Symptom 2: Unexpected Pedal Reaction ............... 34

Symptom 3: The Stopping Distance Is Long .......... 34

Symptom 4: ABS Function Does Not Operate ....... 35

Symptom 5: Pedal Vibration or ABS Operation

Sound Occurs ......................................................... 35

Symptom 6: ABS Warning Lamp Indication Is Not

Normal .................................................................... 35

WHEEL SENSORS ................................................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

Page 827 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual SYSTEM DESCRIPTION

BRC-5

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

SYSTEM DESCRIPTIONPFP:00000

System DiagramEFS005TJ

FunctionsEFS005TK

ABS

lThe Anti-Lock Brake System is a function that detects wheel revoluti NISSAN NAVARA 2005 Repair Owners Manual SYSTEM DESCRIPTION

BRC-5

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

SYSTEM DESCRIPTIONPFP:00000

System DiagramEFS005TJ

FunctionsEFS005TK

ABS

lThe Anti-Lock Brake System is a function that detects wheel revoluti](/img/5/57362/w960_57362-826.png)

SYSTEM DESCRIPTION

BRC-5

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

SYSTEM DESCRIPTIONPFP:00000

System DiagramEFS005TJ

FunctionsEFS005TK

ABS

lThe Anti-Lock Brake System is a function that detects wheel revolution while braking, and it improves

handling stability during sudden braking by electrically preventing 4 wheels lock. Maneuverability is also

improved for avoiding obstacles.

lElectrical system diagnosis by CONSULT-II is available.

EBD

lElectronic Brake Distributor is a function that detects subtle slippages between the front and rear tyre dur-

ing braking, and it improves handling stability by electrically controlling the brake fluid pressure which

results in reduced rear tyre slippage.

lElectrical system diagnosis by CONSULT-II is available.

Operation That Is Not “System Error”EFS005TL

ABS

lWhen starting engine or just after starting vehicle, brake pedal may vibrate or the motor operating noise

may be heard from engine room. This is a normal states of the operation check.

lDuring ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

Fail-Safe FunctionEFS005TM

ABS, EBD SYSTEM

In case of electrical malfunction with ABS, ABS warning lamp will turn on. In case of electrical incidents with

EBD, brake warning lamp and ABS warning lamp will turn on. Simultaneously, ABS become one of following

conditions of Fail-Safe function.

1. For ABS malfunction, only EBD is activated and condition of vehicle is same condition of vehicles without

ABS system.

NOTE:

ABS self-diagnosis sound may be heard.That is a normal condition because a self-diagnosis for “Ignition

switch ON” and “The first starting” are being performed.

2. For EBD malfunction, EBD and ABS become inoperative, and condition of vehicle is same as condition of

vehicles without ABS, EBD system.

SFIA3001E

Page 840 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual BRC-18

[ABS]

TROUBLE DIAGNOSIS

Self-Diagnosis

EFS005TU

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch O NISSAN NAVARA 2005 Repair Owners Manual BRC-18

[ABS]

TROUBLE DIAGNOSIS

Self-Diagnosis

EFS005TU

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch O](/img/5/57362/w960_57362-839.png)

BRC-18

[ABS]

TROUBLE DIAGNOSIS

Self-Diagnosis

EFS005TU

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping vehicle, with engine running, touch “START (NISSAN BASED VHCL)”, “ABS”, “SELF-DIAG

RESULTS” in order on CONSULT-II screen.

CAUTION:

If “START (NISSAN BASED VHCL)” is touched immediately after starting engine or turn on the

ignition switch, “ABS” might not be displayed in the “SELECT SYSTEM” screen. In this case,

repeat the operation from step 1.

6. The self-diagnostic results are displayed. (Touch “PRINT” to print out self-diagnostic results, If necessary.)

lCheck ABS warning lamp if “NO FAILURE” is displayed.

7. Perform the appropriate inspection from display item list, and repair or replace the malfunctioning compo-

nent. Refer toBRC-18, "

Display Item List".

8. Start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

When the wheel sensor malfunctions, after inspecting the wheel sensor system, the ABS warning

lamp and brake warning lamp will not turn off even when the system is normal unless the vehicle

is driving at 30 km/h (19MPH) or more for approximately 1 minute.

ERASE MEMORY

1. Turn ignition switch OFF.

2. Start engine and touch “START (NISSAN BASED VHCL)”, “ABS”, “SELF-DIAG RESULTS”, “ERASE

MEMORY” in order on CONSULT-II screen to erase the error memory.

If “ABS” is not indicated, go toGI-50, "

CONSULT-II Data Link Connector (DLC) Circuit".

CAUTION:

If the error memory is not erased, re-perform the operation from step 4.

3. Perform self-diagnosis again, and make sure that diagnostic memory is erased.

4. Drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute as the final inspection, and make

sure that the ABS warning lamp turn off.

DISPLAY ITEM LIST

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1 Circuit of rear RH wheel sensor is open.

BRC-24, "

Inspection 1

Wheel Sensor System"

(Note 1) RR LH SENSOR-1 Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1 Circuit of front RH wheel sensor is open.

FR LH SENSOR-1 Circuit of front LH wheel sensor is open.

RR RH SENSOR-2When the circuit in the rear RH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2When the circuit in the rear LH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2When the circuit in the front RH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2When the circuit in the front LH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

Page 841 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual TROUBLE DIAGNOSIS

BRC-19

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Note 1: After completing repairs of shorted sensor circuit, when ignition switch is turned ON, ABS warning lamp turns on. Make sure that

ABS w NISSAN NAVARA 2005 Repair Owners Manual TROUBLE DIAGNOSIS

BRC-19

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Note 1: After completing repairs of shorted sensor circuit, when ignition switch is turned ON, ABS warning lamp turns on. Make sure that

ABS w](/img/5/57362/w960_57362-840.png)

TROUBLE DIAGNOSIS

BRC-19

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Note 1: After completing repairs of shorted sensor circuit, when ignition switch is turned ON, ABS warning lamp turns on. Make sure that

ABS warning lamp turns off while driving vehicle at 30 km/h (19 MPH) or more for approximately 1 minute according to self-diagnosis

procedure. In addition, if wheel sensor 2 is displayed for wheels, check wheel sensor circuit and also check control unit power voltage.

Note 2: When errors are detected in several systems, including CAN communication system [U1000], troubleshoot CAN communication

circuit. Refer toBRC-28, "

Inspection 4 CAN Communication Circuit". BATTERY VOLTAGE

[MALFUNCTION]ABS actuator and electric unit (control unit) power voltage is too low.BRC-28, "

Inspection 5

ABS Actuator and Elec-

tric Unit (Control Unit)

Power Supply and

Ground Circuit"

CONTROLLER FAILURE Internal malfunction of ABS actuator and electric unit (control unit)BRC-26, "

Inspection 2

ABS Actuator and Elec-

tric Unit (Control Unit)"

PUMP MOTORDuring actuator motor operation with ON, when actuator motor turns

OFF or when control line for actuator motor relay is open.BRC-26, "

Inspection 3

ABS Actuator Relay or

ABS Motor Relay Cir-

cuit"During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

ABS SENSOR

[MALFUNCTION SIGNAL]Wheel sensor input is malfunction.BRC-24, "

Inspection 1

Wheel Sensor System"

(Note 1)

FR LH IN ABS SOLWhen the control unit detects an error in the front LH inlet solenoid

circuit.

BRC-26, "

Inspection 3

ABS Actuator Relay or

ABS Motor Relay Cir-

cuit"

FR LH OUT ABS SOLWhen the control unit detects an error in the front LH outlet solenoid

circuit.

FR RH IN ABS SOLWhen the control unit detects an error in the front RH inlet solenoid

circuit.

FR RH OUT ABS SOLWhen the control unit detects an error in the front RH outlet solenoid

circuit.

RR LH IN ABS SOLWhen the control unit detects an error in the rear LH inlet solenoid

circuit.

RR LH OUT ABS SOLWhen the control unit detects an error in the rear LH outlet solenoid

circuit.

RR RH IN ABS SOLWhen the control unit detects an error in the rear RH inlet solenoid

circuit.

RR RH OUT ABS SOLWhen the control unit detects an error in the rear RH outlet solenoid

circuit.

ACTUATOR RLY When the control unit detects an error in the actuator relay circuit.

CAN COMM CIRCUIT

[U1000]When there is an error in the CAN communications.BRC-28, "

Inspection 4

CAN Communication

Circuit"(Note 2) Self-diagnostic item Malfunction detecting condition Check system

Page 842 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual BRC-20

[ABS]

TROUBLE DIAGNOSIS

Data Monitor

EFS005TV

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DATA MONITOR” in order on CONSULT-II screen.

CAUTION:

When “START ( NISSAN NAVARA 2005 Repair Owners Manual BRC-20

[ABS]

TROUBLE DIAGNOSIS

Data Monitor

EFS005TV

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DATA MONITOR” in order on CONSULT-II screen.

CAUTION:

When “START (](/img/5/57362/w960_57362-841.png)

BRC-20

[ABS]

TROUBLE DIAGNOSIS

Data Monitor

EFS005TV

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DATA MONITOR” in order on CONSULT-II screen.

CAUTION:

When “START (NISSAN BASED VHCL)” is touched immediately after starting engine or turning on

ignition switch, “ABS” might not be displayed in “SELECT SYSTEM” screen. In this case, repeat

the operation from step 1.

2. At the monitor item selection screen, touch one of the item “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”.

3. Touch “START” to proceed to the data monitor screen.

DISPLAY ITEM LIST

CAUTION:

The display shows the control unit calculation data, so a normal value might be displayed even in the

event the output circuit (harness) is open or short-circuited.

E:ECU INPUT SIGNALS M:MAIN SIGNALS S:SELECTION FROM MENU

SELECT

MONITOR

ITEMMonitor item Display contentData monitor

ConditionReference value in

normal operation

E, M, SFR LH SENSOR

FR RH SENSOR

RR LH SENSOR

RR RH SENSORWheel speed0 [km/h] Vehicle stopped

Nearly matches the speed-

ometer display (±10% or

less)Vehicle running

(Note 1)

E, M, S STOP LAMP SW Brake pedal operationBrake pedal depressed ON

Brake pedal not depressed OFF

E, M, S BATTERY VOLTBattery voltage supplied to the ABS

actuator and electric unit (control

unit)Ignitionswitch ON 10–16V

M, SFR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOLOperation status of all solenoid

valveActuator (solenoid valve) is

active (“Active Test ”with

CONSULT-II) or actuator

relay is inactive (in fail-safe

mode).ON

When the actuator (sole-

noid valve) is not active

and actuator relay is active

(ignition switch ON).OFF

M, S MOTOR RELAYMotor and motor relay operation

statusWhen the motor relay and

motor are operatingON

When the motor relay and

motor are not operatingOFF

M, S ACTUATOR RLY Actuator relay operation statusWhen the actuator relay is

operatingON

When the actuator relay is

not operatingOFF

M, S ABS WARN LAMPABS warning lamp status

(Note 2)When ABS warning lamp is

ON.ON

When ABS warning lamp is

OFF.OFF

S EBD WARN LAMP Brake warning lamp status (Note 2)Brake warning lamp ON ON

Brake warning lamp OFF OFF

S EBD SIGNAL EBD operationEBD active ON

EBD not active OFF