window NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1368 of 3171

EI-30

DOOR FINISHER

DOOR FINISHER

PFP:80900

Removal and InstallationEIS00DYM

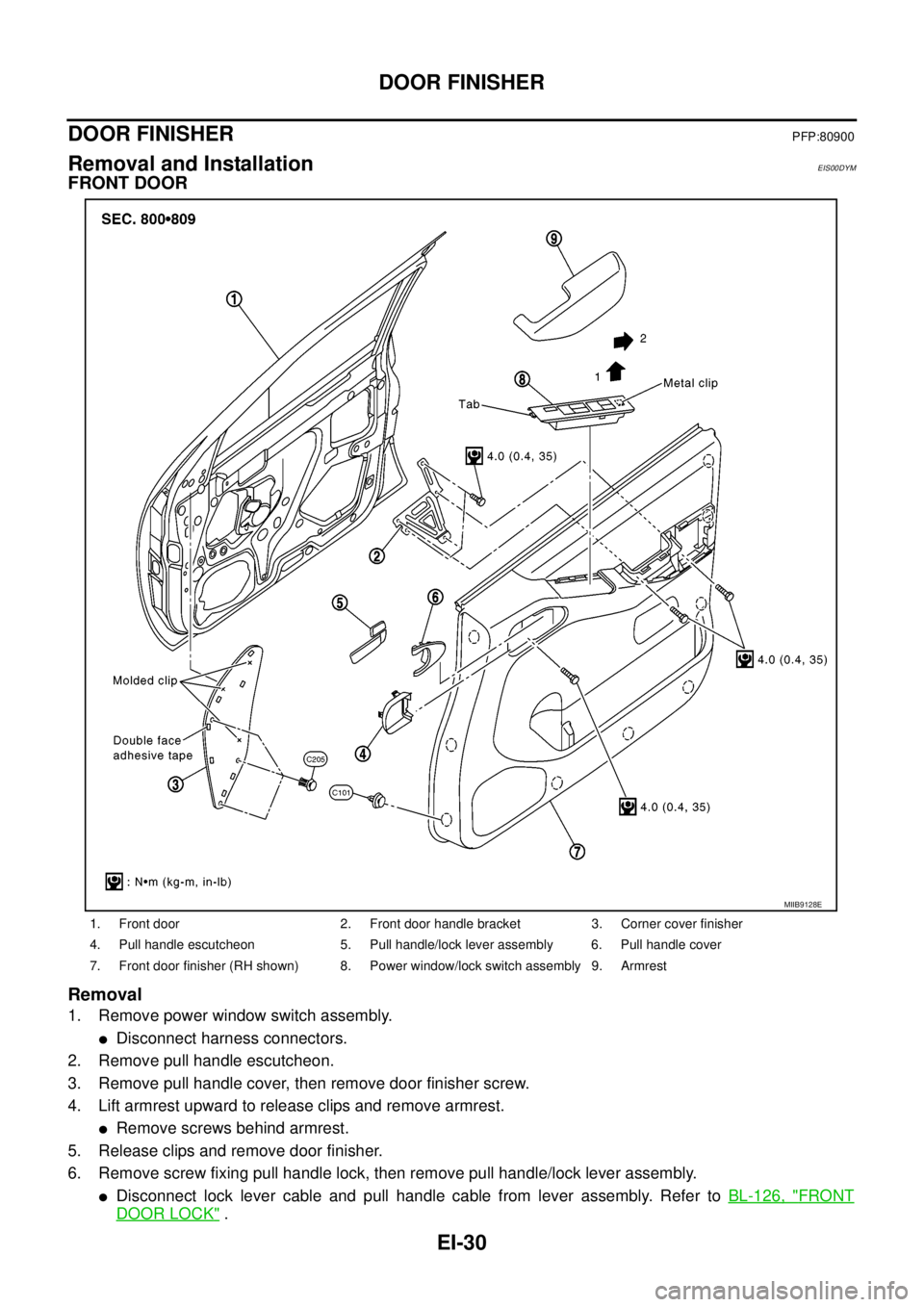

FRONT DOOR

Removal

1. Remove power window switch assembly.

lDisconnect harness connectors.

2. Remove pull handle escutcheon.

3. Remove pull handle cover, then remove door finisher screw.

4. Lift armrest upward to release clips and remove armrest.

lRemove screws behind armrest.

5. Release clips and remove door finisher.

6. Remove screw fixing pull handle lock, then remove pull handle/lock lever assembly.

lDisconnect lock lever cable and pull handle cable from lever assembly. Refer toBL-126, "FRONT

DOOR LOCK".

1. Front door 2. Front door handle bracket 3. Corner cover finisher

4. Pull handle escutcheon 5. Pull handle/lock lever assembly 6. Pull handle cover

7. Front door finisher (RH shown) 8. Power window/lock switch assembly 9. Armrest

MIIB9128E

Page 1369 of 3171

DOOR FINISHER

EI-31

C

D

E

F

G

H

J

K

L

MA

B

EI

Installation

Installation is in the reverse order of removal.

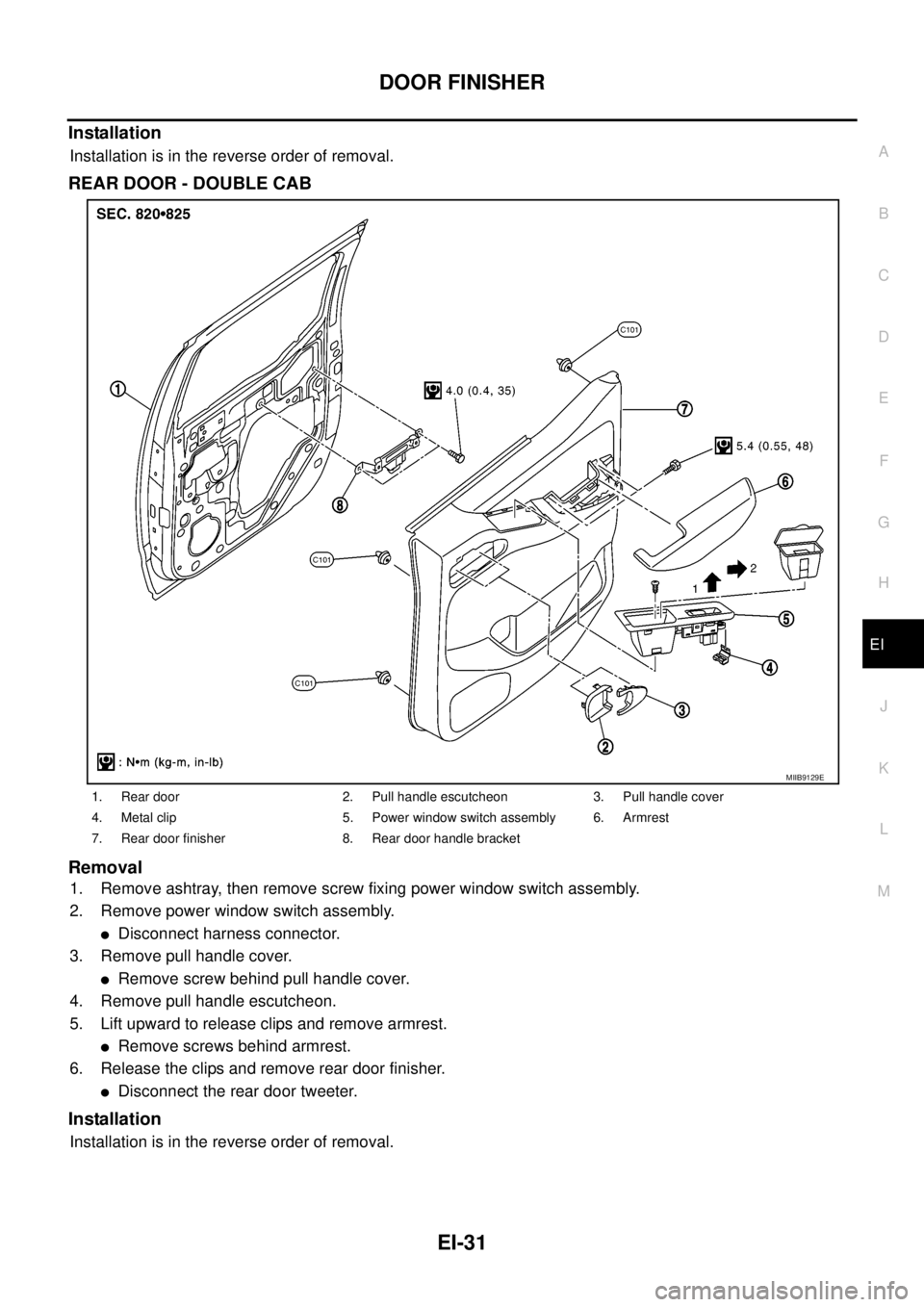

REAR DOOR - DOUBLE CAB

Removal

1. Remove ashtray, then remove screw fixing power window switch assembly.

2. Remove power window switch assembly.

lDisconnect harness connector.

3. Remove pull handle cover.

lRemove screw behind pull handle cover.

4. Remove pull handle escutcheon.

5. Lift upward to release clips and remove armrest.

lRemove screws behind armrest.

6. Release the clips and remove rear door finisher.

lDisconnect the rear door tweeter.

Installation

Installation is in the reverse order of removal.

1. Rear door 2. Pull handle escutcheon 3. Pull handle cover

4. Metal clip 5. Power window switch assembly 6. Armrest

7. Rear door finisher 8. Rear door handle bracket

MIIB9129E

Page 1648 of 3171

GI-26

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

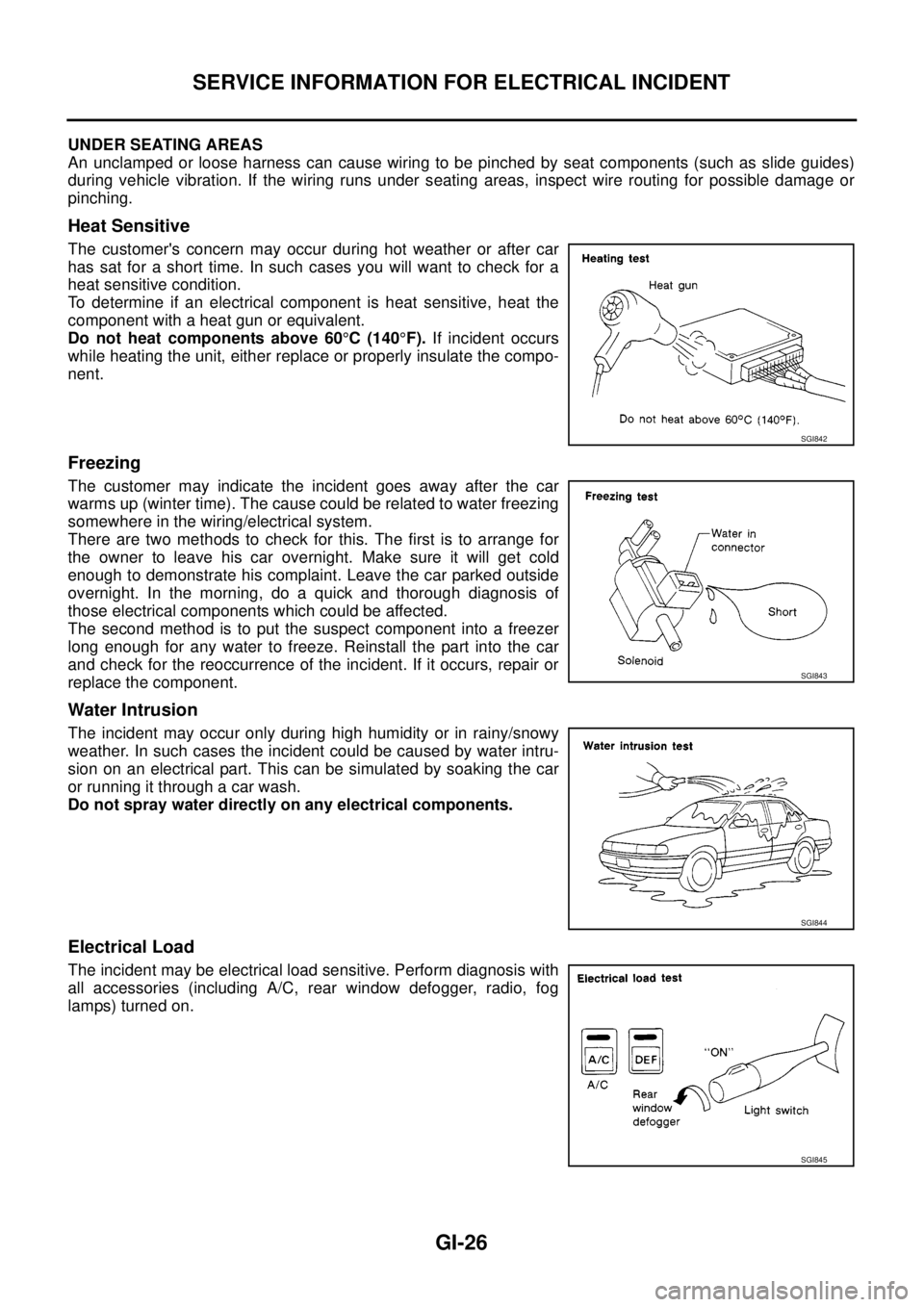

Heat Sensitive

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60°C(140°F).If incident occurs

while heating the unit, either replace or properly insulate the compo-

nent.

Freezing

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freezing

somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked outside

overnight. In the morning, do a quick and thorough diagnosis of

those electrical components which could be affected.

The second method is to put the suspect component into a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

Water Intrusion

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

Do not spray water directly on any electrical components.

Electrical Load

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

SGI842

SGI843

SGI844

SGI845

Page 1687 of 3171

GW-1

GLASSES, WINDOW SYSTEM & MIRRORS

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONGW

A

B

GW

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover..... 3

Handling for Adhesive and Primer ........................... 3

Trouble Diagnosis Precaution .................................. 3

PREPARATION ........................................................... 4

Commercial Service Tool ......................................... 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

POWER WINDOW SYSTEM .................................... 15

Component Parts and Harness Connector Location... 15

System Description ................................................ 15

MANUAL OPERATION ....................................... 16

AUTO OPERATION ............................................ 18

POWER WINDOW LOCK ................................... 18

DRIVER WINDOW ANTI-PINCH FUNCTION ..... 18

Schematic .............................................................. 19Wiring Diagram – WINDOW – ................................ 20

Terminal and Reference Value for Power Window

Main Switch ............................................................ 24

Terminal and Reference Value for Each Door's

Power Window Switch ............................................ 24

Terminal and Reference Value for BCM ................. 25

Work Flow ............................................................... 25

Trouble Diagnosis Symptom Chart ......................... 25

BCM Power Supply and Ground Circuit Check ...... 26

Power Window Main Switch Power Supply and

Ground Circuit Check ............................................. 27

Driver Side Power Window Motor Check ............... 28

Passenger Side Power Window Motor Circuit

Check ..................................................................... 29

Rear LH Power Window Motor Circuit Check ......... 30

Rear RH Power Window Motor Circuit Check ........ 31

Passenger Side Power Window Circuit Check ....... 31

Rear LH Power Window Circuit Check ................... 32

Rear RH Power Window Circuit Check .................. 33

Power Window Switch Check 1 .............................. 33

Power Window Switch Check 2 .............................. 34

FRONT DOOR GLASS AND REGULATOR ............. 35

Removal and Installation ........................................ 35

DOOR GLASS ..................................................... 35

REGULATOR ASSEMBLY .................................. 36

Disassembly and Assembly .................................... 37

REGULATOR ASSEMBLY .................................. 37

Inspection after Installation ..................................... 37

FITTING INSPECTION ....................................... 37

RESET OPERATION ........................................... 37

REAR DOOR GLASS AND REGULATOR ............... 38

Removal and Installation ........................................ 38

DOOR GLASS ..................................................... 38

REGULATOR ASSEMBLY .................................. 39

Disassembly and Assembly .................................... 40

REGULATOR ASSEMBLY .................................. 40

Inspection after Installation ..................................... 40

FITTING INSPECTION ....................................... 40

Page 1688 of 3171

GW-2

SIDE WINDOW GLASS ............................................ 41

Removal and Installation ........................................ 41

REMOVAL ........................................................... 41

INSTALLATION .................................................... 42

REAR WINDOW GLASS AND MOLDING ................ 43

Removal and Installation ........................................ 43

REMOVAL ........................................................... 43

INSTALLATION .................................................... 44

INSIDE MIRROR ....................................................... 45

Wiring Diagram –I/MIRR– ...................................... 45

Removal and Installation ........................................ 46

REMOVAL ........................................................... 46

INSTALLAION ..................................................... 46

REAR WINDOW DEFOGGER .................................. 47

Component Parts and Harness Connector Location... 47

System Description ................................................. 47

CAN Communication System Description .............. 48

Schematic ............................................................... 49

Wiring Diagram –DEF– ........................................... 50

Terminal and Reference Value for BCM ................. 53

Terminal and Reference Value for IPDM E/R ......... 53

Work Flow ............................................................... 53

CONSULT-II Function (BCM) .................................. 54

CONSULT-II BASIC OPERATION PROCEDURE... 54

DATA MONITOR .................................................. 55

ACTIVE TEST ...................................................... 55

Trouble Diagnoses Symptom Chart ........................ 56

BCM Power Supply and Ground Circuit Check ...... 56

Rear Window Defogger Switch Circuit Check ......... 57

Rear Window Defogger Power Supply Circuit

Check ...................................................................... 59

Rear Window Defogger Circuit Check .................... 59

Rear Window Defogger Signal Check .................... 60

Filament Check ....................................................... 61

Filament Repair ....................................................... 61

REPAIR EQUIPMENT ......................................... 61

REPAIRING PROCEDURE ................................. 62

DOOR MIRROR ......................................................... 63

Wiring Diagram – MIRROR – / LHD Models .......... 63

Wiring Diagram – MIRROR – / RHD Models ......... 64

Door Mirror Assembly ............................................. 65

REMOVAL ............................................................ 65

INSTALLATION .................................................... 65

Disassembly and Assembly .................................... 65

DISASSEMBLY .................................................... 65

ASSEMBLY .......................................................... 66

Page 1698 of 3171

GW-12

WINDSHIELD GLASS

lWhile the urethane adhesive is curing, open a door window. This will prevent the glass from being forced

out by passenger compartment air pressure when a door is closed.

lThe molding must be installed securely so that it is in position and leaves no gap.

lInform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

lInstall parts removed.

WARNING:

lKeep heat and open flames away as primers and adhesive are flammable.

lThe materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

lUse in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if

inhaled. If affected by vapor inhalation, immediately move to an area with fresh air.

lDriving the vehicle before the urethane adhesive has completely cured may affect the perfor-

mance of the windshield in case of an accident.

CAUTION:

lDo not use an adhesive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date

printed on the box.

lKeep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

lDo not leave primers or adhesive cartridge unattended with their caps open or off.

lThe vehicle should not be driven for at least 24 hours or until the urethane adhesive has com-

pletely cured. Curing time varies depending on temperature and humidities. The curing time will

increase under lower temperatures and lower humidities.

Page 1701 of 3171

POWER WINDOW SYSTEM

GW-15

C

D

E

F

G

H

J

K

L

MA

B

GW

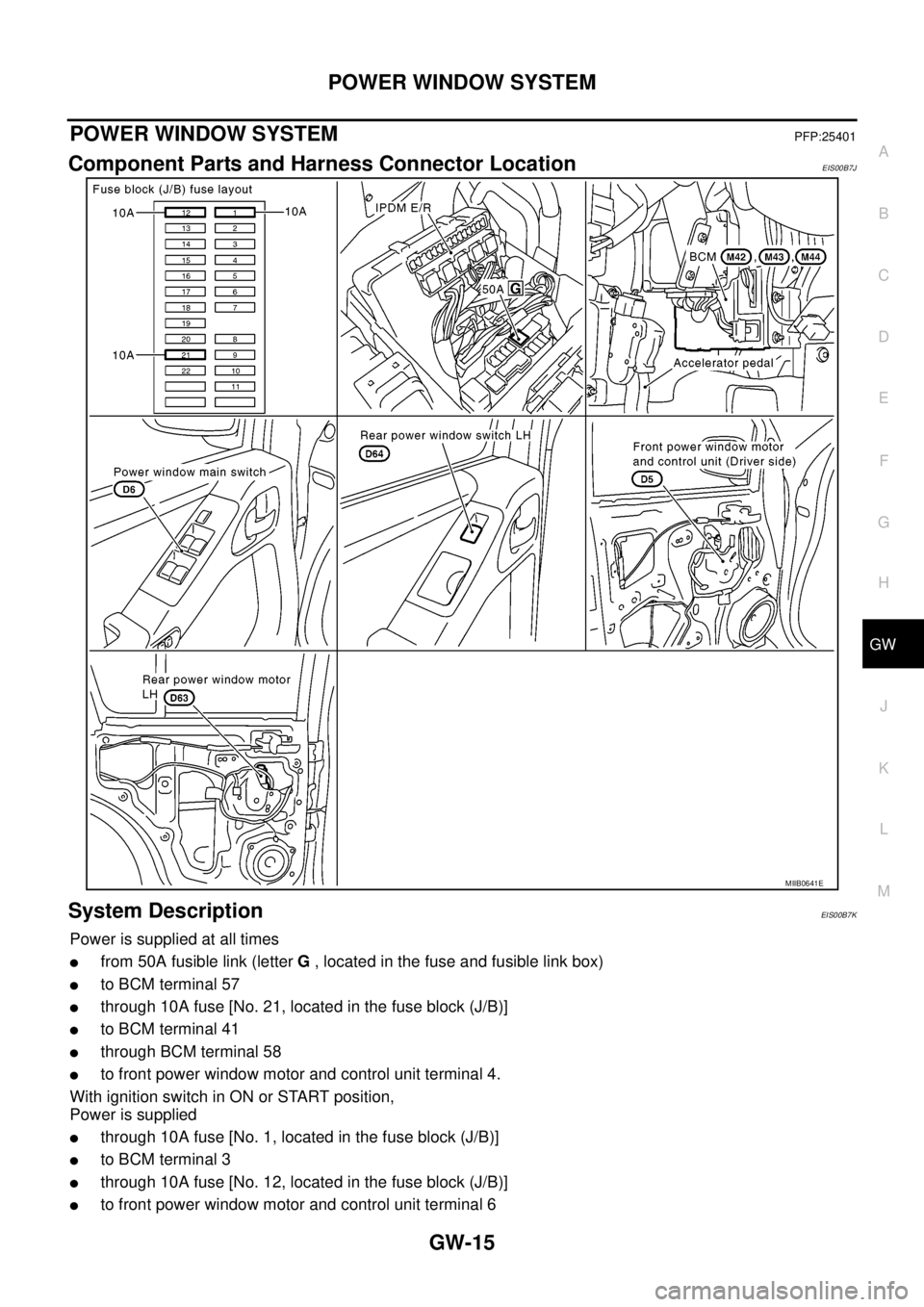

POWER WINDOW SYSTEMPFP:25401

Component Parts and Harness Connector LocationEIS00B7J

System DescriptionEIS00B7K

Power is supplied at all times

lfrom 50A fusible link (letterG, located in the fuse and fusible link box)

lto BCM terminal 57

lthrough 10A fuse [No. 21, located in the fuse block (J/B)]

lto BCM terminal 41

lthrough BCM terminal 58

lto front power window motor and control unit terminal 4.

With ignition switch in ON or START position,

Power is supplied

lthrough 10A fuse [No. 1, located in the fuse block (J/B)]

lto BCM terminal 3

lthrough 10A fuse [No. 12, located in the fuse block (J/B)]

lto front power window motor and control unit terminal 6

MIIB0641E

Page 1702 of 3171

GW-16

POWER WINDOW SYSTEM

lthrough BCM terminal 53

lto power window main switch terminal 2

lto ftont power window switch (passenger side) terminal 1

lto rear power window switches LH and RH terminal 1 (with rear power window).

Ground is supplied

lto BCM terminal 55

lto front power window motor and control unit terminal 3

lto power window main switch terminal 3

lthrough body grounds M21, M80 and M83.

MANUAL OPERATION

Front Driver Side Door

WINDOW UP

When the driver side switch in the power window main switch is pressed in the up position,

Ground is supplied

lto front power window motor and control unit terminal 2

lthrough power window main switch terminal 4

lthrough power window main switch terminal 3

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the driver side switch in the power window main switch is pressed in the down position

Ground is supplied

lto front power window motor and control unit terminal 1

lthrough power window main switch terminal 5

lthrough power window main switch terminal 3

Then, the motor lowers the window until the switch is released.

Front Passenger Side Door

FRONT POWER WINDOW SWITCH (PASSENGER SIDE) OPERATION

WINDOW UP

When the front power window switch (passenger side) is operated in the up position

Power is supplied

lthrough front power window switch (passenger side) terminal 1 and 5

lto front power window motor (passenger side) terminal 2.

Ground is supplied

lto front power window motor (passenger side) terminal 1

lthrough front power window switch (passenger side) terminal 4 and 3

lthrough power window main switch terminal 7

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front power window switch (passenger side) is opeataed in the down position

Power is supplied

lthrough front power window switch (passenger side) terminal 1 and 4

lto front power window motor (passenger side) terminal 1.

Ground is supplied

lto front power window motor (passenger side) terminal 2

lthrough front power window switch (passenger side) terminal 5 and 2

lthrough power window main switch terminal 6

Then, the motor lowers the window until the switch is released.

POWER WINDOW MAIN SWITCH OPERATION

WINDOW UP

When the passenger side switch in power window main switch is operated in the up position

Power is supplied

Page 1703 of 3171

POWER WINDOW SYSTEM

GW-17

C

D

E

F

G

H

J

K

L

MA

B

GW

lthrough power window main switch terminal 6

lto front power window switch (passenger side) terminal 2 and 5

lto front power window motor (passenger side) terminal 2.

Ground is supplied

lto front power window motor (passenger side) terminal 1

lthrough front power window switch (passenger side) terminal 4 and 3

lthrough power window main switch terminal 7

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the passenger side switch in power window main switch is operated in the down position

Power is supplied

lthrough power window main switch terminal 7

lto front power window switch (passenger side) terminal 3 and 4

lto front power window motor (passenger side) terminal 1.

Ground is supplied

lto front power window motor (passenger side) terminal 2

lthrough front power window switch (passenger side) terminal 5 and 2

lthrough power window main switch terminal 6

Then, the motor lowers the window until the switch is released.

Rear Door (LH or RH)

REAR POWER WINDOW SWITCH LH OR RH OPERATION

WINDOW UP

When the rear power window switch LH or RH is operated in the up position

Power is supplied

lthrough rear power window switch LH or RH terminal 1 and 5

lto rear power window motor LH or RH terminal 1.

Ground is supplied

lto rear power window motor LH or RH terminal 2

lthrough rear power window switch LH or RH terminal 4 and 3

lthrough power window main switch 11 (LH) or 9 (RH)

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the rear power window switch LH or RH is pressed in the down position

Power is supplied

lthrough rear power window switch LH or RH terminal 1 and 4

lto rear power window motor LH or RH terminal 2.

Ground is supplied

lto rear power window motor LH or RH terminal 1

lthrough rear power window switch LH or RH terminal 5 and 2

lthrough power window main switch 1 (LH) or 7 (RH)

Then, the motor lowers the window until the switch is released.

POWERWINDOWMAINSWITCHOPERATION

WINDOW UP

When the rear LH or RH switch in the power window main switch is operated in the up position

Power is supplied

lthrough power window main switch terminal 10 (LH) or 8 (RH)

lto rear power window switch LH or RH terminal 5 and 2

lto rear power window motor LH or RH terminal 1.

Ground is supplied

lto rear power window motor LH or RH terminal 2

lthrough rear power window switch LH or RH terminal 4 and 3

Page 1704 of 3171

GW-18

POWER WINDOW SYSTEM

lthrough power window main switch terminal 11 (LH) or 9 (RH).

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the rear LH or RH switch in the power window main switch is operated in the down position

Power is supplied

lthrough power window main switch terminal 11 (LH) or 9 (RH)

lto rear power window switch LH or RH terminal 4 and 3

lto rear power window motor LH or RH terminal 2.

Ground is supplied

lto rear power window motor LH or RH terminal 1

lthrough rear power window switch LH or RH terminal 5 and 2

lthrough power window main switch terminal 10 (LH) or 8 (RH).

Then, the motor raises the window until the switch is released.

AUTO OPERATION

The power window AUTO feature enables the driver to open the window without holding the window switch in

thedownposition.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for front door window LH and RH.

When in the lock position, the power window lock disables power window and door lock/unlock switch RH and

rear power window switch LH and RH by disconnecting switch ground signal. This prevents the power window

motors from operating.

DRIVER WINDOW ANTI-PINCH FUNCTION

During raising operation of driver side window, if door control module detects that foreign object is pinched,

power window lowers approximately 150 mm (5.91 in).

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to power window, it

may lower.

Operation Conditions

lDriver side window is between fully-open and just before fully-closed position (when the limit switch is

ON).

lDuring automatic operation when ignition switch is turned ON.

lDuring automatic or manual operation when ignition switch is other than ON position (when the timer

operates).