wheel NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1168 of 3171

EC-188

DTC P0503 ASCD VEHICLE SPEED SENSOR

WITHOUT CONSULT-II

TESTING CONDITION:

Step 2 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a road test

is expected to be easier, it is unnecessary to lift the vehicle.

1. Start engine.

2. Drivethevehicleatmorethan10km/h(6MPH).

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

5. If DTC is detected, go toEC-188, "

Diagnostic Procedure".

Diagnostic ProcedureEBS01KHS

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Refer toBRC-8, "

TROUBLE DIAGNOSIS".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2.CHECK COMBINATION METER

Check combination meter function.

Refer toDI-4, "

COMBINATION METERS".

>>INSPECTION END

Page 1170 of 3171

EC-190

DTC P0504 ASCD BRAKE SWITCH

On Board Diagnosis Logic

EBS01KHW

The MI will not light up for this diagnosis.

DTC confirmation ProcedureEBS01KHX

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 3 and 4 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

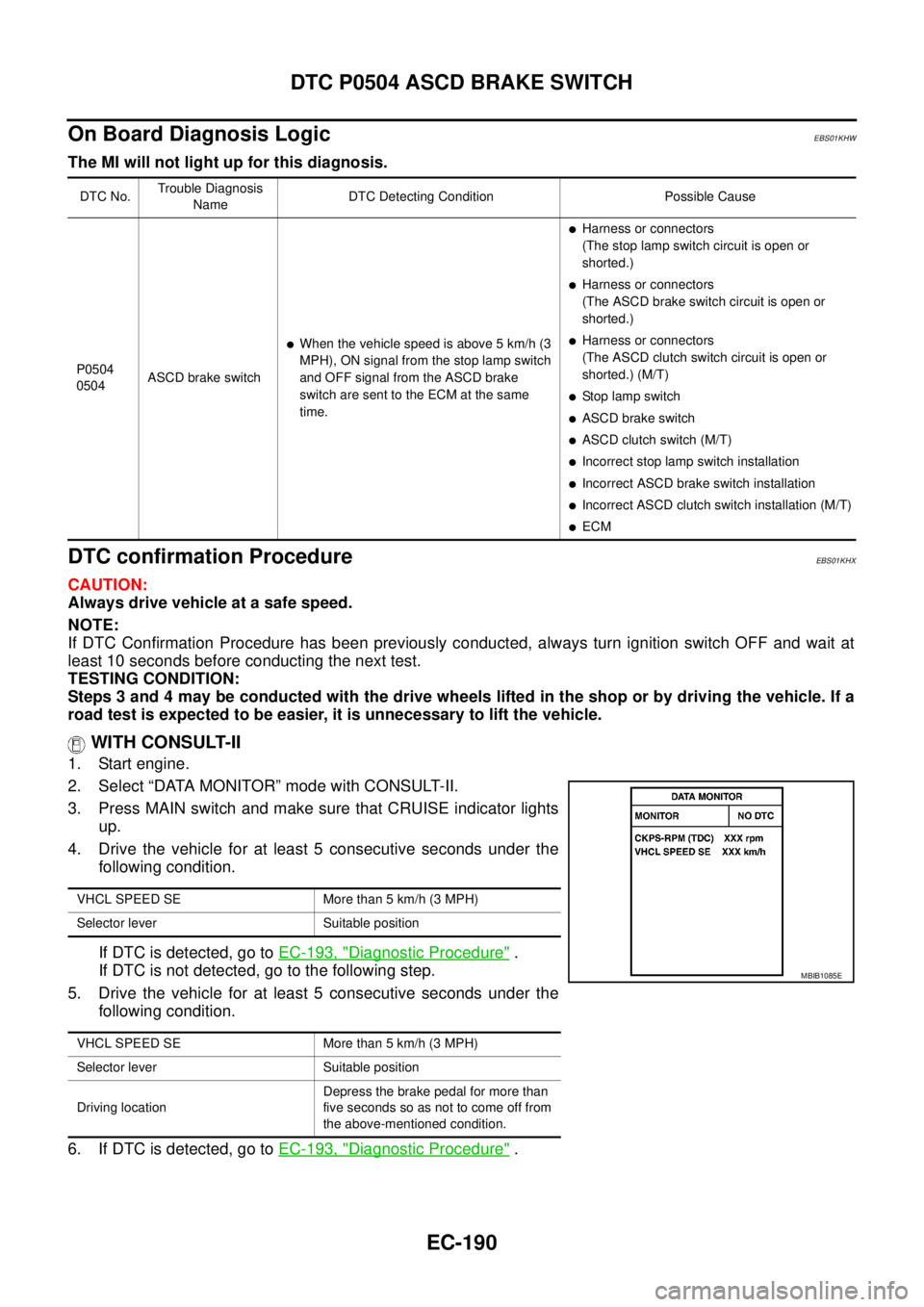

WITH CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Press MAIN switch and make sure that CRUISE indicator lights

up.

4. Drive the vehicle for at least 5 consecutive seconds under the

following condition.

If DTC is detected, go toEC-193, "

Diagnostic Procedure".

If DTC is not detected, go to the following step.

5. Drive the vehicle for at least 5 consecutive seconds under the

following condition.

6. If DTC is detected, go toEC-193, "

Diagnostic Procedure".

DTC No.Trouble Diagnosis

NameDTC Detecting Condition Possible Cause

P0504

0504ASCD brake switch

lWhen the vehicle speed is above 5 km/h (3

MPH), ON signal from the stop lamp switch

and OFF signal from the ASCD brake

switch are sent to the ECM at the same

time.

lHarness or connectors

(The stop lamp switch circuit is open or

shorted.)

lHarness or connectors

(The ASCD brake switch circuit is open or

shorted.)

lHarness or connectors

(The ASCD clutch switch circuit is open or

shorted.) (M/T)

lStop lamp switch

lASCD brake switch

lASCD clutch switch (M/T)

lIncorrectstoplampswitchinstallation

lIncorrect ASCD brake switch installation

lIncorrect ASCD clutch switch installation (M/T)

lECM

VHCL SPEED SE More than 5 km/h (3 MPH)

Selector lever Suitable position

VHCL SPEED SE More than 5 km/h (3 MPH)

Selector lever Suitable position

Driving locationDepress the brake pedal for more than

five seconds so as not to come off from

the above-mentioned condition.

MBIB1085E

Page 1337 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-357

C

D

E

F

G

H

I

J

K

L

MA

EC

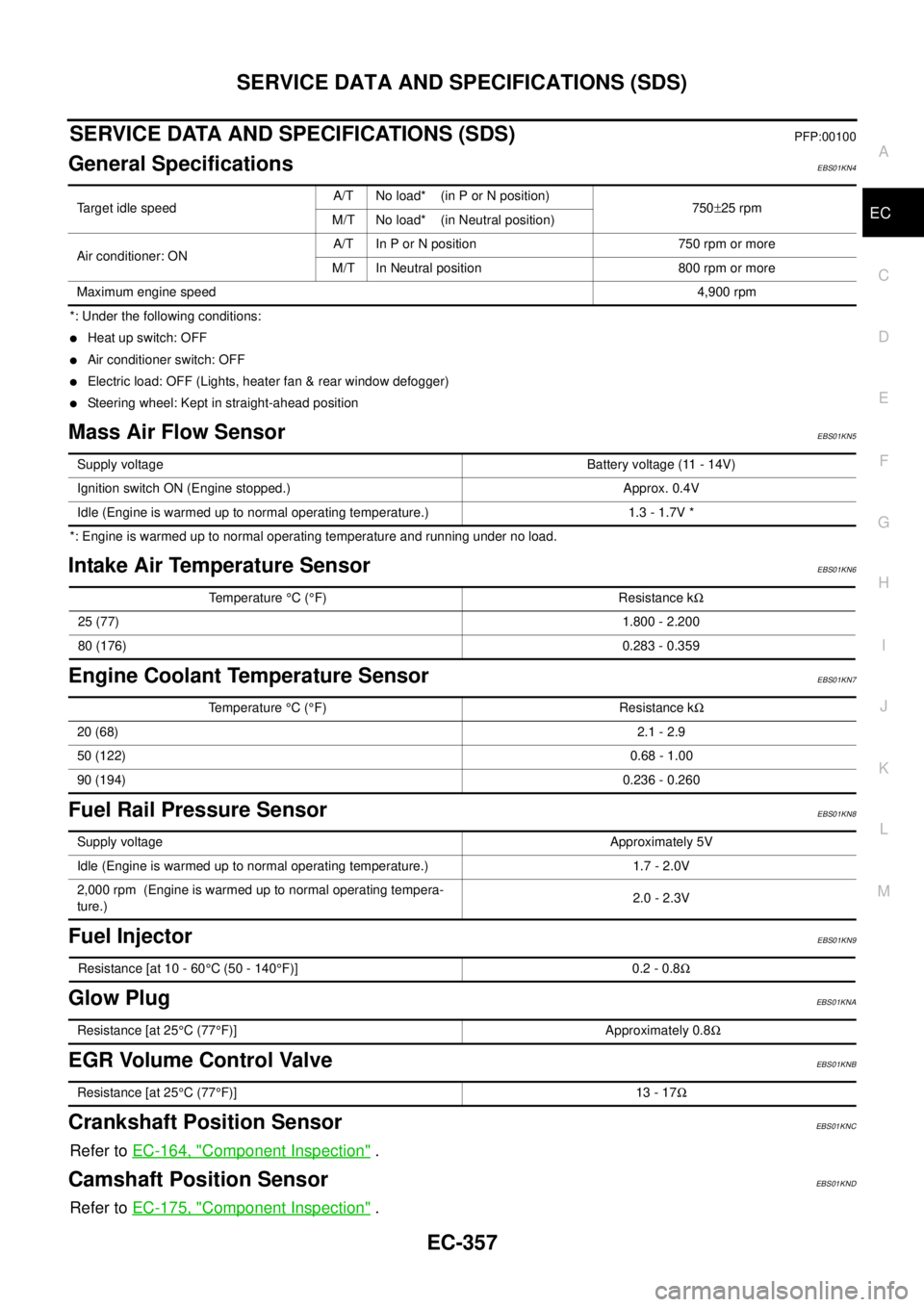

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

General SpecificationsEBS01KN4

*: Under the following conditions:

lHeat up switch: OFF

lAir conditioner switch: OFF

lElectric load: OFF (Lights, heater fan & rear window defogger)

lSteering wheel: Kept in straight-ahead position

Mass Air Flow SensorEBS01KN5

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorEBS01KN6

Engine Coolant Temperature SensorEBS01KN7

Fuel Rail Pressure SensorEBS01KN8

Fuel InjectorEBS01KN9

Glow PlugEBS01KNA

EGR Volume Control ValveEBS01KNB

Crankshaft Position SensorEBS01KNC

Refer toEC-164, "Component Inspection".

Camshaft Position SensorEBS01KND

Refer toEC-175, "Component Inspection".

Target idle speedA/T No load* (in P or N position)

750±25 rpm

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position 750 rpm or more

M/T In Neutral position 800 rpm or more

Maximum engine speed4,900 rpm

Supply voltageBattery voltage (11 - 14V)

Ignition switch ON (Engine stopped.) Approx. 0.4V

Idle (Engine is warmed up to normal operating temperature.) 1.3 - 1.7V *

Temperature°C(°F) Resistance kW

25 (77)1.800 - 2.200

80 (176)0.283 - 0.359

Temperature°C(°F) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Supply voltageApproximately 5V

Idle (Engine is warmed up to normal operating temperature.) 1.7 - 2.0V

2,000 rpm (Engine is warmed up to normal operating tempera-

ture.)2.0 - 2.3V

Resistance [at 10 - 60°C (50 - 140°F)] 0.2 - 0.8W

Resistance [at 25°C(77°F)] Approximately 0.8W

Resistance [at 25°C(77°F)] 13 - 17W

Page 1341 of 3171

PRECAUTIONS

EI-3

C

D

E

F

G

H

J

K

L

MA

B

EI

PRECAUTIONSPFP:00001

Service NoticeEIS00DY1

lWhen removing or installing various parts, place a cloth or padding on the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ2

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1385 of 3171

EM-3

C

D

E

F

G

H

I

J

K

L

M

EMA BEARING .......................................................... 132

MAIN BEARING CAP BOLT DEFORMATION .. 133

CONNECTING ROD BOLT DEFORMATION .... 133

OIL JET ............................................................. 133

OIL JET RELIEF VALVE ................................... 133

FLYWHEEL DEFLECTION ............................... 134

MOVEMENT AMOUNT OF FLYWHEEL ........... 134

DRIVE PLATE ................................................... 134

SERVICE DATA AND SPECIFICATIONS (SDS) .... 135

Standard and Limit ............................................... 135

GENERAL SPECIFICATIONS .......................... 135

INTAKE MANIFOLD AND EXHAUST MANI-FOLD .................................................................135

DRIVE BELTS ...................................................135

CYLINDER HEAD .............................................136

VALVE ...............................................................136

CAMSHAFT .......................................................140

CYLINDER BLOCK ...........................................141

PISTON, PISTON RING AND PISTON PIN ......141

CONNECTING ROD .........................................144

CRANKSHAFT ..................................................144

AVAILABLE MAIN BEARING ............................145

AVAILABLE CONNECTING ROD BEARING ....145

MISCELLANEOUS COMPONENTS .................145

Page 1391 of 3171

PREPARATION

EM-9

C

D

E

F

G

H

I

J

K

L

MA

EM

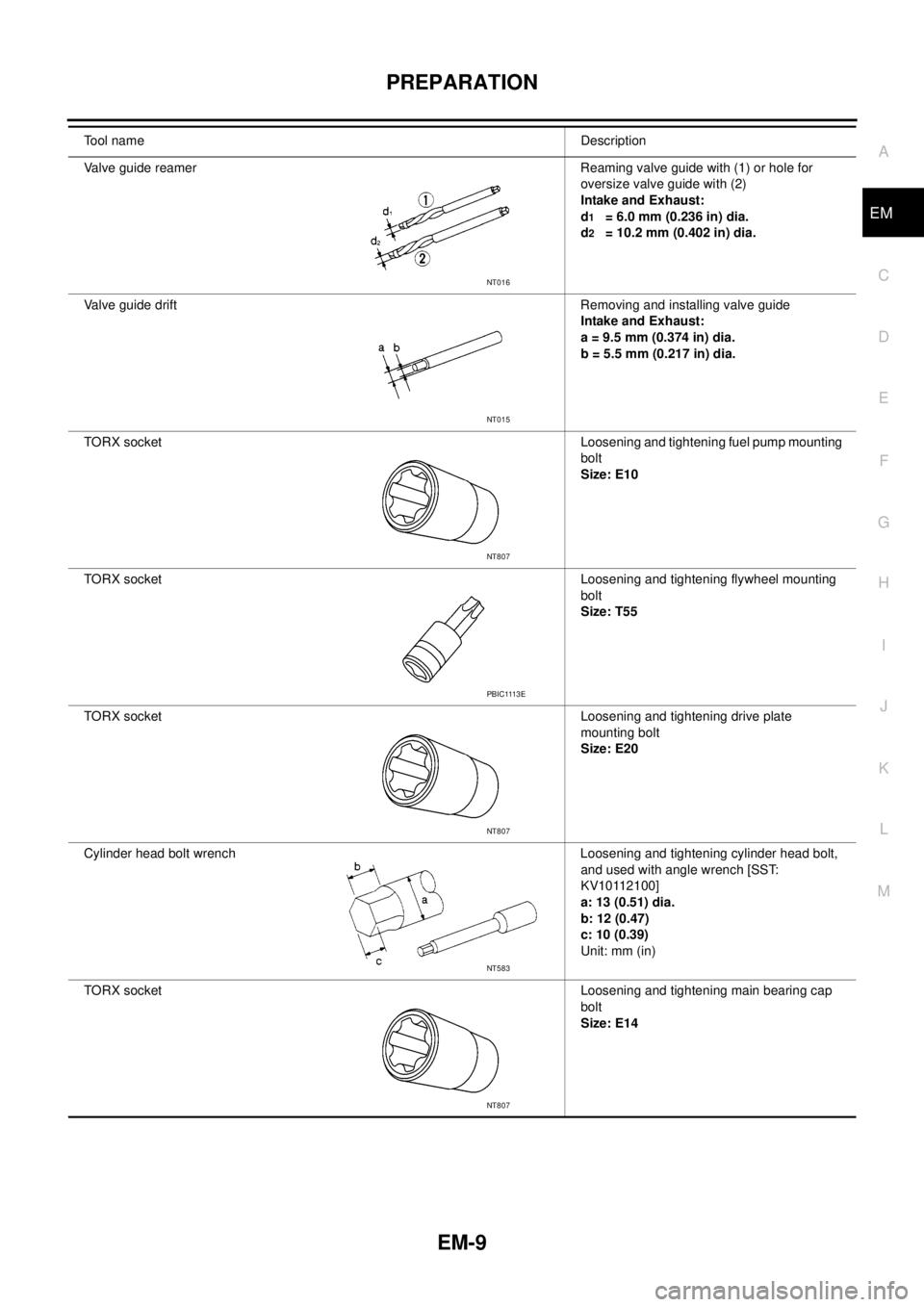

Valve guide reamer Reaming valve guide with (1) or hole for

oversize valve guide with (2)

Intake and Exhaust:

d

1= 6.0 mm (0.236 in) dia.

d

2= 10.2 mm (0.402 in) dia.

Valve guide drift Removing and installing valve guide

Intake and Exhaust:

a = 9.5 mm (0.374 in) dia.

b = 5.5 mm (0.217 in) dia.

TORX socketLoosening and tightening fuel pump mounting

bolt

Size: E10

TORX socketLoosening and tightening flywheel mounting

bolt

Size: T55

TORX socketLoosening and tightening drive plate

mounting bolt

Size: E20

Cylinder head bolt wrench Loosening and tightening cylinder head bolt,

and used with angle wrench [SST:

KV10112100]

a: 13 (0.51) dia.

b: 12 (0.47)

c: 10 (0.39)

Unit: mm (in)

TORX socketLoosening and tightening main bearing cap

bolt

Size: E14 Tool nameDescription

NT016

NT015

NT807

PBIC1113E

NT807

NT583

NT807

Page 1412 of 3171

EM-30

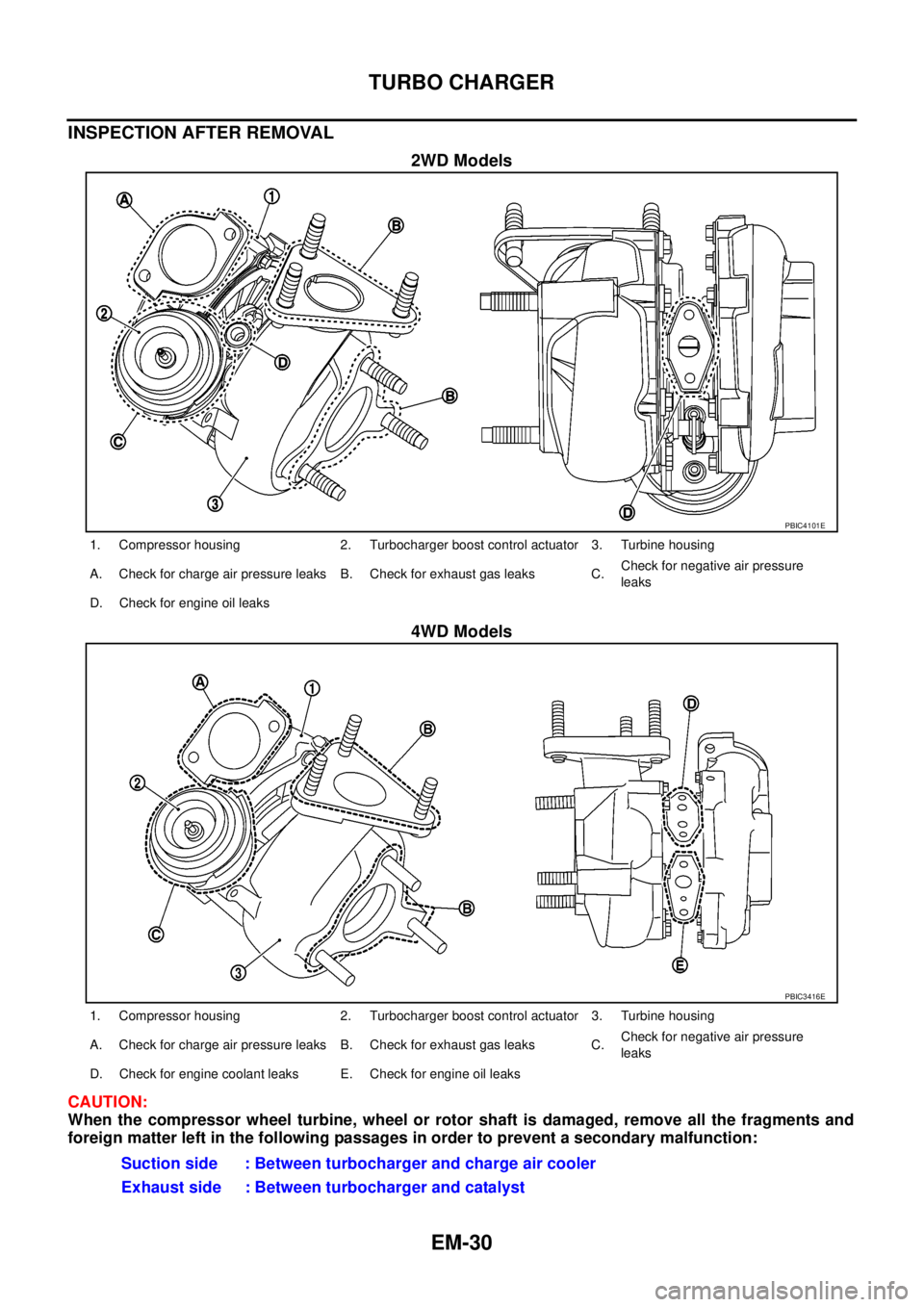

TURBO CHARGER

INSPECTION AFTER REMOVAL

2WD Models

4WD Models

CAUTION:

When the compressor wheel turbine, wheel or rotor shaft is damaged, remove all the fragments and

foreign matter left in the following passages in order to prevent a secondary malfunction:

PBIC4101E

1. Compressor housing 2. Turbocharger boost control actuator 3. Turbine housing

A. Check for charge air pressure leaks B. Check for exhaust gas leaks C.Check for negative air pressure

leaks

D. Check for engine oil leaks

PBIC3416E

1. Compressor housing 2. Turbocharger boost control actuator 3. Turbine housing

A. Check for charge air pressure leaks B. Check for exhaust gas leaks C.Check for negative air pressure

leaks

D. Check for engine coolant leaks E. Check for engine oil leaks

Suction side : Between turbocharger and charge air cooler

Exhaust side : Between turbocharger and catalyst

Page 1413 of 3171

TURBO CHARGER

EM-31

C

D

E

F

G

H

I

J

K

L

MA

EM

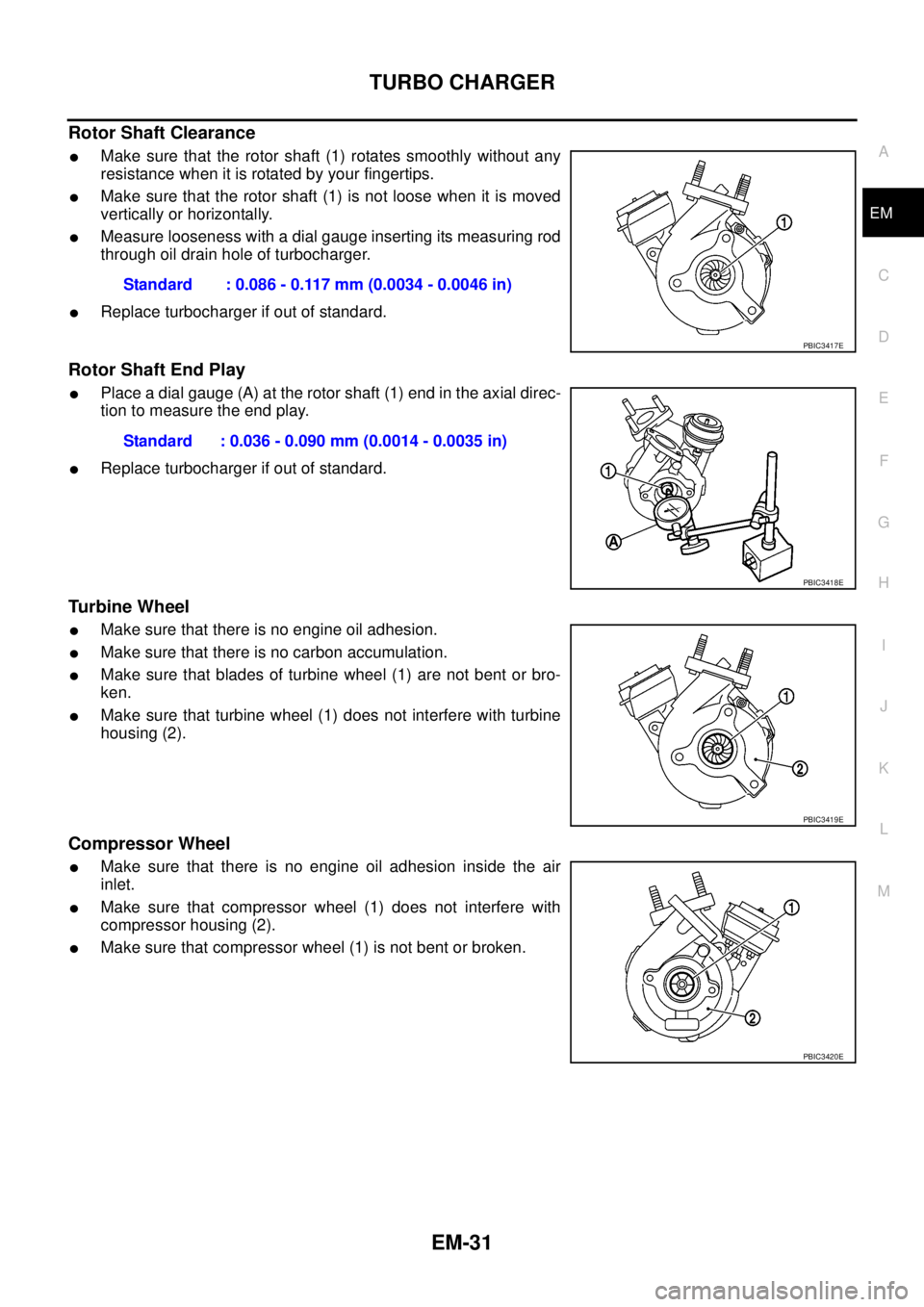

Rotor Shaft Clearance

lMake sure that the rotor shaft (1) rotates smoothly without any

resistance when it is rotated by your fingertips.

lMake sure that the rotor shaft (1) is not loose when it is moved

vertically or horizontally.

lMeasure looseness with a dial gauge inserting its measuring rod

through oil drain hole of turbocharger.

lReplace turbocharger if out of standard.

Rotor Shaft End Play

lPlace a dial gauge (A) at the rotor shaft (1) end in the axial direc-

tion to measure the end play.

lReplace turbocharger if out of standard.

Turbine Wheel

lMake sure that there is no engine oil adhesion.

lMake sure that there is no carbon accumulation.

lMake sure that blades of turbine wheel (1) are not bent or bro-

ken.

lMake sure that turbine wheel (1) does not interfere with turbine

housing (2).

Compressor Wheel

lMake sure that there is no engine oil adhesion inside the air

inlet.

lMake sure that compressor wheel (1) does not interfere with

compressor housing (2).

lMake sure that compressor wheel (1) is not bent or broken.Standard : 0.086 - 0.117 mm (0.0034 - 0.0046 in)

PBIC3417E

Standard : 0.036 - 0.090 mm (0.0014 - 0.0035 in)

PBIC3418E

PBIC3419E

PBIC3420E

Page 1414 of 3171

EM-32

TURBO CHARGER

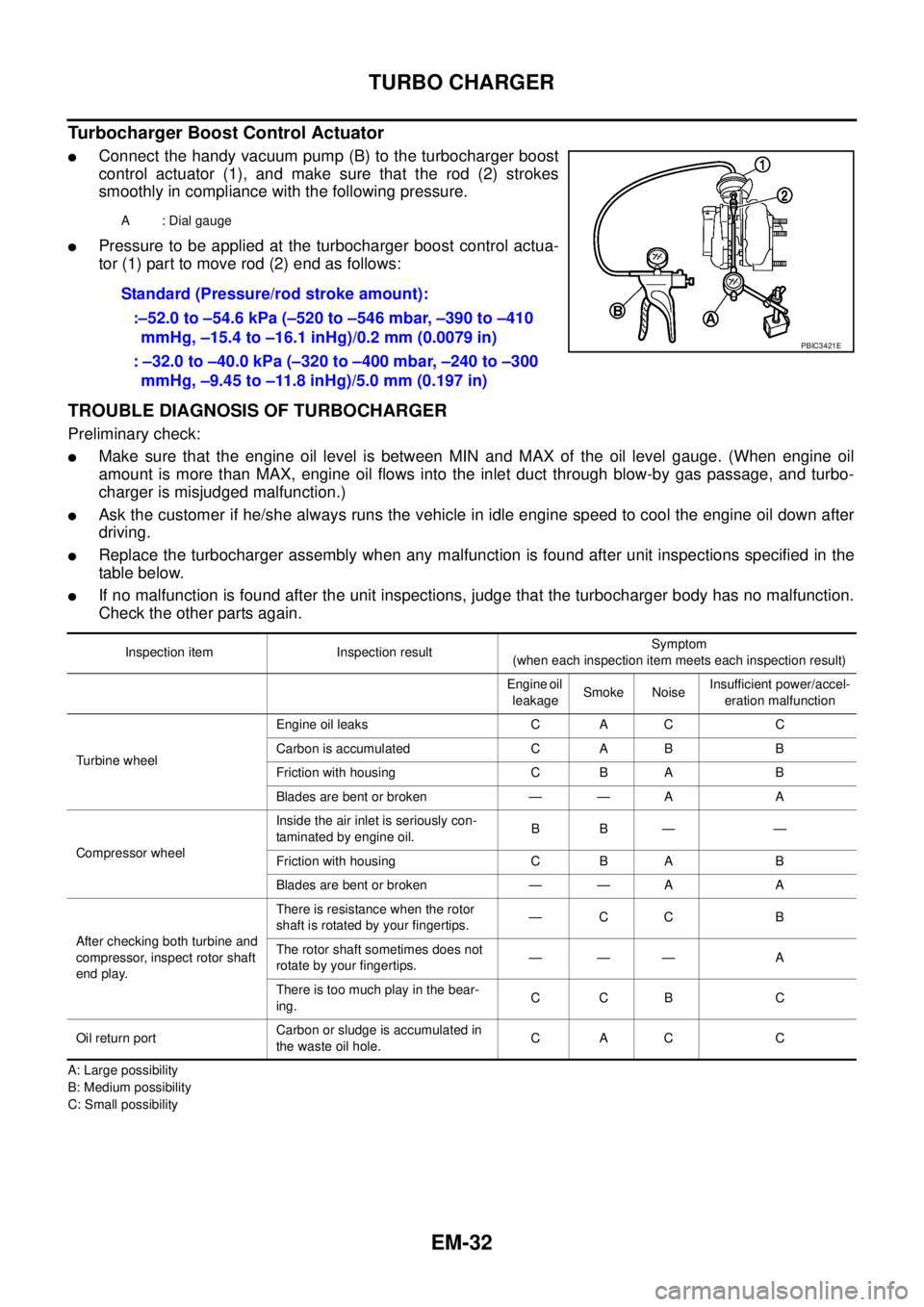

Turbocharger Boost Control Actuator

lConnect the handy vacuum pump (B) to the turbocharger boost

control actuator (1), and make sure that the rod (2) strokes

smoothly in compliance with the following pressure.

lPressure to be applied at the turbocharger boost control actua-

tor (1) part to move rod (2) end as follows:

TROUBLE DIAGNOSIS OF TURBOCHARGER

Preliminary check:

lMake sure that the engine oil level is between MIN and MAX of the oil level gauge. (When engine oil

amount is more than MAX, engine oil flows into the inlet duct through blow-by gas passage, and turbo-

charger is misjudged malfunction.)

lAsk the customer if he/she always runs the vehicle in idle engine speed to cool the engine oil down after

driving.

lReplace the turbocharger assembly when any malfunction is found after unit inspections specified in the

table below.

lIf no malfunction is found after the unit inspections, judge that the turbocharger body has no malfunction.

Check the other parts again.

A: Large possibility

B: Medium possibility

C: Small possibilityA : Dial gauge

Standard (Pressure/rod stroke amount):

:–52.0 to –54.6 kPa (–520 to –546 mbar, –390 to –410

mmHg, –15.4 to –16.1 inHg)/0.2 mm (0.0079 in)

: –32.0 to –40.0 kPa (–320 to –400 mbar, –240 to –300

mmHg, –9.45 to –11.8 inHg)/5.0 mm (0.197 in)

PBIC3421E

Inspection item Inspection resultSymptom

(when each inspection item meets each inspection result)

Engine oil

leakageSmoke NoiseInsufficient power/accel-

eration malfunction

Turbine wheelEngine oil leaks C A C C

Carbon is accumulated C A B B

Friction with housing C B A B

Blades are bent or broken — — A A

Compressor wheelInside the air inlet is seriously con-

taminated by engine oil.BB— —

Friction with housing C B A B

Blades are bent or broken — — A A

After checking both turbine and

compressor, inspect rotor shaft

end play.There is resistance when the rotor

shaft is rotated by your fingertips.—CC B

The rotor shaft sometimes does not

rotate by your fingertips.——— A

There is too much play in the bear-

ing.CCB C

Oil return portCarbon or sludge is accumulated in

the waste oil hole.CAC C

Page 1454 of 3171

EM-72

OIL SEAL

Removal and Installation of Rear Oil Seal

EBS01EK9

REMOVAL

1. Remove transmission and transfer assembly. Refer toMT-16, "TRANSMISSION ASSEMBLY"(M/T mod-

els) andAT- 2 4 7 , "

TRANSMISSION ASSEMBLY"(A/T models).

2. Remove flywheel (M/T models) or drive plate (A/T models). Refer toEM-110, "

CYLINDER BLOCK".

3. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

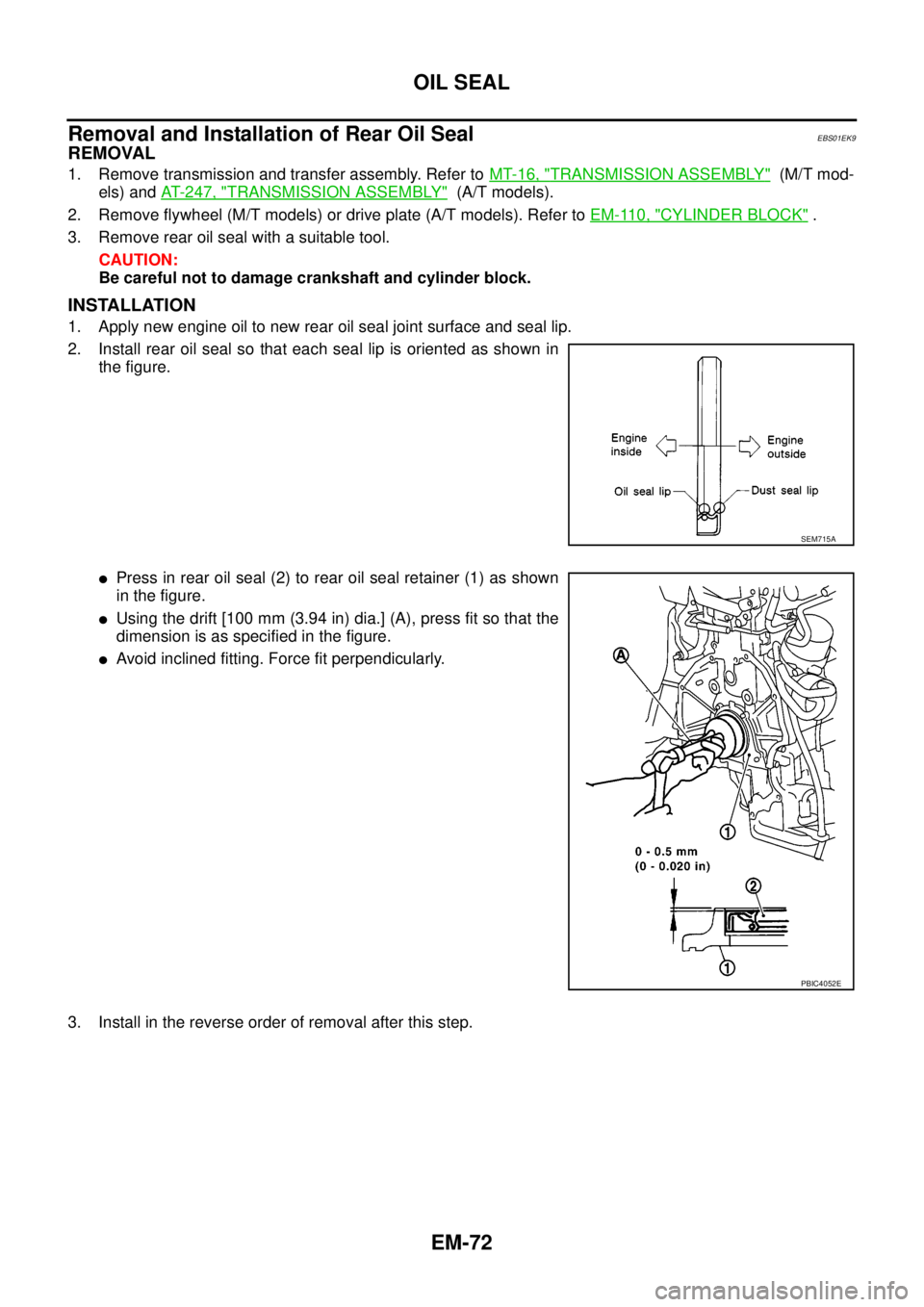

INSTALLATION

1. Apply new engine oil to new rear oil seal joint surface and seal lip.

2. Install rear oil seal so that each seal lip is oriented as shown in

the figure.

lPress in rear oil seal (2) to rear oil seal retainer (1) as shown

in the figure.

lUsing the drift [100 mm (3.94 in) dia.] (A), press fit so that the

dimension is as specified in the figure.

lAvoid inclined fitting. Force fit perpendicularly.

3. Install in the reverse order of removal after this step.

SEM715A

PBIC4052E