wheel NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 559 of 3171

TROUBLE DIAGNOSIS

AV-71

C

D

E

F

G

H

I

J

L

MA

B

AV

THE CURRENT POSITION MARK SHOWS A POSITION THAT IS COMPLETELY INCORRECT.

In the following cases, the current location mark may be displayed in a location that is completely incorrect. If

so, perform position/direction correction.

lWhen location correction has not been done

–If GPS satellite reception is poor and the current location mark slips out of place, it may shift to a com-

pletely unexpected location and not return unless location correction is performed. The position will be

corrected if a GPS signal can be received.

lWhen vehicle has traveled by ferry, or when vehicle has been towed.

VehicleUse of tire chains.

The vehicle mark may deviate from

the correct road.Drivethevehicleforawhile.Ifdis-

tance still deviates, adjust it with

the distance adjustment function. (If

tire chains are removed, recover

the original value.)

Use of tires other than the specified

sizeReplace all tires with the specified

size tire.

Malfunctioning air pressure of tireAdjust all tires to the specified air

pressure.

Replace tireDrive the vehicle for a while. If the

distance is still not in the correct

location, it adjusts with the distance

adjustment function.

Driving

mannerJust after the engine is startedIf vehicle is driven off just after the

engine is started when gyroscope

(angular speed sensor) correction is

not completed, the vehicle can can

be shown in the incorrect direction

and may deviate from the correct

location.Wait for a short while before driving

after starting the engine.

Continuous driving without stoppingWhen driving long distances without

stopping, direction errors may accu-

mulate, and the current location

mark may deviate from the correct

road.Stop and adjust orientation.

Abusive drivingSpinning the wheels or engaging in

other kinds of abusive driving may

result in the system being unable

perform correct detection, and may

cause the vehicle mark to deviate

from the correct road.If after traveling about 10 km (6

MPH) the correct location has not

been restored, perform location

correction and, if necessary, direc-

tion correction.

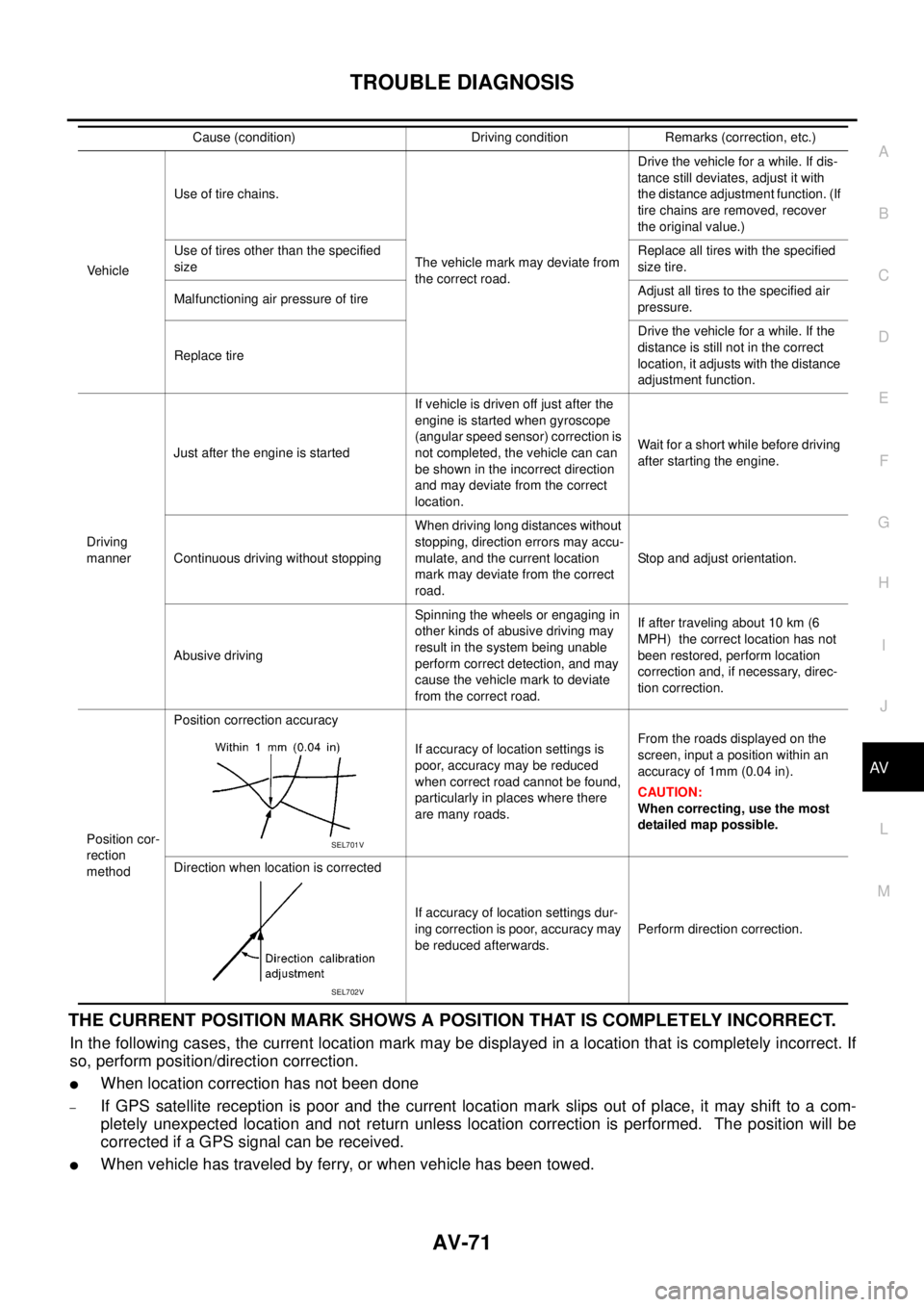

Position cor-

rection

methodPosition correction accuracy

If accuracy of location settings is

poor, accuracy may be reduced

when correct road cannot be found,

particularly in places where there

are many roads.From the roads displayed on the

screen, input a position within an

accuracy of 1mm (0.04 in).

CAUTION:

When correcting, use the most

detailed map possible.

Direction when location is corrected

If accuracy of location settings dur-

ing correction is poor, accuracy may

be reduced afterwards.Perform direction correction. Cause (condition) Driving condition Remarks (correction, etc.)

SEL701V

SEL702V

Page 560 of 3171

AV-72

TROUBLE DIAGNOSIS

–Because calculation of the current location cannot be done when traveling with the ignition OFF, for exam-

ple when traveling by ferry or when being towed, the location before travel is displayed. If the precise loca-

tioncanbedetectedwithGPS,thelocationwillbecorrected.

THE CURRENT POSITION MARK JUMPS.

In the following cases, the current location mark may appear to jump as a result of automatic correction of the

current location.

lWhen map matching has been done

–If current location and the current location mark are different when map matching is done, the current

location mark may seem to jump. At this time, the location may be “corrected” to the incorrect road or to a

location which is not on a road.

lWhen GPS location correction has been done

–If current location and the current location mark are different when location is corrected using GPS mea-

surements, the current location mark may seem to jump. At this time, the location may be “corrected” to a

location which is not on a road.

THE CURRENT LOCATION MARK IS IN A RIVER OR THE SEA.

The navigation system moves the current location mark with no distinction between land and rivers or sea. If

the location mark is somehow out of place, it may appear that the vehicle is driving in a river or the sea.

CURRENT LOCATION MARK ROTATES WITHOUT OPERATION

If the ignition switch is turned ON with the turntable rotating, the rotating condition is recorded as the stop con-

dition. Therefore, the current location mark might rotate when actually stopping.

WHEN DRIVING ON THE SAME ROAD, SOMETIMES THE CURRENT LOCATION MARK IS IN

THE CORRECT PLACE AND SOMETIMES IT IS IN THE INCORRECT PLACE.

The conditions of the GPS antenna (GPS data) and gyroscope (angular speed sensor) change gradually.

Depending on the road traveled and operation of the steering wheel, the location detection results will be dif-

ferent. Therefore, even on a road on which the location has never been incorrect, conditions may cause the

vehicle mark to deviate.

LOCATION CORRECTION BY MAP MATCHING IS SLOW.

lThe map matching function needs to refer to the data of the surrounding area. It is necessary to drive

some distance for the function to work.

lBecause of the way map matching operates, when there are many roads running in similar directions in

the surrounding area a matching determination may be impossible. The location will remain uncorrected

until some special feature is found.

ALTHOUGH THE GPS RECEIVING DISPLAY IS GREEN, THE VEHICLE MARK DOES NOT

RETURN TO THE CORRECT LOCATION.

lGPS accuracy has a malfunction range of about 10 m. In some cases the current location mark may not

be on the correct street, even when GPS location correction is done.

lThe navigation system compares the results of GPS location detection with the results from map-match-

ing location detection. The one that is determined to have higher accuracy is used.

lPosition correction by GPS is not available while the vehicle is stopped.

THE NAME OF THE CURRENT PLACE IS NOT DISPLAYED.

The current place name might not be displayed when there is no name of place information in the map screen.

THE DISPLAY IS DIFFERENT BETWEEN BIRDVIEW®AND (FLAT) MAP DISPLAY.

The following is different at birdview®.

lThe current place name displays names that are primarily in the direction of vehicle travel.

lThe amount of time before the vehicle travel or turn angle is updated on the screen is longer than for the

(flat) map display.

lThe conditions for display of place names, roads, and other data are different for nearby areas and for

more distant areas.

lSome trimming of the character data is done to prevent the display from becoming too complex. In some

cases and in some locations, the display contents may differ.

lThe same place name, street name, etc. may be displayed multiple times.

Page 788 of 3171

BR-2

Assembly ................................................................ 26

DISASSEMBLY ................................................... 26

INSPECTION AFTER DISASSEMBLY ................ 27

ASSEMBLY ......................................................... 28

DISC ROTOR INSPECTION ............................... 28

BRAKE BURNISHING PROCEDURE ................. 29

REAR DRUM BRAKE ............................................... 30

Components ........................................................... 30

Removal and Installation of Drum Brake Assembly... 31

REMOVAL ........................................................... 31

INSPECTION AFTER REMOVAL ........................ 32

INSTALLATION .................................................... 33

Removal and Installation of Wheel Cylinder ........... 34REMOVAL ............................................................ 34

INSTALLATION .................................................... 34

Disassembly and Assembly of Wheel Cylinder ....... 34

DISASSEMBLY .................................................... 34

INSPECTION AFTER DISASSEMBLY ................ 34

ASSEMBLY .......................................................... 34

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

General Specifications ............................................ 35

Brake Pedal ............................................................ 35

Brake Booster ......................................................... 35

Check Valve ............................................................ 35

Front Disc Brake ..................................................... 35

Rear Disc Brake ...................................................... 36

Page 789 of 3171

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DL

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

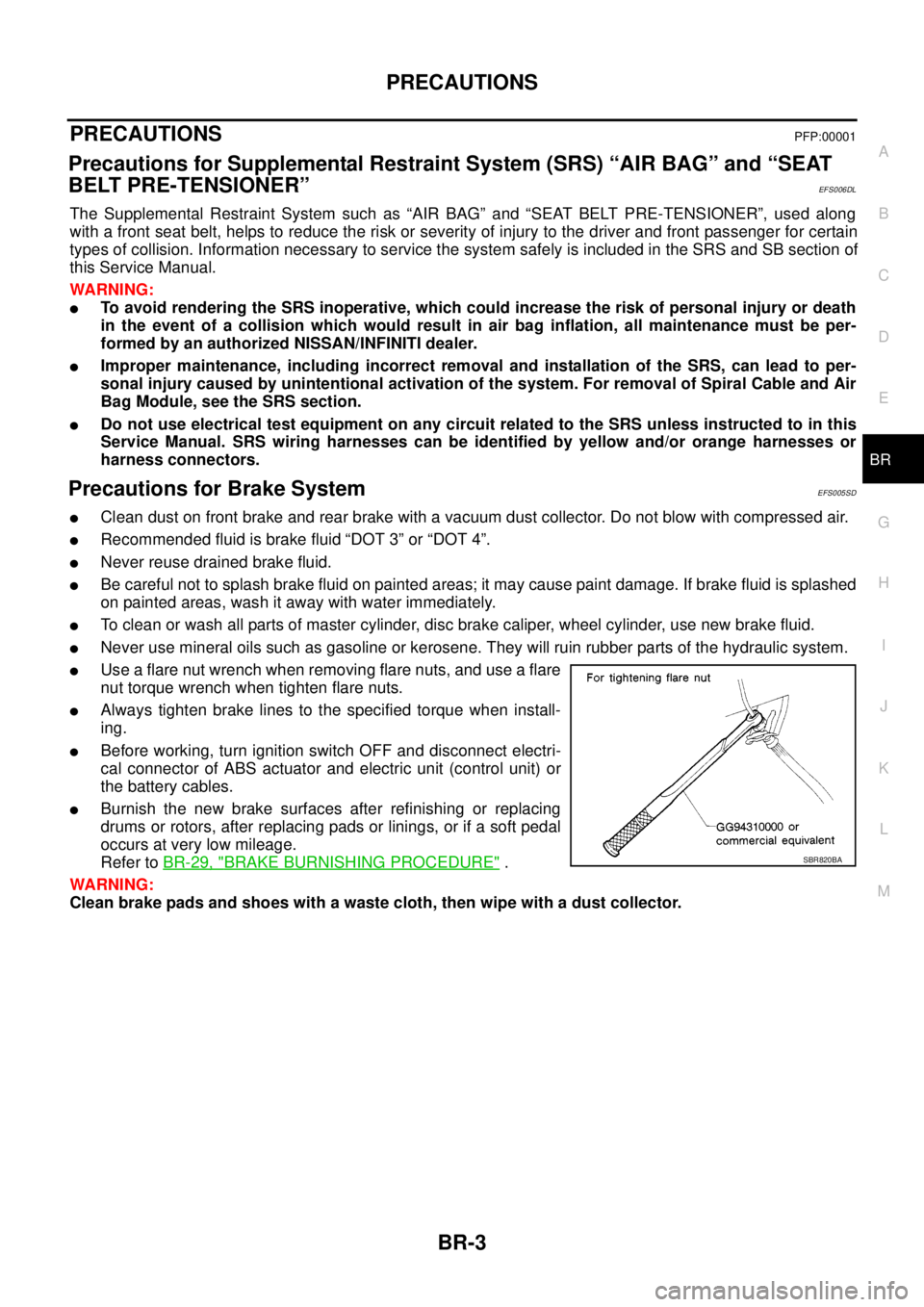

Precautions for Brake SystemEFS005SD

lClean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

lTo clean or wash all parts of master cylinder, disc brake caliper, wheel cylinder, use new brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse a flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lAlways tighten brake lines to the specified torque when install-

ing.

lBefore working, turn ignition switch OFF and disconnect electri-

cal connector of ABS actuator and electric unit (control unit) or

the battery cables.

lBurnish the new brake surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer toBR-29, "

BRAKE BURNISHING PROCEDURE".

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.SBR820BA

Page 791 of 3171

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

BR-5

C

D

E

G

H

I

J

K

L

MA

B

BR

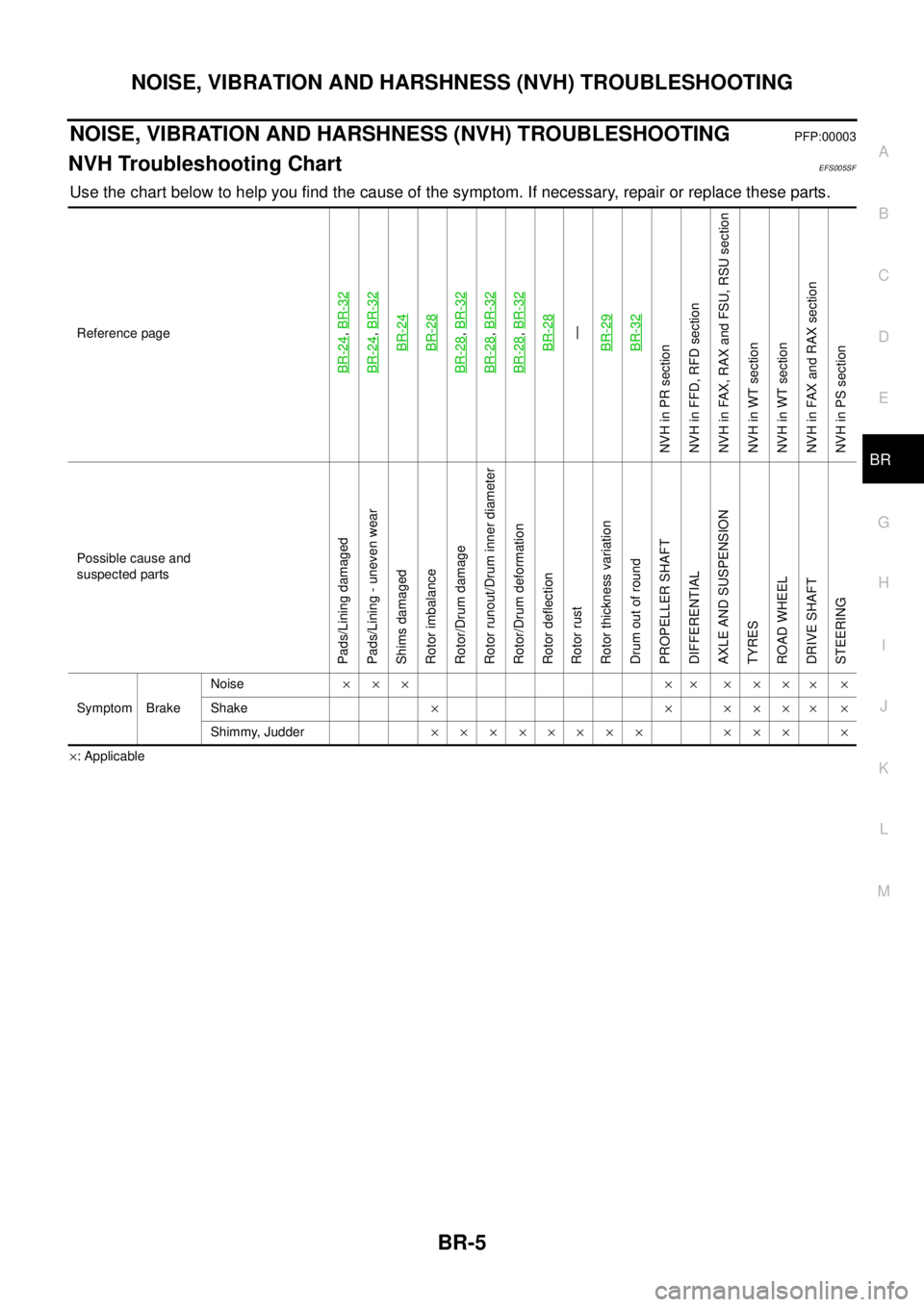

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEFS005SF

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: Applicable Reference page

BR-24

,BR-32

BR-24

,BR-32BR-24BR-28

BR-28

,BR-32

BR-28

,BR-32

BR-28

,BR-32BR-28—

BR-29BR-32

NVHinPRsection

NVH in FFD, RFD section

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX and RAX section

NVH in PS section

Possible cause and

suspected parts

Pads/Lining damaged

Pads/Lining - uneven wear

Shims damaged

Rotor imbalance

Rotor/Drum damage

Rotor runout/Drum inner diameter

Rotor/Drum deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TYRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BrakeNoise´´´ ´´ ´´´

´´

Shake´´´´´

´´

Shimmy, Judder´´´´´´´´ ´´´ ´

Page 796 of 3171

BR-10

BRAKE FLUID

BRAKE FLUID

PFP:KN100

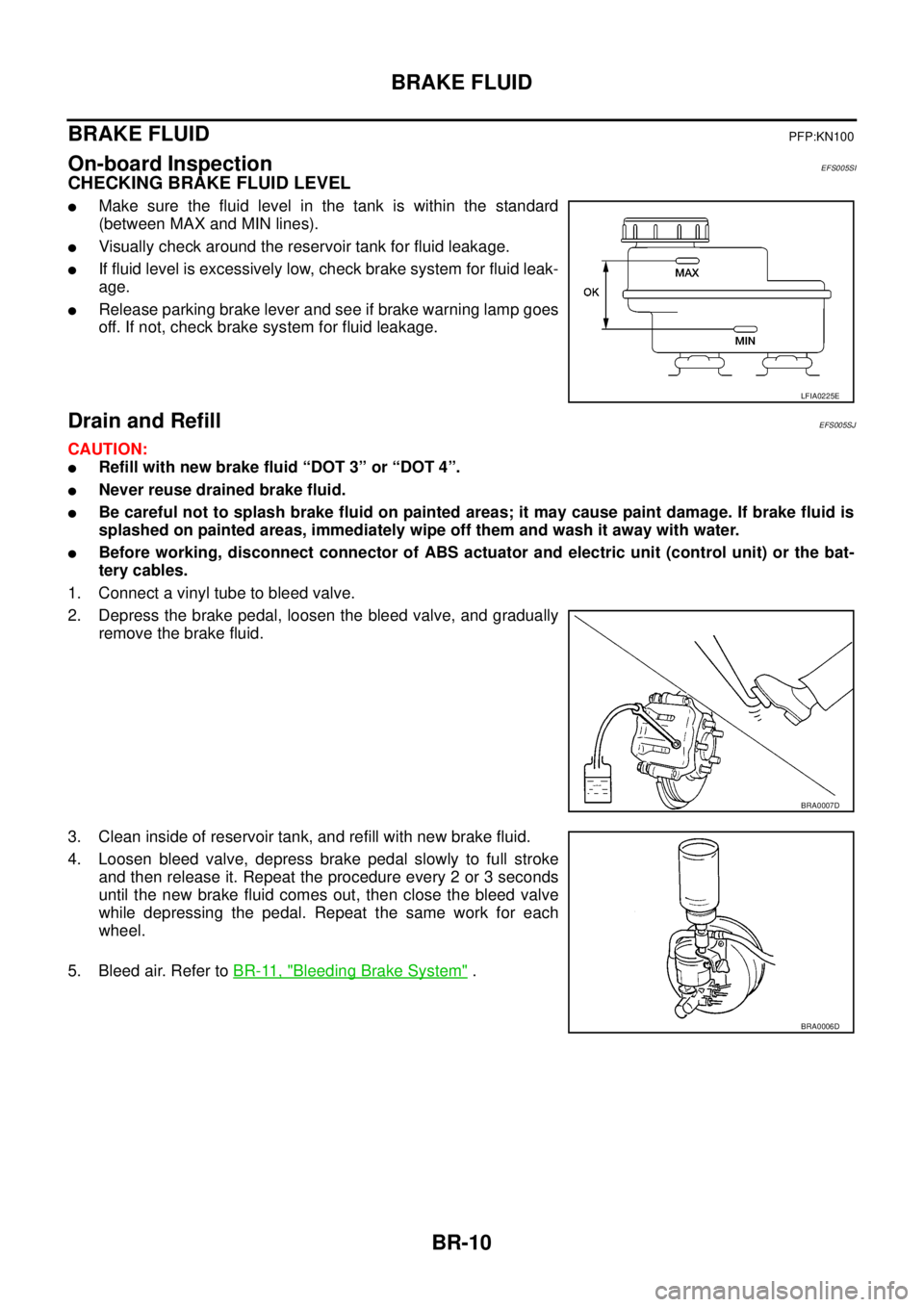

On-board InspectionEFS005SI

CHECKING BRAKE FLUID LEVEL

lMake sure the fluid level in the tank is within the standard

(between MAX and MIN lines).

lVisually check around the reservoir tank for fluid leakage.

lIf fluid level is excessively low, check brake system for fluid leak-

age.

lRelease parking brake lever and see if brake warning lamp goes

off. If not, check brake system for fluid leakage.

Drain and RefillEFS005SJ

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe off them and wash it away with water.

lBefore working, disconnect connector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually

remove the brake fluid.

3. Clean inside of reservoir tank, and refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full stroke

and then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the pedal. Repeat the same work for each

wheel.

5. Bleed air. Refer toBR-11, "

Bleeding Brake System".

LFIA0225E

BRA0007D

BRA0006D

Page 799 of 3171

BRAKE TUBE AND HOSE

BR-13

C

D

E

G

H

I

J

K

L

MA

B

BR

CAUTION:

lAll brake tubes and hoses must be free from excessive bending, twisting and pulling.

lMake sure that there is no interference with other parts when turning steering both clockwise and

counterclockwise.

lBrake tube and hose is an important safety part. Always disassemble the parts and retighten their

fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part is

detected.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe off them and wash it away with water.

lDo not bend or twist brake hose sharply, or strongly pull it.

lCover the open end of brake tube and hoses when disconnecting to prevent entrance of dirt.

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

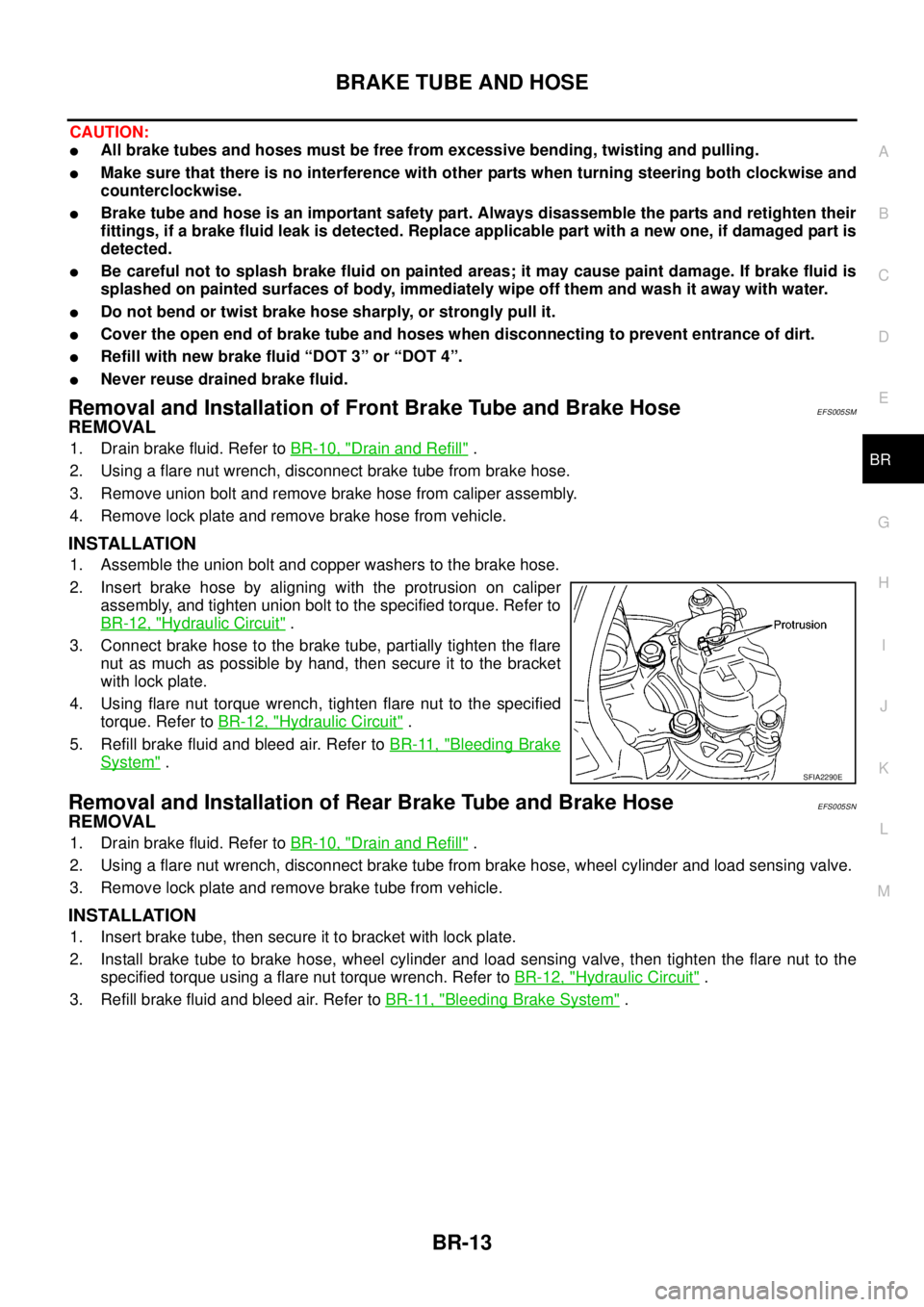

Removal and Installation of Front Brake Tube and Brake HoseEFS005SM

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Using a flare nut wrench, disconnect brake tube from brake hose.

3. Remove union bolt and remove brake hose from caliper assembly.

4. Remove lock plate and remove brake hose from vehicle.

INSTALLATION

1. Assemble the union bolt and copper washers to the brake hose.

2. Insert brake hose by aligning with the protrusion on caliper

assembly, and tighten union bolt to the specified torque. Refer to

BR-12, "

Hydraulic Circuit".

3. Connect brake hose to the brake tube, partially tighten the flare

nut as much as possible by hand, then secure it to the bracket

with lock plate.

4. Using flare nut torque wrench, tighten flare nut to the specified

torque. Refer toBR-12, "

Hydraulic Circuit".

5. Refill brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake

System".

Removal and Installation of Rear Brake Tube and Brake HoseEFS005SN

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Using a flare nut wrench, disconnect brake tube from brake hose, wheel cylinder and load sensing valve.

3. Remove lock plate and remove brake tube from vehicle.

INSTALLATION

1. Insert brake tube, then secure it to bracket with lock plate.

2. Install brake tube to brake hose, wheel cylinder and load sensing valve, then tighten the flare nut to the

specified torque using a flare nut torque wrench. Refer toBR-12, "

Hydraulic Circuit".

3. Refill brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System".

SFIA2290E

Page 802 of 3171

BR-16

LOAD SENSING VALVE

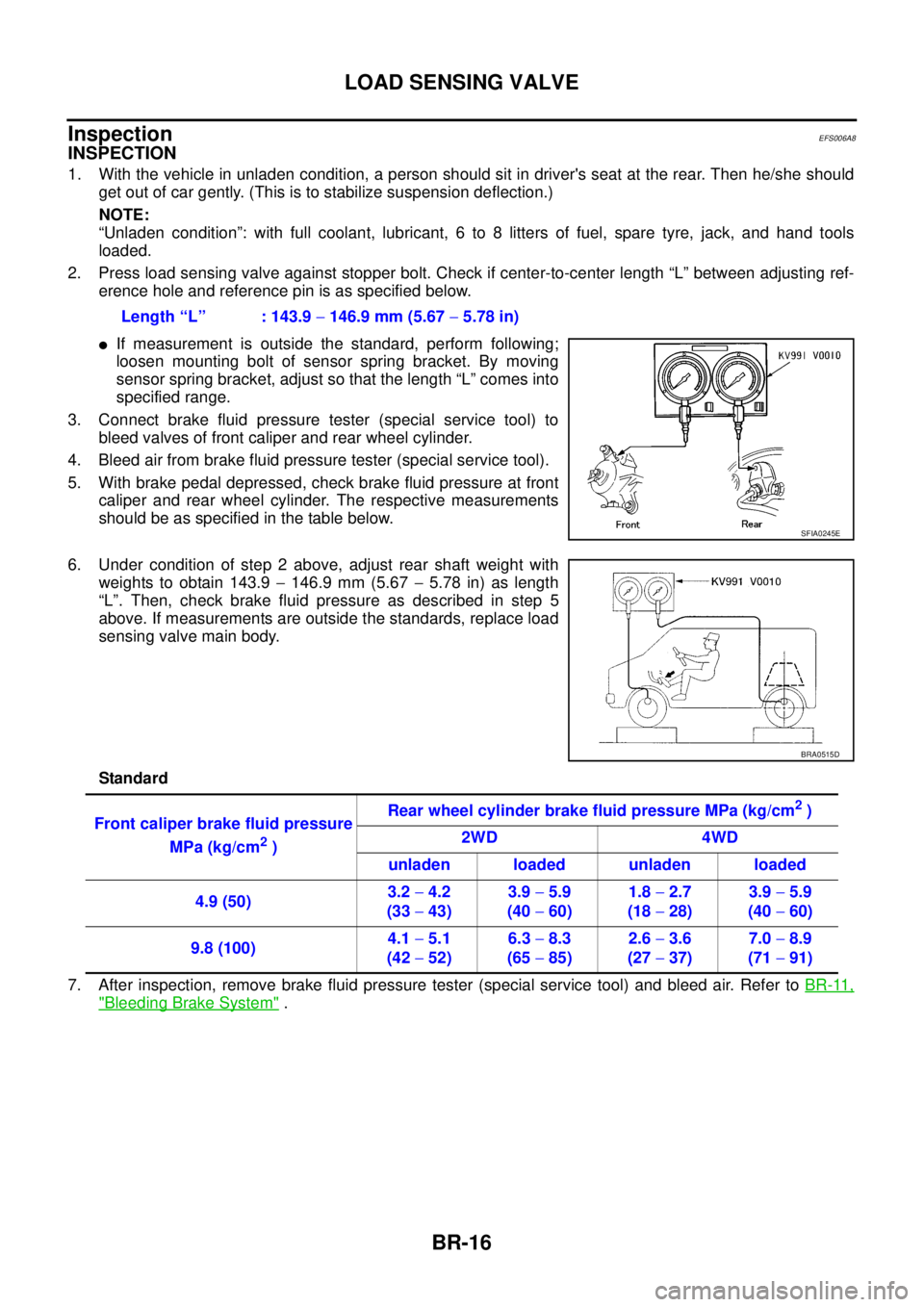

Inspection

EFS006A8

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

“Unladen condition”: with full coolant, lubricant, 6 to 8 litters of fuel, spare tyre, jack, and hand tools

loaded.

2. Press load sensing valve against stopper bolt. Check if center-to-center length “L” between adjusting ref-

erence hole and reference pin is as specified below.

lIf measurement is outside the standard, perform following;

loosen mounting bolt of sensor spring bracket. By moving

sensor spring bracket, adjust so that the length “L” comes into

specified range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 143.9-146.9 mm (5.67-5.78 in) as length

“L”. Then, check brake fluid pressure as described in step 5

above. If measurements are outside the standards, replace load

sensing valve main body.

Standard

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer toBR-11,

"Bleeding Brake System". Length “L” : 143.9-146.9 mm (5.67-5.78 in)

SFIA0245E

BRA0515D

Front caliper brake fluid pressure

MPa (kg/cm

2)Rear wheel cylinder brake fluid pressure MPa (kg/cm

2)

2WD 4WD

unladen loaded unladen loaded

4.9 (50)3.2-4.2

(33-43)3.9-5.9

(40-60)1.8-2.7

(18-28)3.9-5.9

(40-60)

9.8 (100)4.1-5.1

(42-52)6.3-8.3

(65-85)2.6-3.6

(27-37)7.0-8.9

(71-91)

Page 812 of 3171

BR-26

FRONT DISC BRAKE

Removal and Installation of Brake Caliper Assembly

EFS005T1

REMOVAL

1. Remove tyre from vehicle.

2. Fasten disc rotor using wheel nut.

CAUTION:

Align the matching marks of disc rotor and wheel hub, which were marked at the time of removal

when reusing disc rotor.

3. Drain brake fluid. Refer toBR-10, "

Drain and Refill".

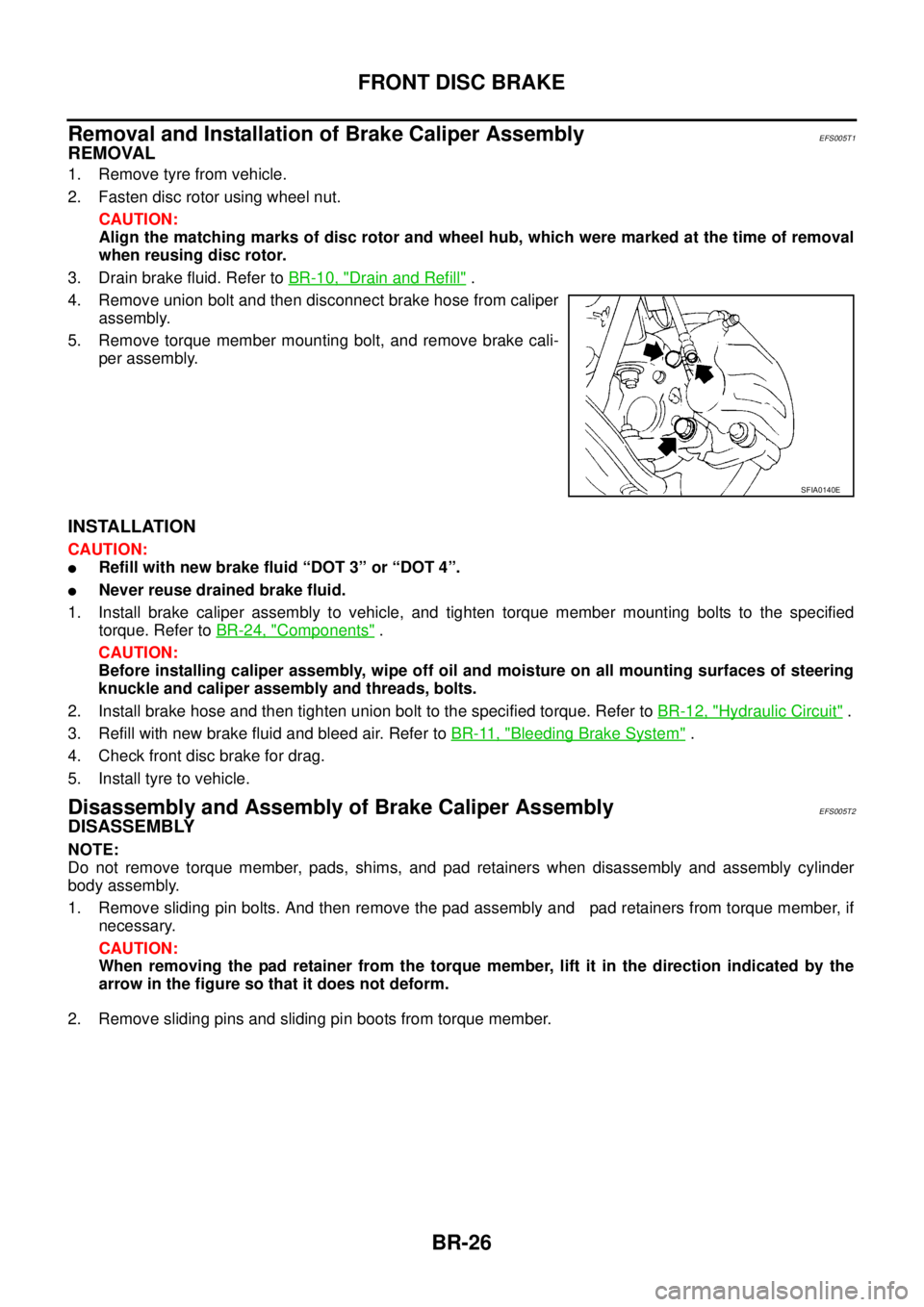

4. Remove union bolt and then disconnect brake hose from caliper

assembly.

5. Remove torque member mounting bolt, and remove brake cali-

per assembly.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Install brake caliper assembly to vehicle, and tighten torque member mounting bolts to the specified

torque. Refer toBR-24, "

Components".

CAUTION:

Before installing caliper assembly, wipe off oil and moisture on all mounting surfaces of steering

knuckle and caliper assembly and threads, bolts.

2. Install brake hose and then tighten union bolt to the specified torque. Refer toBR-12, "

Hydraulic Circuit".

3. Refill with new brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System".

4. Check front disc brake for drag.

5. Install tyre to vehicle.

Disassembly and Assembly of Brake Caliper AssemblyEFS005T2

DISASSEMBLY

NOTE:

Do not remove torque member, pads, shims, and pad retainers when disassembly and assembly cylinder

body assembly.

1. Remove sliding pin bolts. And then remove the pad assembly and pad retainers from torque member, if

necessary.

CAUTION:

When removing the pad retainer from the torque member, lift it in the direction indicated by the

arrow in the figure so that it does not deform.

2. Remove sliding pins and sliding pin boots from torque member.

SFIA0140E

Page 814 of 3171

BR-28

FRONT DISC BRAKE

ASSEMBLY

CAUTION:

When assembling, use only rubber lubricant specified below.

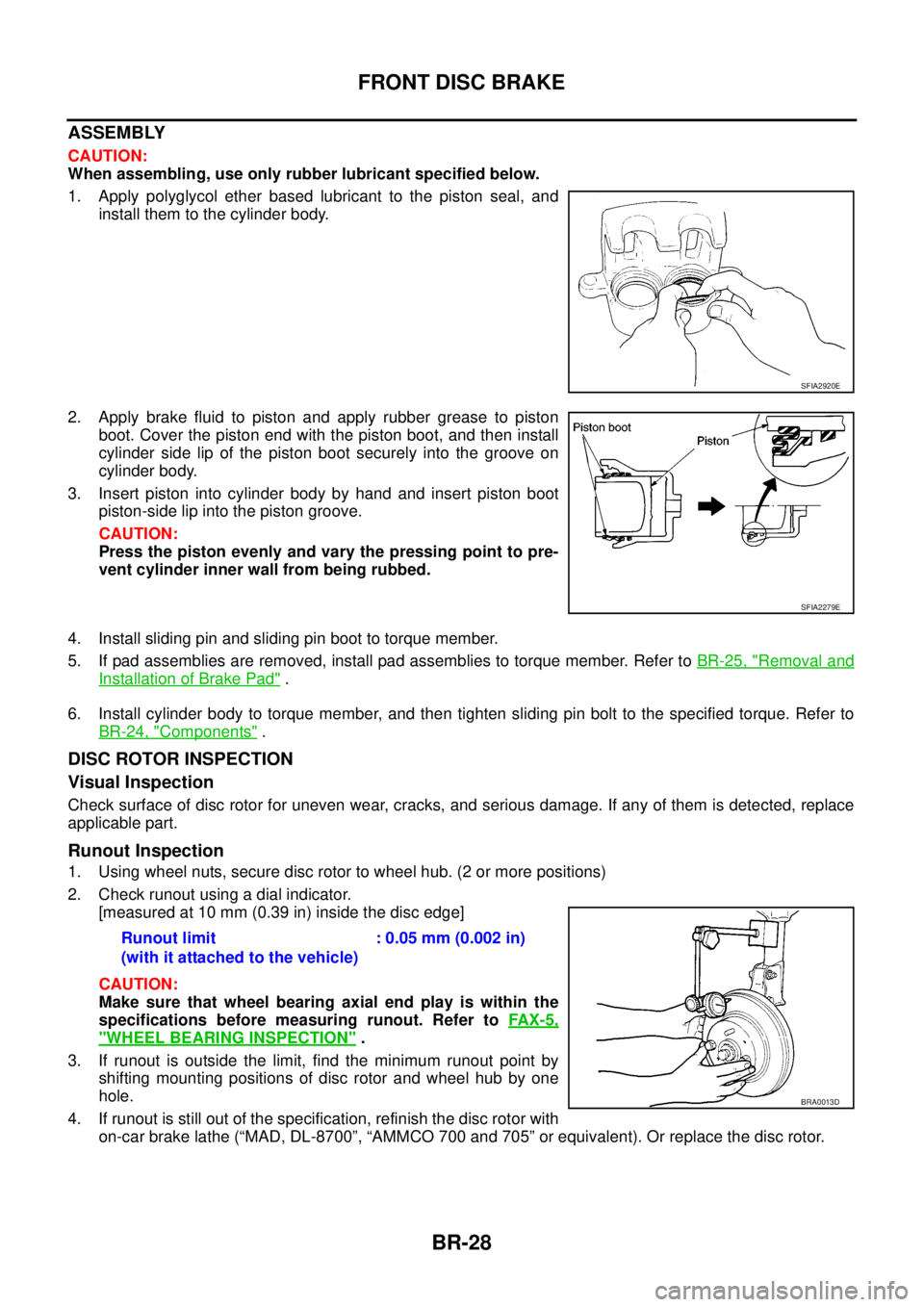

1. Apply polyglycol ether based lubricant to the piston seal, and

install them to the cylinder body.

2. Apply brake fluid to piston and apply rubber grease to piston

boot.Coverthepistonendwiththepistonboot,andtheninstall

cylinder side lip of the piston boot securely into the groove on

cylinder body.

3. Insert piston into cylinder body by hand and insert piston boot

piston-side lip into the piston groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

4. Install sliding pin and sliding pin boot to torque member.

5. If pad assemblies are removed, install pad assemblies to torque member. Refer toBR-25, "

Removal and

Installation of Brake Pad".

6. Install cylinder body to torque member, and then tighten sliding pin bolt to the specified torque. Refer to

BR-24, "

Components".

DISC ROTOR INSPECTION

Visual Inspection

Check surface of disc rotor for uneven wear, cracks, and serious damage. If any of them is detected, replace

applicable part.

Runout Inspection

1. Using wheel nuts, secure disc rotor to wheel hub. (2 or more positions)

2. Check runout using a dial indicator.

[measured at 10 mm (0.39 in) inside the disc edge]

CAUTION:

Make sure that wheel bearing axial end play is within the

specifications before measuring runout. Refer toFAX-5,

"WHEEL BEARING INSPECTION".

3. If runout is outside the limit, find the minimum runout point by

shifting mounting positions of disc rotor and wheel hub by one

hole.

4. If runout is still out of the specification, refinish the disc rotor with

on-car brake lathe (“MAD, DL-8700”, “AMMCO 700 and 705” or equivalent). Or replace the disc rotor.

SFIA2920E

SFIA2279E

Runout limit

(with it attached to the vehicle):0.05mm(0.002in)

BRA0013D